An Experimental Study on Micro-Milling of a Medical Grade Co-Cr-Mo Alloy Produced by Selective Laser Melting

Abstract

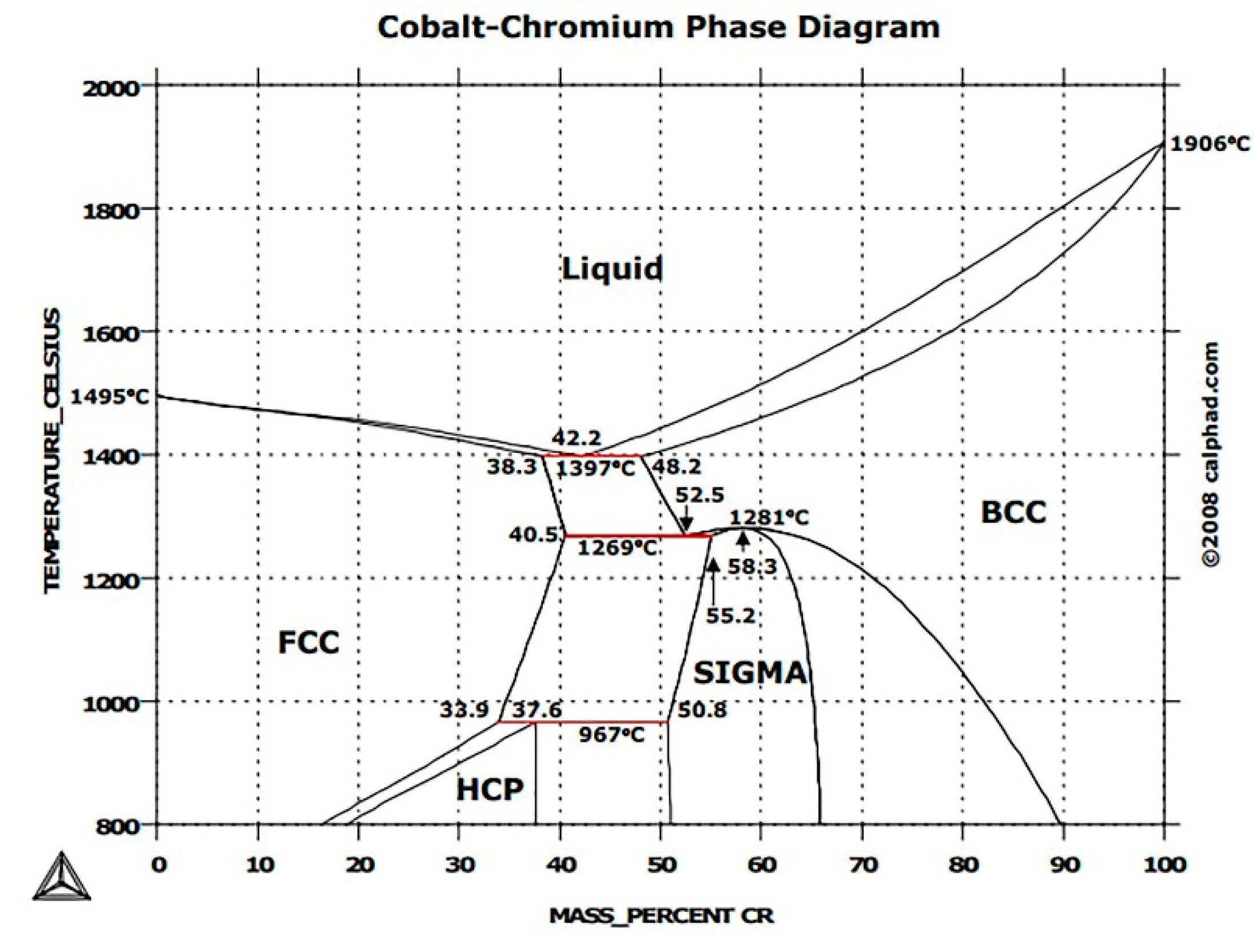

1. Introduction

2. Materials and Methods

3. Experimental Tests

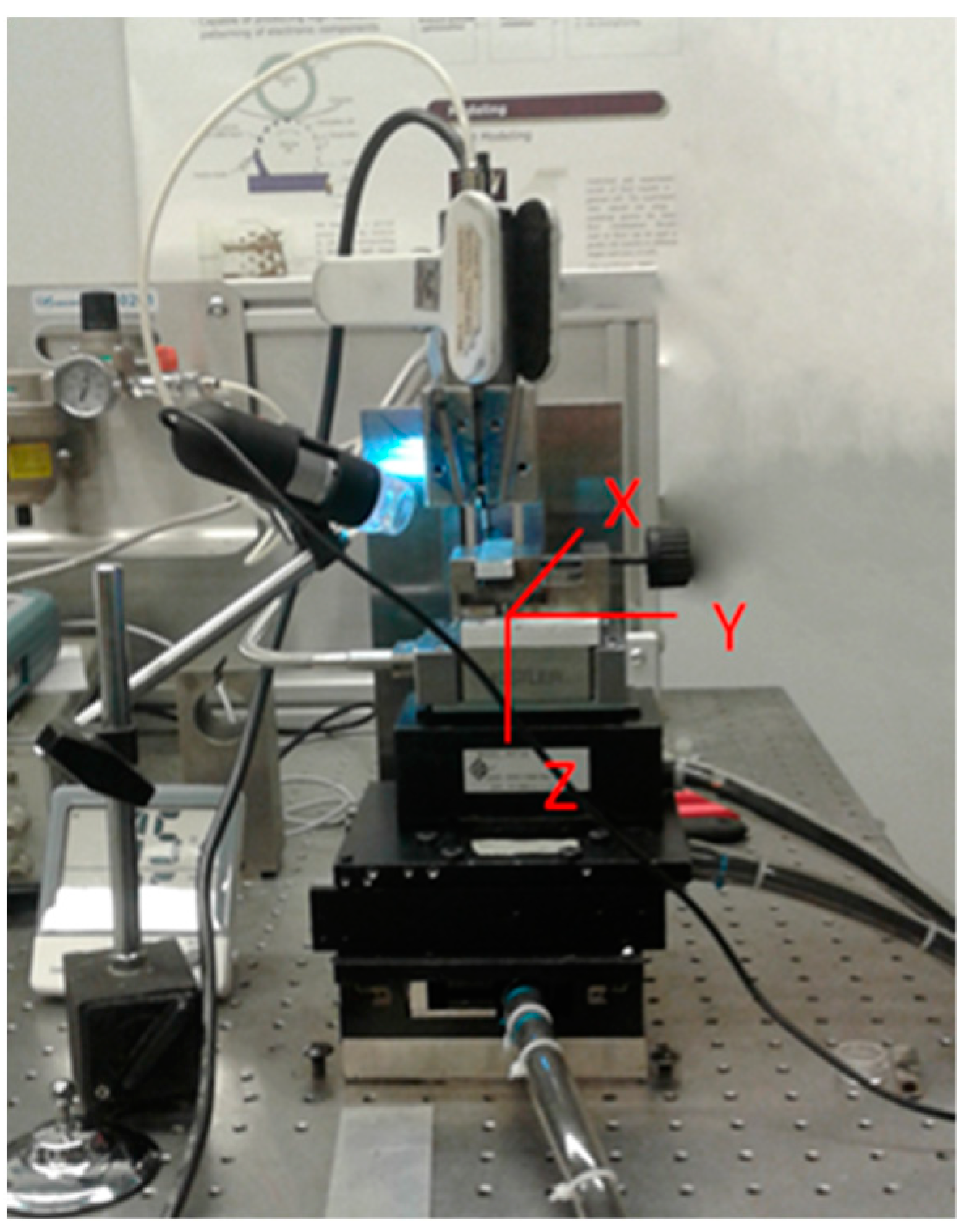

3.1. Preliminary Tests

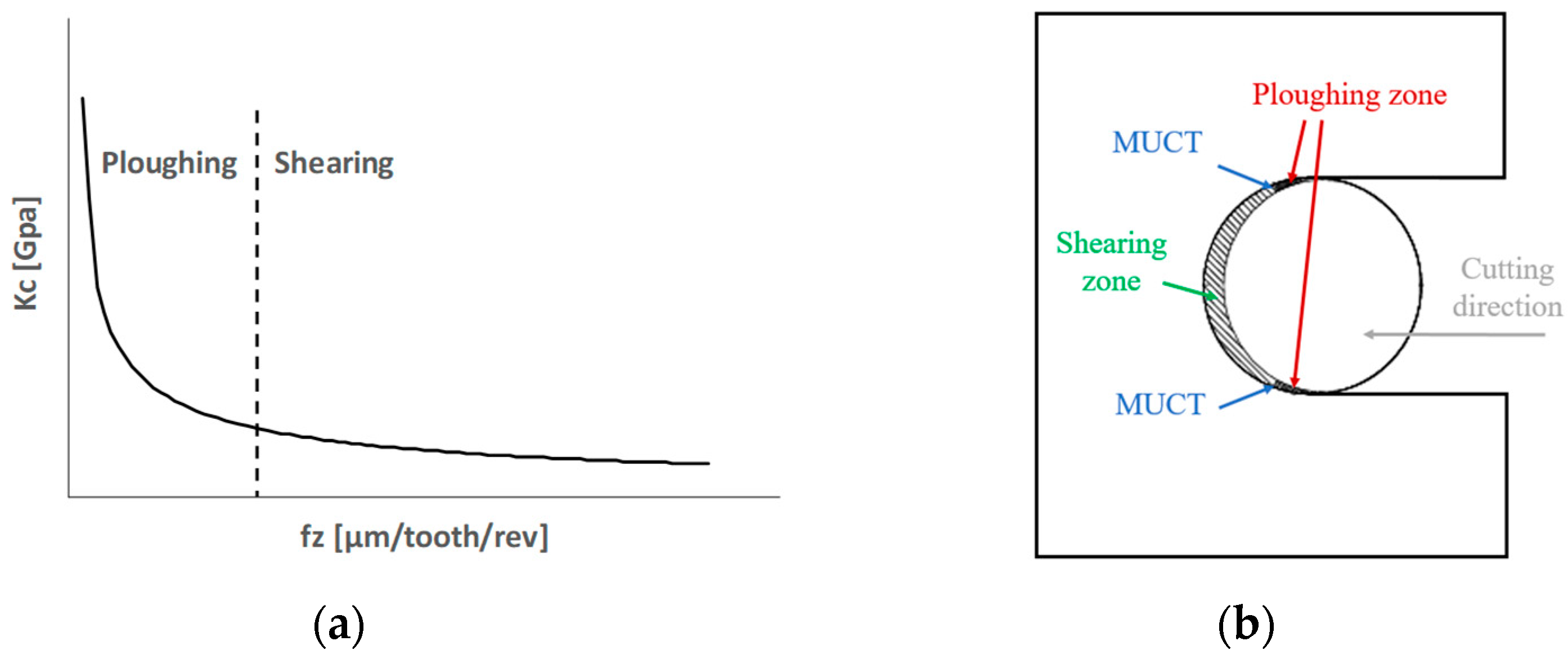

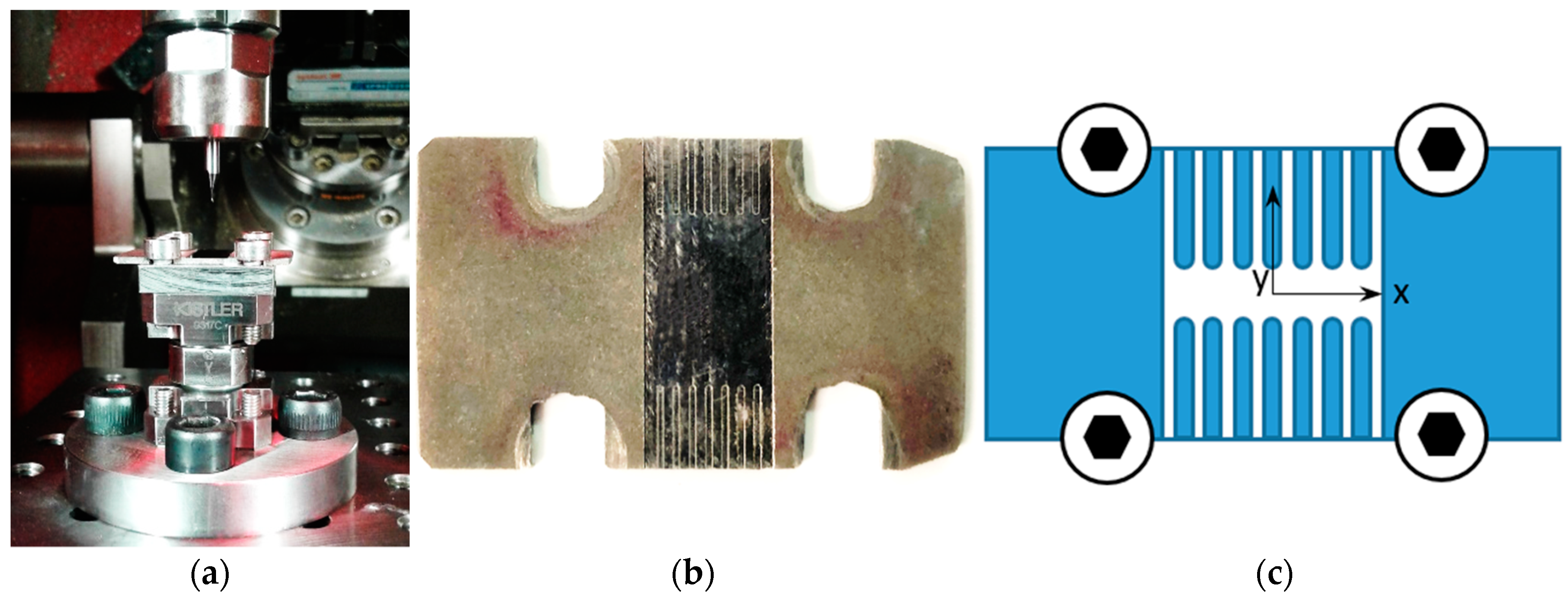

3.2. Force Measurement and MUCT Evaluation

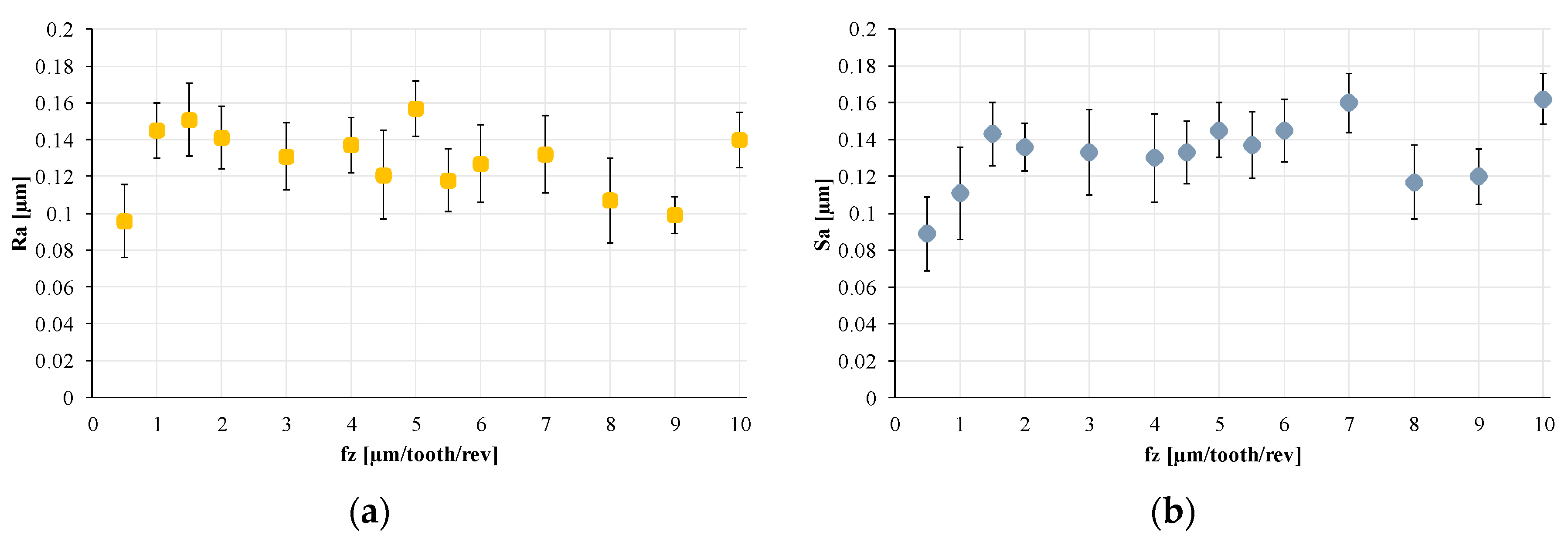

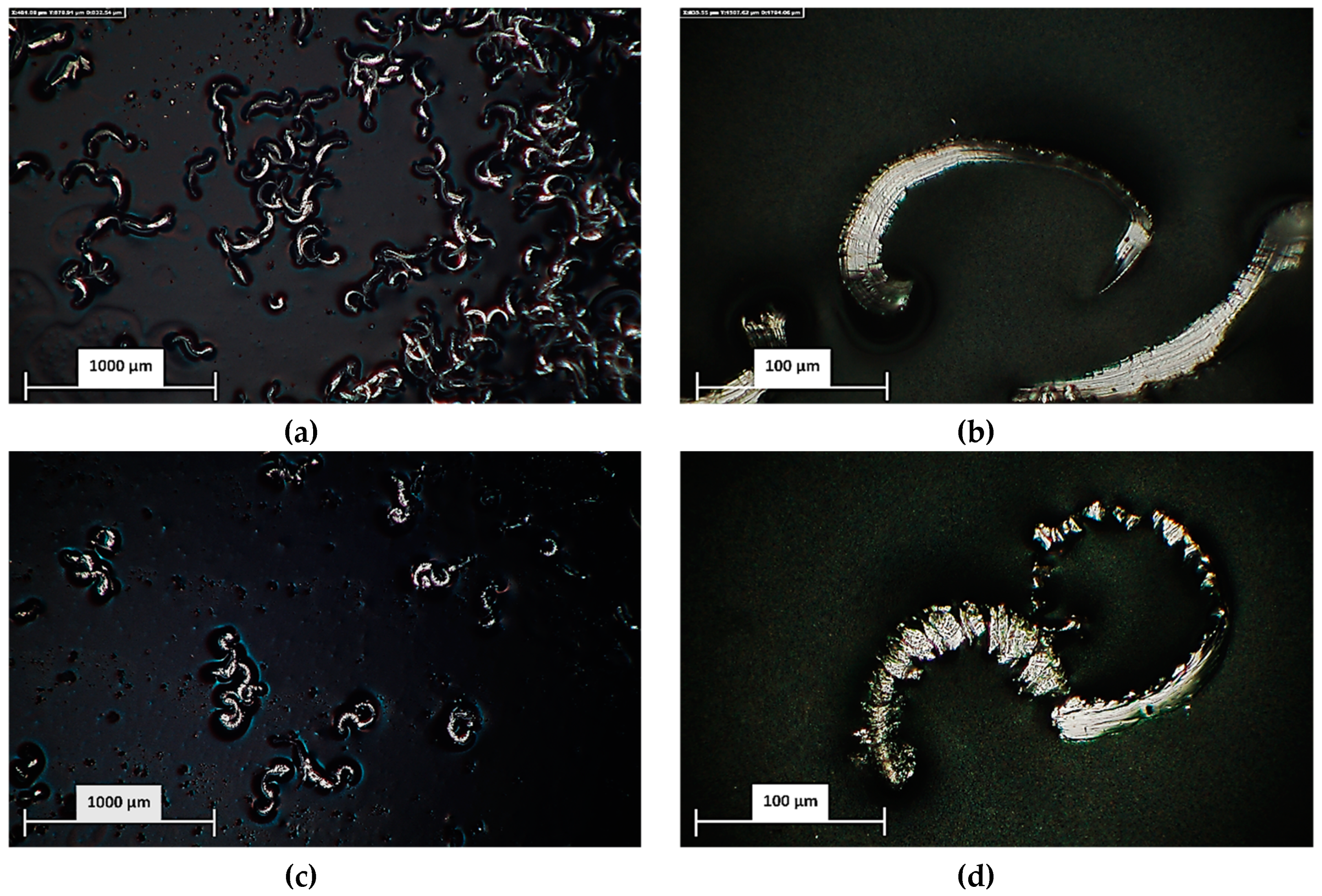

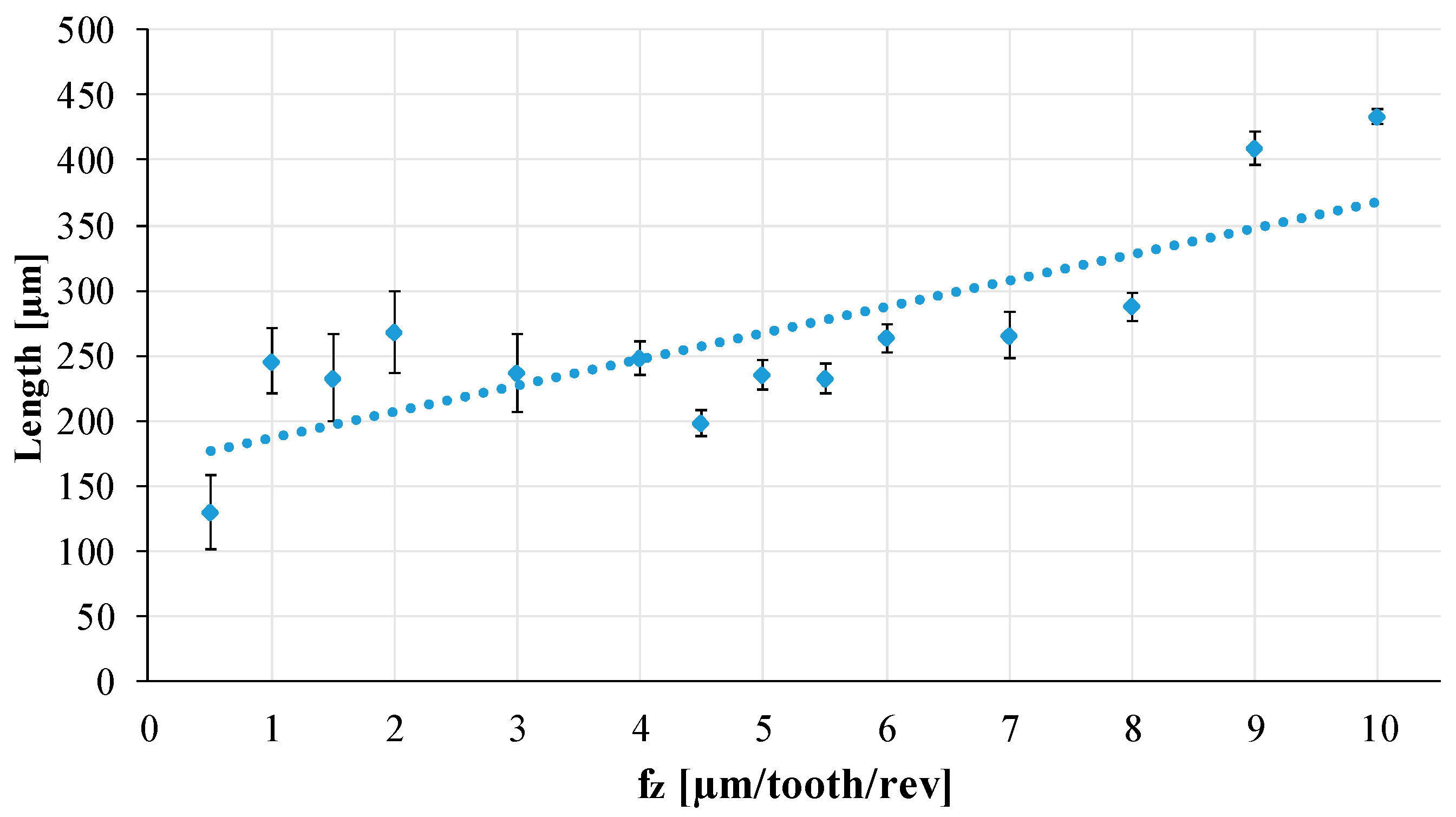

3.3. Surface and Chip Analysis

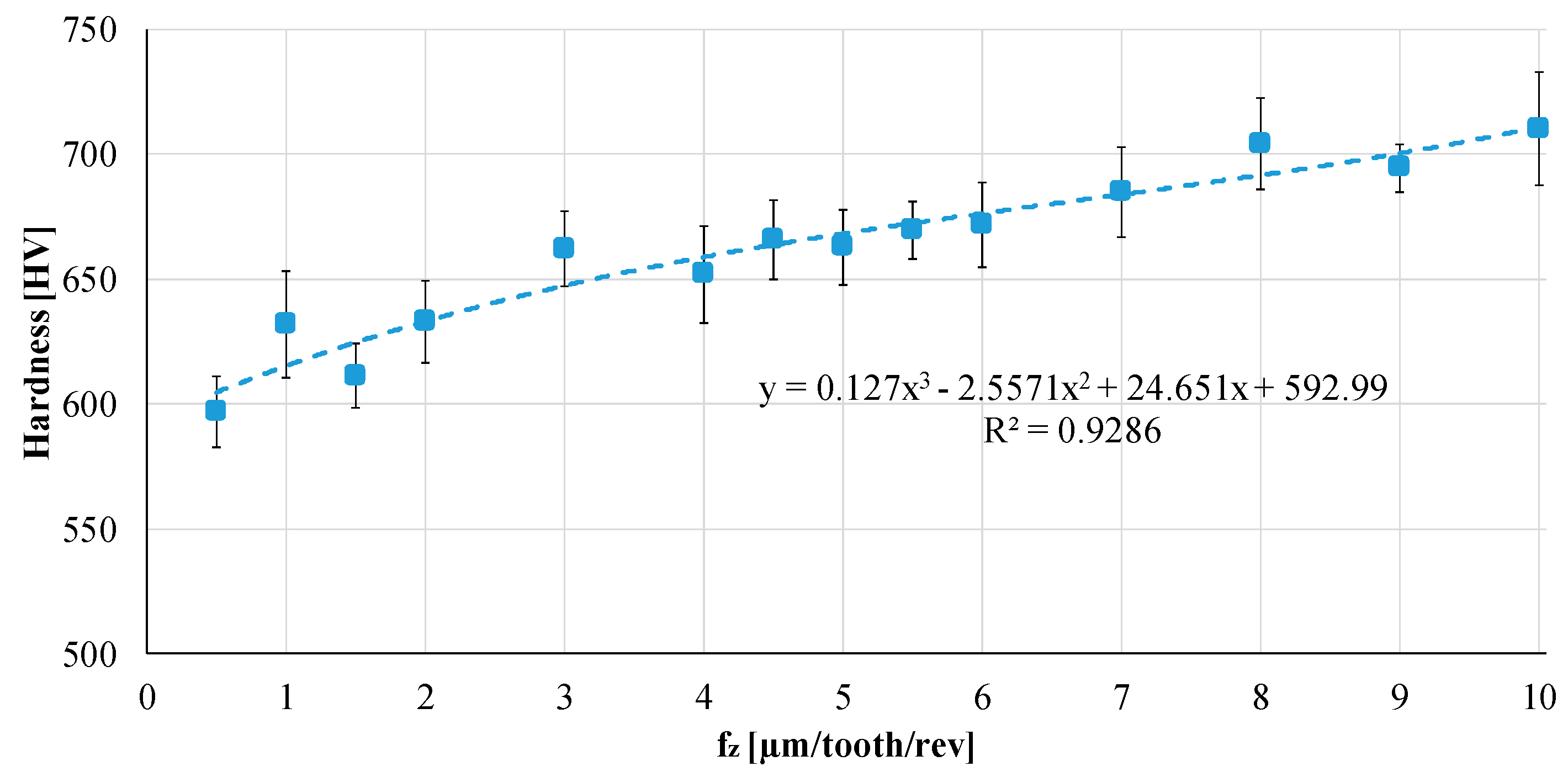

3.4. Microhardness

4. Results and Discussion

4.1. Preliminary Tests

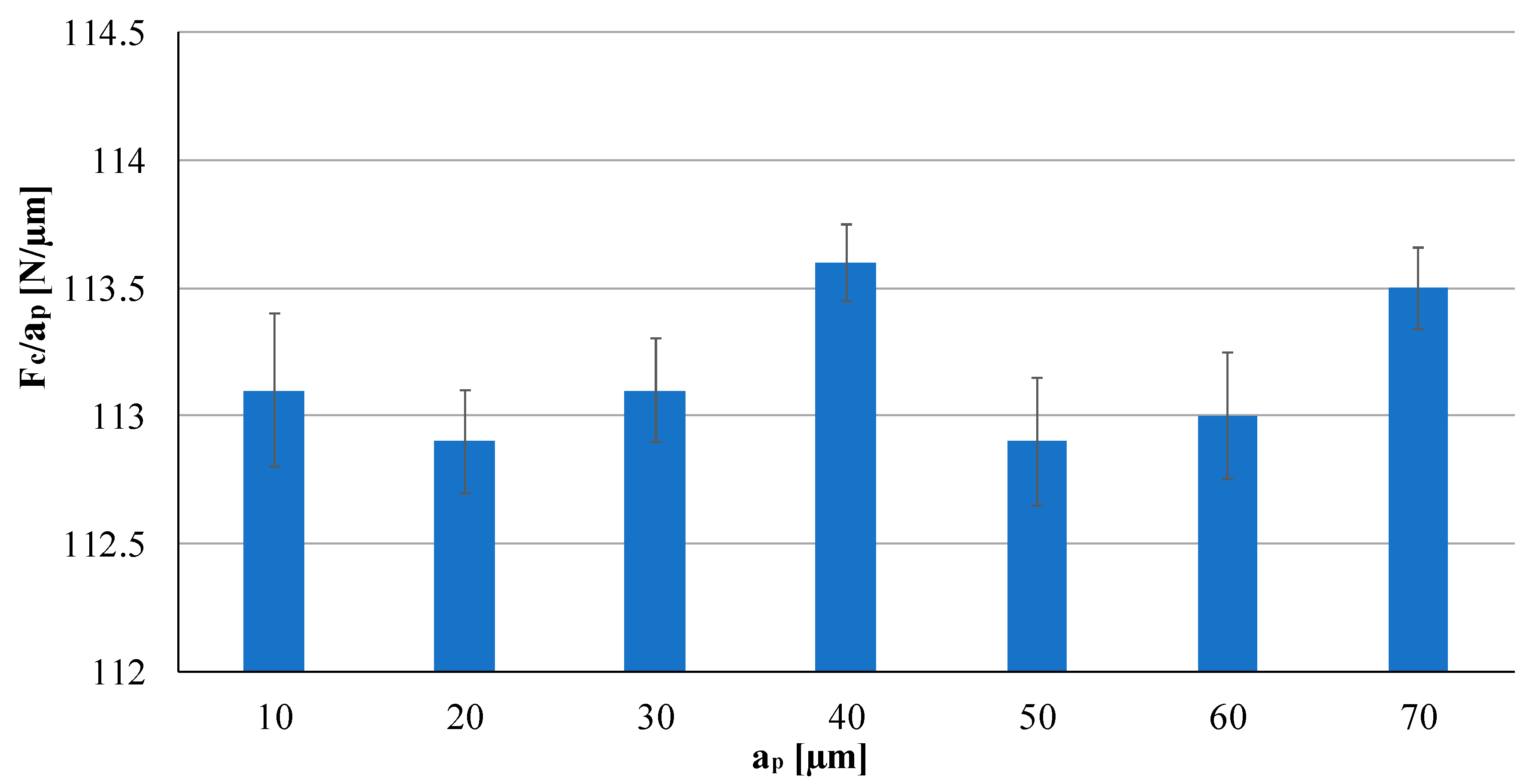

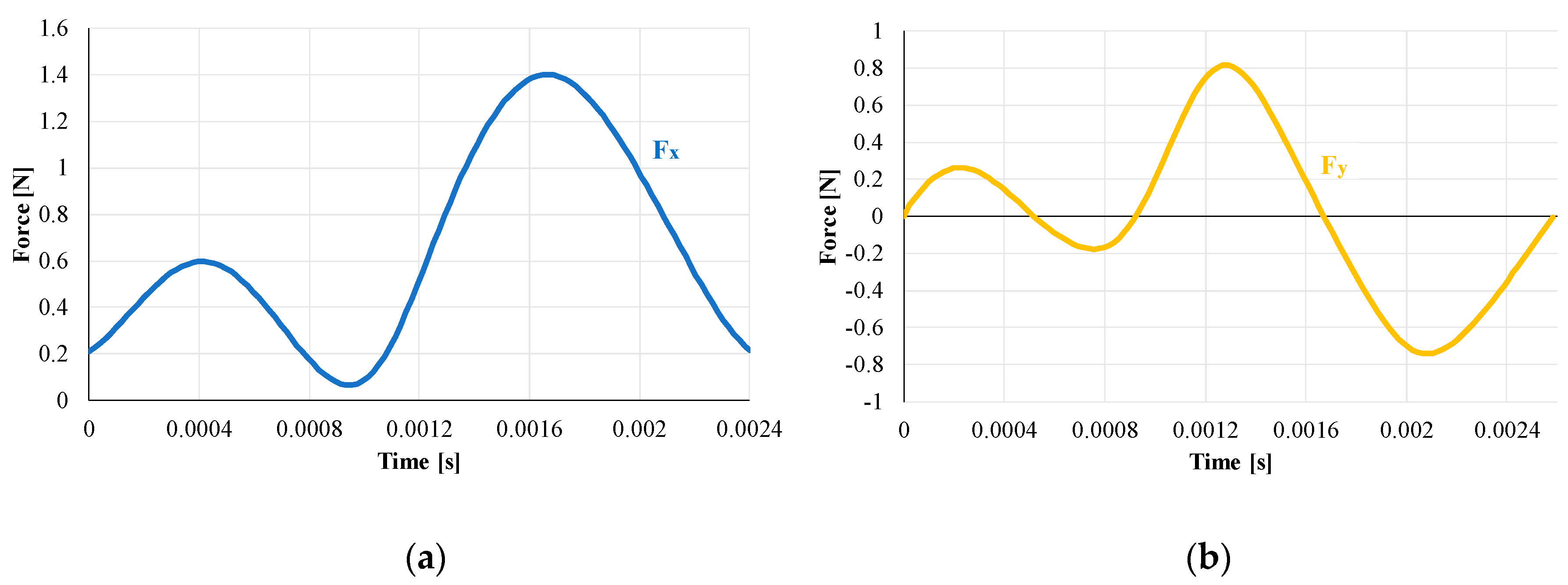

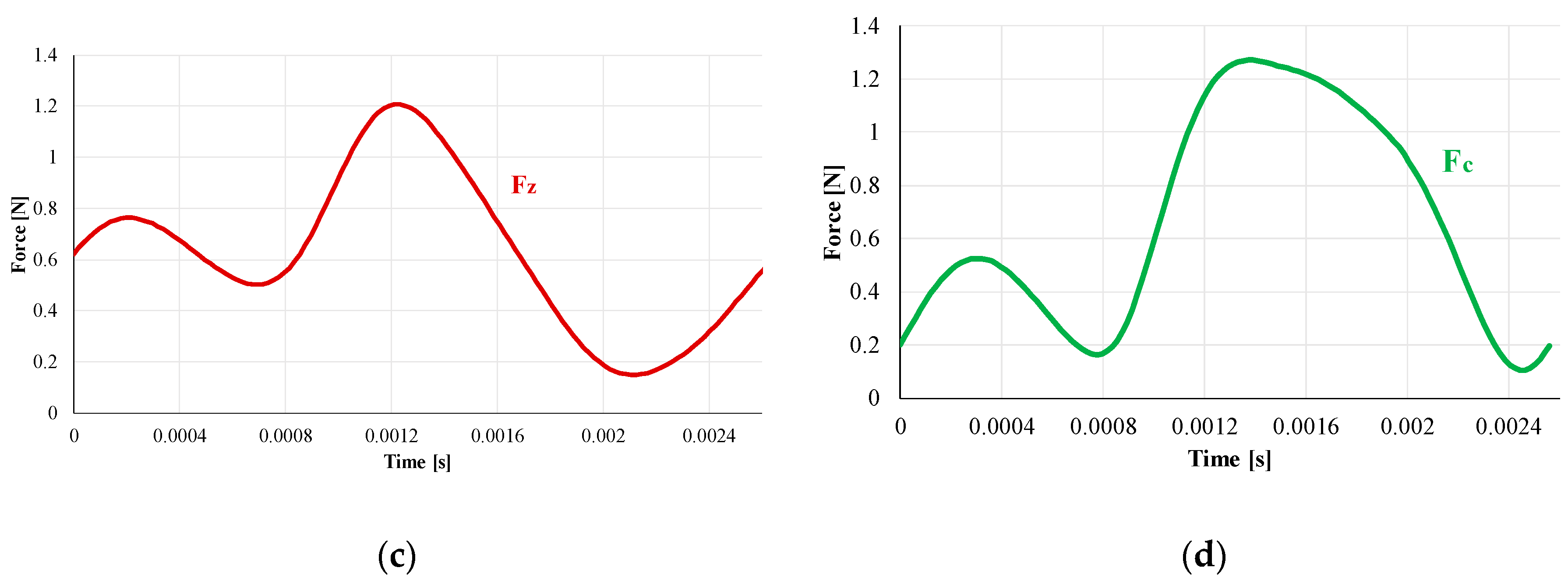

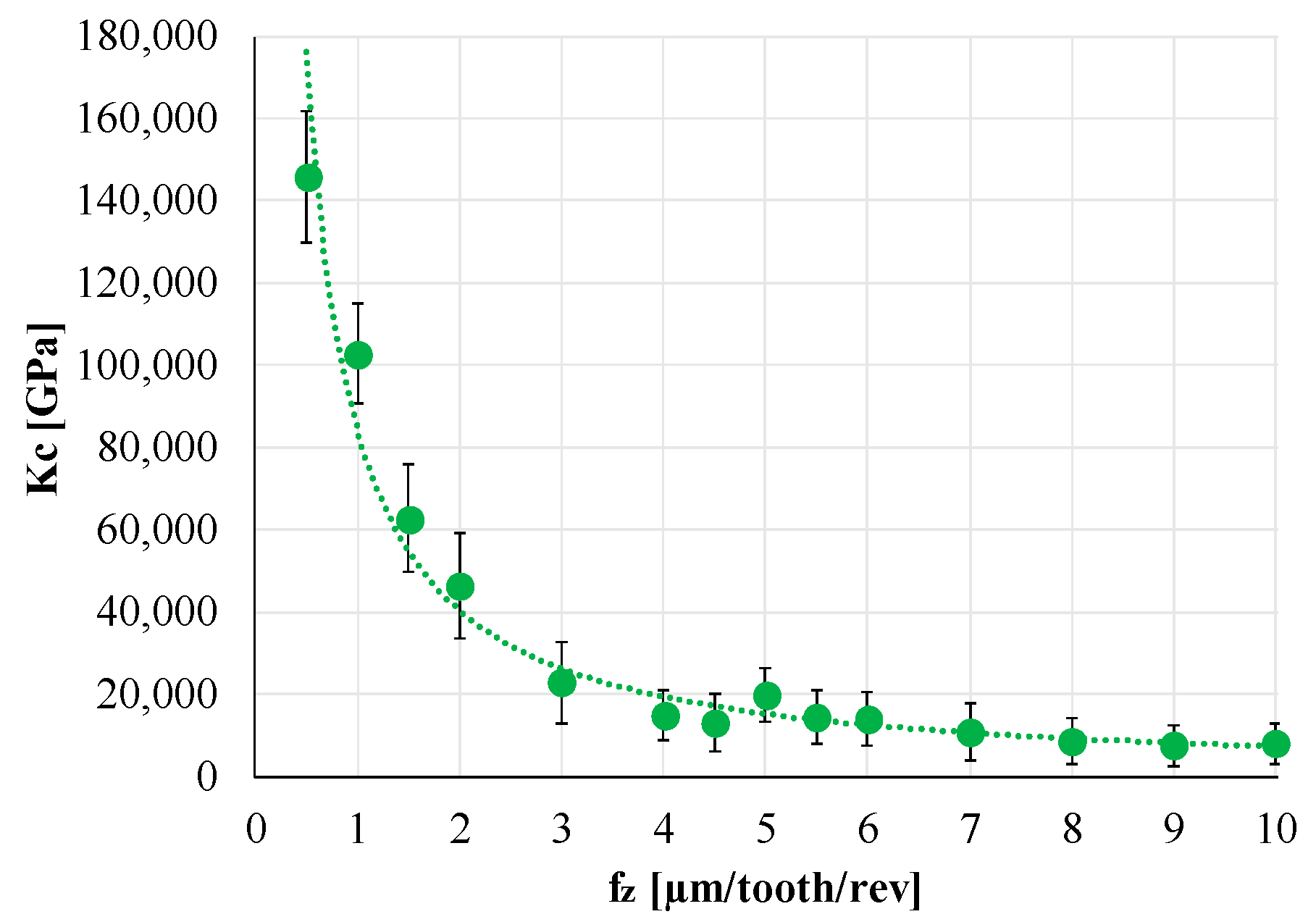

4.2. Force Measurement and MUCT Evaluation

4.3. Surface and Chip Analysis

4.4. Microhardness

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Colpani, A.; Fiorentino, A.; Ceretti, E. 3D printing for health & wealth: fabrication of custom-made medical devices through additive manufacturing. In Proceedings of the 21st International ESAFORM Conference on Material Forming, ESAFORM 2018, Palermo, Italy, 23–25 April 2018. [Google Scholar] [CrossRef]

- Xiu, P.; Jia, Z.; Lv, J.; Yin, C.; Cheng, A.O. Tailored surface treatment of 3D printed porous Ti6Al4V by microarc oxidation for enhanced osseointegration via optimized bone in-growth patterns and interlocked bone/implant interface. ACS Appl. Mater. Inter. 2016, 8, 17964–17975. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive manufacturing: current state, future potential, gaps and needs, and recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef]

- Al Jabbari, Y.S. Physico-mechanical properties and prosthodontic applications of Co-Cr dental alloys: A review of the literature. J. Adv. Prosthodont. 2014, 6, 138–145. [Google Scholar] [CrossRef] [PubMed]

- Mori, M.; Yamanaka, K.; Sato, S.; Wagatsuma, K.; Chiba, A. Microstructures and mechanical properties of biomedical Co-29Cr-6Mo-0.14N alloys processed by hot rolling. Metall. Mater. Trans. A 2012, 43, 3108–3119. [Google Scholar] [CrossRef]

- Bedolla-Gil, Y.; Hernandez-Rodriguez, M. Tribological behavior of a heat-treated cobalt-based alloy. J. Mater. Eng. Perform. 2013, 22, 541–547. [Google Scholar] [CrossRef]

- Sikkenga, C.; Castings, C.A. ASM Handbook, vol. 15: Casting; ASM International: Materials Park, Ohio, 2008; pp. 1114–1118. [Google Scholar]

- Computational Thermodynamics. Available online: www.calphad.com/cobalt-chromium.html (accessed on 24 June 2019).

- Baron, S.; Ahearne, E.; Connolly, P.; Keaveney, S.; Byrne, G. An Assessment of Medical Grade Cobalt Chromium Alloy ASTM F1537 as a "Difficult-to-Cut (DTC)" Material. In Proceedings of the Machine Tool Technologies Research Foundation Annual Meeting, San Francisco, CA, USA; 2015. [Google Scholar]

- Baron, S.; Ahearne, E. An investigation of force components in orthogonal cutting of medical grade cobalt chromium alloy (ASTM F1537). Proc. Inst. Mech. Eng. H 2017, 231, 269–275. [Google Scholar] [CrossRef] [PubMed]

- Badovinac, J.I.; Kavre Piltaver, I.; Peter, R.; Saric, I.; Petravic, M. Formation of oxides on CoCrMo surfaces at room temperature: An XPS study. Appl. Surf. Sci. 2019, 471, 475–481. [Google Scholar] [CrossRef]

- Trimble, D.E.A. Constitutive analysis of biomedical grade Co-27Cr-5Mo alloy at high strain rates. Mater. Sci. Eng. A 2017, 682, 466–474. [Google Scholar] [CrossRef]

- Montero-Ocampo, C.; Juarez, R.; Rodriguez, A.S. Effect of FCC-HCP phase transformation produced by isothermal aging on the corrosion resistance of a Co-27Cr-5Mo-0.05C alloy. Metall. Mater. Trans. A 2002, 33, 2229–2235. [Google Scholar] [CrossRef]

- Liu, R.; Xi, S.Q.; Kapoor, S.; Wu, X.J. Investigation of solidification behavior and associate microstructures of Co-Cr-W and Co-Cr-Mo alloy systems using DSC technique. J. Mater. Sci. 2010, 45, 6225–6234. [Google Scholar] [CrossRef]

- Chen, W. Cutting forces and surface finish when machining medium hardness steel using CBN tools. Int. J. Mach. Tool. Manu. 2000, 40, 455–466. [Google Scholar] [CrossRef]

- Ali, M.Y.; Hung, W.N.P. Micromachining. In Comprehensive Materials Finishing, 1st ed.; Elsevier: Amsterdam, Holland, 2016; Volume 1–3, pp. 322–343. [Google Scholar]

- Fortunato, A.; Lulaj, A.; Melkote, S.; Liverani, E.; Ascari, A.; Umbrello, D. Milling of maraging steel components produced by selective laser melting. Int. J. Adv. Manuf. Tech. 2018, 94, 1895–1902. [Google Scholar] [CrossRef]

- Colpani, A.; Fiorentino, A.; Ceretti, E.; Attanasio, A. Tool wear analysis in micromilling of titanium alloy. Precis. Eng. 2019, 57, 83–94. [Google Scholar] [CrossRef]

- Williams, D.F. On the mechanisms of biocompatibility. Biomaterials 2008, 29, 2941–2953. [Google Scholar] [CrossRef] [PubMed]

- Ahearne, E.; Baron, S. Fundamental mechanisms in orthogonal cutting of medical grade cobalt chromium alloy (ASTM F75). CIRP J. Manuf. Sci. Technol. 2017, 19, 1–6. [Google Scholar] [CrossRef]

- Allegri, G.; Bocchini, F.G.; Ceretti, E.; Fiorentino, A.; Viganò, M. Surface Microgeometry of PM Parts. In Assessment through Advanced Measurement and Statistical Methods. In Proceedings of the Euro PM 2017: International Powder Metallurgy Congress and Exhibition, Milan, Italy, 1–5 October 2017. [Google Scholar]

- UNS R30075 (ASTM F75, ISO 5832-4) Co-Cr-Mo Alloy. Available online: https://www.makeitfrom.com/material-properties/UNS-R30075-ASTM-F75-ISO-5832-4-Co-Cr-Mo-Alloy (accessed on 24 June 2019).

- Huo, D.; Cheng, K. Micro cutting mechanics. In Micro-Cutting: Fundamentals and Applications, 1st ed.; Wiley Hoboken: New Jersey, NJ, USA, 2013; pp. 19–44. [Google Scholar]

- Cheng, K. Machining Dynamics: Fundamentals, Applications and Practices, 1st ed.; Springer Series in Advanced Manufacturing; Springer: Basel, Switzerland, 2009. [Google Scholar] [CrossRef]

- Colpani, A.; Ceretti, E.; Attanasio, A. A Study on Tool Wear for Micromilling Process. In Proceedings of the AIP Conference Proceedings 2113, Vitoria-Gasteiz, Spain, 8–10 May 2019. [Google Scholar]

- Attanasio, A.; Abeni, A.; Özel, T.; Ceretti, E. Finite element simulation of high speed micro milling in the presence of tool run-out with experimental validations. Int. J. Adv. Manuf. Technol. 2019, 100, 25–35. [Google Scholar] [CrossRef]

| Properties | Units | ASTM F75 |

|---|---|---|

| Mechanical properties | ||

| Elastic Modulus | GPa | 210 ÷ 250 |

| Elongation at Break | % | 12 |

| Poisson Ratio | - | 0.29 |

| Shear Modulus | GPa | 82 ÷ 98 |

| Ultimate Tensile Strength | MPa | 780 ÷ 1280 |

| Yield Tensile Strength | MPa | 480 ÷ 840 |

| Thermal properties | ||

| Specific Heat Capacity | J/Kg-K | 450 |

| Thermal Conductivity | W/m-K | 13 |

| Thermal Expansion | µm/m-K | 12 |

| Cutting Diameter | End Cut | Helix | Flute Length | Flutes | Shank Diameter | Overall Length |

|---|---|---|---|---|---|---|

| 508 µm | Square End | 762 µm | 1524 µm | 2 | 1/8 | 38.1 mm |

| Cutting Diameter | ap Max | Total Length | Helix Angle | Flutes | rε |

|---|---|---|---|---|---|

| 0.4 mm | 0.6 mm | 40 mm | 20° | 2 | 5 ± 0.1 µm |

| fz [µm/tooth/rev] | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 1 | 1.5 | 2 | 3 | 4 | 4.5 | 5 | 5.5 | 6 | 7 | 8 | 9 | 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allegri, G.; Colpani, A.; Ginestra, P.S.; Attanasio, A. An Experimental Study on Micro-Milling of a Medical Grade Co-Cr-Mo Alloy Produced by Selective Laser Melting. Materials 2019, 12, 2208. https://doi.org/10.3390/ma12132208

Allegri G, Colpani A, Ginestra PS, Attanasio A. An Experimental Study on Micro-Milling of a Medical Grade Co-Cr-Mo Alloy Produced by Selective Laser Melting. Materials. 2019; 12(13):2208. https://doi.org/10.3390/ma12132208

Chicago/Turabian StyleAllegri, Gabriele, Alessandro Colpani, Paola Serena Ginestra, and Aldo Attanasio. 2019. "An Experimental Study on Micro-Milling of a Medical Grade Co-Cr-Mo Alloy Produced by Selective Laser Melting" Materials 12, no. 13: 2208. https://doi.org/10.3390/ma12132208

APA StyleAllegri, G., Colpani, A., Ginestra, P. S., & Attanasio, A. (2019). An Experimental Study on Micro-Milling of a Medical Grade Co-Cr-Mo Alloy Produced by Selective Laser Melting. Materials, 12(13), 2208. https://doi.org/10.3390/ma12132208