Experimental Research on Uniaxial Compression Constitutive Model of Hybrid Fiber-Reinforced Cementitious Composites

Abstract

1. Introduction

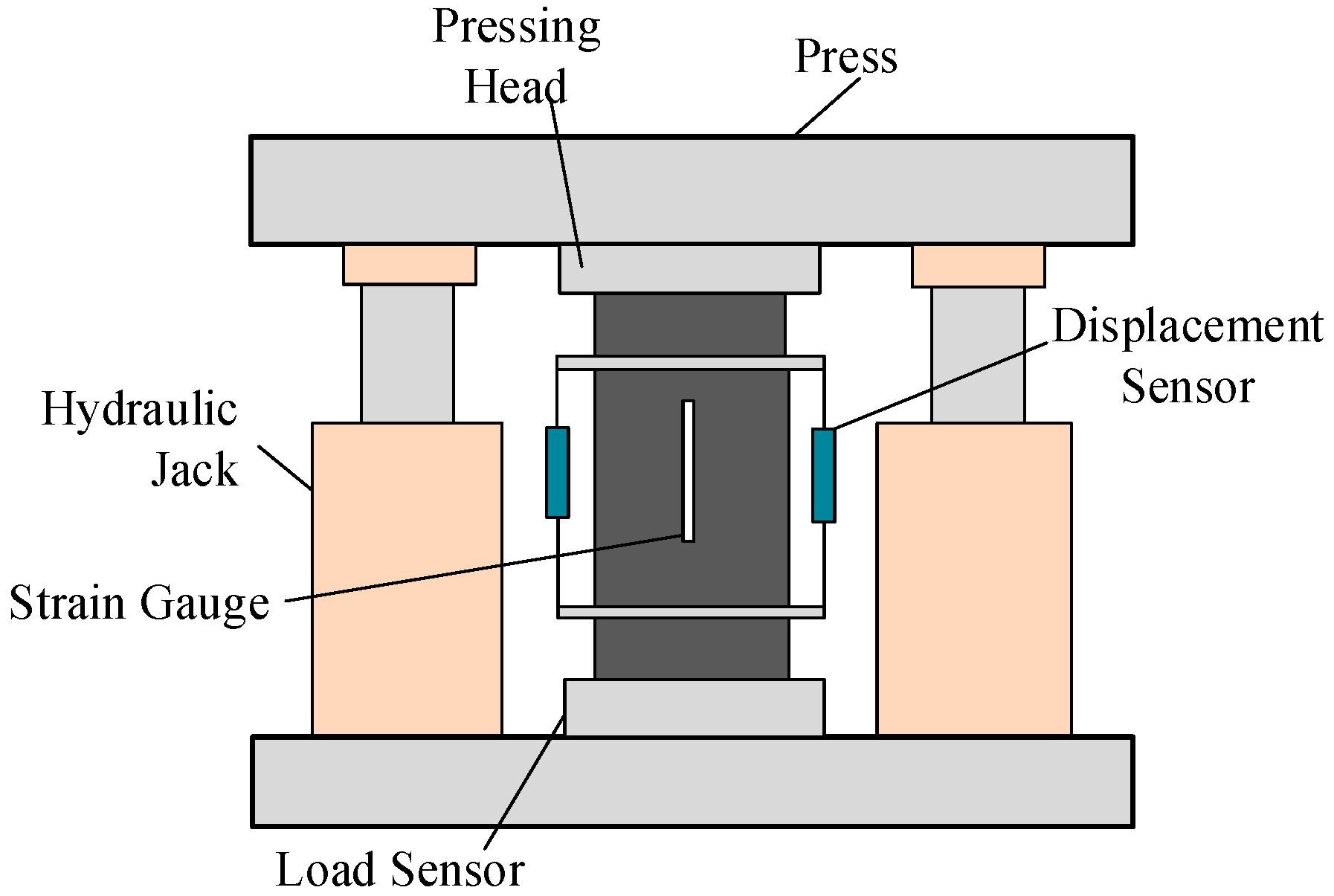

2. Experimental Program

2.1. Materials and Mix Proportions

2.2. Specimen Preparation and Maintenance

- (1)

- Cement, fly ash, and quartz sand are added in turn to the mixer according to the calculated mix proportion and dry mix for 2 min. Hybrid fibers are added slowly during the dry mixing process, ensuring that the process is even and slow.

- (2)

- After the dry mixing is completed, water and water reducer are added according to the mixing ratio and stirred in the mixer for 5 min.

- (3)

- After stirring, the HFRC slurry is poured out and loaded into the template. The process of loading into the template is as fast and uniform as possible.

- (4)

- Place the template on the shaking table and vibrate evenly. In order to prevent the segregation of concrete, the vibration time is ~30 s.

- (5)

- The specimens are demolded 24 h and cured in the standard curing room. The temperature is kept at 20 °C, the relative humidity was 95%, and the curing period was 28 days.

3. Test Results and Analysis

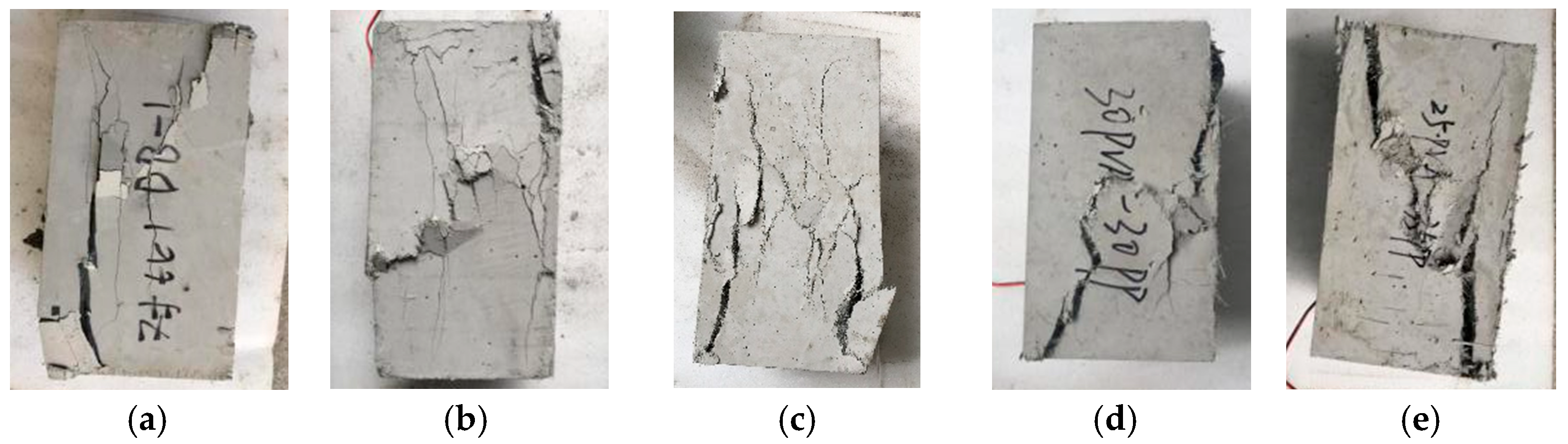

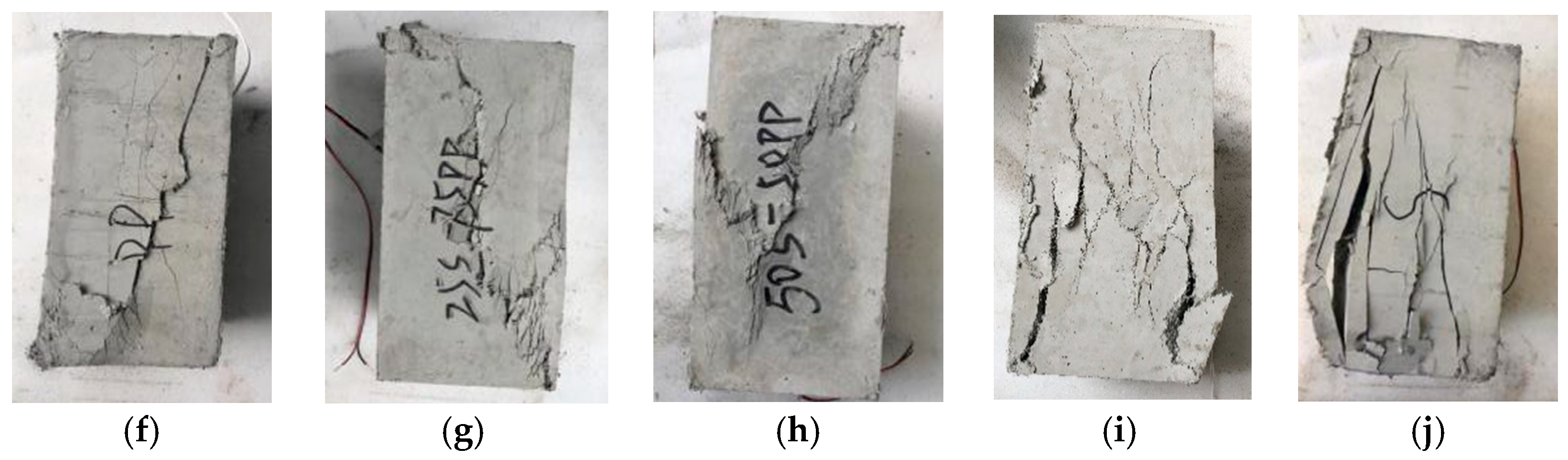

3.1. Failure Process and Failure Patterns

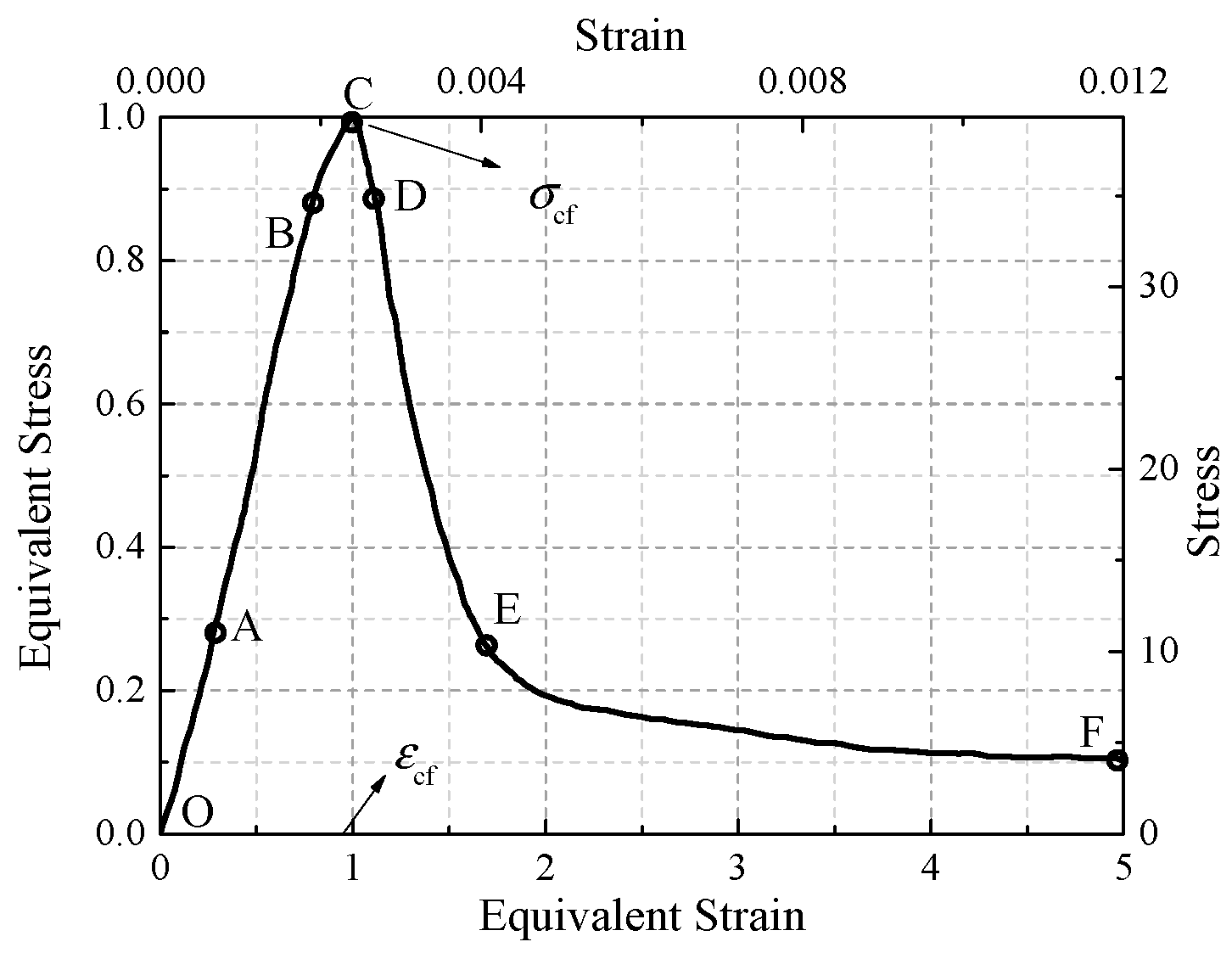

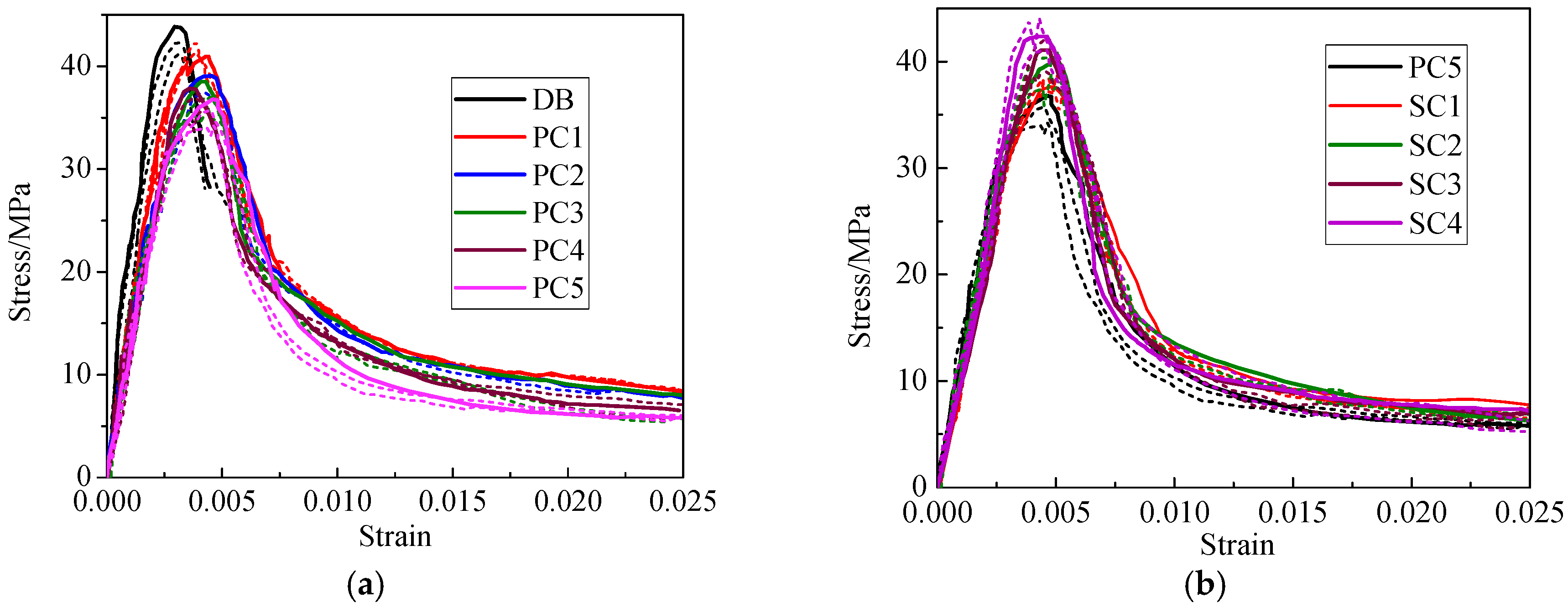

3.2. Stress-Strain Curve under Uniaxial Compression

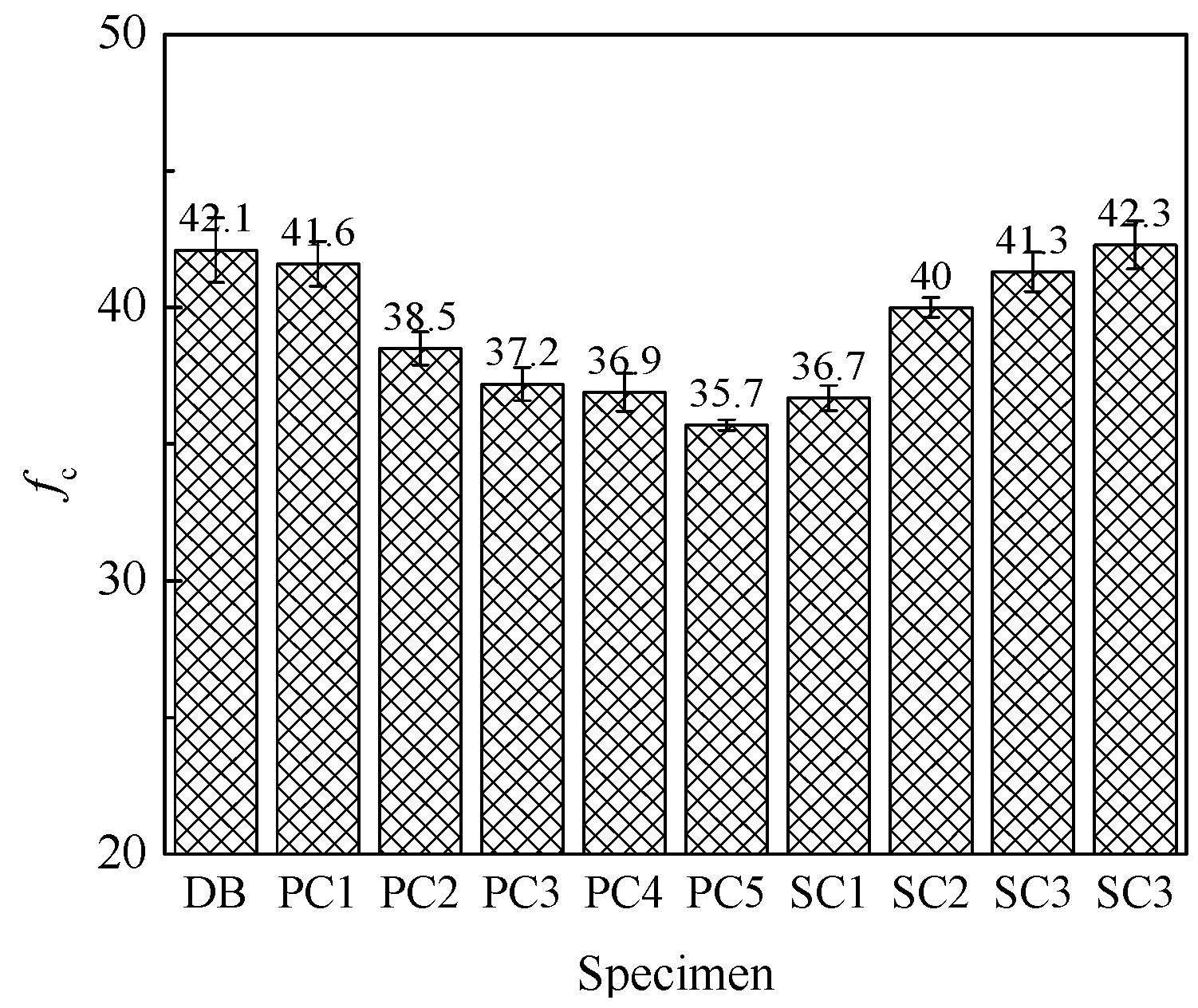

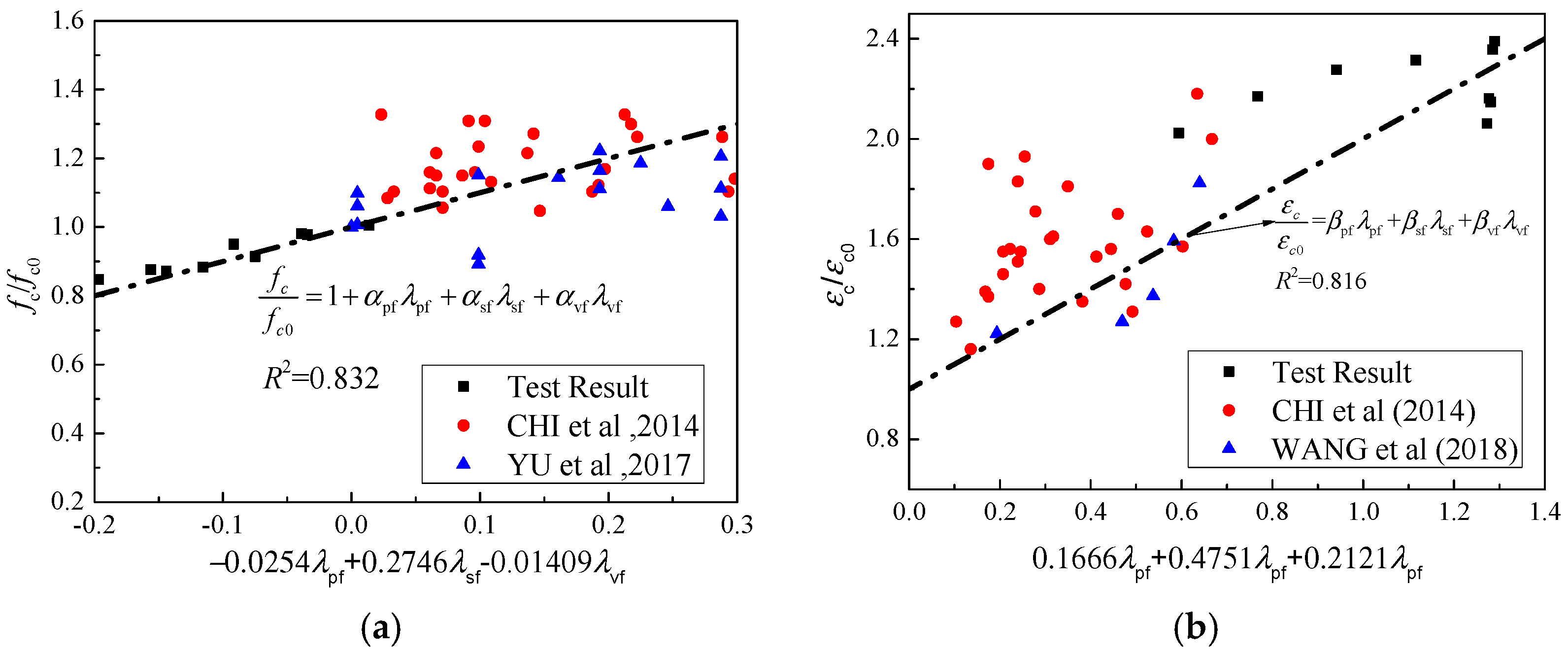

3.3. Peak Stress and Peak Strain

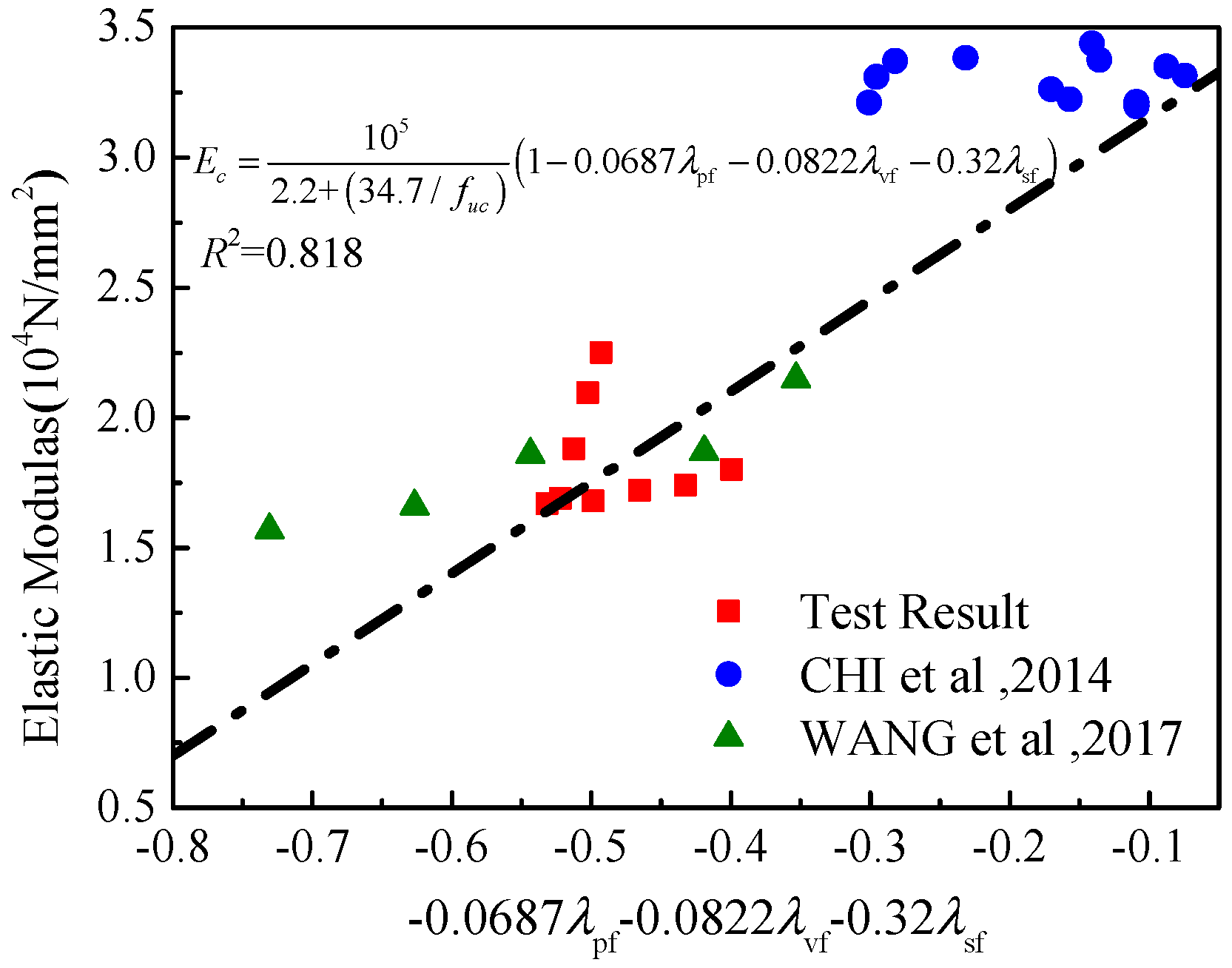

3.4. Elastic Modulus

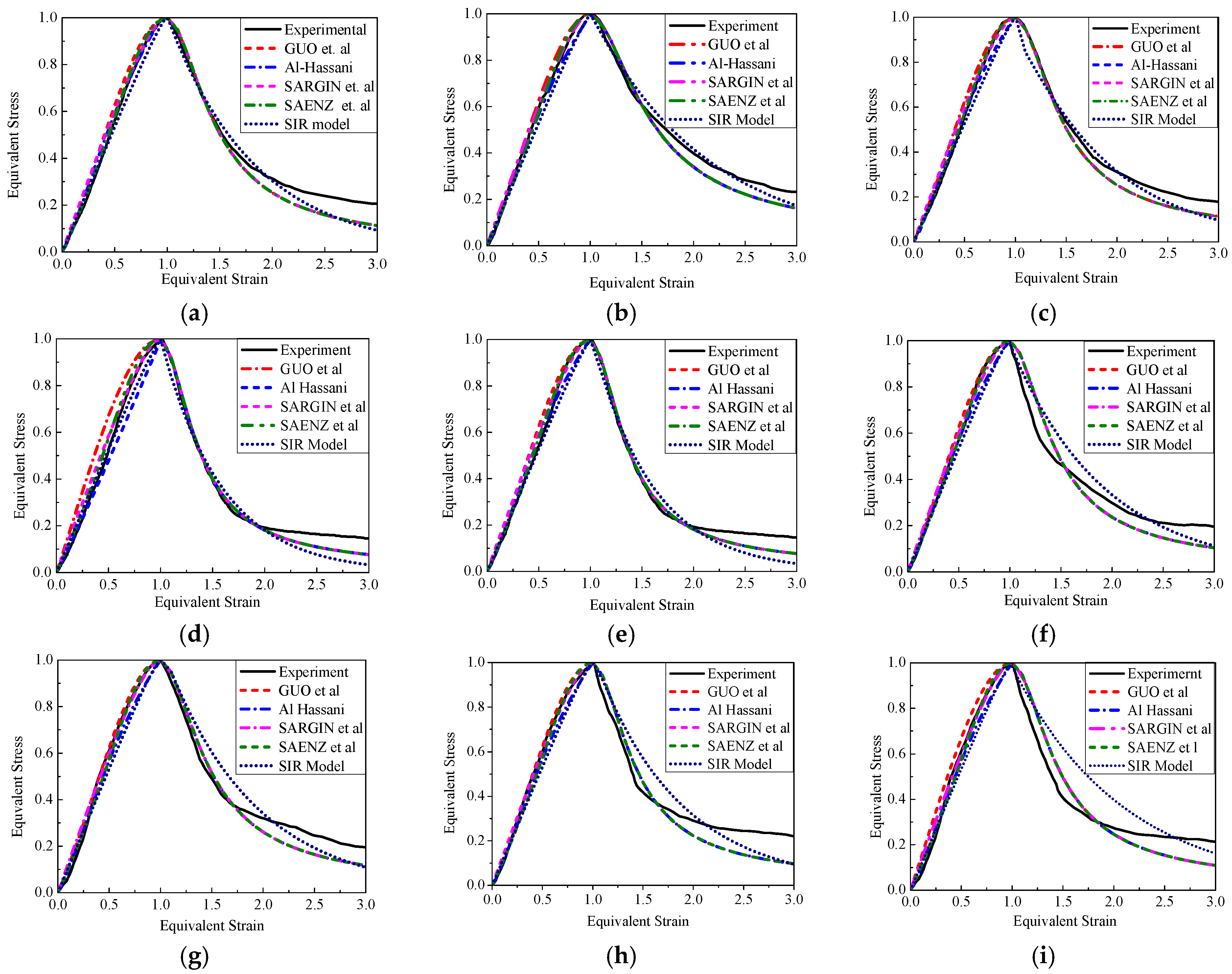

4. Stress-Strain Curve under Uniaxial Compression

4.1. Introduction of SIR Model

4.2. Forms of Stress-Strain Models

4.3. Value of Ascending Section Parameters

4.4. Descending Section Curve Equation

5. Conclusions and Prospect

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hany, N.F.; Hantouche, E.G.; Harajli, M.H. Axial Stress-Strain Model of CFRP-Confined Concrete under Monotonic and Cyclic Loading. J. Compos. Constr. 2015, 19. [Google Scholar] [CrossRef]

- Wang, F.Z.; Li, M.; Qu, Z.Y.; Hu, S.G.; Wang, J. Improvement of the FRP Sheet Bonded to Concrete Substrate by Silane Coupling Agent. J. Wuhan Univ. Technol. Mater. Sci. 2018, 33, 117–123. [Google Scholar] [CrossRef]

- Chi, Y.; Xu, L.; Yu, H. Constitutive modeling of steel-polypropylene hybrid fiber reinforced concrete using a non-associated plasticity and its numerical implementation. Compos. Struct. 2014, 111, 497–509. [Google Scholar] [CrossRef]

- Ou, Y.C.; Tsai, M.S.; Liu, K.Y.; Chang, K.C. Compressive Behavior of Steel-Fiber-Reinforced Concrete with a High Reinforcing Index. J. Mater. Civ. Eng. 2012, 24, 207–215. [Google Scholar] [CrossRef]

- Ahmed, S.F.U.; Maalej, M.; Paramasivam, P. Flexural responses of hybrid steel-polyethylene fiber reinforced cement composites containing high volume fly ash. Constr. Build. Mater. 2007, 21, 1088–1097. [Google Scholar] [CrossRef]

- Lawler, J.S.; Zampini, D.; Shah, S.P. Permeability of cracked hybrid fiber-reinforced mortar under load. ACI Mater. J. 2002, 99, 379–385. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Wang, J. Tensile performance of polyvinyl alcohol-steel hybrid fiber reinforced cementitious composite with impact of water to binder ratio. J. Compos. Mater. 2015, 49, 2169–2186. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.J.; Shi, Y.C.; Li, C.J. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Togay, O. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Qian, C.X.; Stroeven, P. Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Mei, G.; Xu, L.; Li, S.; Chi, Y. Hybrid Effects on Strength of Steel-Polypropylene Hybrid Fiber Reinforced Concrete under Uniaxial and Triaxial Compression. Appl. Mech. Mater. 2013, 268, 782–787. [Google Scholar] [CrossRef]

- Rambo, D.A.S.; Silva, F.D.A.; Filho, R.D.T. Effect of steel fiber hybridization on the fracture behavior of self-consolidating concretes. Cem. Concr. Compos. 2014, 54, 100–109. [Google Scholar] [CrossRef]

- Kang, J.; Kim, K.; Lim, Y.M.; Bolander, J.E. Modeling of fiber-reinforced cement composites: Discrete representation of fiber pullout. Int. J. Solids Struct. 2014, 51, 1970–1979. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Waldmann, D.; Bui, T.Q. Role of interfacial transition zone in phase field modeling of fracture in layered heterogeneous structures. J. Computat. Phys. 2019, 386, 585–610. [Google Scholar] [CrossRef]

- Nguyen, T.H.A.; Bui, T.Q.; Hirose, S. Smoothing gradient damage model with evolving anisotropic nonlocal interactions tailored to low-order finite elements. Comput. Methods Appl. Mech. Eng. 2017, 328. [Google Scholar] [CrossRef]

- Chi, Y.; Xu, L.; Zhang, Y. Experimental study on hybrid fiber-reinforced concrete subjected to uniaxial compression. J. Mater. Civ. Eng. 2014, 26, 211–218. [Google Scholar] [CrossRef]

- Wang, Z.; Zuo, J.; Zhang, J. Mechanical Properties of Hybrid Fiber Reinforced Engineered Cementitious Composites under Uniaxial Compression. J. Build. Mater. 2018, 21, 639–644. [Google Scholar] [CrossRef]

- Yu, J.; Zhai, T.; Liang, X. Fluidity and Mechanical Properties of Steel-PVA Fiber Reinforced Concrete. J. Build. Mater. 2018, 21, 402–407. [Google Scholar] [CrossRef]

- He, H.; Han, E.; Cong, M. Constitutive Relation of Engineering Material Based on SIR Model and HAM. J. Appl. Math. 2014, 1–13. [Google Scholar] [CrossRef]

- Guo, Z. The Strength and Deformation of Concrete-Experimental Results and Constitutive Relationship; Tsinghua University Press: Beijing, China, 2004. [Google Scholar]

- Al-Hassani, H.M.; Khalil, W.I.; Danha, L.S. Proposed Model for Uniaxial Compression Behavior of Reactive Powder Concrete. J. Babylon Univ. Eng. Sci. 2015, 23, 591–606. [Google Scholar]

| Code | Cement kg/m3 | Fly Ash kg/m3 | Quartz Sand kg/m3 | Water kg/m3 | Water Reducing g/m3 | PVA Fiber/% | PP Fiber/% | Steel Fiber/% |

|---|---|---|---|---|---|---|---|---|

| DB | 475 | 710 | 415 | 400 | 35 | - | - | - |

| PC1 | 475 | 710 | 415 | 400 | 35 | 2 | - | - |

| PC2 | 475 | 710 | 415 | 400 | 35 | 1.5 | 0.5 | - |

| PC3 | 475 | 710 | 415 | 400 | 35 | 1 | 1 | - |

| PC4 | 475 | 710 | 415 | 400 | 35 | 0.5 | 1.5 | - |

| PC5 | 475 | 710 | 415 | 400 | 35 | - | 2 | - |

| SC1 | 475 | 710 | 415 | 400 | 35 | - | - | 2 |

| SC2 | 475 | 710 | 415 | 400 | 35 | - | 0.5 | 1.5 |

| SC3 | 475 | 710 | 415 | 400 | 35 | - | 1 | 1 |

| SC4 | 475 | 710 | 415 | 400 | 35 | - | 1.5 | 0.5 |

| Component | SiO2 | CaO | Al2O3 | Fe2O3 | MgO | SO3 | Oher | Loss |

|---|---|---|---|---|---|---|---|---|

| Mass Percent | 21.69 | 62.55 | 4.38 | 3.34 | 2.08 | 2.89 | 1.41 | 1.59 |

| Code | fcu | fc0 | ff | εc0/% | εf/% | ε0.85/% | E0 | Ef0 |

|---|---|---|---|---|---|---|---|---|

| DB | 55.6 | 42.1 | 42.1 | 1.80 | 1.80 | - | 2.27 | - |

| PC1 | 52.8 | 41.2 | 41.8 | 4.25 | 4.34 | 5.03 | 1.79 | 1.78 |

| PC2 | 50.0 | 38.5 | 39.1 | 4.57 | 4.64 | 5.32 | 1.73 | 1.72 |

| PC3 | 47.9 | 37.2 | 37.5 | 4.78 | 4.77 | 5.48 | 1.67 | 1.68 |

| PC4 | 46.1 | 36.9 | 36.2 | 4.86 | 4.80 | 5.45 | 1.71 | 1.76 |

| PC5 | 45.2 | 35.7 | 35.1 | 5.02 | 4.97 | 5.59 | 1.66 | 1.63 |

| SC1 | 47.6 | 36.7 | 36.8 | 4.95 | 4.92 | 5.50 | 1.68 | 1.62 |

| SC2 | 50.6 | 40.0 | 40.2 | 4.51 | 4.73 | 5.51 | 1.87 | 1.90 |

| SC3 | 53.6 | 41.3 | 41.1 | 4.54 | 4.42 | 5.23 | 2.12 | 2.15 |

| SC4 | 54.1 | 42.3 | 42.4 | 4.33 | 4.24 | 5.11 | 2.21 | 2.22 |

| Expression Form | Formula Source | Expression |

|---|---|---|

| Polynomial | Guo [20] | |

| Rational fraction | Sargin, et al. [20] | |

| Al-Hassani [21] | ||

| Saenz, et al. [20] | ||

| Exponential | SIR Model [19] |

| Stage | Source | Parameter | PC1 | PC2 | PC3 | PC4 | PC5 | SC1 | SC2 | SC3 | SC4 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ascending Section | Guo, et al. [20] | A | 1.337 | 1.466 | 1.578 | 2.371 | 1.420 | 1.405 | 1.387 | 1.391 | 1.42 |

| R2 | 0.987 | 0.991 | 0.986 | 0.989 | 0.981 | 0.981 | 0.979 | 0.984 | 0.977 | ||

| Al-Hassani [21] | a | 0.021 | 0.038 | 0.087 | 0.071 | 0.032 | 0.098 | 0.087 | 0.0135 | 0.045 | |

| b | 1.37 | 1.62 | 1.81 | 1.97 | 2.29 | 1.76 | 1.88 | 1.21 | 1.73 | ||

| c | 2.08 | 7.93 | 93.11 | 23.98 | 108.67 | 20.18 | 90.19 | 65.10 | 81.09 | ||

| d | 1.45 | 1.98 | 1.99 | 2.01 | 2.34 | 1.97 | 2.09 | 1.43 | 1.92 | ||

| R2 | 0.993 | 0.994 | 0.996 | 0.996 | 0.995 | 0.993 | 0.996 | 0.995 | 0.995 | ||

| Sargin, et al. [20] | A | 1.253 | 1.281 | 1.312 | 1.378 | 1.431 | 1.409 | 1.377 | 1.365 | 1.309 | |

| R2 | 0.994 | 0.993 | 0.995 | 0.993 | 0.995 | 0.992 | 0.996 | 0.994 | 0.993 | ||

| Saenz, et al. [20] | A | 1.094 | 1.117 | 1.181 | 1.277 | 1.295 | 1.247 | 1.234 | 1.212 | 1.197 | |

| R2 | 0.994 | 0.995 | 0.995 | 0.994 | 0.994 | 0.995 | 0.994 | 0.996 | 0.994 | ||

| SIR Model [19] | a | −1.92 | −2.02 | 1.43 | −1.87 | −2.34 | −2.91 | −2.65 | −2.22 | −1.89 | |

| b | −1.32 | −1.51 | 1.98 | −1.28 | −1.99 | −2.10 | −2.19 | −1.62 | −1.21 | ||

| c | 19.21 | 21.21 | 16.92 | 28.87 | 22.11 | 17.87 | 26.76 | 24.12 | 31.11 | ||

| R2 | 0.992 | 0.995 | 0.995 | 0.993 | 0.995 | 0.994 | 0.994 | 0.995 | 0.996 | ||

| Descending Section | Guo, et al. [20] | B | 9.06 | 3.36 | 4.91 | 5.08 | 18.31 | 6.41 | 7.62 | 6.98 | 5.41 |

| R2 | 0.968 | 0.980 | 0.974 | 0.961 | 0.959 | 0.946 | 0.942 | 0.934 | 0.971 | ||

| SIR Model [19] | a | −22.07 | −10.8 | −1.18 | −2.14 | −2.31 | −1.06 | −1.25 | −1.19 | −1.12 | |

| b | −19.7 | −22.6 | −22.1 | −21.4 | −22.38 | −21.8 | −21.2 | −22.1 | −22.4 | ||

| c | −6.09 | 2.43 | 3.41 | −3.31 | 9.80 | 2.55 | 3.34 | 3.10 | 2.98 | ||

| R2 | 0.971 | 0.988 | 0.985 | 0.975 | 0.967 | 0.975 | 0.972 | 0.964 | 0.945 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, T.; He, H.; Yan, W. Experimental Research on Uniaxial Compression Constitutive Model of Hybrid Fiber-Reinforced Cementitious Composites. Materials 2019, 12, 2370. https://doi.org/10.3390/ma12152370

Cui T, He H, Yan W. Experimental Research on Uniaxial Compression Constitutive Model of Hybrid Fiber-Reinforced Cementitious Composites. Materials. 2019; 12(15):2370. https://doi.org/10.3390/ma12152370

Chicago/Turabian StyleCui, Tao, Haoxiang He, and Weiming Yan. 2019. "Experimental Research on Uniaxial Compression Constitutive Model of Hybrid Fiber-Reinforced Cementitious Composites" Materials 12, no. 15: 2370. https://doi.org/10.3390/ma12152370

APA StyleCui, T., He, H., & Yan, W. (2019). Experimental Research on Uniaxial Compression Constitutive Model of Hybrid Fiber-Reinforced Cementitious Composites. Materials, 12(15), 2370. https://doi.org/10.3390/ma12152370