Research on Fractal Characteristics and Energy Dissipation of Concrete Suffered Freeze-Thaw Cycle Action and Impact Loading

Abstract

:1. Introduction

2. Freeze-Thaw Cycle Test and Variation Rules of Basic Physical Parameters

2.1. Freeze-Thaw Cycle Test

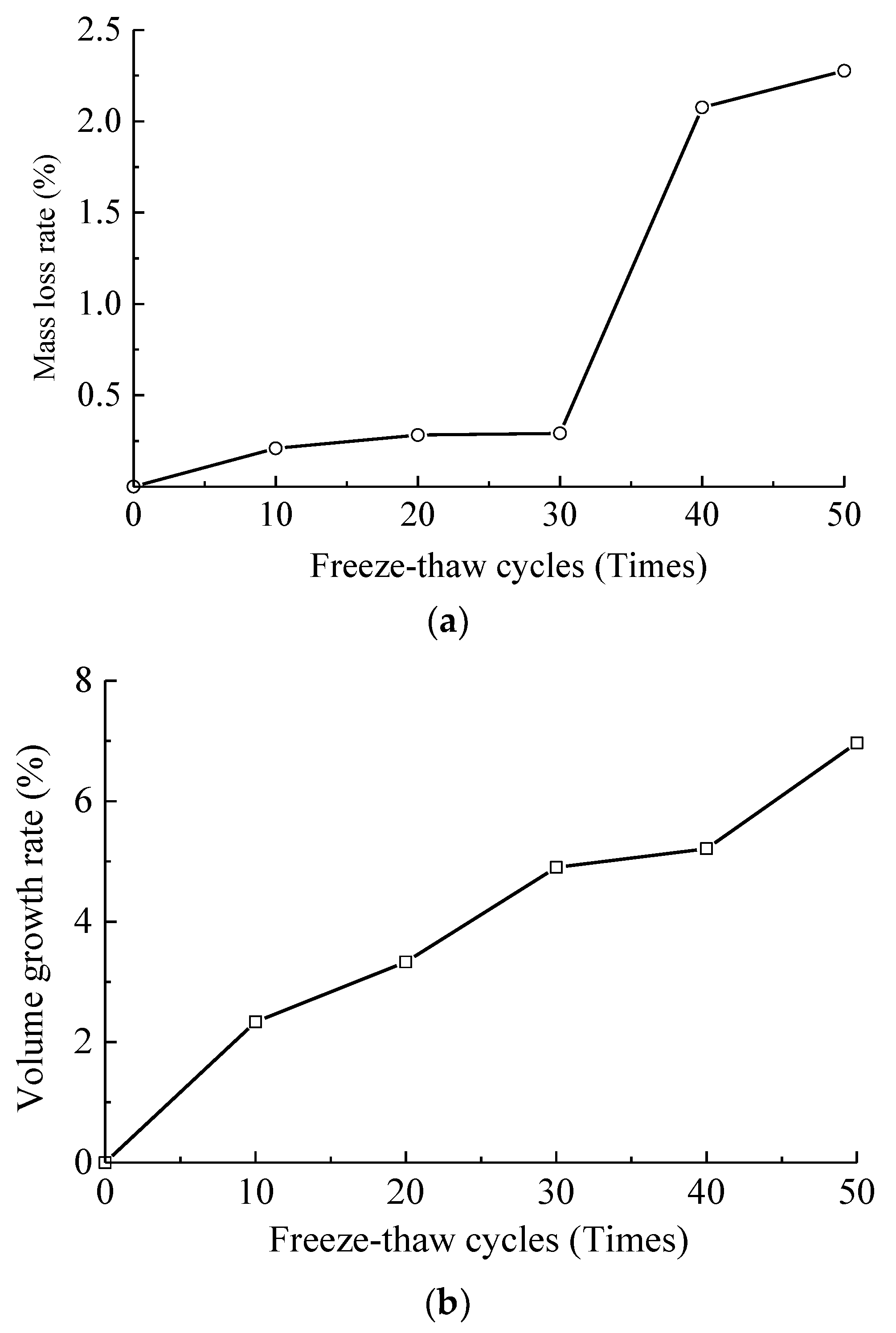

2.2. Freeze-Thaw Deterioration Characteristics of Concrete

2.3. Variation Rules of Basic Physical Quantity

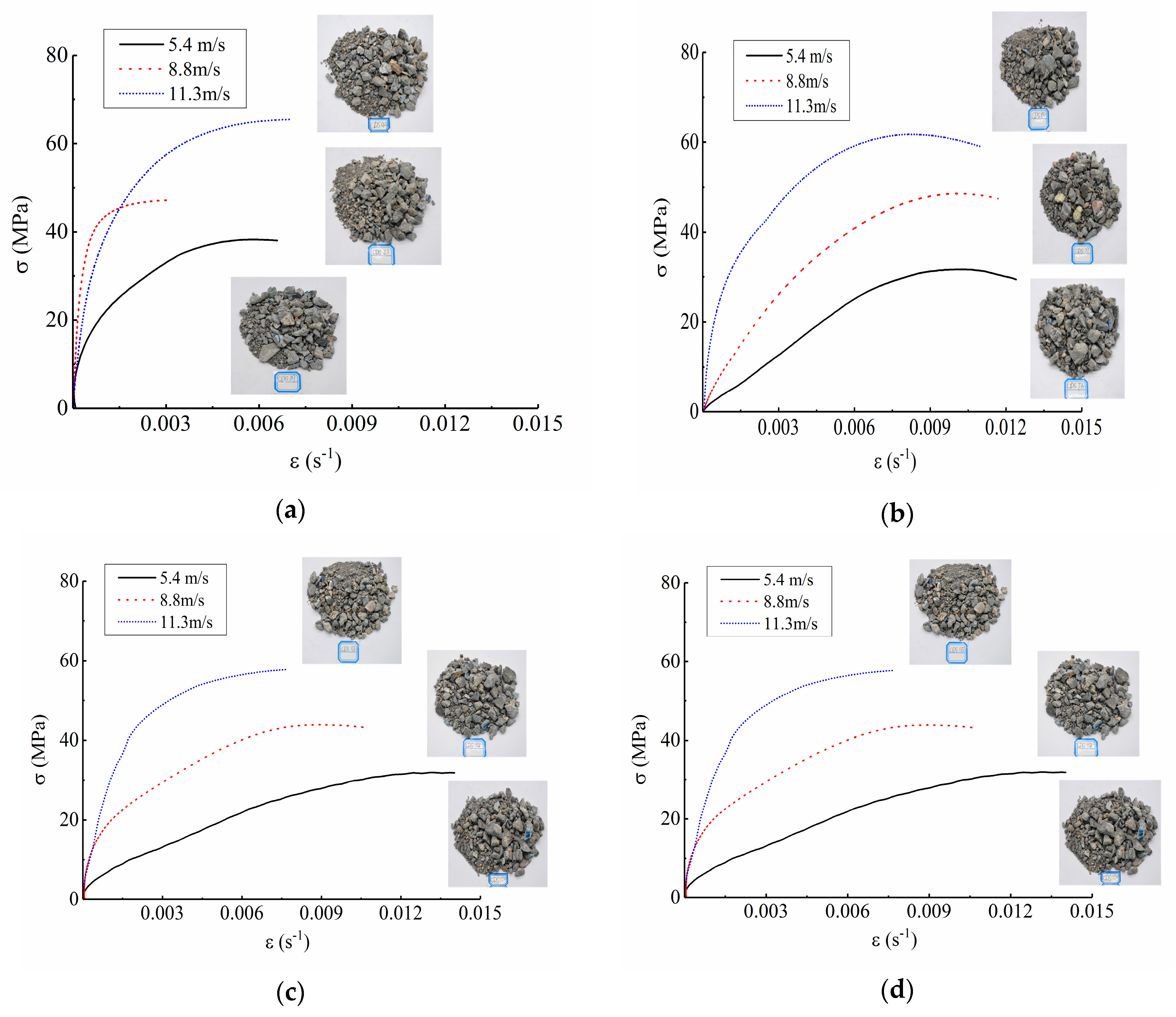

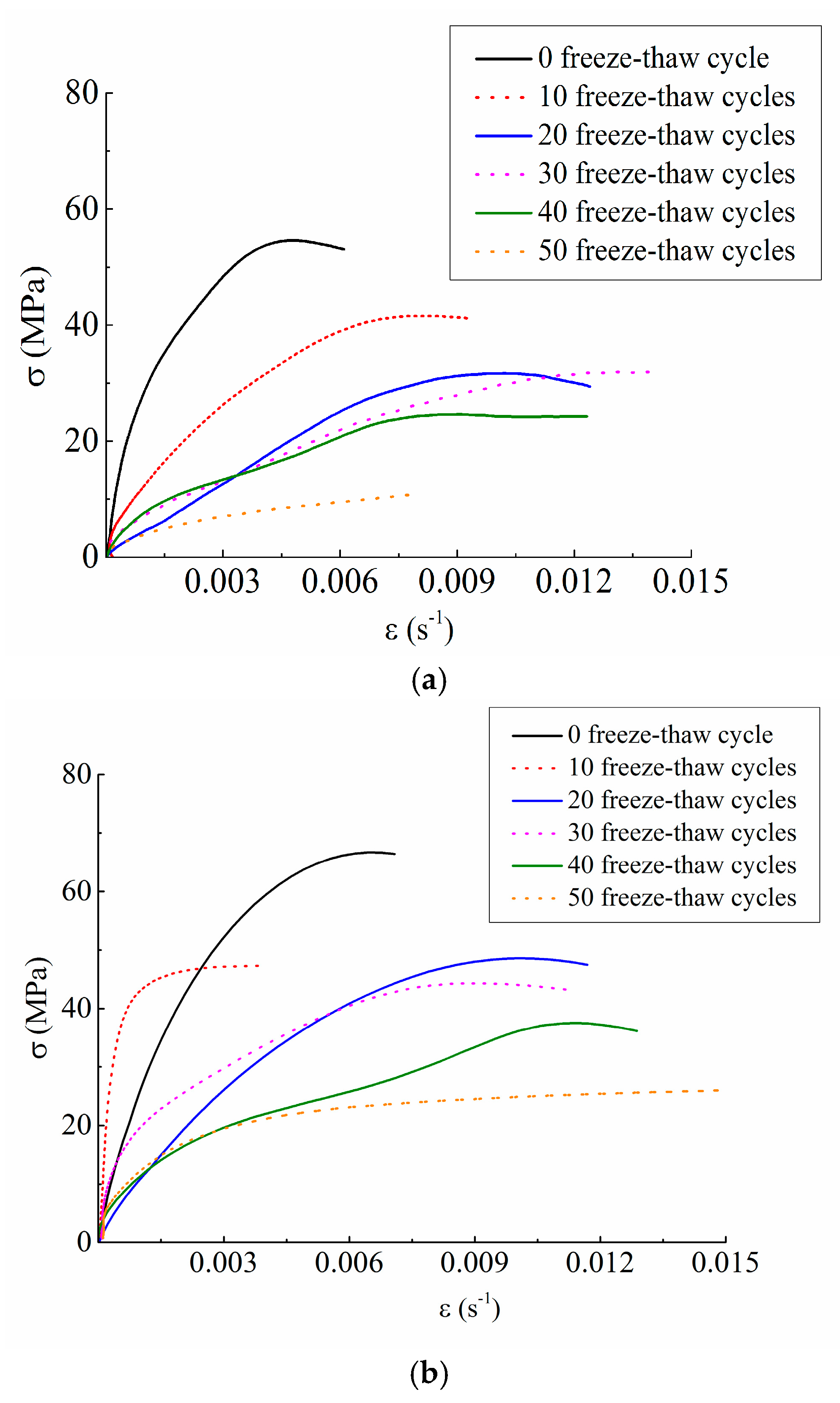

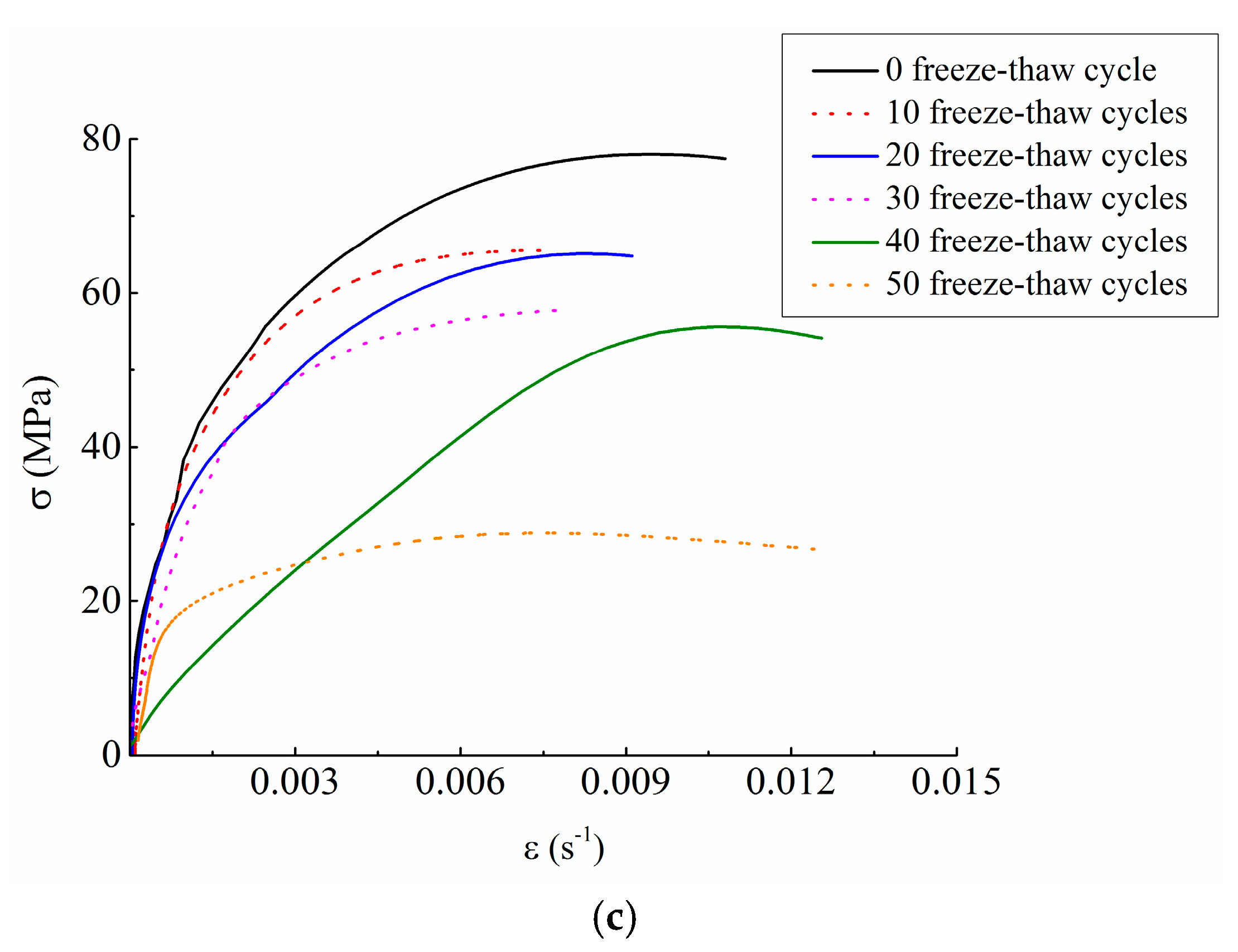

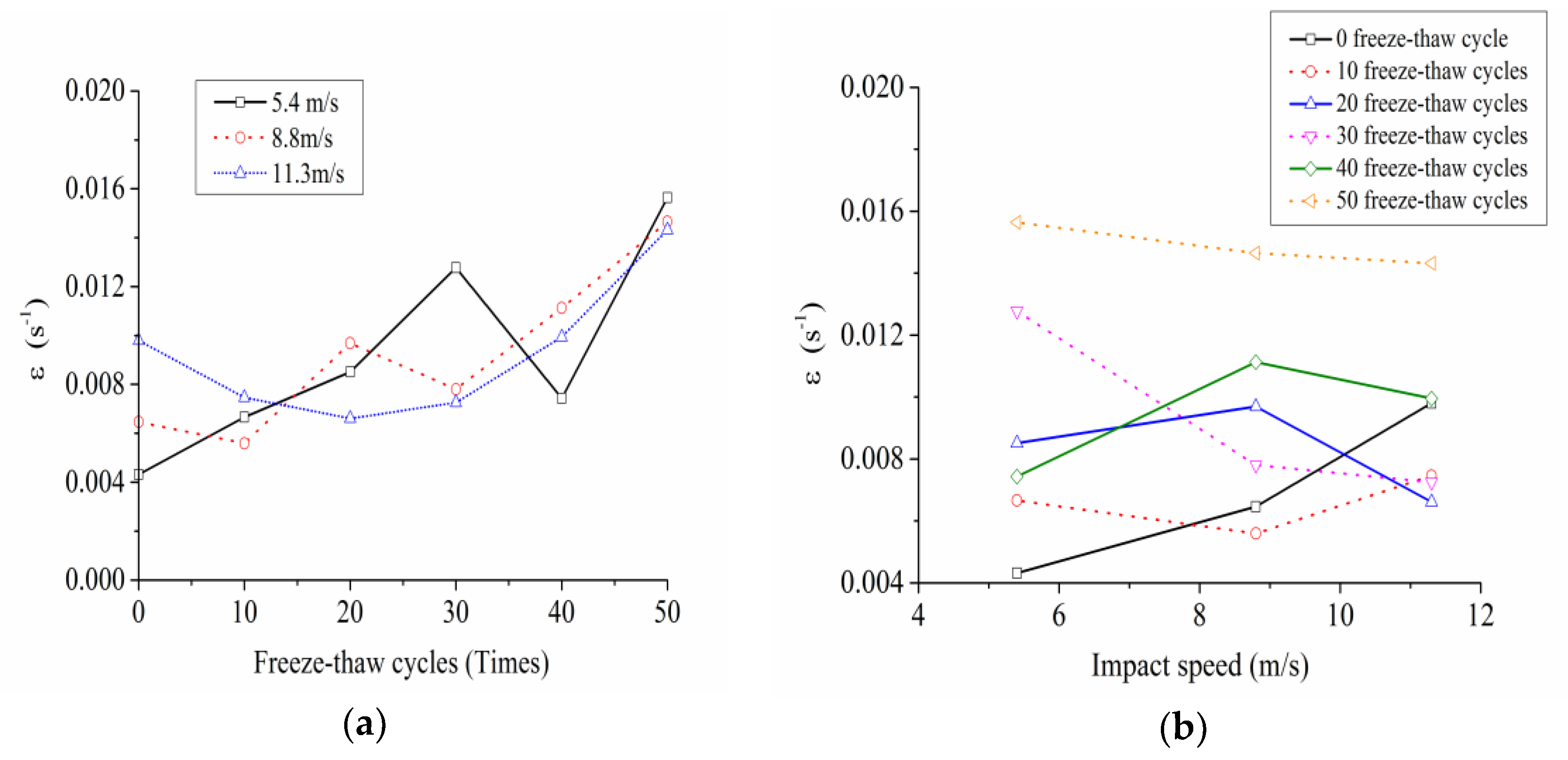

3. Impact Compression Test and Results Discussion

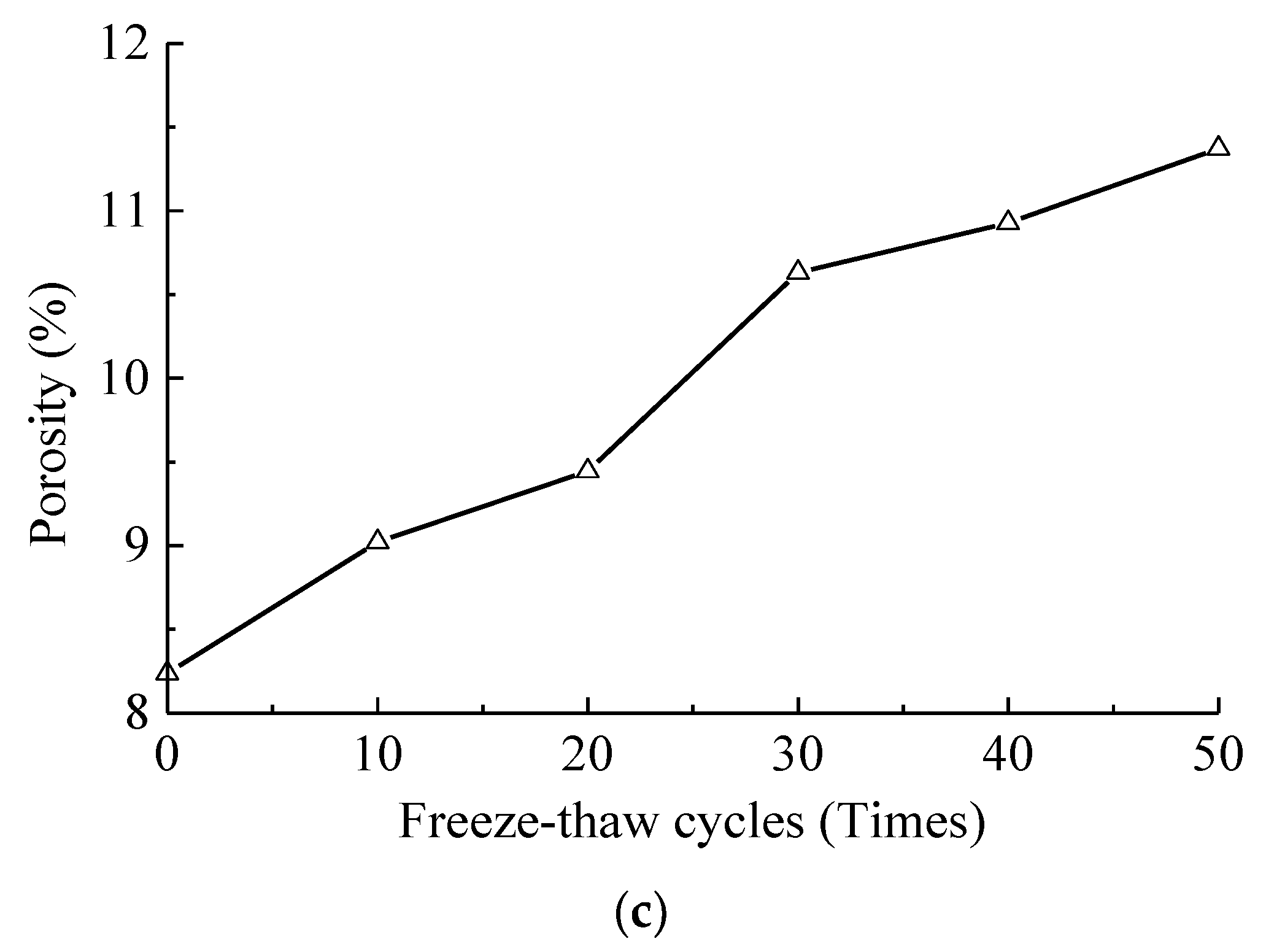

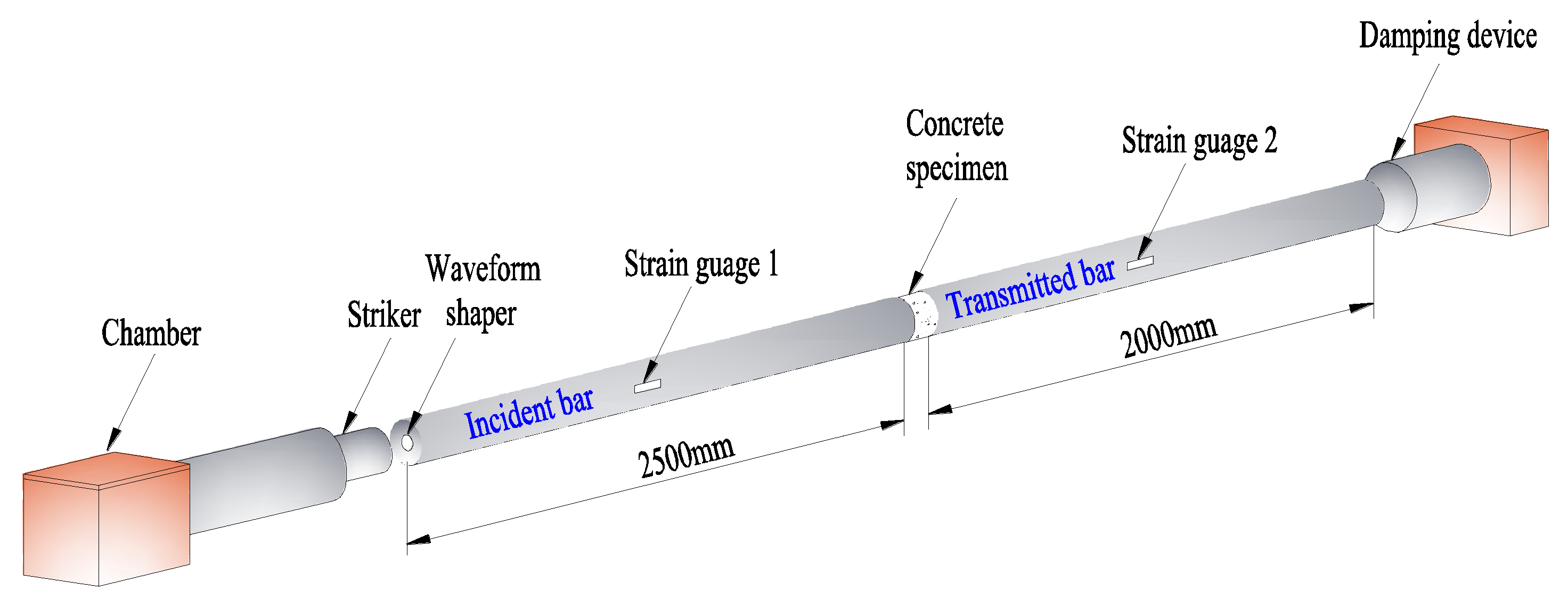

3.1. Impact Compression Test

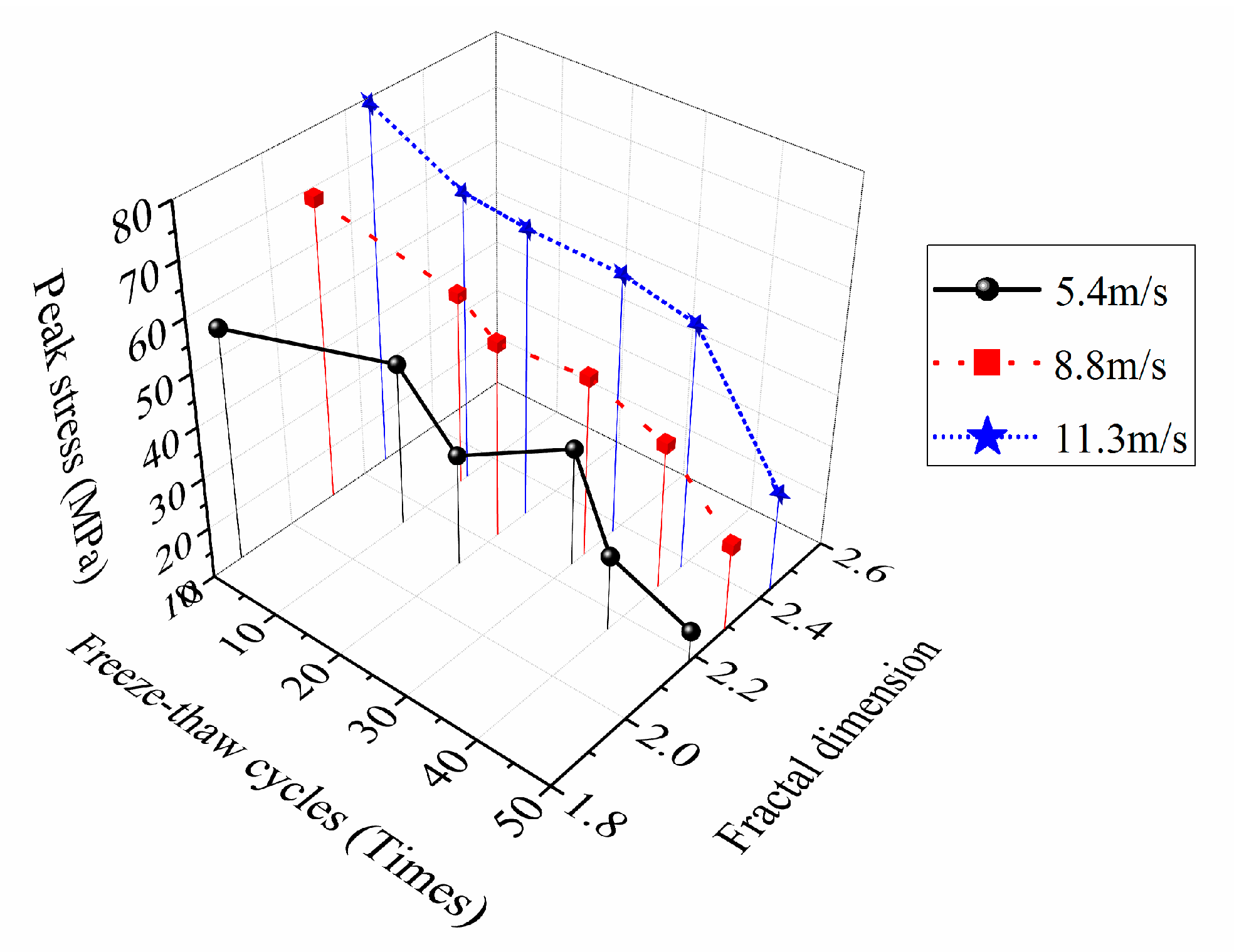

3.2. Test Results Discussion

4. Fractal Characteristics of Crushing Blocks

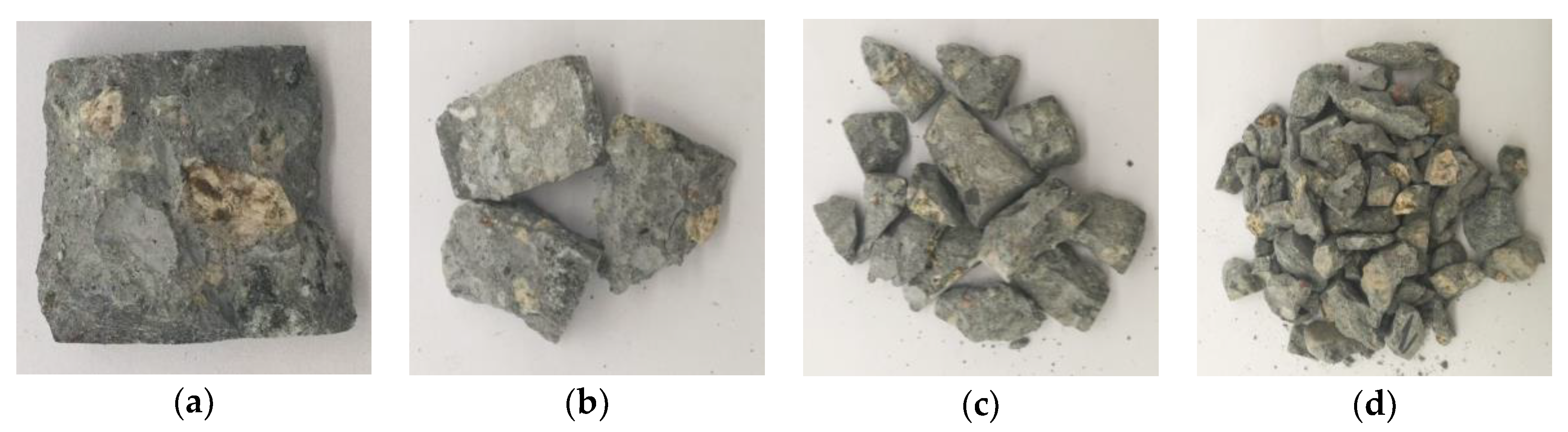

4.1. Screening Statistical Test

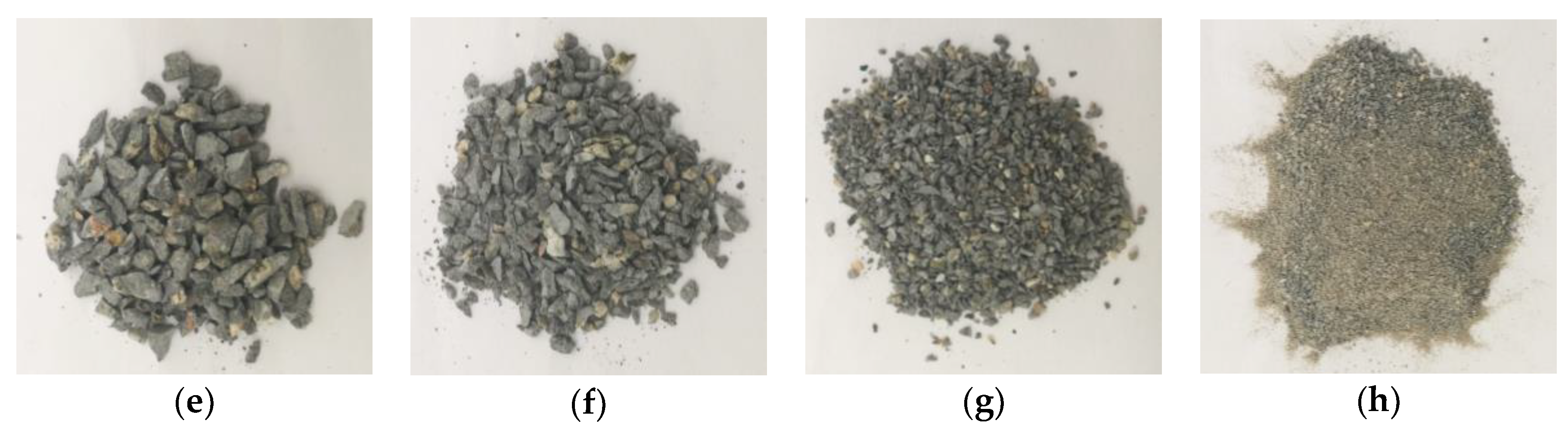

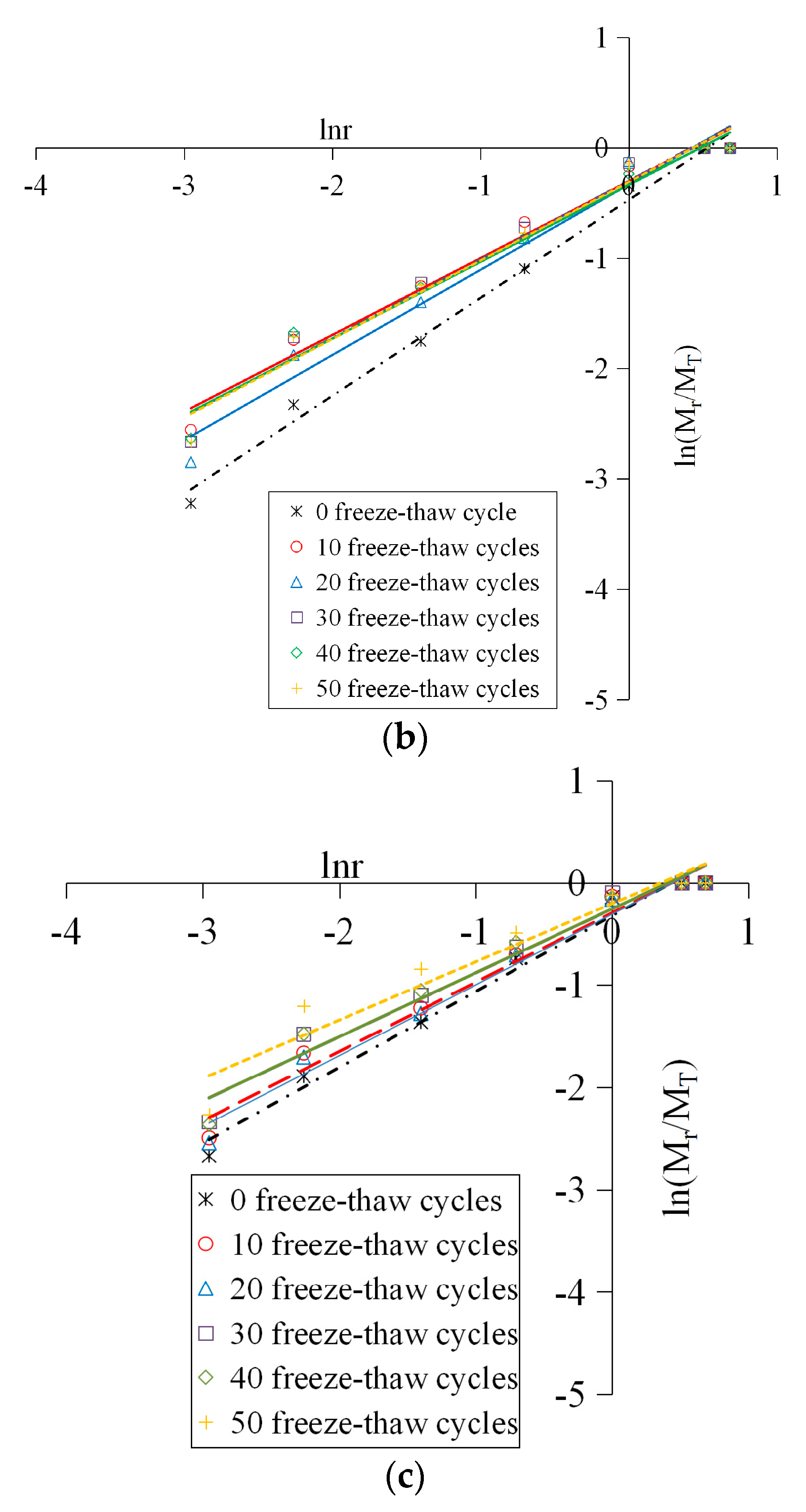

4.2. Scale-Mass Distribution Rules of Crushing Blocks

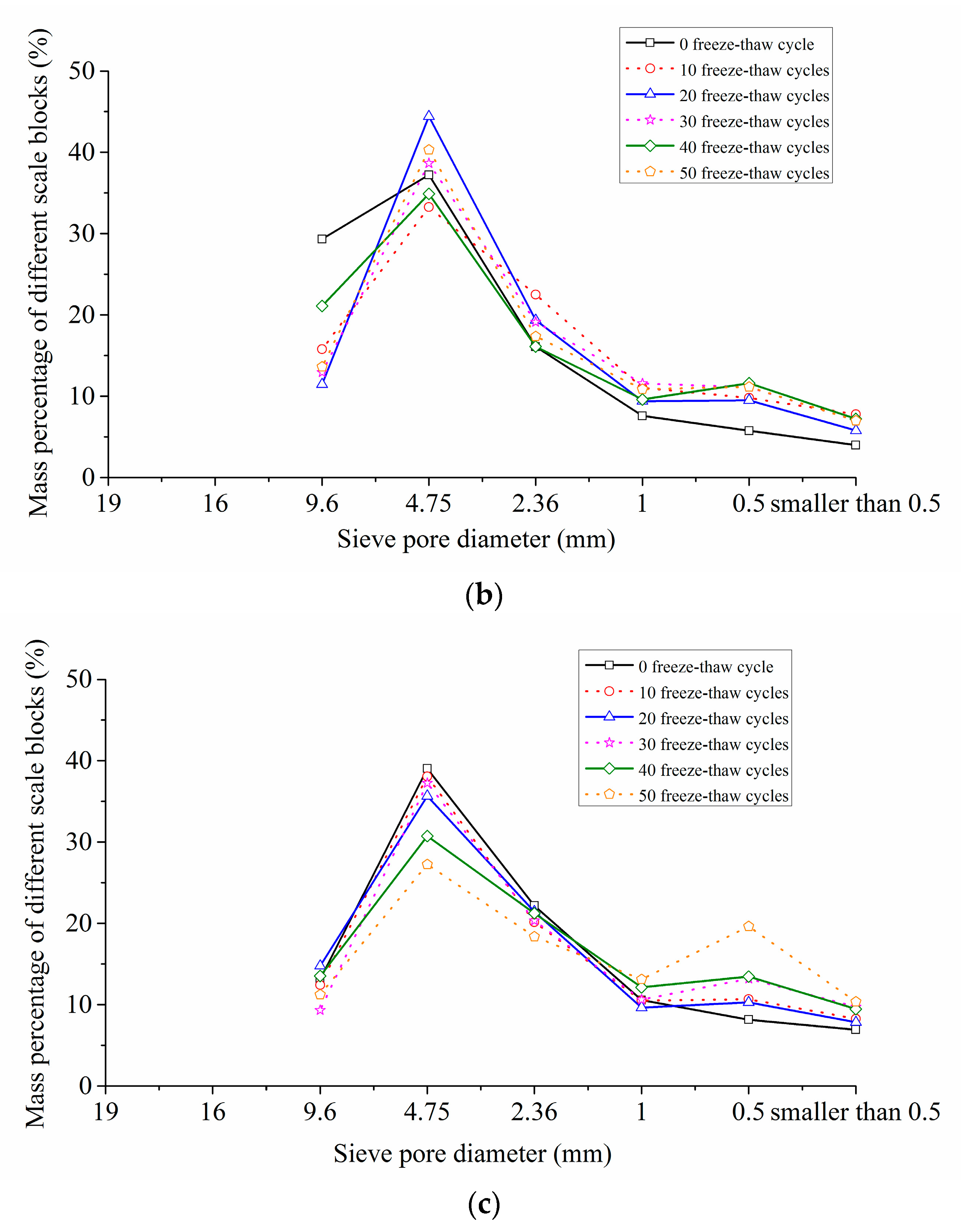

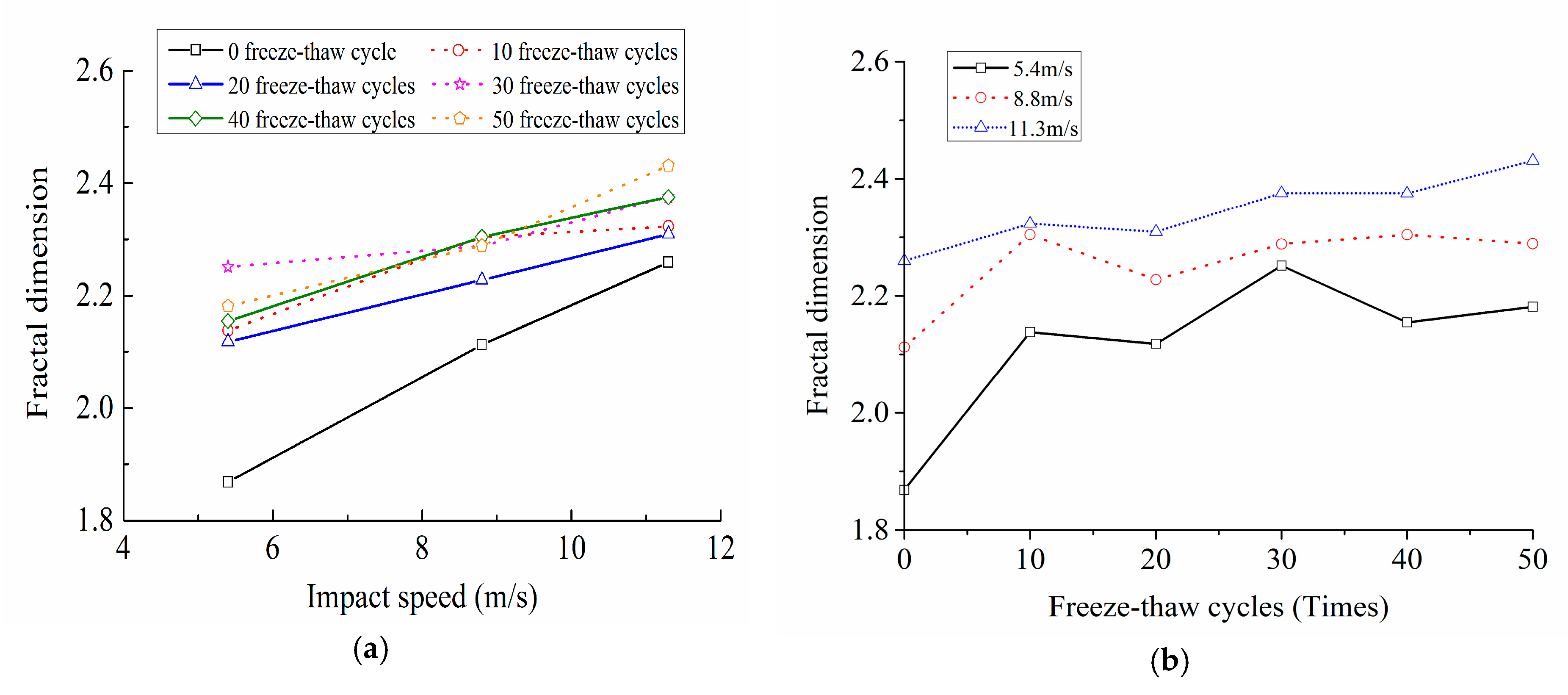

4.3. Fractal Characteristics of Crushing Blocks

5. Analysis of Energy Dissipation

5.1. Energy Dissipation Principles of SHPB Test

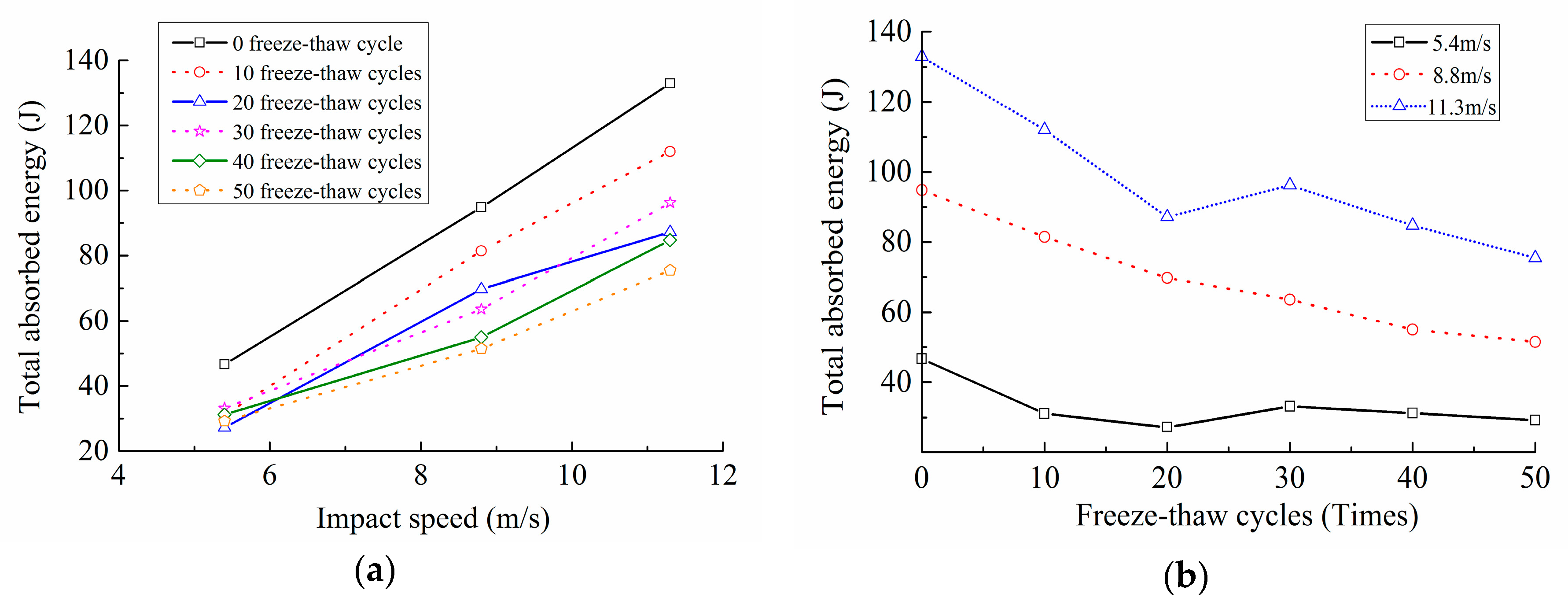

5.2. Analysis on Calculation Results of the Energy Consumption

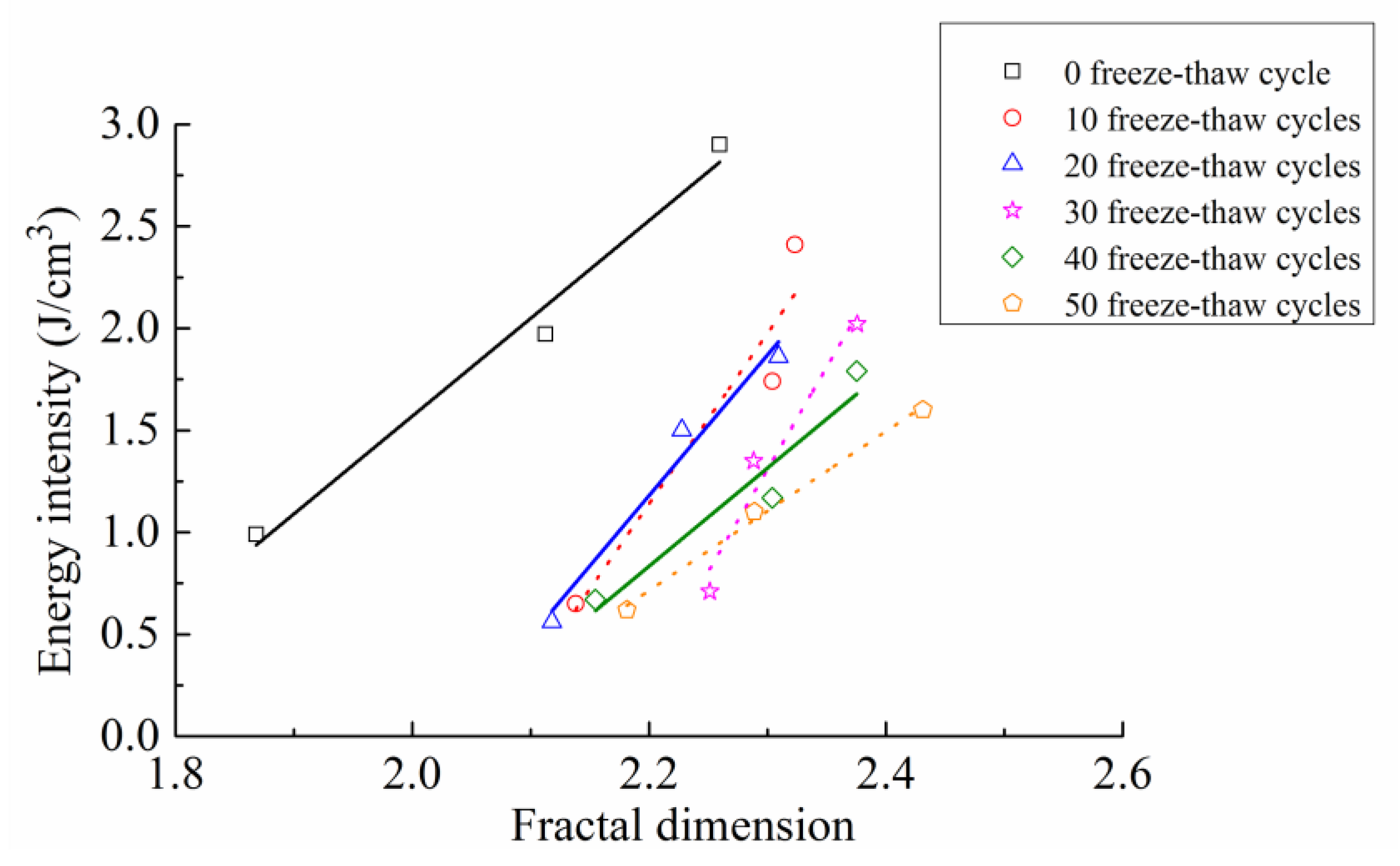

5.3. Relationship between the Energy Consumption Density and the Fractal Dimension

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, G.S.; Lu, D.C.; Du, X.L.; Li, M. Dynamic multiaxial strength criterion for concrete developed based on the S criterion. Chin. J. Theor. Appl. Mech. 2016, 48, 636–653. [Google Scholar]

- Xie, H.P.; Peng, R.D.; Ju, Y.; Zhou, H.W. On energy analysis of rock failure. Chin. J. Rock Mech. Eng. 2005, 24, 2604–2608. [Google Scholar]

- Xie, H.P.; Peng, R.D.; Ju, Y. Energy dissipation of rock deformation and fracture. Chin. J. Rock Mech. Eng. 2004, 23, 3565–3570. [Google Scholar]

- Shi, J.S.; Xu, J.Y.; Ren, W.B.; Su, H.Y. Research on energy dissipation and fractal characteristics of concrete after exposure to elevated temperatures under impact loading. Acta Armamentarii 2014, 35, 703–710. [Google Scholar]

- Mandeibrot, B.B. The Fractal Geometry of Nature; W.H. Freeman and Company: New York, NY, USA, 1982; pp. 1–17. [Google Scholar]

- Griffith, A.A. The phenomenon of rupture and flow in solids. Philos. Trans. R. Soc. 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Weibull, W. A Statistical Theory for the Strength of Materials; Mathematical Society: Stockholm, Sweden, 1939. [Google Scholar]

- Turcotte, D.L. Fractal and fragmentation. J. Geophys. Res. 1986, 91, 1921–1926. [Google Scholar] [CrossRef]

- Cao, M.S.; Ren, Q.W. Fractal behavior of concrete crack and its application to damage assessment. Key Eng. Mater. 2006, 312, 325–332. [Google Scholar] [CrossRef]

- Li, Y.Y.; Zhang, S.C.; Zhang, X. Classification and fractal characteristics of coal rock fragments under uniaxial cyclic loading conditions. Arab. J. Geosci. 2018, 11, 201. [Google Scholar] [CrossRef]

- Zhai, Y.; Li, Y.B.; Li, Y.; Jiang, W.Q.; Liu, X.Y. Research on the impact loading and energy dissipation of concrete after elevated temperature under different heating gradients and cooling methods. Materials 2018, 11, 1651. [Google Scholar] [CrossRef]

- Ren, W.B.; Xu, J.Y.; Liu, Y.F.; Su, H.Y. Fractal characteristics of fragments of basalt fiber reinforced concrete after elevated temperatures under impact loading. J. Vib. Shock 2014. [Google Scholar] [CrossRef]

- Jalilzadeh, A.M.; Kheyroddin, A.; Gholhaki, M. The effect of constant and seasonal changes of ambient conditions on long-term behavior of high-rise concrete structures. Struct. Des. Tall Spec. Build. 2018, 27, e1548. [Google Scholar] [CrossRef]

- Islam, M.M.; Alam, M.T.; Islam, M.S. Effect of fly ash on freeze–thaw durability of concrete in marine environment. Aust. J. Struct. Eng. 2018, 19, 1–16. [Google Scholar] [CrossRef]

- Lv, T.H.; Chen, X.W.; Chen, G. Analysis on the waveform features of the split Hopkinson pressure bar tests of plain concrete specimen. Int. J. Impact Eng. 2017, 103, 107–123. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Weinberg, K. A review on split Hopkinson bar experiments on the dynamic characterisation of concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Y.M.; Yan, H.D.; Mu, R. Damage and damage resistance of high strength concrete under the action of load and freeze-thaw cycles. Cem. Concr. Res. 1999, 29, 1519–1523. [Google Scholar] [CrossRef]

- Al-Salloum, Y.; Almusallam, T.; Ibrahim, S.M.; Abbas, H.; Alsayed, S. Rate dependent behavior and modeling of concrete based on SHPB experiments. Cem. Concr. Compos. 2015, 55, 34–44. [Google Scholar] [CrossRef]

- Huang, L.L.; Shi, W. Study on the dynamic performance of steel fiber reinforced concrete in SHPB experiment. Adv. Mater. Res. 2013, 700, 140–143. [Google Scholar] [CrossRef]

- Xiao, S.Z.; Wang, T.; Chen, J.Y. Influence of freeze-thaw cycling temperature on dynamic compressive properties of ceramsite concrete. Bull. Chin. Ceram. Soc. 2018, 37, 3935–3938. [Google Scholar]

- Zhou, Y.X.; Xia, K.W.; Li, X.B.; Li, H.B.; Ma, G.W.; Zhao, J.; Zhou, Z.L.; Dai, F. Suggested methods for determining the dynamic strength parameters and model fracture toughness of rock materials. Int. J. Rock Mech. Min. Sci. 2012, 49, 105–112. [Google Scholar] [CrossRef]

- Li, W.M.; Xu, J.Y.; Shen, L.J.; Li, Q. Experimental techniques of dynamic stress equilibrium and nearly constant strain rate loading for 100-mm-diameter SHPB test. J. Vib. Shock 2008, 27, 129–133. [Google Scholar]

- Xu, J.Y.; Liu, S. Research on fractal characteristics of marble fragments subjected to impact loading. Rock Soil Mech. 2012, 33, 3225–3229. [Google Scholar]

- He, M.C.; Yang, G.X.; Miao, J.L.; Jia, X.N.; Jiang, T.T. Classification and research methods of rock burst experimental fragments. Chin. J. Rock Mech. Eng. 2009, 28, 1522–1528. [Google Scholar]

- Tao, J.L. SHPB Experimental Technique; Science Pressure: Beijing, China, 2014; pp. 2–50. [Google Scholar]

- Deng, Y.; Chen, M.; Jin, Y.; Zou, D.W. Investigation of the dynamic characteristics and energy consumption for breaking rocks using the impact load. Pet. Drill. Tech. 2016, 44, 27–32. [Google Scholar]

- Zhang, Z.X.; Kou, S.Q.; Jiang, L.G.; Lindqvist, P.A. Effects of loading rate on rock fracture: Fracture characteristics and energy partitioning. Int. J. Rock Mech. Min. Sci. 2000, 37, 745–762. [Google Scholar] [CrossRef]

| Item | Cement | Gravel | Sand | Fly Ash | Water Reducing Agent | Water |

|---|---|---|---|---|---|---|

| Proportion | 1 | 3.80 | 2.03 | 0.40 | 0.02 | 0.56 |

| Item | Density g/cm3 | Initial Setting Time (min) | Final Setting Time (min) | Stability | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|---|---|---|

| Values | 3.05 | 208 | 260 | qualified | 8.6 | 51 |

| Sieve Diameter (mm) | 19.0 | 16.0 | 9.5 | 4.75 | 2.36 |

| Cumulative weight of screen residue (%) | 0 | 2 | 42 | 97 | 99 |

| Sieve Diameter (mm) | 4.75 | 2.36 | 1.25 | 0.63 | 0.315 | 0.16 |

| Cumulative weight of screen residue (%) | 2.8 | 9.7 | 21.4 | 48.1 | 70.5 | 99.4 |

| Impact Loading Speed (m/s) | Freeze-Thaw Cycles (Times) | Greater Than 19 mm | 16~19 mm | 9.6~16 mm | 4.75~9.6 mm | 2.36~4.75 mm | 1~2.36 mm | 0.5~1 mm | Smaller Than 0.5 mm |

|---|---|---|---|---|---|---|---|---|---|

| 5.4 | 0 | 10.39 | 18.40 | 24.94 | 31.88 | 8.56 | 2.83 | 1.96 | 1.52 |

| 10 | — | — | 25.47 | 37.16 | 18.52 | 7.30 | 7.30 | 4.17 | |

| 20 | — | 6.28 | 24.39 | 35.63 | 16.65 | 6.30 | 7.48 | 3.61 | |

| 30 | — | — | 15.40 | 37.65 | 20.67 | 9.11 | 11.65 | 5.89 | |

| 40 | — | — | 19.19 | 41.32 | 18.74 | 8.27 | 8.54 | 4.32 | |

| 50 | — | — | 13.00 | 41.27 | 20.33 | 9.81 | 9.57 | 4.58 | |

| 8.8 | 0 | — | — | 29.32 | 37.22 | 16.09 | 7.58 | 5.76 | 3.99 |

| 10 | — | — | 15.78 | 33.26 | 22.51 | 11.04 | 9.80 | 7.78 | |

| 20 | — | — | 11.46 | 44.41 | 19.36 | 9.40 | 9.50 | 5.79 | |

| 30 | — | — | 12.95 | 38.66 | 19.13 | 11.57 | 11.11 | 7.01 | |

| 40 | — | — | 21.09 | 34.89 | 16.11 | 9.60 | 11.62 | 7.21 | |

| 50 | — | — | 13.63 | 40.30 | 17.37 | 10.87 | 11.15 | 7.00 | |

| 11.3 | 0 | — | — | 13.14 | 39.03 | 22.17 | 10.56 | 8.16 | 6.92 |

| 10 | — | — | 12.43 | 38.08 | 20.16 | 10.50 | 10.67 | 8.27 | |

| 20 | — | — | 14.78 | 35.66 | 21.45 | 9.64 | 10.28 | 7.84 | |

| 30 | — | — | 9.31 | 37.26 | 20.33 | 10.62 | 13.20 | 9.73 | |

| 40 | — | — | 13.53 | 30.74 | 21.24 | 12.14 | 13.46 | 9.47 | |

| 50 | — | — | 11.23 | 27.26 | 18.37 | 13.12 | 19.63 | 10.35 |

| No. | Specimen Number | Freeze-Thaw Cycles (Times) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | CDS3 | 0 | 5.4 | 97.45 | 46.65 | 44.81 | 1.84 | 96.05 | 3.95 | 0.99 |

| 2 | CDS4 | 0 | 8.8 | 339.34 | 94.83 | 88.86 | 5.97 | 93.71 | 6.29 | 1.97 |

| 3 | CDS7 | 0 | 11.3 | 502.28 | 132.90 | 122.25 | 10.65 | 91.98 | 8.02 | 2.90 |

| 4 | CDS37 | 10 | 5.4 | 90.01 | 31.08 | 29.85 | 1.23 | 96.05 | 3.95 | 0.65 |

| 5 | CDS41 | 10 | 8.8 | 292.17 | 81.44 | 76.32 | 5.12 | 93.71 | 6.29 | 1.74 |

| 6 | CDS44 | 10 | 11.3 | 474.74 | 111.99 | 103.01 | 8.98 | 91.98 | 8.02 | 2.41 |

| 7 | CDS73 | 20 | 5.4 | 84.08 | 27.20 | 23.13 | 1.07 | 96.05 | 3.95 | 0.56 |

| 8 | CDS77 | 20 | 8.8 | 276.27 | 69.74 | 65.35 | 4.39 | 93.71 | 6.29 | 1.50 |

| 9 | CDS80 | 20 | 11.3 | 548.70 | 87.21 | 80.22 | 6.99 | 91.98 | 8.02 | 1.86 |

| 10 | CDS110 | 30 | 5.4 | 99.04 | 33.20 | 31.89 | 1.31 | 96.05 | 3.95 | 0.71 |

| 11 | CDS112 | 30 | 8.8 | 287.92 | 63.59 | 59.59 | 4.00 | 93.71 | 6.29 | 1.35 |

| 12 | CDS115 | 30 | 11.3 | 451.84 | 96.23 | 88.52 | 7.71 | 91.98 | 8.02 | 2.02 |

| 13 | CDS145 | 40 | 5.4 | 89.96 | 31.20 | 29.97 | 1.23 | 96.05 | 3.95 | 0.67 |

| 14 | CDS148 | 40 | 8.8 | 281.76 | 54.98 | 51.52 | 3.46 | 93.71 | 6.29 | 1.17 |

| 15 | CDS152 | 40 | 11.3 | 466.64 | 84.72 | 77.93 | 6.79 | 91.98 | 8.02 | 1.79 |

| 16 | CDS181 | 50 | 5.4 | 105.08 | 29.20 | 28.05 | 1.15 | 96.05 | 3.95 | 0.62 |

| 17 | CDS185 | 50 | 8.8 | 357.04 | 51.48 | 48.24 | 3.24 | 93.71 | 6.29 | 1.10 |

| 18 | CDS188 | 50 | 11.3 | 523.69 | 75.46 | 69.41 | 6.05 | 91.98 | 8.02 | 1.60 |

| Freeze-Thaw Cycles (Times) | Fitting Formula Expressions | R | R2 |

|---|---|---|---|

| 0 | 0.9919 | 0.9839 | |

| 10 | 0.9069 | 0.8224 | |

| 20 | 0.9716 | 0.9440 | |

| 30 | 0.9528 | 0.9079 | |

| 40 | 0.9294 | 0.8638 | |

| 50 | 0.9976 | 0.9953 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhai, Y.; Liu, X.; Liang, W. Research on Fractal Characteristics and Energy Dissipation of Concrete Suffered Freeze-Thaw Cycle Action and Impact Loading. Materials 2019, 12, 2585. https://doi.org/10.3390/ma12162585

Li Y, Zhai Y, Liu X, Liang W. Research on Fractal Characteristics and Energy Dissipation of Concrete Suffered Freeze-Thaw Cycle Action and Impact Loading. Materials. 2019; 12(16):2585. https://doi.org/10.3390/ma12162585

Chicago/Turabian StyleLi, Yan, Yue Zhai, Xuyang Liu, and Wenbiao Liang. 2019. "Research on Fractal Characteristics and Energy Dissipation of Concrete Suffered Freeze-Thaw Cycle Action and Impact Loading" Materials 12, no. 16: 2585. https://doi.org/10.3390/ma12162585

APA StyleLi, Y., Zhai, Y., Liu, X., & Liang, W. (2019). Research on Fractal Characteristics and Energy Dissipation of Concrete Suffered Freeze-Thaw Cycle Action and Impact Loading. Materials, 12(16), 2585. https://doi.org/10.3390/ma12162585