Heat Source Modeling in Selective Laser Melting

Abstract

1. Introduction

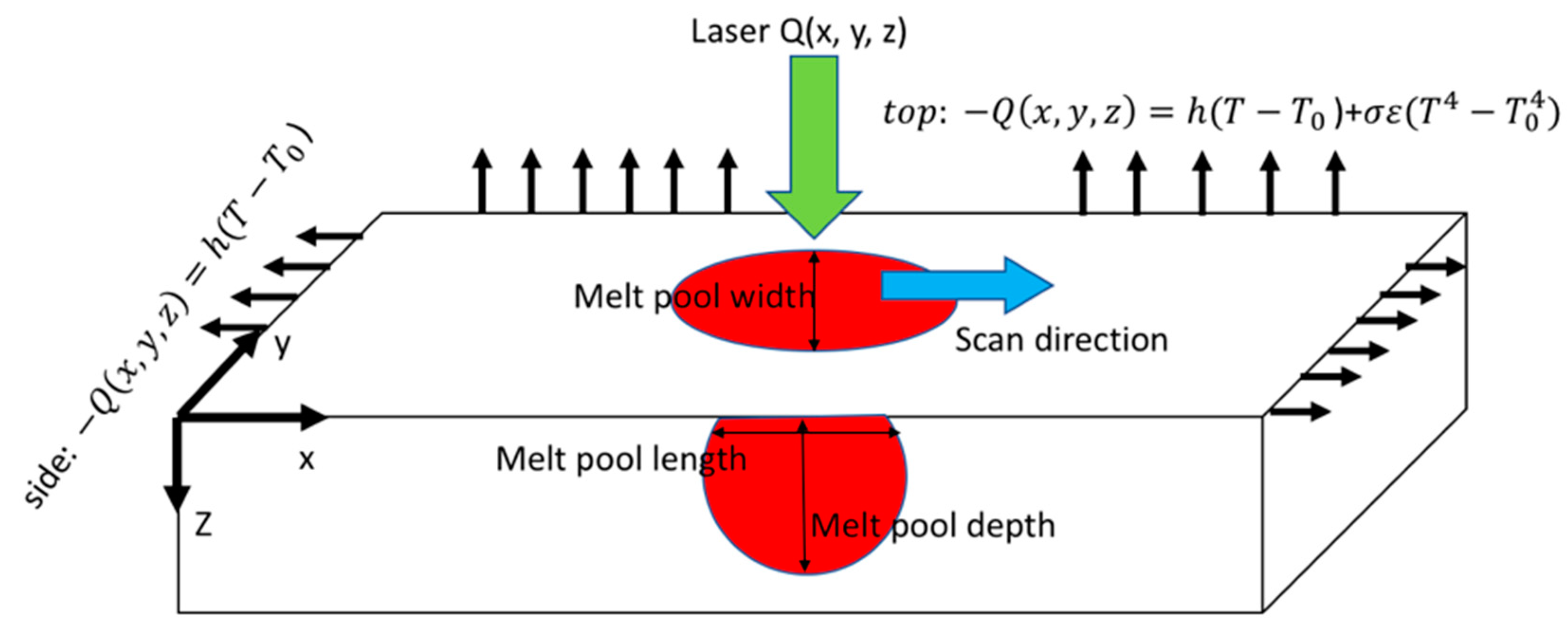

2. Methodology

2.1. Steady State Moving Point Heat Source

2.2. Transient Moving Point Heat Source

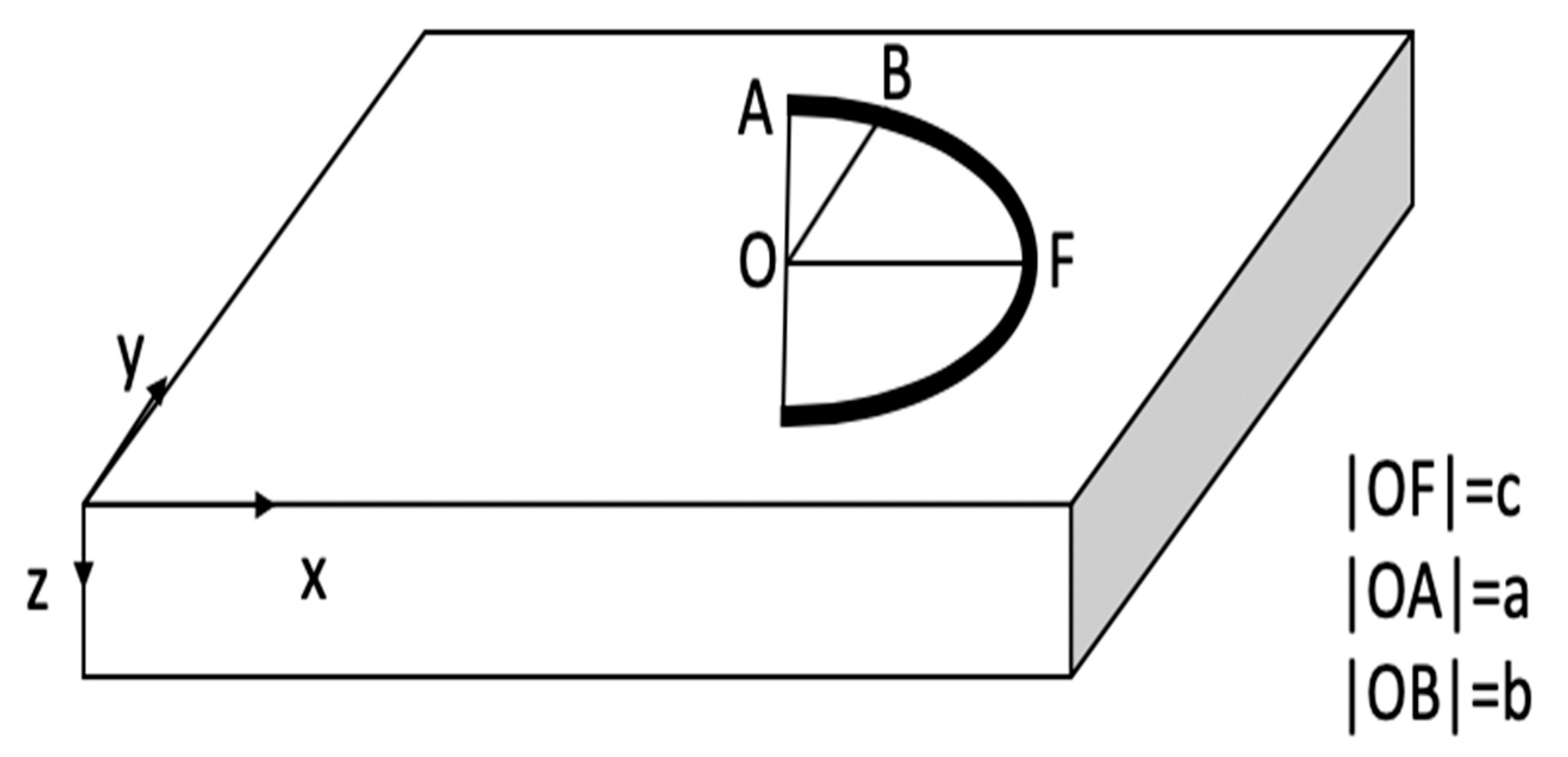

2.3. Transient Semi-Elliptical Moving Heat Source

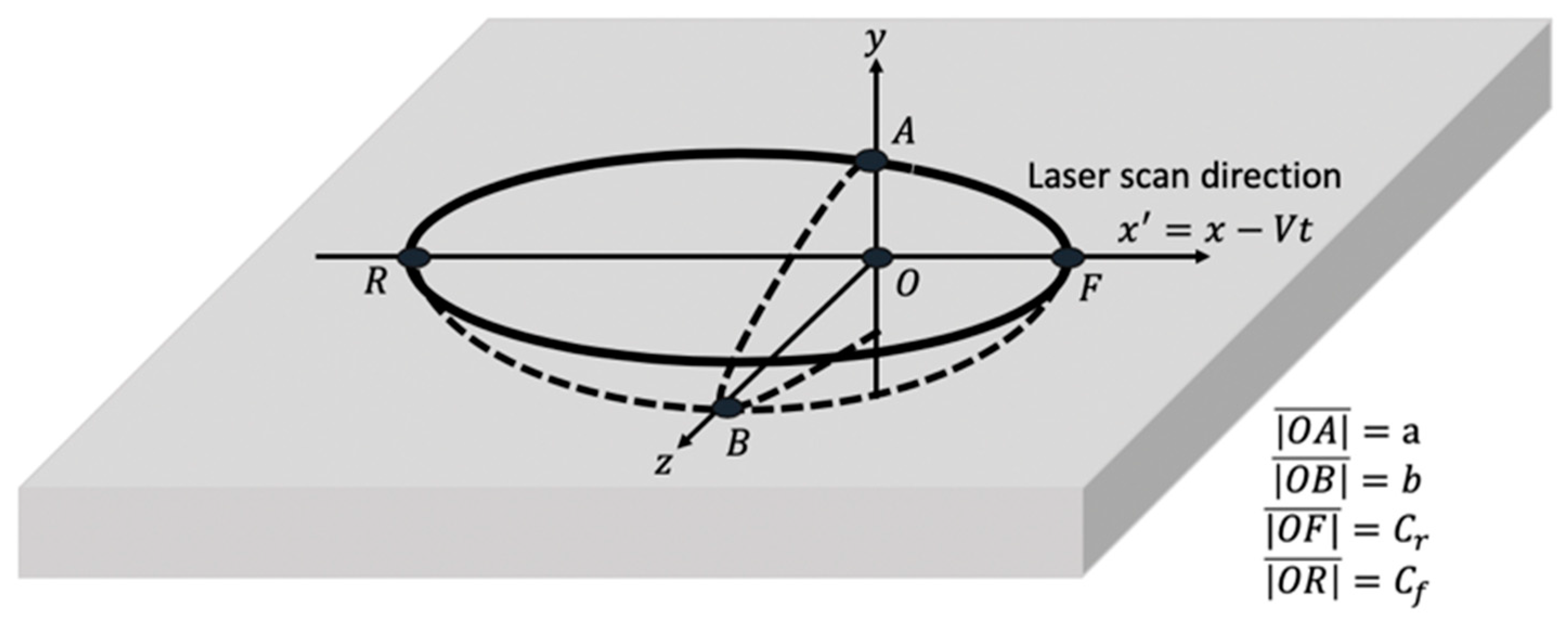

2.4. Transient Double Elliptical Moving Heat Source

2.5. Transient Uniform Moving Heat Source

3. Results and Discussion

3.1. Experimental Procedure

3.2. Modeling Results

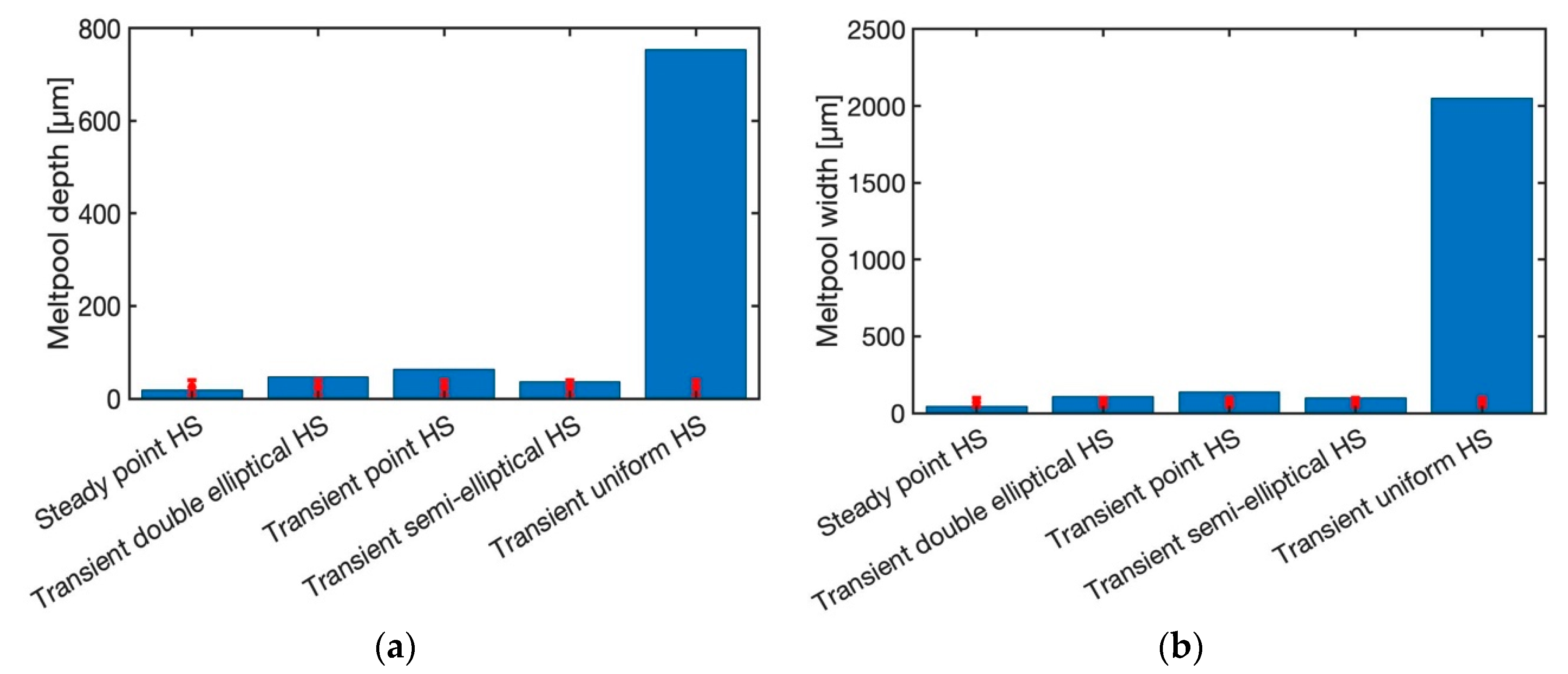

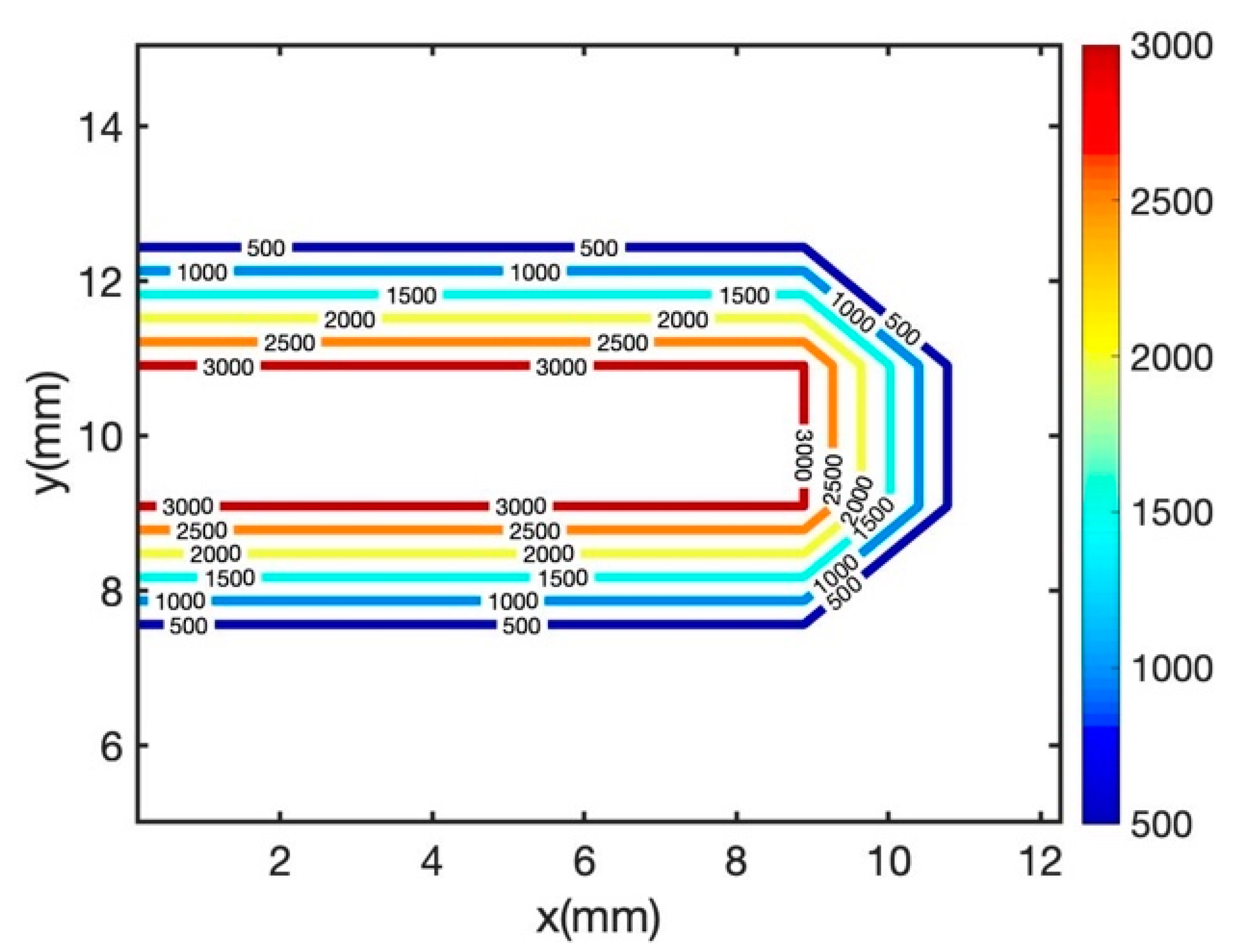

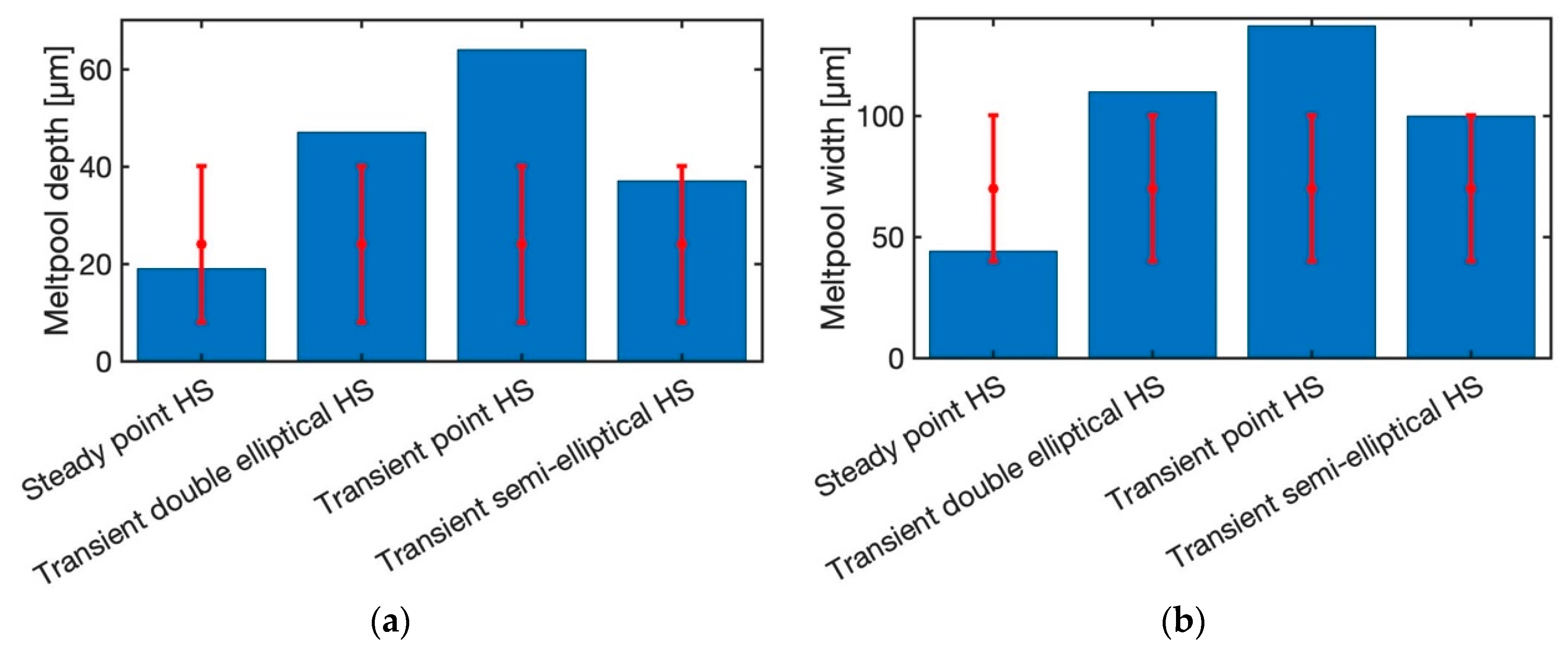

3.2.1. Comparison of Different Heat Source Geometry

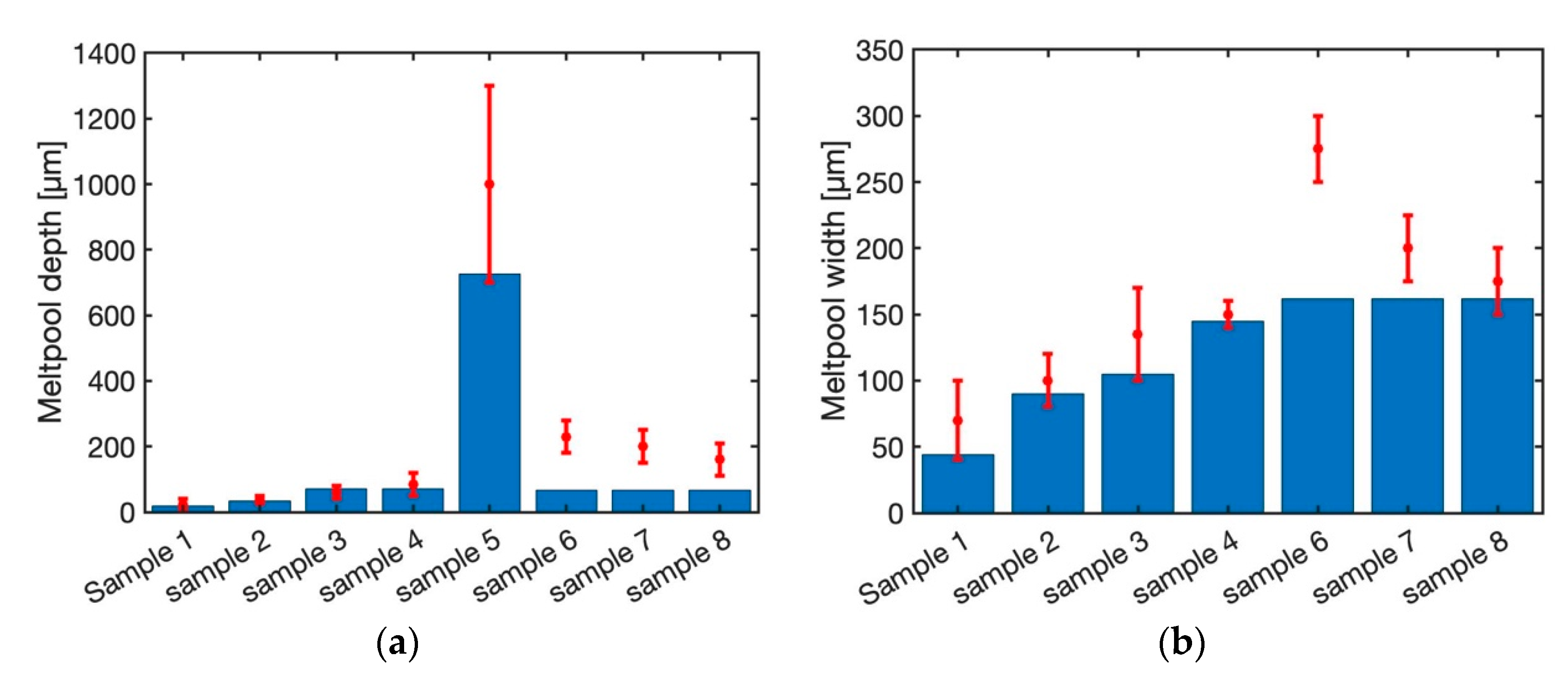

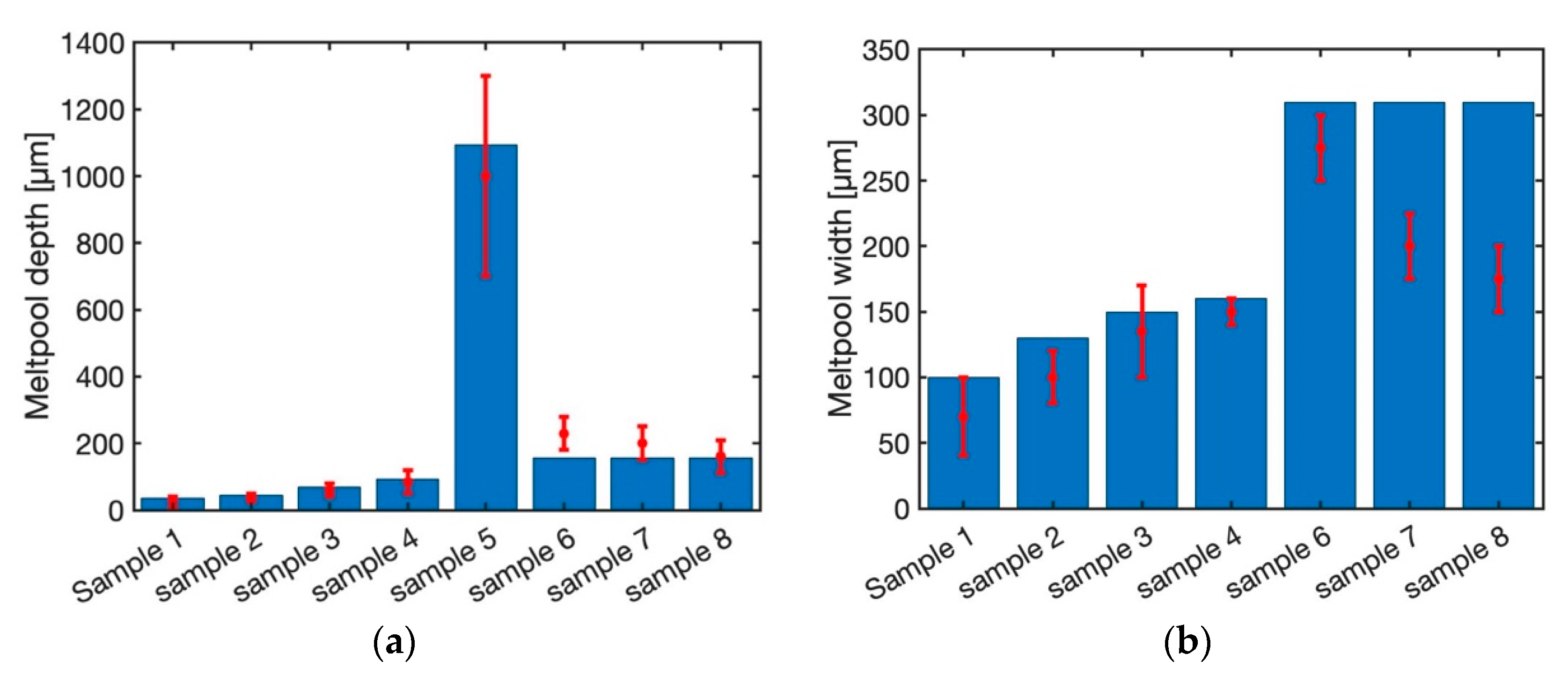

3.2.2. Region of Applicability of Each Model Based on Laser Power and Scan Speed

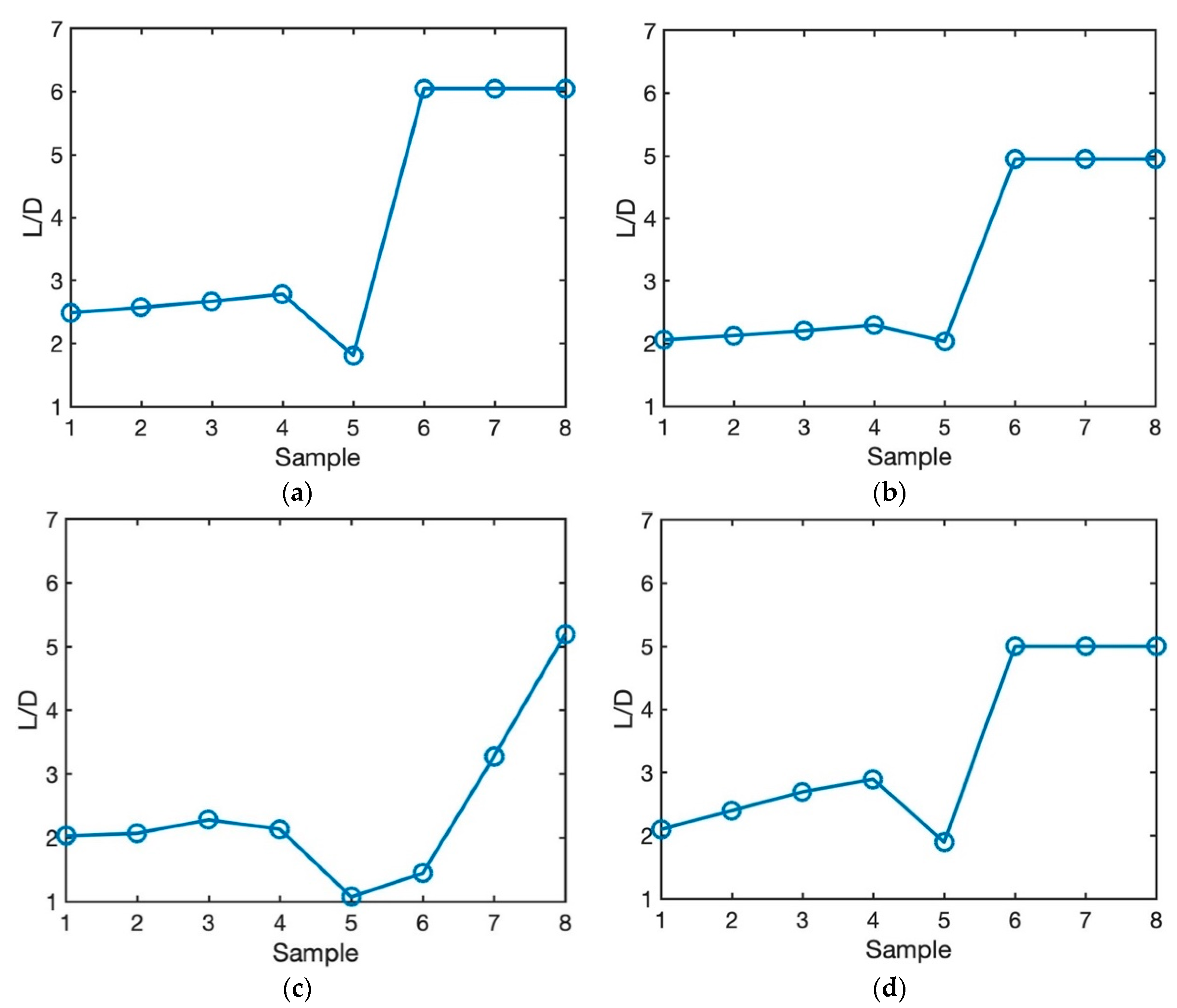

3.2.3. Effect of Process Parameters on Balling Effect

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Malhotra, R. Effect of Particle Shape on Neck Growth and Shrinkage of Nanoparticles. In Proceedings of the 2017 Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June 2017. [Google Scholar]

- Yang, Y. Temperature-Dependent Thermoelastic Analysis of Multi-Dimensional Functionally Graded Materials. Ph.D. Thesis, University of Pittsburgh, Pittsburgh, PA, USA, 2016. [Google Scholar]

- Clijsters, S.; Craeghs, T.; Buls, S.; Kempen, K.; Kruth, J.-P. In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. Int. J. Adv. Manuf. Technol. 2014, 75, 1089–1101. [Google Scholar] [CrossRef]

- Craeghs, T.; Clijsters, S.; Yasa, E.; Bechmann, F.; Berumen, S.; Kruth, J.-P. Determination of geometrical factors in Layerwise Laser Melting using optical process monitoring. Opt. Lasers Eng. 2011, 49, 1440–1446. [Google Scholar] [CrossRef]

- Mendez, P.F.; Lu, Y.; Wang, Y. Scaling Analysis of a Moving Point Heat Source in Steady-State on a Semi-Infinite Solid. J. Heat Transf. 2018, 140, 081301. [Google Scholar] [CrossRef]

- Gebhardt, A.; Schmidt, F.-M.; Hötter, J.-S.; Sokalla, W.; Sokalla, P. Additive Manufacturing by selective laser melting the realizer desktop machine and its application for the dental industry. Phys. Procedia 2010, 5, 543–549. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.; Le, T.; Austin, S.; Gibb, A.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Rümann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Mirkoohi, E.; Bocchini, P.; Liang, S.Y. Inverse analysis of residual stress in orthogonal cutting. J. Manuf. Process. 2019, 38, 462–471. [Google Scholar] [CrossRef]

- Ganeriwala, R.; Strantza, M.; King, W.; Clausen, B.; Phan, T.; Levine, L.; Brown, D.; Hodge, N. Evaluation of a thermomechanical model for prediction of residual stress during laser powder bed fusion of Ti-6Al-4V. Addit. Manuf. 2019, 27, 489–502. [Google Scholar] [CrossRef]

- Tabei, A.; Mirkoohi, E.; Garmestani, H.; Liang, S. Modeling of texture development in additive manufacturing of Ni-based superalloys. Int. J. Adv. Manuf. Technol. 2019, 1–10. [Google Scholar] [CrossRef]

- Zhao, X.; Iyer, A.; Promoppatum, P.; Yao, S.-C. Numerical modeling of the thermal behavior and residual stress in the direct metal laser sintering process of titanium alloy products. Addit. Manuf. 2017, 14, 126–136. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Bocchini, P.; Liang, S.Y. An analytical modeling for process parameter planning in the machining of Ti-6Al-4V for force specifications using an inverse analysis. Int. J. Adv. Manuf. Technol. 2018, 98, 2347–2355. [Google Scholar] [CrossRef]

- Feng, Y.; Hung, T.-P.; Lu, Y.-T.; Lin, Y.-F.; Hsu, F.-C.; Lin, C.-F.; Lu, Y.-C.; Lu, X.; Liang, S.Y. Inverse Analysis of Inconel 718 Laser-Assisted Milling to Achieve Machined Surface Roughness. Int. J. Precis. Eng. Manuf. 2018, 19, 1611–1618. [Google Scholar] [CrossRef]

- Feng, Y.; Hung, T.-P.; Lu, Y.-T.; Lin, Y.-F.; Hsu, F.-C.; Lin, C.-F.; Lu, Y.-C.; Lu, X.; Liang, S.Y. Surface roughness modeling in Laser-assisted End Milling of Inconel 718. Mach. Sci. Technol. 2019, 1–19. [Google Scholar] [CrossRef]

- Zeng, K.; Pal, D.; Stucker, B. A review of thermal analysis methods in laser sintering and selective laser melting. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012. [Google Scholar]

- Lombera, G.; Cervera, G.B.M. Numerical prediction of temperature and density distributions in selective laser sintering processes. Rapid Prototyp. J. 1999, 5, 21–26. [Google Scholar]

- Loh, L.-E.; Chua, C.-K.; Yeong, W.-Y.; Song, J.; Mapar, M.; Sing, S.-L.; Liu, Z.-H.; Zhang, D.-Q. Numerical investigation and an effective modelling on the Selective Laser Melting (SLM) process with aluminium alloy 6061. Int. J. Heat Mass Transf. 2015, 80, 288–300. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Bocchini, P.; Liang, S.Y. Analytical temperature predictive modeling and non-linear optimization in machining. Int. J. Adv. Manuf. Technol. 2019, 102, 1557–1566. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Bocchini, P.; Liang, S.Y. An Analytical Modeling for Designing the Process Parameters for Temperature Specifications in Machining. Preprints 2018, 2018, 070528. [Google Scholar]

- Feng, Y.; Lu, Y.-T.; Lin, Y.-F.; Hung, T.-P.; Hsu, F.-C.; Lin, C.-F.; Lu, Y.-C.; Liang, S.Y. Inverse analysis of the cutting force in laser-assisted milling on Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 905–914. [Google Scholar] [CrossRef]

- Chiumenti, M.; Neiva, E.; Salsi, E.; Cervera, M.; Badia, S.; Moya, J.; Chen, Z.; Lee, C.; Davies, C. Numerical modelling and experimental validation in Selective Laser Melting. Addit. Manuf. 2017, 18, 171–185. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Jagdale, V.; Srinivasan, G.; El-Wardany, T.; Michaleris, P. Thermal modeling of Inconel 718 processed with powder bed fusion and experimental validation using in situ measurements. Addit. Manuf. 2016, 11, 7–15. [Google Scholar] [CrossRef]

- Rodriguez, E.; Mireles, J.; Terrazas, C.A.; Espalin, D.; Perez, M.A.; Wicker, R.B. Approximation of absolute surface temperature measurements of powder bed fusion additive manufacturing technology using in situ infrared thermography. Addit. Manuf. 2015, 5, 31–39. [Google Scholar] [CrossRef]

- Fischer, P.; Locher, M.; Romano, V.; Weber, H.; Kolossov, S.; Glardon, R. Temperature measurements during selective laser sintering of titanium powder. Int. J. Mach. Tools Manuf. 2004, 44, 1293–1296. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Andreotta, R.; Ladani, L.; Brindley, W. Finite element simulation of laser additive melting and solidification of Inconel 718 with experimentally tested thermal properties. Finite Elements Anal. Des. 2017, 135, 36–43. [Google Scholar] [CrossRef]

- Roberts, I.; Wang, C.J.; Esterlein, R.; Stanford, M.; Mynors, D. A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- Antony, K.; Arivazhagan, N.; Senthilkumaran, K. Numerical and experimental investigations on laser melting of stainless steel 316L metal powders. J. Manuf. Process. 2014, 16, 345–355. [Google Scholar] [CrossRef]

- Wessels, H.; Bode, T.; Weißenfels, C.; Wriggers, P.; Zohdi, T.I. Investigation of heat source modeling for selective laser melting. Comput. Mech. 2018, 63, 949–970. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Ning, J.; Bocchini, P.; Fergani, O.; Chiang, K.-N.; Liang, S.Y. Thermal Modeling of Temperature Distribution in Metal Additive Manufacturing Considering Effects of Build Layers, Latent Heat, and Temperature-Sensitivity of Material Properties. J. Manuf. Mater. Process. 2018, 2, 63. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Li, L. The significance of deposition point standoff variations in multiple-layer coaxial laser cladding (coaxial cladding standoff effects). Int. J. Mach. Tools Manuf. 2004, 44, 573–584. [Google Scholar] [CrossRef]

- Peyre, P.; Aubry, P.; Fabbro, R.; Neveu, R.; Longuet, A. Analytical and numerical modelling of the direct metal deposition laser process. J. Phys. D Appl. Phys. 2008, 41, 025403. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Clarendon Press: Oxford, UK, 1959. [Google Scholar]

- Paul, R.; Anand, S. Process energy analysis and optimization in selective laser sintering. J. Manuf. Syst. 2012, 31, 429–437. [Google Scholar] [CrossRef]

- Fu, C.H.; Guo, Y.B. Three-Dimensional Temperature Gradient Mechanism in Selective Laser Melting of Ti-6Al-4V. J. Manuf. Sci. Eng. 2014, 136, 061004. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Wu, C. Temperature field and microstructure of Ti6Al4V laser melting deposition bath. Chin. J. Lasers 2017, 44, 113–120. (In Chinese) [Google Scholar]

- Soylemez, E. Modeling The Melt Pool Of The Laser Sintered Ti6al4v Layers With Goldak’S Double-Ellipsoidal Heat Source. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2018. [Google Scholar]

- Goldak, J. A double ellipsoid finite element model for welding heat sources. IIW Doc. No. 1985, 212. [Google Scholar]

- Nguyen, N.T.; Ohta, A.; Matsuoka, K.; Suzuki, N.; Maeda, Y. Analytical solutions for transient temperature of semi-infinite body subjected to 3-D moving heat sources. Weld. J. 1999, 78, 265. [Google Scholar]

- Lundbäck, A.; Alberg, H.; Henrikson, P. Simulation and validation of TIG-welding and post weld heat treatment of an Inconel 718 plate. In Proceedings of the International Seminar on Numerical Analysis of Weldability, Graz, Austria, 29 September−1 October 2003; pp. 683–696. [Google Scholar]

- Nguyen, N.T.; Mai, Y.W.; Simpson, S.; Ohta, A. Analytical Approximate Solution for Double Ellipsoidal Heat Source in Finite Thick Plate. Weld. J. 2004, 83, 82. [Google Scholar]

- Kruth, J.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Balling phenomena during direct laser sintering of multi-component Cu-based metal powder. J. Alloy. Compd. 2007, 432, 163–166. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Wang, Z.; Wang, L.; Liu, J.; Jiang, W. Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl. Surf. Sci. 2010, 256, 4350–4356. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater. Des. 2009, 30, 2903–2910. [Google Scholar] [CrossRef]

| Sample | 1 [37] | 2 [37] | 3 [37] | 4 [37] | 5 [38] | 6 [39] | 7 [39] | 8 [39] |

|---|---|---|---|---|---|---|---|---|

| Laser power (W) | 20 | 40 | 60 | 80 | 500 | 300 | 300 | 300 |

| Scan speed (mm/s) | 200 | 200 | 200 | 200 | 6 | 400 | 800 | 1200 |

| Laser spot radius (µm) | 26 | 26 | 26 | 26 | 26 | 50 | 50 | 50 |

| Layer thickness (µm) | 30 | 30 | 30 | 30 | 45 | 30 | 30 | 30 |

| Absorption ratio | 0.77 | 0.77 | 0.77 | 0.77 | 0.77 | 0.77 | 0.77 | 0.77 |

| Properties | Ti-6Al-4V |

|---|---|

| Liquidus temperature (°C) | 1655 |

| Solidus temperature (°C) | 1605 |

| Thermal conductivity (W/m°C) | |

| Specific Heat (J/kg°C) | |

| Density (kg/m3) | |

| Latent heat (J/g) | 286 |

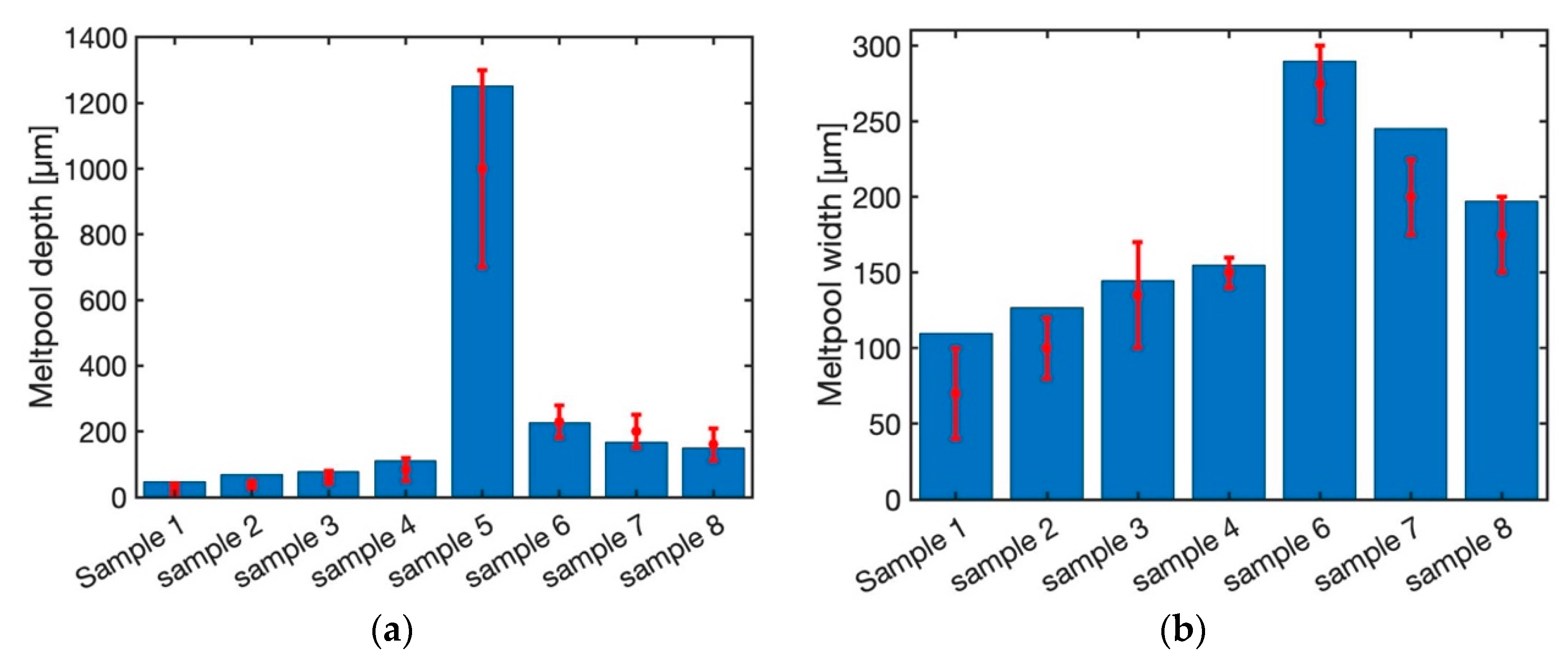

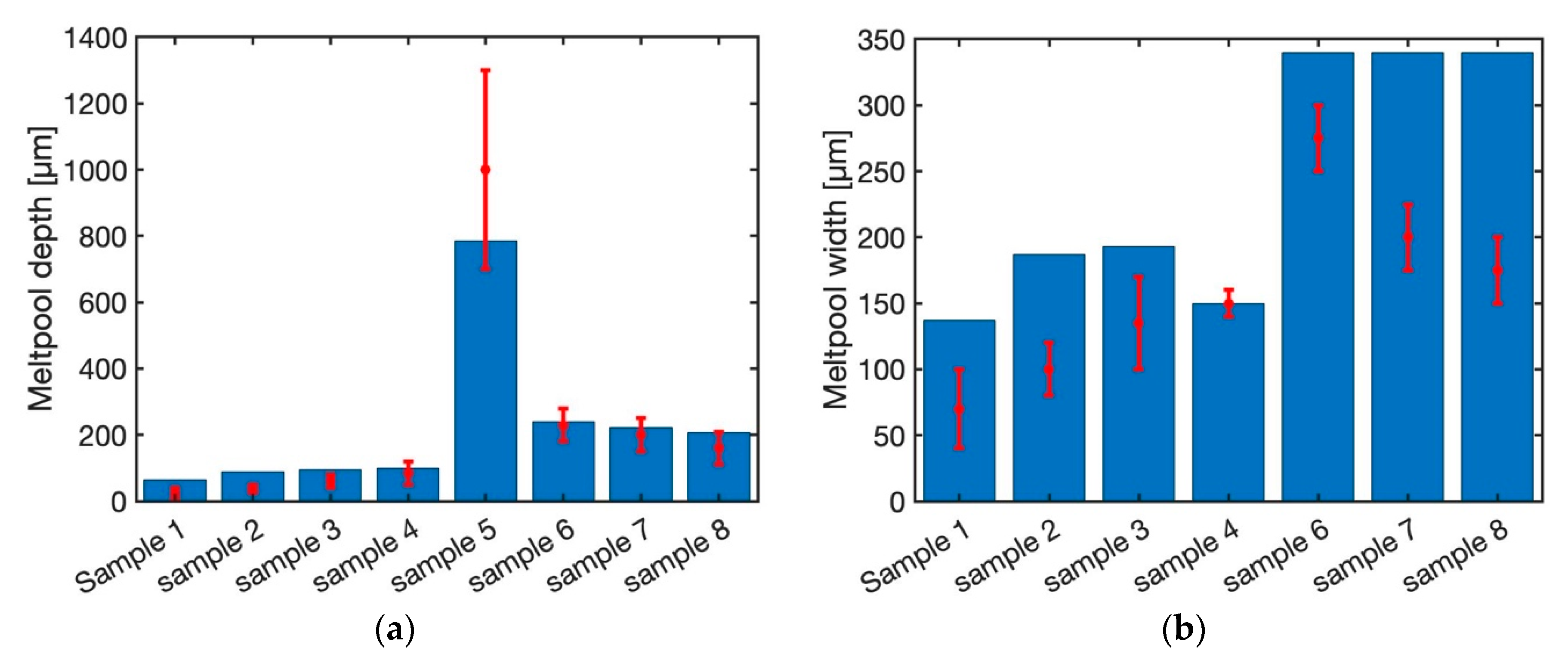

| Sample | Steady State Moving Point Heat Source (HS) | Transient Moving Point HS | Semi-Elliptical HS | Double-Elliptical HS | Experiment | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Depth (µm) | Width (µm) | Depth (µm) | Width (µm) | Depth (µm) | Width (µm) | Depth (µm) | Width (µm) | Depth (µm) | Width (µm) | |

| 1 | 19 | 44 | 64 | 137 | 37 | 100 | 47 | 110 | 24−40 [37] | 70−100 [37] |

| 2 | 33 | 90 | 89 | 187 | 46 | 130 | 68 | 127 | 37−50 [37] | 80−120 [37] |

| 3 | 71 | 105 | 95 | 193 | 68 | 150 | 78 | 145 | 50−80 [37] | 110−170 [37] |

| 4 | 72 | 145 | 100 | 150 | 94 | 160 | 111 | 155 | 85−110 [37] | 140−160 [37] |

| 5 | 727 | -- | 786 | -- | 1095 | -- | 1252 | -- | 700−1300 [38] | -- |

| 6 | 67 | 162 | 241 | 340 | 156 | 310 | 227 | 290 | 190−280 [39] | 250−300 [39] |

| 7 | 67 | 162 | 222 | 340 | 156 | 310 | 168 | 245 | 150−250 [39] | 185−225 [39] |

| 8 | 67 | 162 | 206 | 340 | 156 | 310 | 150 | 197 | 110−210 [39] | 150−200 [39] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirkoohi, E.; Seivers, D.E.; Garmestani, H.; Liang, S.Y. Heat Source Modeling in Selective Laser Melting. Materials 2019, 12, 2052. https://doi.org/10.3390/ma12132052

Mirkoohi E, Seivers DE, Garmestani H, Liang SY. Heat Source Modeling in Selective Laser Melting. Materials. 2019; 12(13):2052. https://doi.org/10.3390/ma12132052

Chicago/Turabian StyleMirkoohi, Elham, Daniel E. Seivers, Hamid Garmestani, and Steven Y. Liang. 2019. "Heat Source Modeling in Selective Laser Melting" Materials 12, no. 13: 2052. https://doi.org/10.3390/ma12132052

APA StyleMirkoohi, E., Seivers, D. E., Garmestani, H., & Liang, S. Y. (2019). Heat Source Modeling in Selective Laser Melting. Materials, 12(13), 2052. https://doi.org/10.3390/ma12132052