Property Comparison of Alkali-Activated Carbon Steel Slag (CSS) and Stainless Steel Slag (SSS) and Role of Blast Furnace Slag (BFS) Chemical Composition

Abstract

1. Introduction

2. Materials and Methods

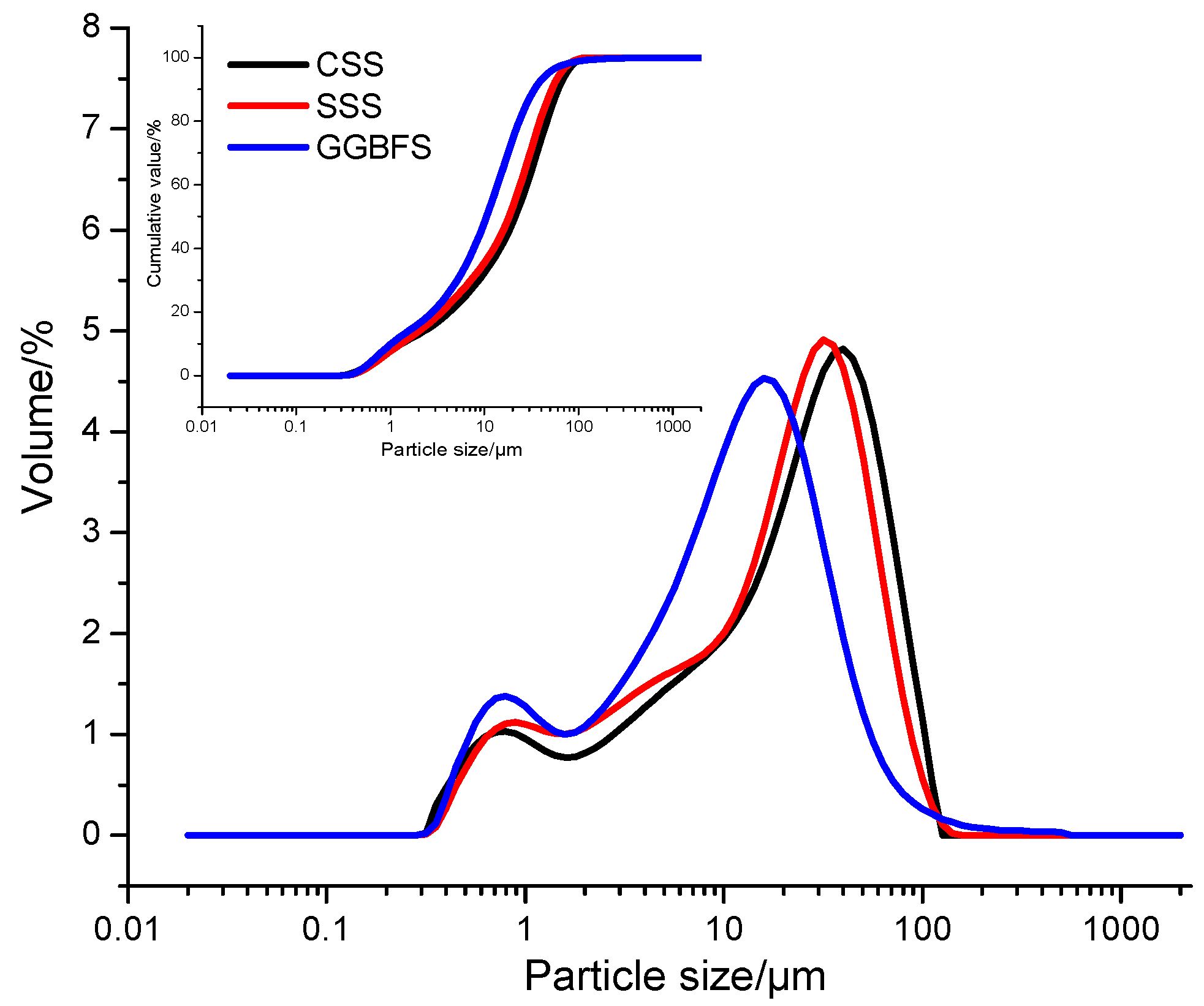

2.1. Materials

2.2. Mixes Design and Specimens Preparation

2.3. Testing Methods

2.3.1. Unconfined Compressive Strength Test

2.3.2. Non-Evaporable Water Content Test

2.3.3. Phase Analysis

2.3.4. TG-DTG Analysis

2.3.5. FT-IR Analysis

2.3.6. Microstructure Analysis

3. Results and Discussion

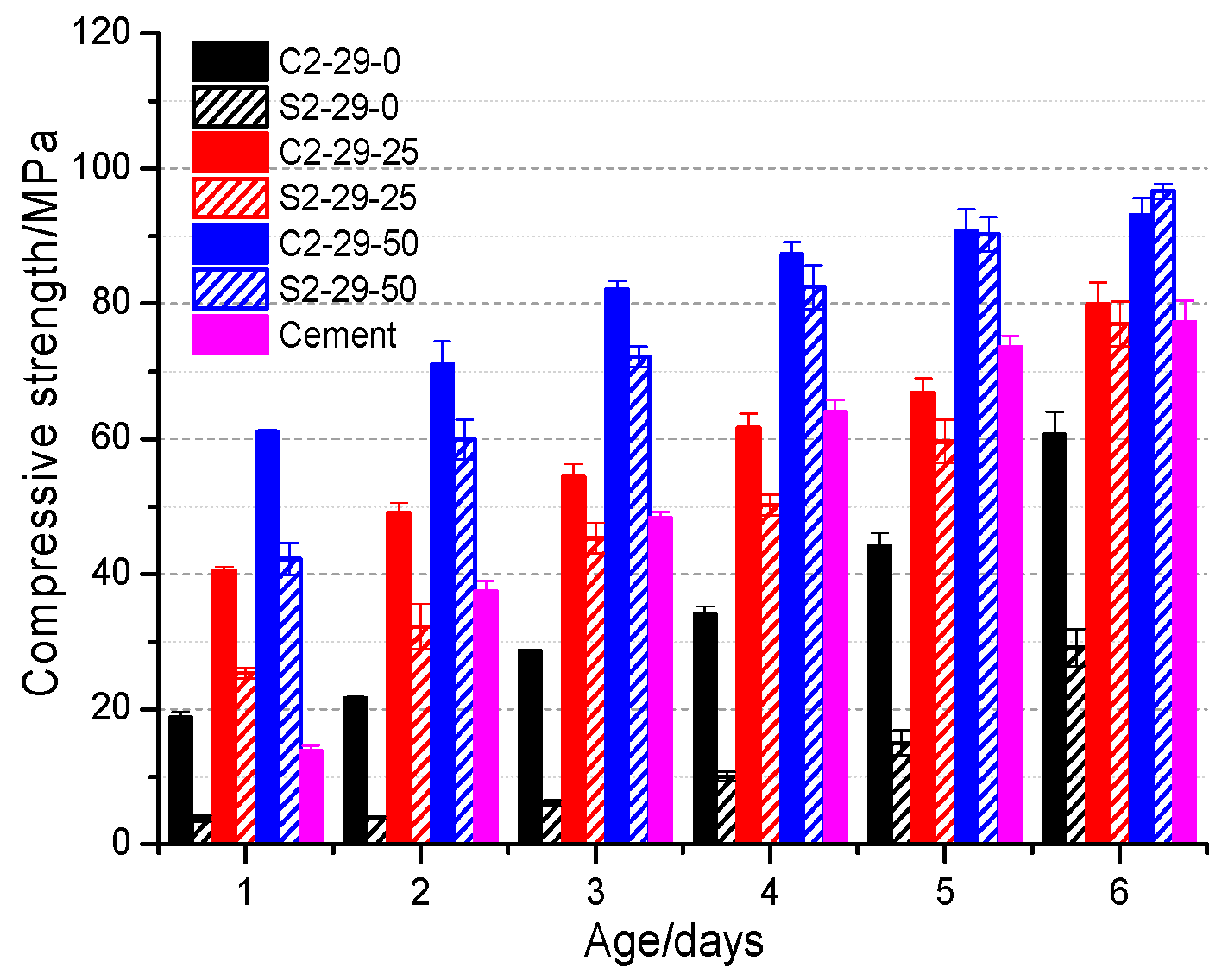

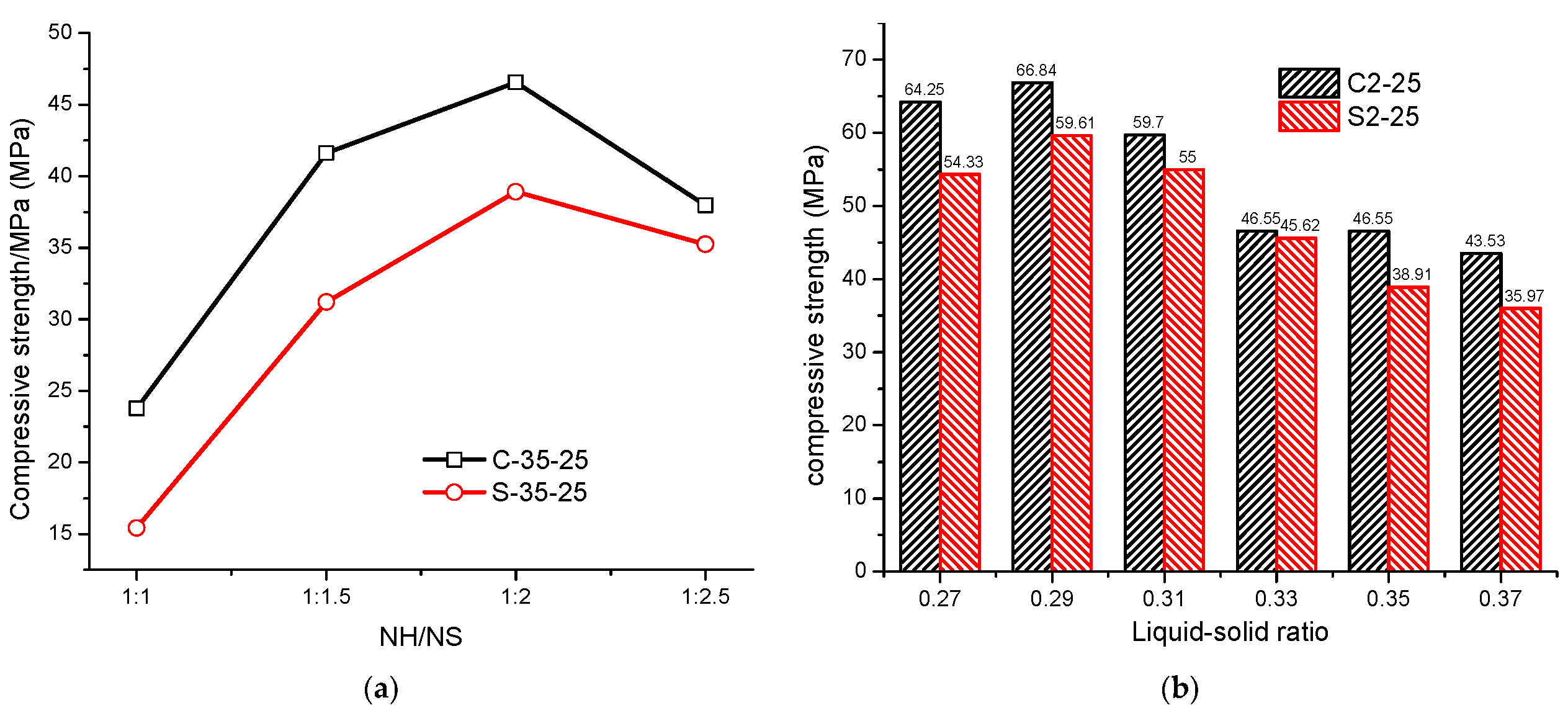

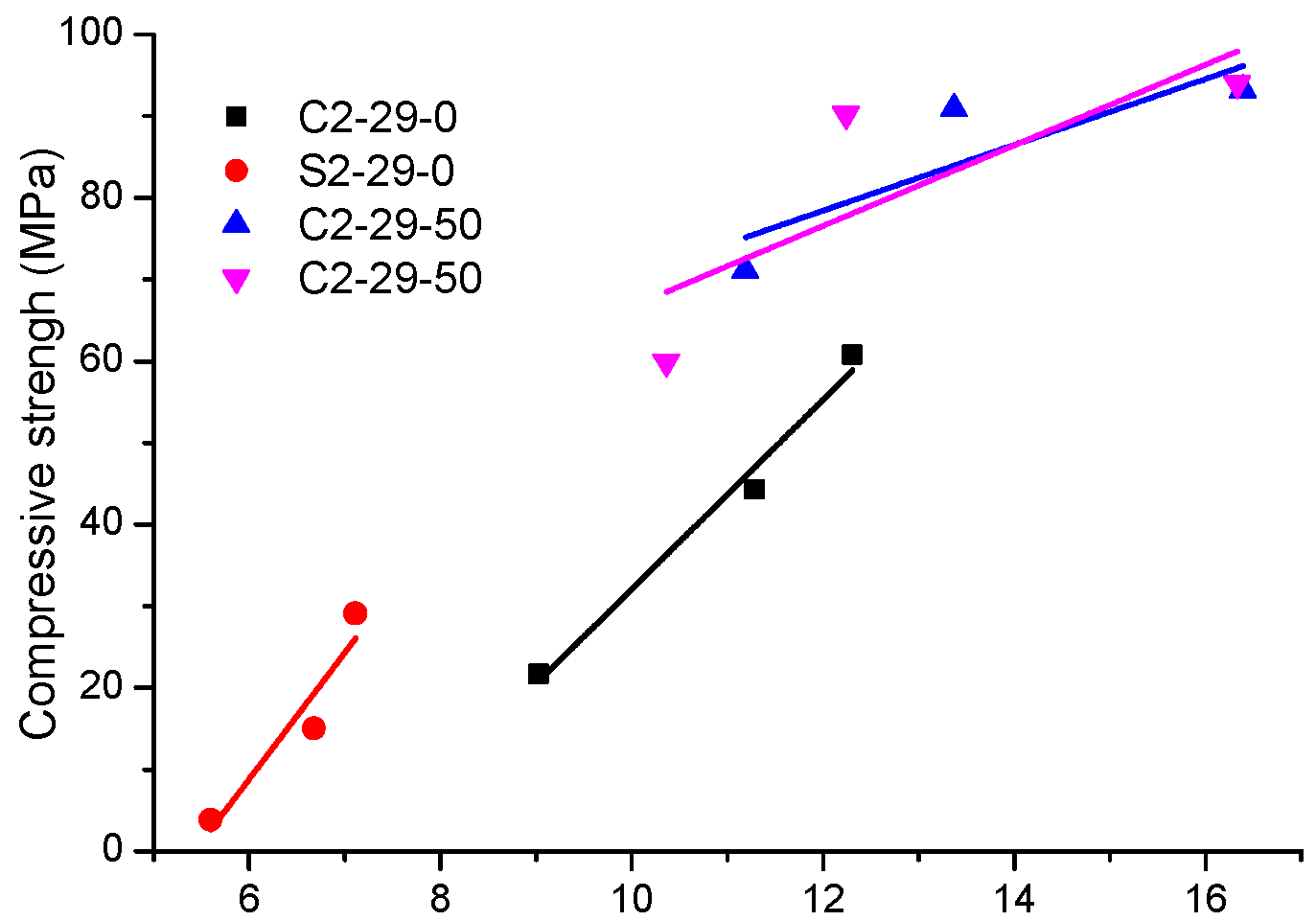

3.1. Unconfined Compressive Strength

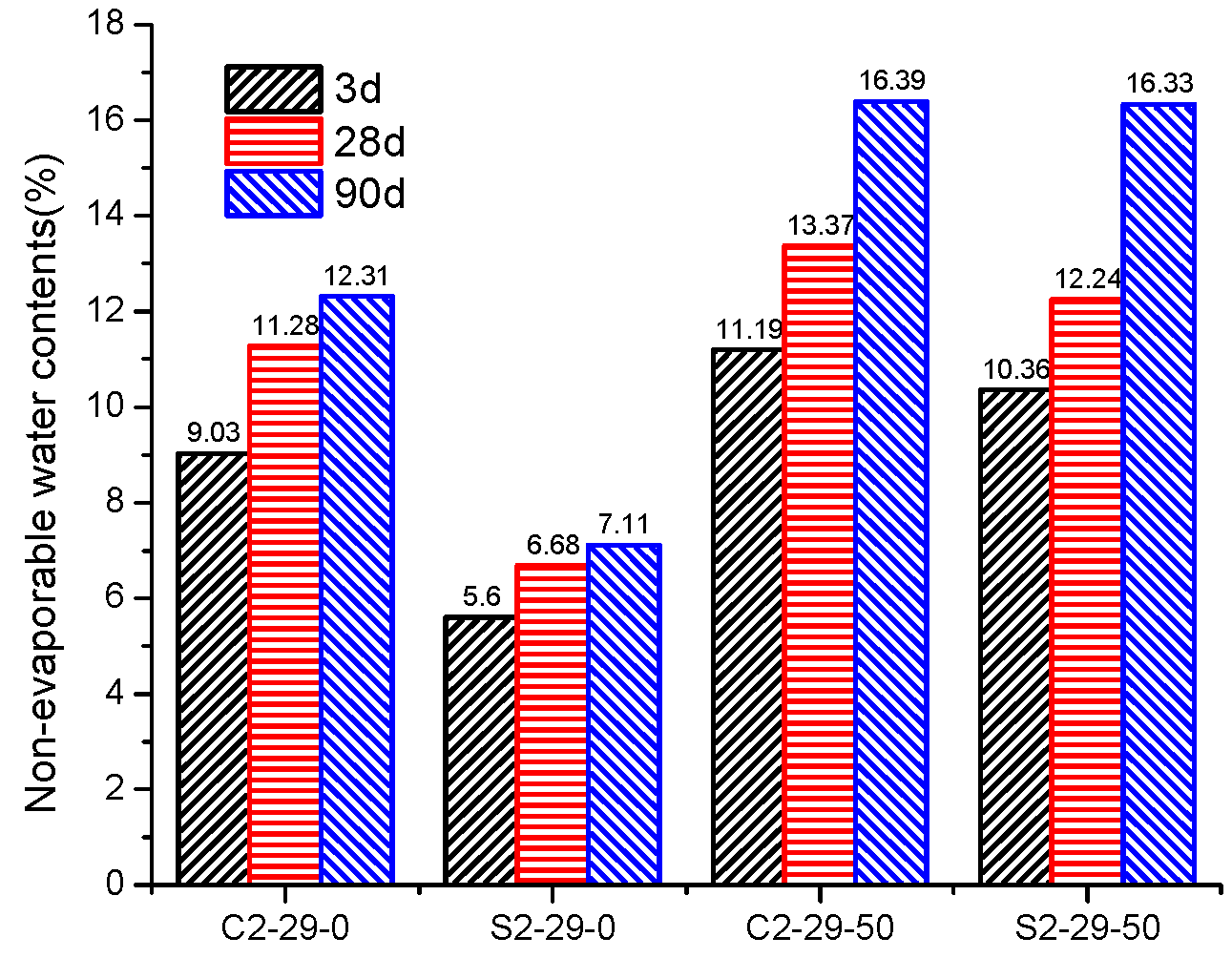

3.2. Non-Evaporable Water

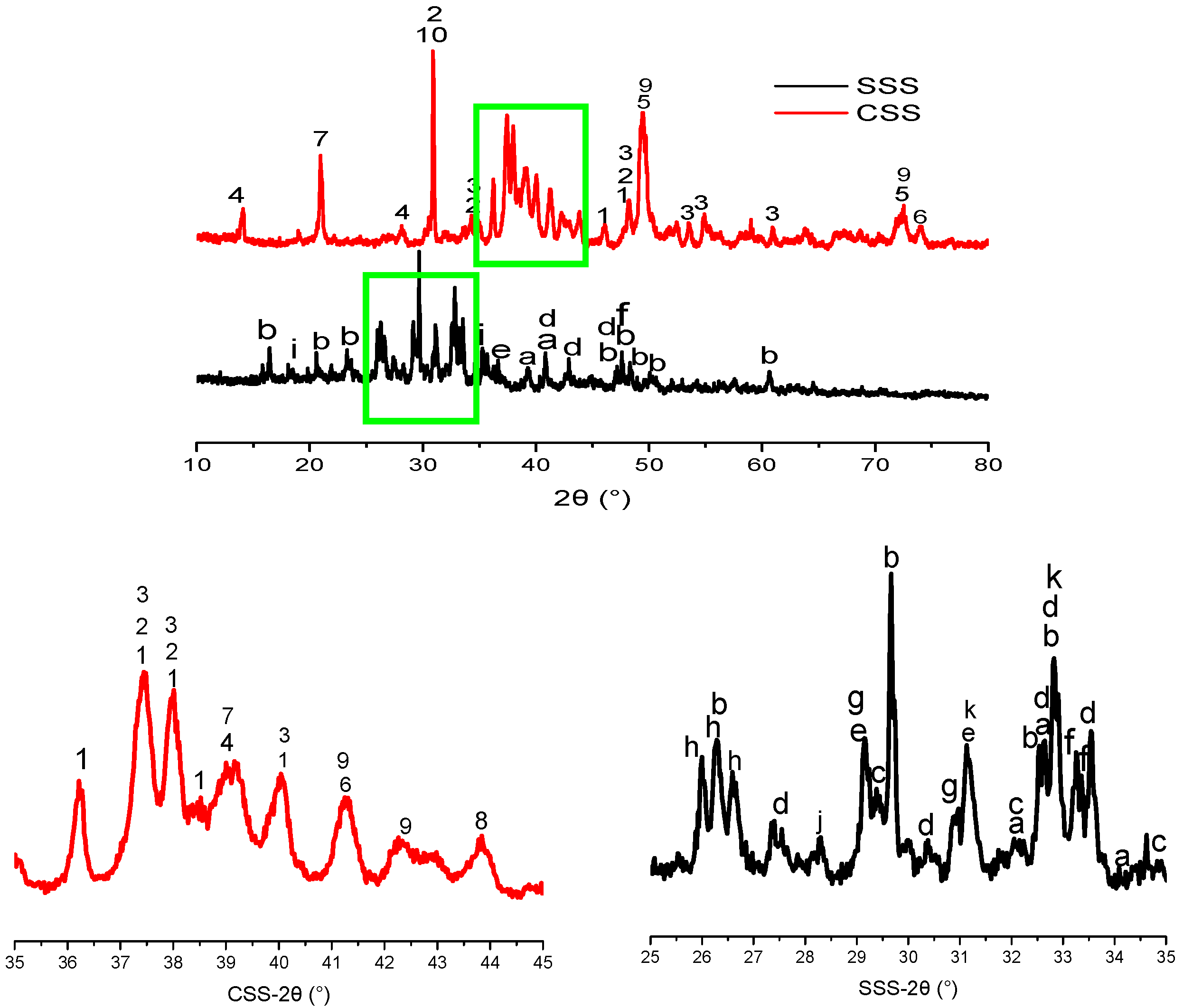

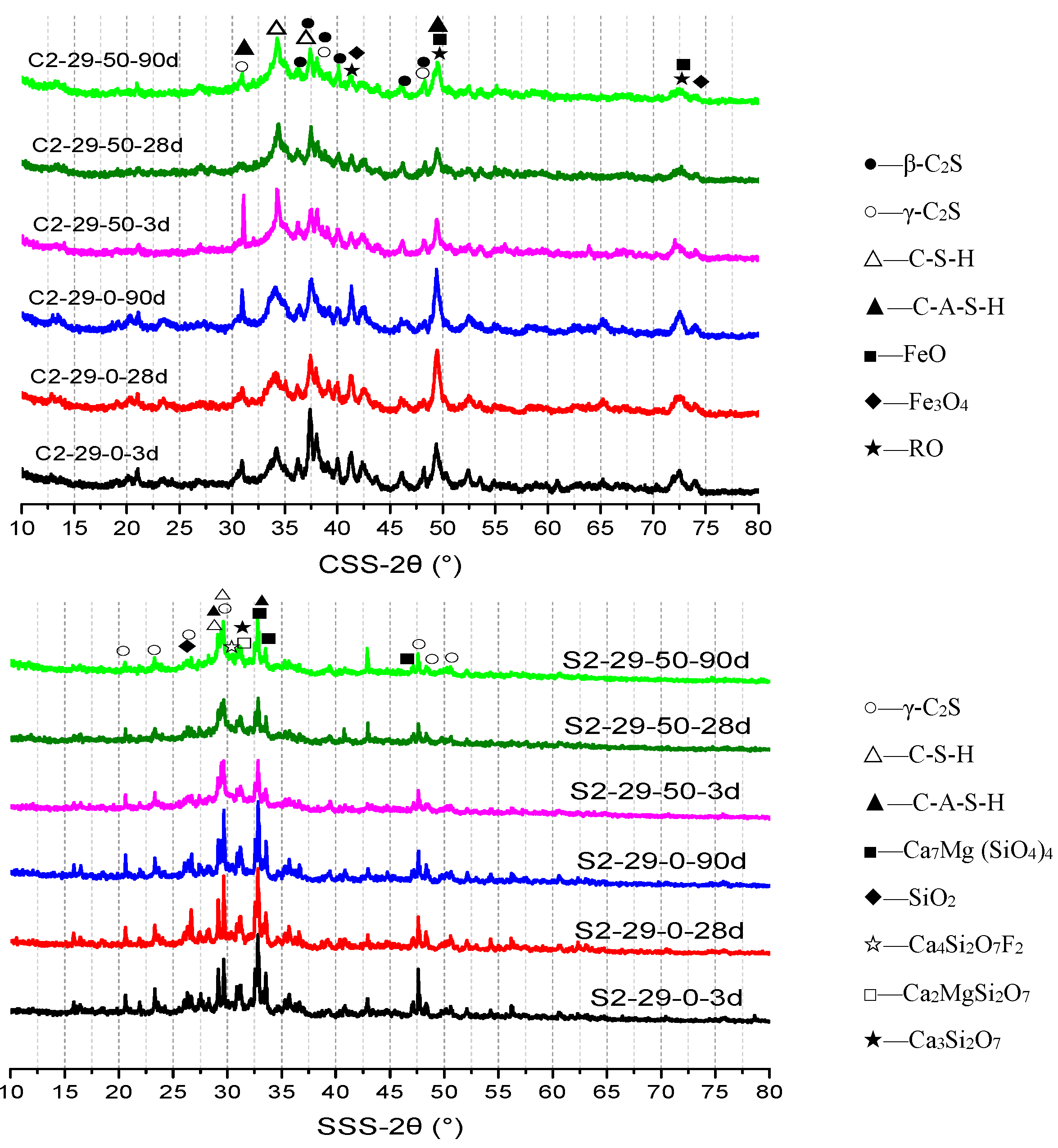

3.3. XRD Analysis

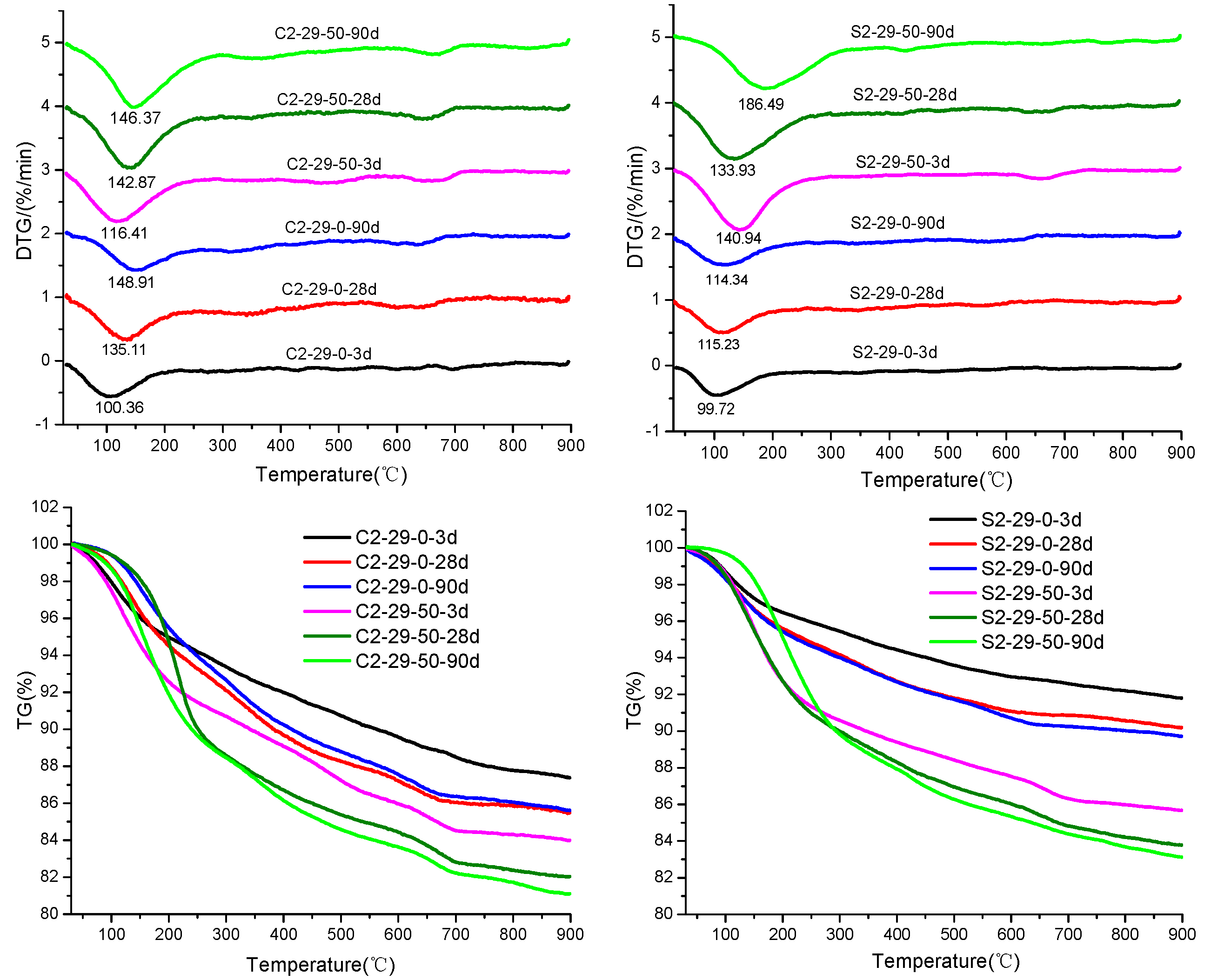

3.4. TG-DTG Analysis

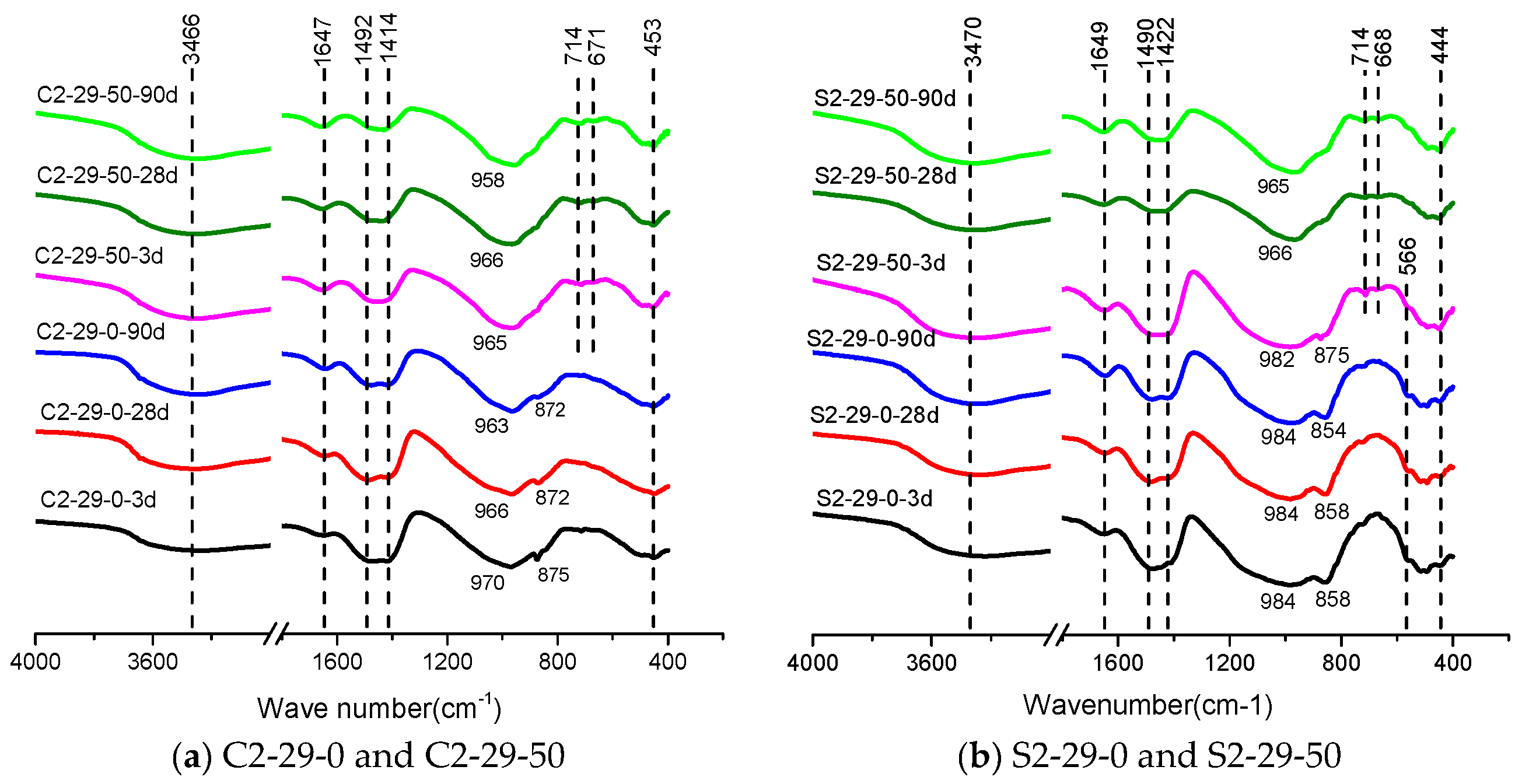

3.5. FT-IR analysis

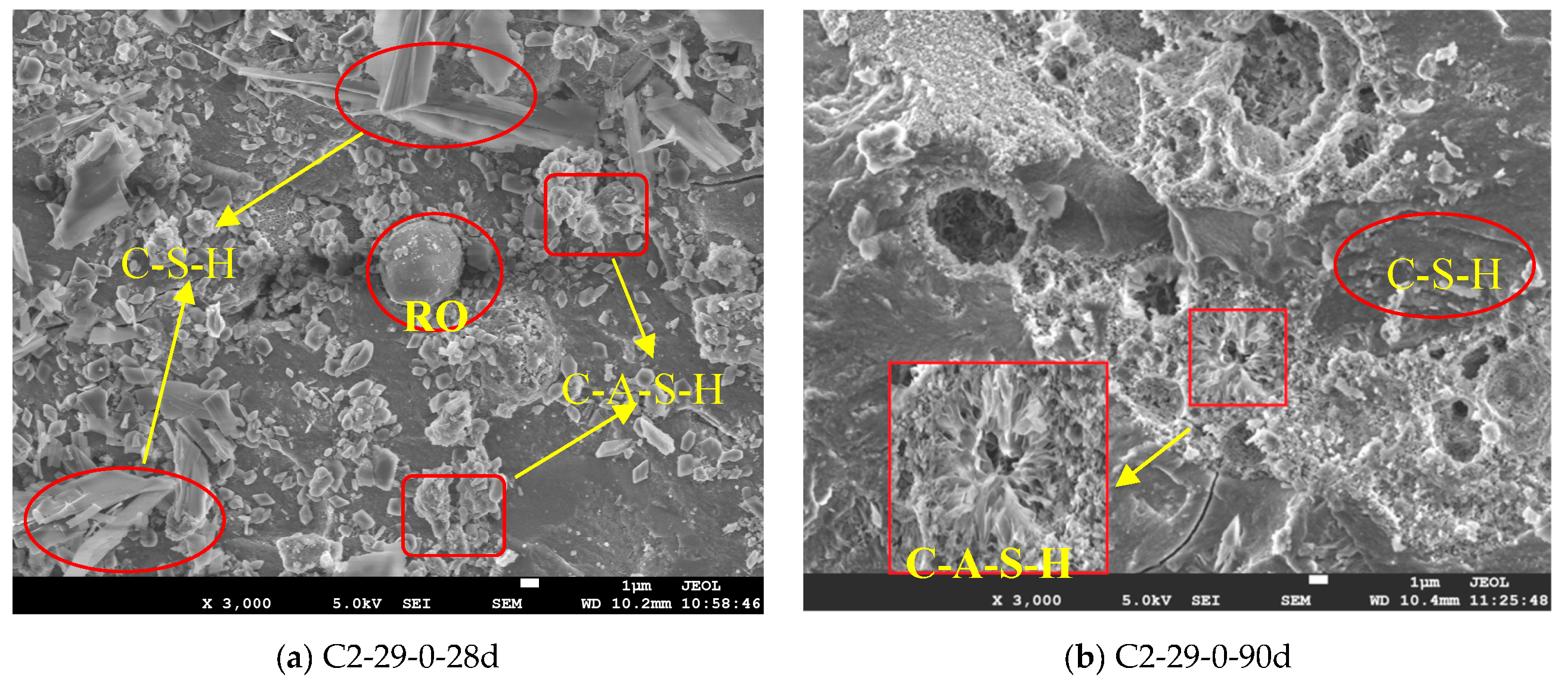

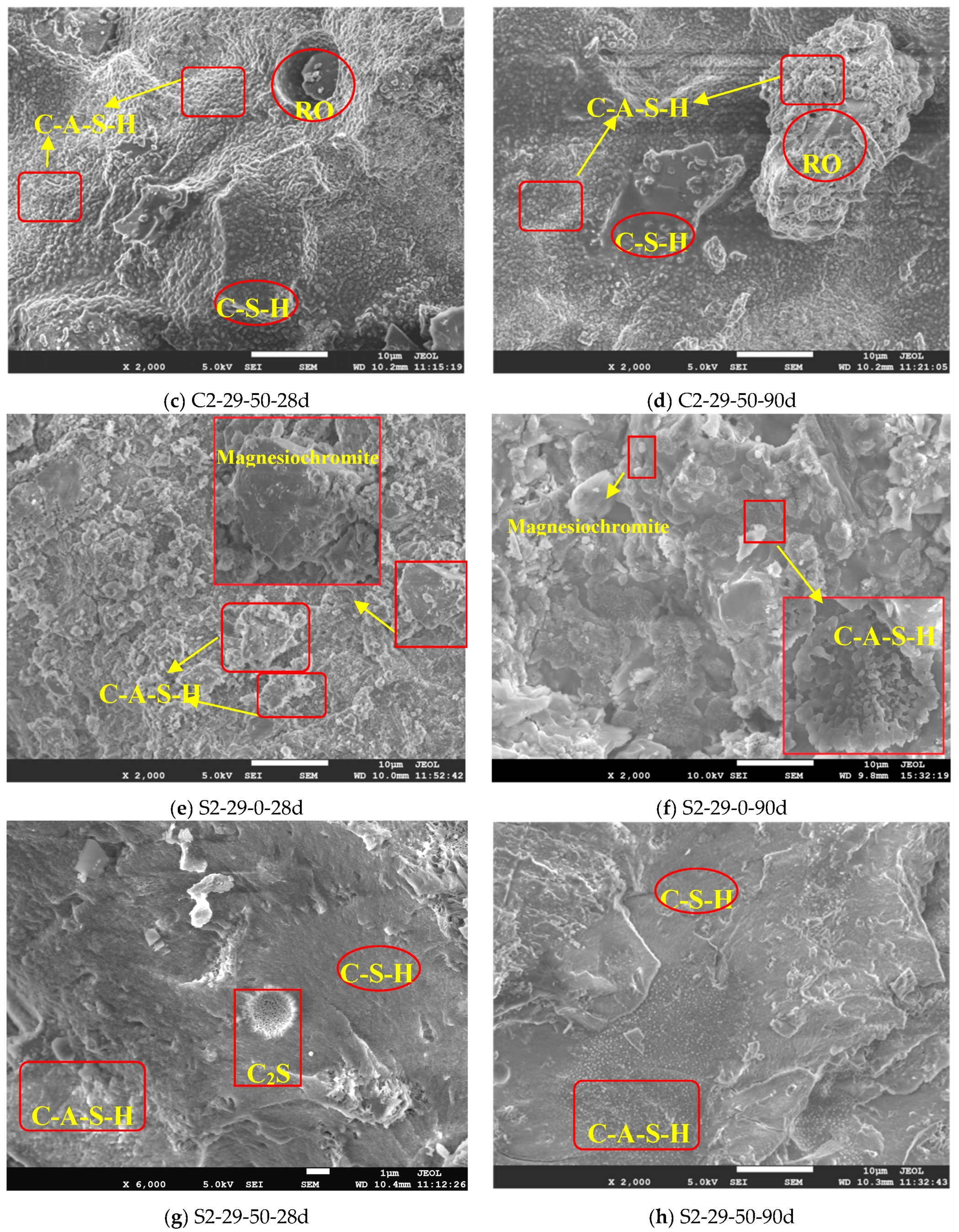

3.6. SEM-EDS Analysis

4. Reaction Mechanism

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jiang, Y.; Ling, T.C.; Shi, C.J.; Pan, S.Y. Characteristics of steel slags and their use in cement and concrete—A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Yi, H.; Xu, G.P.; Cheng, H.G.; Wang, J.S.; Wan, Y.F.; Chen, H. An overview of utilization of steel slag. In Proceedings of the 7th International Conference on Waste Management and Technology, Ancona, Italy, 12–14 May 2014; pp. 791–801. [Google Scholar]

- Shi, W.; Li, H.; Liao, G.; Pei, G.; Lin, Y. Carbon steel slag and stainless steel slag for removal of arsenic from stimulant and real groundwater. Int. J. Environ. Sci. Technol. 2018, 15, 2337–2348. [Google Scholar] [CrossRef]

- World Steel Association. Steel Statistical Yearbook 2018; World Steel Association: Brussels, Belgium, 2018. [Google Scholar]

- ISSF. Available online: http://www.worldstainless.org/crude_steel_production/crude_2018 (accessed on 20 September 2019).

- Pacheco, T.F.; Castro, G.J.; Jalali, S. Alkali-activated binders: A review. Part 2. About materials and binders manufacture. Constr. Build. Mater. 2008, 22, 1315–1322. [Google Scholar] [CrossRef]

- Le, D.H.; Sheen, Y.N.; Bui, Q.B. An assessment on volume stabilization of mortar with stainless steel slag sand. Constr. Build. Mater. 2017, 155, 200–208. [Google Scholar] [CrossRef]

- Wu, X.; Hong, Z.; Hou, X.; Li, H. Study on steel slag and fly ash composite Portland cement. Cem. Concr. Res. 1999, 29, 1103–1106. [Google Scholar]

- Shi, C.J. Characteristics and cementitious properties of ladle slag fines from steel production. Cem. Concr. Res. 2002, 32, 459–462. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.Y. Hydration properties of basic oxygen furnace steel slag. Constr. Build. Mater. 2010, 24, 1134–1140. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhao, S.Y.; Zhao, X.G.; He, T.S. Cementitious property modification of basic oxygen furnace steel slag. Constr. Build. Mater. 2013, 48, 575–579. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, D.W.; Li, L.; Wang, J.X.; Shao, N.N.; Wang, D.M. Microstructure and phase evolution of alkali-activated steel slag during early age. Constr. Build. Mater. 2019, 204, 158–165. [Google Scholar] [CrossRef]

- Sheen, Y.N.; Wang, H.Y.; Sun, T.H. A study of engineering properties of cement mortar with stainless steel oxidizing slag and reducing slag resource materials. Constr. Build. Mater. 2013, 40, 239–245. [Google Scholar] [CrossRef]

- Yuksel, I. A review of steel slag usage in construction industry for sustainable development. Environ. Dev. Sustain. 2017, 19, 369–384. [Google Scholar] [CrossRef]

- Shi, C.J. Steel Slag—Its Production, Processing, Characteristics, and Cementitious Properties. J. Mater. Civil. Eng. 2004, 16, 230–236. [Google Scholar] [CrossRef]

- Shi, C.J.; Hu, S.F. Cementitious properties of ladle slag fines under autoclave curing conditions. Cem. Concr. Res. 2003, 33, 1851–1856. [Google Scholar] [CrossRef]

- Salman, M.; Cizer, Ö.; Pontikes, Y.; Vandewalle, L.; Blanpain, B.; Koen, V.B. Effect of curing temperatures on the alkali activation of crystalline continuous casting stainless steel slag. Constr. Build. Mater. 2014, 71, 308–316. [Google Scholar] [CrossRef]

- Salman, M.; Cizer, Ö.; Pontikes, Y.; Snellings, R.; Vandewalle, L.; Blanpain, B.; Koen, V.B. Cementitious binders from activated stainless steel refining slag and the effect of alkali solutions. J. Hazard. Mater. 2015, 286, 211–219. [Google Scholar] [CrossRef]

- Kriskova, L.; Pontikes, Y.; Cizer, Ö.; Mertens, G.; Veulemans, W.; Geysen, D.; Jones, P.T.; Vandewalle, L.; Koen, V.B.; Blanpain, B. Effect of mechanical activation on the hydraulic properties of stainless steel slags. Cem. Concr. Res. 2012, 42, 778–788. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, J.W.; Yan, P.Y. Cementitious properties of super-fine steel slag. Powder Technol. 2013, 245, 35–39. [Google Scholar] [CrossRef]

- Yang, S.G.; Wang, J.F.; Cui, S.P.; Liu, H.; Wang, X.L. Impact of four kinds of alkanolamines on hydration of steel slag-blended cementitious materials. Constr. Build. Mater. 2017, 131, 655–666. [Google Scholar] [CrossRef]

- Kriskova, L.; Eroli, M.; Iacobescu, R.I.; Onisei, S.; Vecchiocattivi, F.; Pontike, Y. Transformation of stainless steel slag toward a reactive cementitious binder. J. Am. Ceram. Soc. 2018, 101, 1727–1736. [Google Scholar] [CrossRef]

- Gonzalez, P.L.L.; Novais, R.M.; Labrincha, J.A.; Blanpain, B.; Pontikes, Y. Modifications of basic-oxygen-furnace slag microstructure and their effect on the rheology and the strength of alkali-activated binders. Cem. Concr. Res. 2019, 97, 143–153. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C.J. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Zhu, W.P.; Yang, E.H. Alkali-activated ground granulated blast-furnace slag incorporating incinerator fly ash as a potential binder. Constr. Build. Mater. 2016, 112, 1005–1012. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Liu, L.C.; Xu, Y.; Wang, Y.C.; Xu, D.L. A new alkali-activated steel slag-based cementitious material for photocatalytic degradation of organic pollutan from waste water. J. Hazard. Mater. 2012, 209, 146–150. [Google Scholar] [CrossRef]

- Sakulich, A.R.; Miller, A.; Barsoum, M.W. Chemical and microstructural characterization of 20-month-old alkali activated slag cement. J. Am. Ceram. Soc. 2010, 93, 1741–1748. [Google Scholar] [CrossRef]

- Melo, A.A.; Cincotto, M.A.; Repette, W.L. Drying and autogenous shrinkage of pastes and mortars with activated slag. Cem. Concr. Res. 2008, 38, 565–574. [Google Scholar] [CrossRef]

- Cengiz, D.A.; Cahit, B.; Özlem, Ç. Influence of activator on the strength and drying shrinkage of alkali-activated slag mortar. Constr. Build. Mater. 2009, 23, 548–555. [Google Scholar]

- Collins, F.; Sanjayan, J.G. Cracking tendency of alkali-activated slag concrete subjected to restrained shrinkage. Cem. Concr. Res. 2000, 30, 791–798. [Google Scholar] [CrossRef]

- Hu, S.G.; Wang, H.X.; Zhang, G.Z.; Ding, Q.J. Bonding and abrasion resistance of geopolymeric repair material made with steel slag. Cement. Concrete. Comp. 2008, 30, 239–244. [Google Scholar] [CrossRef]

- Peng, X.Q.; Liu, C.; Li, S.; Jiang, Y.; Zeng, L. Research on the setting and hardening performance of alkali-activated steel slag-slag based cementitious materials. J. Hunan Univ. 2015, 42, 47–52. (In Chinese) [Google Scholar]

- Cui, X.W.; Ni, W.; Ren, C. Hydration Mechanism of All Solid Waste Cementitious Materials Based on Steel Slag and Blast Furnace Slag. Chin. J. Mater. Res. 2017, 31, 687–693. (In Chinese) [Google Scholar]

- Tsai, C.J.; Huang, R.; Lin, W.T.; Wang, H.N. Mechanical and cementitious characteristics of ground granulated blast furnace slag and basic oxygen furnace slag blended mortar. Mater. Des. 2014, 60, 267–273. [Google Scholar] [CrossRef]

- Kriskova, L.; Pontikes, Y.; Zhang, F.; Jones, P.T.; Balen, K.V.; Blanpain, B. Influence of mechanical and chemical activation on the hydraulic properties of gamma dicalcium silicate. Cem. Concr. Res. 2014, 55, 59–68. [Google Scholar] [CrossRef]

- Kriskova, L.; Pontikes, Y.; Cizer, O.; Malfliet, A.; Dijkmans, J.; Sels, B.; Balen, K.V.; Blanpain, B. Hydraulic behavior of mechanically and chemically activated synthetic merwinite. J. Am. Ceram. Soc. 2014, 97, 3973–3981. [Google Scholar] [CrossRef]

- Yi, C.; Ma, H.Q.; Chen, H.Y.; Wang, J.X.; Shi, J.; Li, Z.H.; Yu, M.K. Preparation and characterization of coal gangue geopolymers. Constr. Build. Mater. 2018, 187, 318–326. [Google Scholar]

- Cheng, H.; Lin, K.L.; Cui, R.; Hwang, C.L.; Chang, Y.M.; Cheng, T.W. The effects of SiO2/Na2O molar ratio on the characteristics of alkali-activated waste catalyst–metakaolin based geopolymers. Constr. Build. Mater. 2018, 95, 710–720. [Google Scholar] [CrossRef]

- Lee, N.K.; Lee, H.K. Reactivity and reaction products of alkali-activated, fly ash/slag paste. Constr. Build. Mater. 2015, 81, 303–312. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.H.; Li, L.T. A review: The comparison between alkali-activated slag (Si+Ca) and metakaolin (Si+Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Firdous, R.; Stephan, D.; Djobo, J.N.Y. Natural pozzolan based geopolymers: A review on mechanical, microstructural and durability characteristics. Constr. Build. Mater. 2018, 190, 1251–1263. [Google Scholar] [CrossRef]

- Moraes, J.C.B.; Tashima, M.M.; Akasaki, J.L.; Melges, J.L.P.; Monzó, J.; Borrachero, M.V.; Soriano, L.; Payá, J. Effect of sugar cane straw ash (SCSA) as solid precursor and the alkaline activator composition on alkali-activated binders based on blast furnace slag (BFS). Constr. Build. Mater. 2017, 144, 214–224. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Nicolas, R.S.; Hamdan, S.; Deventer, J.S.J.V. Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem. Concr. Comp. 2014, 45, 125–135. [Google Scholar] [CrossRef]

- Nochaiya, T.; Wongkeo, W.; Pimraksa, K.; Chaipanich, A. Microstructural, physical, and thermal analyses of Portland cement–fly ash–calcium hydroxide blended pastes. J. Therm. Anal. Calorim. 2010, 100, 101–108. [Google Scholar] [CrossRef]

- Tuyan, M.; Andiç-Çakir, Ö.; Ramyar, K. Effect of alkali activator concentration and curing condition on strength and microstructure of waste clay brick powder-based geopolymer. Compos. Part B Eng. 2018, 135, 242–252. [Google Scholar] [CrossRef]

- Yu, P.; Kirkpatrick, R.J.; Poe, B.; McMillan, P.F.; Cong, X. Structure of calcium silicate hydrate (CSH): Near-, mid-, and far-infrared spectroscopy. J. Am. Ceram. Soc. 1999, 82, 742–748. [Google Scholar] [CrossRef]

- Heikala, M.; Nassar, M.Y.; El-Sayed, G.; Ibrahim, S.M. Physico-chemical, mechanical, microstructure and durability characteristics of alkali activated Egyptian slag. Constr. Build. Mater. 2014, 69, 60–72. [Google Scholar] [CrossRef]

- Feng, X.J.; Min, X.M. Study on the structure and characteristic of dicalcium silicate with quantum chemistry calculations. J. Wuhan Univ. Technol. 1994, 16, 1–6. (In Chinese) [Google Scholar]

- Salman, M.; Cizer, O.; Pontikes, Y.; Snellings, R.; Dijkman, J.; Sels, B.; Vandewalle, L.; Blanpain, B.; Balen, K.V. Alkali Activation of AOD Stainless Steel Slag Under Steam Curing Conditions. J. Am. Ceram. Soc. 2015, 98, 3062–3074. [Google Scholar] [CrossRef]

- Xu, B.; Pu, X.C. Study on the relationship between the phase separation of slag glass and the latent hydraulic activity of BFS. J. Chin. Ceram. Soc. 1997, 25, 729–733. [Google Scholar]

- Puertas, F.; Palacios, M.; Manzano, H.; Dolado, J.S.; Rico, A.; Rodríguez, J. A model for the C-A-S-H gel formed in alkali-activated slag cements. J. Eur. Ceram. Soc. 2011, 31, 2043–2056. [Google Scholar] [CrossRef]

- Lodeiro, I.G.; Jimenez, A.F.; Palomo, A.; Macphee, D.E. Effect on fresh C-S-H gels of the simultaneous addition of alkali and aluminium. Cem. Concr. Res. 2010, 40, 27–32. [Google Scholar] [CrossRef]

- Renaudin, G.; Russias, J.; Leroux, F.; Cau-dit-Coumes, C.; Frizon, F. Structural characterization of C–S–H and C–A–S–H samples—Part II: Local environment investigated by spectroscopic analyses. J. Solid State Chem. 2009, 182, 3320–3329. [Google Scholar] [CrossRef]

- Yang, J.B.; Li, D.X.; Fang, Y. Effect of synthetic CaO-Al2O3-SiO2-H2O on the early-stage performance of alkali-activated slag. Constr. Build. Mater. 2018, 167, 65–72. [Google Scholar] [CrossRef]

- Thomas, J.J.; Jennings, H.M.; Chen, J.J. Influence of Nucleation Seeding on the Hydration Mechanisms of Tricalcium Silicate and Cement. J. Phys. Chem. C 2009, 113, 4327–4334. [Google Scholar] [CrossRef]

| Materials | CaO | SiO2 | Al2O3 | MgO | Fe2O3 | SO3 | Cr2O3 | MnO | Ti2O |

|---|---|---|---|---|---|---|---|---|---|

| CSS | 41.36 | 19.79 | 9.78 | 4.02 | 20.73 | 0.47 | 0.55 | 1.06 | 0.77 |

| SSS | 39.90 | 34.19 | 12.30 | 2.28 | 4.70 | 0.64 | 1.88 | 0.55 | 1.30 |

| BFS | 38.44 | 30.58 | 14.04 | 10.57 | 0.35 | 2.36 | — | 0.57 | 1.93 |

| Cement | 62.09 | 20.88 | 5.57 | 2.43 | 2.40 | 5.02 | — | — | 0.31 |

| CSS | SSS | ||||

|---|---|---|---|---|---|

| No. | Mineral Phase | Chemical Formula | No. | Mineral Phase | Chemical Formula |

| 1 | Larnite (β-C2S) | Ca2SiO4 | a | Larnite (β-C2S) | Ca2SiO4 |

| 2 | γ-C2S | Ca2SiO4 | b | γ-C2S | Ca2SiO4 |

| 3 | C3S | Ca3SiO5 | c | C3S | Ca3SiO5 |

| 4 | Srebrodolskite | Ca2Fe2O5 | d | Bredigite | Ca7Mg (SiO4)4 |

| 5 | Wustite | FeO | e | Akermanite | Ca2MgSi2O7 |

| 6 | Magnetite | Fe3O4 | f | Merwinite | Ca3Mg (SiO4)2 |

| 7 | Mayenite | Ca12Al14O33 | g | Cuspidine | Ca4Si2O7F2 |

| 8 | Calcium Oxide | CaO | h | SiO2 | SiO2 |

| 9 | RO | Mg1−xFexO | i | Magnesiochromite (chromium spinels) | MgCr2O4 |

| 10 | SiO2 | SiO2 | j | Fluorite | CaF2 |

| k | Rankinite | Ca3Si2O7 | |||

| Specimens | Liquid-Solid Ratio | NH:NSa | BFS/CSSa | Specimens | Liquid-Solid Ratio | NH:NS a | BFS/CSS a |

|---|---|---|---|---|---|---|---|

| C2-29-0 | 0.29 | 1:2 | 0:100 | S2-29-0 | 0.29 | 1:2 | 0:100 |

| C2-29-25 | 0.29 | 1:2 | 25:75 | S2-29-25 | 0.29 | 1:2 | 25:75 |

| C2-29-50 | 0.29 | 1:2 | 50:50 | S2-29-50 | 0.29 | 1:2 | 50:50 |

| C1-35-25 | 0.35 | 1:1 | 25:75 | S1-35-25 | 0.35 | 1:1 | 25:75 |

| C1.5-35-25 | 0.35 | 1:1.5 | 25:75 | S1.5-35-25 | 0.35 | 1:1.5 | 25:75 |

| C2-35-25 | 0.35 | 1:2 | 25:75 | S2-35-25 | 0.35 | 1:2 | 25:75 |

| C2.5-35-25 | 0.35 | 1:2.5 | 25:75 | S2.5-35-25 | 0.35 | 1:2.5 | 25:75 |

| C2-27-25 | 0.27 | 1:2 | 25:75 | S2-27-25 | 0.27 | 1:2 | 25:75 |

| C2-31-25 | 0.31 | 1:2 | 25:75 | S2-31-25 | 0.31 | 1:2 | 25:75 |

| C2-33-25 | 0.33 | 1:2 | 25:75 | S2-33-25 | 0.33 | 1:2 | 25:75 |

| C2-37-25 | 0.37 | 1:2 | 25:75 | S2-37-25 | 0.37 | 1:2 | 25:75 |

| OPC | 0.29 | - | - | - | - | - | - |

| Specimen | Mass Losses (%) | |||||

|---|---|---|---|---|---|---|

| 3 Days | 28 Days | 90 Days | ||||

| 35–300 °C | Tatal | 35–300 °C | Tatal | 35–300 °C | Tatal | |

| C2-29-0 | 6.51 | 12.50 | 7.93 | 14.54 | 7.39 | 14.42 |

| S2-29-0 | 4.51 | 8.16 | 5.77 | 9.73 | 5.84 | 10.12 |

| C2-29-50 | 9.15 | 15.85 | 11.45 | 17.97 | 11.49 | 18.83 |

| S2-29-50 | 9.32 | 14.23 | 10.03 | 16.23 | 10.22 | 16.91 |

| Specimen | Ca | Al | Si | Ca/Si | Al/Si |

|---|---|---|---|---|---|

| C2-29-0 | 10.55 | 4.74 | 8.37 | 1.260 | 0.566 |

| C2-29-50 | 14.68 | 2.73 | 8.05 | 1.824 | 0.339 |

| S2-29-0 | 12.82 | 3.02 | 11.61 | 1.104 | 0.260 |

| S2-29-50 | 11.21 | 1.64 | 7.62 | 1.472 | 0.215 |

| Cement | 17.43 | 3.56 | 8.63 | 2.019 | 0.142 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Yi, C.; Zhu, H.; Ma, H. Property Comparison of Alkali-Activated Carbon Steel Slag (CSS) and Stainless Steel Slag (SSS) and Role of Blast Furnace Slag (BFS) Chemical Composition. Materials 2019, 12, 3307. https://doi.org/10.3390/ma12203307

Liu J, Yi C, Zhu H, Ma H. Property Comparison of Alkali-Activated Carbon Steel Slag (CSS) and Stainless Steel Slag (SSS) and Role of Blast Furnace Slag (BFS) Chemical Composition. Materials. 2019; 12(20):3307. https://doi.org/10.3390/ma12203307

Chicago/Turabian StyleLiu, Jinyan, Cheng Yi, Hongguang Zhu, and Hongqiang Ma. 2019. "Property Comparison of Alkali-Activated Carbon Steel Slag (CSS) and Stainless Steel Slag (SSS) and Role of Blast Furnace Slag (BFS) Chemical Composition" Materials 12, no. 20: 3307. https://doi.org/10.3390/ma12203307

APA StyleLiu, J., Yi, C., Zhu, H., & Ma, H. (2019). Property Comparison of Alkali-Activated Carbon Steel Slag (CSS) and Stainless Steel Slag (SSS) and Role of Blast Furnace Slag (BFS) Chemical Composition. Materials, 12(20), 3307. https://doi.org/10.3390/ma12203307