Effect of Silicone Rubber of a Waste Composite Insulator on Cement Mortar Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Silicone Rubber Modification

2.3. Mix Proportions

2.4. Sample Preparation and Test Methods

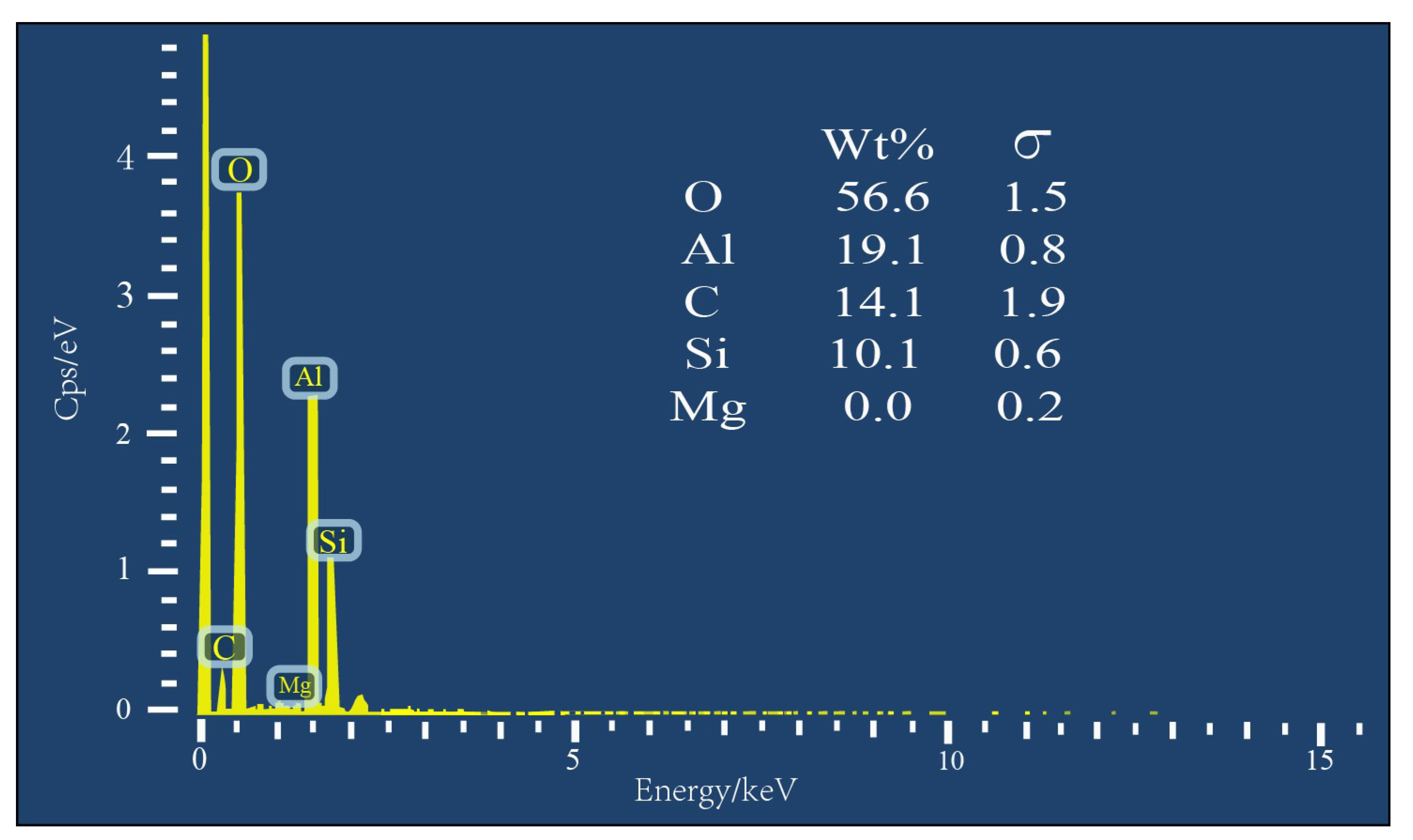

2.4.1. SEM and EDS Tests

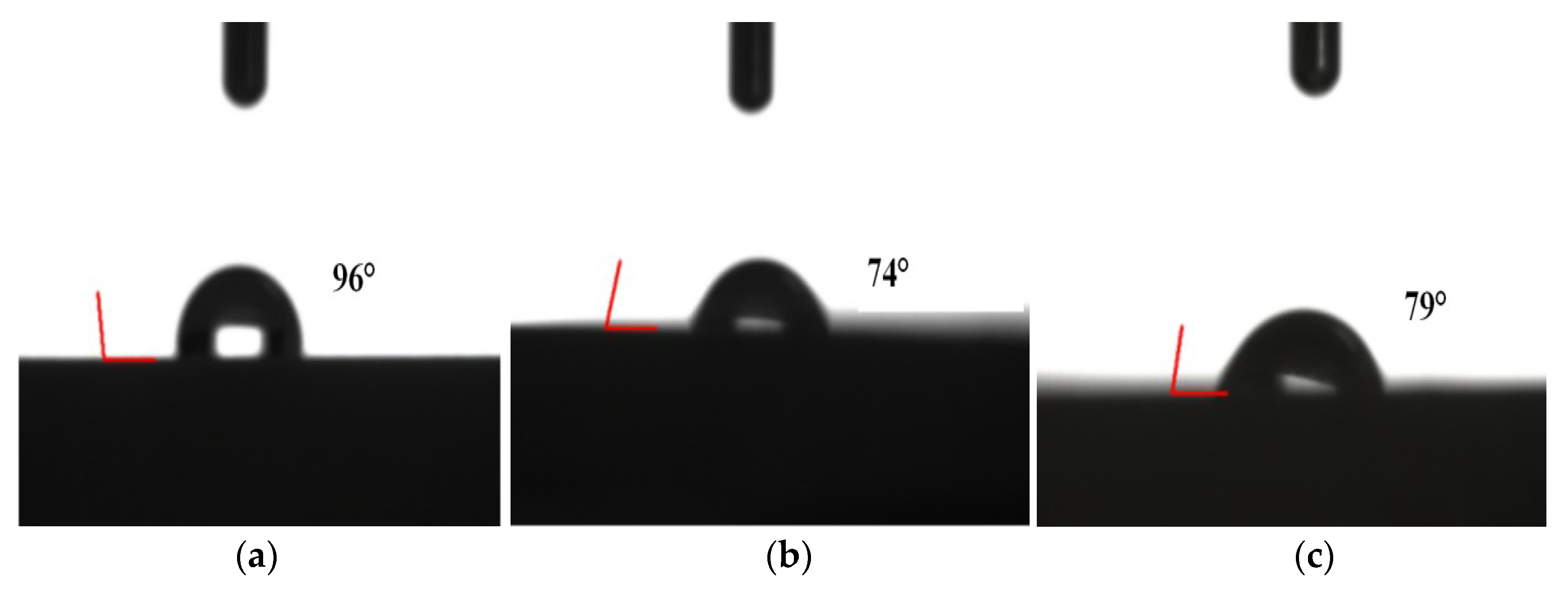

2.4.2. Contact Angle Test

2.4.3. Sample Preparation

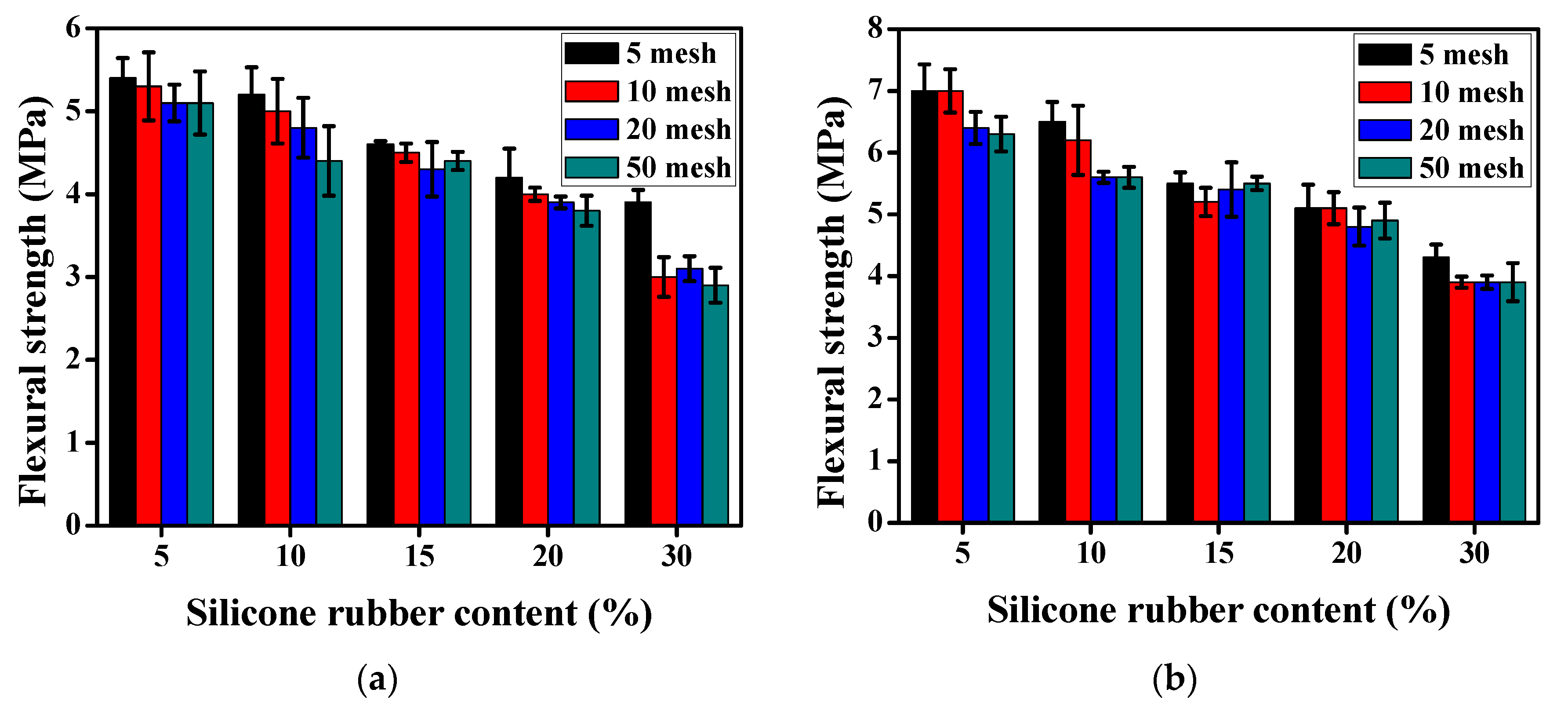

2.4.4. Mechanical Strength Test

2.4.5. Thermal Conductivity Test

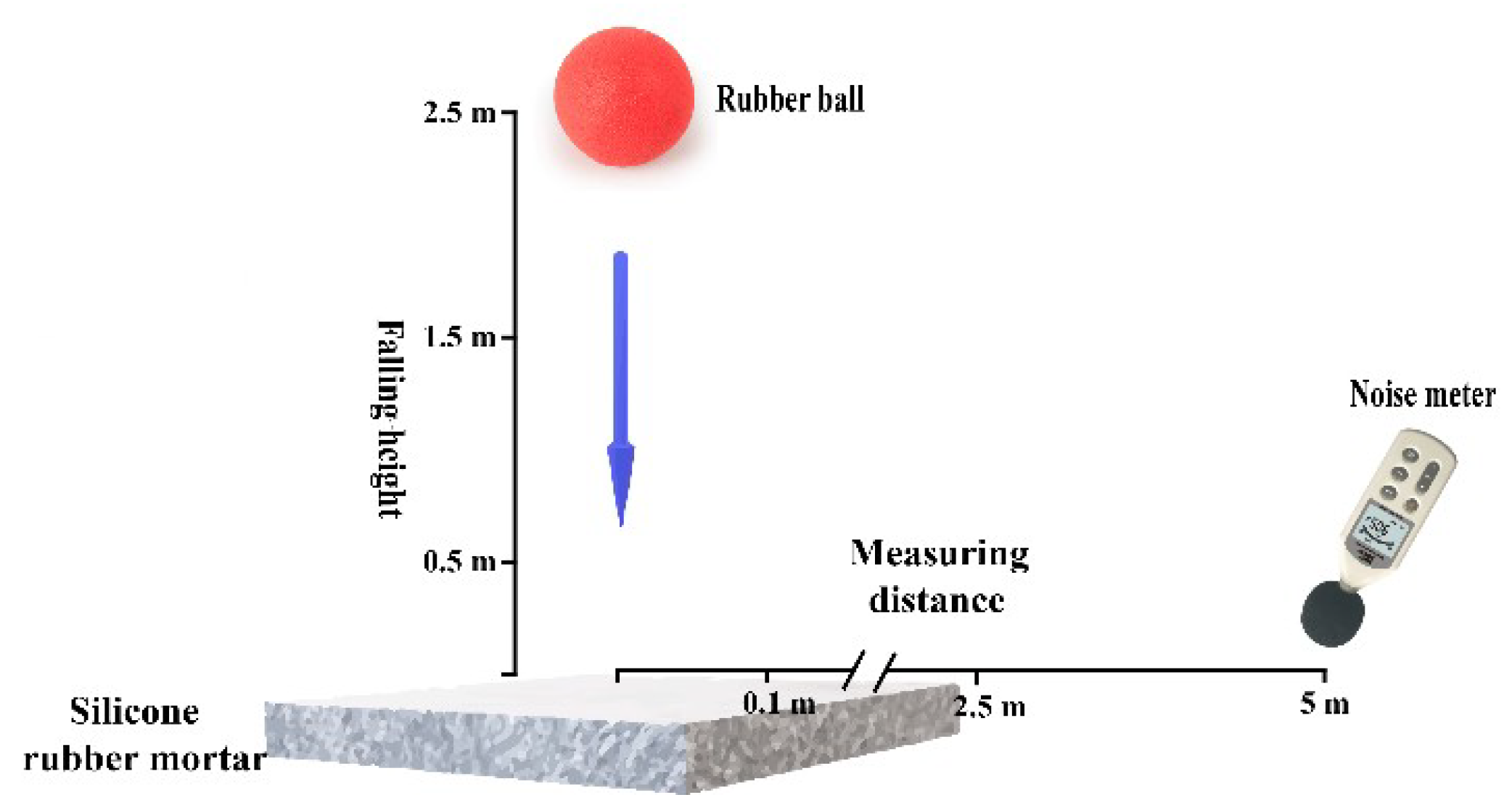

2.4.6. Noise Reduction Test

3. Results

3.1. Characterization of Silicone Rubber

3.1.1. SEM and EDS

3.1.2. Contact Angle

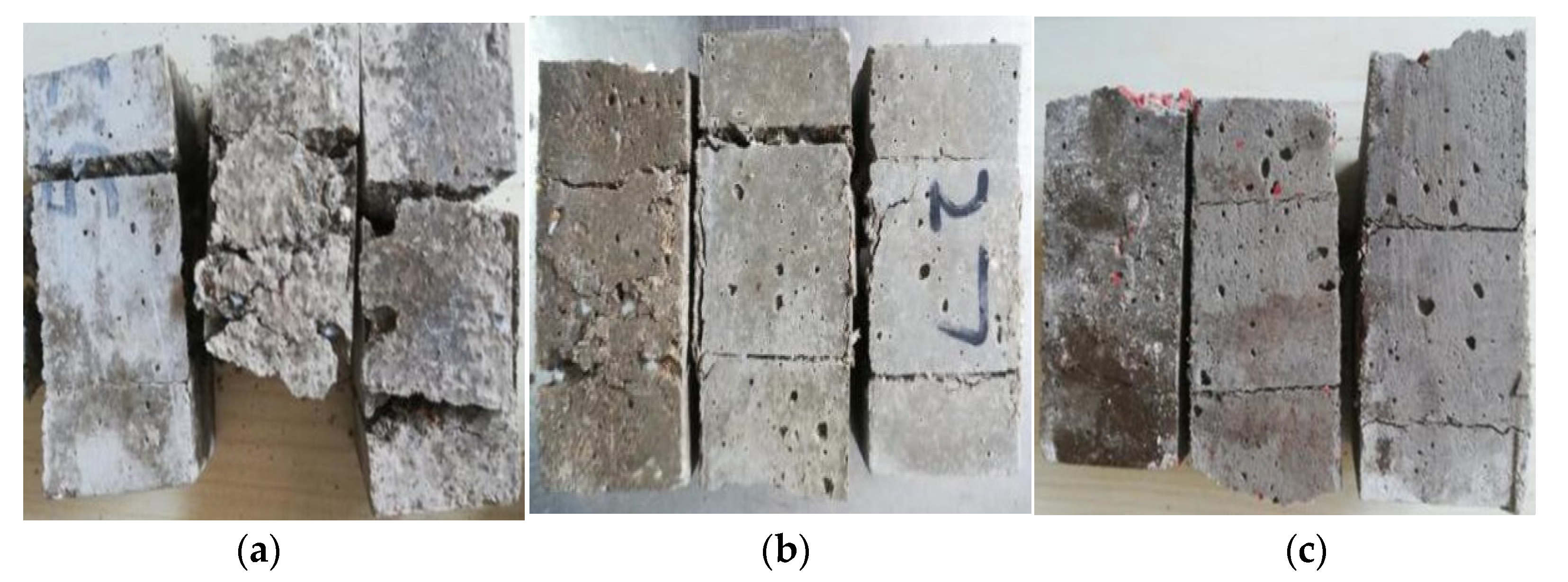

3.2. Mechanical Strength

3.2.1. Effect of Silicone Rubber on the Mechanical Strength of Mortar

3.2.2. Effect of the Modified Silicone Rubber on the Mechanical Strength of Mortar

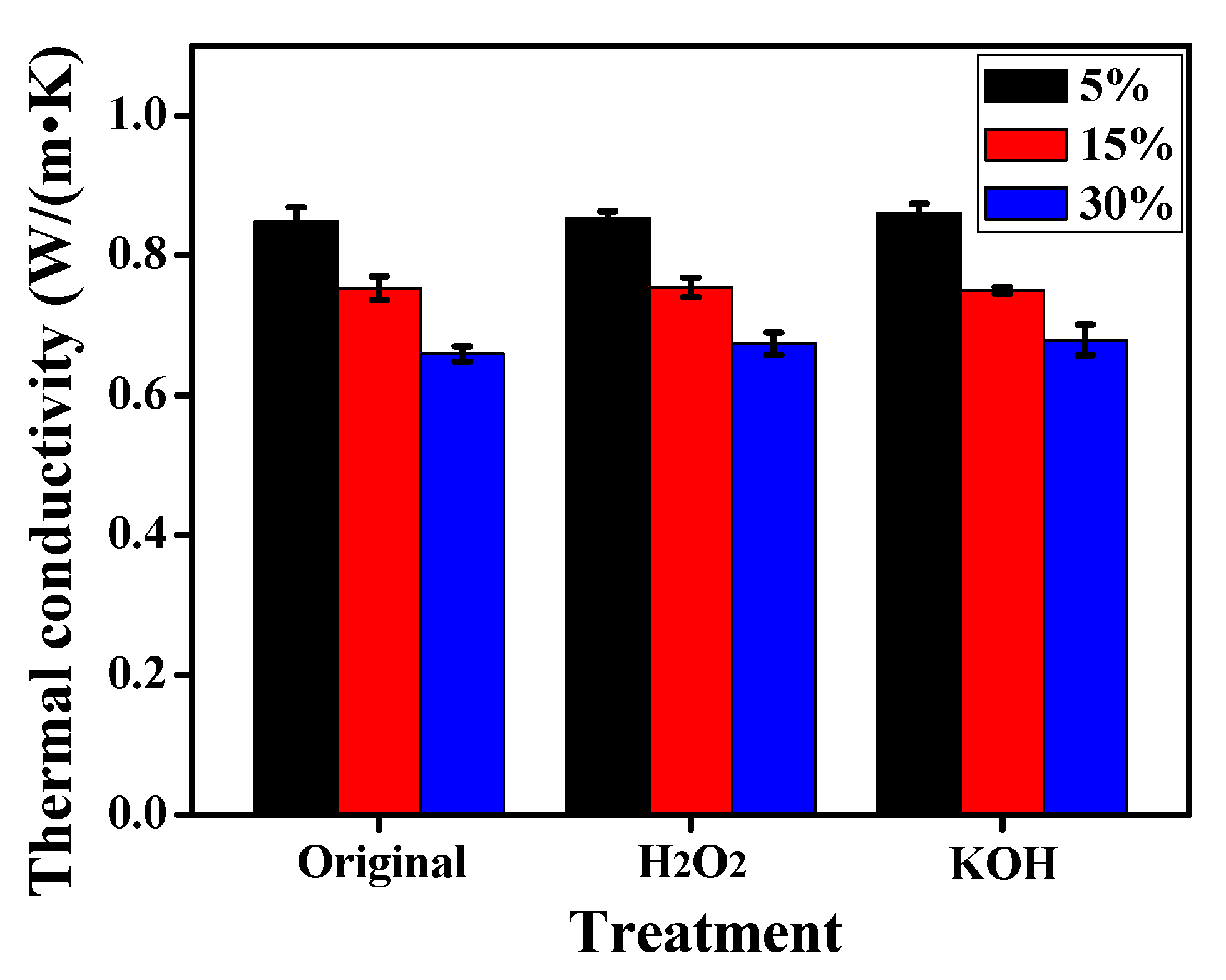

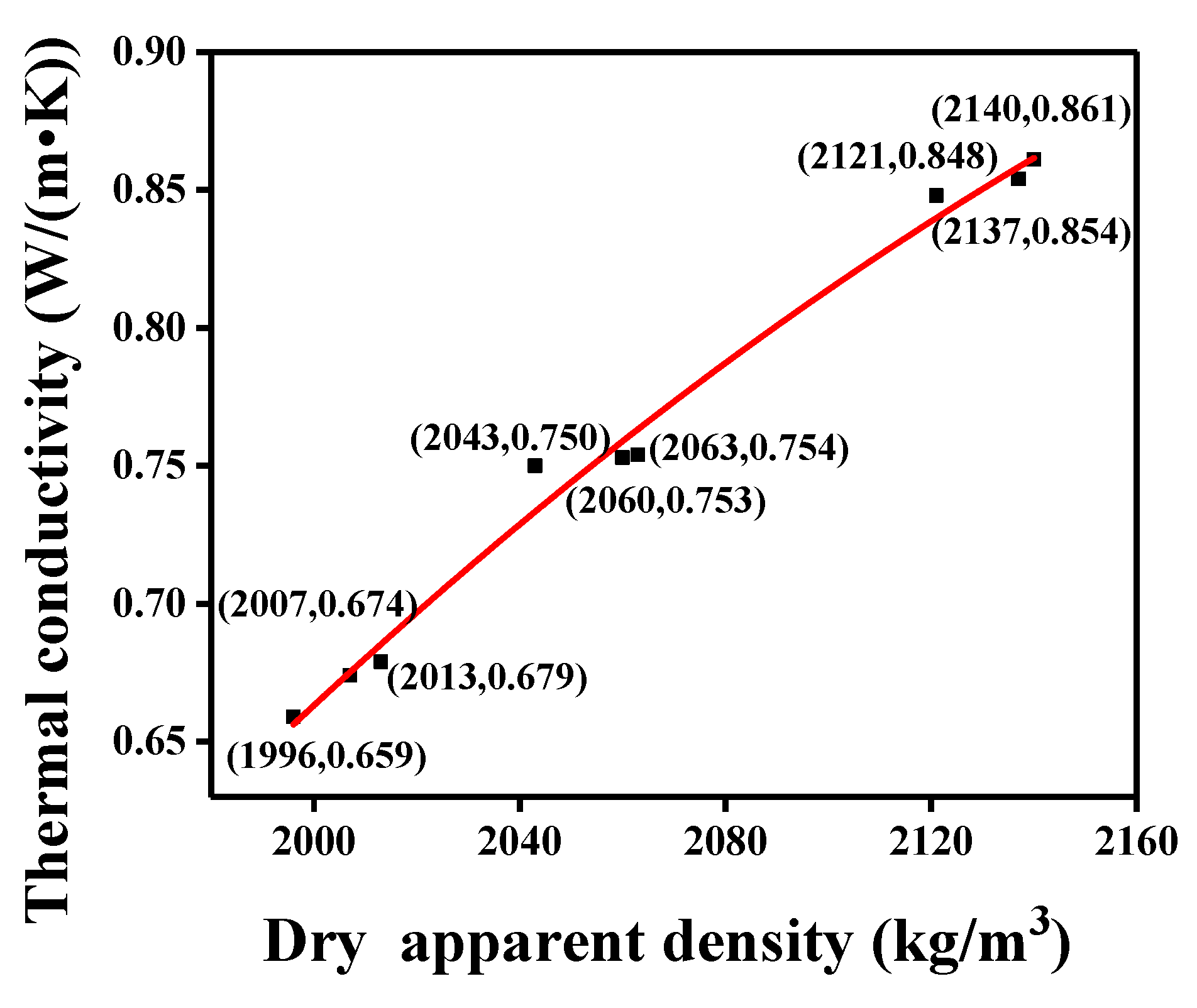

3.3. Thermal Insulation

3.3.1. Thermal Conductivity

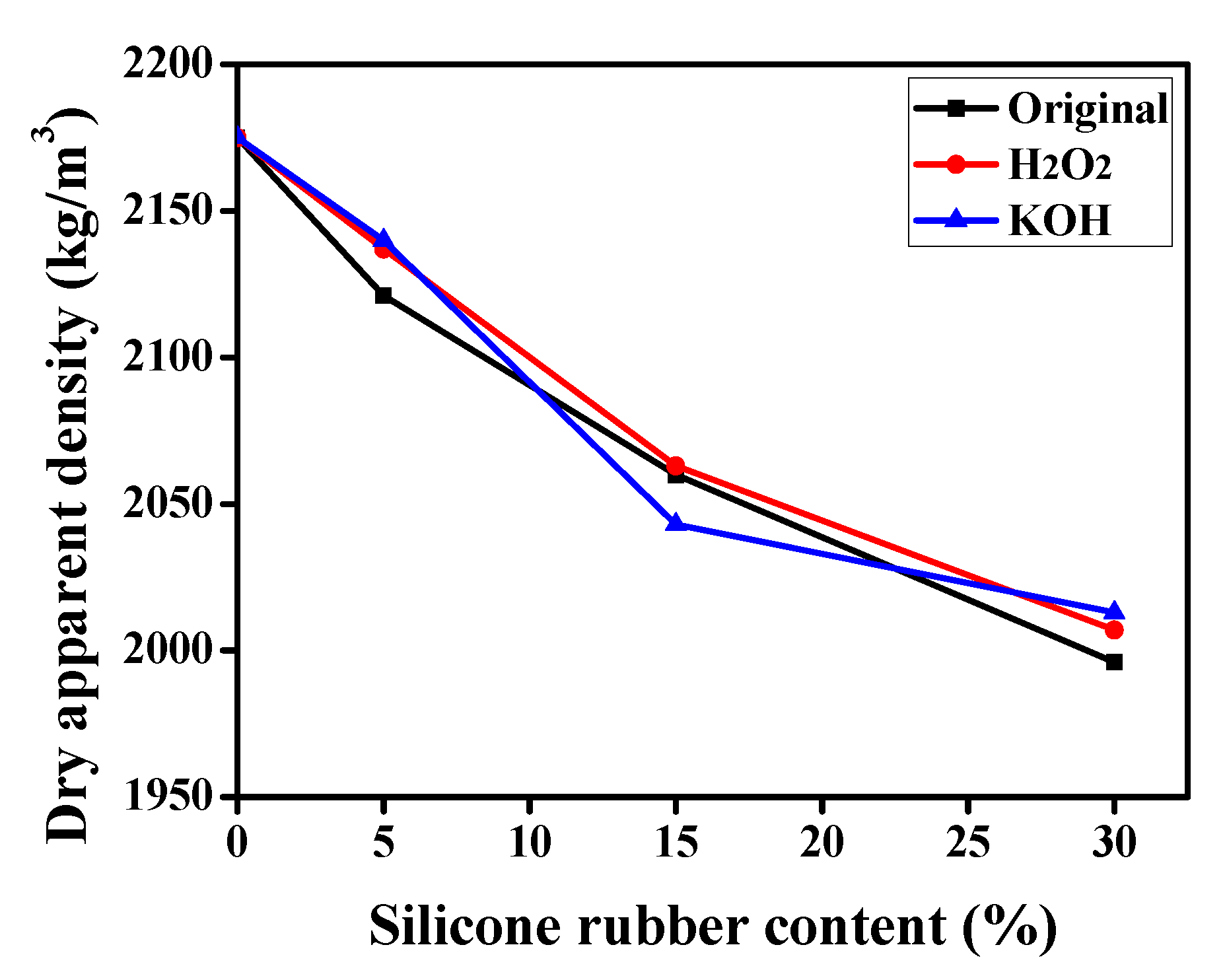

3.3.2. Dry Apparent Density

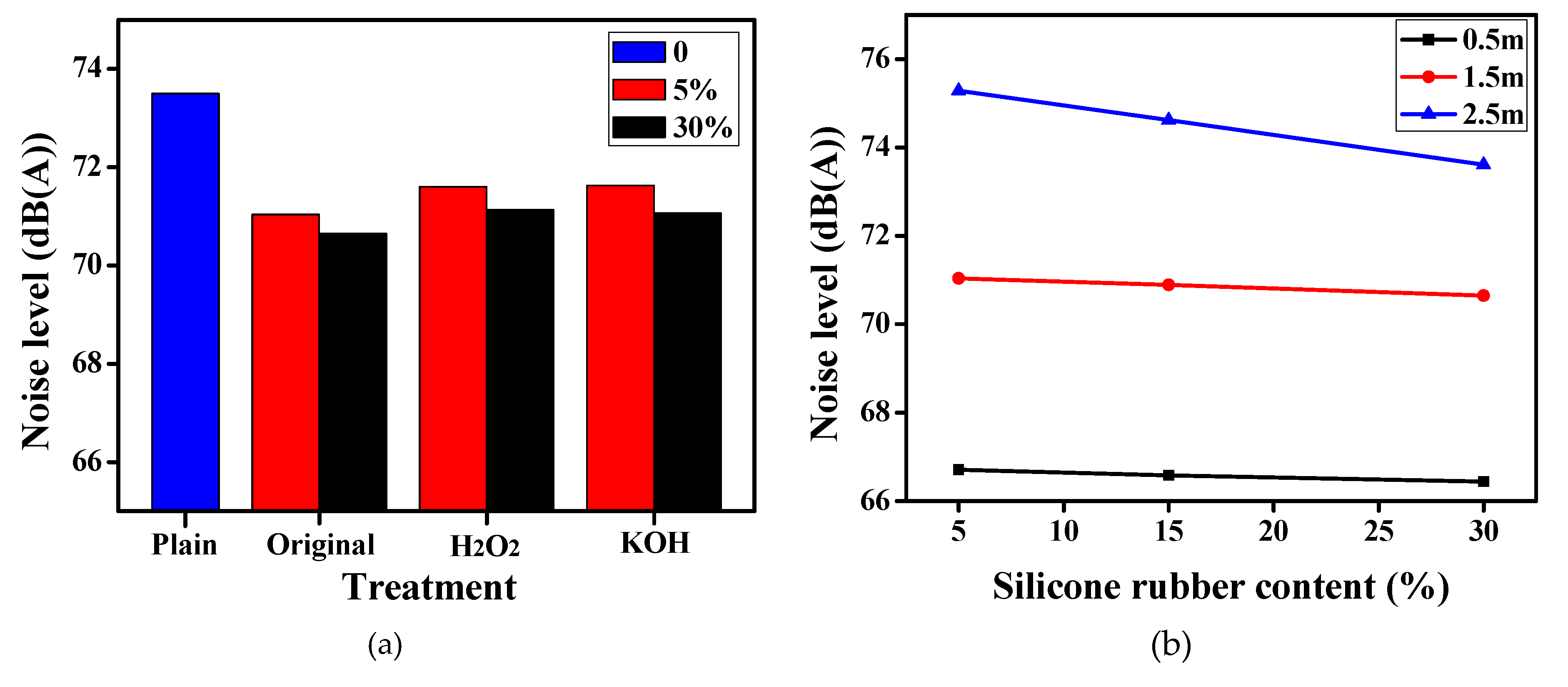

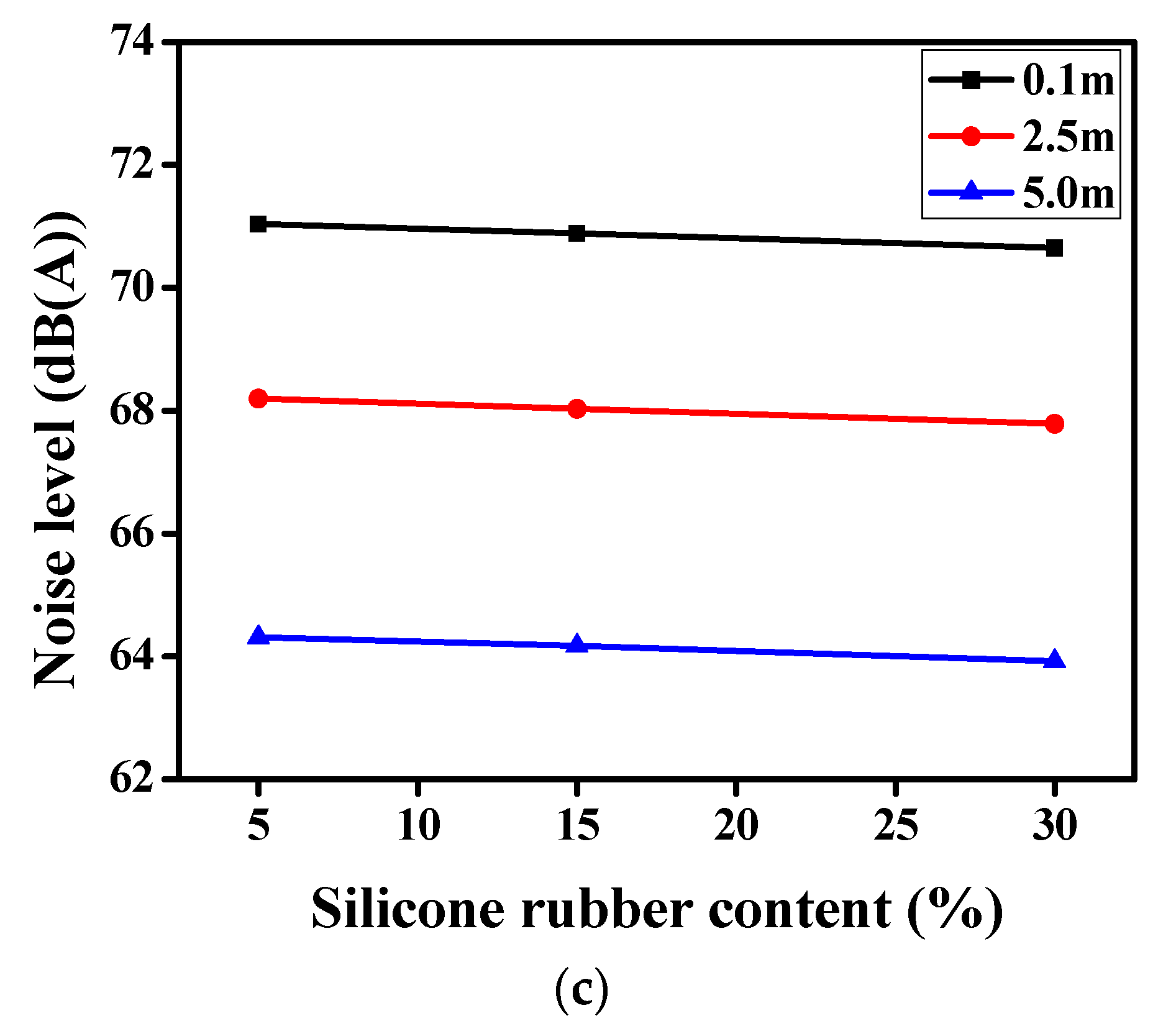

3.4. Noise Reduction

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Verma, A.R.; Reddy, B.S. Accelerated aging studies of silicon-rubber based polymeric insulators used for HV transmission lines. Polym. Test. 2017, 62, 124–131. [Google Scholar] [CrossRef]

- Buontempo, R.C.; Dellallibera, A.A.; Costa, E.C.M.; Pissolato, J.; Mello, D.R.D.; Mei, L.H.I. Electrical assessment of commercial 6.0-kV HTV silicone rubber for power insulation. Measurement 2016, 89, 114–119. [Google Scholar] [CrossRef]

- Liang, X.D.; Gao, Y.F.; Wang, J.F.; Li, S.H. Rapid development of silicone rubber composite insulator in China. High Volt. Eng. 2016, 42, 2888–2896. (In Chinese) [Google Scholar]

- Zhang, G.J.; Zhao, L.; Zhou, R.D.; Shen, W.W.; Liang, X.D. Review on aging characterization and evaluation of silicon rubber composite insulator. High Volt. Appar. 2016, 52, 0001–0015. (In Chinese) [Google Scholar]

- Cardoso, R.; Balestro, A.C.; Dellallibera, A.; Costa, E.C.M.; Angelini, J.M.G.; Mei, L.H.I. Silicone insulators of power transmission lines with a variable inorganic load concentration: Electrical and physiochemical analyses. Measurement 2014, 50, 63–73. [Google Scholar] [CrossRef]

- Arshad; Nekahi, A.; Mcmeekin, S.G.; Farzaneh, M. Measurement of surface resistance of silicone rubber sheets under polluted and dry band conditions. Electr. Eng. 2017, 100, 1729–1738. [Google Scholar] [CrossRef]

- Jalal, M.; Nassir, N.; Jalal, H. Waste tire rubber and pozzolans in concrete a trade-off between cleaner production and mechanical properties in a greener concrete. J. Clean. Prod. 2019, 238, 117882. [Google Scholar] [CrossRef]

- Oikonomou, N.; Mavridou, S. Improvement of chloride ion penetration resistance in cement mortars modified with rubber from worn automobile tires. Cement Concrete Compos. 2009, 31, 403–407. [Google Scholar] [CrossRef]

- Batayneh, M.K.; Marie, I.; Asi, I. Promoting the use of crumb rubber concrete in developing countries. Waste Manag. 2008, 28, 2171–2176. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Bakar, B.H.A.; Akil, H.M.; Ismail, H. Performance of rubberized and hybrid rubberized concrete structures under static and impact load conditions. Exp. Mech. 2013, 53, 377–384. [Google Scholar] [CrossRef]

- Ganesan, N.; Raj, J.B.; Shashikala, A.P. Flexural fatigue behavior of self compacting rubberized concrete. Constr. Build. Mater. 2013, 44, 7–14. [Google Scholar] [CrossRef]

- Youssf, O.; Hassanli, R.; Mills, J.E. Mechanical performance of FRP-confined and unconfined crumb rubber concrete containing high rubber content. J. Build. Eng. 2017, 11, 115–126. [Google Scholar] [CrossRef]

- Abdelaleem, B.H.; Ismail, M.K.; Hassan, A.A.A. The combined effect of crumb rubber and synthetic fibers on impact resistance of self-consolidating concrete. Constr. Build. Mater. 2018, 162, 816–829. [Google Scholar] [CrossRef]

- Sukontasukkul, P. Use of crumb rubber to improve thermal and sound properties of pre-cast concrete panel. Constr. Build. Mater. 2009, 23, 1084–1092. [Google Scholar] [CrossRef]

- Kader, M.M.A.; Abdel-Wehab, S.M.; Helal, M.A.; Hassan, H.H. Evaluation of thermal insulation and mechanical properties of waste rubber/natural rubber composite. HBRC J. 2012, 8, 69–74. [Google Scholar] [CrossRef]

- Sofi, A. Effect of waste tyre rubber on mechanical and durability properties of concrete—A review. Ain Shams Eng. J. 2018, 9, 2691–2700. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; İpek, S. Abrasion and freezing–thawing resistance of pervious concretes containing waste rubbers. Constr. Build. Mater. 2014, 73, 19–24. [Google Scholar] [CrossRef]

- Topçu, I.B.; Demir, A. Durability of Rubberized Mortar and Concrete. J. Mater. Civ. Eng. 2007, 19, 173–178. [Google Scholar] [CrossRef]

- Bravo, M.; Brito, J.D. Concrete made with used tyre aggregate: Durability-related performance. J. Clean. Prod. 2012, 25, 42–50. [Google Scholar] [CrossRef]

- Kardos, A.J.; Durham, S.A. Strength, durability, and environmental properties of concrete utilizing recycled tire particles for pavement applications. Constr. Build. Mater. 2015, 98, 832–845. [Google Scholar] [CrossRef]

- Chou, L.H.; Lin, C.N.; Lu, C.K.; Lee, C.H.; Lee, M.T. Improving rubber concrete by waste organic sulfur compounds. Waste Manag. Res. 2010, 28, 29–35. [Google Scholar] [CrossRef] [PubMed]

- Albano, C.; Camacho, N.; Reyes, J.; Feliu, J.L.; Hernández, M. Influence of scrap rubber addition to Portland I concrete composites: Destructive and non-destructive testing. Compos. Struct. 2005, 71, 439–446. [Google Scholar] [CrossRef]

- Marques, A.C.; Akasaki, J.L.; Trigo, A.P.M.; Marques, M.L. Influence of the surface treatment of tire rubber residues added in mortars. Rev. IBRACON Estrut. Mater. 2008, 1, 113–120. [Google Scholar] [CrossRef]

- Mohammadi, I.; Khabbaz, H.; Vessalas, K. Enhancing mechanical performance of rubberised concrete pavements with sodium hydroxide treatment. Mater. Struct. 2016, 49, 813–827. [Google Scholar] [CrossRef]

- Rivas-Vázquez, L.P.; Suárez-Orduña, R.; Hernández-Torres, J.; Aquino-Bolaños, E. Effect of the surface treatment of recycled rubber on the mechanical strength of composite concrete/rubber. Mater. Struct. 2015, 48, 2809–2814. [Google Scholar] [CrossRef]

- He, L.; Ma, Y.; Liu, Q.; Mu, Y. Surface modification of crumb rubber and its influence on the mechanical properties of rubber-cement concrete. Constr. Build. Mater. 2016, 120, 403–407. [Google Scholar] [CrossRef]

- Onuaguluchi, O. Effects of surface pre-coating and silica fume on crumb rubber-cement matrix interface and cement mortar properties. J. Clean. Prod. 2015, 104, 339–345. [Google Scholar] [CrossRef]

- Siddika, A.; Mamun, M.A.A.; Alyousef, R.; Amran, Y.H.M.; Aslani, F.; Alabduljabbar, H. Properties and utilizations of waste tire rubber in concrete: A review. Constr. Build. Mater. 2019, 224, 711–731. [Google Scholar] [CrossRef]

- Xue, Y.; Li, X.; Zhang, D.; Wang, H.; Chen, Y.; Chen, Y. Comparison of ATH and SiO2 fillers filled silicone rubber composites for HTV insulators. Compos. Sci. Technol. 2018, 155, 137–143. [Google Scholar] [CrossRef]

- Arshad; Nekahi, A.; Mcmeekin, S.G.; Farzaneh, M. Effect of pollution severity and dry band location on the flashover characteristics of silicone rubber surfaces. Electr. Eng. 2017, 99, 1053–1063. [Google Scholar] [CrossRef]

- Wang, C.; Li, T.; Tu, Y.; Yuan, Z.; Li, R.; Zhang, F.; Gong, B. Heating phenomenon in unclean composite insulators. Eng. Fail. Anal. 2016, 65, 48–56. [Google Scholar] [CrossRef]

- Verma, A.R.; Reddy, B.S. Aging studies on polymeric insulators under DC stress with controlled climatic conditions. Polym. Test. 2018, 68, 185–192. [Google Scholar] [CrossRef]

- Richardson, A.E.; Coventry, K.A.; Ward, G. Freeze/thaw protection of concrete with optimum rubber crumb content. J. Clean. Prod. 2012, 23, 96–103. [Google Scholar] [CrossRef]

- Jung, K.C.; Roh, I.T.; Chang, S.H. Thermal behavior and performance evaluation of epoxy-based polymer concretes containing silicone rubber for use as runway repair materials. Compos. Struct. 2015, 119, 195–205. [Google Scholar] [CrossRef]

- Roh, I.T.; Jung, K.C.; Chang, S.H.; Cho, Y.H. Characterization of compliant polymer concretes for rapid repair of runways. Constr. Build. Mater. 2015, 78, 77–84. [Google Scholar] [CrossRef]

- Si, R.; Guo, S.; Dai, Q. Durability performance of rubberized mortar and concrete with NaOH-Solution treated rubber particles. Constr. Build. Mater. 2017, 153, 496–505. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Nehdi, M.; Khan, A.; Nehdi, M. Cementitious composites containing recycled tire rubber: An overview of engineering properties and potential applications. Cement Concrete Aggreg. 2001, 23, 3–10. [Google Scholar]

- Yang, L.H.; Zhu, H.; Zhang, Y.M. Effect of crumb rubber on pore structure of cement mortar. J. Tianjin Univ. 2011, 44, 1083–1087. (In Chinese) [Google Scholar]

- Mu, Q.; Feng, S.; Diao, G. Thermal conductivity of silicone rubber filled with ZnO. Polym. Compos. 2007, 28, 125–130. [Google Scholar] [CrossRef]

- Wongsa, A.; Sata, V.; Nematollahi, B.; Sanjayan, J.; Chindaprasirt, P. Mechanical and thermal properties of lightweight geopolymer mortar incorporating crumb rubber. J. Clean. Prod. 2018, 195, 1069–1980. [Google Scholar] [CrossRef]

- Jafari, K.; Toufigh, V. Experimental and analytical evaluation of rubberized polymer concrete. Constr. Build. Mater. 2017, 155, 495–510. [Google Scholar] [CrossRef]

| Property | Specific Density (kg/m3) | Normal Consistency (%) | Initial Setting Time (min) | Final Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | ||

|---|---|---|---|---|---|---|---|---|

| 7 days | 28 days | 7 days | 28 days | |||||

| Cement | 3100 | 28.35 | 235 | 305 | 30.2 | 46.7 | 5.8 | 7.3 |

| Description of Mortar | Cement | Water | River Sand | Silicone Rubber |

|---|---|---|---|---|

| Plain | 503.68 | 251.84 | 1511.04 | 0 |

| Replacing 5%; 5 mesh | 503.68 | 251.84 | 1435.49 | 42.05 |

| Replacing 10%; 5 mesh | 503.68 | 251.84 | 1359.94 | 84.10 |

| Replacing 15%; 5 mesh | 503.68 | 251.84 | 1284.38 | 126.15 |

| Replacing 20%; 5 mesh | 503.68 | 251.84 | 1208.83 | 168.20 |

| Replacing 30%; 5 mesh | 503.68 | 251.84 | 1057.73 | 252.30 |

| Replacing 5%; 10 mesh | 503.68 | 251.84 | 1435.49 | 42.05 |

| Replacing 10%; 10 mesh | 503.68 | 251.84 | 1359.94 | 84.10 |

| Replacing 15%; 10 mesh | 503.68 | 251.84 | 1284.38 | 126.15 |

| Replacing 20%; 10 mesh | 503.68 | 251.84 | 1208.83 | 168.20 |

| Replacing 30%; 10 mesh | 503.68 | 251.84 | 1057.73 | 252.30 |

| Replacing 5%; 20 mesh | 503.68 | 251.84 | 1435.49 | 42.05 |

| Replacing 10%; 20 mesh | 503.68 | 251.84 | 1359.94 | 84.10 |

| Replacing 15%; 20 mesh | 503.68 | 251.84 | 1284.38 | 126.15 |

| Replacing 20%; 20 mesh | 503.68 | 251.84 | 1208.83 | 168.20 |

| Replacing 30%; 20 mesh | 503.68 | 251.84 | 1057.73 | 252.30 |

| Replacing 5%; 50 mesh | 503.68 | 251.84 | 1435.49 | 42.05 |

| Replacing 10%; 50 mesh | 503.68 | 251.84 | 1359.94 | 84.10 |

| Replacing 15%; 50 mesh | 503.68 | 251.84 | 1284.38 | 126.15 |

| Replacing 20%; 50 mesh | 503.68 | 251.84 | 1208.83 | 168.20 |

| Replacing 30%; 50 mesh | 503.68 | 251.84 | 1057.73 | 252.30 |

| Description of Mortar | Cement | Water | River Sand | Silicone Rubber |

|---|---|---|---|---|

| Replacing 5%; 5 mesh | 503.68 | 251.84 | 1435.49 | 42.05 |

| Replacing 15%; 5 mesh | 503.68 | 251.84 | 1284.38 | 126.15 |

| Replacing 30%; 5 mesh | 503.68 | 251.84 | 1057.73 | 252.30 |

| Replacing 5%; 5 mesh; KOH treated | 503.68 | 251.84 | 1435.49 | 42.05 |

| Replacing 15%; 5 mesh; KOH treated | 503.68 | 251.84 | 1284.38 | 126.15 |

| Replacing 30%; 5 mesh; KOH treated | 503.68 | 251.84 | 1057.73 | 252.30 |

| Replacing 5%; 5 mesh; H2O2 treated | 503.68 | 251.84 | 1435.49 | 42.05 |

| Replacing 15%; 5 mesh; H2O2 treated | 503.68 | 251.84 | 1284.38 | 126.15 |

| Replacing 30%; 5 mesh; H2O2 treated | 503.68 | 251.84 | 1057.73 | 252.30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, G.; Shen, Z.; Yu, Y.; Fan, L.; Cao, H.; Yin, C. Effect of Silicone Rubber of a Waste Composite Insulator on Cement Mortar Properties. Materials 2019, 12, 2796. https://doi.org/10.3390/ma12172796

Qin G, Shen Z, Yu Y, Fan L, Cao H, Yin C. Effect of Silicone Rubber of a Waste Composite Insulator on Cement Mortar Properties. Materials. 2019; 12(17):2796. https://doi.org/10.3390/ma12172796

Chicago/Turabian StyleQin, Gang, Zhongshuo Shen, Yongqiang Yu, Lidan Fan, Hongwei Cao, and Chaowei Yin. 2019. "Effect of Silicone Rubber of a Waste Composite Insulator on Cement Mortar Properties" Materials 12, no. 17: 2796. https://doi.org/10.3390/ma12172796

APA StyleQin, G., Shen, Z., Yu, Y., Fan, L., Cao, H., & Yin, C. (2019). Effect of Silicone Rubber of a Waste Composite Insulator on Cement Mortar Properties. Materials, 12(17), 2796. https://doi.org/10.3390/ma12172796