Estimation of Hydration Degree of Blended Cements with the Help of k-Values

Abstract

1. Introduction

2. Materials and Methods

- w/c—water to cement ratio (-) prescribed for selected exposure classes;

- Leq—equivalent mass of binder;

- mw—dosage of water (kg);

- mc—dosage of OPC (kg);

- k—k-value (-);

- ma—dosage of used additive (kg);

- 0.95—reflects content of clinker in the used Portland cement.

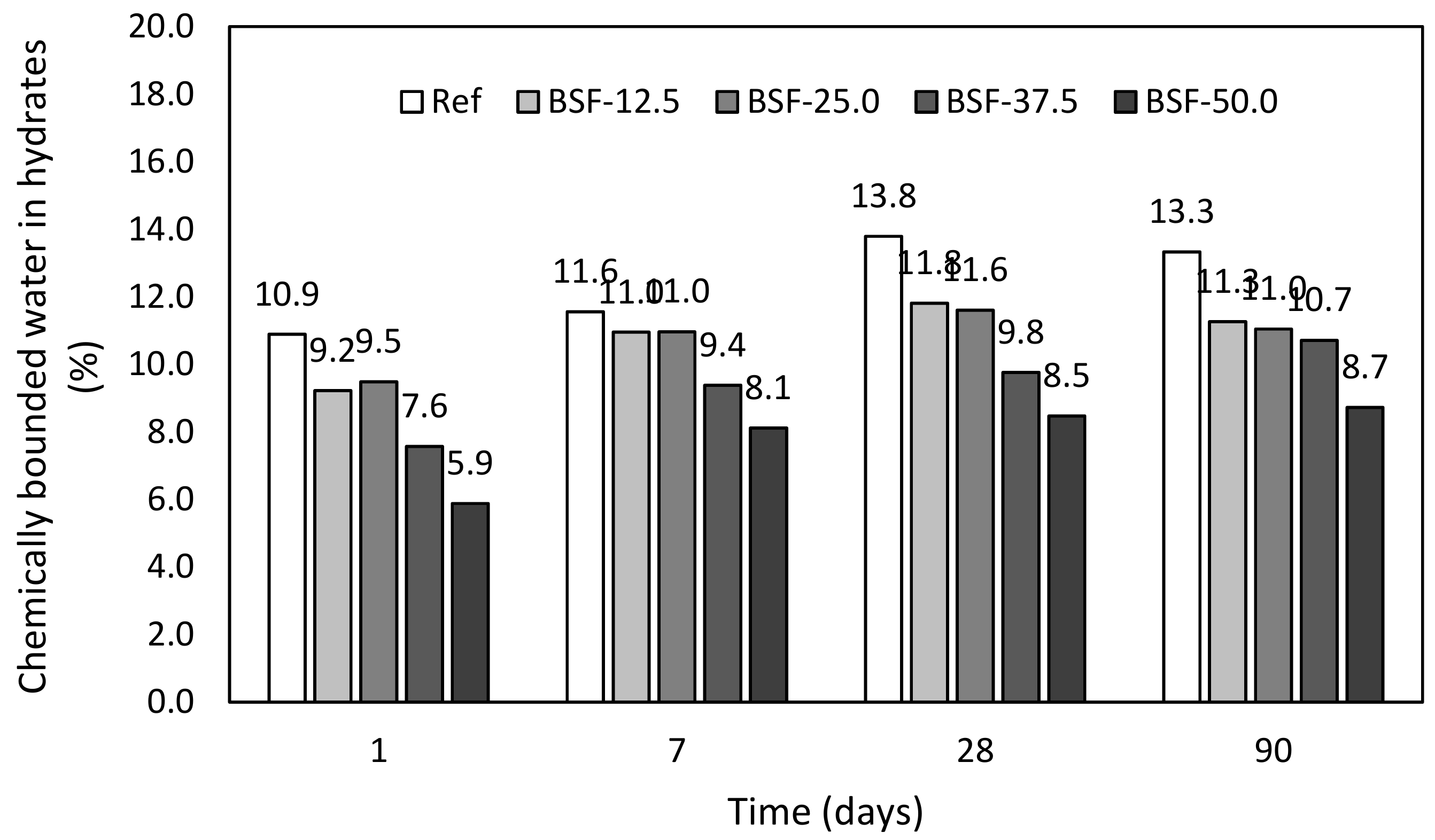

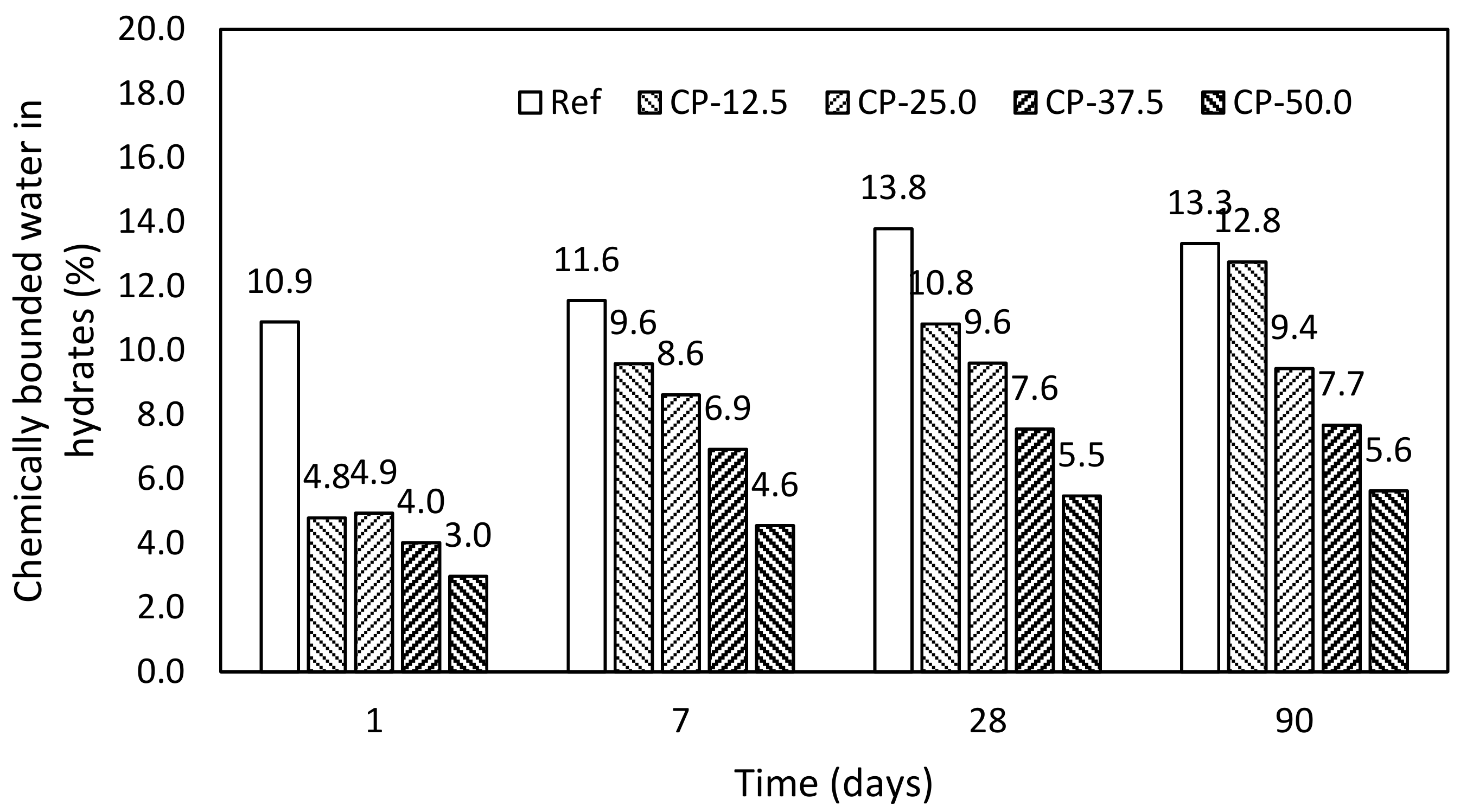

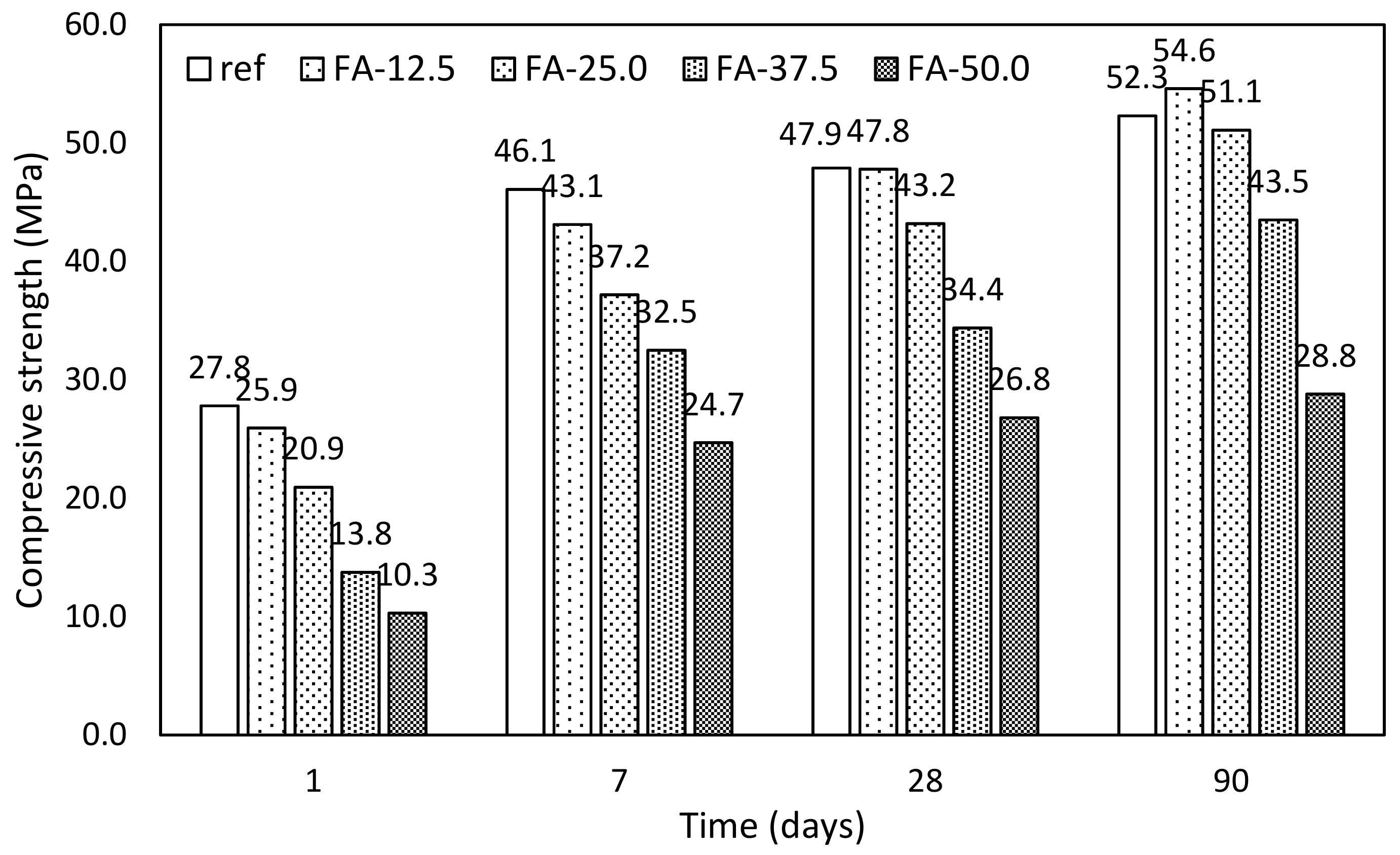

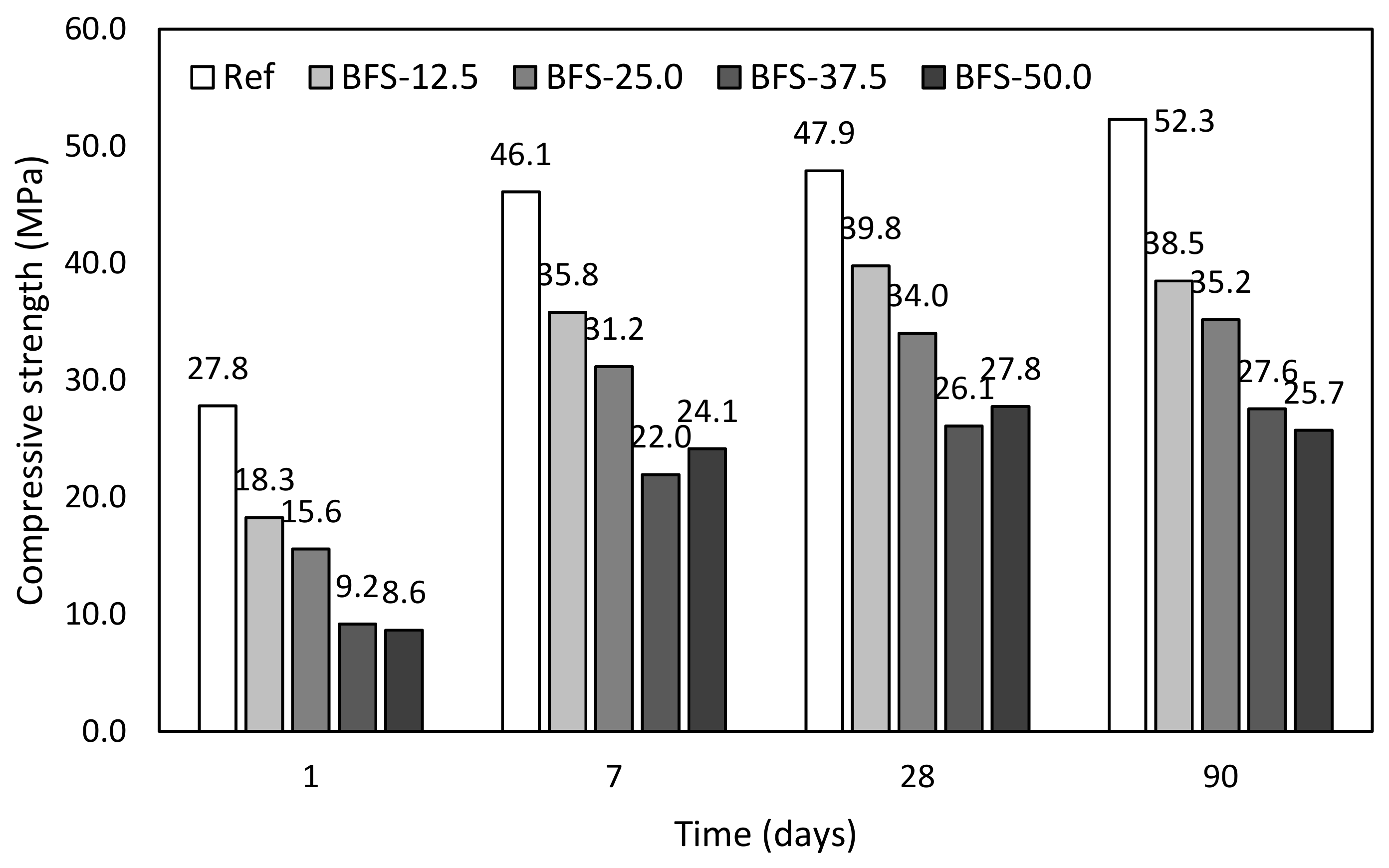

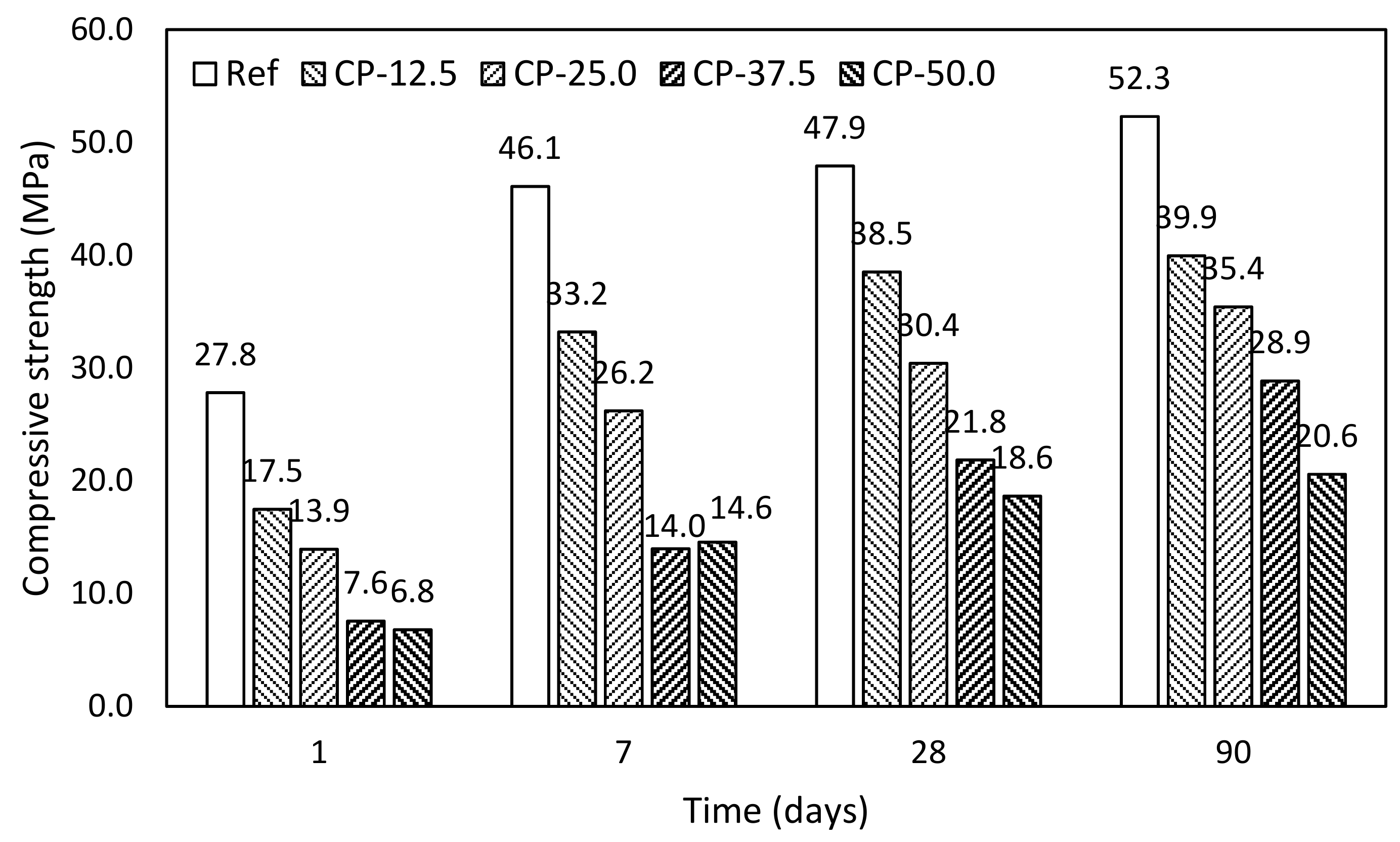

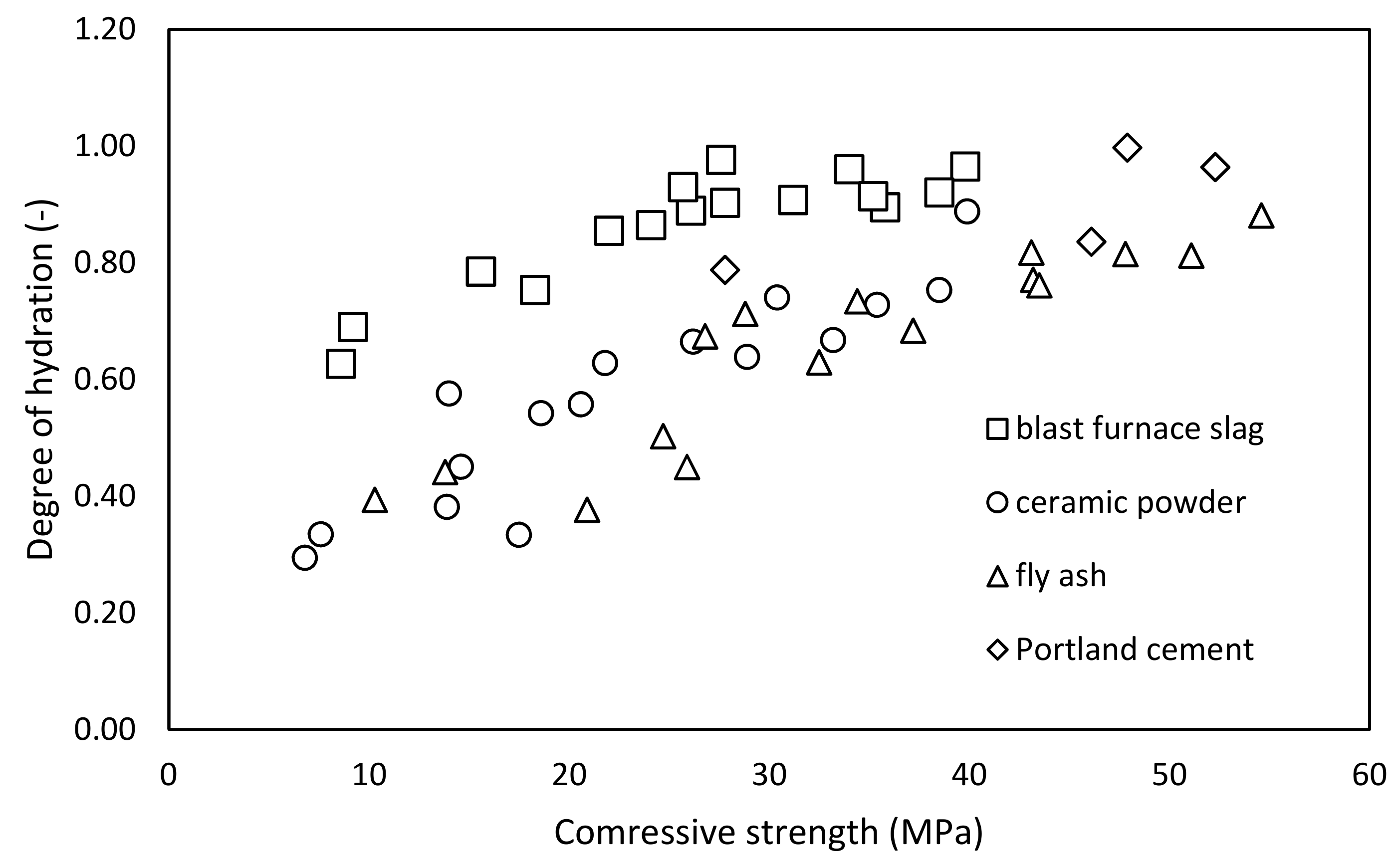

3. Results and Discussion

4. Conclusions

- Decomposition of non-aqueous phases in used mineral additive is necessary for inclusion in the calculation of hydration degree;

- The physical effect dominates in the hydration mechanism of ceramic powder. Despite the relatively high mechanical performance of mortar samples, their contribution to hydrate formation is very low;

- The inclusion of an activity index inspired by the k-value in the hydration degree calculation exhibited good fit with the obtained results of compressive strength. The k-value 0.20 was set for ceramic powder with respect to its substance;

- The estimation of the ultimate value of chemically bounded water is crucial for the determination of the hydration degree during time-limited experiments, especially for systems incorporating blast furnace slag.

Author Contributions

Funding

Conflicts of Interest

References

- Maddalena, R.; Roberts, J.J.; Hamilton, A. Can Portland cement be replaced by low-carbon alternative materials? A study on the thermal properties and carbon emissins of innovative cements. J. Clean. Prod. 2018, 186, 933–943. [Google Scholar] [CrossRef]

- Razi, P.Z.; Razak, H.A.; Khalid, N.H.A. Sustainability, eco-point and engineering performance of different workability OPC fly-ash mortar mixes. Materials 2016, 9, 341. [Google Scholar] [CrossRef] [PubMed]

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- Pronina, N.; Krüger, S.; Bornhöft, H.; Deubener, J.; Ehrenberg, A. Cooling history of a wet-granulated blast furnace slag (GBS). J. Non Cryst. Solids 2018, 499, 344–349. [Google Scholar] [CrossRef]

- British Standard. 197-1 ED. 2: Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements; British Standards Institution: London, UK, 2012. [Google Scholar]

- Lee, K.M.; Lee, H.K.; Lee, S.H.; Kim, G.Y. Autogenous shrinkage of concrete containing granulated blast-furnace slag. Cem. Concr. Res. 2006, 36, 1279–1285. [Google Scholar] [CrossRef]

- Darquennes, A.; Olivier, K.; Benboudjema, F.; Gagné, R. Self-healing at early-age, a way to improve the chloride resistance of blast-furnace slag cementitious materials. Constr. Build. Mater. 2016, 113, 1017–1028. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Gong, X.; Nie, Z.; Cui, S.; Wang, Z.; Chen, W. Environmental impact analysis of blast furnace slag applied to ordinary Portland cement production. J. Clean. Prod. 2016, 120, 221–230. [Google Scholar] [CrossRef]

- Ward, C.; French, D. Determination of glass content and estimation of glass composition in fly ash using quantitative X-ray diffractometry. Fuel 2006, 85, 2268–2277. [Google Scholar] [CrossRef]

- Poon, C.S.; Qiao, X.C.; Lin, Z.S. Pozzolanic properties of reject fly ash in blended cement pastes. Cem. Concr. Res. 2003, 33, 1857–1865. [Google Scholar] [CrossRef]

- Cristelo, N.; Tavares, P.; Lucas, E.; Miranda, T.; Oliveira, D. Quantitative and qualitative assessment of the amorphous phase of a Class F fly ash dissolved during alkali activation reactions–Effect of mechanical activation, solution concentration and temperature. Compos. Part B 2016, 103, 1–14. [Google Scholar] [CrossRef]

- Da Silva, P.R.; de Brito, J. Experimental study of the porosity and microstructure of self-compacting concrete (SCC) with binary and ternary mixes of fly ash and limestone filler. Constr. Build. Mater. 2015, 86, 101–112. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Influence of recycled aggregates and high contents of fly ash on concrete fresh properties. Cem. Concr. Compos. 2017, 84, 198–213. [Google Scholar] [CrossRef]

- Puthipad, N.; Ouchi, M.; Rath, S.; Attachaiyawuth, A. Enhancement in self-compactability and stability in volume of entrained air in self-compacting concrete with high volume fly ash. Constr. Build. Mater. 2016, 128, 349–360. [Google Scholar] [CrossRef]

- Rivera, F.; Martínez, P.; Castro, J.; López, M. Massive volume fly-ash concrete: A more sustainable material with fly ash replacing cement and aggregates. Cem. Concr. Compos. 2015, 63, 104–112. [Google Scholar] [CrossRef]

- Zobal, O.; Padevet, P.; Smilauer, V.; Kopecký, L.; Bittnar, Z. Experimental analysis of mechanical and material properties of concrete Orlik dam after 50 years. In Proceedings of the 30th DANUBlA-ADRIA Symposium on Advances in Experimental Mechanics, Primosten, Croatia, 25–28 September 2013; pp. 189–190. [Google Scholar]

- Singh, N.; Singh, S.P. Carbonation resistance and microstructural analysis of Low and High Volume Fly Ash Self Compacting Concrete containing Recycled Concrete Aggregates. Constr. Build. Mater. 2016, 127, 828–842. [Google Scholar] [CrossRef]

- British Standard. 206: Concrete—Specification, Performance, Production and Conformity; British Standards Institution: London, UK, 2014. [Google Scholar]

- Celik, K.; Meral, C.; Petek Gursel, A.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Keppert, M.; Doušová, B.; Reiterman, P.; Koloušek, D.; Záleská, M.; Černý, R. Application of heavy metals sorbent as reactive component in cementitious composites. J. Clean. Prod. 2018, 199, 565–573. [Google Scholar] [CrossRef]

- Huseien, G.F.; Sam, A.R.M.; Mirza, J.; Tahir, M.M.; Asaad, M.A.; Ismail, M.; Shah, K.W. Waste ceramic powder incorporated alkali activated mortars exposed to elevated Temperatures: Performance evaluation. Constr. Build. Mater. 2018, 187, 307–317. [Google Scholar] [CrossRef]

- Holčapek, O.; Reiterman, P.; Konvalinka, P. Cyclic temperature loading residual flexural strength of refraktory slabs. Acta Polytech. 2017, 57, 97–104. [Google Scholar] [CrossRef][Green Version]

- Pavlík, Z.; Trník, A.; Kulovaná, T.; Scheinherrová, L.; Rahhal, V.; Irassar, E.; Černý, R. DSC and TG Analysis of a Blended Binder Based on Waste Ceramic Powder and Portland Cement. Int. J. Thermophys. 2016, 37, 1–14. [Google Scholar] [CrossRef]

- Navrátilová, E.; Rovnaníková, P. Pozzolanic properties of brick powders and their effect on the properties of modified lime mortars. Constr. Build. Mater. 2016, 120, 530–539. [Google Scholar] [CrossRef]

- Kannan, D.M.; Aboubakr, S.H.; EL-Dieb, A.S.; Reda Taha, M.M. High performance concrete incorporating ceramic waste powder as large partial replacement of Portland cement. Constr. Build. Mater. 2017, 144, 35–41. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 2013, 37, 319–327. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; Kanaan, D.M. Ceramic waste powder an alternative cement replacement—Characterization and evaluation. Sustain. Mater. Technol. 2018, 17, e00063. [Google Scholar] [CrossRef]

- Turanli, L.; Bektas, F.; Monteiro, P.J. Use of ground clay brick as a pozzolanic material to reduce the alkali–Silica reaction. Cem. Concr. Res. 2003, 33, 1539–1542. [Google Scholar] [CrossRef]

- Xie, T.; Visintin, P. A unified approach for mix design of concrete containing supplementary cementitious materials based on reactivity moduli. J. Clean. Prod. 2018, 203, 68–82. [Google Scholar] [CrossRef]

- Fan, C.; Miller, S.A. Reducing greenhouse gas emissions for prescribed concrete compressive strength. Constr. Build. Mater. 2018, 167, 918–928. [Google Scholar] [CrossRef]

- Bediako, M.; Purohir, S.S.; Kevern, J.T. An Investigation into Ghanaian Calcined Clay as a Supplementary Cementitious Material. ACI Mater. J. 2017, 114. [Google Scholar] [CrossRef]

- Younsi, A.; Turcry, P.; Rozière, E.; Aït-Mokhtar, A.; Loukili, A. Performance-based design and carbonation of concrete with high fly ash content. Cem. Concr. Compos. 2011, 33, 993–1000. [Google Scholar] [CrossRef]

- Kayali, O.; Sharfuddin Ahmed, M. Assessment of high volume replacement fly ash concrete—Concept of performance index. Constr. Build. Mater. 2013, 39, 71–76. [Google Scholar] [CrossRef]

- Gruyaert, E.; Maes, M.; De Belie, N. Performance of BFS concrete: K-Value concept versus equivalent performance concept. Constr. Build. Mater. 2013, 47, 441–455. [Google Scholar] [CrossRef]

- Ribeiro, A.B.; Santos, T.; Gonçalves, A. Performance of concrete exposed to natural carbonation: Use of the k -value concept. Constr. Build. Mater. 2018, 175, 360–370. [Google Scholar] [CrossRef]

- Deboucha, W.; Leklou, N.; Khelidj, A.; Oudjit, M.N. Hydration development of mineral additives blended cement using thermogravimetric analysis (TGA): Methodology of calculating the degree of hydration. Constr. Build. Mater. 2017, 146, 687–701. [Google Scholar] [CrossRef]

- Bhatty, J.I.; Reid, K.J. Use of thermal analysis in the hydration studies of a type 1 portland cement produced from mineral tailings. Thermochim. Acta 1985, 91, 95–105. [Google Scholar] [CrossRef]

- Reiterman, P.; Holčapek, O.; Zobal, O.; Keppert, M. Freeze-Thaw Resistance of Cement Screed with Various Supplementary Cementitious Materials. Rev. Adv. Mater. Sci. 2019, 58, 66–74. [Google Scholar] [CrossRef]

- Reiterman, P. Estimation of pozzolanic activity of artificial mineral additive using thermal analysis. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 385, p. 12046. [Google Scholar] [CrossRef]

- De Weerdt, K.; Haha, M.B.; Le Saout, G.; Kjellsen, K.O.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Bílek, V.; Mec, P.; Zidek, L.; Moravec, T. Concretes with ternary binders—Thinking about frost resistence. Cem. Wapno Beton. 2015, 2015, 72. [Google Scholar]

- Monteagudo, S.M.; Moragues, A.; Gálvez, J.C.; Casati, M.J.; Reyes, E. The degree of hydration assessment of blended cement pastes by differential thermal and thermogravimetric analysis. Morphological evolution of the solid phases. Thermochim. Acta 2014, 592, 37–51. [Google Scholar] [CrossRef]

- British Standard. 196-1 Methods of Testing Cement—Part 1: Determination of Strength; British Standards Institution: London, UK, 2016. [Google Scholar]

- Poon, C.S.; Lam, L.; Wong, Y.L. A study on high strength concrete prepared with large volumes of low calcium fly ash. Cem. Concr. Res. 2000, 30, 447–455. [Google Scholar] [CrossRef]

- Siddique, R. Performance characteristics of high-volume Class F fly ash concrete. Cem. Concr. Res. 2004, 34, 487–493. [Google Scholar] [CrossRef]

- Han, S.-H.; Kim, J.-K.; Park, Y.-D. Prediction of compressive strength of fly ash concrete by new apparent activation energy function. Cem. Concr. Res. 2003, 33, 965–971. [Google Scholar] [CrossRef]

- De la Varga, I.; Castro, J.; Bentz, D.; Weiss, J. Application of internal curing for mixtures containing high volumes of fly ash. Cem. Concr. Compos. 2012, 34, 1001–1008. [Google Scholar] [CrossRef]

- Atiş, C.D. High-Volume Fly Ash Concrete with High Strength and Low Drying Shrinkage. J. Mater. Civ. Eng. 2003, 15, 153–156. [Google Scholar] [CrossRef]

- Oner, A.; Akyuz, S. An experimental study on optimum usage of GGBS for the compressive strength of concrete. Cem. Concr. Compos. 2007, 29, 505–514. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. Performance of sustainable concretes containing very high volume Class-F fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2017, 162, 1407–1417. [Google Scholar] [CrossRef]

- Kuder, K.; Lehman, D.; Berman, J.; Hannesson, G.; Shogren, R. Mechanical properties of self consolidating concrete blended with high volumes of fly ash and slag. Constr. Build. Mater. 2012, 34, 285–295. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. The properties of the self-compacting concrete with fly ash and ground granulated blast furnace slag mineral admixtures. J. Clean. Prod. 2015, 95, 66–74. [Google Scholar] [CrossRef]

- Reiterman, P.; Keppert, M. Effect of Ceramic Powder Particle Size Distribution on its Reactivity in Lime-Based Binders. Mater. Sci. Forum 2017, 908, 40–44. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Reusing ceramic wastes in concrete. Constr. Build. Mater. 2010, 24, 832–838. [Google Scholar] [CrossRef]

- Higashiyama, H.; Yagishita, F.; Sano, M.; Takahashi, O. Compressive strength and resistance to chloride penetration of mortars using ceramic waste as fine aggregate. Constr. Build. Mater. 2012, 26, 96–101. [Google Scholar] [CrossRef]

- Naceri, A.; Hamina, M.C. Use of waste brick as a partial replacement of cement in mortar. Waste Manag. 2009, 29, 2378–2384. [Google Scholar] [CrossRef] [PubMed]

- Heikal, M.; Zohdy, K.M.; Abdelkreem, M. Mechanical, microstructure and rheological characteristics of high performance self-compacting cement pastes and concrete containing ground clay bricks. Constr. Build. Mater. 2013, 38, 101–109. [Google Scholar] [CrossRef]

- Meddah, M.S.; Ismail, M.A.; El-Gamal, S.; Fitriani, H. Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr. Build. Mater. 2018, 166, 400–412. [Google Scholar] [CrossRef]

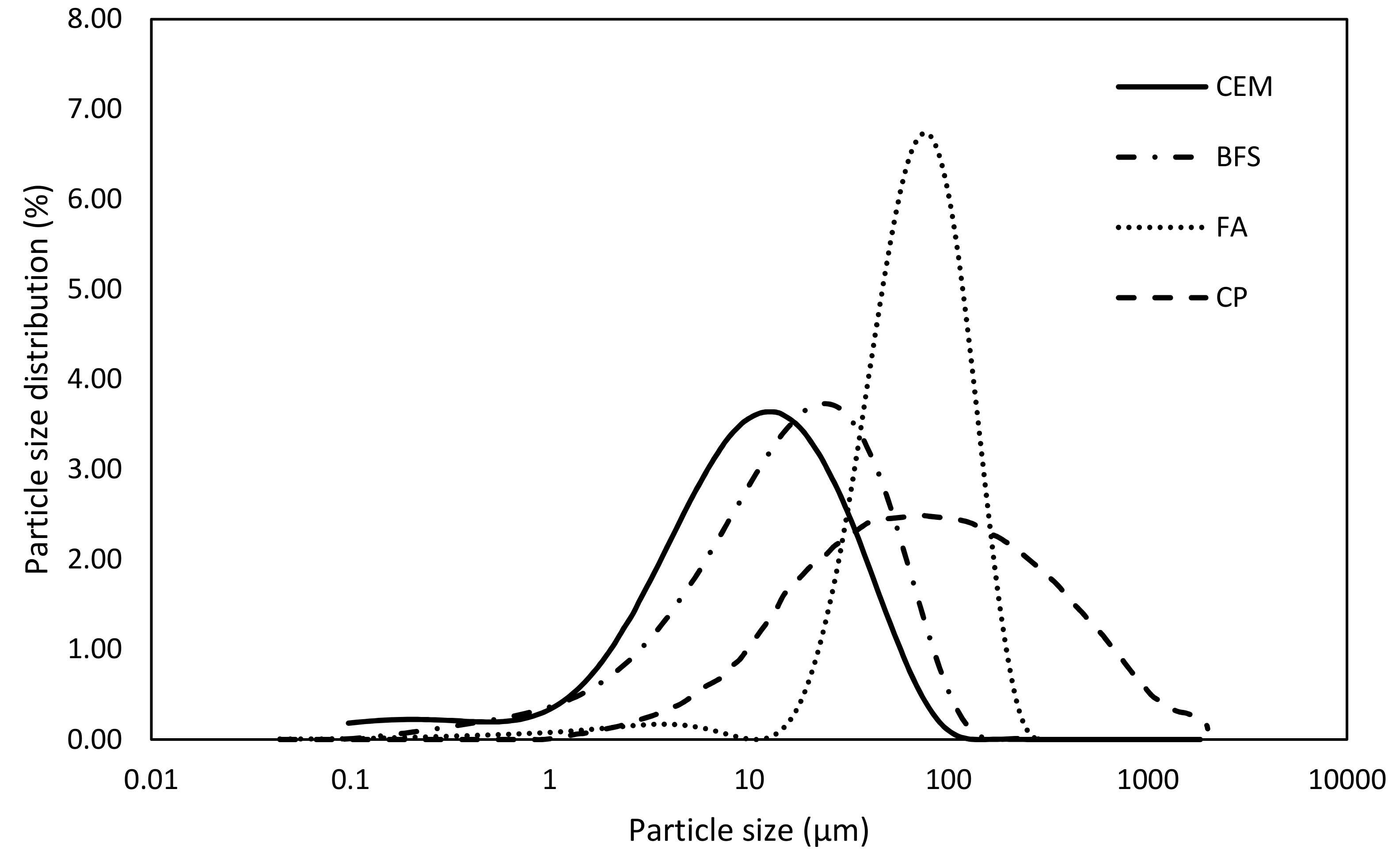

| Component | Ceramic Powder | Blast Furnace Slag | Fly Ash | Portland Cement |

|---|---|---|---|---|

| SiO2 | 50.7 | 36.0 | 52.4 | 18.5 |

| Al2O3 | 20.0 | 9.0 | 35.9 | 6.5 |

| Fe2O3 | 6.2 | 0.3 | 4.9 | 2.4 |

| CaO | 11.6 | 43.5 | 1.2 | 64.9 |

| MgO | 4.8 | 8.3 | 0.8 | 1.0 |

| K2O | 3.2 | 0.5 | 1.4 | 1.2 |

| Na2O | 1.3 | 0.5 | - | 0.1 |

| TiO2 | 0.8 | 0.3 | 2.4 | - |

| SO3 | 1.0 | 0.5 | 0.2 | 4.9 |

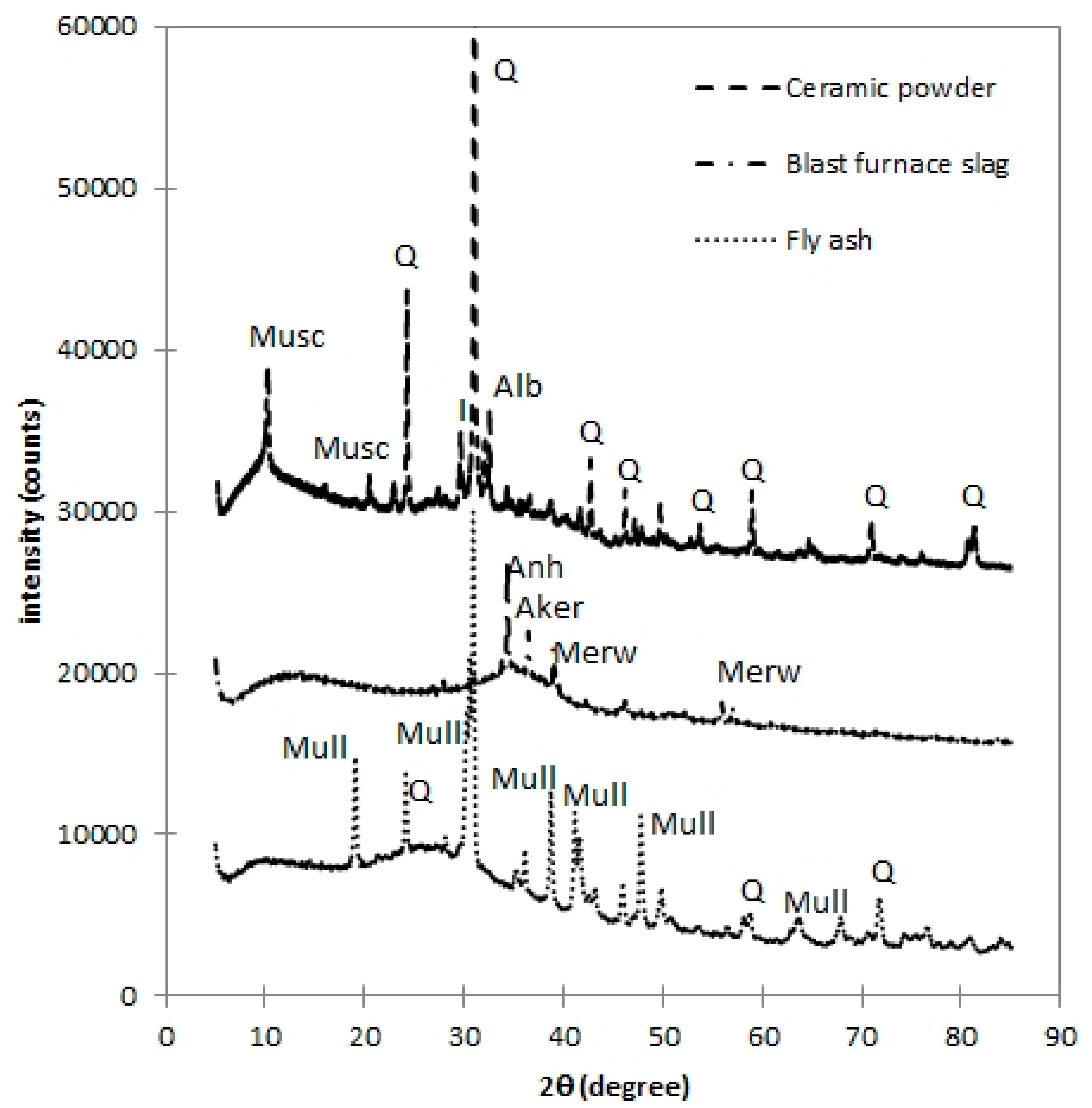

| Component | Summary Formula | Fly Ash | Blast Furnace Slag | Ceramic Powder |

|---|---|---|---|---|

| Amorphous portion | - | 62.8 | 83.4 | 27.1 |

| Quartz | SiO2 | 5.8 | - | 25.2 |

| Hematite | Fe2O3 | - | - | 2.8 |

| Albite | NaAlSi3O8 | - | - | 14.0 |

| Microcline | KAlSi3O8 | - | - | 7.0 |

| Muscovite | KAl2(AlSi3O10)(OH)2 | - | - | 12.9 |

| Illite | K0.65Al2(Al0.65Si3.35O10)(OH)2 | - | - | 3.4 |

| Diopside | CaMgSi2O6 | - | - | 4.8 |

| Akermanite | Ca2MgSi2O7 | - | 2.8 | 2.4 |

| Mullite | Al6Si2O13 | 31.1 | - | - |

| Anhydrite | CaSO4 | - | 7.5 | - |

| Merwinite | Ca3MgSi2O8 | - | 5.8 | - |

| Mineral Additive | k-Value |

|---|---|

| Blast furnace slag | 0.9 |

| Silica fume | 2.0 |

| Fly ash (F class) | 0.4 |

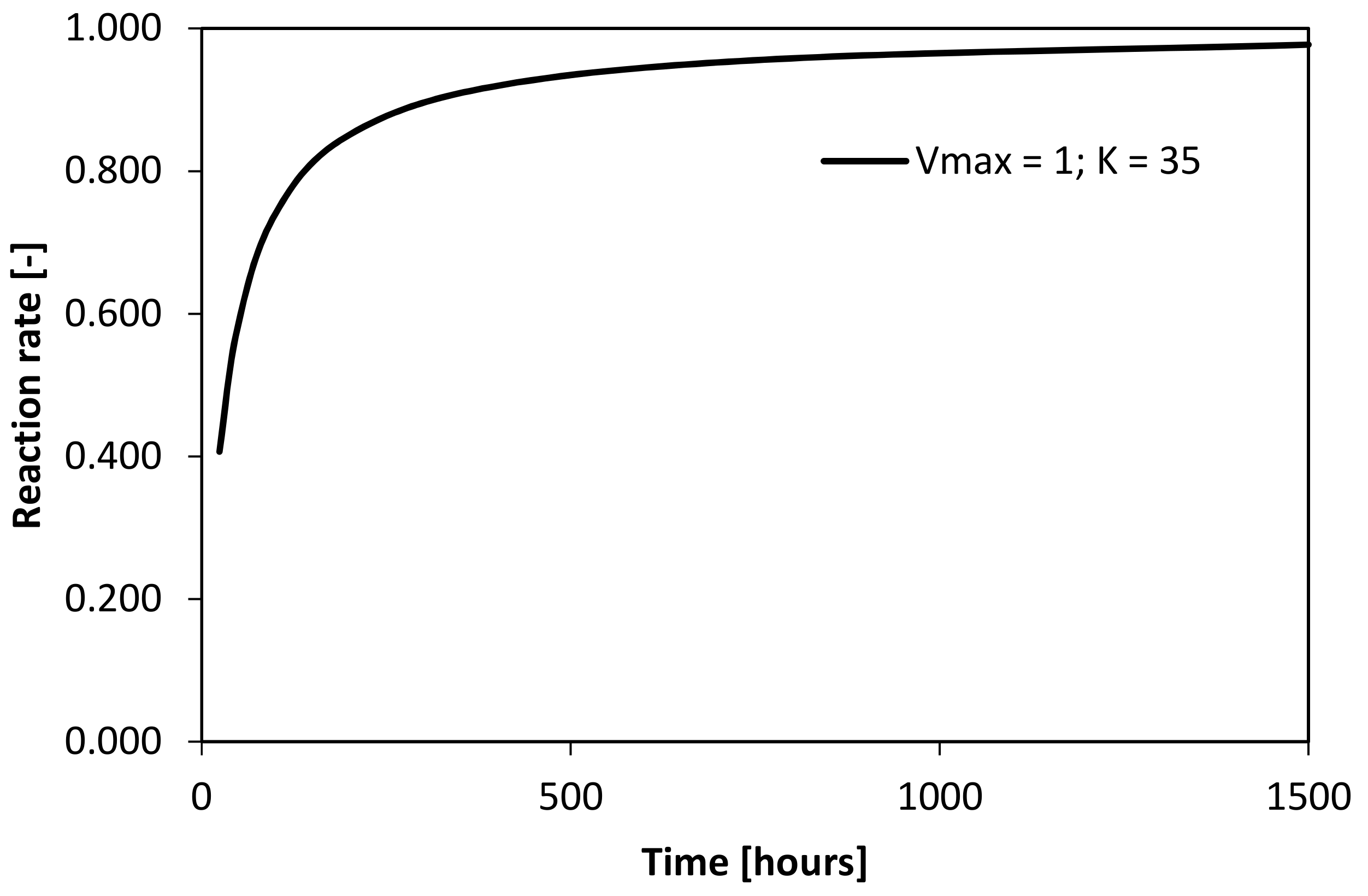

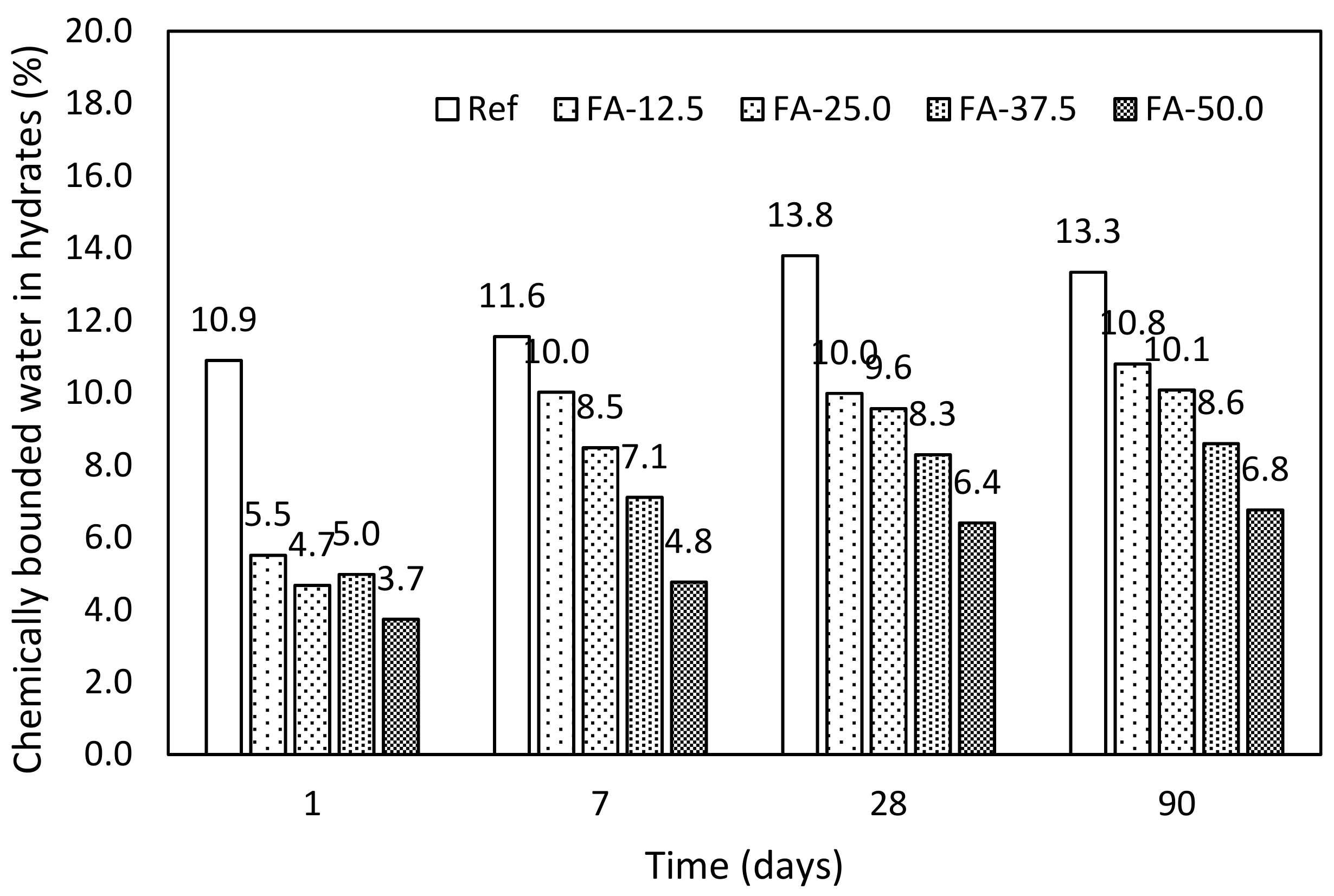

| Replacement (%) | Fly Ash | Blast Furnace Slag | Ceramic Powder | |||

|---|---|---|---|---|---|---|

| Hhyd∞ (%) | K (-) | Hhyd∞ (%) | K (-) | Hhyd∞ (%) | K (-) | |

| 0 | 13.14 | 5.44 | 13.14 | 5.44 | 13.14 | 5.44 |

| 12.0 | 10.80 | 22.00 | 11.55 | 6.19 | 12.22 | 40.78 |

| 25.0 | 10.08 | 28.20 | 11.33 | 4.60 | 9.73 | 23.25 |

| 37.5 | 8.40 | 17.67 | 10.22 | 8.62 | 7.82 | 22.84 |

| 50.0 | 6.41 | 21.60 | 8.68 | 11.38 | 5.56 | 22.11 |

| Studied Materials | The Degree of Hydration (-) | |||

|---|---|---|---|---|

| 1 day | 7 days | 28 days | 90 days | |

| Ref. | 0.83 | 0.88 | 1.05 | 1.01 |

| FA-12.5 | 0.51 | 0.93 | 0.92 | 1.00 |

| FA-25.0 | 0.46 | 0.84 | 0.95 | 1.00 |

| FA-37.5 | 0.59 | 0.85 | 0.99 | 1.02 |

| FA-50.0 | 0.58 | 0.74 | 1.00 | 1.05 |

| BSF-12.5 | 0.80 | 0.95 | 1.02 | 0.98 |

| BSF-25.0 | 0.84 | 0.97 | 1.02 | 0.97 |

| BSF-37.5 | 0.74 | 0.92 | 0.96 | 1.05 |

| BSF-50.0 | 0.68 | 0.93 | 0.98 | 1.00 |

| CP-12.5 | 0.39 | 0.79 | 0.89 | 1.04 |

| CP-25.0 | 0.51 | 0.89 | 0.99 | 0.97 |

| CP-37.5 | 0.51 | 0.89 | 0.97 | 0.98 |

| CP-50.0 | 0.53 | 0.82 | 0.99 | 1.01 |

| Studied Materials | The Degree of Hydration (-) | |||

|---|---|---|---|---|

| 1 day | 7 days | 28 days | 90 days | |

| Ref. | 0.79 | 0.84 | 1.00 | 0.96 |

| FA-12.5 | 0.45 | 0.82 | 0.81 | 0.88 |

| FA-25.0 | 0.38 | 0.68 | 0.77 | 0.81 |

| FA-37.5 | 0.44 | 0.63 | 0.73 | 0.76 |

| FA-50.0 | 0.39 | 0.50 | 0.67 | 0.71 |

| BSF-12.5 | 0.75 | 0.90 | 0.97 | 0.92 |

| BSF-25.0 | 0.78 | 0.91 | 0.96 | 0.91 |

| BSF-37.5 | 0.69 | 0.85 | 0.89 | 0.98 |

| BSF-50.0 | 0.63 | 0.86 | 0.90 | 0.93 |

| CP-12.5 | 0.33 | 0.67 | 0.75 | 0.89 |

| CP-25.0 | 0.38 | 0.66 | 0.74 | 0.73 |

| CP-37.5 | 0.33 | 0.58 | 0.63 | 0.64 |

| CP-50.0 | 0.29 | 0.45 | 0.54 | 0.56 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reiterman, P.; Holčapek, O.; Davidová, V.; Jaskulski, R.; Keppert, M. Estimation of Hydration Degree of Blended Cements with the Help of k-Values. Materials 2019, 12, 2420. https://doi.org/10.3390/ma12152420

Reiterman P, Holčapek O, Davidová V, Jaskulski R, Keppert M. Estimation of Hydration Degree of Blended Cements with the Help of k-Values. Materials. 2019; 12(15):2420. https://doi.org/10.3390/ma12152420

Chicago/Turabian StyleReiterman, Pavel, Ondřej Holčapek, Vendula Davidová, Roman Jaskulski, and Martin Keppert. 2019. "Estimation of Hydration Degree of Blended Cements with the Help of k-Values" Materials 12, no. 15: 2420. https://doi.org/10.3390/ma12152420

APA StyleReiterman, P., Holčapek, O., Davidová, V., Jaskulski, R., & Keppert, M. (2019). Estimation of Hydration Degree of Blended Cements with the Help of k-Values. Materials, 12(15), 2420. https://doi.org/10.3390/ma12152420