Sustainable, Fluorine-Free, Low Cost and Easily Processable Materials for Hydrophobic Coatings on Flexible Plastic Substrates

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents and Substrates

2.2. Deposition Technique

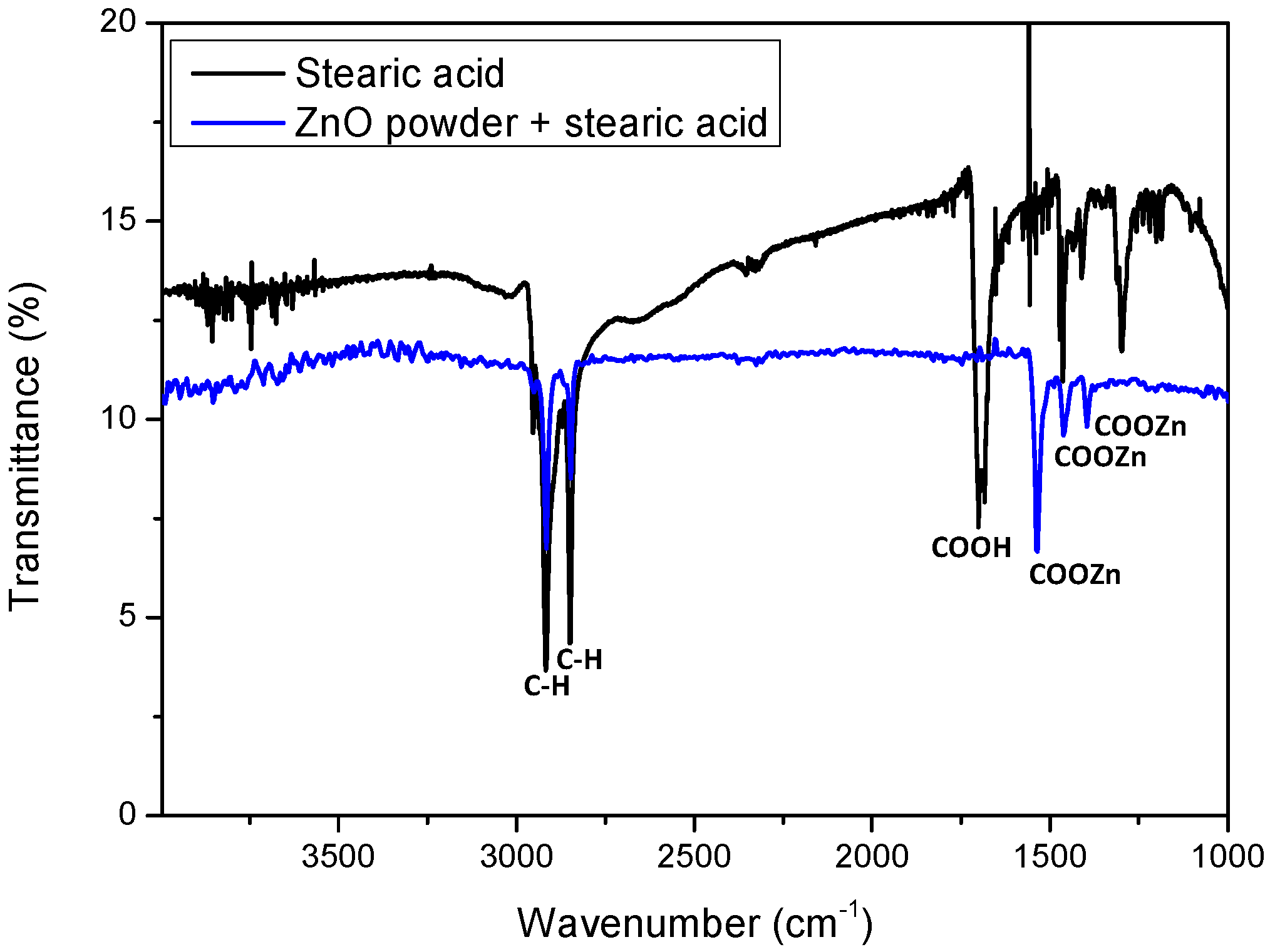

2.3. ZnO Nanopowder Functionalization with Stearic Acid

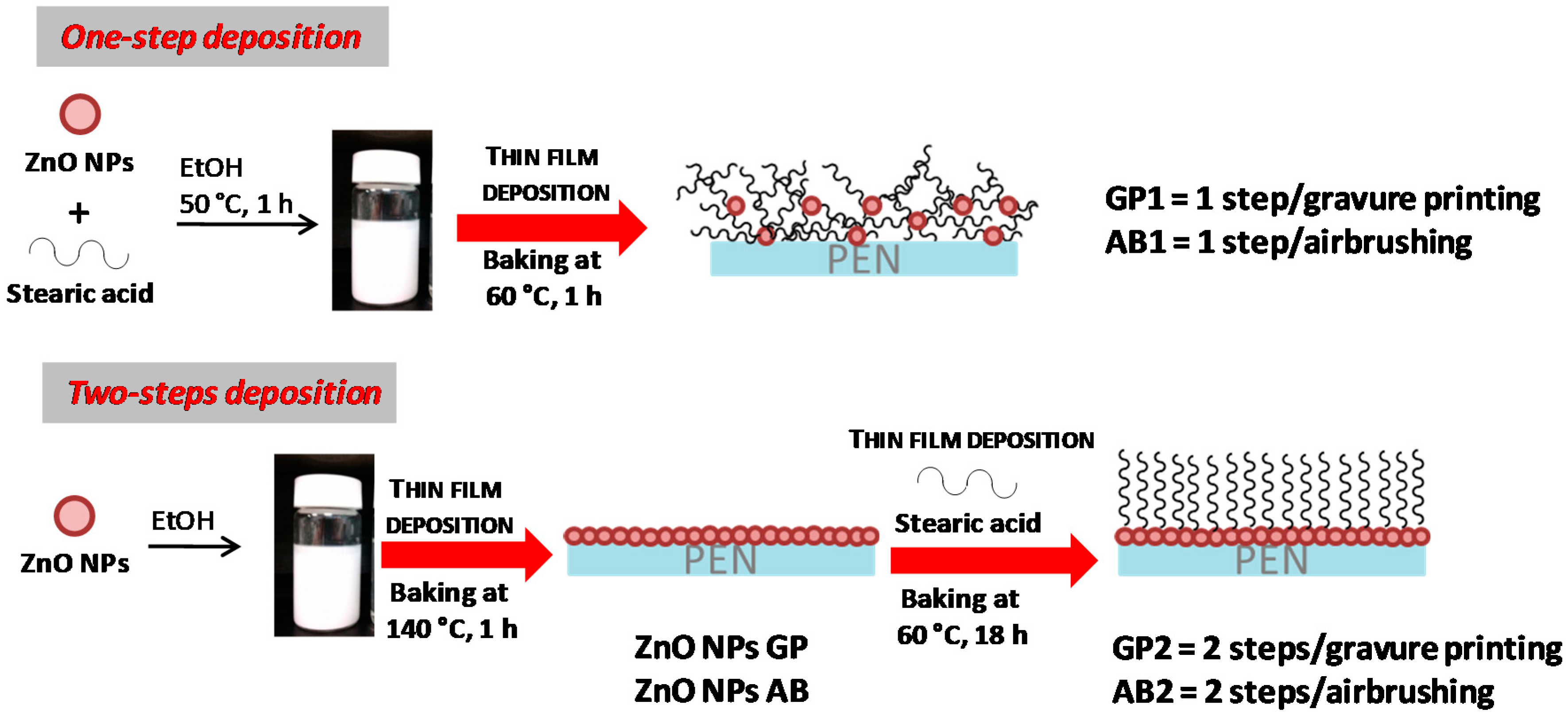

2.4. One-Step Deposition Process

2.5. Two-Steps Deposition Process

2.6. Characterizations

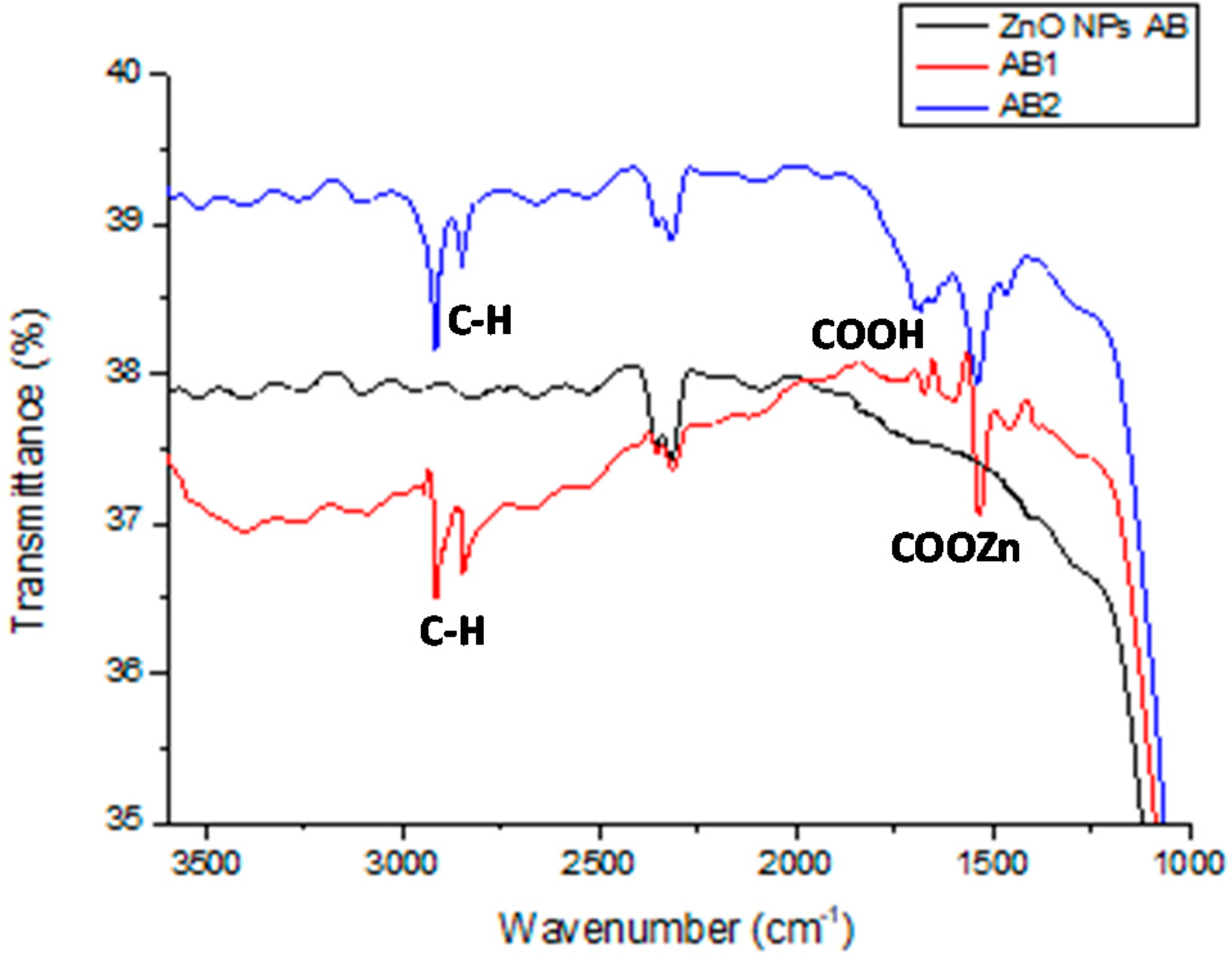

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rolland, J.P.; Van Dam, R.M.; Schorzman, D.A.; Quake, S.R.; DeSimone, J.M. Solvent-resistant photocurable “liquid teflon” for microfluidic device fabrication. J. Am. Chem. Soc. 2004, 126, 2322–2323. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Sathasivam, S.; Song, J.; Crick, C.R.; Carmalt, C.J.; Parkin, I.P. Robust self-cleaning surfaces that function when exposed to either air or oil. Science 2015, 347, 1132–1135. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Hongtao, L.; Wei, Z. Preparation of anti-corrosion superhydrophobic coatings by an Fe-based micro/nano composite electro-brush plating and blackening process. RSC Adv. 2015, 5, 103000–103012. [Google Scholar] [CrossRef]

- Huang, J.; Wei, S.; Zhang, L.; Yang, Y.; Yang, S.; Shen, Z. Fabricating the superhydrophobic nickel and improving its antifriction performance by the laser surface texturing. Materials 2019, 12, 1155. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Sheng, X.; Jiang, L. The dewetting properties of lotus leaves. Langmuir 2009, 25, 1371–1376. [Google Scholar] [CrossRef] [PubMed]

- Maity, J.; Kothary, P.; O’Rear, E.A.; Jacob, C. Preparation and comparison of hydrophobic cotton fabric obtained by direct fluorination and admicellar polymerization of fluoromonomers. Ind. Eng. Chem. Res. 2010, 49, 6075–6079. [Google Scholar] [CrossRef]

- Esmeryan, K.D.; Avramova, I.A.; Castano, C.E.; Ivanova, I.A.; Mohammadi, R.; Radeva, E.I.; Stoyanova, D.S.; Vladkova, T.G. Early stage anti-bioadhesion behavior of superhydrophobic soot based coatings towards Pseudomonas putida. Mater. Des. 2018, 160, 395–404. [Google Scholar] [CrossRef]

- Yamamoto, M.; Nishikawa, N.; Mayama, H.; Nonomura, Y.; Yokojima, S.; Nakamura, S.; Uchida, K. Theoretical explanation of the lotus effect: Superhydrophobic property changes by removal of nanostructures from the surface of a lotus leaf. Langmuir 2015, 31, 7355–7363. [Google Scholar] [CrossRef] [PubMed]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Brassard, J.-D.; Sarkar, D.K.; Perron, J. Fluorine based superhydrophobic coatings. Appl. Sci. 2012, 2, 453–464. [Google Scholar] [CrossRef]

- Esmeryan, K.D.; Castano, C.E.; Bresslera, A.H.; Abolghasemibizakia, M.; Mohammadi, R. Rapid synthesis of inherently robust and stable superhydrophobic carbon soot coatings. Appl. Surf. Sci. 2016, 369, 341–347. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, P.; Qian, L.; Xiao, H. Fabrication of superhydrophobic paper surface via wax mixture coating. Chem. Eng. J. 2014, 250, 431–436. [Google Scholar] [CrossRef]

- Hu, Z.; Deng, Y. Superhydrophobic surface fabricated from fatty acid-modified precipitated calcium carbonate. Ind. Eng. Chem. Res. 2010, 49, 5625–5630. [Google Scholar] [CrossRef]

- Su, X.; Li, H.; Lai, X.; Zhang, L.; Liang, T.; Feng, Y.; Zeng, X. Polydimethylsiloxane-based superhydrophobic surfaces on steel substrate: Fabrication, reversibly extreme wettability and oil–water separation. ACS Appl. Mater. Interfaces 2017, 9, 3131–3141. [Google Scholar] [CrossRef] [PubMed]

- Onda, T.; Shibuichi, S.; Satoh, N.; Tsujii, K. Super-water-repellent fractal surfaces. Langmuir 1996, 12, 2125–2127. [Google Scholar] [CrossRef]

- Lau, C.; Anitole, K.; Hodes, C.; Lai, D.; Pfahles-Hutchens, A.; Seed, J. Perfluoroalkyl acids: A review of monitoring and toxicological findings. Toxicol. Sci. 2007, 99, 366–394. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the sacred lotus or escape from contamination in biological surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Gurav, A.B.; Xu, Q.; Latthe, S.S.; Vhatkar, R.S.; Liu, S.; Yoon, H.; Yoon, H.S. Superhydrophobic coatings prepared from methyl-modified silica particles using simple dip-coating method. Ceram. Int. 2015, 41, 3017–3023. [Google Scholar] [CrossRef]

- Lee, M.; Kwak, G.; Yong, K. Wettability control of ZnO nanoparticles for universal applications. ACS Appl. Mater. Interfaces 2011, 3, 3350–3356. [Google Scholar] [CrossRef]

- Kołodziejczak-Radzimska, A.; Jesionowski, T. Zinc oxide—From synthesis to application: A review. Materials 2014, 7, 2833–2881. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, B.; Xu, C. Fabrication of superhydrophobic surface of hierarchical ZnO thin films by using stearic acid. Superlattices Microstruct. 2012, 51, 128–134. [Google Scholar] [CrossRef]

- Rezayi, T.; Entezari, M.H. Wettability properties vary with different morphologies of ZnO nanoparticles deposited on glass and modified by stearic acid. New J. Chem. 2016, 40, 2582–2591. [Google Scholar] [CrossRef]

- Gurav, A.B.; Latthe, S.S.; Vhatkar, R.S.; Lee, J.; Kim, D.; Park, J.; Yoon, S.S. Superhydrophobic surface decorated with vertical ZnO nanorodsmodified by stearic acid. Ceram. Int. 2014, 40, 7151–7160. [Google Scholar] [CrossRef]

- Qing, Y.; Yang, C.; Sun, Y.; Zheng, Y.; Shang, Y.; Liu, C. Simple method for preparing ZnO superhydrophobic surfaces with micro/nano roughness. J. Adhes. Sci. Technol. 2015, 29, 2153–2159. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Z.; Liu, J.; Lei, E.; Liu, Z. Effects of seed layers on controlling of the morphology of ZnO nanostructures and superhydrophobicity of ZnO nanostructure/stearic acid composite films. Mater. Chem. Phys. 2016, 183, 306–314. [Google Scholar] [CrossRef]

- Xu, C.-L.; Wang, Y.-Z. Self-assembly of stearic acid into nano flowers induces the tunable surface wettability of polyimide film. Mater. Des. 2018, 138, 30–38. [Google Scholar] [CrossRef]

- Ramesh, M.; Boopathi, K.M.; Huang, T.-Y.; Huang, Y.-C.; Tsao, C.-S.; Chu, C.-W. Using an airbrush pen for layer-by-layer growth of continuous perovskite thin films for hybrid solar cells. ACS Appl. Mater. Interfaces 2015, 7, 2359–2366. [Google Scholar] [CrossRef]

- Kopola, P.; Aernouts, T.; Guillerez, S.; Jin, H.; Tuomikoski, M.; Maaninen, A.; Hast, J. High efficient plastic solar cells fabricated with a high-throughput gravure printing method. Sol. Energy Mater. Sol. Cells 2010, 94, 1673–1680. [Google Scholar] [CrossRef]

- Sico, G.; Montanino, M.; Tania, C.; De Girolamo, A.; Mauro, D.; Minarini, C. Gravure printing for thin film ceramics manufacturing from nanoparticles. Ceram. Int. 2018, 44, 19526–19534. [Google Scholar] [CrossRef]

- Hong, R.; Pan, T.; Qian, J.; Li, H. Synthesis and surface modification of ZnO nanoparticles. Chem. Eng. J. 2006, 119, 71–81. [Google Scholar] [CrossRef]

- Shang, J.; Flury, M.; Harsh, J.B.; Zollars, R.L. Comparison of different methods to measure contact angles of soil colloids. J. Colloid Interface Sci. 2008, 328, 299–307. [Google Scholar] [CrossRef] [PubMed]

- Paetzold, R.; Winnacker, A.; Henseler, D.; Cesari, V.; Heuser, K. Permeation rate measurements by electrical analysis of calcium corrosion. Rev. Sci. Instrum. 2003, 74, 5147–5150. [Google Scholar] [CrossRef]

- Santoro, E.; Aprano, S.; Sico, G.; Fiorillo, M.R.; Maglione, M.G.; Tassini, P.; Rubino, A.; Minarini, C. Evaluation of the stability of different encapsulated blue OLEDs. In Proceedings of the Fotonica AEIT Italian Conference on Photonics technologies, Turin, Italy, 6–8 May 2015. [Google Scholar]

- Tang, E.; Cheng, G.; Ma, X. Preparation of nano-ZnO/PMMA composite particles via grafting of the copolymer onto the surface of zinc oxide nanoparticles. Powder Technol. 2006, 161, 209–214. [Google Scholar] [CrossRef]

- Susanna, G.; Salamandra, L.; Brown, T.M.; Di Carlo, A.; Brunetti, F.; Reale, A. Airbrush spray-coating of polymer bulk-heterojunction solar cells. Sol. Energy Mater. Sol. Cells 2011, 95, 1775–1778. [Google Scholar] [CrossRef]

- Reale, A.; LaNotte, L.; Salamandra, L.; Polino, G.; Susanna, G.; Brown, T.M.; Brunetti, F.; DiCarlo, A. Spray coating for polymer solar cells: An up-to-date overview. Energy Technol. 2015, 3, 385–406. [Google Scholar] [CrossRef]

- Kuan, C.Y.; Hon, M.H.; Chou, J.M.; Leu, I.C. Wetting characteristics on micro/nanostructured zinc oxide coatings. J. Electrochem. Soc. 2009, 156, 32–36. [Google Scholar] [CrossRef]

- Myint, M.T.Z.; Kumar, N.S.; Hornyak, G.L.; Dutta, J. Hydrophobic/hydrophilic switching on zinc oxide micro-textured surface. Appl. Surf. Sci. 2013, 264, 344–348. [Google Scholar] [CrossRef]

- Graff, G.L.; Williford, R.E.; Burrows, P.E. Mechanisms of vapor permeation through multilayer barrier films: Lag time versus equilibrium permeation. J. Appl. Phys. 2004, 96, 1840–1849. [Google Scholar] [CrossRef]

- Majee, S.; Cerqueira, M.F.; Tondelier, D.; Geffroy, B.; Bonnassieux, Y.; Alpuim, P.; Bourée, J.E. The effect of argon plasma treatment on the permeation barrier properties of silicon nitride layers. Surf. Coat. Technol. 2013, 235, 361–366. [Google Scholar] [CrossRef]

- Klumbies, H.; Müller-Meskamp, L.; Nehm, F.; Leo, K. Note: Influence of calcium corrosion on the performance of an adjacent permeation barrier. Rev. Sci. Instrum. 2014, 85, 16104. [Google Scholar] [CrossRef] [PubMed]

- Bülow, T.; Gargouri, H.; Siebert, M.; Rudolph, R.; Johannes, H.-H.; Kowalsky, W. Moisture barrier properties of thin organic-inorganic multilayers prepared by plasma-enhanced ALD and CVD in one reactor. Nanoscale Res. Lett. 2014, 9, 223. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Rastogi, V.K.; Samyn, P. Bio-based coatings for paper applications. Coatings 2015, 5, 887–930. [Google Scholar] [CrossRef]

- Wu, H.-Y.; Liu, T.-X.; Hsu, C.-H.; Cho, Y.-S.; Xu, Z.-J.; Liao, S.-C.; Zeng, B.-H.; Jiang, Y.-L.; Lien, S.-Y. Thin-film coated plastic wrap for food packaging. Materials 2017, 10, 821. [Google Scholar] [CrossRef] [PubMed]

- Findenig, G.; Leimgruber, S.; Kargl, R.; Spirk, S.; Stana-Kleinschek, K.; Ribitsch, V. Creating water vapor barrier coatings from hydrophilic components. ACS Appl. Mater. Interfaces 2012, 4, 3199–3206. [Google Scholar] [CrossRef] [PubMed]

- Yadav, J.; Datta, M.; Gour, V.S. Developing hydrophobic paper as a packaging material using epicuticular wax: A sustainable approach. BioResources 2014, 9, 5066–5072. [Google Scholar] [CrossRef][Green Version]

| Optical Transmittance (%, @400–800 nm) | Thickness (nm) | Roughness (Sq, nm) | |

|---|---|---|---|

| PEN | 99–98 | - | 12.3 ± 2.2 |

| ZnONPs (GP) | 99–98 | 232 ± 10 | 10.6 ± 1.6 |

| ZnONPs (AB) | 99–98 | 115 ± 15 | 8.4 ± 1.2 |

| GP2 | 98–97 | 305 ± 12 | 12.1 ± 1.5 |

| AB2 | 99–98 | 160 ± 24 | 10.3 ± 2.2 |

| GP1 | 99–98 | 240 ± 11 | 13.3 ± 1.8 |

| AB1 | 99–98 | 140 ± 21 | 14.2 ± 1.7 |

| Water Contact Angle (°) | Contact Angle Image | |

|---|---|---|

| PEN | 68 ± 5 |  |

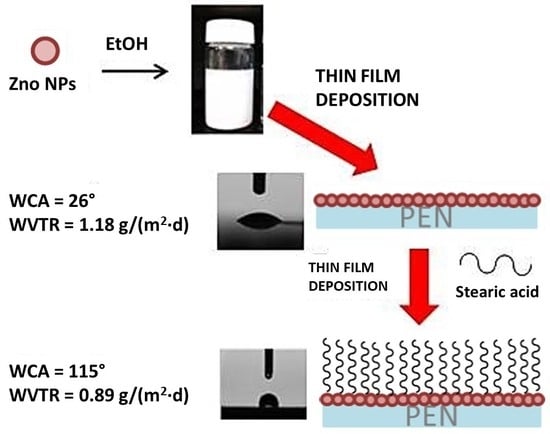

| ZnONPs (GP) | 26 ± 4 |  |

| ZnONPs (AB) | 100 ± 3 |  |

| GP2 | 115 ± 4 |  |

| AB2 | 102 ± 6 |  |

| GP1 | 99 ± 3 |  |

| AB1 | 95 ± 6 |  |

| WVTR (g/(m2·d)) | Lag Time (h) | |

|---|---|---|

| PEN | 1.58 ±0.13 | 1.51 ± 0.32 |

| ZnONPs (GP) | 1.18 ± 0.11 | 2.13 ± 0.45 |

| ZnONPs (AB) | 1.24 ± 0.15 | 2.33 ± 0.41 |

| GP2 | 1.27 ± 0.18 | 2.47 ± 0.28 |

| AB2 | 1.02 ± 0.20 | 2.26 ± 0.33 |

| GP1 | 0.89 ± 0.16 | 2.63 ± 0.38 |

| AB1 | 0.96 ± 0.21 | 2.98 ± 0.42 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prontera, C.T.; Sico, G.; Montanino, M.; De Girolamo Del Mauro, A.; Tassini, P.; Maglione, M.G.; Minarini, C.; Manini, P. Sustainable, Fluorine-Free, Low Cost and Easily Processable Materials for Hydrophobic Coatings on Flexible Plastic Substrates. Materials 2019, 12, 2234. https://doi.org/10.3390/ma12142234

Prontera CT, Sico G, Montanino M, De Girolamo Del Mauro A, Tassini P, Maglione MG, Minarini C, Manini P. Sustainable, Fluorine-Free, Low Cost and Easily Processable Materials for Hydrophobic Coatings on Flexible Plastic Substrates. Materials. 2019; 12(14):2234. https://doi.org/10.3390/ma12142234

Chicago/Turabian StyleProntera, Carmela T., Giuliano Sico, Maria Montanino, Anna De Girolamo Del Mauro, Paolo Tassini, Maria G. Maglione, Carla Minarini, and Paola Manini. 2019. "Sustainable, Fluorine-Free, Low Cost and Easily Processable Materials for Hydrophobic Coatings on Flexible Plastic Substrates" Materials 12, no. 14: 2234. https://doi.org/10.3390/ma12142234

APA StyleProntera, C. T., Sico, G., Montanino, M., De Girolamo Del Mauro, A., Tassini, P., Maglione, M. G., Minarini, C., & Manini, P. (2019). Sustainable, Fluorine-Free, Low Cost and Easily Processable Materials for Hydrophobic Coatings on Flexible Plastic Substrates. Materials, 12(14), 2234. https://doi.org/10.3390/ma12142234