Tribological Properties of Single (AlSi7/SiCp, AlSi7/GCsf) and Hybrid (AlSi7/SiCp + GCsf) Composite Layers Formed in Sleeves via Centrifugal Casting

Abstract

:1. Introduction

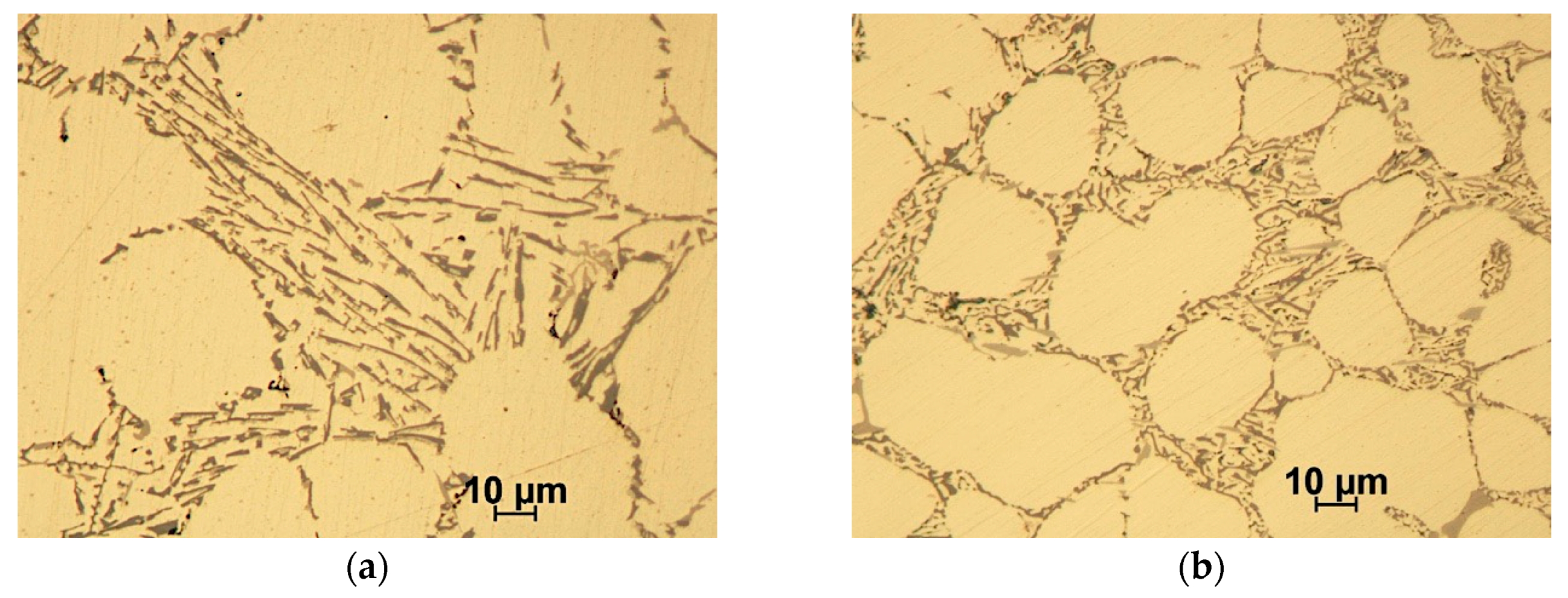

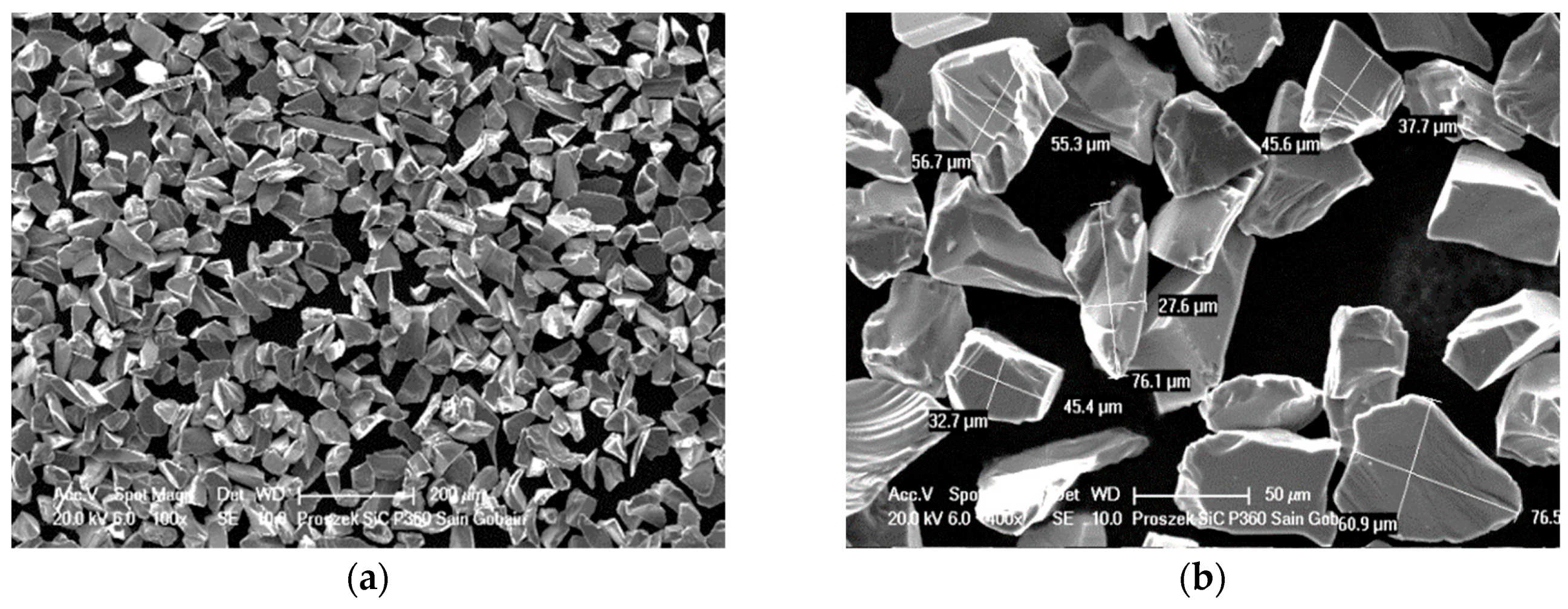

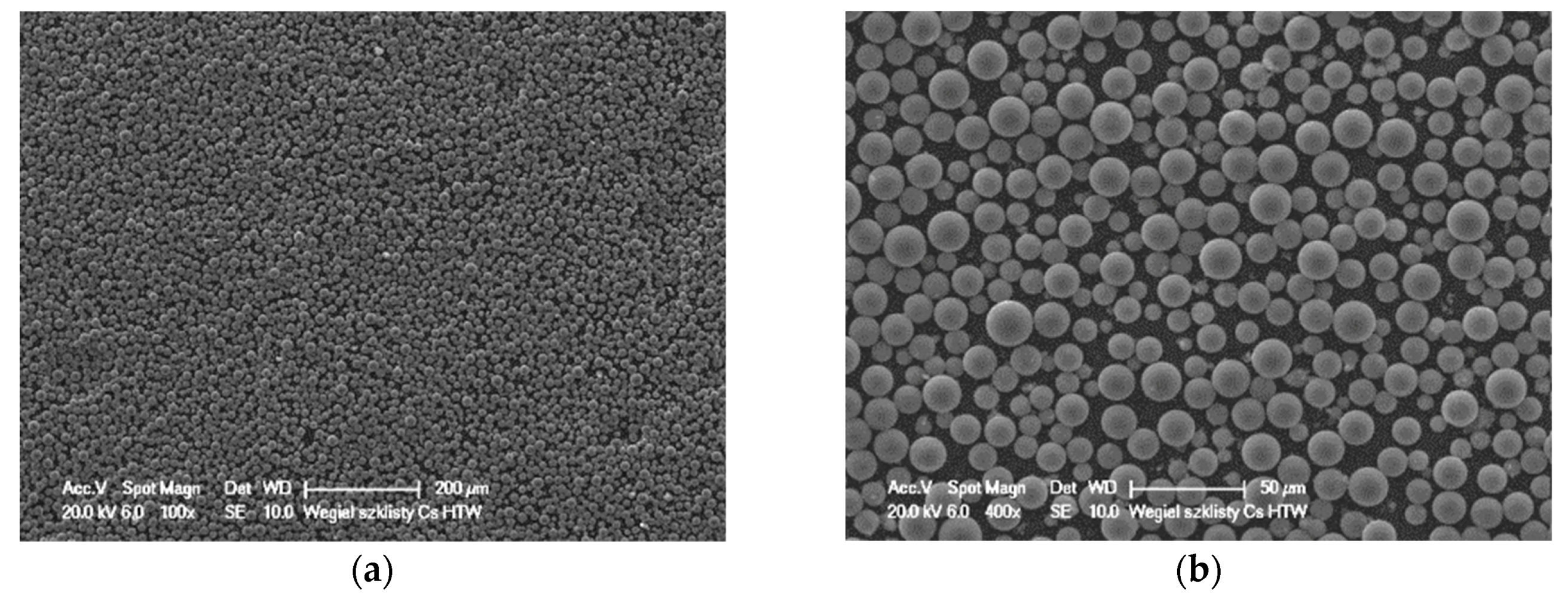

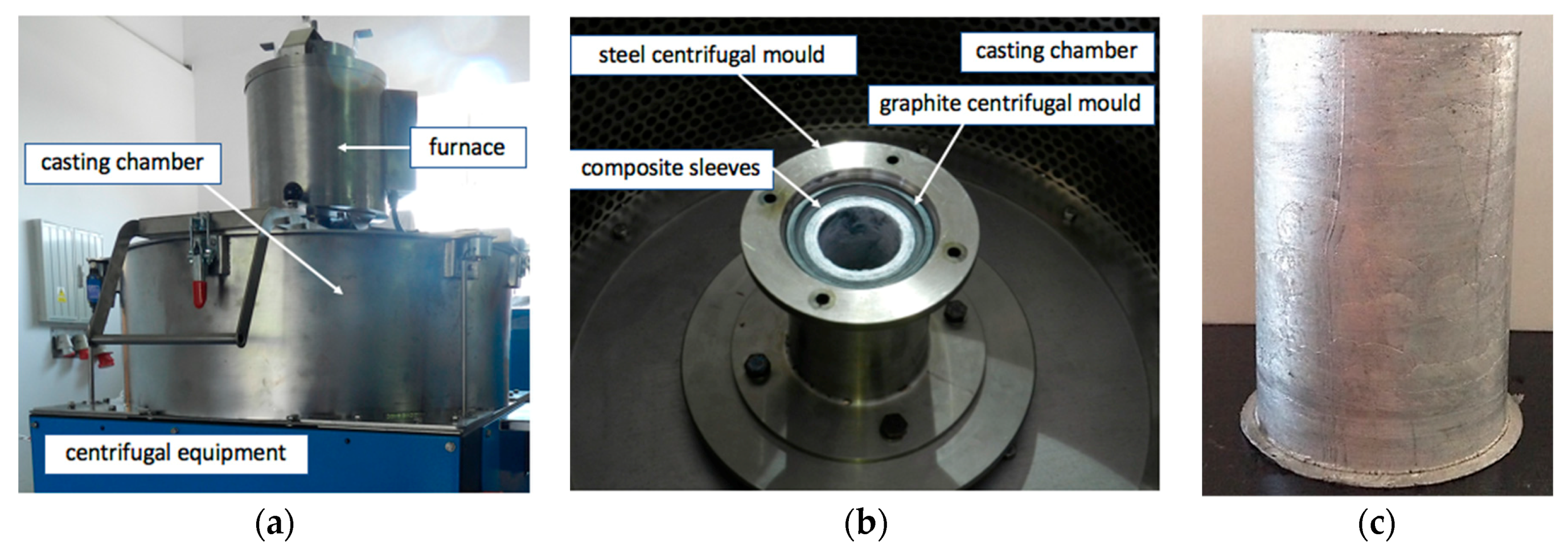

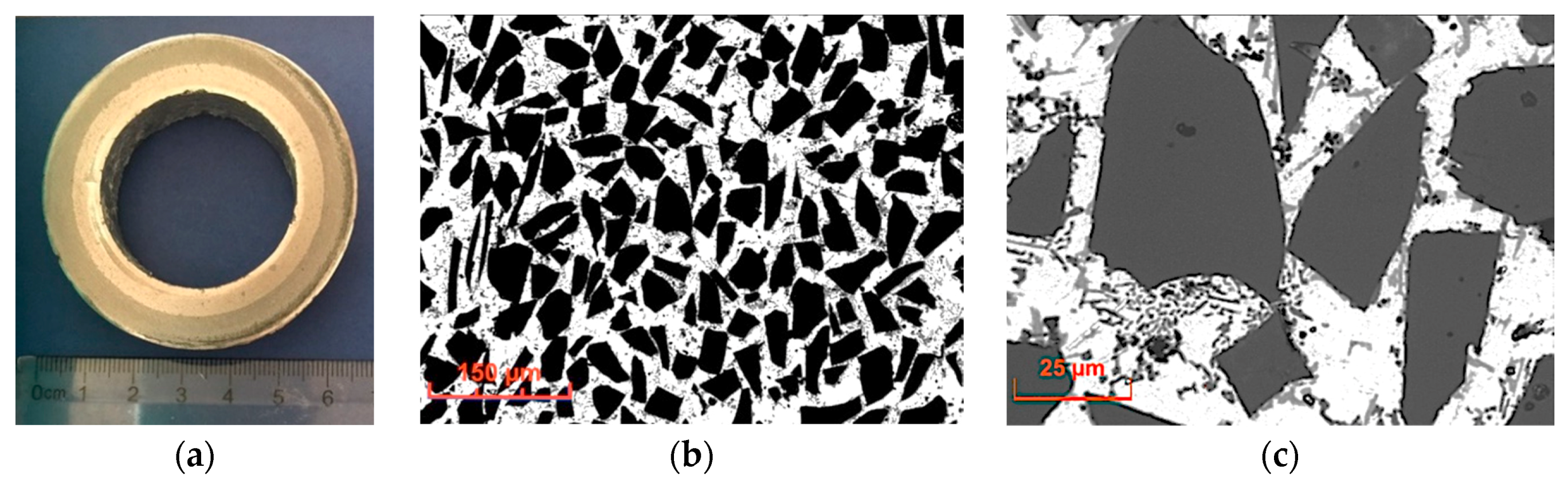

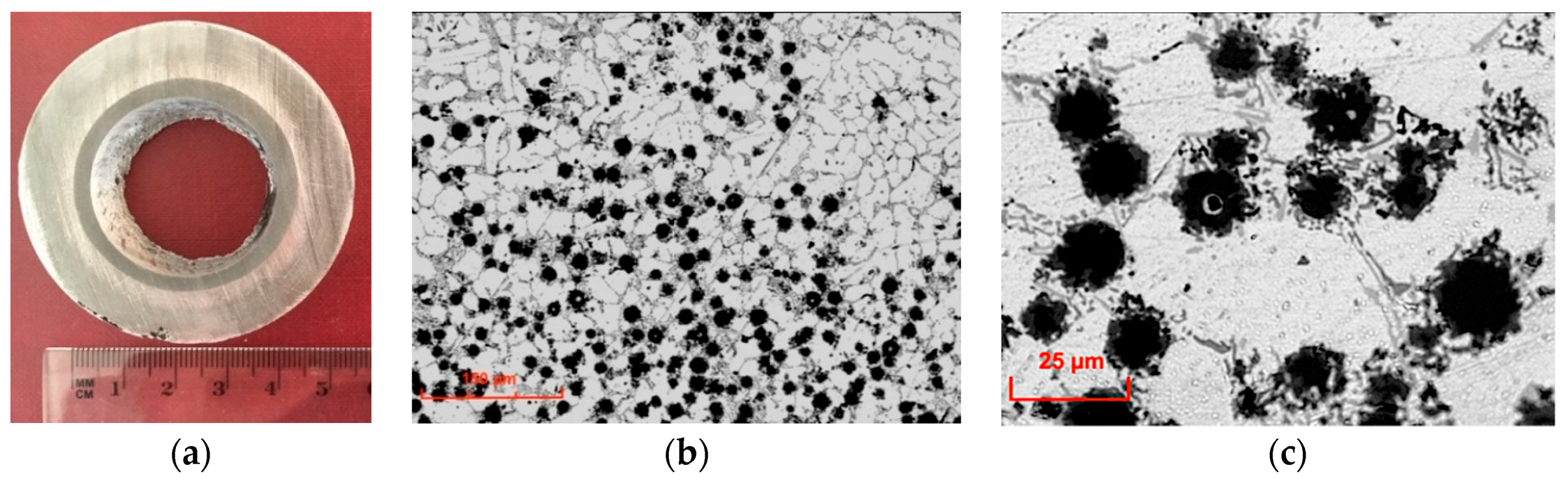

2. Materials and Methods

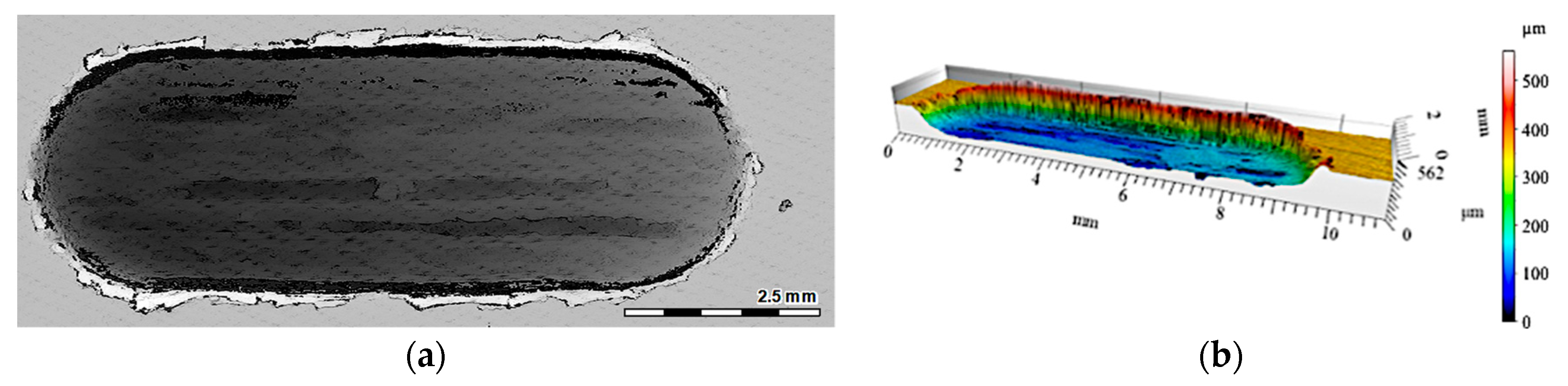

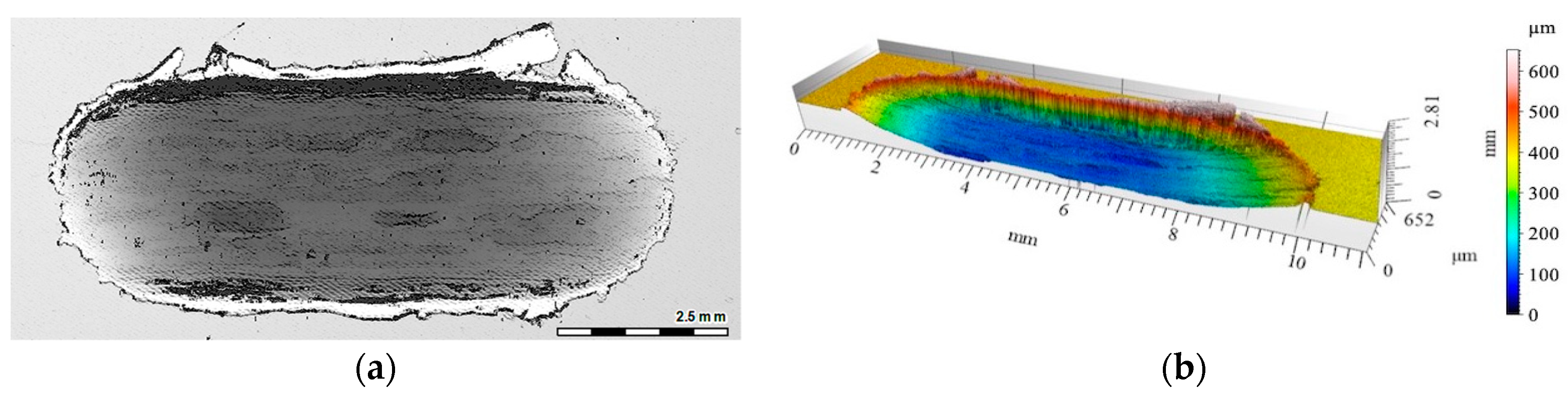

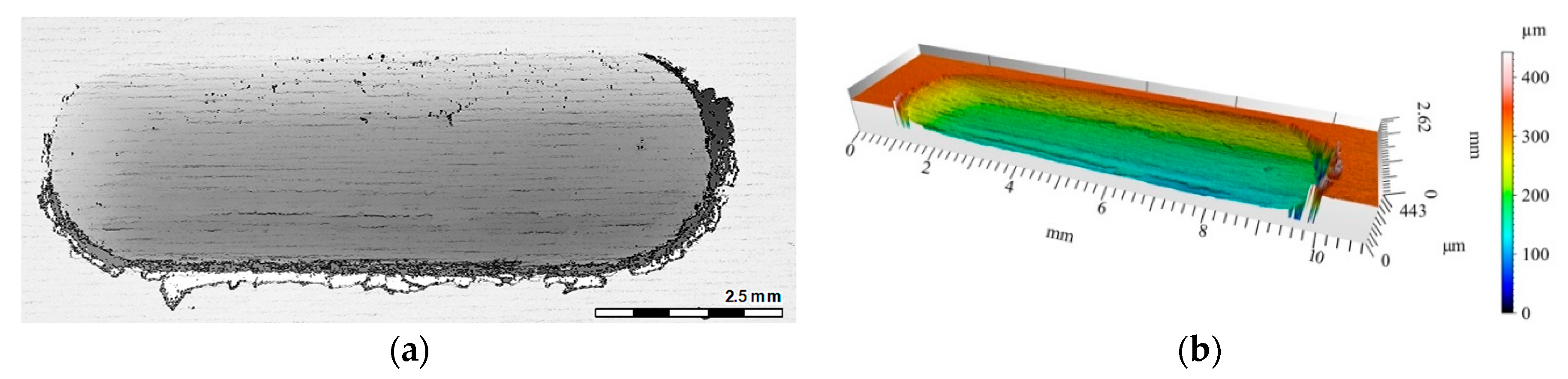

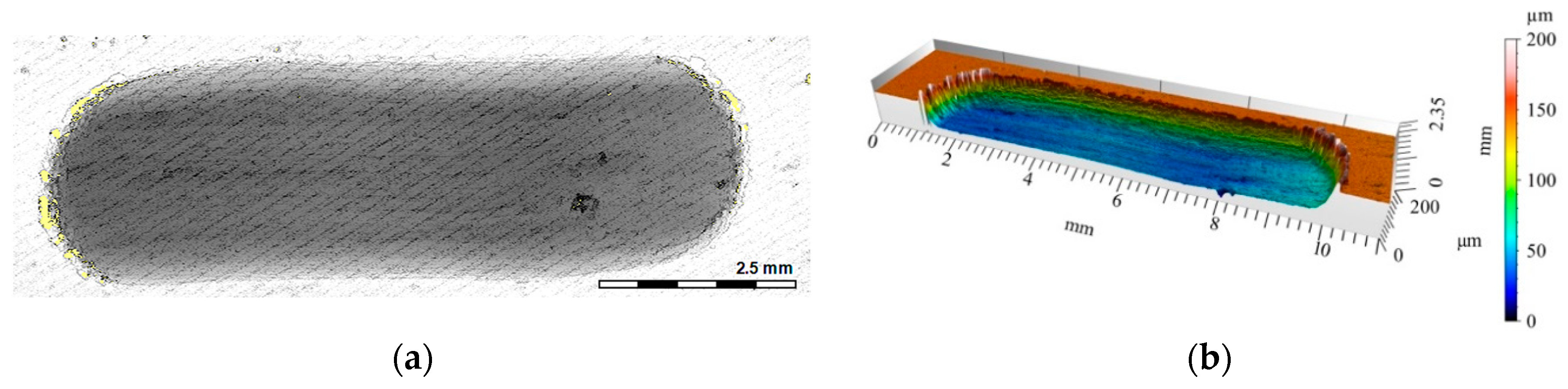

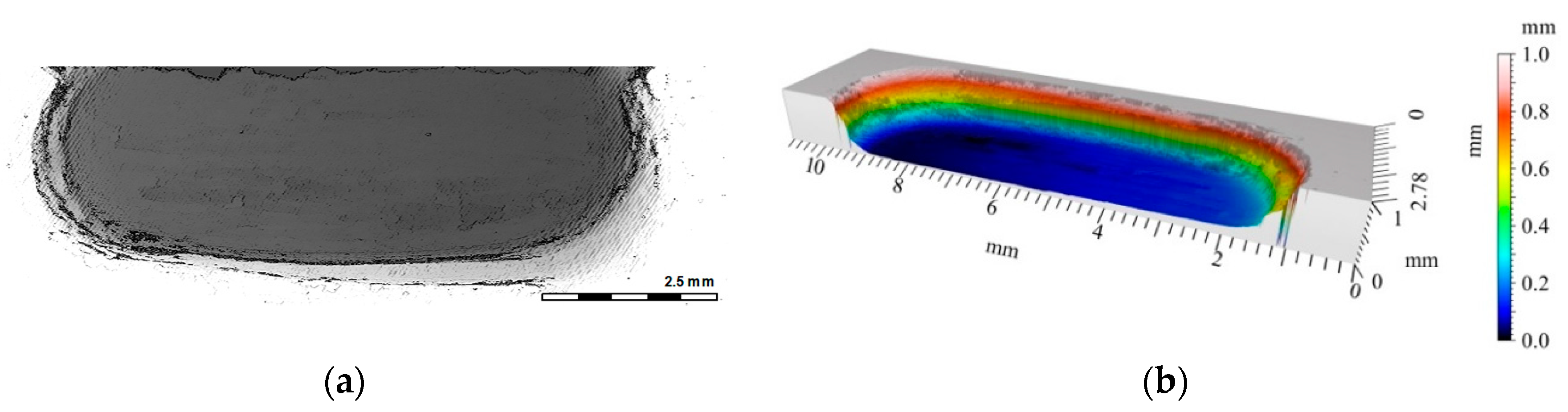

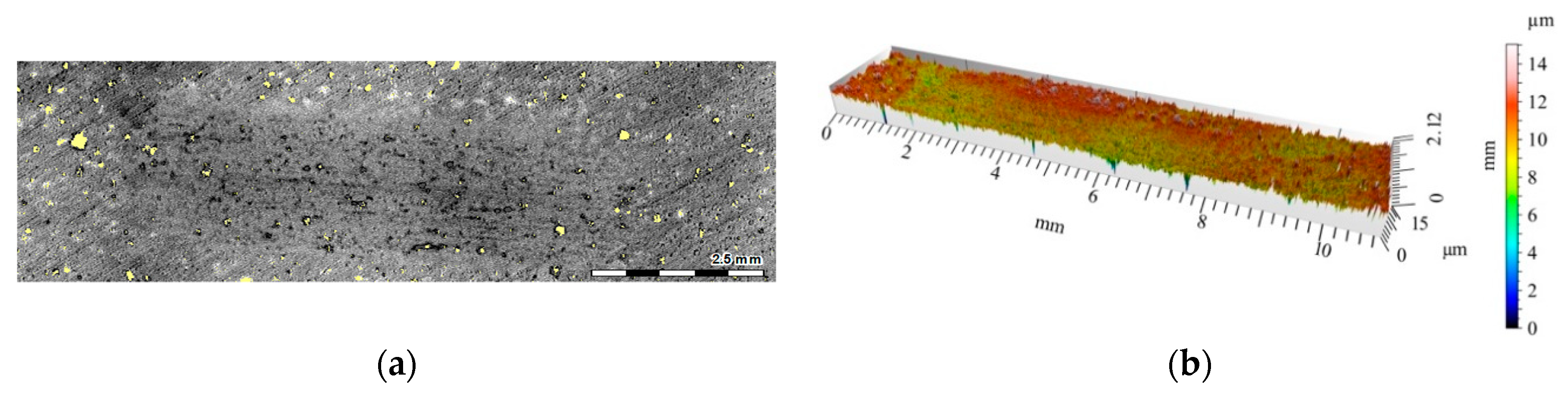

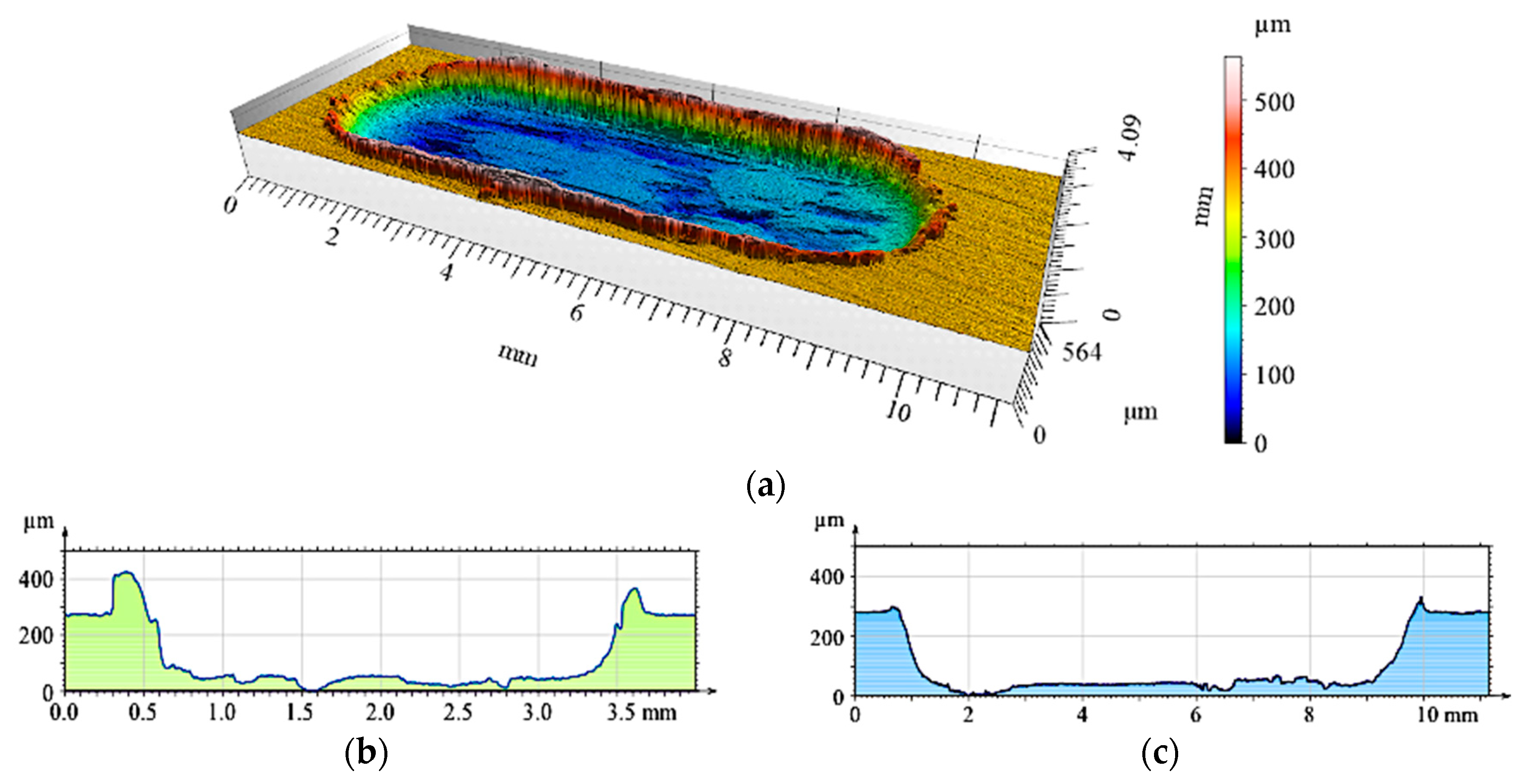

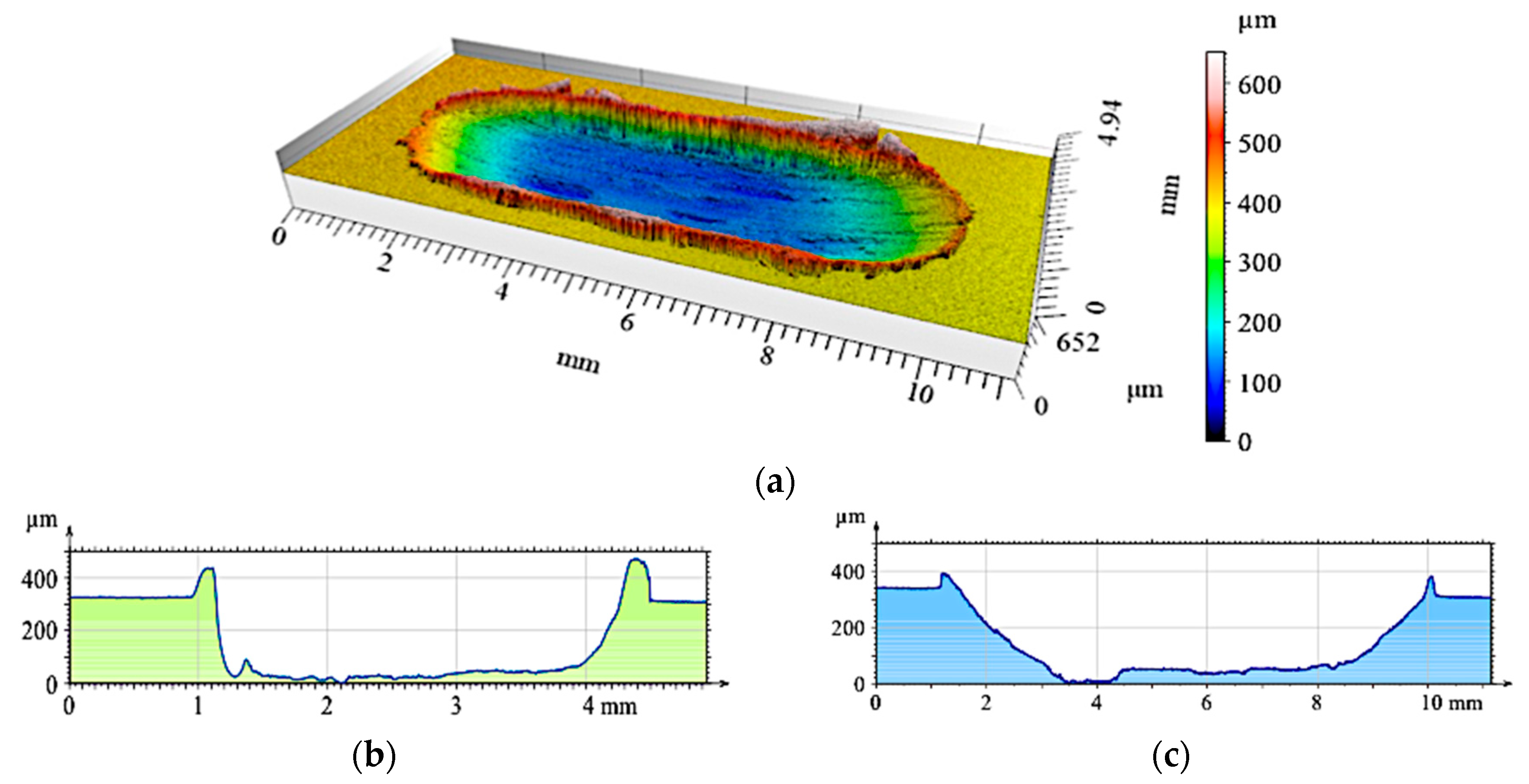

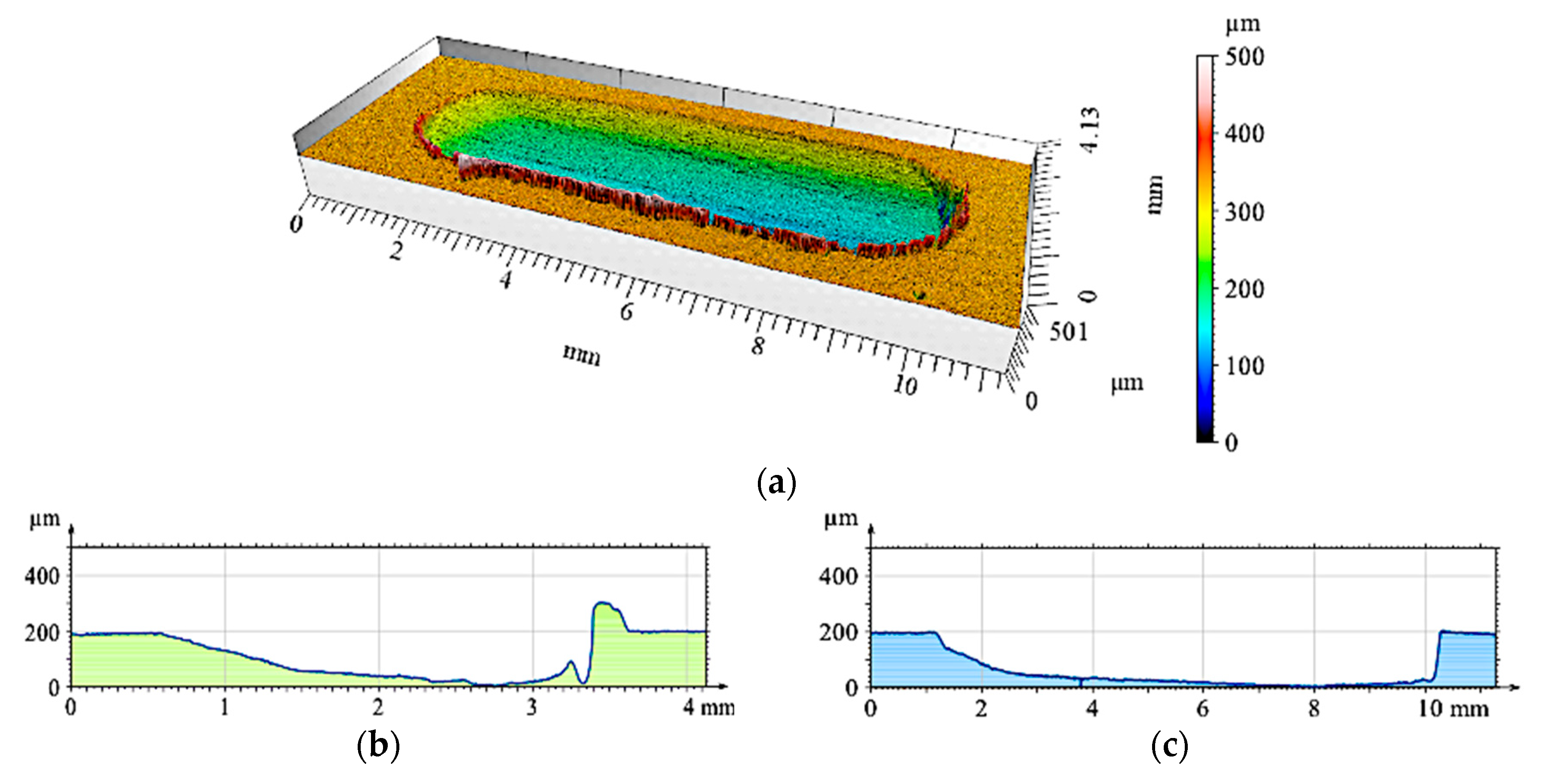

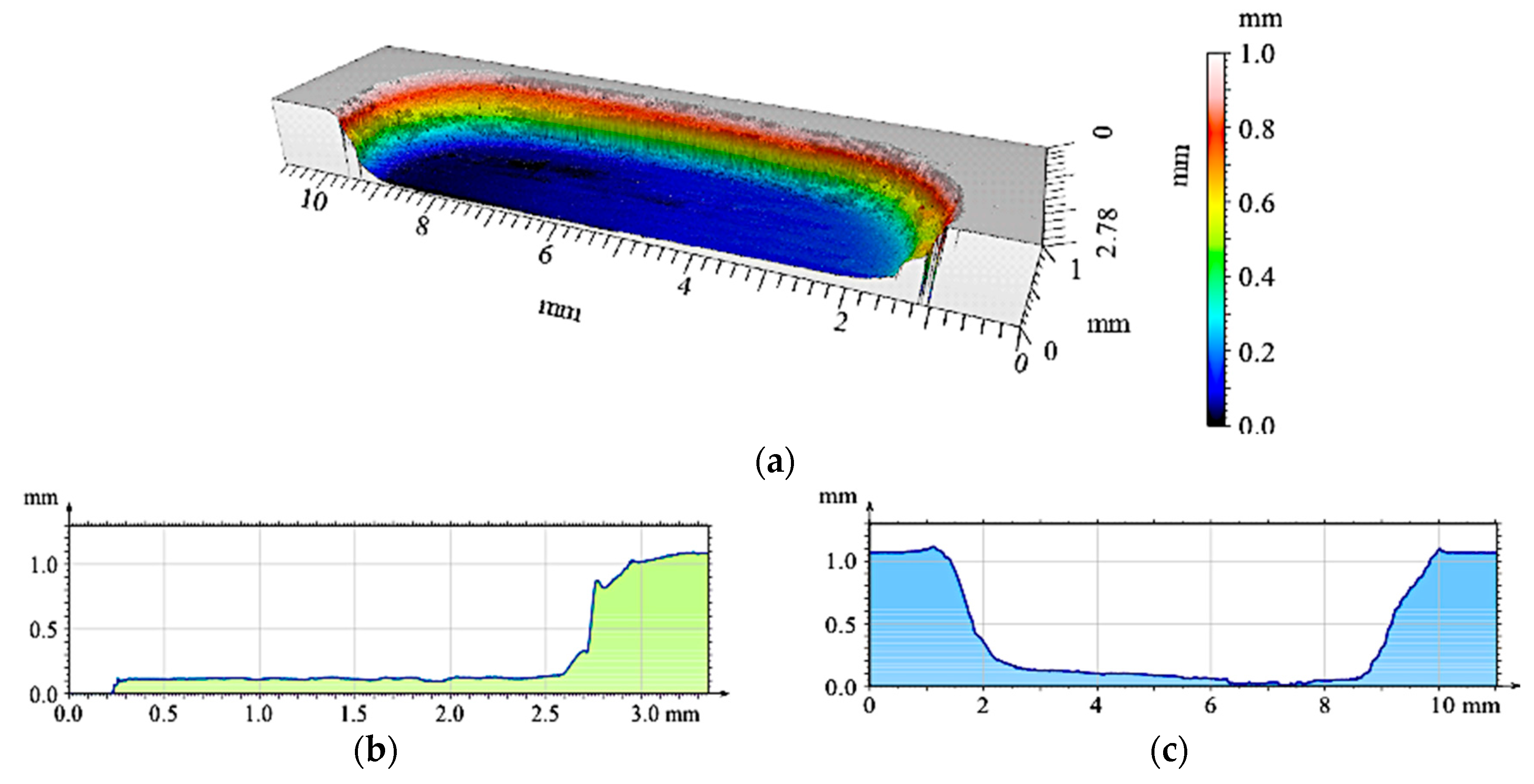

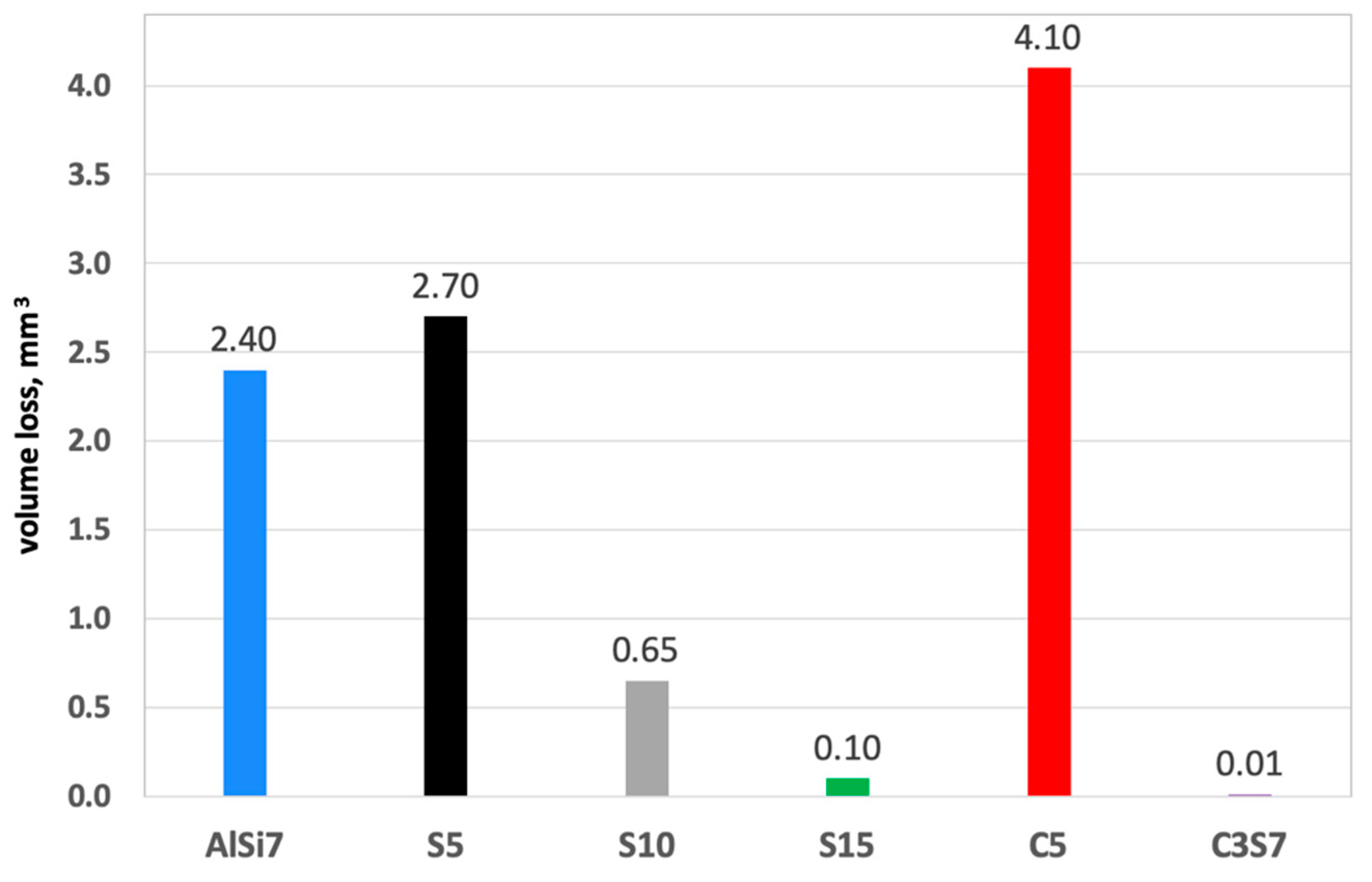

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rohatgi, P.K.; Gupta, N.; Daoud, A. Synthesis and processing of cast metal matrix composites and their applications. ASM Handb. 2008, 15, 1149–1164. [Google Scholar] [CrossRef]

- Alpas, A.T.; Zhang, J. Effect of microstructure (particulate size and volume fraction) and counterface material on the sliding wear-resistance of particulate-reinforced aluminum-matrix composites. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 1994, 25, 969–983. [Google Scholar] [CrossRef]

- Liang, Y.N.; Ma, Z.Y.; Li, S.Z.; Li, S.; Bi, J. Effect of particle size on wear behavior of SiC particulate-reinforced aluminum alloy composites. J. Mater Sci. Lett. 1995, 1, 114–116. [Google Scholar] [CrossRef]

- Wieczorek, J. Tribological properties and a wear model of aluminium matrix composites—SiC particles designed for metal forming. Arch. Metall. Mater. 2015, 60, 111–115. [Google Scholar] [CrossRef]

- Yalcin, Y.; Akbulut, H. Dry wear properties of A356-SiC particle reinforced MMCs produced by two melting routes. Mater. Des. 2006, 27, 872–881. [Google Scholar] [CrossRef]

- Kaur, K.; Anant, R.; Pandey, O.P. Tribological behaviour of SiC particle reinforced Al–Si alloy. Tribol. Lett. 2011, 44, 41–58. [Google Scholar] [CrossRef]

- Dyzia, M. Aluminum Matrix Composite (AlSi7Mg2Sr0.03/SiCp) Pistons Obtained by Mechanical Mixing Method. Materials 2018, 11, 42. [Google Scholar] [CrossRef] [PubMed]

- Omrani, E.; Moghadam, A.D.; Algazzar, M.; Menezes, P.L.; Rohatgi, P.K. Effect of graphite particles on improving tribological properties Al-16Si-5Ni-5 graphite self-lubricating composite under fully flooded and starved lubrication conditions for transportation applications. Int. J Adv. Manuf. Technol. 2016, 87, 929–939. [Google Scholar] [CrossRef]

- Yang, J.B.; Lin, C.B.; Wang, T.C.; Chu, H.Y. The tribological characteristics of A356.2A1 alloy/Gr((p)) composites. Wear 2004, 257, 941–952. [Google Scholar] [CrossRef]

- Formanek, B.; Jozwiak, S.; Szczucka-Lasota, B.; Dolata-Grosz, A.; Bojar, Z. Intermetallic alloys with ceramic particles and technological concept for high loaded materials. J. Mater Process. Tech. 2005, 162, 46–51. [Google Scholar] [CrossRef]

- Sleziona, J.; Dyzia, M.; Myalski, J.; Wieczorek, J. The structure and properties of sinters produced from composite powders Al-Al2O3-Al3Fe-Al3Ti. J. Mater Process. Tech. 2005, 162, 127–130. [Google Scholar] [CrossRef]

- Maziarz, W.; Wójcik, A.; Bobrowski, P.; Bigos, A.; Szymański, Ł.; Kurtyka, P.; Rylko, N.; Olejnik, E. SEM and TEM studies on in-situ cast Al-TiC composites. Mater. Trans. 2019, 60, 714–717. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Torabi Parizi, M. Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mater. Des. 2012, 34, 106–111. [Google Scholar] [CrossRef]

- Ahamed, H.; Senthilkumar, V. Experimental investigation on newly developed ultrafine-grained aluminium based nano-composites with improved mechanical properties. Mater. Des. 2012, 37, 182–192. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles—A Review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Kannan, C.; Ramanujam, R. Comparative study on the mechanical and microstructural characterisation of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting. J. Adv. Res. 2017, 8, 309–319. [Google Scholar] [CrossRef]

- Dolata-Grosz, A.; Formanek, B.; Sleziona, J.; Wieczorek, J. Al-FeAl-TiAl-Al2O3 composite with hybrid reinforcement. J. Mater Process. Tech. 2005, 162, 33–38. [Google Scholar] [CrossRef]

- Ahlatci, H.; Koçer, T.; Candan, E.; Çimenoğlu, H. Wear behaviour of Al/(Al2O3p + SiCp) hybrid composites. Tribol. Int. 2006, 39, 213–220. [Google Scholar] [CrossRef]

- Naplocha, K.; Granat, K. Dry sliding wear of Al/Saffil/C hybrid metal matrix composites. Wear 2008, 265, 1734–1740. [Google Scholar] [CrossRef]

- Dolata, A.J.; Dyzia, M.; Walke, W. Influence of particles type and shape on the corrosion resistance of aluminium hybrid composites. Solid State Phenom. 2012, 191, 81–87. [Google Scholar] [CrossRef]

- Dyzia, M. AlSi7Mg/SiC and heterophase SiC(p) + C(g) composite for use in cylinder-piston system of air compressor. Solid State Phenom. 2011, 176, 49–54. [Google Scholar] [CrossRef]

- Vencl, A.; Bobic, I.; Stojanovic, B. Tribological properties of A356 Al-Si alloy composites under dry sliding conditions. Ind. Lubr. Tribol. 2014, 66, 66–74. [Google Scholar] [CrossRef]

- Suresha, S.; Sridhara, B.K. Friction characteristics of aluminium silicon carbide graphite hybrid composites. Mater. Des. 2012, 34, 576–583. [Google Scholar] [CrossRef]

- Radhika, N.; Subramaniam, R. Wear behavior of aluminium/alumina/graphite hybrid metal matrix composites using Taguchi’s techniques. Ind. Lubr. Tribol. 2013, 65, 166–174. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Hekner, B.; Myalski, J.; Pawlik, T.; Sopicka-Lizer, M. Effect of carbon in fabrication Al-SiC nanocomposites for tribological application. Materials 2017, 10, 679. [Google Scholar] [CrossRef]

- Hekner, B.; Myalski, J.; Valle, N.; Botor-Probierz, A.; Sopicka-Lizer, M.; Wieczorek, J. Friction and wear behavior of Al-SiC(n) hybrid composites with carbon addition. Compos. Part B—Eng. 2017, 108, 291–300. [Google Scholar] [CrossRef]

- Boczkal, S.; Dolata, A.J.; Nowak, M. Effect of SiC and GR reinforcement particles on the structure and functional properties of composite casting. Arch. Metall. Mater. 2016, 61, 399–404. [Google Scholar] [CrossRef]

- Kang, H.G.; Zhang, D.L.; Cantor, B. The microstructures of locally reinforced squeeze-cast Al-alloy metal-matrix composites. J. Microsc. 1993, 169, 239–245. [Google Scholar] [CrossRef]

- Dolata, A.J. Tribological properties of AlSi12-Al2O3 interpenetrating composite layers in comparison with unreinforced matrix alloy. Materials 2017, 10, 1045. [Google Scholar] [CrossRef]

- Prasad, S.V.; Asthana, R. Aluminum metal–matrix composites for automotive applications: Tribological considerations. Tribol. Lett. 2004, 17, 445–453. [Google Scholar] [CrossRef]

- Kainer, K.U. Basics of metal matrix composites. In Metal Matrix Composites: Custom-made Materials for Automotive and Aerospace Engineering; Wiley-VCH: Weinheim, Germany, 2006; pp. 1–54. ISBN 3-527-31360-5. [Google Scholar]

- El-Gallab, M.; Sklad, M. Machining of Al/SiC particulate metal-matrix composites Part I: Tool performance. J. Mater. Process. Tech. 1998, 83, 151–158. [Google Scholar] [CrossRef]

- Cyboron, J.; Karolus, M.; Putyra, P.; Dyzia, M.; Ratuszek, W. Structure properties of AlSi7Mg/SiC composite produced by stir casting method. Acta Physica Polonica A 2016, 130, 969–971. [Google Scholar] [CrossRef]

- Wieczorek, J.; Dyzia, M.; Dolata, A.J. Machinability of aluminium matrix composites. Solid State Phenom. 2012, 191, 75–80. [Google Scholar] [CrossRef]

- Sobczak, J.J.; Drenchev, L. Metallic functionally graded materials: A specific class of advanced composites. J. Mater. Sci. Technol. 2013, 29, 297–316. [Google Scholar] [CrossRef]

- Gao, J.W.; Wang, C.Y. Modeling the solidification of functionally graded materials by centrifugal casting. Mater. Sci. Eng. A 2000, 292, 207–215. [Google Scholar] [CrossRef]

- Rajan, T.P.D.; Pai, B.C. Formation of solidification microstructures in centrifugal cast functionally graded aluminium composites. Trans. Indian Inst. Met. 2009, 62, 383–389. [Google Scholar] [CrossRef]

- Bernat, Ł.; Jackowski, J.; Szymański, P. SiC particle distribution in castings made from composite suspension A359/SiCp with various casting conditions. Compos. Theory Pract. 2015, 15, 168–173. [Google Scholar]

- Radhika, N.; Raghu, R. Development of functionally graded aluminium composites using centrifugal casting and influence of reinforcements on mechanical and wear properties. Trans. Nonferrous Met. Soc. China 2016, 26, 905–916. [Google Scholar] [CrossRef]

- Lin, X.D.; Liu, C.M.; Xiao, H.B. Fabrication of Al-Si-Mg functionally graded materials tube reinforced with in situ Si/Mg2Si particles by centrifugal casting. Compos. Part B-Eng. 2013, 45, 8–21. [Google Scholar] [CrossRef]

- Rajan, T.P.D.; Pai, B.C. Processing of functionally graded aluminium matrix composites by centrifugal casting technique. Mater. Sci. Forum. 2011, 690, 157–161. [Google Scholar] [CrossRef]

- Huang, X.; Liu, C.; Lv, X.; Liu, G.; Li, F. Aluminum alloy pistons reinforced with SiC fabricated by centrifugal casting. J. Mater. Process. Tech. 2011, 211, 1540–1546. [Google Scholar] [CrossRef]

- Łągiewka, M.; Konopka, Z. The influence of graphite addition on the abrasive wear of AlMg10 alloy matrix composites reinforced with SiC particles. Arch. Foundry Eng. 2014, 14, 51–54. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Chandramohan, G.; Mukund, K.; Ashwin, M.; Prabu, M. Dry sliding wear behavior of Al 2219/SiCp-Gr hybrid metal matrix composites. J. Mater. Eng. Perform. 2006, 15, 668–674. [Google Scholar] [CrossRef]

- Myalski, J.; Wieczorek, J.; Dolata-Grosz, A. Tribological properties of heterophase composites with an aluminium matrix. J. Achiev. Mater. Manuf. Eng. 2006, 15, 53–57. [Google Scholar]

- Dolata-Grosz, A. Interaction of Al-Si alloys with SiC/C ceramic particles and their influence on microstructure of composites. Solid State Phenom. 2011, 176, 55–62. [Google Scholar] [CrossRef]

- Dolata, A.J.; Golak, S.; Ciepliński, P. The Eulerian multiphase model of centrifugal casting process of particle reinforced Al matrix composites. Composites Theory Pract. 2017, 17, 200–205. [Google Scholar]

| Alloy Composition | Si | Fe | Cu | Mn | Mg | Zn | Sr | Al |

|---|---|---|---|---|---|---|---|---|

| AlSi7Mg0.6 * | 6.51 | 0.261 | 0.287 | 0.356 | 0.389 | 0.0665 | <0.0001 | 92.1 |

| AlSi7Mg2Sr0.03 ** | 6.21 | 0.272 | 0.265 | 0.356 | 1.43 | 0.0598 | 0.0377 | 91.2 |

| Designation | Material | Volume of Particles [wt.%] | Range of Particle Size [μm] |

|---|---|---|---|

| AlSi7 | AlSi7Mg2Sr0.03 matrix | - | - |

| S5 | AlSi7Mg2Sr0.03/SiCp | 5 | 30–70 |

| S10 | AlSi7Mg2Sr0.03/SiCpB | 10 | 30–70 |

| S15 | AlSi7Mg2Sr0.03/SiCp | 15 | 30–70 |

| C5 | AlSi7Mg2Sr0.03/GCsf | 5 | 10–20 |

| C3S7 | AlSi7Mg2Sr0.03/SiCp + GCsf | 7 + 3 | 30–70 and 10–20, respectively |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolata, A.J.; Dyzia, M.; Wieczorek, J. Tribological Properties of Single (AlSi7/SiCp, AlSi7/GCsf) and Hybrid (AlSi7/SiCp + GCsf) Composite Layers Formed in Sleeves via Centrifugal Casting. Materials 2019, 12, 2803. https://doi.org/10.3390/ma12172803

Dolata AJ, Dyzia M, Wieczorek J. Tribological Properties of Single (AlSi7/SiCp, AlSi7/GCsf) and Hybrid (AlSi7/SiCp + GCsf) Composite Layers Formed in Sleeves via Centrifugal Casting. Materials. 2019; 12(17):2803. https://doi.org/10.3390/ma12172803

Chicago/Turabian StyleDolata, Anna Janina, Maciej Dyzia, and Jakub Wieczorek. 2019. "Tribological Properties of Single (AlSi7/SiCp, AlSi7/GCsf) and Hybrid (AlSi7/SiCp + GCsf) Composite Layers Formed in Sleeves via Centrifugal Casting" Materials 12, no. 17: 2803. https://doi.org/10.3390/ma12172803

APA StyleDolata, A. J., Dyzia, M., & Wieczorek, J. (2019). Tribological Properties of Single (AlSi7/SiCp, AlSi7/GCsf) and Hybrid (AlSi7/SiCp + GCsf) Composite Layers Formed in Sleeves via Centrifugal Casting. Materials, 12(17), 2803. https://doi.org/10.3390/ma12172803