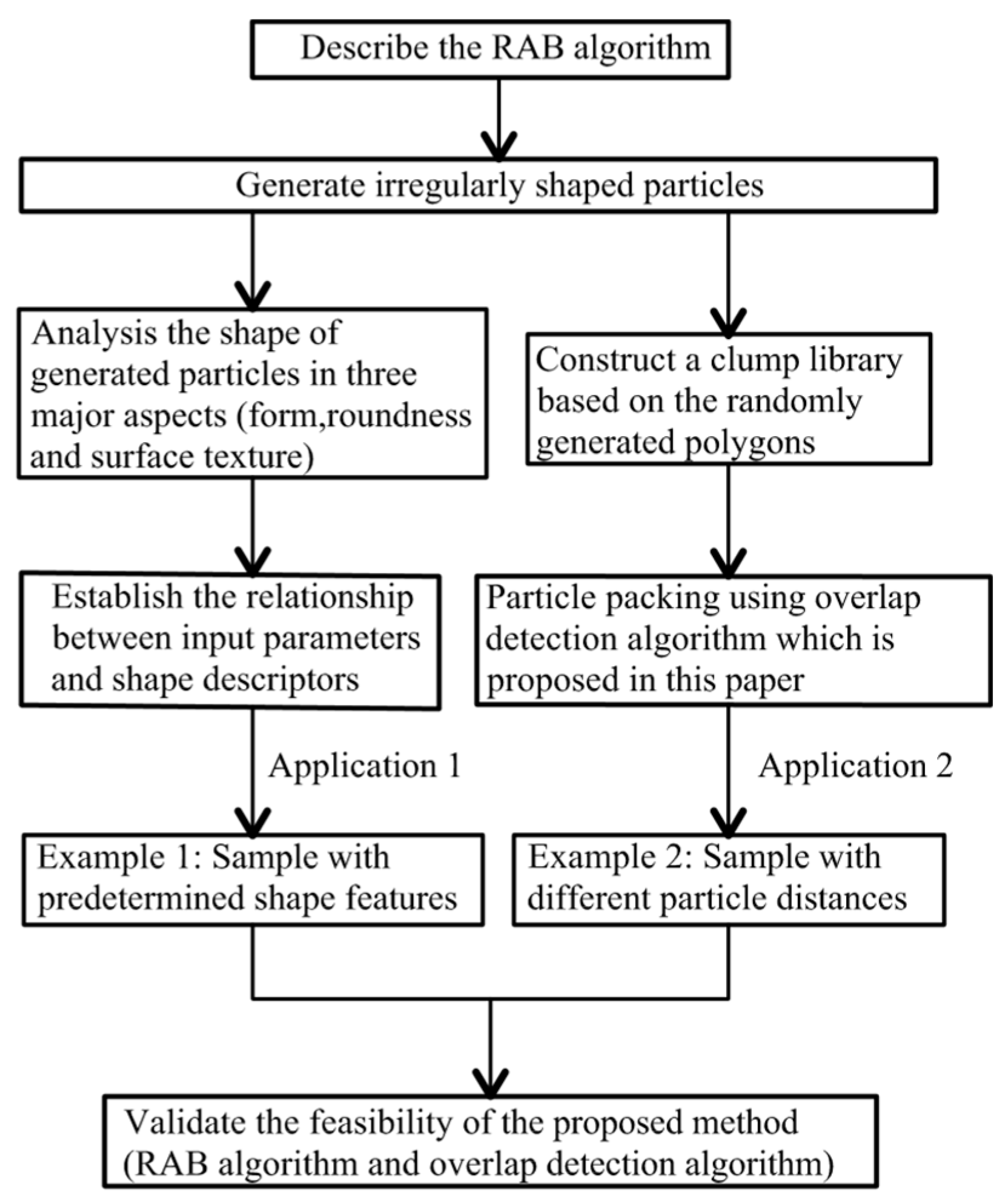

A Random Angular Bend Algorithm for Two- Dimensional Discrete Modeling of Granular Materials

Abstract

1. Introduction

2. Particle Generation

2.1. Z-R Shape Function

2.2. Generation of Irregularly Shaped Polygon

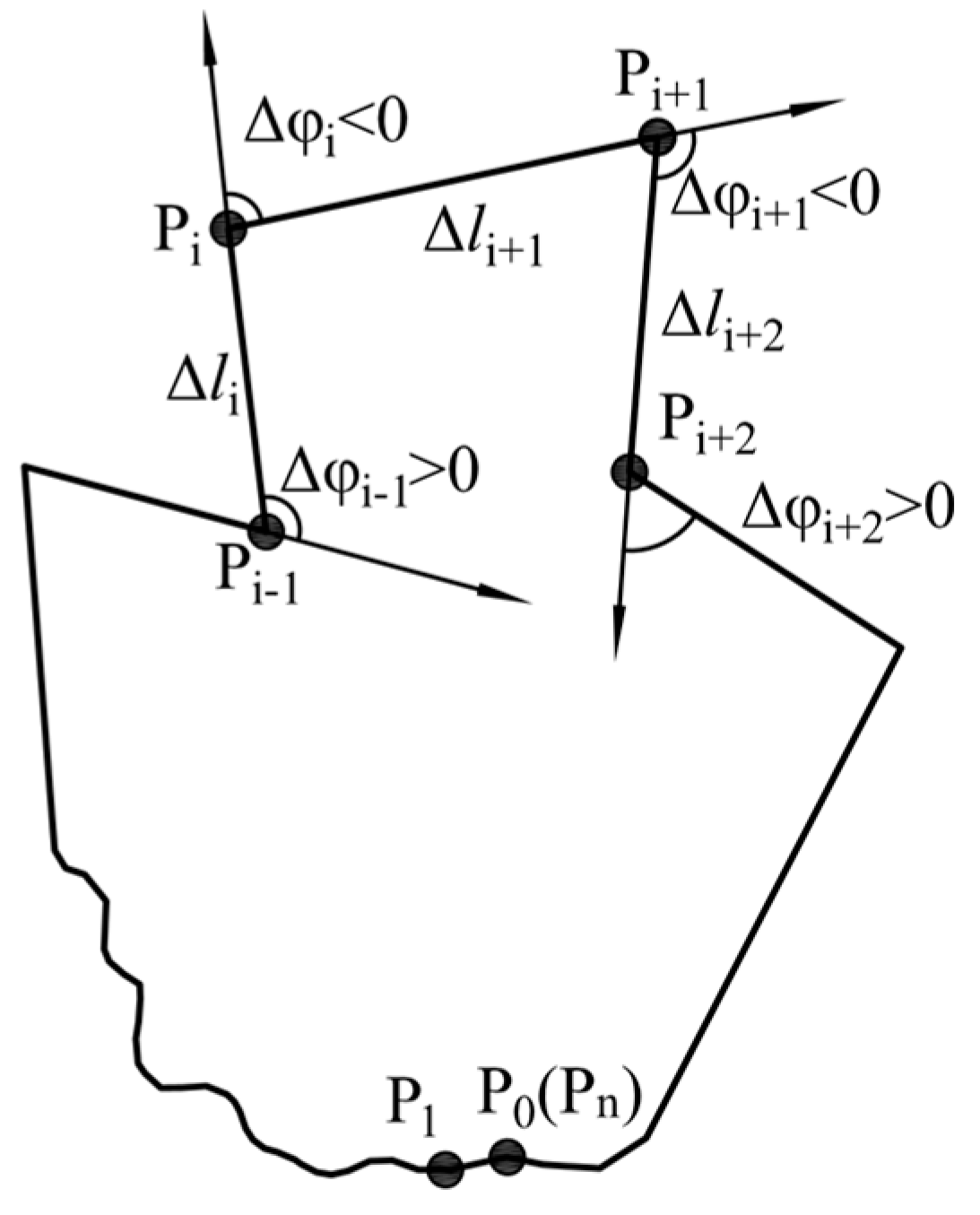

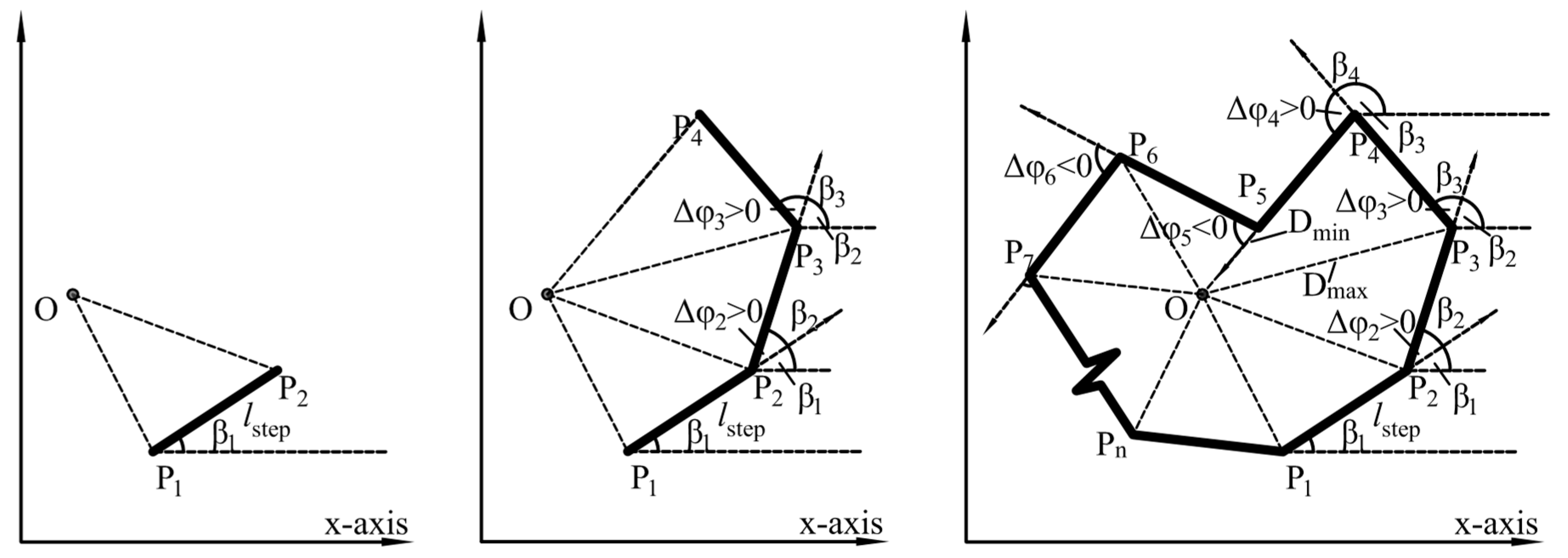

- Define a random point O as the center and a point P1 (x1, y1) as initial starting point of the polygon to be generated.

- Determine the position of the sequential points to be generated. To determine the position of sequential points, a series of angular turns need to be conducted. The common approach to solve this problem is to treat the polygon segments as vectors. The counterclockwise angle that vector makes with the positive x-axis is βi. For i=1, βi is a random number varying uniformly between 0 and 2π. For i >1, the value of this angel can be calculated by Equation (6)where Δφi is the angle bend at point Pi, which is treated as a uniformly distributed random variable. In the procedures of generating randomly shaped polygon, the orientation of the angle should be taken into account and are randomly assigned. For i >1, the coordinates of Pi in a Cartesian coordinate system can be represented by Equation (7)βi = βi−1 + Δφi (i >1)where lstep is constant step length.

- To ensure the points on the polygon are generated counterclockwise, the point Pi should be at the left side of line OPi-1 or on the line (for example, point P5 in Figure 3). This can be validated using the cross product of vector and . The calculation of the cross product is conducted through Equation (3). If this condition is satisfied, proceed with step 4; otherwise, repeat from step 2.

- Calculate DOPi —the distance between O and the generated point Pi(xi, yi). There are two parameters required to be inputted in advance in this part. They are the minimum distance Dmin and the maximum distance Dmax between the center O and the generated points. If the distance is within the specified range (Dmin ≤ DOPi ≤ Dmax) then the point is stored as a new vertex. Otherwise repeat from step 2.

- If a point cannot be generated within specified times of trials, then remove the vertex stored in the previous step and repeat from step 2.

- The summation of all the angular bends from the initial starting point and the point generated in the previous step is φ (φ=∑Δφi). In case of the generation of spiral polygon (a spiral polygon is a simple polygon whose boundary chain contains exactly one concave subchain [38]), φ should equal to 2π [39]. Consequently, repeat steps 2, 3, and 4 until the value of φ is larger than or equal to 2π.

3. Analysis of the Generated Particle Shape

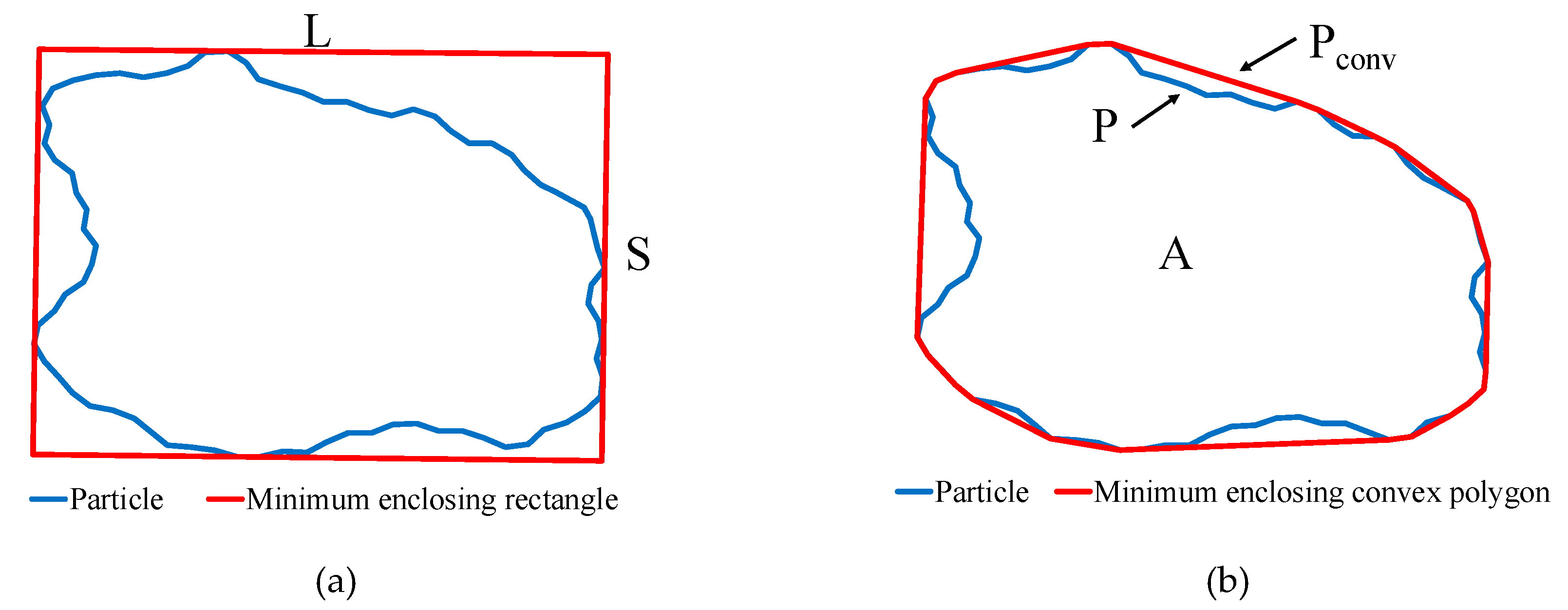

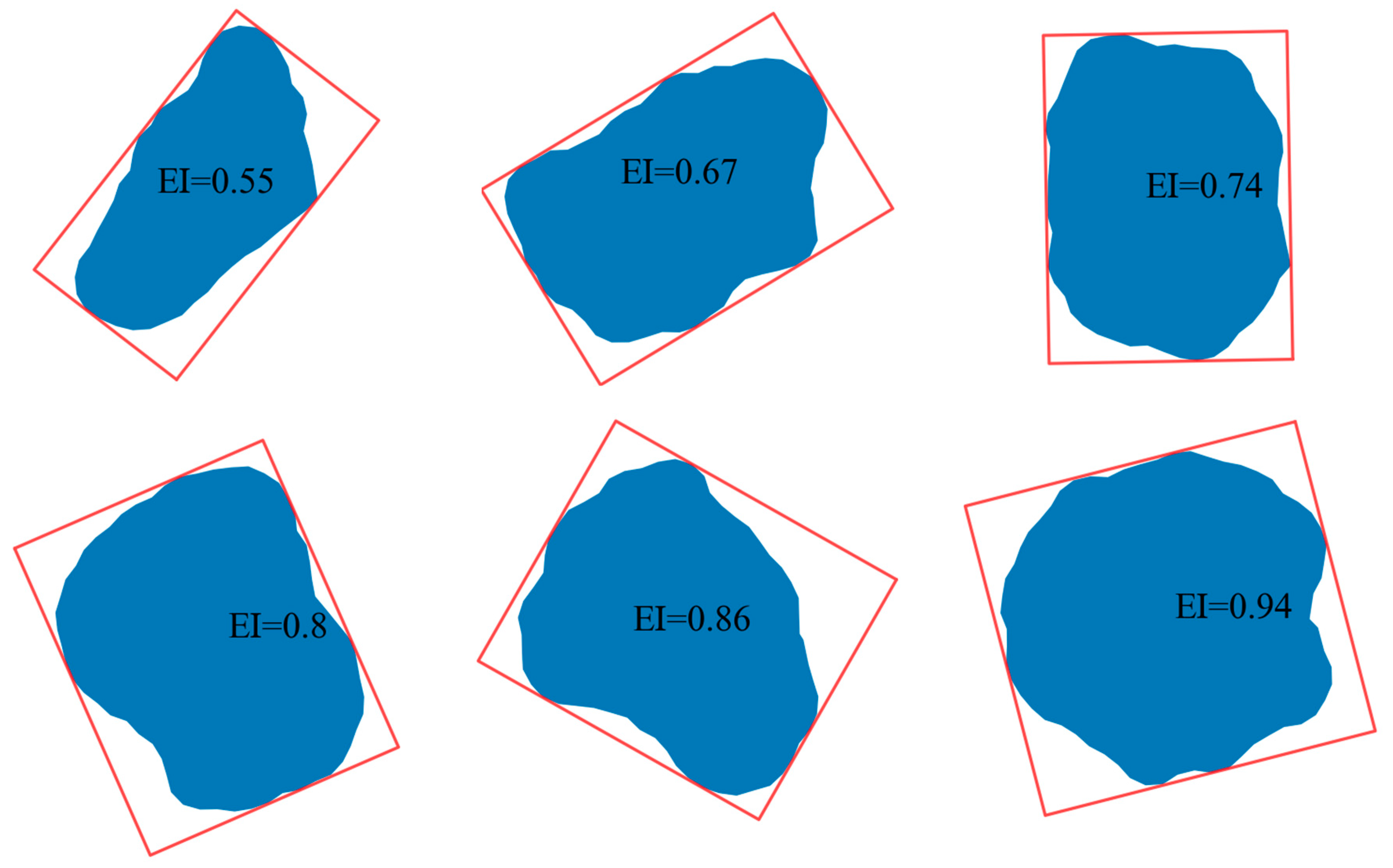

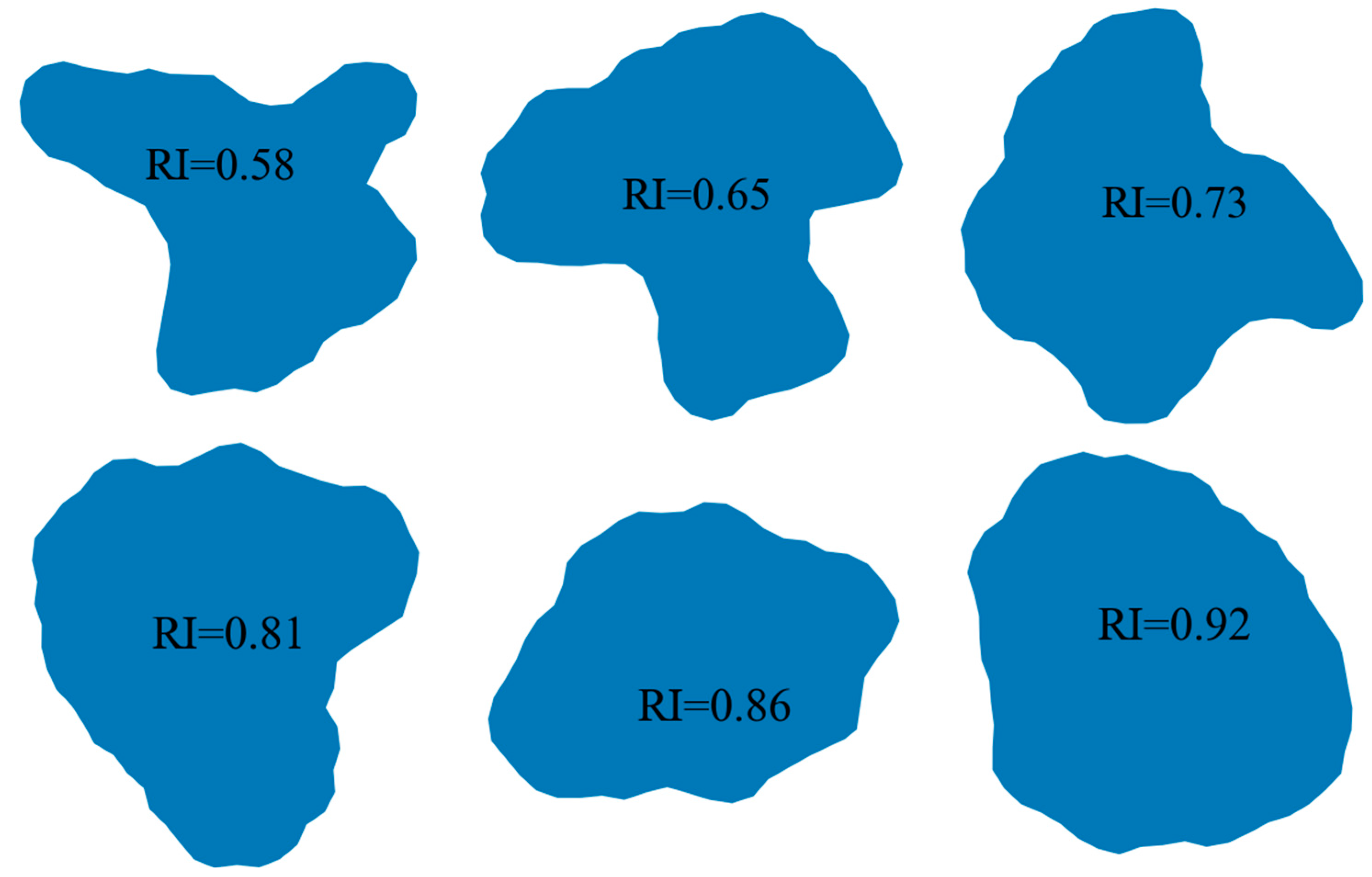

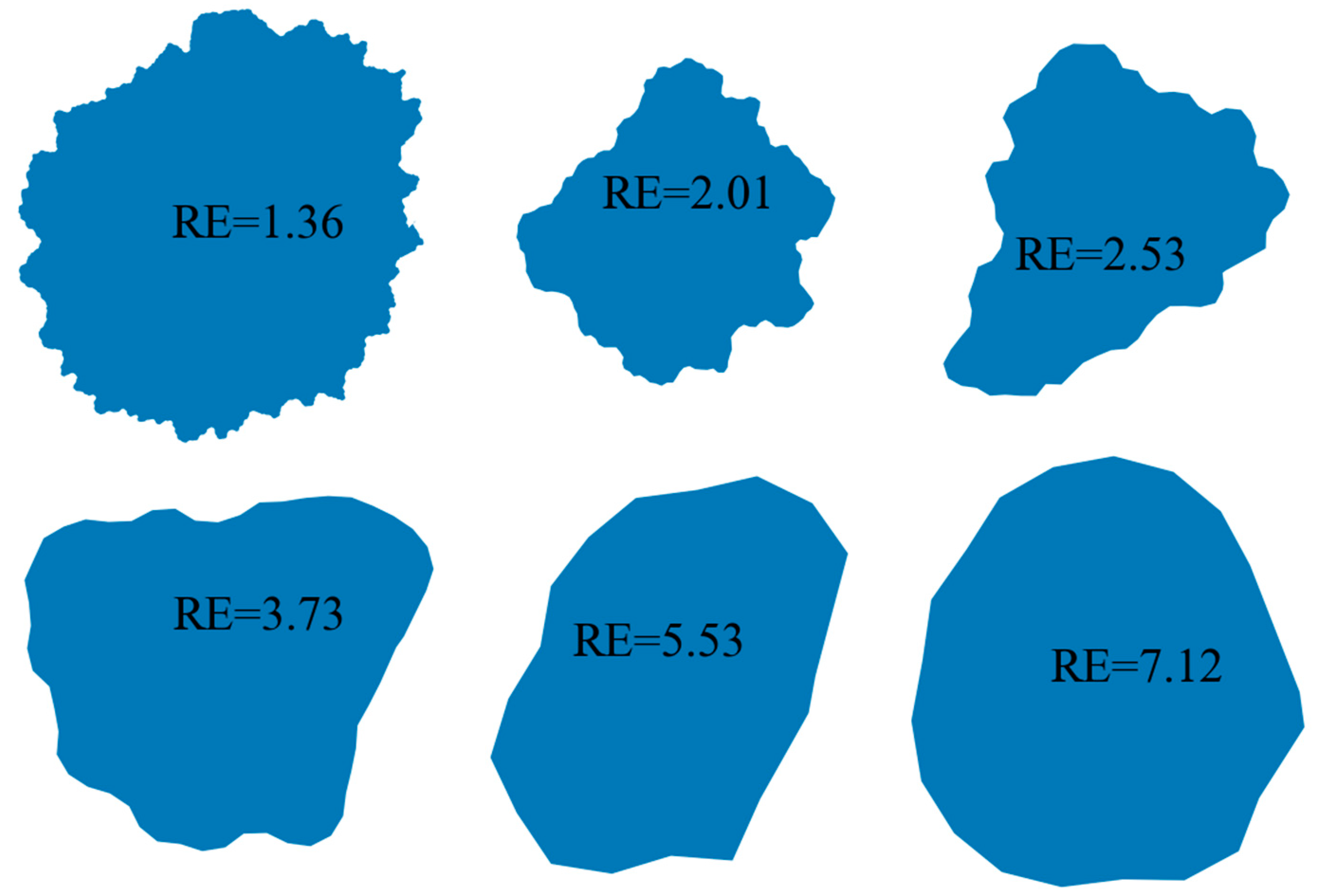

3.1. Shape Descriptors

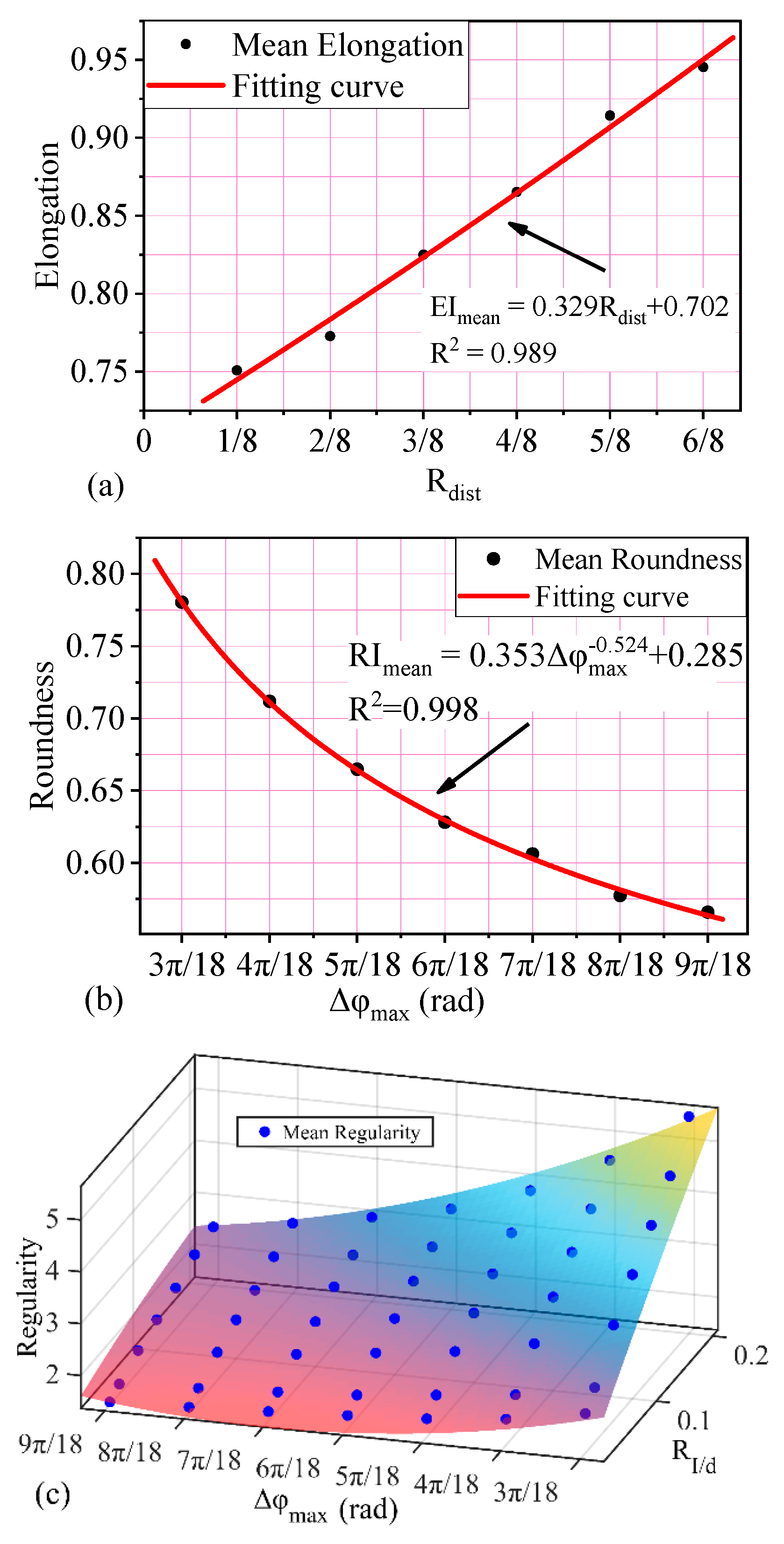

3.2. Relationship between Input Parameters and Shape Descriptors

4. Overlap Detection Algorithm

- Construct a clump library based on the randomly generated polygons.

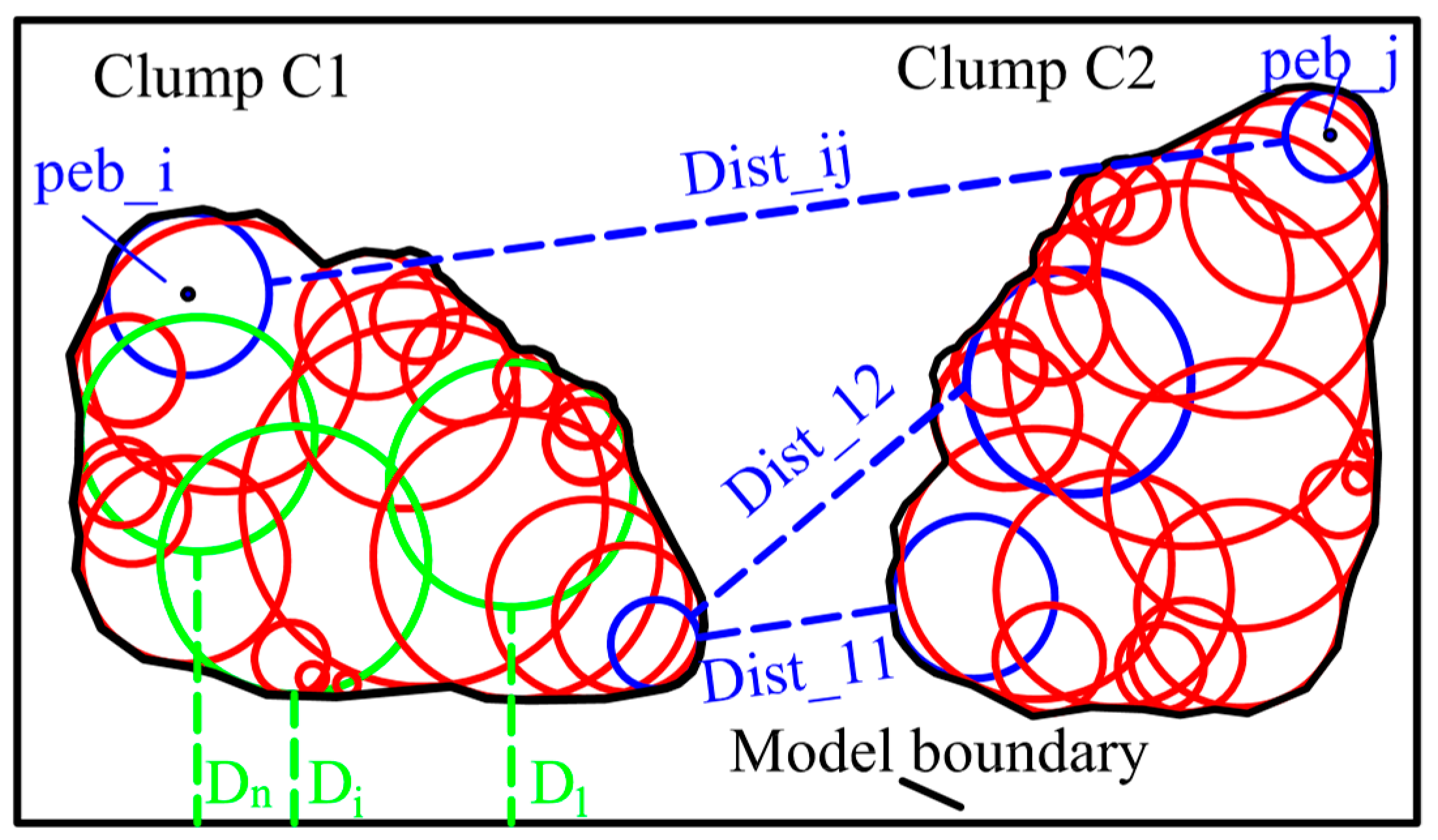

- Select a clump from the library and specify the position randomly in the model domain. It is obvious that the shape of a clump is determined by the position and radii of the comprising pebbles. Based on the pebble information, the minimum distance between the clump and the boundary of model can be determined by calculating the distance (Di) between each pebble and the model boundary (see Figure 10).

- Detect overlap between the clump and model boundary. If the minimum distance between them is greater than or equal to zero, it suggest that the clump does not intersect with the boundaries of model. If this condition is satisfied, store the clump information; otherwise, repeat from step 2.

- Put next clump in the model domain and calculate the minimum distance between this clump and the packed clumps (or the model boundary) based on the position and radii of all the pebbles. If this clump do not overlap with the packed clumps or exceed the model boundary, store the clump and pebble information; otherwise, repeat this step.

- Repeat step 4 until a given condition is satisfied (e.g., the number of all the clumps, the area of all the clumps).

5. Application of Proposed Algorithm

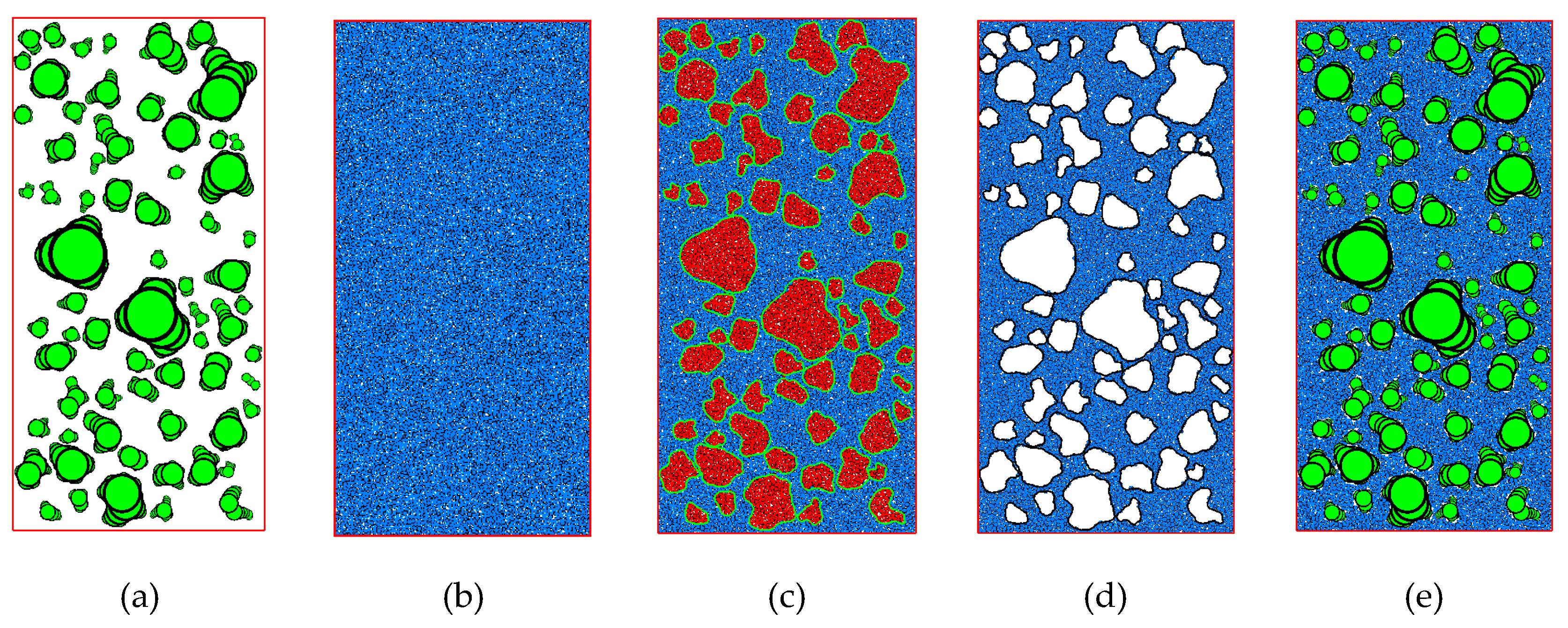

5.1. Modeling of Granular Mixture Materials

- Code the RAB algorithm in Python and input parameters Rdist, Rl/d, and Δφmax to simulate the geometric model of individual coarse particle with irregular shape.

- Import the generated geometric model into PFC2D to construct clump library. The clumps are created based on mid-surface method. These clumps are used to represent realistic coarse particle.

- Put coarse particles into the model domain based on the overlap detection algorithm which is proposed above (Figure 11a).

- Generate sample that is composed of single disk to simulate fine particles in the same model domain (Figure 11b). The size of particle and the porosity of fine particles specimen should be in a given range.

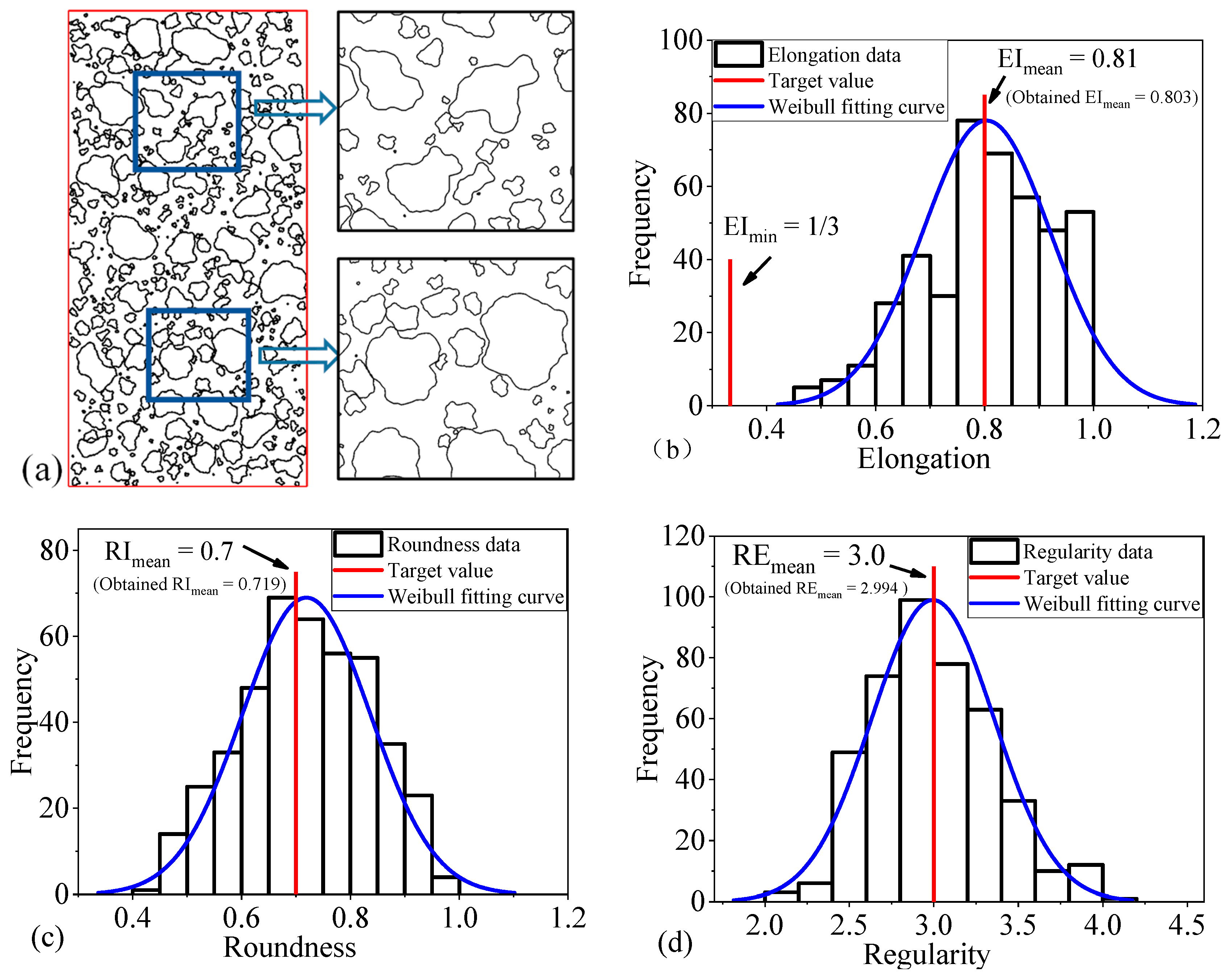

5.2. Granular Mixture with Predetermined Coarse Particle Shape Features

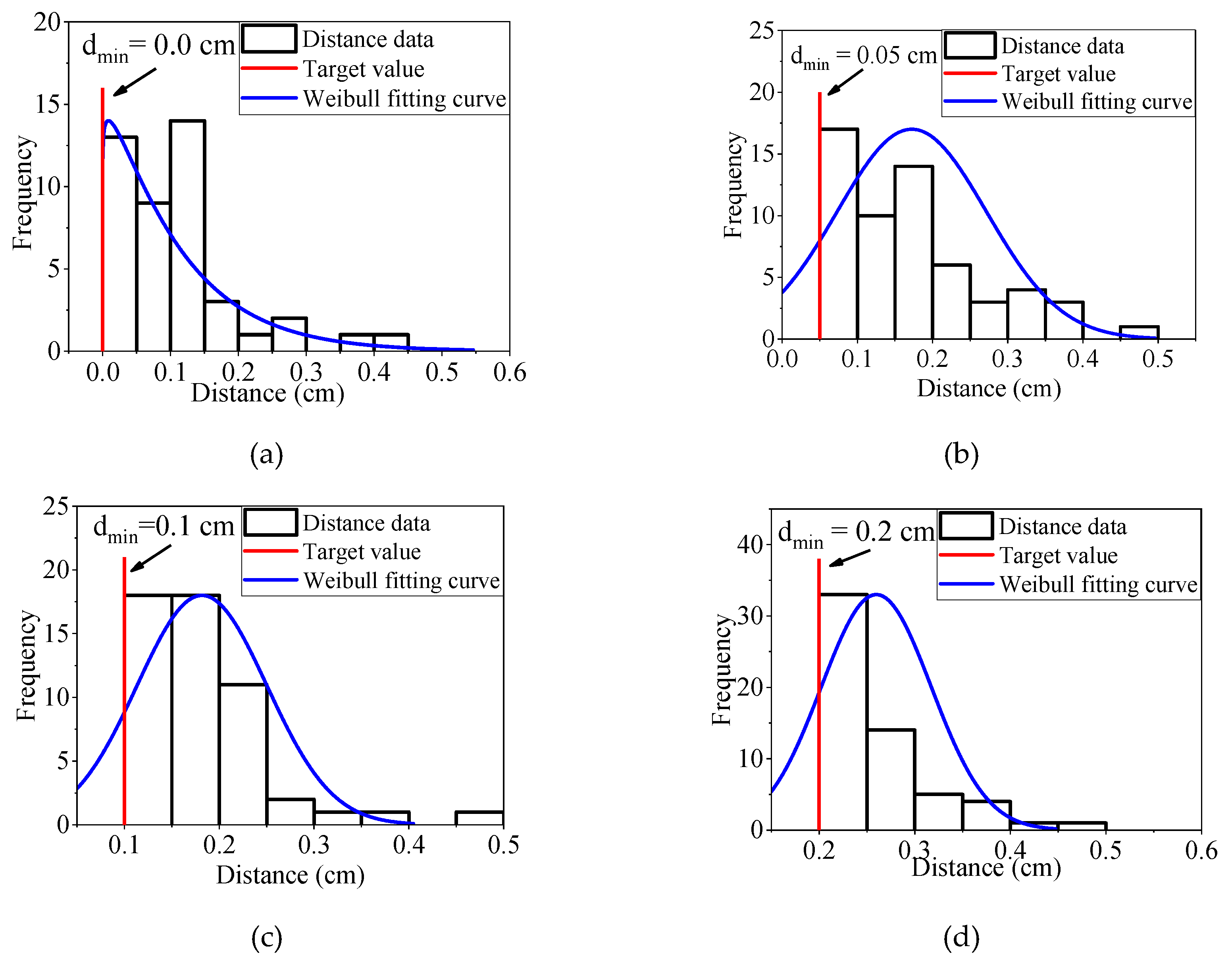

5.3. Granular Mixture with Different Coarse Particle Distances

6. Conclusions

- The proposed RAB algorithm shows a good performance in the generation of randomly shaped polygons (especially for nonstar-like particle reconstruction based on image information).

- Three representative parameters (Rdist, Rl/d, and Δφmax) in RAB algorithm could quantitatively control the shape feature of generated polygons by control three shape descriptors (elongation index, roundness index, and regularity). Besides, these three parameters have definitude physical meaning, which makes the RAB algorithm easier to understand.

- The proposed overlap detection algorithm is able to allocate particle to the model domain easily by calculating the minimum distance between coarse particles or the distance between coarse particle and the model boundary.

Author Contributions

Funding

Conflicts of Interest

List of symbols

| l | Arc length from point P0 up to the vertex Pi |

| φ | Cumulative angular bends |

| Pi | The ith vertex on the polygon |

| Δli | Edge length |

| Δφi | Angular bend at vertex Pi |

| Lall | The total length of the polygon. |

| βi | The counterclockwise angle that vector makes with the positive x-axis |

| lstep | Constant step length |

| EI | Elongation index |

| S | The width of the smallest rectangular box containing the particle |

| L | The length of the smallest rectangular box containing the particle |

| RI | Roundness index |

| A | The projected area of the particle |

| P | The perimeter of the particle |

| RE | Regularity index |

| Pconv | The convex perimeter of the particle |

| DOPi | The distance between O and the generated point Pi |

| Dmin | The minimum distance between the center O and the generated points |

| Dmax | The maximum distance between the center O and the generated points |

| Rdist | The ratio between Dmin and Dmax |

| Rl/d | The ratio between lsteplength and Dmax |

| Δφmax | The maximum value of angle bend |

| EImin | The minimum value of elongation |

| EImean | The mean value of elongation |

| RImean | The mean value of roundness |

| REmean | The mean value of regularity |

| Di | The distance between pebble and the model boundary |

| Dist_ij | The distance between pebble peb_i in clump C1 and pebble peb_j in C2 |

| dmin | The minimum distance between coarse particles |

References

- Weinhart, T.; Thornton, A.R.; Einav, I. Editorial: Modelling and computational challenges in granular materials. Comput. Part. Mech. 2016, 3, 291–292. [Google Scholar] [CrossRef][Green Version]

- Sinnott, M.D.; Cleary, P.W. The effect of particle shape on mixing in a high shear mixer. Comput. Part. Mech. 2016, 3, 477–504. [Google Scholar] [CrossRef]

- Bayesteh, H.; Ghasempour, T. Role of the location and size of soluble particles in the mechanical behavior of collapsible granular soil: A DEM simulation. Comput. Part. Mech. 2018. [Google Scholar] [CrossRef]

- Cundall, P.A. A computer model for simulating progressive, large-scale movement in blocky rock system. In Proceedings of the International Symposium on Rock Mechanics, Nancy, France, 4–6 october 1971. [Google Scholar]

- Cundall, P.A.; Strack, O.D. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Kun, F.; Herrmann, H.J. A study of fragmentation processes using a discrete element method. Comput. Method. Appl. Mech. Eng. 1996, 138, 3–18. [Google Scholar] [CrossRef]

- Cho, N.; Martin, C.D.; Sego, D.C. A clumped particle model for rock. Int. J. Rock Mech. Min. Sci. 2007, 44, 997–1010. [Google Scholar] [CrossRef]

- Suchorzewski, J.; Tejchman, J.; Nitka, M. Discrete element method simulations of fracture in concrete under uniaxial compression based on its real internal structure. Int. J. Damage Mech. 2018, 27, 578–607. [Google Scholar] [CrossRef]

- Bandeira, A.A.; Zohdi, T.I. 3D numerical simulations of granular materials using DEM models considering rolling phenomena. Comput. Part. Mech. 2019, 6, 97–131. [Google Scholar] [CrossRef]

- Rong, G.; Liu, G.; Hou, D.; Zhou, C.b. Effect of particle shape on mechanical behaviors of rocks: A numerical study using clumped particle model. Sci. World J. 2013, 2013. [Google Scholar] [CrossRef]

- Santamarina, J.; Cho, G.C. Soil behaviour: The role of particle shape. In Proceedings of the Advances in Geotechnical Engineering: The Skempton Conference, London, UK, 29–31 March 2004; pp. 604–617. [Google Scholar]

- Guan, Y.; Liu, X.; Wang, E.; Wang, S. The Stability Analysis Method of the Cohesive Granular Slope on the Basis of Graph Theory. Materials 2017, 10, 240. [Google Scholar] [CrossRef]

- Miao, Y.H.; Yu, W.X.; Hou, Y.; Guo, L.Y.; Wang, L.B. Investigating the Functions of Particles in Packed Aggregate Blend using a Discrete Element Method. Materials 2019, 12, 556. [Google Scholar] [CrossRef] [PubMed]

- Ting, J.M.; Meachum, L.; Rowell, J.D. Effect Of Particle-Shape on the Strength And Deformation Mechanisms Of Ellipse-Shaped Granular Assemblages. Eng. Comput. 1995, 12, 99–108. [Google Scholar] [CrossRef]

- Ting, J.M.; Khwaja, M.; Meachum, L.R.; Rowell, J.D. An Ellipse-Based Discrete Element Model for Granular-Materials. Int. J. Numer. Anal. Method. Geomech. 1993, 17, 603–623. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Routbort, J.L.; Singh, D. Particle shape effects on thermophysical properties of alumina nanofluids. J. Appl. Phys. 2009, 106. [Google Scholar] [CrossRef]

- Chen, W.; Donohue, T.; Katterfeld, A.; Williams, K. Comparative discrete element modelling of a vibratory sieving process with spherical and rounded polyhedron particles. Granul. Matter 2017, 19, 81. [Google Scholar] [CrossRef]

- Wang, J.; Yu, H.S.; Langston, P.; Fraige, F. Particle shape effects in discrete element modelling of cohesive angular particles. Granul. Matter 2011, 13, 1–12. [Google Scholar] [CrossRef]

- Li, T.; Peng, Y.; Zhu, Z.; Zou, S.; Yin, Z. Discrete Element Method Simulations of the Inter-Particle Contact Parameters for the Mono-Sized Iron Ore Particles. Materials 2017, 10, 520. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.M.; Kwan, A.K.H.; Chan, H.C. Mesoscopic study of concrete I: Generation of random aggregate structure and finite element mesh. Comput. Struct. 1999, 70, 533–544. [Google Scholar] [CrossRef]

- Liu, Q.; Jiang, Y.; Wu, Z.; He, J. A Voronoi element based-numerical manifold method (VE-NMM) for investigating micro/macro-mechanical properties of intact rocks. Eng. Fract. Mech. 2018, 199, 71–85. [Google Scholar] [CrossRef]

- Mollon, G.; Zhao, J. Fourier–Voronoi-based generation of realistic samples for discrete modelling of granular materials. Granul. Matter 2012, 14, 621–638. [Google Scholar] [CrossRef]

- Shan, P.; Lai, X. Mesoscopic structure PFC∼ 2D model of soil rock mixture based on digital image. J. Vis. Commun. Image Represent. 2019, 58, 407–415. [Google Scholar] [CrossRef]

- Zheng, J.; Hryciw, R.D. An image based clump library for DEM simulations. Granul. Matter 2017, 19, 26. [Google Scholar] [CrossRef]

- Zheng, J.; Hryciw, R.D. A corner preserving algorithm for realistic DEM soil particle generation. Granul. Matter 2016, 18, 84. [Google Scholar] [CrossRef]

- Zhao, L.; Huang, D.; Dan, H.C.; Zhang, S.; Li, D. Reconstruction of granular railway ballast based on inverse discrete Fourier transform method. Granul. Matter 2017, 19, 74. [Google Scholar] [CrossRef]

- Wang, X.; Liang, Z.; Nie, Z.; Gong, J. Stochastic numerical model of stone-based materials with realistic stone-inclusion features. Constr. Build. Mater. 2018, 197, 830–848. [Google Scholar] [CrossRef]

- Nie, Z.; Zhu, Y.; Wang, X.; Gong, J. Investigating the effects of Fourier-based particle shape on the shear behaviors of rockfill material via DEM. Granul. Matter 2019, 21, 22. [Google Scholar] [CrossRef]

- Bowman, E.T.; Soga, K.; Drummond, W. Particle shape characterisation using Fourier descriptor analysis. Géotechnique 2001, 51, 545–554. [Google Scholar] [CrossRef]

- Su, D.; Yan, W.M. Quantification of angularity of general-shape particles by using Fourier series and a gradient-based approach. Constr. Build. Mater. 2018, 161, 547–554. [Google Scholar] [CrossRef]

- Zahn, C.T.; Roskies, R.Z. Fourier descriptors for plane closed curves. IEEE Trans. Comput. 1972, 100, 269–281. [Google Scholar] [CrossRef]

- Python. Python Programming Language. 2018. Available online: https://www.python.org/ (accessed on 10 May 2018).

- Itasca, PFC Documentation, Release 5.0; Itasca Consulting Group Inc.: Minneapolis, MN, USA, 2014.

- Taghavi, R. Automatic clump generation based on mid-surface. In Proceedings of the 2nd International FLAC/DEM Symposium, Melbourne, Australia, 14–16 February 2011; pp. 791–797. [Google Scholar]

- Hundal, H.S.; Rohani, S.; Wood, H.C.; Pons, M.N. Particle shape characterization using image analysis and neural networks. Powder Technol. 1996, 91, 217–227. [Google Scholar] [CrossRef]

- Cormen, T.H.; Leiserson, C.E.; Rivest, R.L.; Stein, C. Introduction to Algorithms; MIT press: Cambridge, MA, USA, 2009. [Google Scholar]

- MacLeod, N. Generalizing and extending the eigenshape method of shape space visualization and analysis. Paleobiology 1999, 25, 107–138. [Google Scholar]

- Everett, H.; Corneil, D.G. Recognizing Visibility Graphs of Spiral Polygons. J. Algorithm. 1990, 11, 1–26. [Google Scholar] [CrossRef]

- Bernard-Michel, B.; Rohani, S.; Pons, M.N.; Vivier, H.; Hundal, H.S. Classification of crystal shape using Fourier descriptors and mathematical morphology. Part. Part. Syst. Charact. 1997, 14, 193–200. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Mohammad, L.; Abadie, C. Unified method to quantify aggregate shape angularity and texture using Fourier analysis. J. Mater. Civi. Eng. 2005, 17, 498–504. [Google Scholar] [CrossRef]

- Blott, S.J.; Pye, K. Particle shape: A review and new methods of characterization and classification. Sedimentology 2008, 55, 31–63. [Google Scholar] [CrossRef]

- Janoo, V. Quantification of Shape, Angularity, and Surface Texture of Base Course Materials; Cold Regions Research and Engineering Lab: Hanover, NH, USA, 1998. [Google Scholar]

- Zhang, W.G.; Goh, A.T.C. Multivariate adaptive regression splines for analysis of geotechnical engineering systems. Comput. Geotech. 2013, 48, 82–95. [Google Scholar] [CrossRef]

- Zhang, W.; Goh, A.T.C. Multivariate adaptive regression splines and neural network models for prediction of pile drivability. Geosci. Front. 2016, 7, 45–52. [Google Scholar] [CrossRef]

- Zhou, W.; Wu, W.; Ma, G.; Ng, T.T.; Chang, X.L. Undrained behavior of binary granular mixtures with different fines contents. Powder Technol. 2018, 340, 139–153. [Google Scholar] [CrossRef]

| Group | Number of Particles | Δφmax (rad) | Rdist | Rl/d |

|---|---|---|---|---|

| Group 1 | 1000 | [π/6, π/2] | 1/3 | 1/10 |

| Group 2 | 1000 | π/3 | [0,3/5] | 1/10 |

| Group 3 | 1000 | π/3 | 1/3 | [0.01, 0.2] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Wang, L.; Zhang, W. A Random Angular Bend Algorithm for Two- Dimensional Discrete Modeling of Granular Materials. Materials 2019, 12, 2169. https://doi.org/10.3390/ma12132169

Wang Z, Wang L, Zhang W. A Random Angular Bend Algorithm for Two- Dimensional Discrete Modeling of Granular Materials. Materials. 2019; 12(13):2169. https://doi.org/10.3390/ma12132169

Chicago/Turabian StyleWang, Zhenyu, Lin Wang, and Wengang Zhang. 2019. "A Random Angular Bend Algorithm for Two- Dimensional Discrete Modeling of Granular Materials" Materials 12, no. 13: 2169. https://doi.org/10.3390/ma12132169

APA StyleWang, Z., Wang, L., & Zhang, W. (2019). A Random Angular Bend Algorithm for Two- Dimensional Discrete Modeling of Granular Materials. Materials, 12(13), 2169. https://doi.org/10.3390/ma12132169