Experimental Study on Shear Performance of Cast-In-Place Ultra-High Performance Concrete Structures

Abstract

1. Introduction

2. Experimental Program

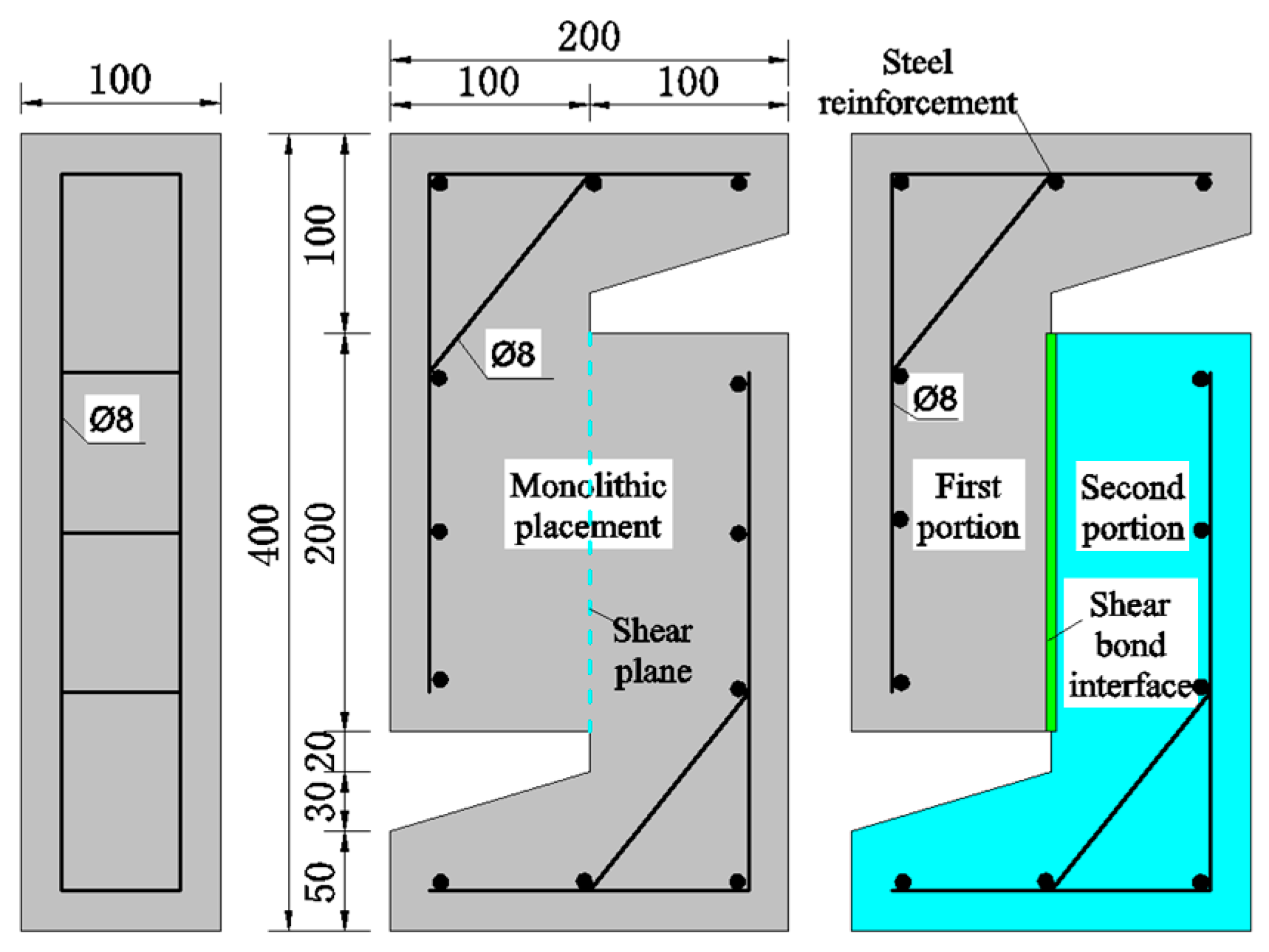

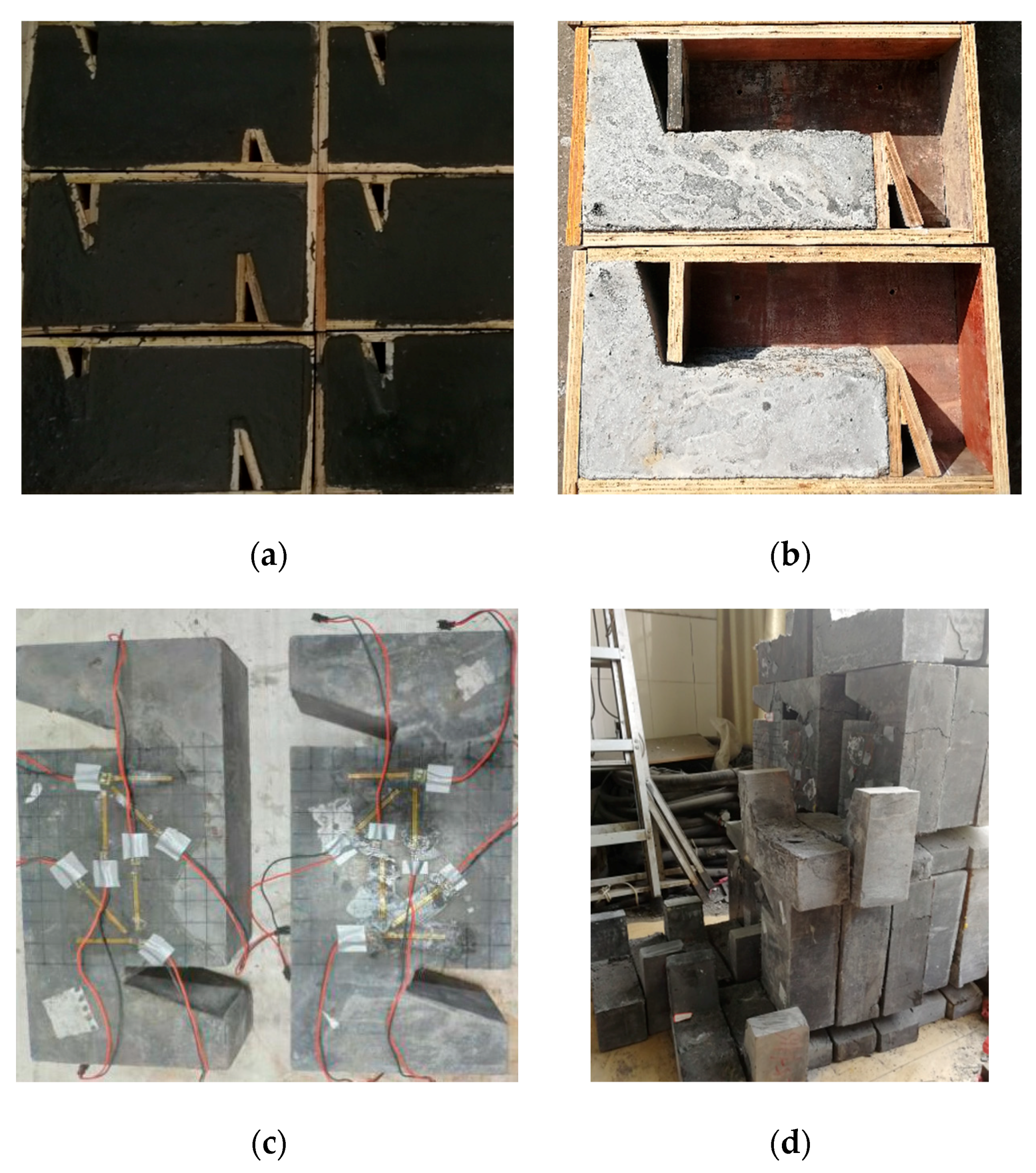

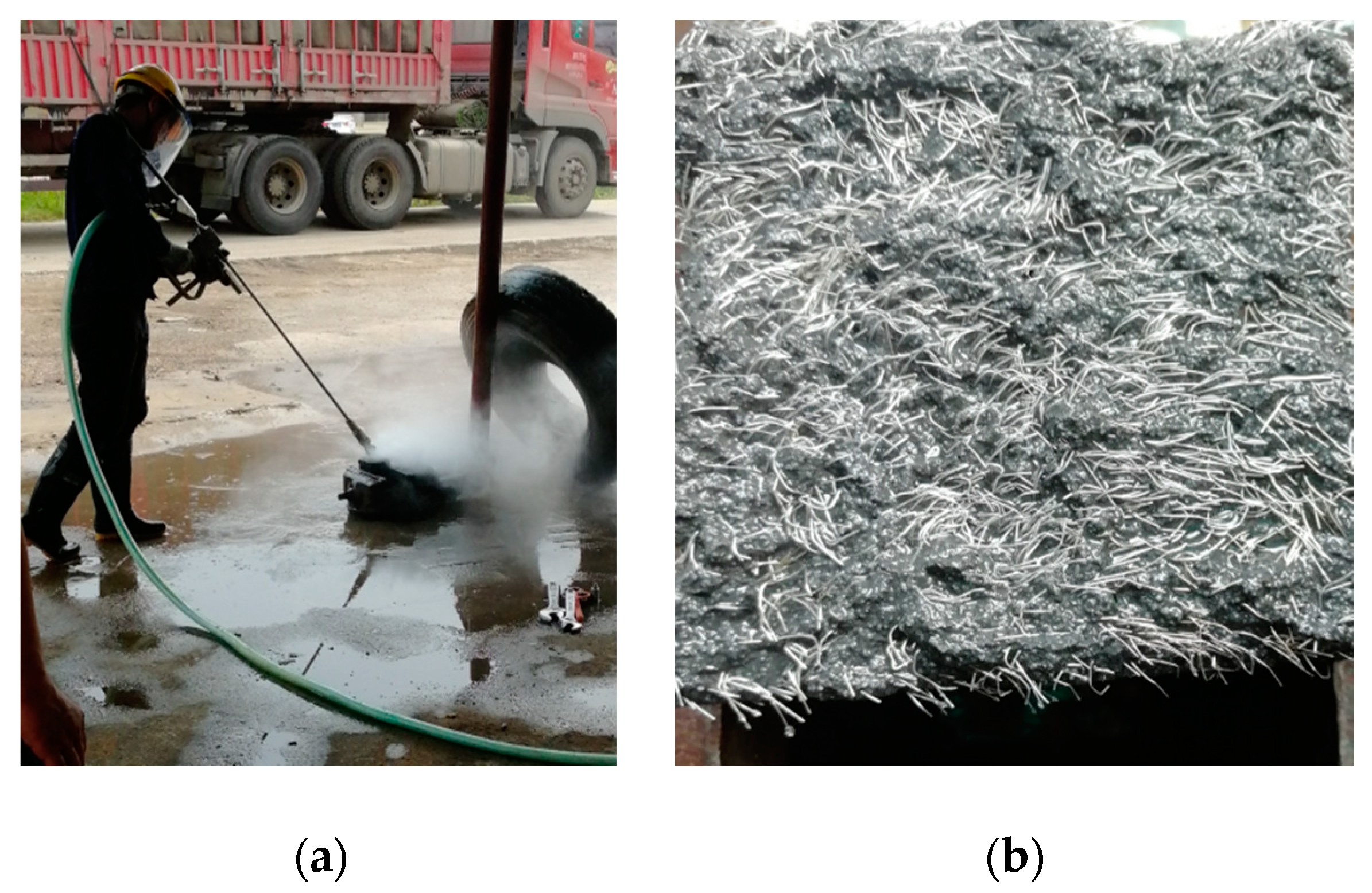

2.1. Experimental Specimens

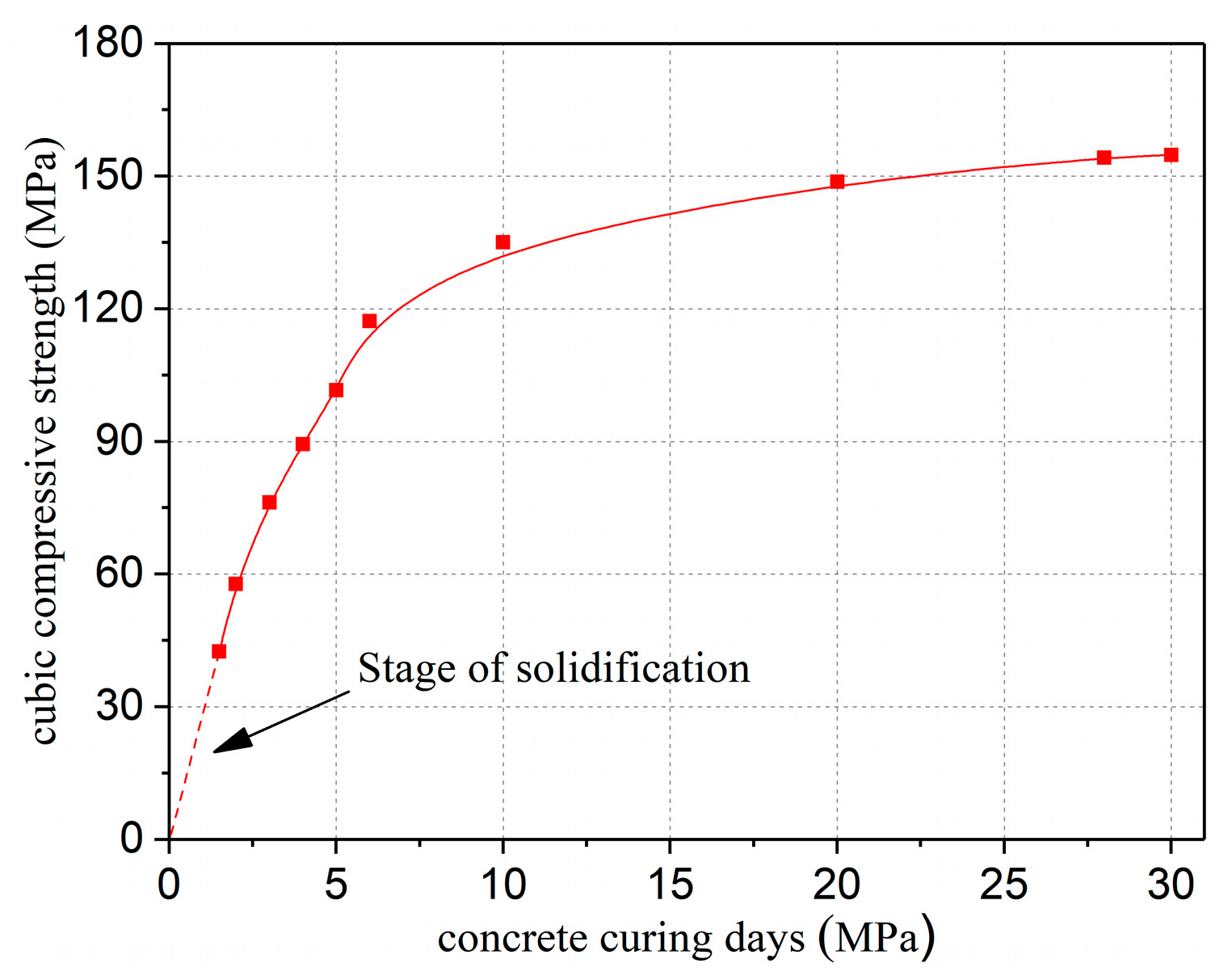

2.2. Material Properties

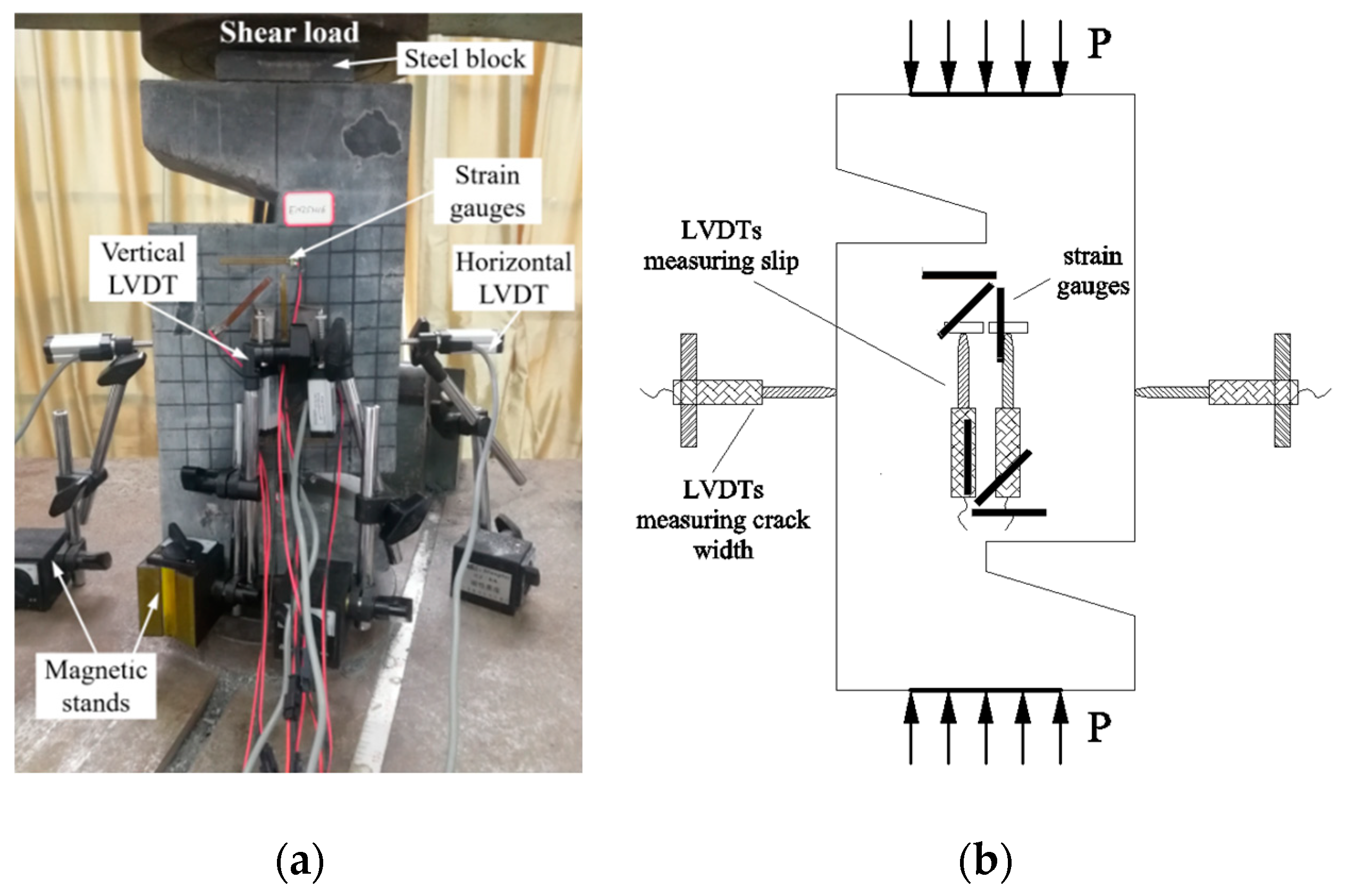

2.3. Loading Process and Measuring Arrangement

3. Experimental Results and Discussion

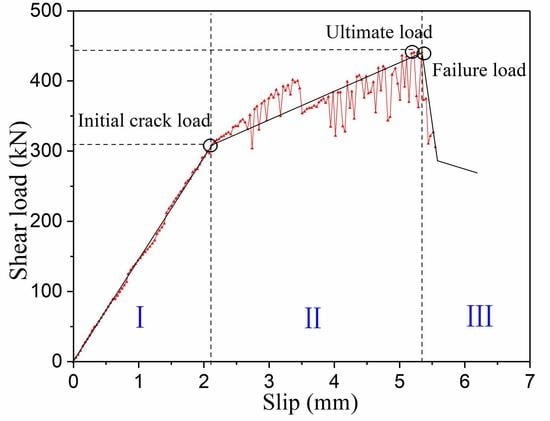

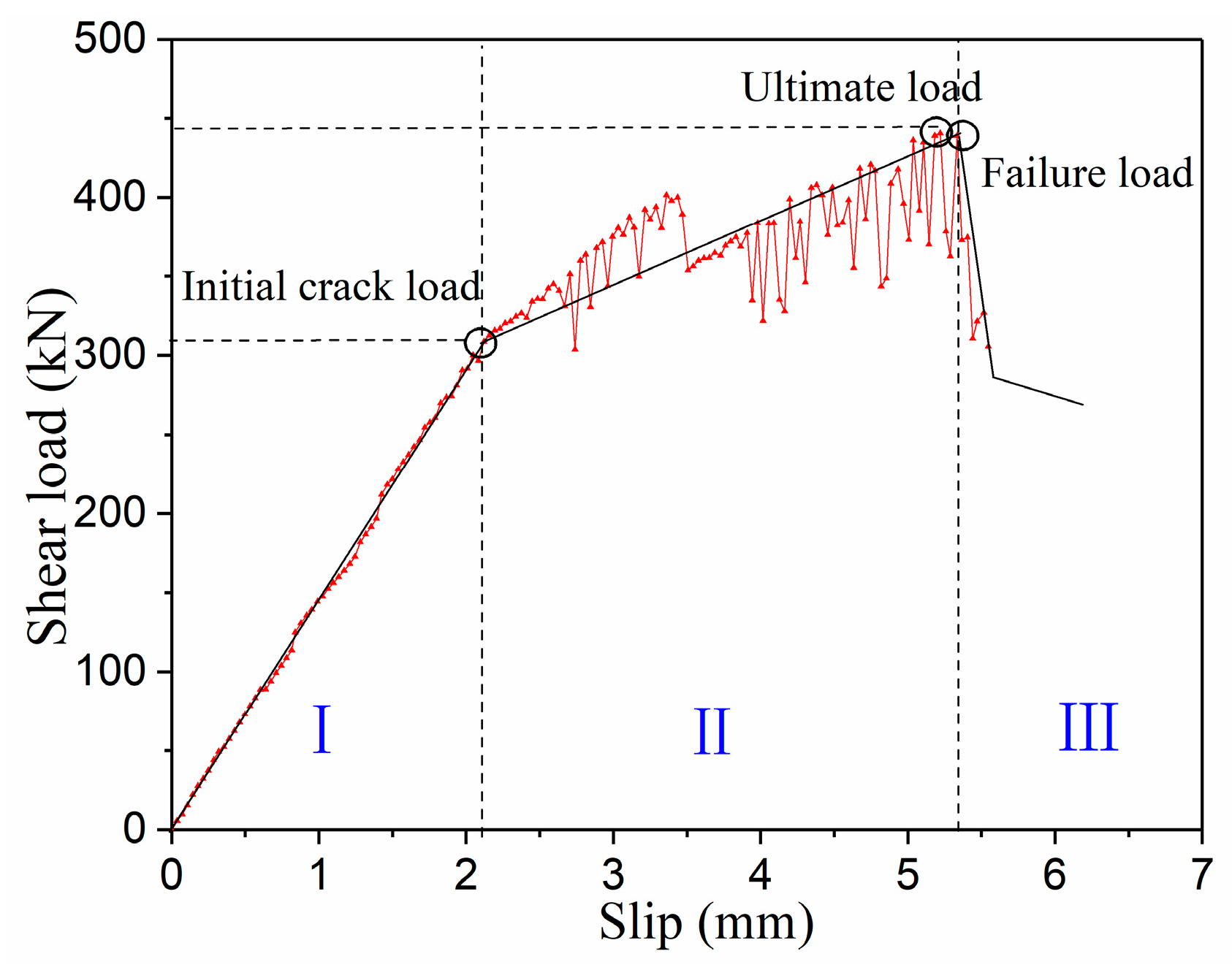

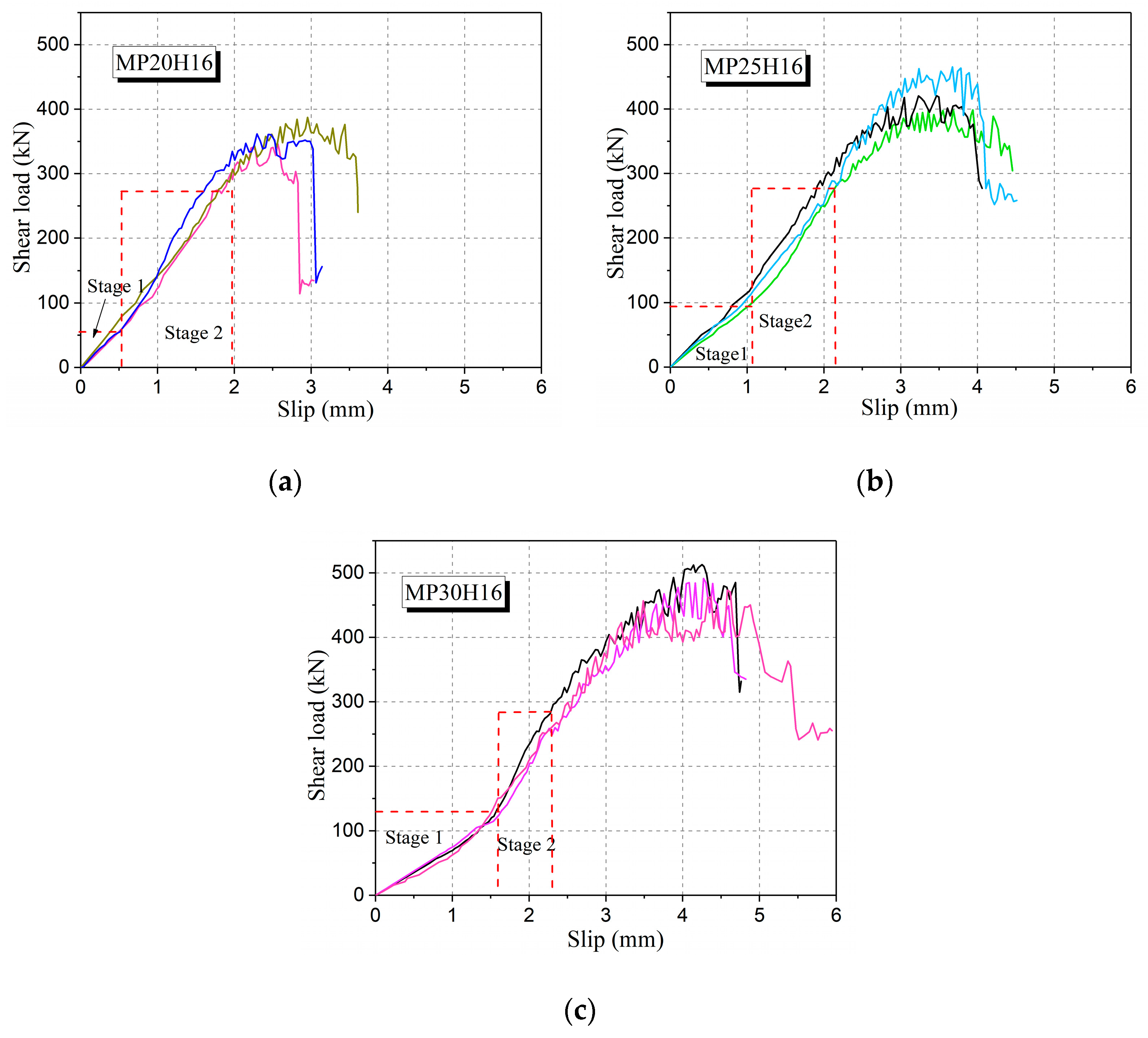

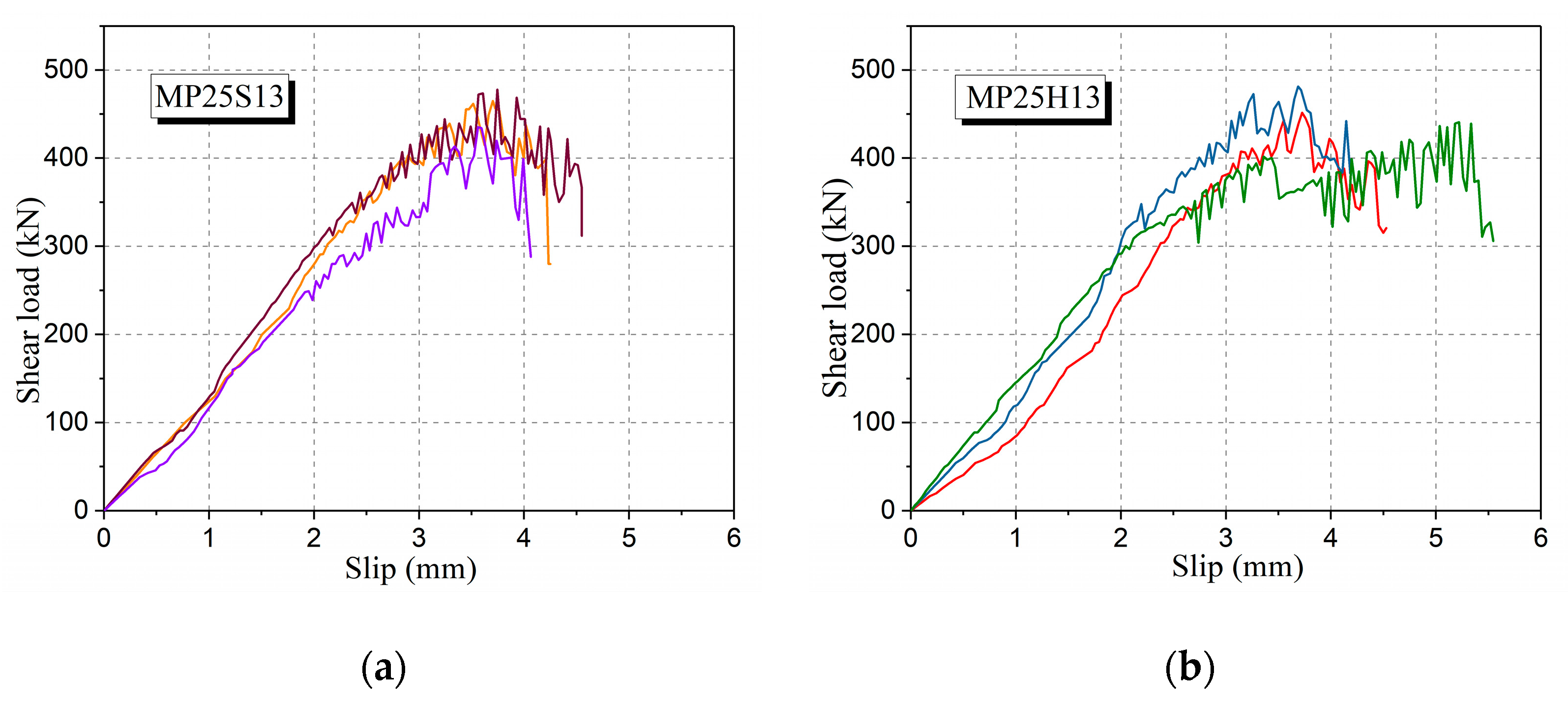

3.1. Test Results and Analysis of the MPSs

3.1.1. Load-Carrying Capacity and Failure Modes

3.1.2. Shear Strength Results

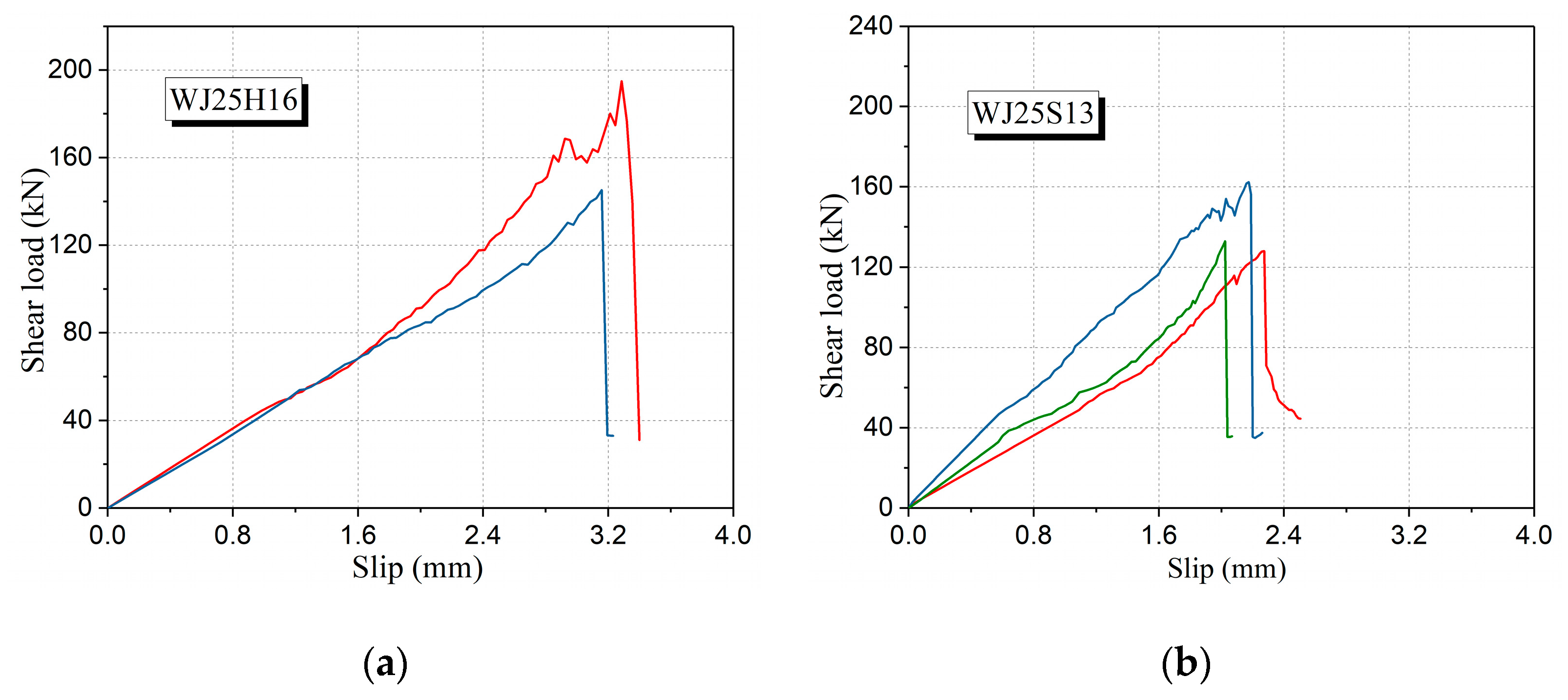

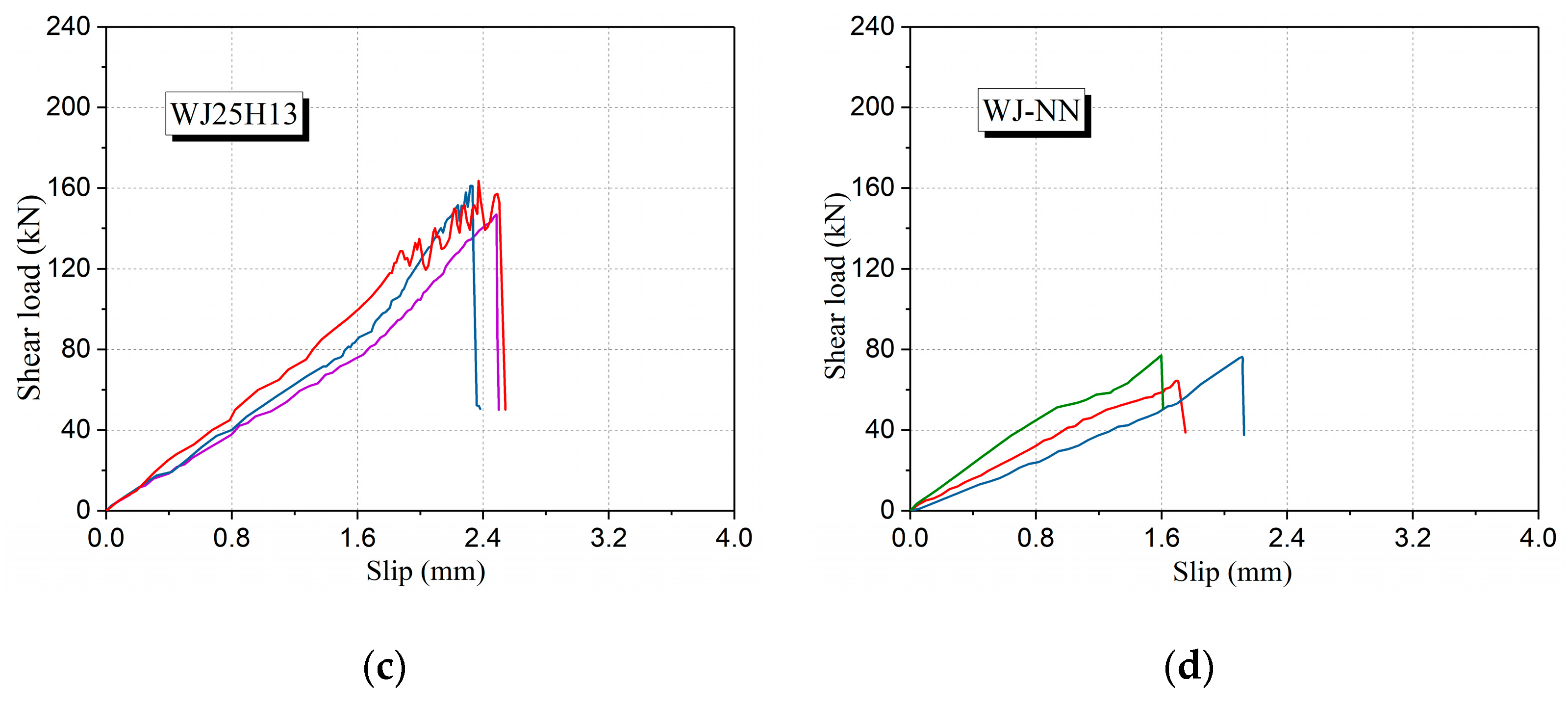

3.2. Test Results and Analysis of the WJTSs

3.2.1. Load-Carrying Capacity and Failure Modes

3.2.2. Shear Strength Results

4. Analytical Study

4.1. Interaction of Compressive and Shear Strength of the MPSs

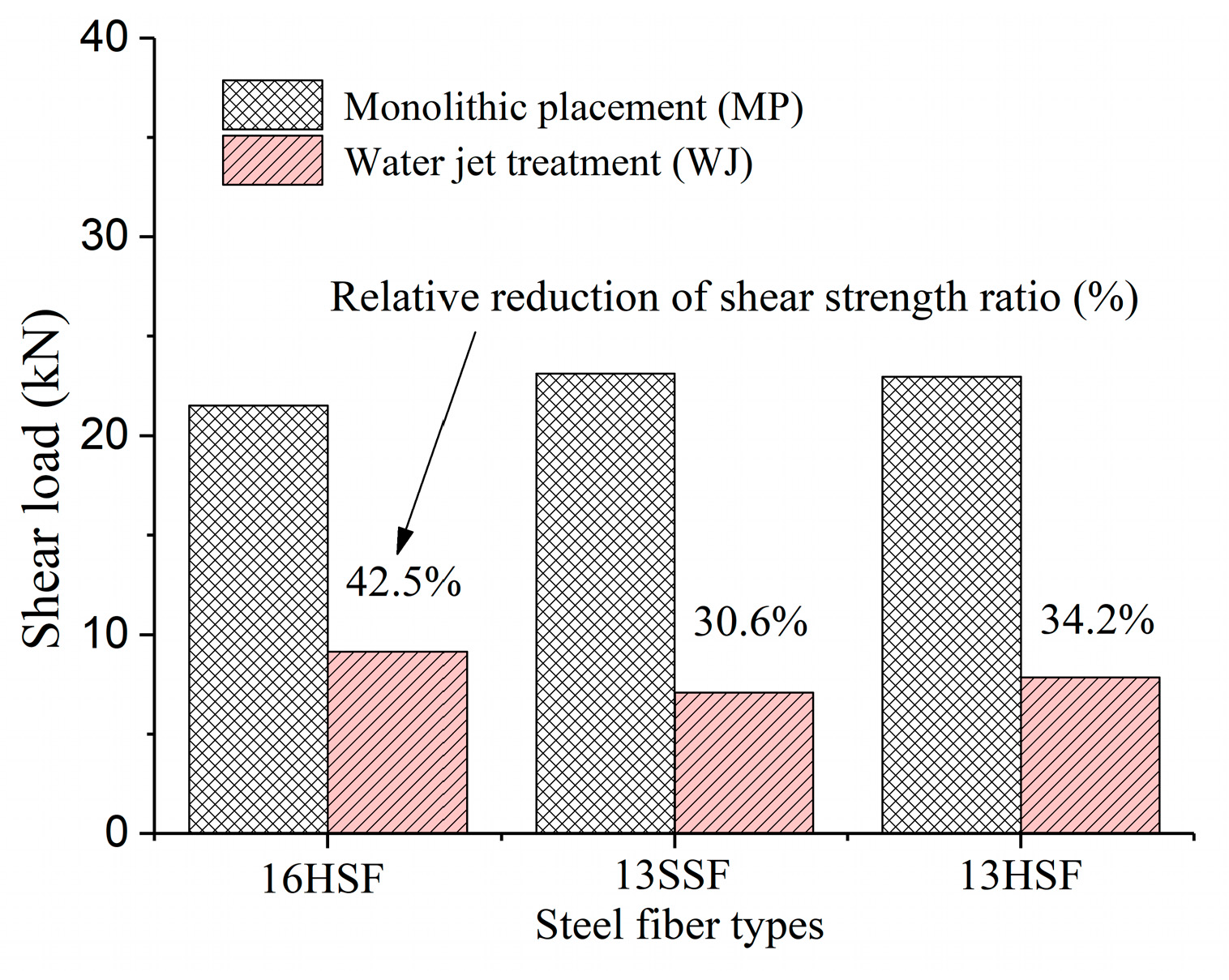

4.2. Relative Reduction of Shear Strength Ratio of the WJTSs

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- French, R.; Maher, E.; Smith, M.; Stone, M.; Kim, J.; Krauthammer, T. Direct shear behavior in concrete materials. Int. J. Impact Eng. 2017, 108, 89–100. [Google Scholar] [CrossRef]

- Zhou, X.; Mickleborough, N.; Li, Z. Shear strength of joints in precast concrete segmental bridges. ACI Struct. J. 2005, 102, 3–11. [Google Scholar]

- Park, J.-S.; Kim, Y.-J.; Cho, J.-R.; Jeon, S.-J. Early-age strength of ultra-uigh performance concrete in various curing conditions. Materials 2015, 8, 5537–5553. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Peng, G.-F.; Shui, G.-S.; Zhang, G. Mechanical Properties and Anti-Spalling Behavior of Ultra-High Performance Concrete with Recycled and Industrial Steel Fibers. Materials 2019, 12, 783. [Google Scholar] [CrossRef]

- French Association of Civil Engineering-French Authorities of Civil Engineering Structure Design, and Control (AFGC-Sétra). Ultra High Performance Fibre-Reinforced Concretes; French Association of Civil Engineering: Paris, France, 2013. [Google Scholar]

- Tam, C.M.; Tam, V.W.; Ng, K. Assessing drying shrinkage and water permeability of reactive powder concrete produced in Hong Kong. Constr. Build. Mater. 2012, 26, 79–89. [Google Scholar] [CrossRef]

- Zhou, M.; Lu, W.; Song, J.; Lee, G.C. Application of Ultra-High Performance Concrete in bridge engineering. Constr. Build. Mater. 2018, 186, 1256–1267. [Google Scholar] [CrossRef]

- Blais, P.Y.; Couture, M. Precast, Prestressed Pedestrian Bridge World’s First Reactive Powder Concrete Structure. PCI J. 1999, 44, 60–71. [Google Scholar] [CrossRef]

- Almansour, H.; Lounis, Z. Innovative design approach of precast–prestressed girder bridges using ultra high performance concrete. Can. J. Civ. Eng. 2010, 37, 511–521. [Google Scholar] [CrossRef]

- Hsin, Y.L.; Hong, H. Reliability analysis of direct shear and flexural failure modes of RC slabs under explosive loading. Eng. Struct. 2002, 24, 189–198. [Google Scholar] [CrossRef]

- Yang, M.; Huang, C.K.; Liu, Y. Experimental research on shear behavior of high-strength SFRC. J. Dalian Univ. Tech. 2005, 45, 842–846. [Google Scholar]

- Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Influence of yield stress and compressive strength on direct shear behaviour of steel fibre-reinforced concrete. Constr. Build. Mater. 2012, 27, 6–14. [Google Scholar] [CrossRef]

- Ronald, F.Z. Fiber-reinforced concrete: An overview after 30 years of development. Cement Concrete Comp. 1997, 19, 107–122. [Google Scholar]

- Kim, Y.-J.; Chin, W.-J.; Jeon, S.-J. Interface Shear Strength at Joints of Ultra-High Performance Concrete Structures. Int. J. Concr. Struct. Mater. 2018, 12, 2–14. [Google Scholar] [CrossRef]

- Lee, C.H.; Kim, Y.J.; Chin, W.J.; Choi, E.S. Shear Strength of Ultra High Performance Fiber Reinforced Concrete (UHPFRC) Precast Bridge Joint. In High Performance Fiber Reinforced Cement Composites; Parra-Montesinos, G.J., Reinhardt, H.W., Naaman, A.E., Eds.; Springer: Dordrecht, The Netherlands, 2012; pp. 413–420. [Google Scholar]

- Shao, X.; Pan, R.; Zhan, H.; Fan, W.; Yang, Z.; Lei, W. Experimental Verification of the Feasibility of a Novel Prestressed Reactive Powder Concrete Box-Girder Bridge Structure. J. Bridg. Eng. 2017, 22, 4017015. [Google Scholar] [CrossRef]

- Shamass, R.; Zhou, X.; Alfano, G. Finite-Element Analysis of Shear-Off Failure of Keyed Dry Joints in Precast Concrete Segmental Bridges. J. Bridg. Eng. 2015, 20, 4014084. [Google Scholar] [CrossRef]

- Ke, L.; Li, C.X.; Luo, N.H.; He, J.; Jiao, Y.; Liu, Y. Enhanced comprehensive performance of bonding interface between CFRP and steel by a novel film adhesive. Comp. Struct. 2019, 229, 111393. [Google Scholar] [CrossRef]

- Li, C.; Ke, L.; He, J.; Chen, Z.; Jiao, Y. Effects of mechanical properties of adhesive and CFRP on the bond behavior in CFRP-strengthened steel structures. Compos. Struct. 2018, 211, 163–174. [Google Scholar] [CrossRef]

- Lee, H.-S.; Jang, H.-O.; Cho, K.-H. Evaluation of Bonding Shear Performance of Ultra-High-Performance Concrete with Increase in Delay in Formation of Cold Joints. Materials 2016, 9, 362. [Google Scholar] [CrossRef]

- AASHTO Highway Subcommittee on Bridges and Structures, AASHTO LRFD bridge design specifications. American Association of State Highway and Transportation Officials, 7th ed.; AASHTO: Washington, DC, USA, 2015. [Google Scholar]

- JTG 3362-201, Specifications for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts; Ministry of Transport of the People’s Republic of China: Beijing, China, 2018; (In Chinese).

- Kim, H.S.; Chin, W.J.; Cho, J.R.; Kim, Y.J.; Yoon, H. An Experimental Study on the Behavior of Shear Keys According to the Curing Time of UHPC. Engineering 2015, 7, 212–218. [Google Scholar] [CrossRef]

- Hussein, H.H.; Sargand, S.M.; Al Rikabi, F.T.; Steinberg, E.P. Laboratory evaluation of ultrahigh performance concrete shear key for prestressed adjacent precast concrete box girder bridges. J. Bridge Eng. 2016, 22, 04016113. [Google Scholar] [CrossRef]

- Sargand, S.M.; Walsh, K.K.; Hussein, H.H.; Al Rikabi, F.T.; Steinberg, E.P. Modeling the shear connection in adjacent box-beam bridges with ultrahigh performance concrete joints. II: Load transfer mechanism. J. Bridge Eng. 2017, 22, 04017044. [Google Scholar] [CrossRef]

- Jang, H.-O.; Lee, H.-S.; Cho, K.; Kim, J. Experimental study on shear performance of plain construction joints integrated with ultra-high performance concrete (UHPC). Constr. Build. Mater. 2017, 152, 16–23. [Google Scholar] [CrossRef]

- Islam, M.A.; Farhat, Z.; Bonnell, J. High Pressure Water-Jet Technology for the Surface Treatment of Al-Si Alloys and Repercussion on Tribological Properties. J. Surf. Eng. Mater. Adv. Technol. 2011, 1, 112–120. [Google Scholar] [CrossRef]

- Zhang, Z.; Shao, X.D.; Li, W.G. Axial tensile behavior test of ultra high performance concrete. China J. Highw. Transp. 2015, 8, 50. (in Chinese). [Google Scholar]

- Mansur, M.A.; Vinayagam, T.; Tan, K.-H. Shear Transfer across a Crack in Reinforced High-Strength Concrete. J. Mater. Civ. Eng. 2008, 20, 294–302. [Google Scholar] [CrossRef]

| Cement | Quartz Sand | Cementitious Material | Water | Superplasticizer |

|---|---|---|---|---|

| 1.00 | 1.00 | 1.690 | 0.304 | 0.041 |

| Types | Density (g·cm−3) | Length (mm) | Diameter (mm) | Ratios of Length–Diameter | Modulus of Elasticity (GPa) | Tensile Strength (MPa) | External Features |

|---|---|---|---|---|---|---|---|

| 13SSF | 7.8 | 13 | 0.2 | 65 | 205 | 2850 | straight-type |

| 13HSF | 7.8 | 13 | 0.2 | 65 | 205 | 2850 | hooked-type |

| 16HSF | 7.8 | 16 | 0.2 | 80 | 205 | 2850 | hooked-type |

| Specimen Type | Specimen Number | Steel Fiber Volume Fraction | Types of Steel Fibers |

|---|---|---|---|

| MPSs | MP25S13 | 2.5% | 13SSF |

| MP25H13 | 2.5% | 13HSF | |

| MP20H16 | 2.0% | 16HSF | |

| MP25H16 | 2.5% | 16HSF | |

| MP30H16 | 3.0% | 16HSF | |

| WJTSs | WJ25S13 | 2.5% | 13SSF |

| WJ25H13 | 2.5% | 13HSF | |

| WJ25H16 | 2.5% | 16HSF | |

| WJ-NN | 0 | / |

| Specimens | Cubic Compressive Strength (fcu) | Average Cubic Compressive Strength (fcu) | Coefficient of Variation | Flexural Strength (fcf) | Average Flexural Strength (fcf) | Coefficient of Variation |

|---|---|---|---|---|---|---|

| MN25S13 | 163.90 | 165.50 | 0.010 | 36.92 | 38.75 | 0.036 |

| 164.72 | 39.09 | |||||

| 167.89 | 40.25 | |||||

| MN25H13 | 164.10 | 161.43 | 0.012 | 35.50 | 36.43 | 0.033 |

| 160.77 | 35.68 | |||||

| 159.42 | 38.11 | |||||

| MN20H16 | 152.21 | 150.25 | 0.011 | 31.78 | 32.81 | 0.035 |

| 150.38 | 32.24 | |||||

| 148.15 | 34.42 | |||||

| MN25H16 | 158.24 | 159.35 | 0.023 | 44.52 | 40.49 | 0.070 |

| 155.60 | 38.45 | |||||

| 164.21 | 38.51 | |||||

| MN30H16 | 184.38 | 178.50 | 0.026 | 42.17 | 42.66 | 0.077 |

| 173.12 | 46.89 | |||||

| 178.01 | 38.92 |

| Specimen Number | Initial Crack Load /kN | Ultimate Load /kN | Ultimate Load /kN (Average) | Shear Strength τ/MPa | Shear Strength τ/MPa (Average) | Coefficient of Variation | / | (Average) |

|---|---|---|---|---|---|---|---|---|

| MP20H16 | 262.2 | 340.7 | 360.1 | 17.04 | 18.01 | 0.055 | 1.299 | 1.296 |

| 294.3 | 387.5 | 19.38 | 1.317 | |||||

| 276.6 | 352.0 | 17.60 | 1.273 | |||||

| MP25H16 | 278.6 | 405.6 | 430.6 | 20.28 | 21.53 | 0.059 | 1.456 | 1.604 |

| 254.1 | 420.8 | 21.04 | 1.656 | |||||

| 273.8 | 465.5 | 23.28 | 1.700 | |||||

| MP30H16 | 286.4 | 515.6 | 494.5 | 25.78 | 24.72 | 0.035 | 1.800 | 1.669 |

| 296.4 | 494.8 | 24.74 | 1.669 | |||||

| 307.3 | 473.0 | 23.65 | 1.539 | |||||

| MP25S13 | 291.0 | 469.8 | 462.7 | 23.49 | 23.13 | 0.028 | 1.614 | 1.560 |

| 307.2 | 473.6 | 23.68 | 1.542 | |||||

| 291.5 | 444.6 | 22.23 | 1.525 | |||||

| MP25H13 | 284.2 | 454.3 | 459.8 | 22.72 | 22.98 | 0.035 | 1.599 | 1.630 |

| 261.3 | 481.5 | 24.08 | 1.843 | |||||

| 306.2 | 443.5 | 22.18 | 1.447 |

| Specimen Number | Initial Crack Load /kN | Ultimate Load /kN | Ultimate Load /kN (Average) | Shear Strength τ/MPa | Shear Strength τ/MPa (Average) | Coefficient of Variation | / | / (Average) |

|---|---|---|---|---|---|---|---|---|

| WJ25H16 | 159.7 | 205.60 | 182.9 | 10.28 | 9.15 | 0.139 | 1.287 | 1.188 |

| 160.5 | 195.40 | 9.77 | 1.217 | |||||

| 139.5 | 147.75 | 7.39 | 1.059 | |||||

| WJ25S13 | 115.9 | 128.4 | 141.8 | 6.42 | 7.09 | 0.110 | 1.108 | 1.042 |

| 154.9 | 163.7 | 8.18 | 1.057 | |||||

| 129.3 | 133.2 | 6.66 | 1.030 | |||||

| WJ25H13 | 141.2 | 146.9 | 157.1 | 7.35 | 7.86 | 0.046 | 1.040 | 1.153 |

| 140.1 | 161.3 | 8.06 | 1.151 | |||||

| 128.8 | 163.2 | 8.16 | 1.267 | |||||

| WJ-NN | 67.2 | 70.2 | 74.1 | 3.51 | 3.71 | 0.039 | 1.045 | 1.040 |

| 70.0 | 75.2 | 3.76 | 1.074 | |||||

| 77.0 | 77.0 | 3.85 | 1.000 |

| Specimen Number | Ratios of Length-Diameter | Volume Fraction of Fibers | Characteristic Coefficient of Steel Fibers | Shear Strength /MPa | Cubic Compressive Strength /MPa | Shear Strength /MPa | / |

|---|---|---|---|---|---|---|---|

| MP20H16 | 80 | 2.0% | 1.6 | 18.01 | 150.25 | 20.11 | 0.90 |

| MP25H16 | 80 | 2.5% | 2.0 | 21.53 | 159.35 | 22.58 | 0.95 |

| MP30H16 | 80 | 3.0% | 2.4 | 24.72 | 178.50 | 24.69 | 1.00 |

| MP25H13 | 65 | 2.5% | 1.625 | 22.98 | 161.43 | 22.02 | 1.04 |

| MP25S13 | 65 | 2.5% | 1.625 | 23.13 | 165.50 | 22.29 | 1.04 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Feng, Z.; Ke, L.; Pan, R.; Nie, J. Experimental Study on Shear Performance of Cast-In-Place Ultra-High Performance Concrete Structures. Materials 2019, 12, 3254. https://doi.org/10.3390/ma12193254

Li C, Feng Z, Ke L, Pan R, Nie J. Experimental Study on Shear Performance of Cast-In-Place Ultra-High Performance Concrete Structures. Materials. 2019; 12(19):3254. https://doi.org/10.3390/ma12193254

Chicago/Turabian StyleLi, Chuanxi, Zheng Feng, Lu Ke, Rensheng Pan, and Jie Nie. 2019. "Experimental Study on Shear Performance of Cast-In-Place Ultra-High Performance Concrete Structures" Materials 12, no. 19: 3254. https://doi.org/10.3390/ma12193254

APA StyleLi, C., Feng, Z., Ke, L., Pan, R., & Nie, J. (2019). Experimental Study on Shear Performance of Cast-In-Place Ultra-High Performance Concrete Structures. Materials, 12(19), 3254. https://doi.org/10.3390/ma12193254