1. Introduction

There has been a sharply increasing demand recently for difficult-to-cut materials in various industrial fields such as medical devices and aerospace. However, because difficult-to-cut materials have exceptional mechanical properties including high strength and abrasion resistance, they are difficult to machine using conventional machining (CM). For example, using CM, tool life and machining quality decrease due to the high cutting force required [

1,

2,

3]. Consequently, many researchers have been actively studying advanced methods for machining difficult-to-cut materials efficiently. One of these, thermally assisted machining (TAM), is attracting attention as an effective method. TAM is a machining method where difficult-to-cut materials are softened by an external heat source prior to engaging the cutting tool. Three types of TAM method have mainly been studied, according to the type of heat source: laser assisted machining (LAM), induction assisted machining (IAM), and plasma assisted machining (PAM). The most active study among these is LAM, where current research and LAM devices have been investigated [

4,

5]. The development of a control method of a complex tool path and the development of a high-performance tool were proposed as a future research direction. A thermal model was developed to calculate the temperature during the LAM [

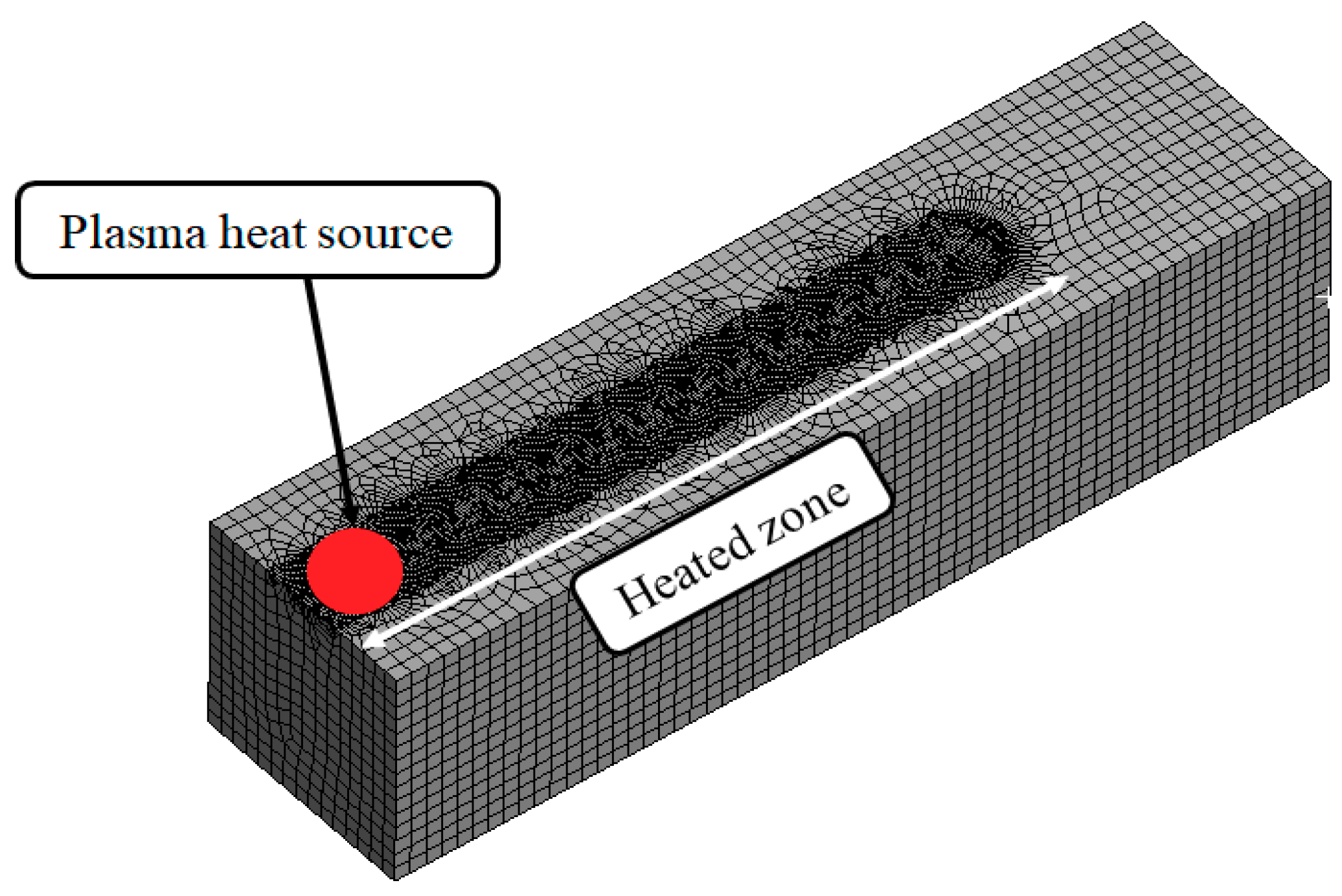

6,

7,

8]. Through the developed model, the thermal distribution of the workpiece was obtained and appropriate machining conditions were presented. Numerous research on the machinability of various difficult-to-cut materials have been conducted. Research has been carried out to improve the machinability of Inconel 718, which has high toughness [

9,

10]. A study was also conducted on the machining of brittle materials such as ceramics and glass [

11,

12,

13,

14]. Furthermore, hybrid processes that combine LAM and other processes have been proposed [

15,

16]. One TAM method, PAM, is more attractive commercially because it is lower in price than the LAM. In addition, since its spot size is larger than that of lasers, PAM has an advantage in the milling process. If an entire section is heated by a small spot, it creates a technical problem because the torch must be rotated at the same rotational speed of the cutting tool. On the other hand, the use of larger spots allows heating including all radial cutting depths, directly in front of the end mill [

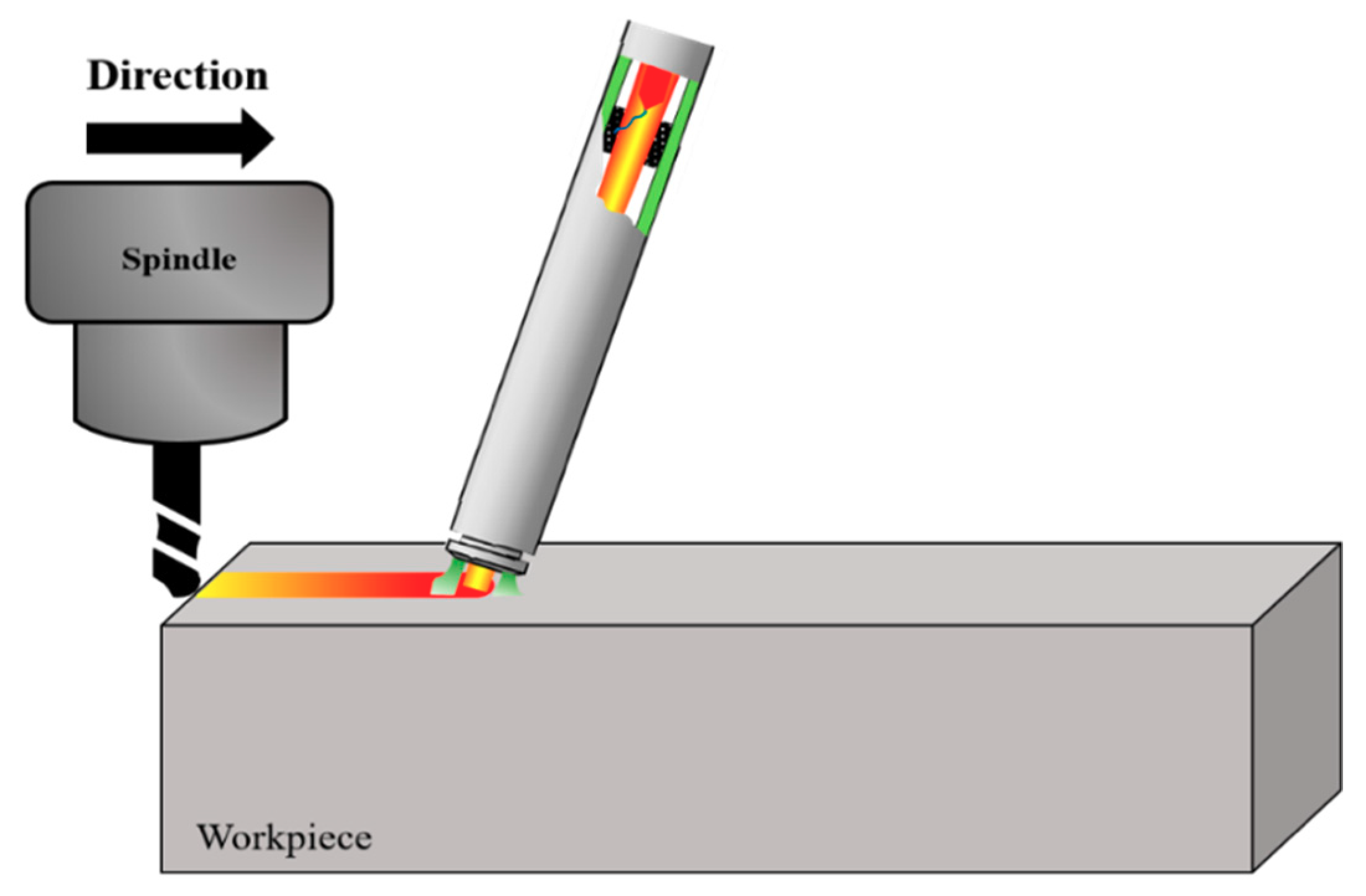

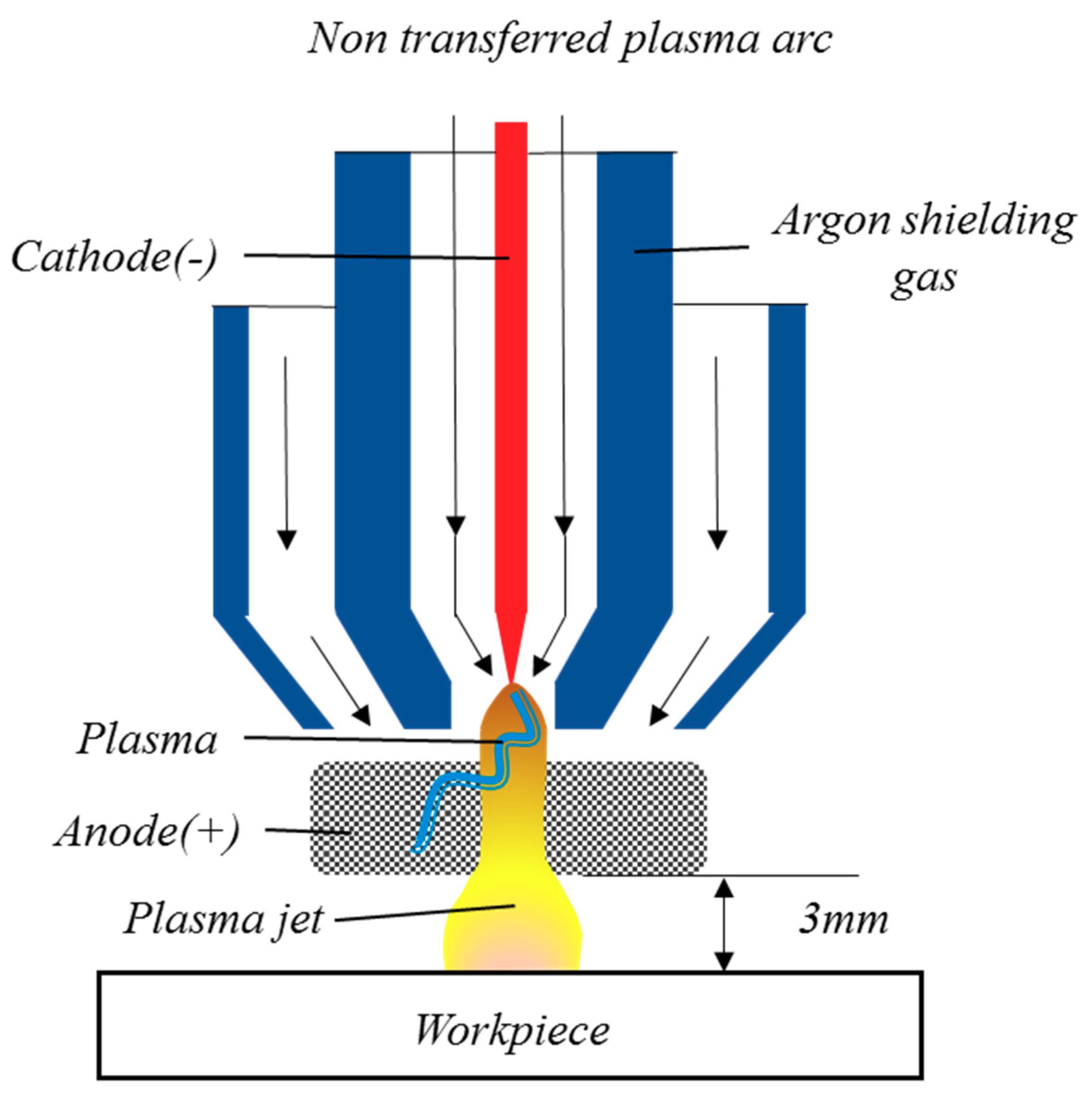

17].

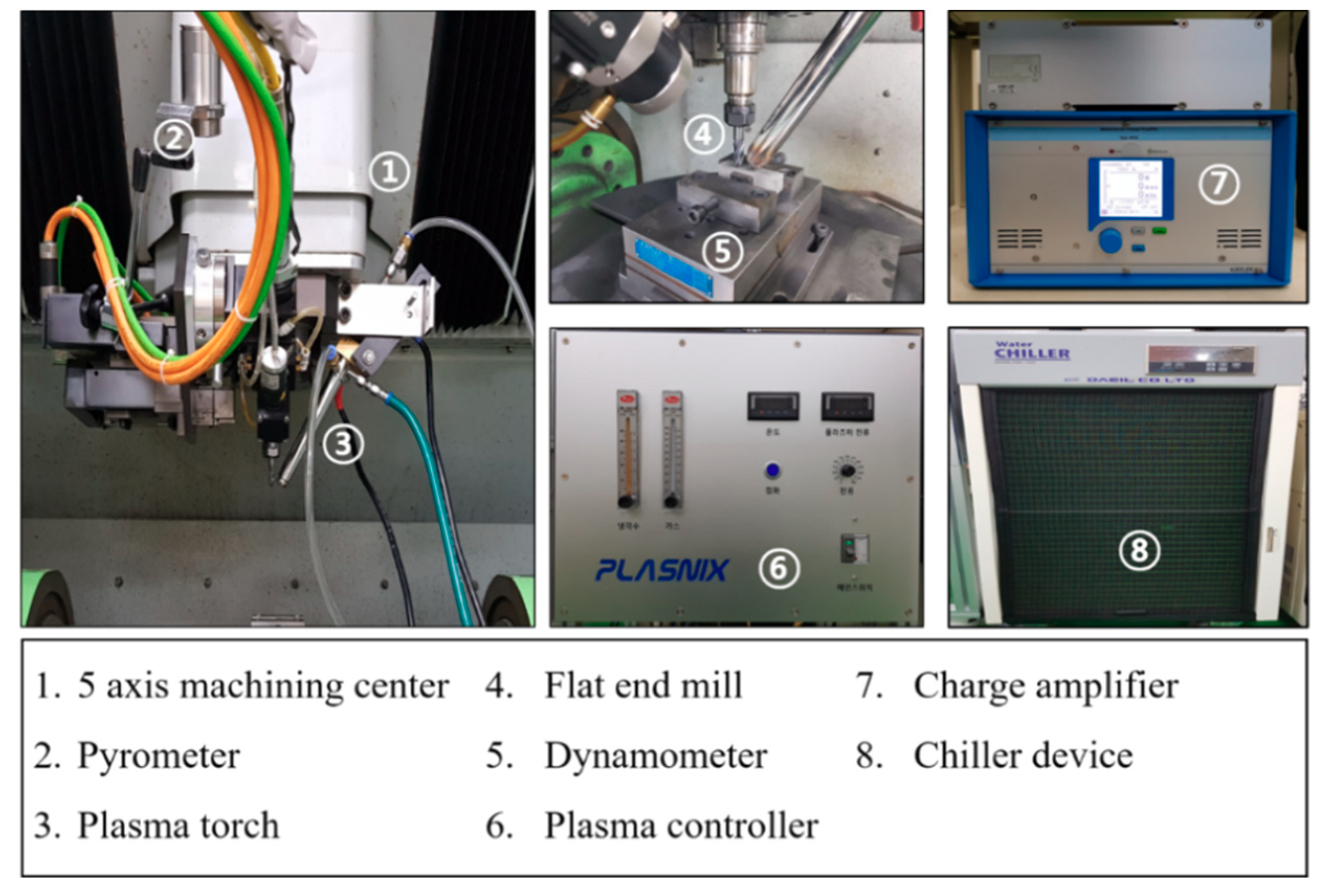

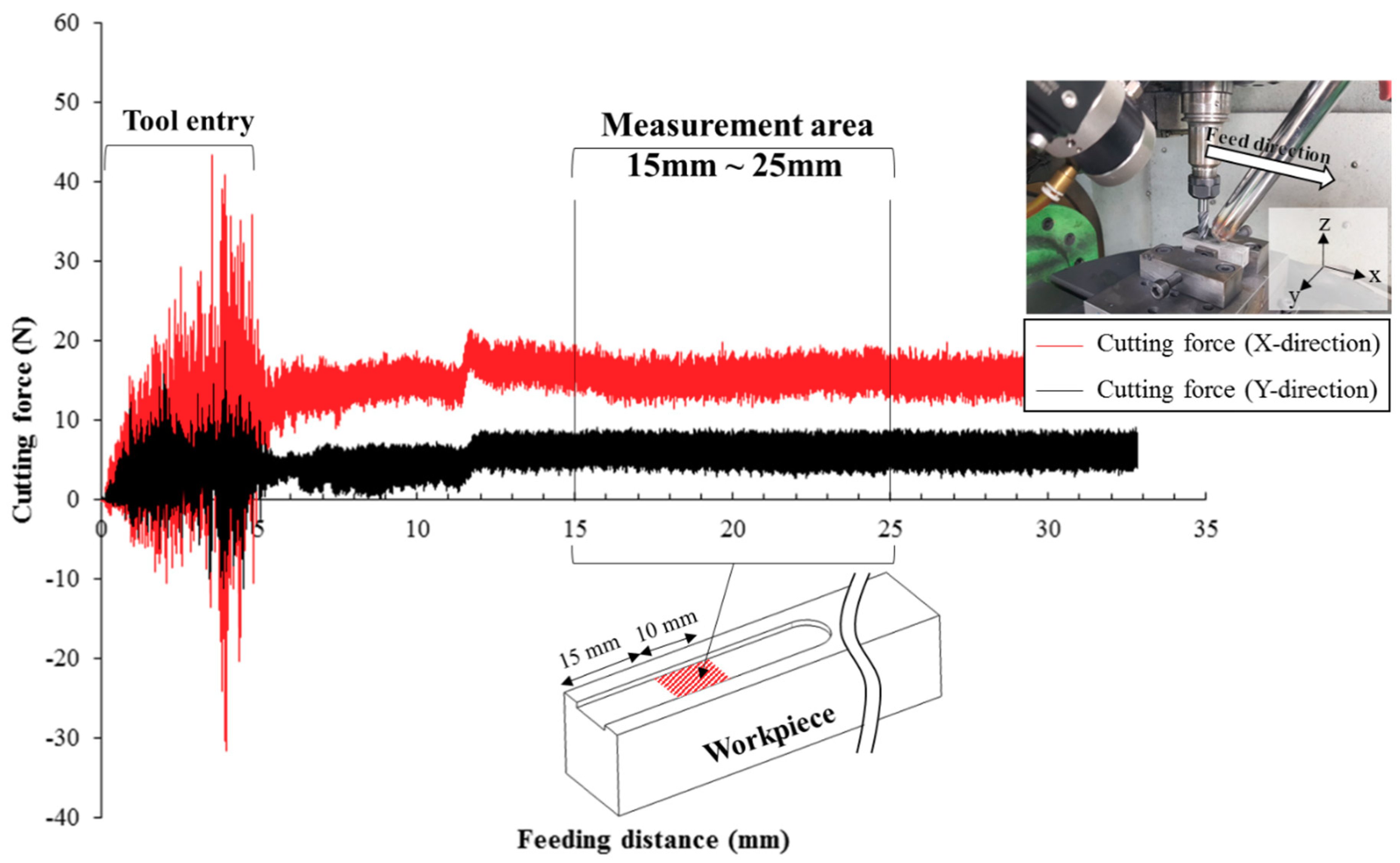

In PAM, it is very important to study the proper conditions because cutting force and machining quality will vary depending on the machining conditions. PAM has various machining conditions such as feed rate, spindle speed, depth of cut, power, gas flow rate, torch angle, and so on.

Previous PAM research has been conducted with a focus on machining characteristics. Lopez de Lacalle et al. [

17] analyzed tool wear and cutting force using PAM and established that PAM reduced the cutting force by 25% and increased productivity by 350%. Moon and Lee [

18] analyzed the cutting force and surface roughness of an AISI 1045 material using PAM and established that PAM reduced the cutting force and surface roughness by 61 to 15% and 79 to 5%, respectively. Kitagawa and Maekawa [

19] studied the tool wear and machinability of ceramic materials after applying a plasma heat source to the turning process. Lee et al. [

20] studied the machining characteristics according to torch angle, by setting the plasma torch angle as a machining variable.

Studies on the preheating effect of PAM have also been carried out. Kim et al. [

21] studied the preheating effect on cylindrical shaped specimens using PAM. Baek et al. [

22] studied the preheating effect of laser-plasma heat sources and proposed an appropriate preheating method for effective machining. Lee and Lee [

23] studied cutting force by setting the plasma power and gas flow rate as a machining variable and proposed using 2 kW of power and 25 l/min of gas flow rate. Leshock et al. [

24] studied heating and operating parameters and systematically analyzed the process control of plasma enhanced machining. They established that PAM reduced the cutting force by 30% and increased tool life by 40%. Wang et al. [

25] studied combinations of traditional turning with cryogenically enhanced machining and plasma enhanced machining. Using the proposed machining method, the cutting force and surface roughness were reduced and tool life was extended. They established that PAM reduced the cutting force and surface roughness by 30 to 50% and 250%, and increased tool life by 156%.

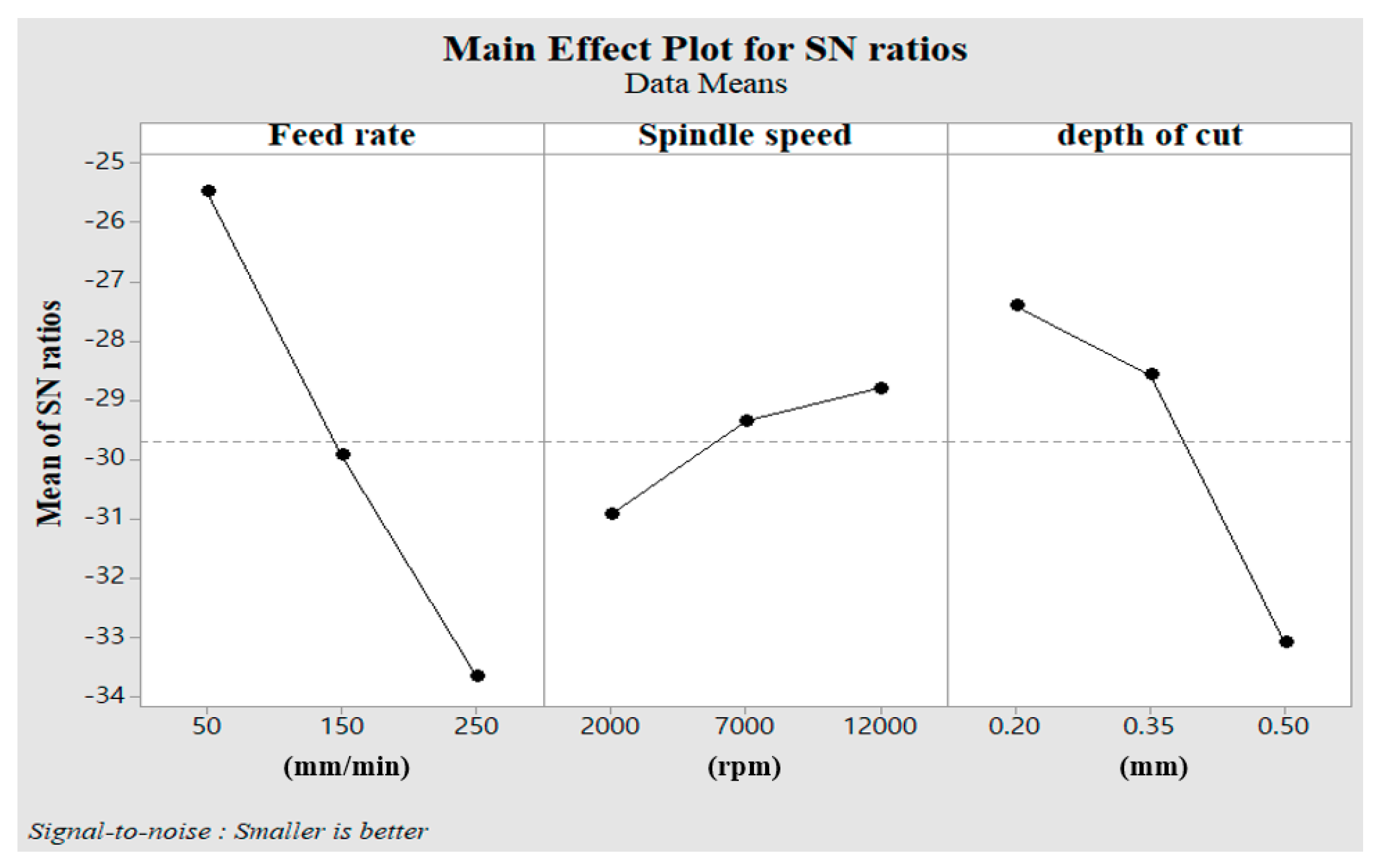

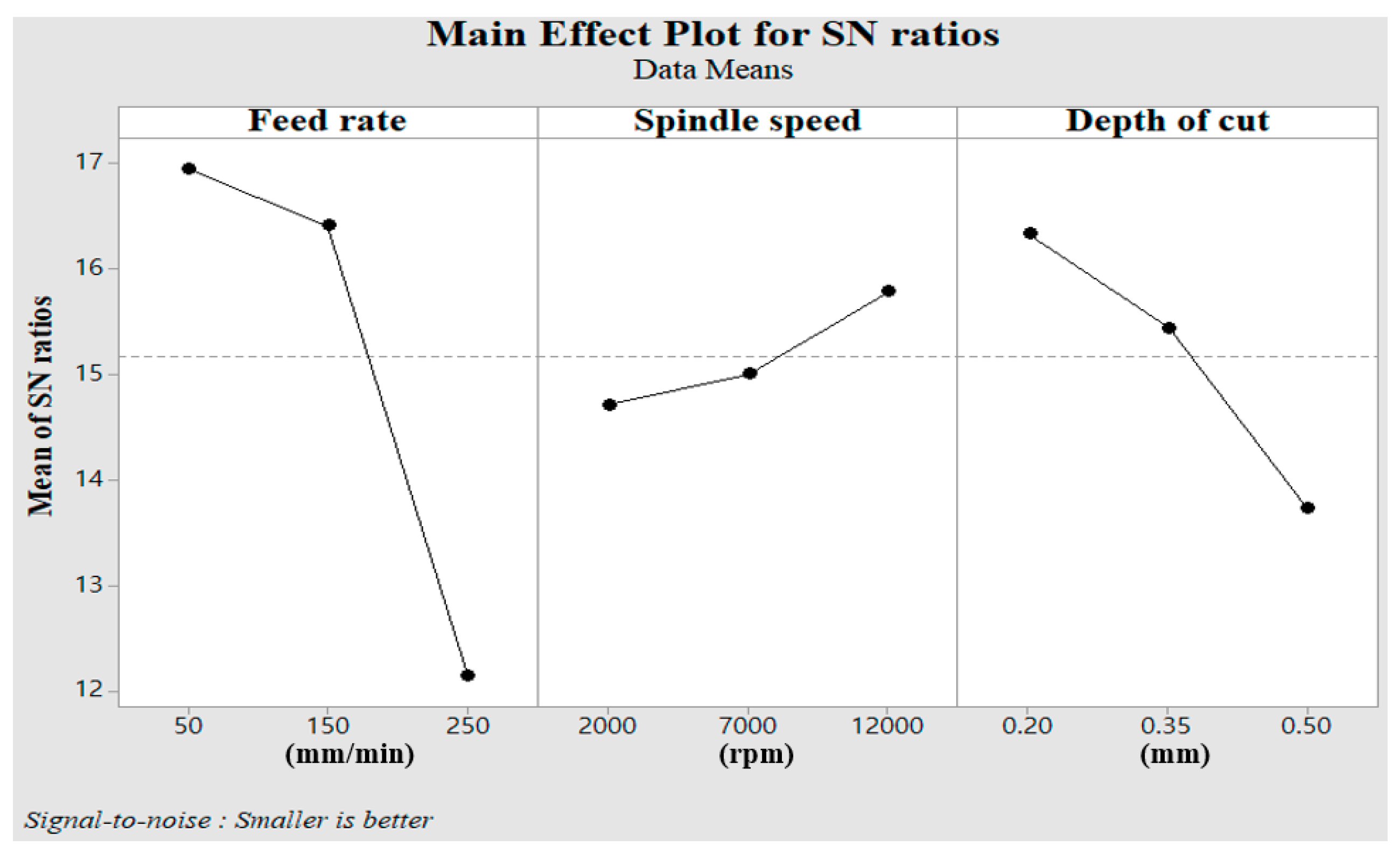

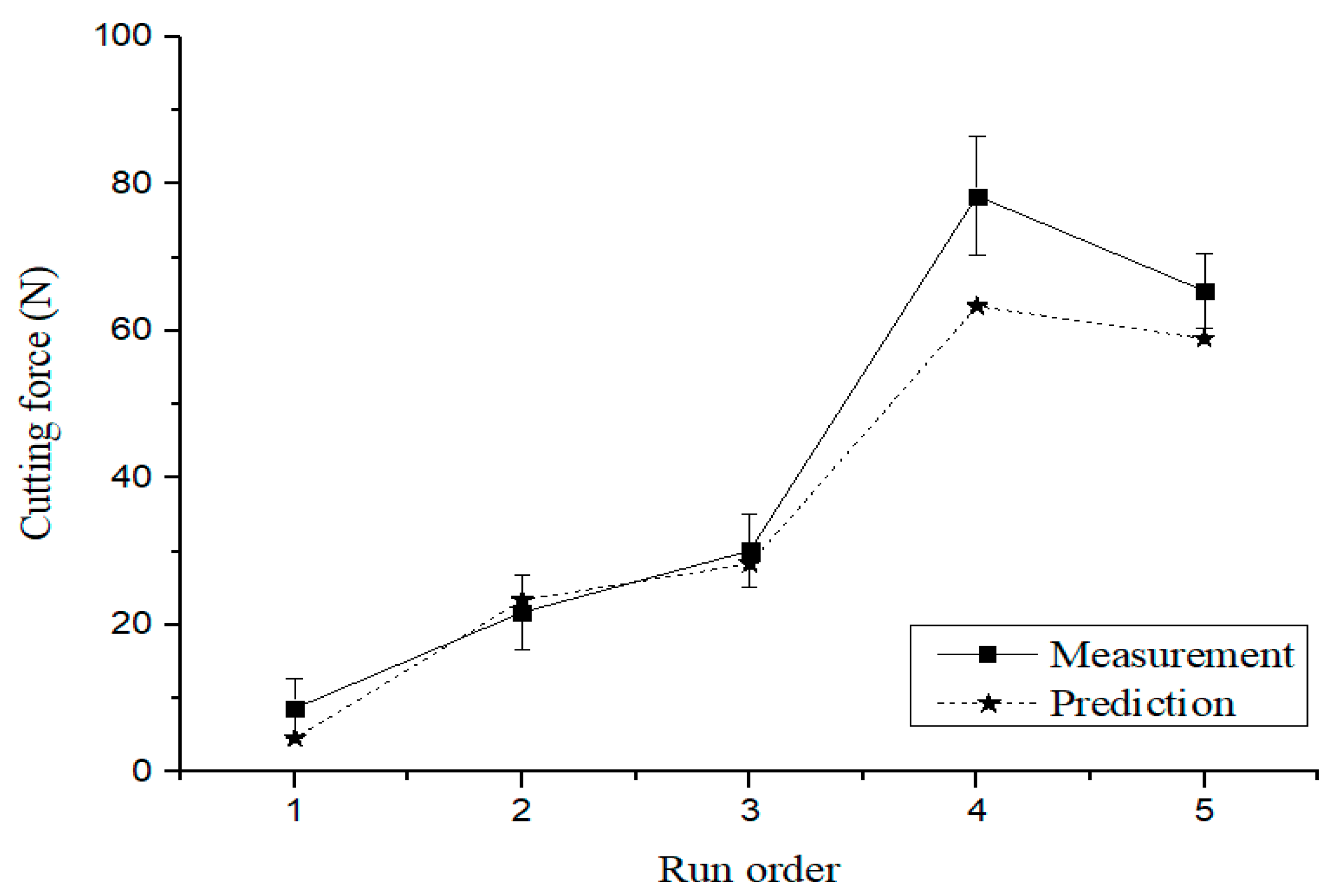

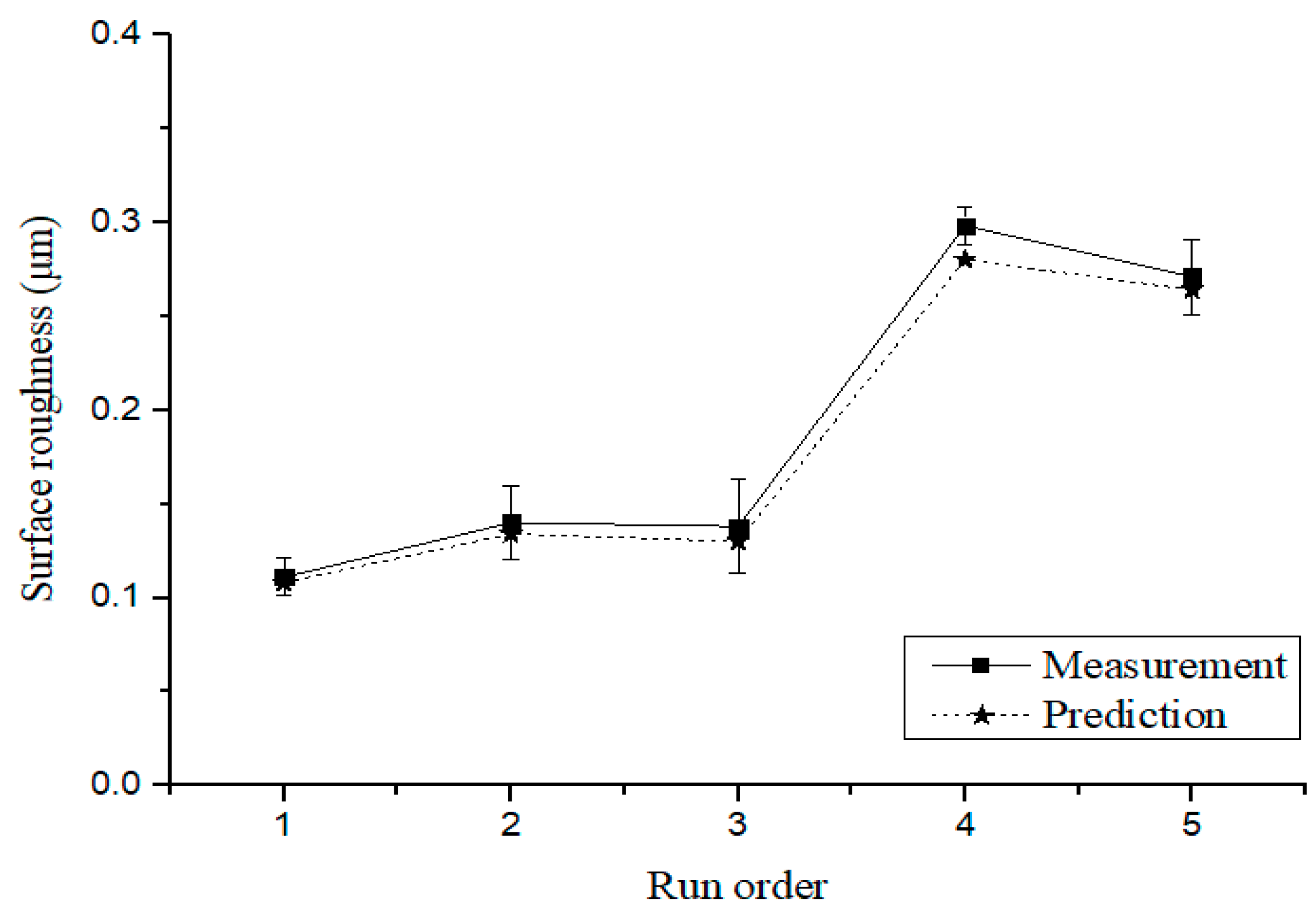

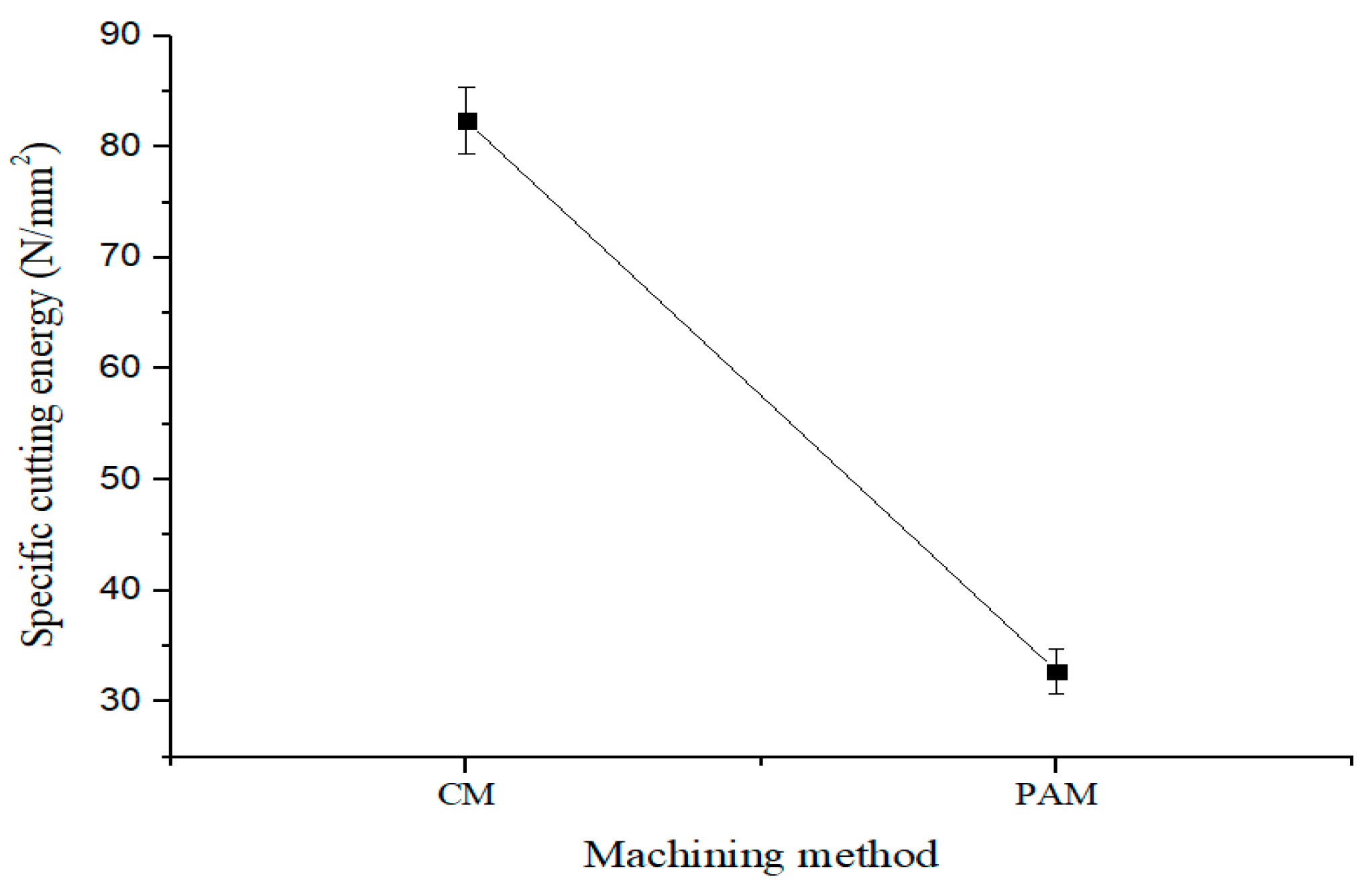

Most of the studies have focused on the aspects of tool life and surface roughness, however, the effect of spindle speed and depth of cut is not well understood. On the other hand, our paper focused on the effect of each factor (feed rate, spindle speed, and depth of cut on cutting force and surface roughness), optimal machining conditions of PAM, and compared CM with PAM through the analysis of energy efficiency. In this paper, the optimal machining conditions for PAM were analyzed by investigating machining characteristics such as cutting force and surface roughness. The selected factors were feed rate, spindle speed, and depth of cut. The experimental optimal machining conditions were determined using the Taguchi method. The influence of factors on the PAM were analyzed using the Taguchi method. Then, the relative characteristics of the factors were determined through analysis of variance. The optimal PAM machining conditions were analyzed using response optimization. In addition, the suitability of the analysis results were evaluated by comparing the results of the prediction equation and the verification experiment. Finally, the energy efficiency of the PAM was analyzed by comparing the specific cutting energy of the CM and the PAM.