Strengthening Mechanism of Titanium Boride Whisker-Reinforced Ti-6Al-4V Alloy Matrix Composites with the TiB Orientation Perpendicular to the Loading Direction

Abstract

:1. Introduction

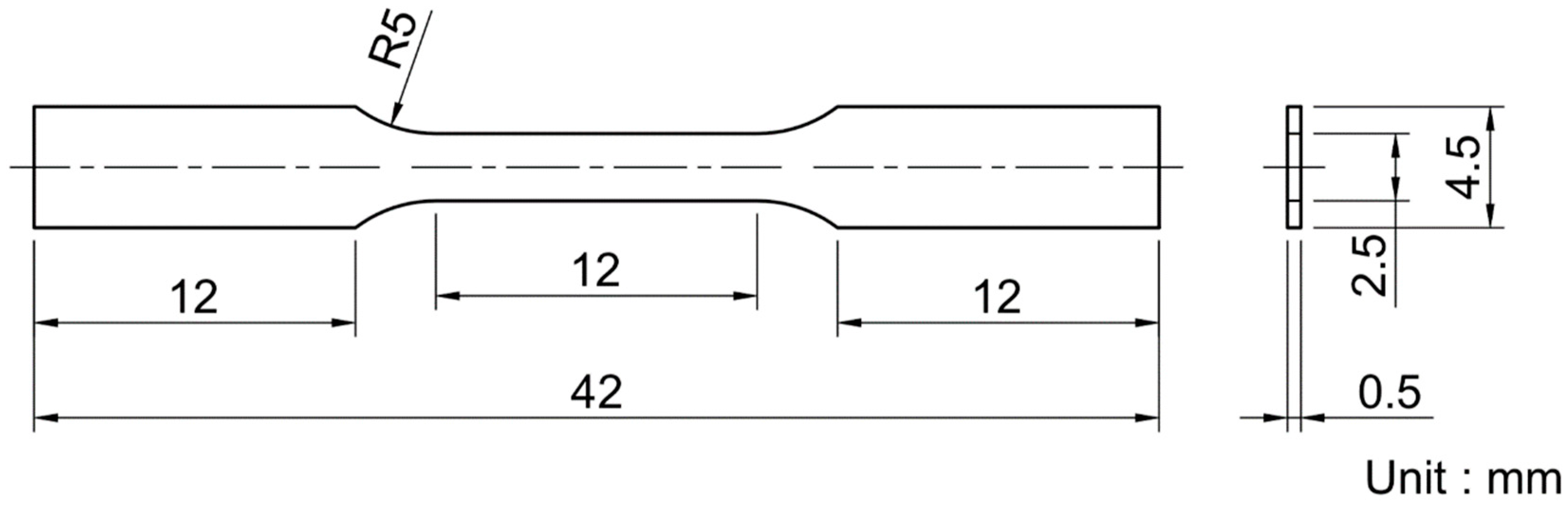

2. Experimental Procedure

3. Models

3.1. Halpin-Tsai Model

3.2. Shear-Lag Model

4. Results and Discussion

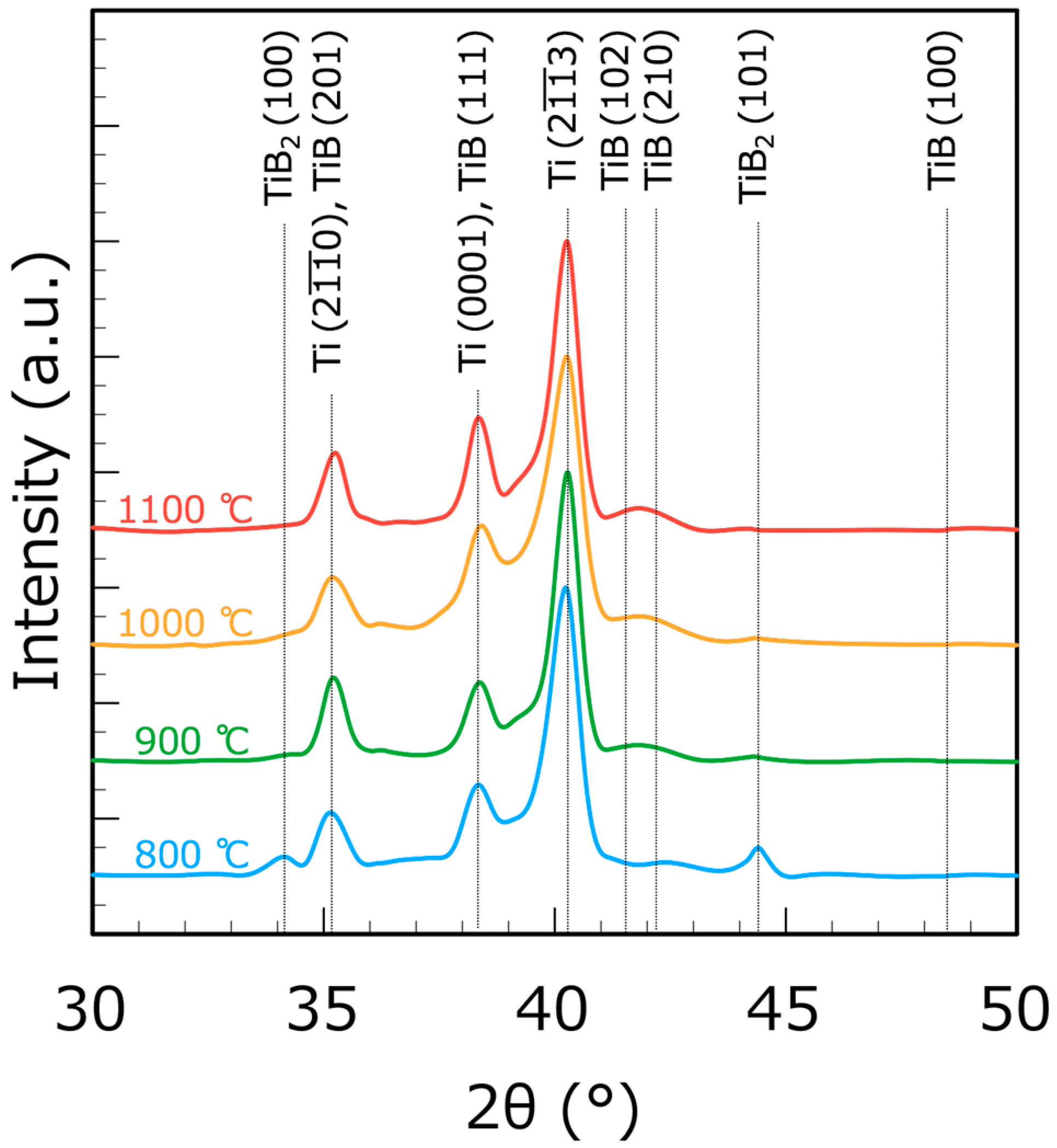

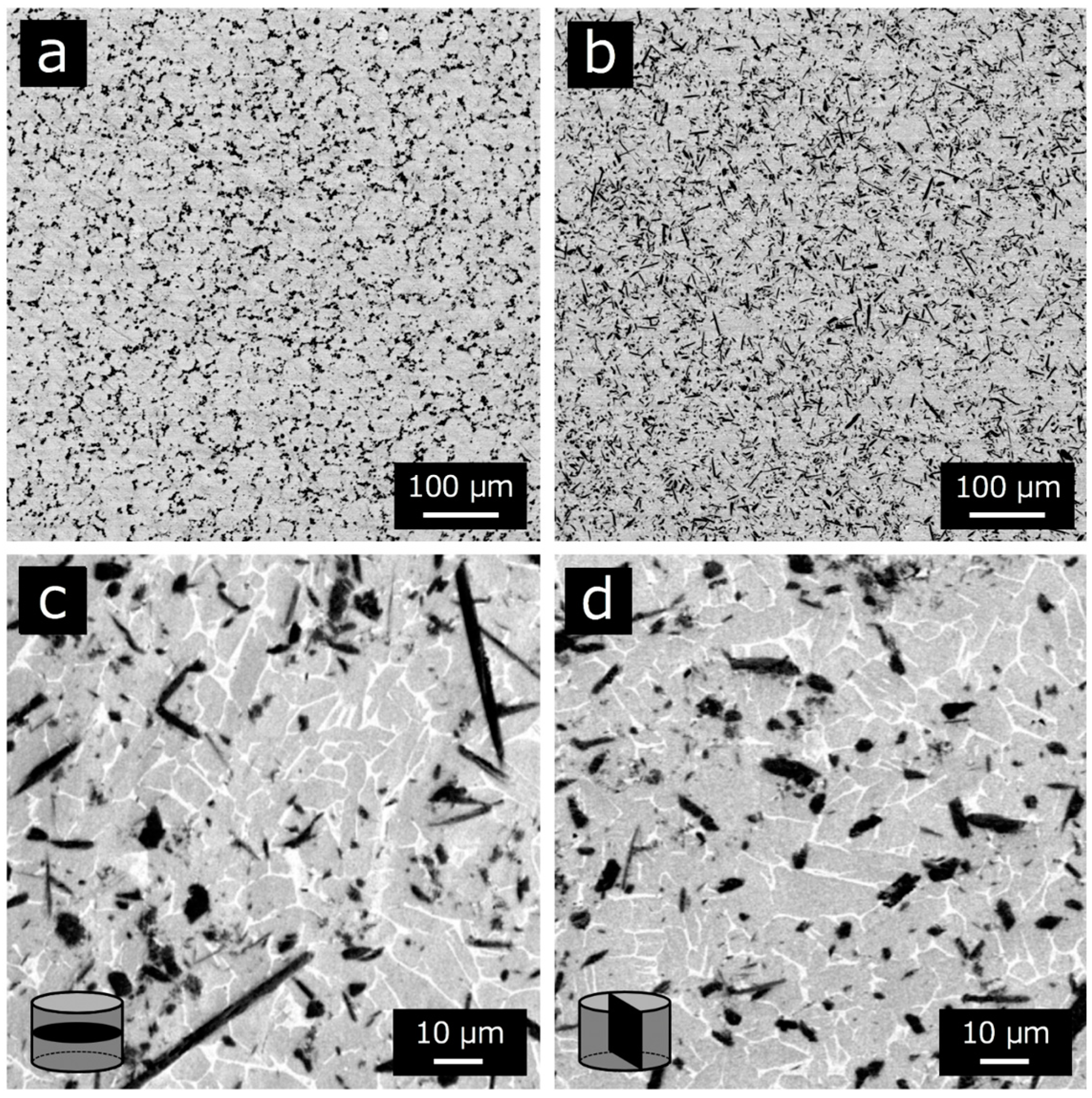

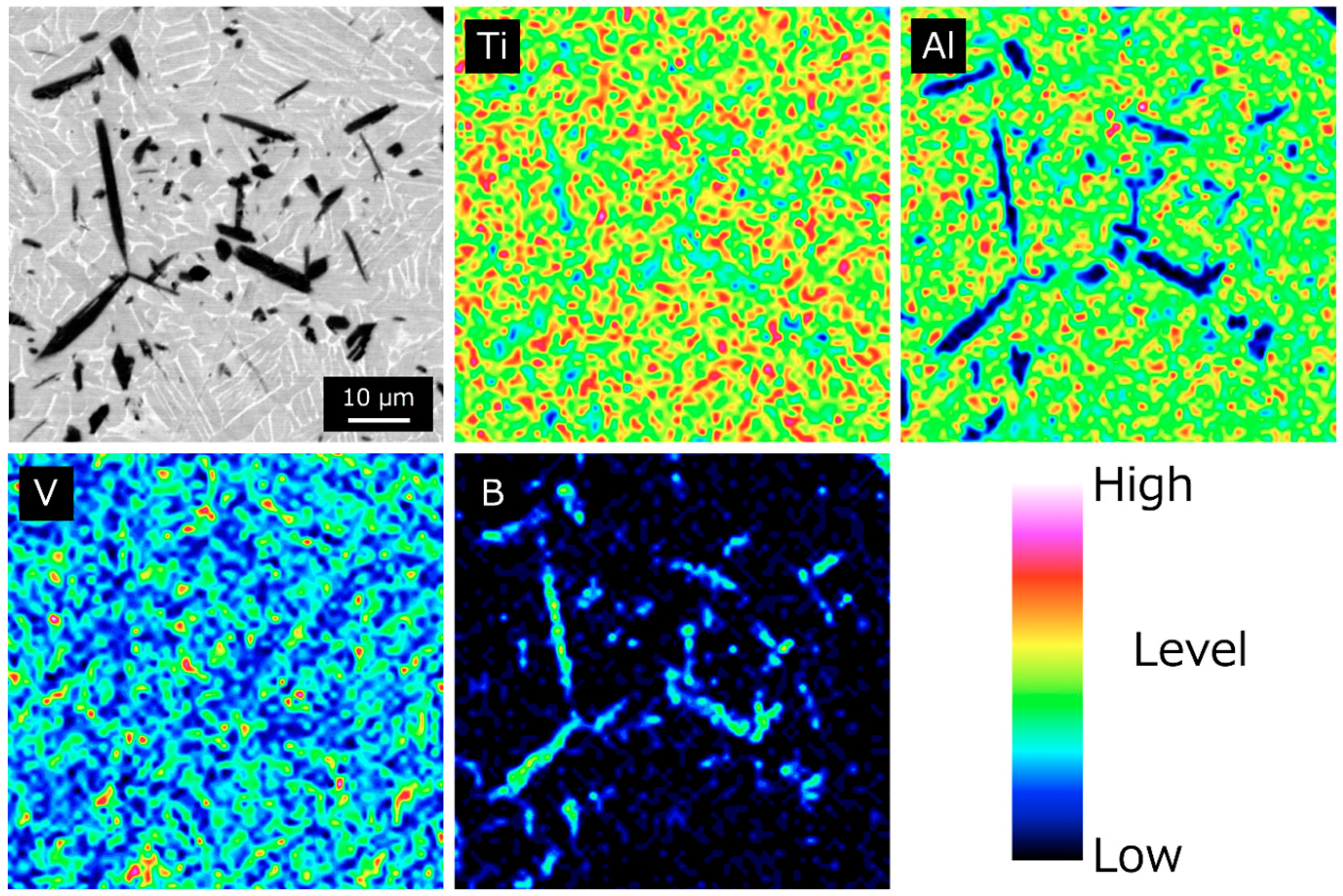

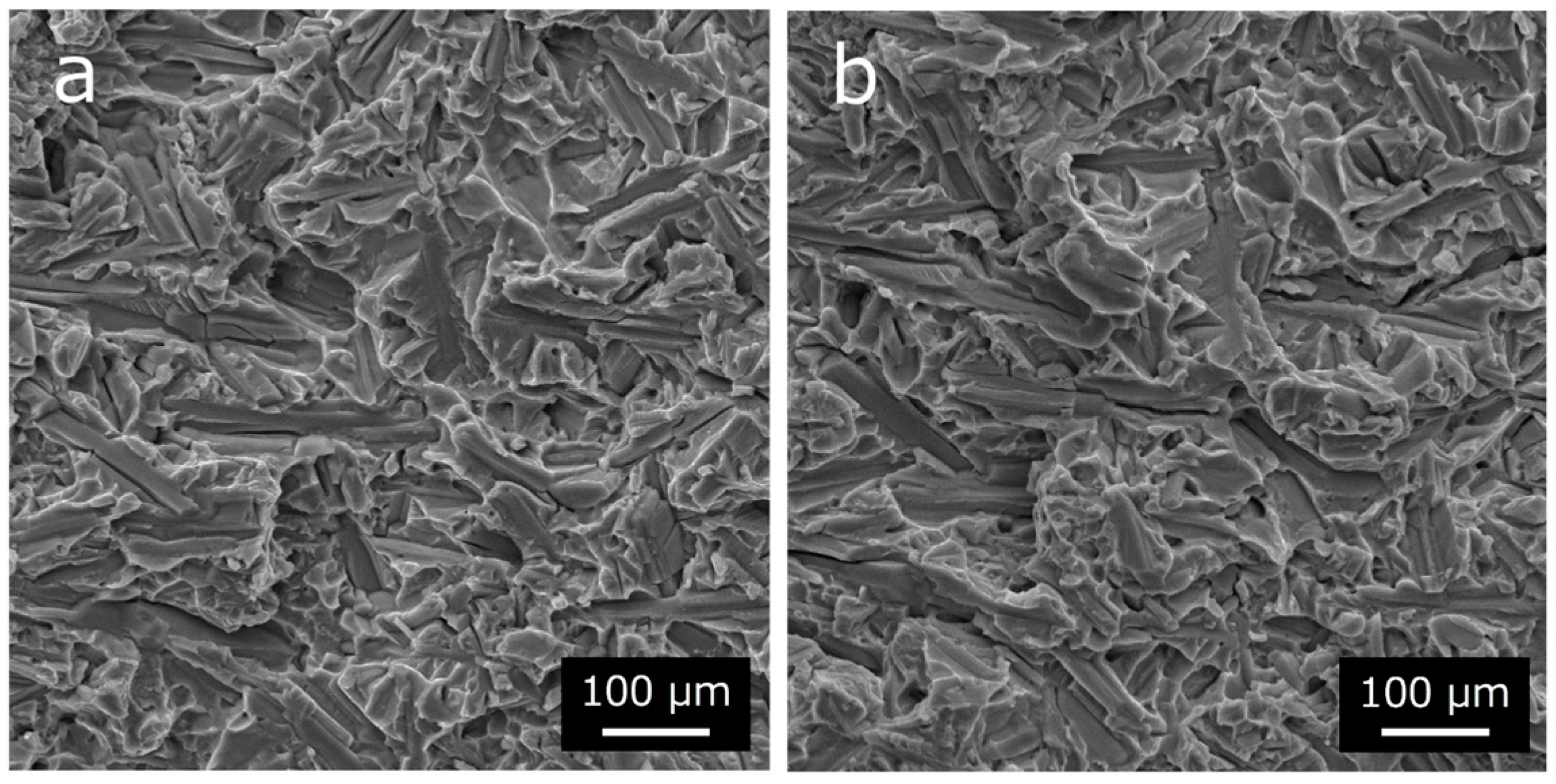

4.1. Microstructure

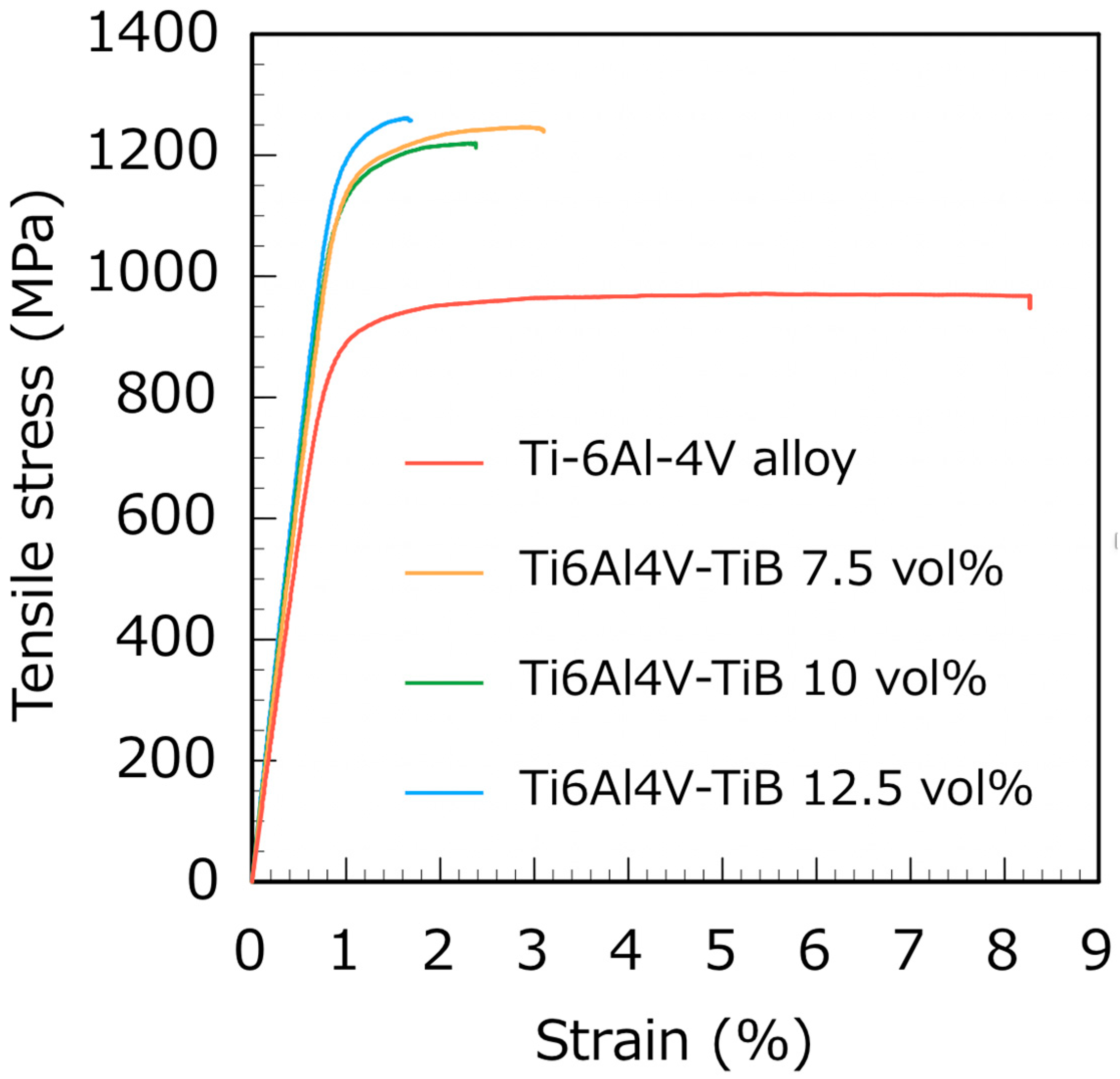

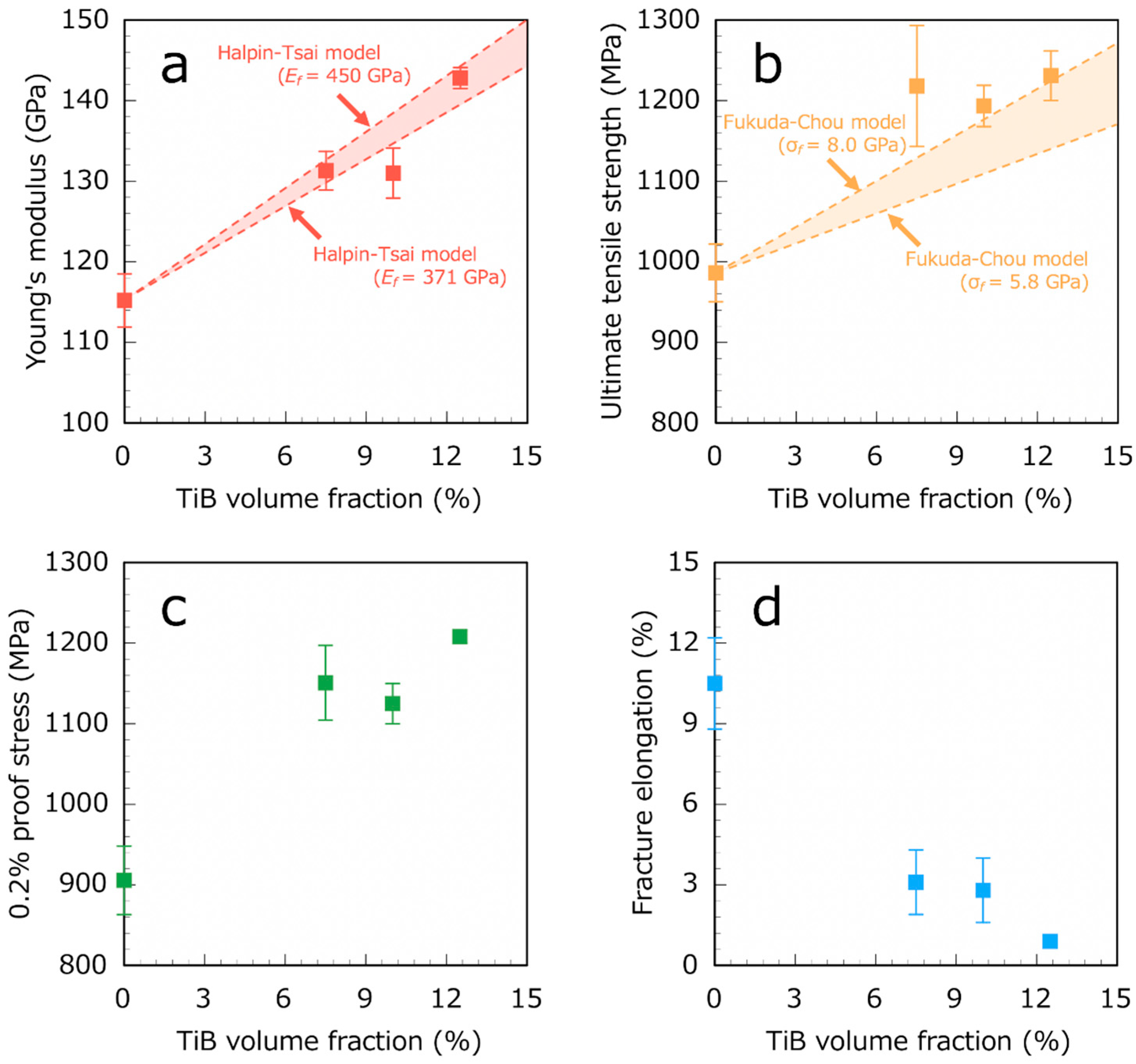

4.2. Tensile Properties

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chandran, K.S.R.; Panda, K.B.; Sahay, S.S. TiBw-reinforced Ti composites: Processing, properties, application prospects, and research needs. JOM 2004, 56, 42–48. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing and properties of titanium-titanium boride (TiBw) matrix composites (a review). J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Liu, G.; Zhu, D.; Shang, J.K. Temperature dependence of fracture toughness in TiC-particulate reinforced Ti-1b6Al-1b4V matrix composite. Scr. Metall. Mater. 1993, 28, 729–732. [Google Scholar] [CrossRef]

- Gorsse, S.; Chaminade, J.P.; Petitcorps, Y.L. In situ preparation of titanium base composites reinforced by TiB single crystals using a powder metallurgy technique. Compos. A Appl. Sci. Manuf. 1998, A29, 1229–1234. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Tjong, S.C.; Gen, L. In-situ Ti-TiB metal-matrix composite prepared by a reactive pressing process. Scr. Mater. 2000, 42, 367–373. [Google Scholar] [CrossRef]

- Radhakrishna Bhat, B.V.R.; Subramanyam, J.; Bhanu Prasad, V.V. Preparation of Ti-TiB-TiC & Ti-TiB composites by in-situ reaction hot pressing. Mater. Sci. Eng. 2002, A325, 126–130. [Google Scholar]

- Boehlert, C.J.; Tamirisakandala, S.; Curtinc, W.A.; Miracle, D.B. Assessment of in situ TiB whisker tensile strength and optimization of TiB-reinforced titanium alloy design. Scr. Mater. 2009, 61, 245–248. [Google Scholar] [CrossRef]

- Arti, R.R.; Ravichandran, K.S.; Jha, S.K. Elastic properties of in-situ processed Ti–TiB composites measured by impulse excitation of vibration. Mater. Sci. Eng. 1999, A271, 150–159. [Google Scholar]

- Soboyejo, W.O.; Shen, W.; Srivatsan, T.S. An investigation of fatigue crack nucleation and growth in a Ti–6Al–4V/TiB in situ composite. Mech. Mater. 2004, 36, 141–159. [Google Scholar] [CrossRef]

- Emura, S.; Yang, S.J.; Hagiwara, M. Room-temperature tensile and high-cycle-fatigue strength of fine TiB particulate-reinforced Ti-22Al-27Nb composites. Metall. Mater. Trans. 2004, A35, 2971–2979. [Google Scholar] [CrossRef]

- Fan, Z.; Chandrasekaran, L.; Ward-Close, C.M.; Miodownik, A.P. The effect of pre-consolidation heat treatment on TiB morphology and mechanical properties of rapidly solidified Ti-6Al-4V-xB alloys. Scri. Metall. Mater. 1995, 32, 833–838. [Google Scholar] [CrossRef]

- Gorsse, S.; Miracle, D.B. Mechanical properties of Ti-6Al-4V/TiB composites with randomly oriented and aligned TiB reinforcements. Acta Mater. 2003, 51, 2427–2442. [Google Scholar] [CrossRef]

- Kobayashi, M.; Fumani, K.; Suzuki, S.; Ouchi, C. Manufacturing process and mechanical properties of fine TiB dispersed Ti–6Al–4V alloy composites obtained by reaction sintering. Mater. Sci. Eng. 1998, A243, 279–284. [Google Scholar] [CrossRef]

- Sailer, R.; McCarthy, G. JCPDS 44-1294; The International Centre for Diffraction Data: Newtown Square, PA, USA, 1993; Available online: http://www.icdd.com (accessed on 15 April 2019).

- Norton, J.T.; Blumenthal, H.; Sindeband, S.J. Structure of diborides of titanium, zirconium, columbium, tantalum and vanadium. Metall Trans. 1949, 185, 749–751. [Google Scholar] [CrossRef]

- Post, B.; Glaser, F.W. Borides of some transition metals. J. Chem. Phys. 1952, 20, 1050–1055. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar]

- Kelly, A.; Tyson, W.R. Tensile properties of fibre-reinforced metals: copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Kurita, H.; Estili, M.; Kwon, H.; Miyazaki, T.; Zhou, W.; Silvain, J.-F.; Kawasaki, A. Load-bearing contribution of multi-walled carbon nanotubes on tensile response of aluminum. Compos. A Appl. Sci. Manuf. 2015, A68, 133–139. [Google Scholar] [CrossRef]

- Fukuda, H.; Chou, T.W. A probabilistic theory of the strength of short-fibre composites with variable fibre length and orientation. J. Mater. Sci. 1982, 17, 1003–1011. [Google Scholar] [CrossRef]

- Ropars, L.; Dehmas, M.; Gourdet, S.; Delfosse, J.; Tricker, D.; Aeby-Gautier, E. Structure evolutions in a Ti-6Al-4V matrix composite reinforced with TiB, characterised using high energy X-ray diffraction. J. Alloy Compd. 2015, 624, 179–188. [Google Scholar] [CrossRef]

- Madtha, S.; Lee, C.; Chandran, K.S.R. Physical and mechanical properties of nanostructured titanium boride (TiB) ceramic. J. Am. Ceram. Soc. 2008, 91, 1319–1321. [Google Scholar] [CrossRef]

- Cao, G.; Geng, L.; Naka, M. Elastic Properties of titanium monoboride measured by nanoindentation. J. Am. Ceram. Soc. 2006, 89, 3836–3838. [Google Scholar] [CrossRef]

- Nakane, S.; Takano, Y.; Yoshinaka, M.; Hirota, K.; Yamaguchi, O. Fabrication and mechanical properties of titanium boride ceramics. Comm. Am. Ceram. Soc. 1999, 82, 1627–1628. [Google Scholar] [CrossRef]

- Wang, L.; Niinomi, M.; Takahashi, S.; Hagiwara, M.; Emura, S.; Kawabe, Y.; Kim, S.J. Relationship between fracture toughness and microstructure of Ti-6Al-2Sn-4Zr-2Mo alloy reinforced with TiB particles. Mater. Sci. Eng. 1999, A263, 319–325. [Google Scholar] [CrossRef]

- Kurita, H.; Sakayanagi, K.; Kikuchi, S.; Yodoshi, N.; Gourdet, S.; Narita, F. Crack initiation behavior of titanium boride whisker reinforced titanium matrix composites during small punch testing. Mater. Des. Process. Commun. 2019, 1, e80. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurita, H.; Suzuki, S.; Kikuchi, S.; Yodoshi, N.; Gourdet, S.; Narita, F. Strengthening Mechanism of Titanium Boride Whisker-Reinforced Ti-6Al-4V Alloy Matrix Composites with the TiB Orientation Perpendicular to the Loading Direction. Materials 2019, 12, 2401. https://doi.org/10.3390/ma12152401

Kurita H, Suzuki S, Kikuchi S, Yodoshi N, Gourdet S, Narita F. Strengthening Mechanism of Titanium Boride Whisker-Reinforced Ti-6Al-4V Alloy Matrix Composites with the TiB Orientation Perpendicular to the Loading Direction. Materials. 2019; 12(15):2401. https://doi.org/10.3390/ma12152401

Chicago/Turabian StyleKurita, Hiroki, Shiori Suzuki, Shoichi Kikuchi, Noriharu Yodoshi, Sophie Gourdet, and Fumio Narita. 2019. "Strengthening Mechanism of Titanium Boride Whisker-Reinforced Ti-6Al-4V Alloy Matrix Composites with the TiB Orientation Perpendicular to the Loading Direction" Materials 12, no. 15: 2401. https://doi.org/10.3390/ma12152401

APA StyleKurita, H., Suzuki, S., Kikuchi, S., Yodoshi, N., Gourdet, S., & Narita, F. (2019). Strengthening Mechanism of Titanium Boride Whisker-Reinforced Ti-6Al-4V Alloy Matrix Composites with the TiB Orientation Perpendicular to the Loading Direction. Materials, 12(15), 2401. https://doi.org/10.3390/ma12152401