Comparative Study on Viscoelastic Evaluation Methods of Polymer Materials Based on Ultrasonic Method

Abstract

:1. Introduction

2. Ultrasonic-based Viscoelastic Evaluation Method

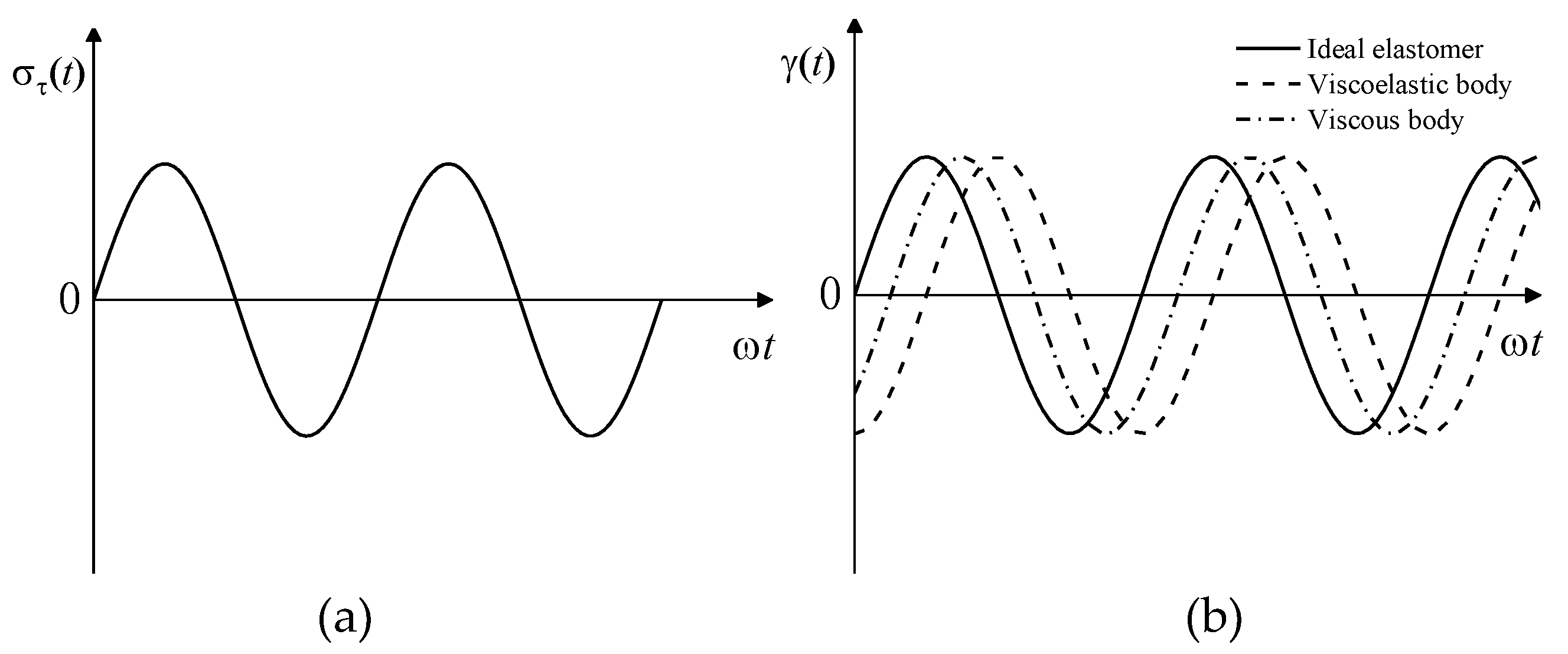

2.1. Viscoelastic Evaluation Method

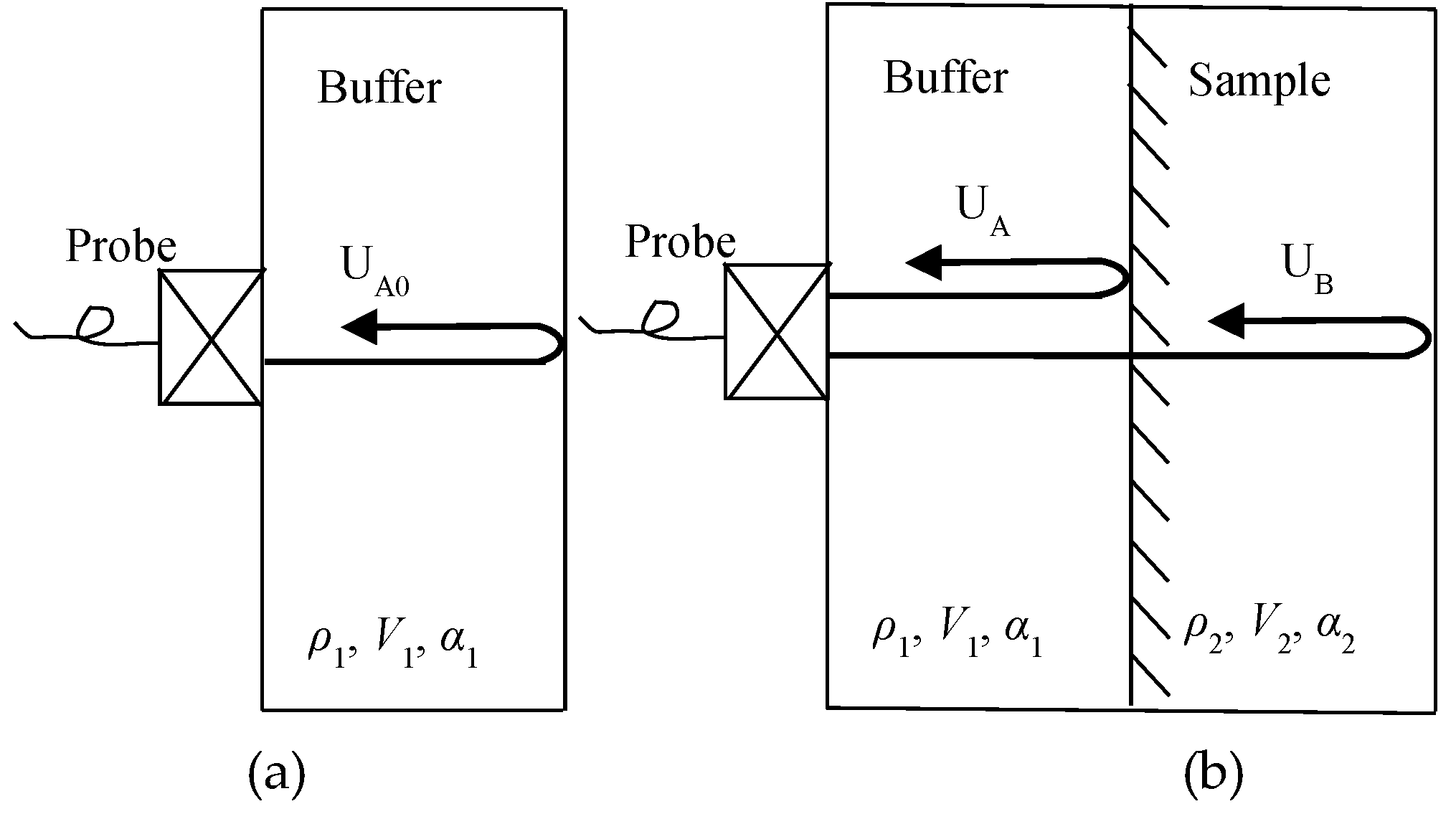

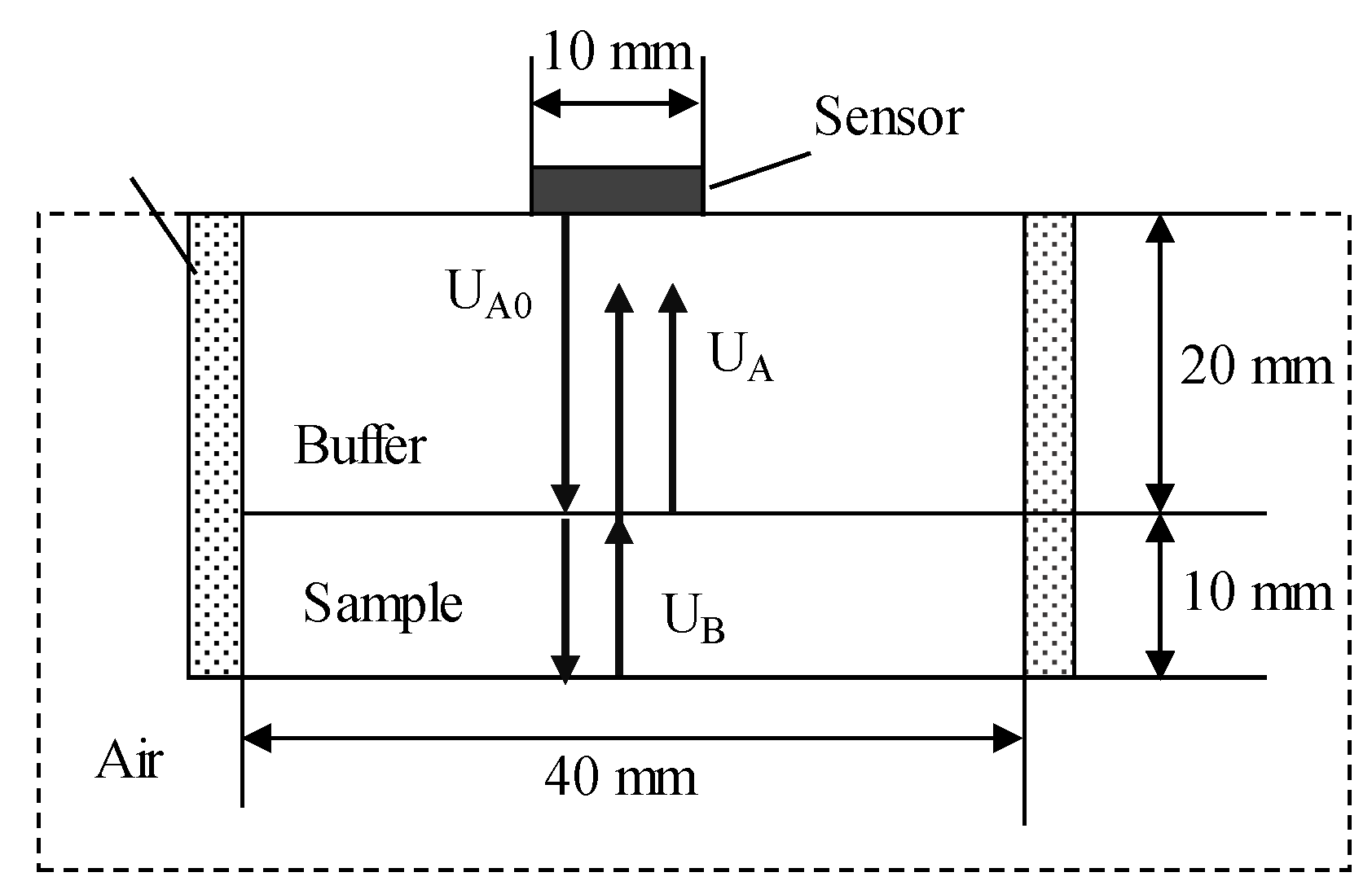

2.2. Bottom Reflection Method to Evaluate Material Viscoelasticity

2.3. Evaluation of Viscoelastic Properties of Materials by the Surface Reflection Method

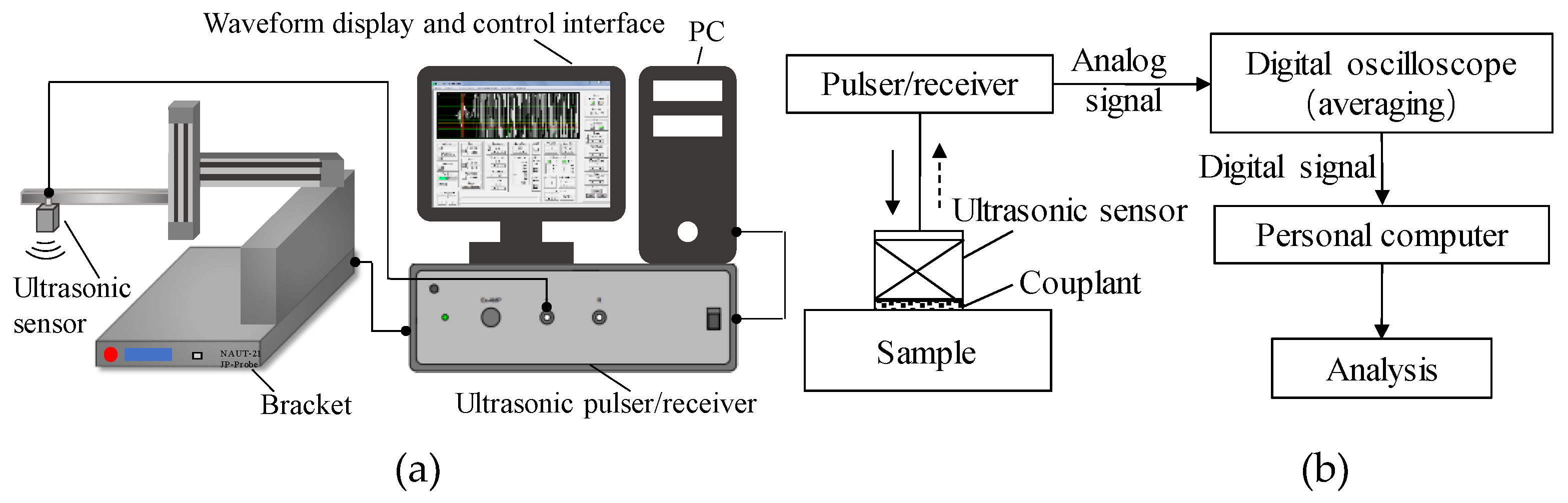

3. Viscoelastic Evaluation of Different Rubber Materials by the BRM

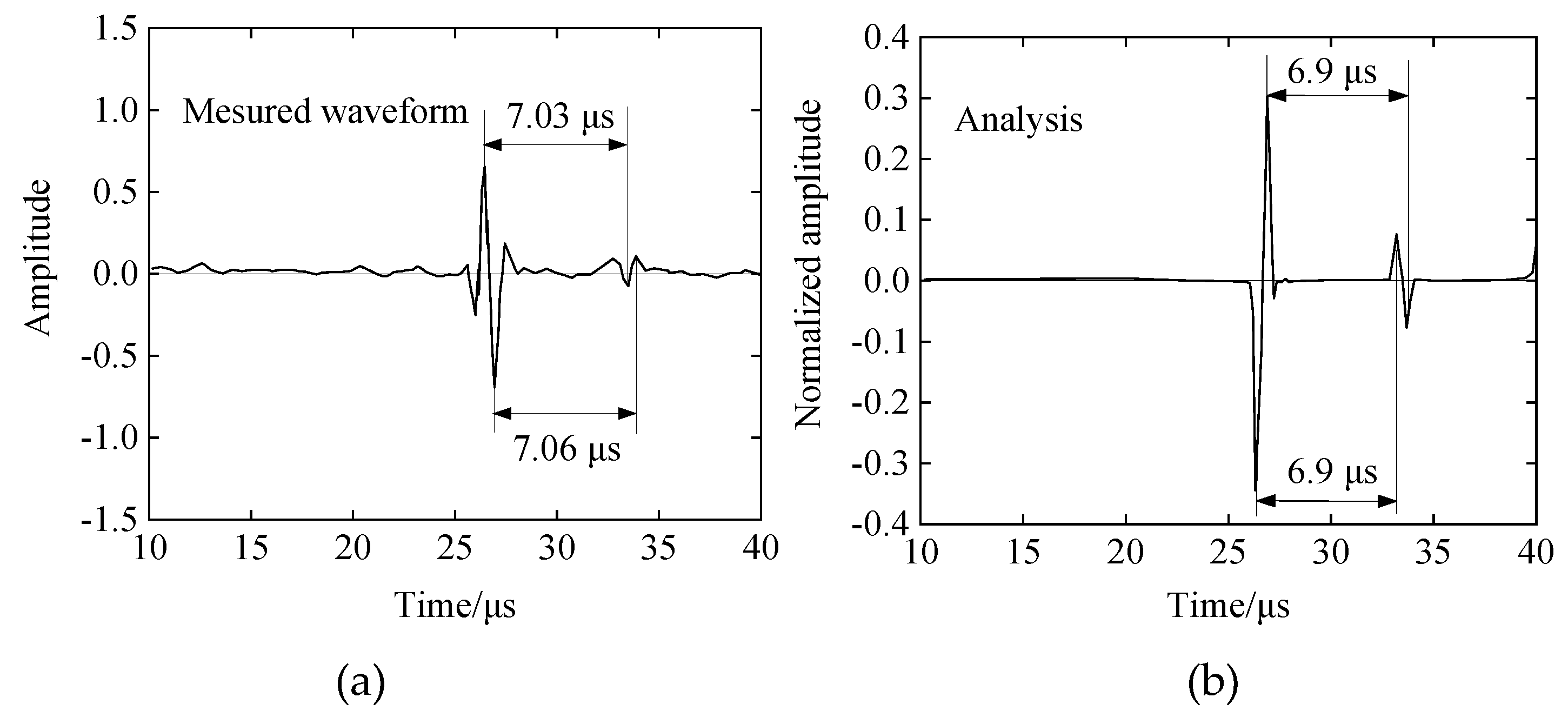

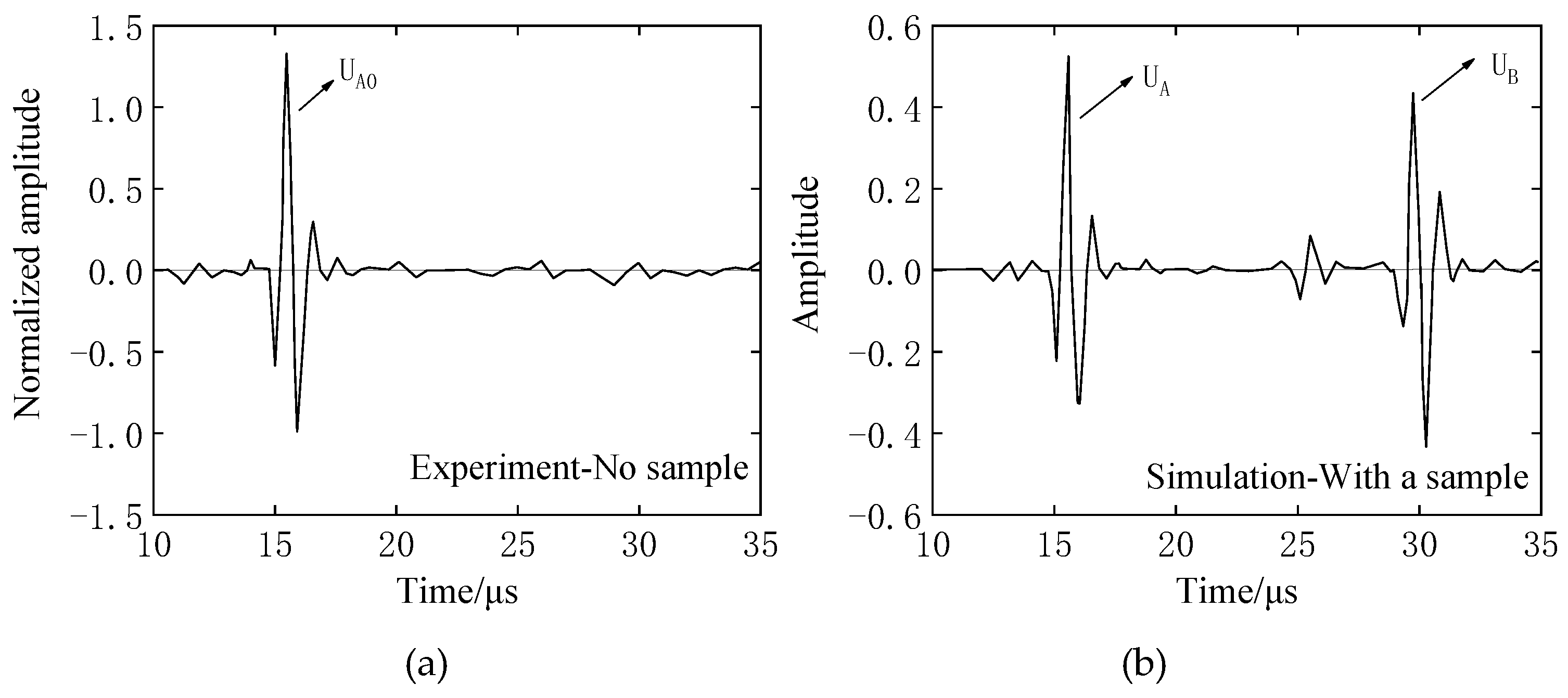

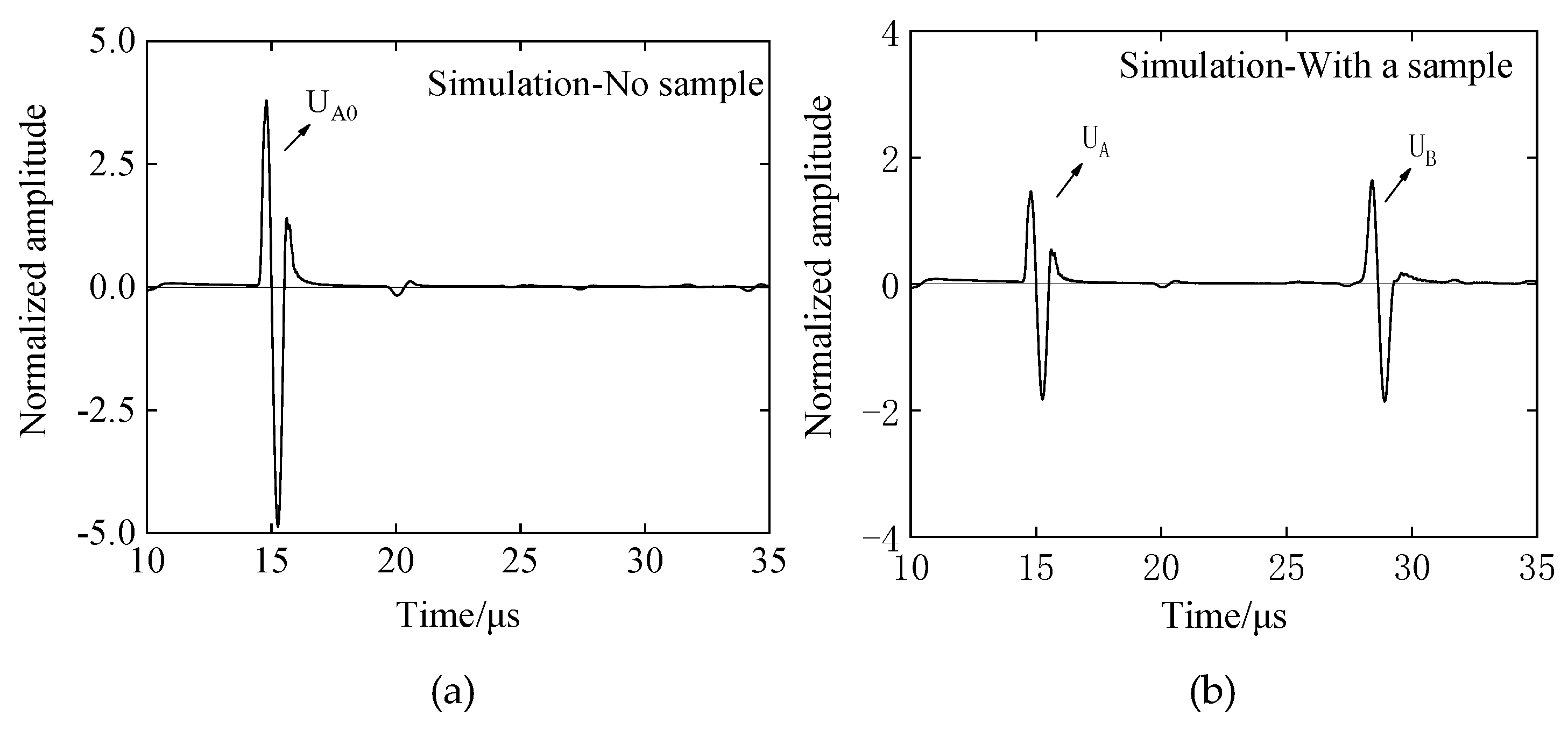

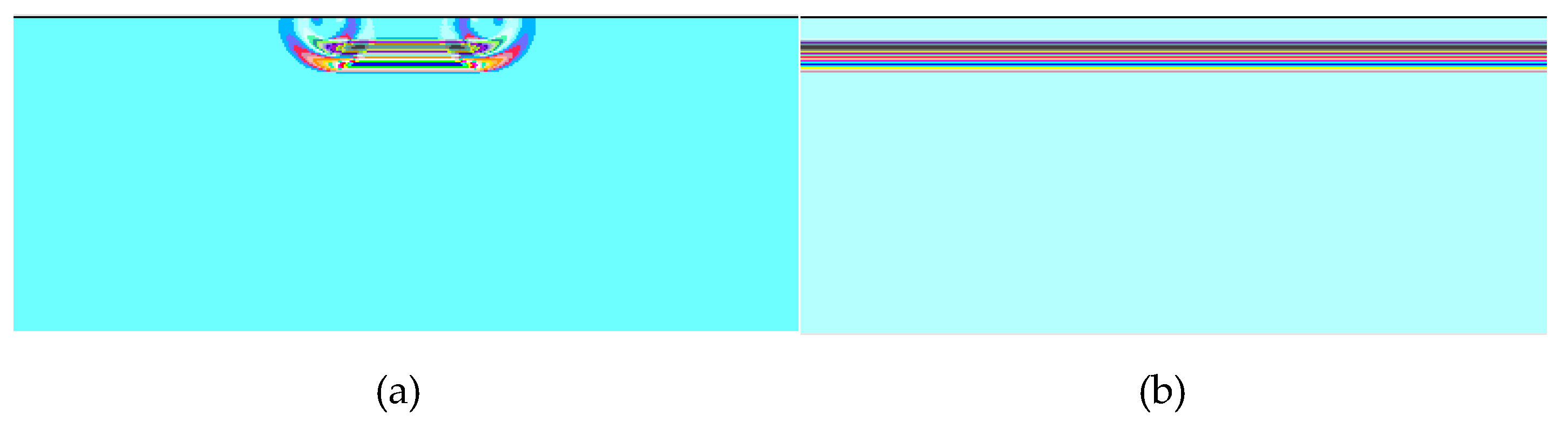

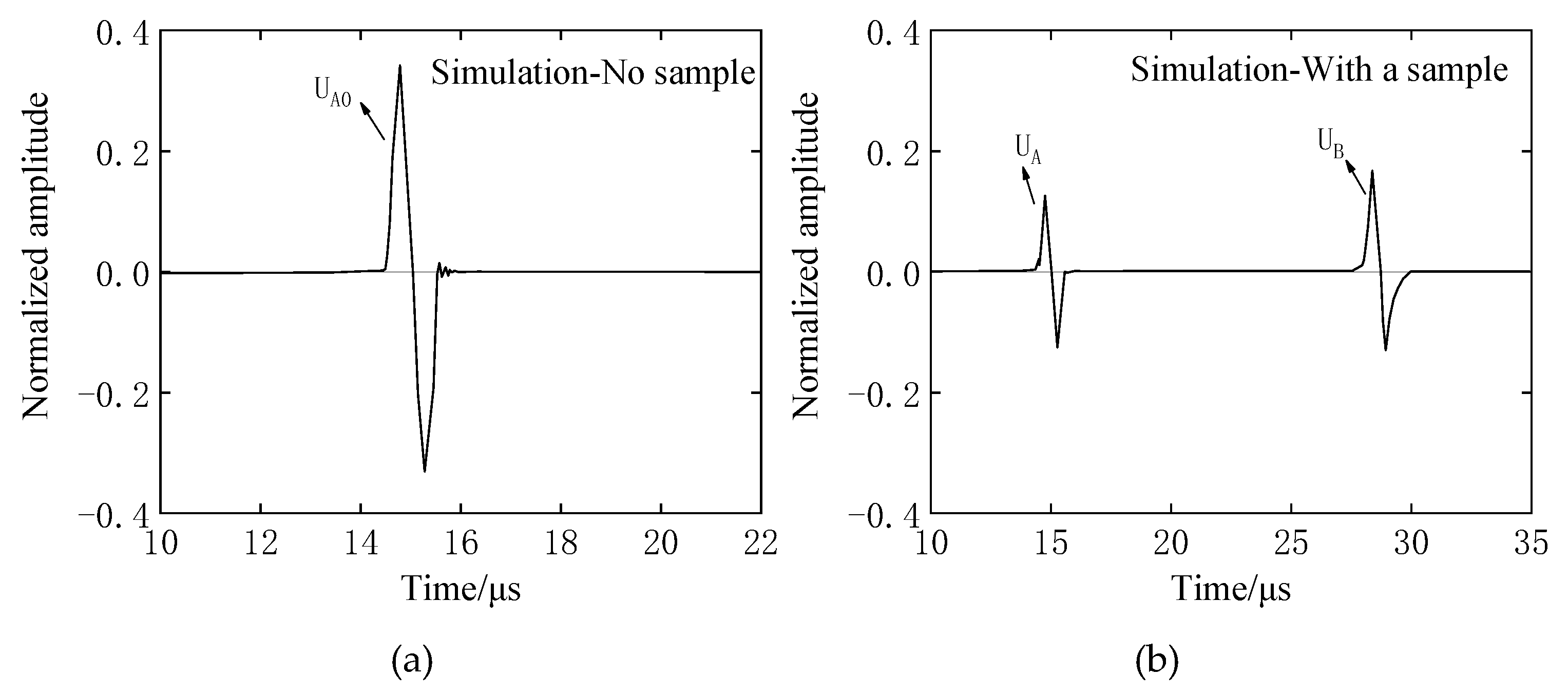

3.1. Simulation Analysis Feasibility Verification

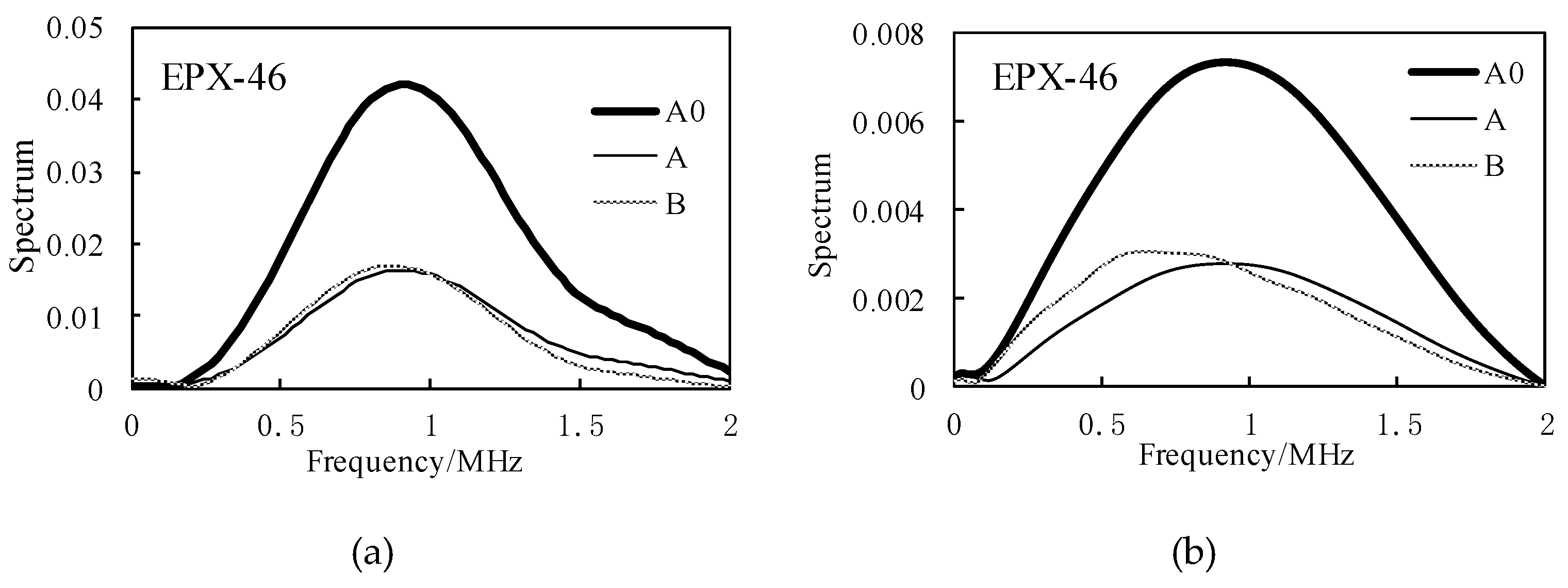

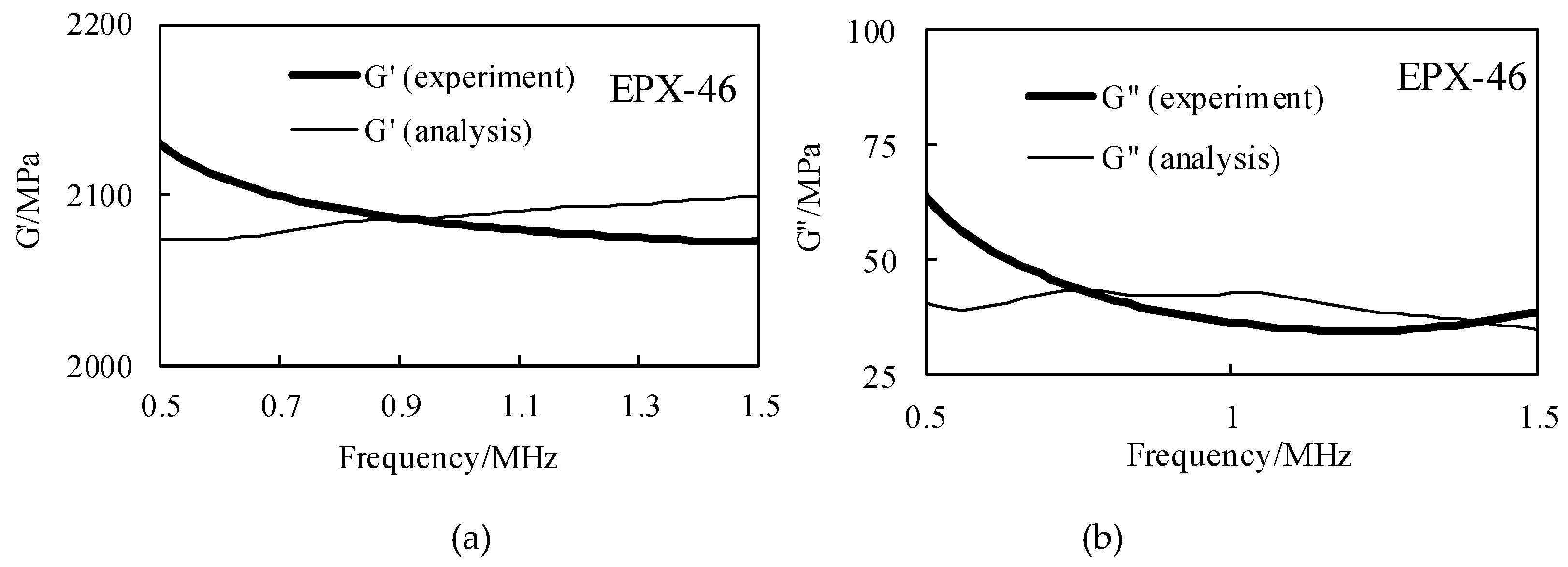

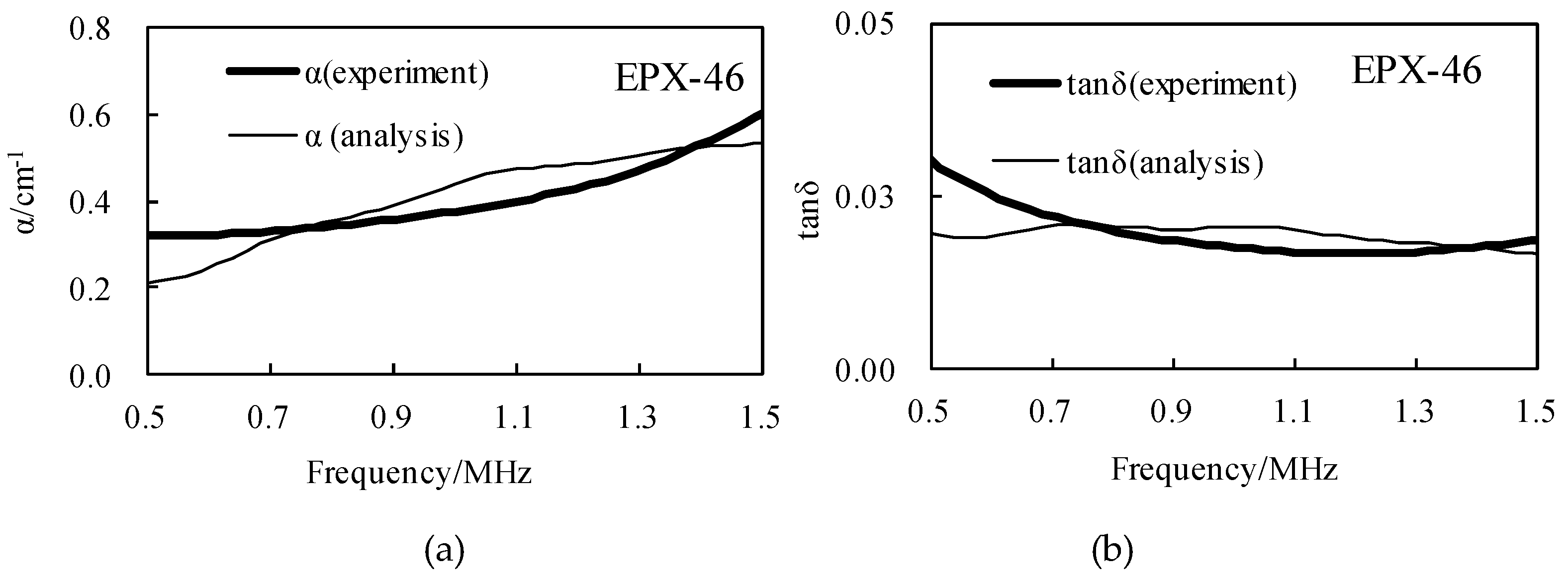

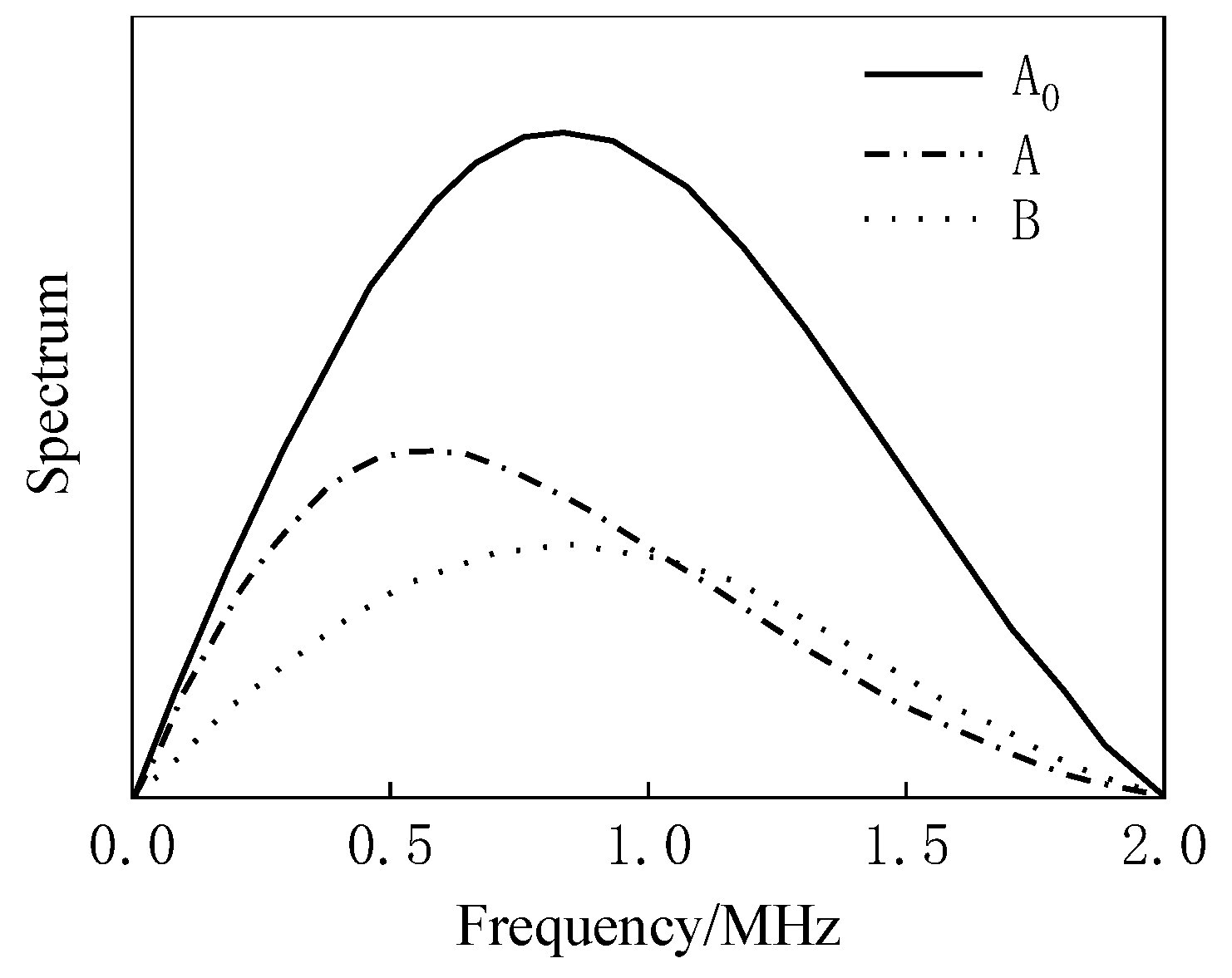

3.2. Research on the BRM through Experimentation and Simulation

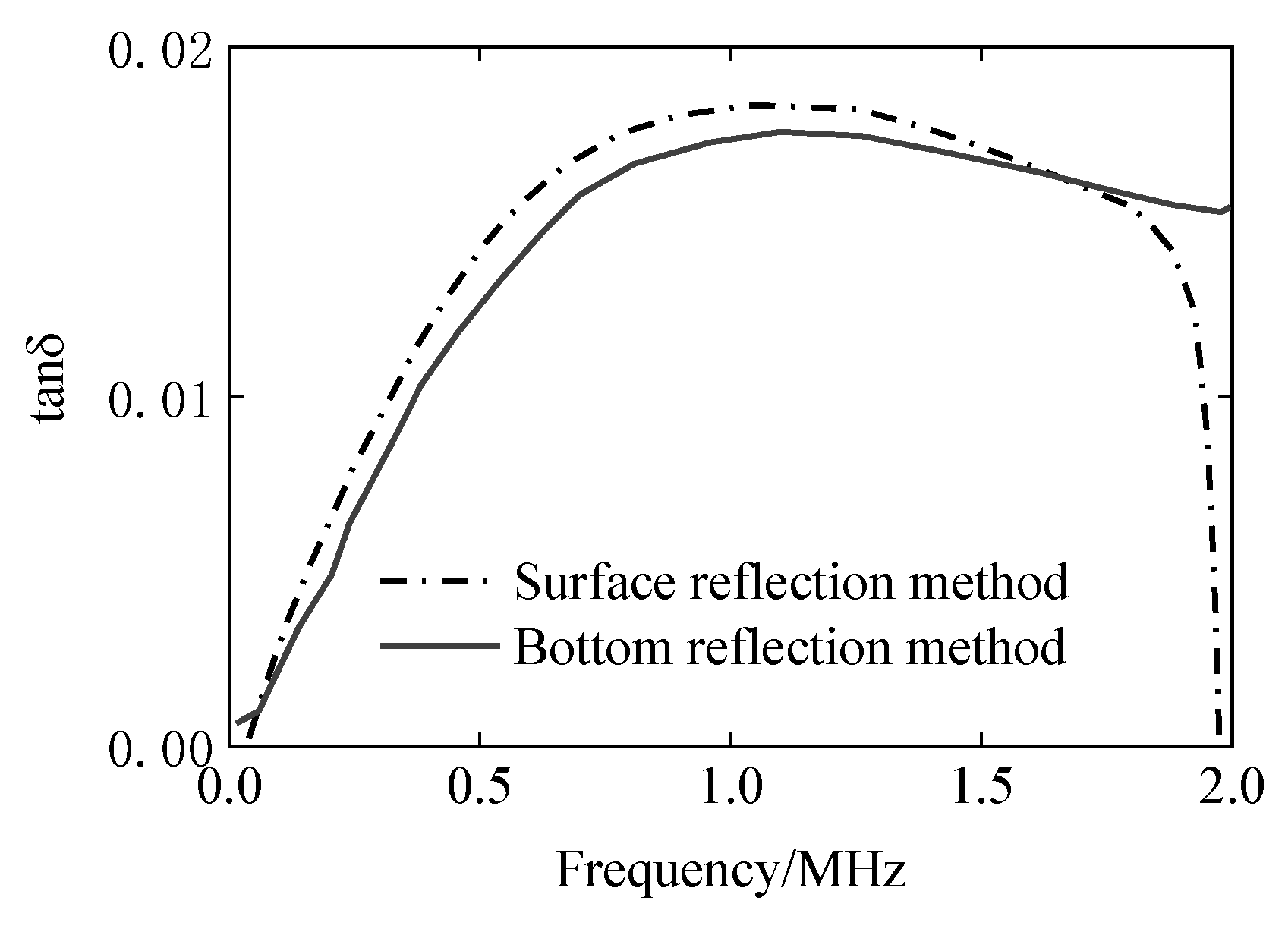

4. Viscoelastic Evaluation by the SRM and Comparative Analysis of Results

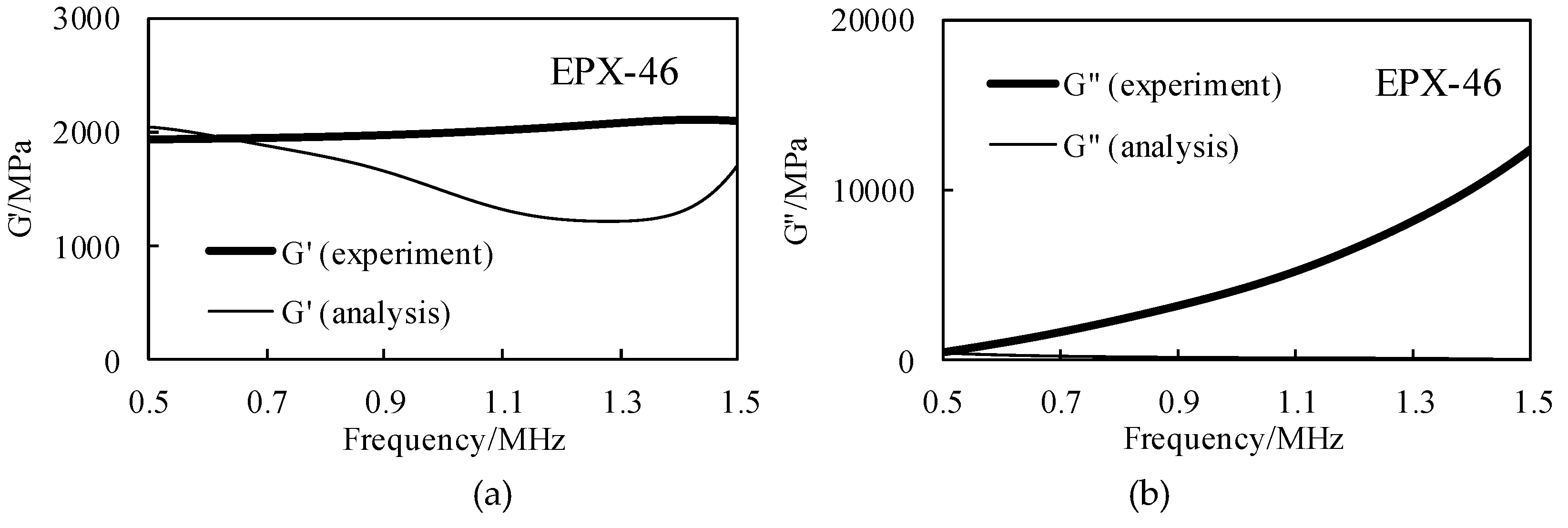

4.1. Research on the SRM through Experimentation and Simulation

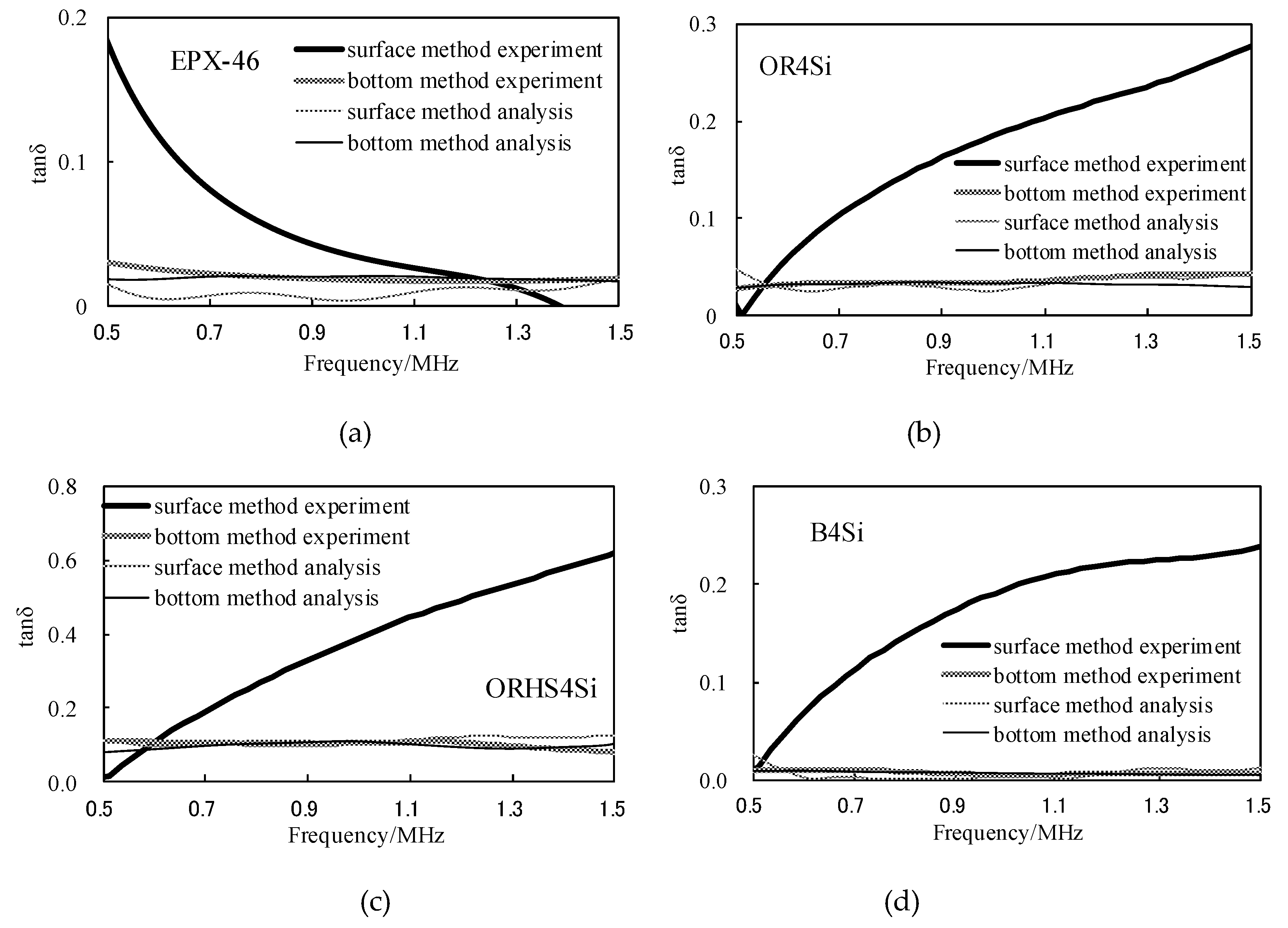

4.2. Result Analysis and Optimization

4.3. Verification of optimization method

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maierhofer, C.; Krause, M.; Niederleithinger, E.; Wiggenhauser, H. Non- Destructive Testing Methods at Bam for Damage Assessment and Quality Assurance in Civil Engineering. In Proceedings of the International Symposium Non-Destructive Testing in Civil Engineering, Berlin, Germany, 16–19 September 2003. [Google Scholar]

- Suo, H.Y. The Application and Research of Ultrasonic Nondestructive Testing Technology. Master’s Thesis, Nanjing University of Posts and Telecommunications, Nanjing, China, June 2012. [Google Scholar]

- Richardson, M.O.W.; Wisheart, M.J. Review of Low-Velocity Impact Properties of Composite Materials. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1123–1131. [Google Scholar] [CrossRef]

- Michel, J.C.; Moulinec, H.; Suquet, P. Effective Properties of Composite Materials with Periodic Microstructure: A Computational Approach. Comput. Methods Appl. Mech. Eng. 1999, 172, 109–143. [Google Scholar] [CrossRef]

- Snarskii, A.; Zorinets, D.; Shamonin, M.; Kalita, V. Theoretical Method for Calculation of Effective Properties of Composite Materials with Reconfigurable Microstructure: Electric and Magnetic Phenomena. arXiv 2019, arXiv:1903.11031v1. Available online: https://arxiv.org/abs/1903.11031?context=cond-mat.mtrl-sci (accessed on 4 March 2019). [CrossRef]

- Williams, J.H., Jr.; Nayebhashemi, H.; Lee, S.S. Ultrasonic Attenuation and Velocity in as/3501-6 Graphite/Epoxy Fiber Composite. J. Nondestr. Eval. 1980, 1, 137–148. [Google Scholar] [CrossRef]

- Ge, T.S. Solid Internal Friction and Ultrasonic Attenuation. Physical 1987, 16, 547–551. [Google Scholar]

- Bragoli, P.B.J.; Almond, D.P.; Mcenaney, B. Ultrasonic Attenuation in Graphite. Carbon 1988, 26, 108–110. [Google Scholar] [CrossRef]

- Xu, S.M.; Cai, X.S.; Huang, C.Y.; Xu, F.; Li, J. Particle Sizing Based on Ultrasonic Attenuation. Chin. J. Sci. Instrum. 2004, 25, 1–2. [Google Scholar]

- Zhang, X.; Chen, J.; Li, L.; Li, X.M. Effects on Ultrasonic Scattering Attenuation Coefficient of Morphological Characteristics of Voids Effects on Ultrasonic Scattering Attenuation Coefficient of Morphological Characteristics of Voids in Compositee Materials. China Mech. Eng. 2010, 21, 1735–1741. [Google Scholar]

- Hunt, J.D.; Alliger, G. Rubber—Application of Radiation to Tire Manufacture. Radiat. Phys. Chem. 1979, 14, 39–53. [Google Scholar] [CrossRef]

- Yoon, S.C.; Sang, H.C.; Kim, J.G. Application of the Rubber Panel Structure for Railway Crossings. Key Eng. Mater. 2007, 353–358, 2753–2757. [Google Scholar] [CrossRef]

- Wojcik, G.; Mould, J.; Ayter, S.; Carcione, L. A Study of Second Harmonic Generation by Focused Medical Transducer Pulses. In Proceedings of the Ultrasonics Symposium, Sendai, Japan, 5–8 Octomber 1998; pp. 1583–1588. [Google Scholar]

- Ivey, D.G.; Mrowca, B.A.; Guth, E. Propagation of Ultrasonic Bulk Waves in High Polymers. J. Appl. Phys. 1949, 20, 486–492. [Google Scholar] [CrossRef]

- Yasuda Masamori, H.M. Relationship between Ultrasonic Dispersion and Damping in Polymeric Materials. Mach. Theory 1995, 61, 10. [Google Scholar]

- Hidekazu, F. (Ed.) Fundamentals and Applications of Acoustics; Ohm Corporation: Manchester, UK, 1993. [Google Scholar]

- Cunningham, J.R.; Ivey, D.G. Dynamic Properties of Various Rubbers at High Frequencies. J. Appl. Phys. 1956, 27, 967–974. [Google Scholar] [CrossRef]

- Lim, R.; Hackman, R.H. Acoustic Attenuation in Syntactic Foam and Heavy Silicone Rubber Composites. J. Acoust. Soc. Am. 1989, 85, S131. [Google Scholar] [CrossRef]

- Chang, J.J.; Li, Y.Y.; Feng, Z.Z.; Zhong, H.Y.; Wan, T.L.; Chao, L. Study on the Viscoelasticity Measurement of Materials Based on Surface Reflected Waves. Materials 2019, 12, 1875. [Google Scholar] [CrossRef] [PubMed]

- Cahng, J.J. Ultrasonic Evaluation of Viscoelasticity of Polymer Composites. Nondestruct. Test. 2007, 29, 57–59. [Google Scholar]

- Wei, Q.A. Dissertation Submitted for the Degree of. Master on Measuring and Testing Technologies and Instruments. Master’s Thesis, Nanchang Hangkong University, Nanxhang, Jiangxi, China, June 2016. [Google Scholar]

- Chang, J.J.; Lin, C.X.; Sun, D.P. Ultrasonic Evaluation of Viscoelasticity of Rubber Friction Materials. Lubr. Eng. 2007, 32, 55–58. [Google Scholar]

- Aköz, A.Y.; Kadıoğlu, F.; Tekin, G. Quasi-Static and Dynamic Analysis of Viscoelastic Plates. Mech. Time Depend. Mater. 2015, 19, 483–503. [Google Scholar] [CrossRef]

- Lubliner, J. A Model of Rubber Viscoelasticity. Mech. Res. Commun. 1985, 12, 93–99. [Google Scholar] [CrossRef]

- Weaver, R.L.; Sachse, W.; Niu, L. Transient Ultrasonic Waves in a Viscoelastic Plate: Theory. J. Acoust. Soc. Am. 1989, 85, 2255. [Google Scholar] [CrossRef]

- Marple, S.L., Jr. Digital Spectral Analysis with Applications. J. Acoust. Soc. Am. 1989, 86, 2043. [Google Scholar] [CrossRef]

- Welch, P.D. The Use of Fast Fourier Transform for the Estimation of Power Spectra: A Method Based on Time Averaging over Short, Modified Periodograms. IEEE Trans. Audio Electroacoust 1967, 15, 70–73. [Google Scholar] [CrossRef]

- Yang, L.J.; Zhang, B.H.; Ye, X.Z. Fast Fourier Transform and Its Applications. Opto-Electron. Eng. 2004, 31, 1–3. [Google Scholar]

- Guidarelli, G.; Marini, A.; Palmieri, L. Ultrasonic Method for Determining Attenuation Coefficients in Plate-Shaped Materials. J. Acoust. Soc. Am. 1998, 94, 1476–1481. [Google Scholar] [CrossRef]

- Dong, Z.Y.; Hu, J.B. Reasearches on the Evaluation of Material Damage Using the Ultrasonic Wave Attenuation Coefficent Method. Chem. Eng. Mach. 2007, 34, 139–143. [Google Scholar]

- Gao, X.J.; Zhang, Z. Research of the Relationship between Pore Morphology and Ultrasonic Attenuation Coefficient in Cfrp. J. Mater. Eng. 2012, 70, 59–63. [Google Scholar]

- Ghosh, A.; Antony, P.; Bhattacharya, A.K.; Bhowmick, A.K.; De, S.K. Replacement of Virgin Rubbers by Waste Ground Vulcanizates in Blends of Silicone Rubber and Fluororubber Based on Tetrafluoroethylene/Propylene/Vinylidene Fluoride Terpolymer. J. Appl. Polym. Sci. 2010, 82, 2326–2341. [Google Scholar] [CrossRef]

- Imiela, M.; Anyszka, R.; Bieliński, D.M.; Pdzich, Z.; Zarzecka-Napiera, M.; Szumera, M. Effect of Carbon Fibers on Thermal Properties and Mechanical Strength of Ceramizable Composites Based on Silicone Rubber. J. Therm. Anal. Calorim. 2016, 124, 197–203. [Google Scholar] [CrossRef]

- Nagy, G.; Feher, Z.; Pungor, E. Application of Silicone Rubber-Based Graphite Electrodes for Continuous Flow Measurements Part Ii. Voltammetric Study of Active Substances Injected into Electrolyte Streams. Anal. Chim. Acta. 1970, 52, 47–54. [Google Scholar] [CrossRef]

- Wang, J. Preparation and Characteristics of a Novel Silicone Rubber Nanocomposite Based on Organophilic Montmorillonite. High Perform. Polym. 2006, 18, 325–340. [Google Scholar] [CrossRef]

- Mou, Q.H. Preparation and Properties of Thermal Silicone Rubber. Mater. Rev. 2009, 23, 110. [Google Scholar]

- Moustafa, A.H.A. Ultrasonic Measurement of the Sound Velocity and Attenuation in Some Polymers. J. Acoust. Soc. Am. 1997, 101, 3131. [Google Scholar]

| Specification of the pulser/receiver | |

| Pulse configuration | square burst pulse or chirp waves |

| Bandwidth | 300 Hz~10 MHz |

| Low pass (MHz) | 1.00, 2.00, 5.00 |

| High pass (MHz) | 0.01, 0.20, 1.00 |

| Gain | 0 to 80 dB |

| Output impedance | 50 Ω |

| Specification of the A/D transition | |

| Sampling Clock | 100 MHz |

| Analogue bandwidth | DC~50 MHz |

| Input impedance | 50 Ω or 10 kΩ |

| Sample Name | Filler | Hardness (HA) of Material | Glass Transition Temperature by DMA (°C) | Velocity (m/s) | Density ρ2 (kg/mm3) |

|---|---|---|---|---|---|

| EPX-46 | Silica | 41 | −66 | 1463 | 0.98 |

| OR4Si | Silica | 45 | −50 | 1546 | 1.077 |

| ORHS4Si | Silica | 48 | −24 | 1723 | 1.106 |

| B4Si | Silica | 45 | −105 | 1520 | 1.059 |

| Sample | By Experiment | By Analysis | Difference Rate |

|---|---|---|---|

| EPX-46 | 0.377 | 0.402 | 6.31% |

| OR4Si | 0.688 | 0.744 | 7.53% |

| ORHS4Si | 2.036 | 2.228 | 8.62% |

| B4Si | 0.102 | 0.114 | 10.68% |

| Sample | By Experiment | By Analysis | Difference Rate |

|---|---|---|---|

| EPX-46 | 0.018 | 0.0198 | 9.2% |

| OR4Si | 0.034 | 0.0357 | 4.6% |

| ORHS4Si | 0.105 | 0.108 | 3.0% |

| B4Si | 0.005 | 0.0056 | 10.7% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.-y.; Chang, J.-j.; Huang, L.; Tang, Y.-h. Comparative Study on Viscoelastic Evaluation Methods of Polymer Materials Based on Ultrasonic Method. Materials 2019, 12, 2948. https://doi.org/10.3390/ma12182948

Li Y-y, Chang J-j, Huang L, Tang Y-h. Comparative Study on Viscoelastic Evaluation Methods of Polymer Materials Based on Ultrasonic Method. Materials. 2019; 12(18):2948. https://doi.org/10.3390/ma12182948

Chicago/Turabian StyleLi, Yuan-yuan, Jun-jie Chang, Lin Huang, and Yong-hui Tang. 2019. "Comparative Study on Viscoelastic Evaluation Methods of Polymer Materials Based on Ultrasonic Method" Materials 12, no. 18: 2948. https://doi.org/10.3390/ma12182948

APA StyleLi, Y.-y., Chang, J.-j., Huang, L., & Tang, Y.-h. (2019). Comparative Study on Viscoelastic Evaluation Methods of Polymer Materials Based on Ultrasonic Method. Materials, 12(18), 2948. https://doi.org/10.3390/ma12182948