Investigation of the Flow Properties of CBM Based on Stochastic Fracture Network Modeling

Abstract

1. Introduction

2. The CBM Industry with a Worldwide View

3. SFN Reconstruction and Processing

3.1. Basic Theory and Method of SFN Reconstruction

3.2. SFN Image Processing

3.3. Image function

4. Numerical Simulation of Gas Flow in the Coal Seam

4.1. Basic Assumptions

- (1)

- The coal seam is represented by an SFN and treated as a dual-porosity reservoir that is composed of fractures and the coal matrix.

- (2)

- FGPs consist of density, length, aperture, and orientation.

- (3)

- The flow in the coal seam is a single phase and saturated Darcy flow.

- (4)

- Gas absorption is described by the Langmuir law.

- (5)

- Coupling effects of multiple physical fields are ignored.

4.2. Fracture Flow Model

4.3. Governing Equations and Boundary Conditions

4.4. Numerical Simulation Results

5. Parametric Study

5.1. Influence of Fracture Density on CBM Flow

5.2. Influence of Fracture Length on CBM Flow

5.3. Influence of Fracture Aperture on CBM Flow

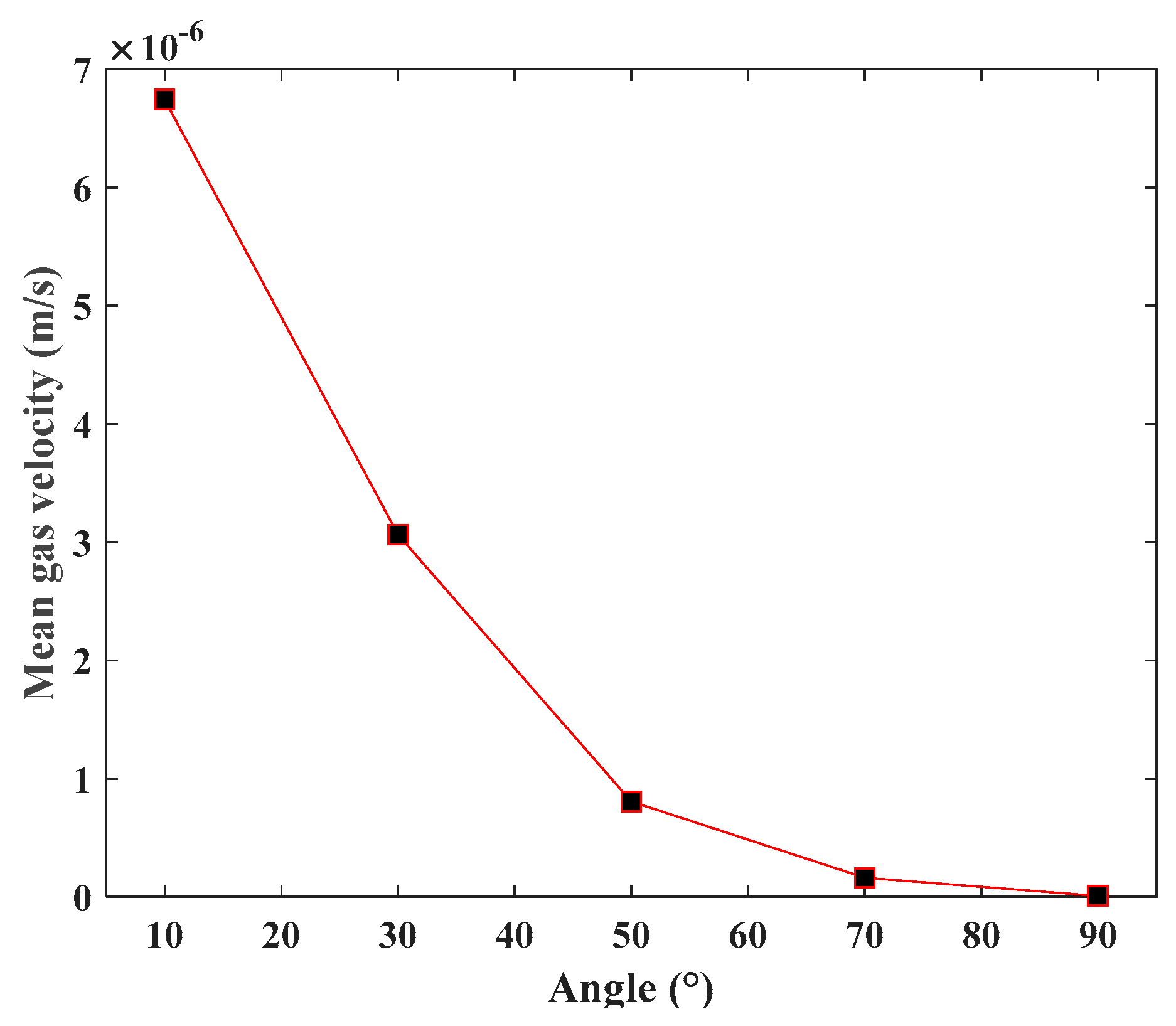

5.4. Influence of Fracture Orientation on CBM Flow

5.5. Influence of Fracture Size on CBM Flow

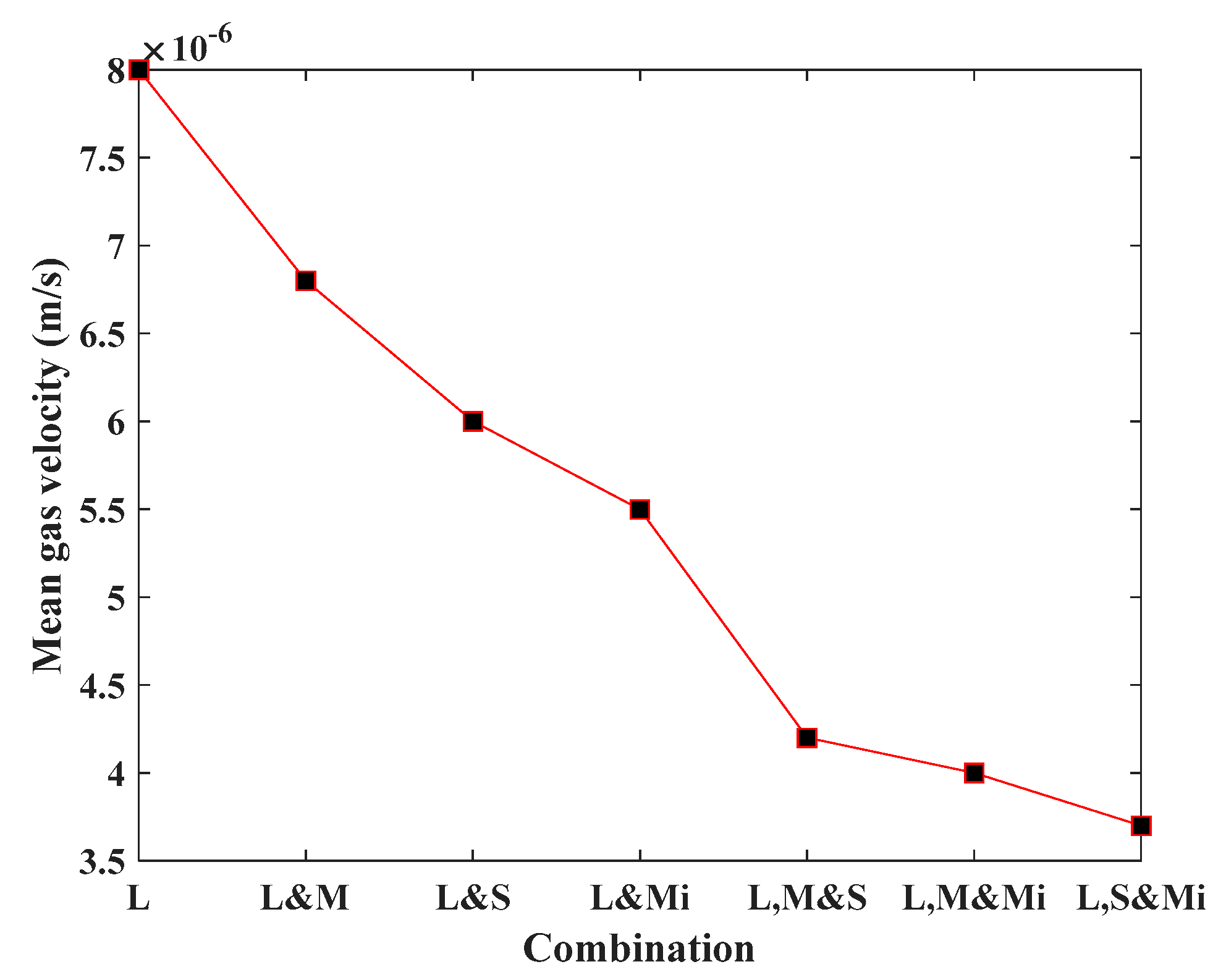

5.6. Influence of Distribution Patterns of FGPs on CBM Flow

6. CBM Extraction Simulation Based on SFN Modeling

6.1. Governing Equations and Parameters

6.2. Simulation Results Analysis

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xu, H.; Sang, S.; Yang, J.; Jin, J.; Hu, Y.; Liu, H.; Li, J.; Zhou, X.; Ren, B. Selection of suitable engineering modes for CBM development in zones with multiple coalbeds: A case study in western Guizhou Province, Southwest China. J. Nat. Gas Sci. Eng. 2016, 36, 1264–1275. [Google Scholar] [CrossRef]

- Mostaghimi, P.; Armstrong, R.T.; Gerami, A.; Hu, Y.; Jing, Y.; Kamali, F.; Liu, M.; Liu, Z.; Lu, X.; Ramandi, H.L.; et al. Cleat-scale characterisation of coal: An overview. J. Nat. Gas Sci. Eng. 2017, 39, 143–160. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Cao, S.G.; Li, Y.; Guo, P.; Yang, H.; Yang, T. Effect of moisture content on methane adsorption- and desorption-induced deformation of tectonically deformed coal. Adsorpt. Sci. Technol. 2018, 36, 1648–1668. [Google Scholar] [CrossRef]

- Li, H.; Ogawa, Y.; Shimada, S. Mechanism of methane flow through sheared coals and its role on methane recovery. Fuel 2003, 82, 1271–1279. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, Y.; Wang, W.; Xu, R. Research on comprehensive CBM extraction technology and its applications in China’s coal mines. J. Nat. Gas Sci. Eng. 2014, 20, 200–207. [Google Scholar] [CrossRef]

- Sharp, J.M.; Simmons, C.T. The Compleat Darcy: New lessons learned from the first english translation of Les Fontaines Publiques de la Ville de Dijon. Groundwater 2010, 43, 457–460. [Google Scholar] [CrossRef]

- Ta, D.; Cao, S.; Steyl, G.; Yang, H.; Li, Y. Prediction of Groundwater Inflow into an Iron Mine: A Case Study of the Thach Khe Iron Mine, Vietnam. Mine Water Environ. 2019, 38, 310–324. [Google Scholar] [CrossRef]

- Berkowitz, B. Characterizing flow and transport in fractured geological media: A review. Adv. Water Resour. 2002, 25, 861–884. [Google Scholar] [CrossRef]

- Fu, Q.; Cloutier, A.; Laghdir, A.; Stevanovic, T. Surface Chemical Changes of Sugar Maple Wood Induced by Thermo-Hygromechanical (THM) Treatment. Materials 2019, 12, 1946. [Google Scholar] [CrossRef]

- Bear, J. Dynamics of fluids in porous media. Eng. Geol. 1972, 7, 174–175. [Google Scholar] [CrossRef]

- Snow, D.T. Anisotropie Permeability of Fractured Media. Water Resour. Res. 1969, 5, 1273–1289. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, S.; Gu, Z.; Sun, Y. Fracture Behavior and Energy Analysis of 3D Concrete Mesostructure under Uniaxial Compression. Materials 2019, 12, 1929. [Google Scholar] [CrossRef] [PubMed]

- Barenblatt, G.; Zheltov, I.; Kochina, I. Basic concepts in the theory of seepage of homogeneous liquids in fissured rocks. J. Appl. Math. Mech. 1960, 24, 1286–1303. [Google Scholar] [CrossRef]

- Lei, Q.; Latham, J.-P.; Tsang, C.F. The use of discrete fracture networks for modelling coupled geomechanical and hydrological behaviour of fractured rocks. Comput. Geotech. 2017, 85, 151–176. [Google Scholar] [CrossRef]

- Ren, J.; Guo, P.; Guo, Z.; Wang, Z. A Lattice Boltzmann Model for Simulating Gas Flow in Kerogen Pores. Transp. Porous Media 2015, 106, 285–301. [Google Scholar] [CrossRef]

- Belayneh, M.; Cosgrove, J.W. Fracture-pattern variations around a major fold and their implications regarding fracture prediction using limited data: An example from the Bristol Channel Basin. Geol. Soc. Lond. Spéc. Publ. 2004, 231, 89–102. [Google Scholar] [CrossRef]

- Pollard, D.D.; Renshaw, C.E. Numerical simulation of fracture set formation: A fracture mechanics model consistent with experimental observations. J. Geophys. Res. Space Phys. 1994, 99, 9359–9372. [Google Scholar]

- Davy, P.; Le Goc, R.; Darcel, C. A model of fracture nucleation, growth and arrest, and consequences for fracture density and scaling. J. Geophys. Res. Solid Earth 2013, 118, 1393–1407. [Google Scholar] [CrossRef]

- Boadu, F.K. Fractured rock mass characterization parameters and seismic properties: Analytical studies. J. Appl. Geophys. 1997, 37, 1–19. [Google Scholar] [CrossRef]

- Dershowitz, W.S.; Einstein, H.H. Characterizing rock joint geometry with joint system models. Rock Mech. Rock Eng. 1988, 21, 21–51. [Google Scholar] [CrossRef]

- Neuman, S.P. Multiscale relationships between fracture length, aperture, density and permeability. Geophys. Res. Lett. 2015, 35, 1092–1104. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, X.; Chen, B.; Yang, F.; Zhang, Y.; Wang, P.; Robinson, I. Three-Dimensional Characterization of Hardened Paste of Hydrated Tricalcium Silicate by Serial Block-Face Scanning Electron Microscopy. Materials 2019, 12, 1882. [Google Scholar] [CrossRef] [PubMed]

- Boadu, F. Relating the hydraulic properties of a fractured rock mass to seismic attributes: Theory and numerical experiments. Int. J. Rock Mech. Min. Sci. 1997, 34, 885–895. [Google Scholar] [CrossRef]

- Spanier, J.; Gelbard, E.M.; Bell, G. Monte Carlo Principles and Neutron Transport Problems. Phys. Today 1970, 23, 56–57. [Google Scholar] [CrossRef]

- Giacobbo, F.; Patelli, E. Monte Carlo simulation of nonlinear reactive contaminant transport in unsaturated porous media. Ann. Nucl. Energy 2008, 34, 51–63. [Google Scholar] [CrossRef]

- Adler, P.M.; Thovert, J.F. Fractures and Fracture Networks; Springer: Dordrecht, The Netherlands, 1999; p. 15. [Google Scholar]

- Cacas, M.C.; Daniel, J.M.; Letouzey, J. Nested geological modelling of naturally fractured reservoirs. Pet. Geosci. 2001, 7, S43–S52. [Google Scholar] [CrossRef]

- Hanano, M. Contribution of fractures to formation and production of geothermal resources. Renew. Sustain. Energy Rev. 2004, 8, 223–236. [Google Scholar] [CrossRef]

- Alghalandis, Y.F.; Dowd, P.A.; Xu, C. The RANSAC Method for Generating Fracture Networks from Micro-seismic Event Data. Math. Geol. 2013, 45, 207–224. [Google Scholar]

- Mardia, K.V.; Nyirongo, V.B.; Walder, A.N.; Xu, C.; Dowd, P.A.; Fowell, R.J.; Kent, J.T. Markov Chain Monte Carlo Implementation of Rock Fracture Modelling. Math. Geol. 2007, 39, 355–381. [Google Scholar] [CrossRef]

- Xu, C.; Dowd, P. A new computer code for discrete fracture network modelling. Comput. Geosci. 2010, 36, 292–301. [Google Scholar] [CrossRef]

- Pardo-Igúzquiza, E.; Dowd, P.A.; Xu, C.; Durán-Valsero, J.J. Stochastic simulation of karst conduit networks. Adv. Water Resour. 2012, 35, 141–150. [Google Scholar] [CrossRef]

- Seifollahi, S.; Dowd, P.A.; Xu, C.; Fadakar, A.Y. A Spatial Clustering Approach for Stochastic Fracture Network Modelling. Rock Mech. Rock Eng. 2014, 47, 1225–1235. [Google Scholar] [CrossRef]

- Nelson, R.A. Geologic Analysis of Naturally Fractured Reservoirs, 2nd ed.; Gulf Professional Publishing: Woburn, MA, USA, 2001; pp. 323–332. [Google Scholar]

- Cacace, M.; Blöcher, G.; Watanabe, N.; Moeck, I.; Börsing, N.; Scheck-Wenderoth, M.; Kolditz, O.; Huenges, E. Modelling of fractured carbonate reservoirs: Outline of a novel technique via a case study from the Molasse Basin, southern Bavaria, Germany. Environ. Earth Sci. 2013, 70, 3585–3602. [Google Scholar] [CrossRef]

- Yeh, H.D.; Chang, Y.C. Recent advances in modeling of well hydraulics. Adv. Water Resour. 2013, 51, 27–51. [Google Scholar] [CrossRef]

- Choi, S.; Wold, M. Simulation of Fluid Flow in Coal Using a Discrete Fracture Network Model. In Proceedings of the SPE Asia Pacific Oil and Gas Conference, Melbourne, Australia, 7–10 November 1994. [Google Scholar]

- Lorig, L.J.; Darcel, C.; Damjanac, B.; Pierce, M.; Billaux, D. Application of discrete fracture networks in mining and civil geomechanics. Min. Technol. 2015, 124, 239–254. [Google Scholar] [CrossRef]

- Jing, Y.; Armstrong, R.T.; Mostaghimi, P. Rough-walled discrete fracture network modelling for coal characterisation. Fuel 2017, 191, 442–453. [Google Scholar] [CrossRef]

- Maryška, J.; Severýn, O.; Vohralík, M. Numerical simulation of fracture flow with a mixed-hybrid FEM stochastic discrete fracture network model. Comput. Geosci. 2005, 8, 217–234. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Aminian, K.; Rodvelt, G. Chapter 4—Evaluation of Coalbed Methane Reservoirs. Coal Bed Methane 2014, 43, 63–91. [Google Scholar]

- Koyama, T.; Neretnieks, I.; Jing, L. A numerical study on differences in using Navier–Stokes and Reynolds equations for modeling the fluid flow and particle transport in single rock fractures with shear. Int. J. Rock Mech. Min. Sci. 2008, 45, 1082–1101. [Google Scholar] [CrossRef]

- Fu, X.H.; Qin, Y. Theories and Techniques of Permeability Prediction of Multiphase Medium Coalbed-Methane Reservoirs; China Mining University Press: Xuzhou, China, 2003. [Google Scholar]

- Wang, J.; Kabir, A.; Liu, J.; Chen, Z. Effects of non-Darcy flow on the performance of coal seam gas wells. Int. J. Coal Geol. 2012, 93, 62–74. [Google Scholar] [CrossRef]

| Distribution | Probability Density Function | Random Variable |

|---|---|---|

| Uniform | ||

| Normal | ||

| Exponential | ||

| Lognormal |

| Parameter | Value |

|---|---|

| Gas dynamic viscosity (µ) | 11.067 [Pa.s] |

| Matrix permeability (km) | 0.02 [mD] |

| Matrix porosity (φm) | 0.01 |

| Gas pressure of inlet (P1) | 1 [MPa] |

| Gas pressure of outlet (P2) | 0 [MPa] |

| Coal seam temperature (T) | 310 [K] |

| Density (m−2) | Orientation (°) | Length (m) | Aperture (m) | |||

|---|---|---|---|---|---|---|

| Mean | Standard Deviation | Mean | Standard Deviation | Mean | Standard Deviation | |

| 3.2 | 10/100 | 3° | 2.3 | 0.1 | 0.03 | 0.002 |

| Fracture Size | Fracture Aperture (mm) | Length (m) | Density (m−1) |

|---|---|---|---|

| Large (L) | >100 | >10 | 1~10 |

| Middle (M) | 10~100 | 1~10 | 10~100 |

| Small (S) | 5~15 | 0.01~1 | 10~200 |

| Micro (Mi) | <10 | 0.01~0.1 | 20~500 |

| Fractures | Density (m−2) | Orientation (°) | Length (m) | Aperture (m) | |||

|---|---|---|---|---|---|---|---|

| Mean | Standard Deviation | Mean | Standard Deviation | Mean | Standard Deviation | ||

| Large | 0.03 | 45/135 | 3 | 11 | 0.5 | 0.11 | 0.01 |

| Middle | 1 | 45/135 | 3 | 2.3 | 0.1 | 0.03 | 0.002 |

| Small | 30 | 45 | - | 0.4 | 0.05 | 0.005 | 0 |

| Micro | 100 | 45 | - | 0.06 | 0.01 | 0.001 | 0 |

| Parameter | Value |

|---|---|

| Gas density under standard conditions (ρgs) | 0.716 [kg/m3] |

| Langmuir pressure constant (PL) | 3.034 [MPa] |

| Langmuir volume constant (VL) | 0.036 [m3/kg] |

| Density of coal skeleton (ρs) | 1370 [kg/ m3] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Li, Y.; Fantuzzi, N.; Zhao, Y.; Liu, Y.-B.; Peng, B.; Chen, J. Investigation of the Flow Properties of CBM Based on Stochastic Fracture Network Modeling. Materials 2019, 12, 2387. https://doi.org/10.3390/ma12152387

Zhang B, Li Y, Fantuzzi N, Zhao Y, Liu Y-B, Peng B, Chen J. Investigation of the Flow Properties of CBM Based on Stochastic Fracture Network Modeling. Materials. 2019; 12(15):2387. https://doi.org/10.3390/ma12152387

Chicago/Turabian StyleZhang, Bo, Yong Li, Nicholas Fantuzzi, Yuan Zhao, Yan-Bao Liu, Bo Peng, and Jie Chen. 2019. "Investigation of the Flow Properties of CBM Based on Stochastic Fracture Network Modeling" Materials 12, no. 15: 2387. https://doi.org/10.3390/ma12152387

APA StyleZhang, B., Li, Y., Fantuzzi, N., Zhao, Y., Liu, Y.-B., Peng, B., & Chen, J. (2019). Investigation of the Flow Properties of CBM Based on Stochastic Fracture Network Modeling. Materials, 12(15), 2387. https://doi.org/10.3390/ma12152387