A Comparative Study between Knocked-Down Aligned Carbon Nanotubes and Buckypaper-Based Strain Sensors

Abstract

:1. Introduction

- (1)

- (2)

- (3)

- (4)

- As vertically aligned CNT forests (VA-CNTs), synthesized by laser-oriented deposition (LOD) method directly into the matrices, allowing the incorporation of CNTs due to the covalent bounds formed during the process [10]. Furthermore, a dramatic change of materials resistivity via LOD application is reported in the literature [11].

- Buckypapers, in which CNTs are randomly dispersed with two different solvents and show an isotropic electrical behavior, and;

- Knocked-down VA-CNTs, which are highly aligned in one direction and show anisotropic electrical properties (and were developed in our previous work [3]).

2. Materials and Methods

2.1. Aligned CNT/PI Samples Preparation

2.2. CNT Buckypaper Samples Preparation

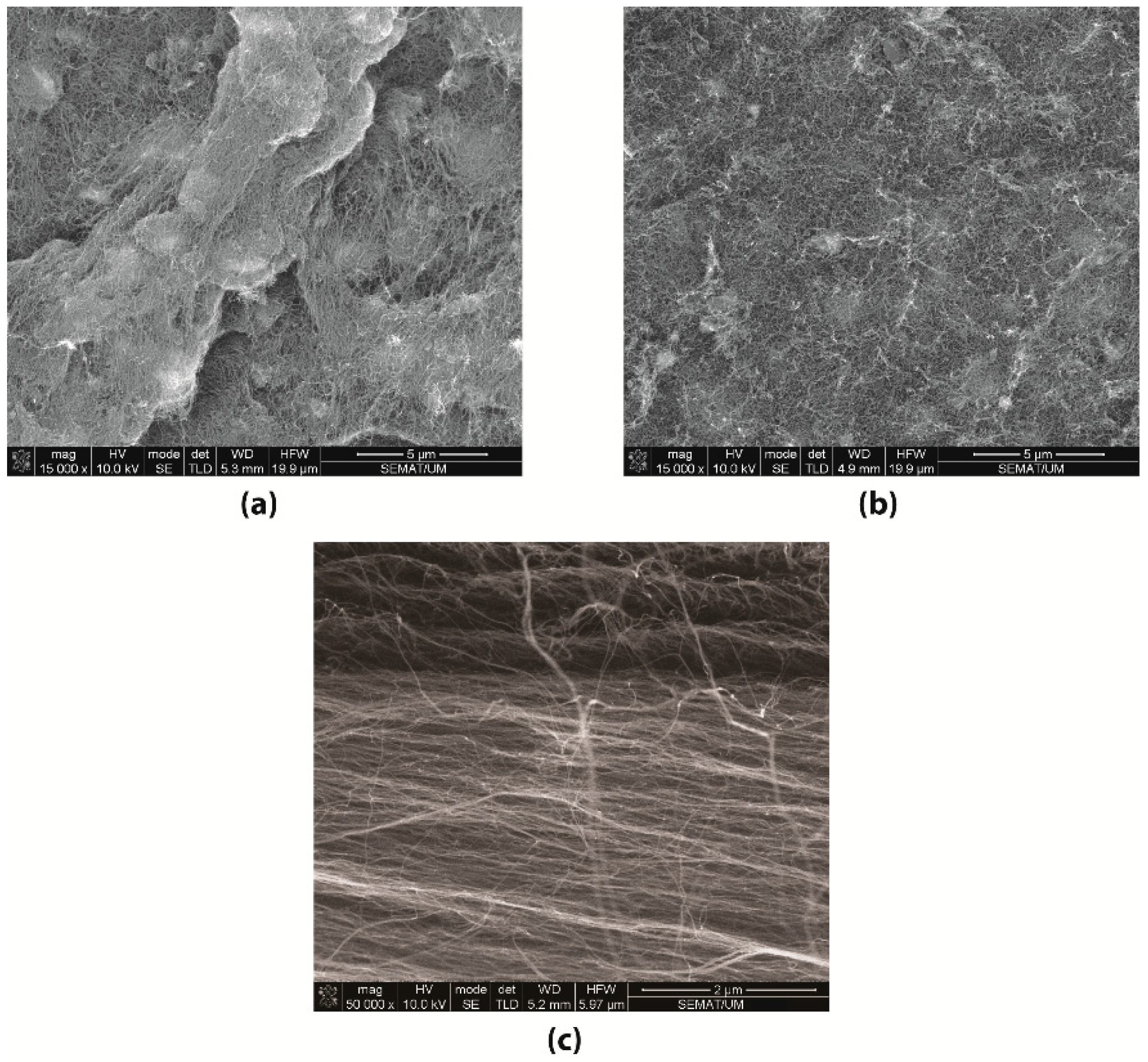

2.3. SEM Analysis

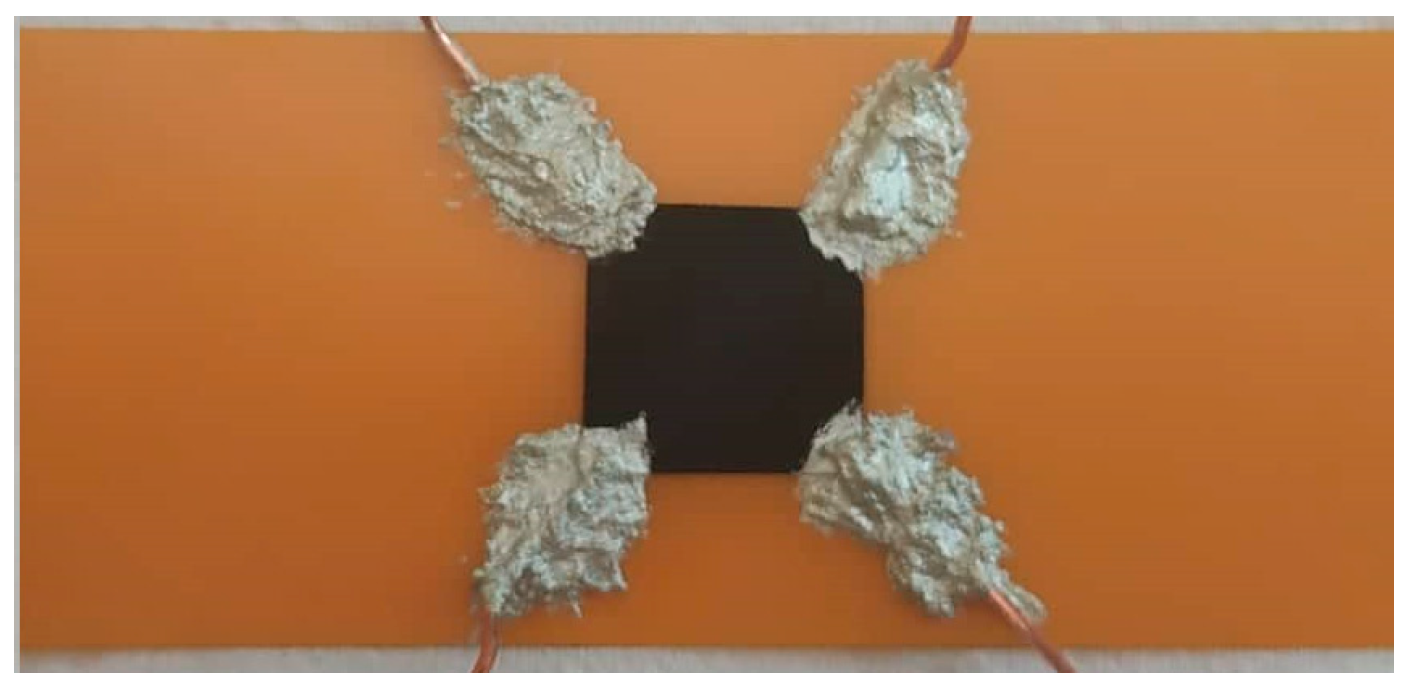

2.4. Electrical Resistivity versus Strain Measurements

3. Results

3.1. SEM Analysis

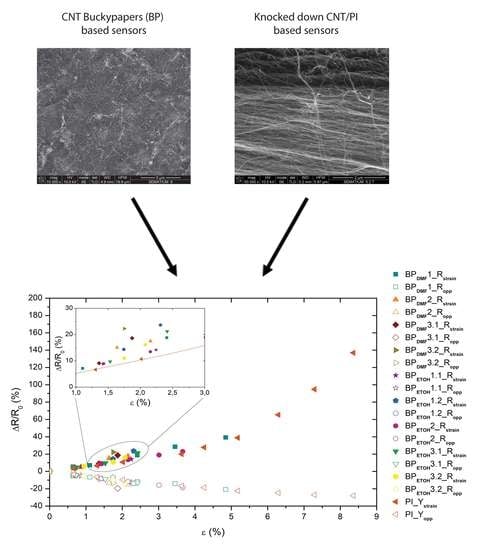

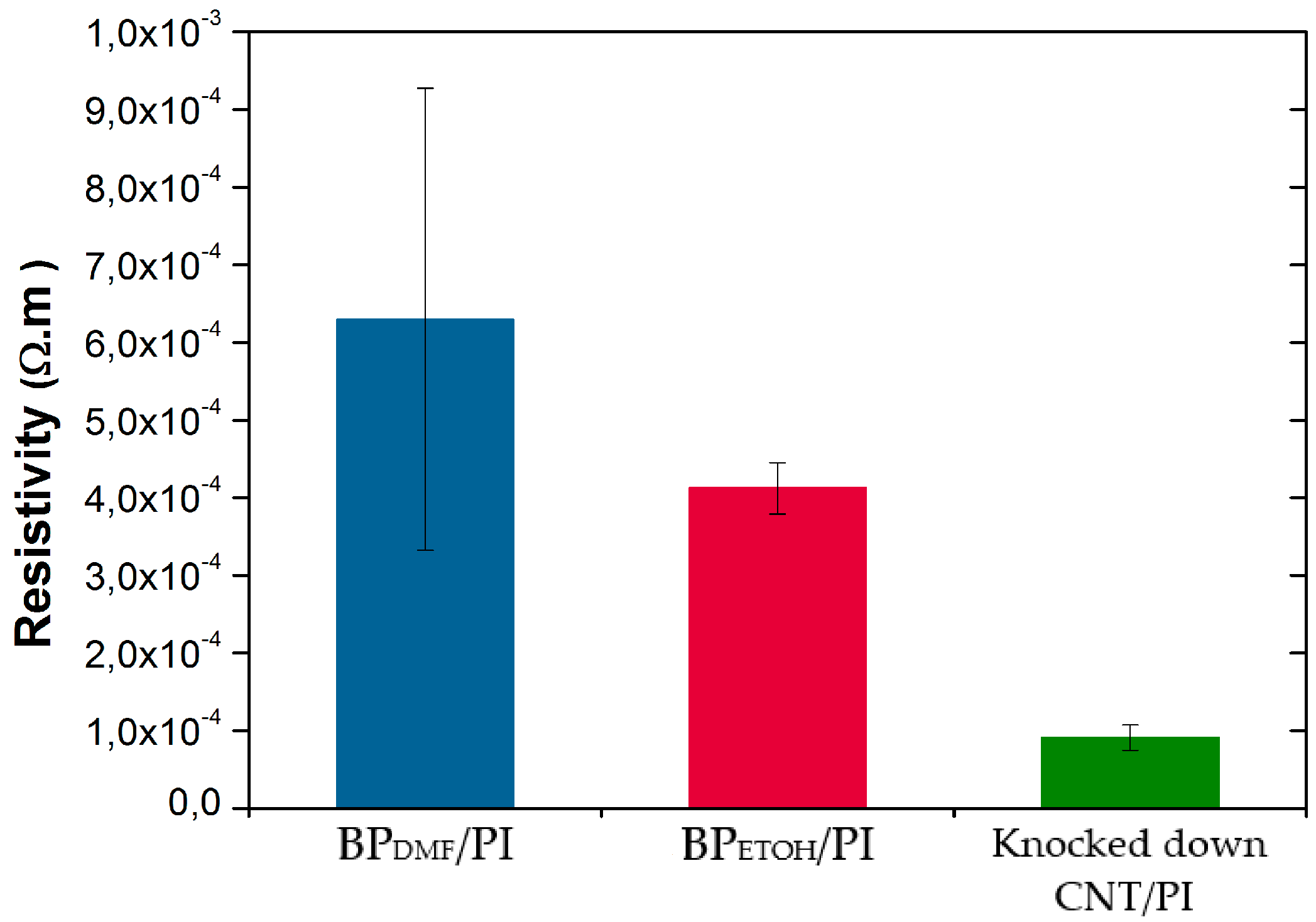

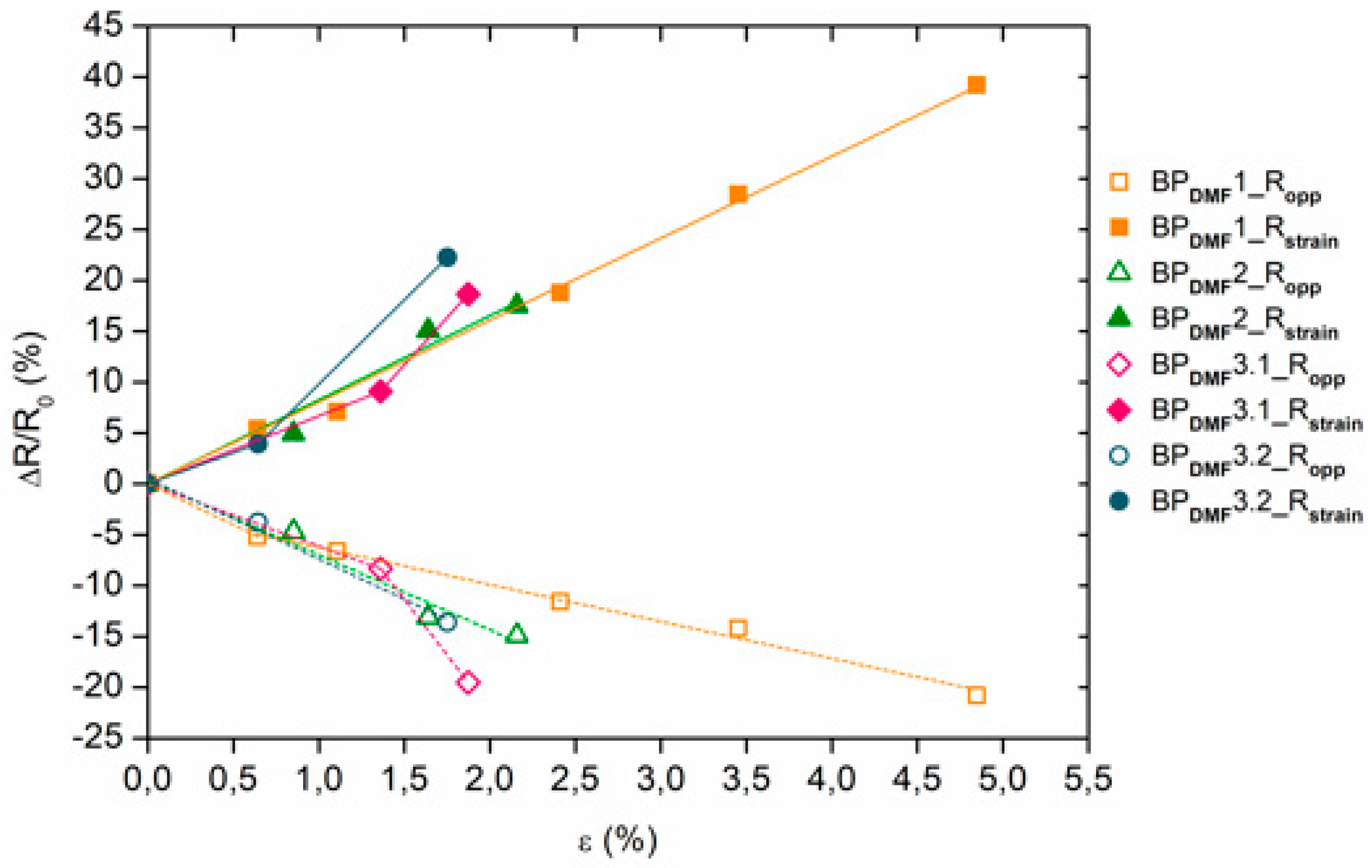

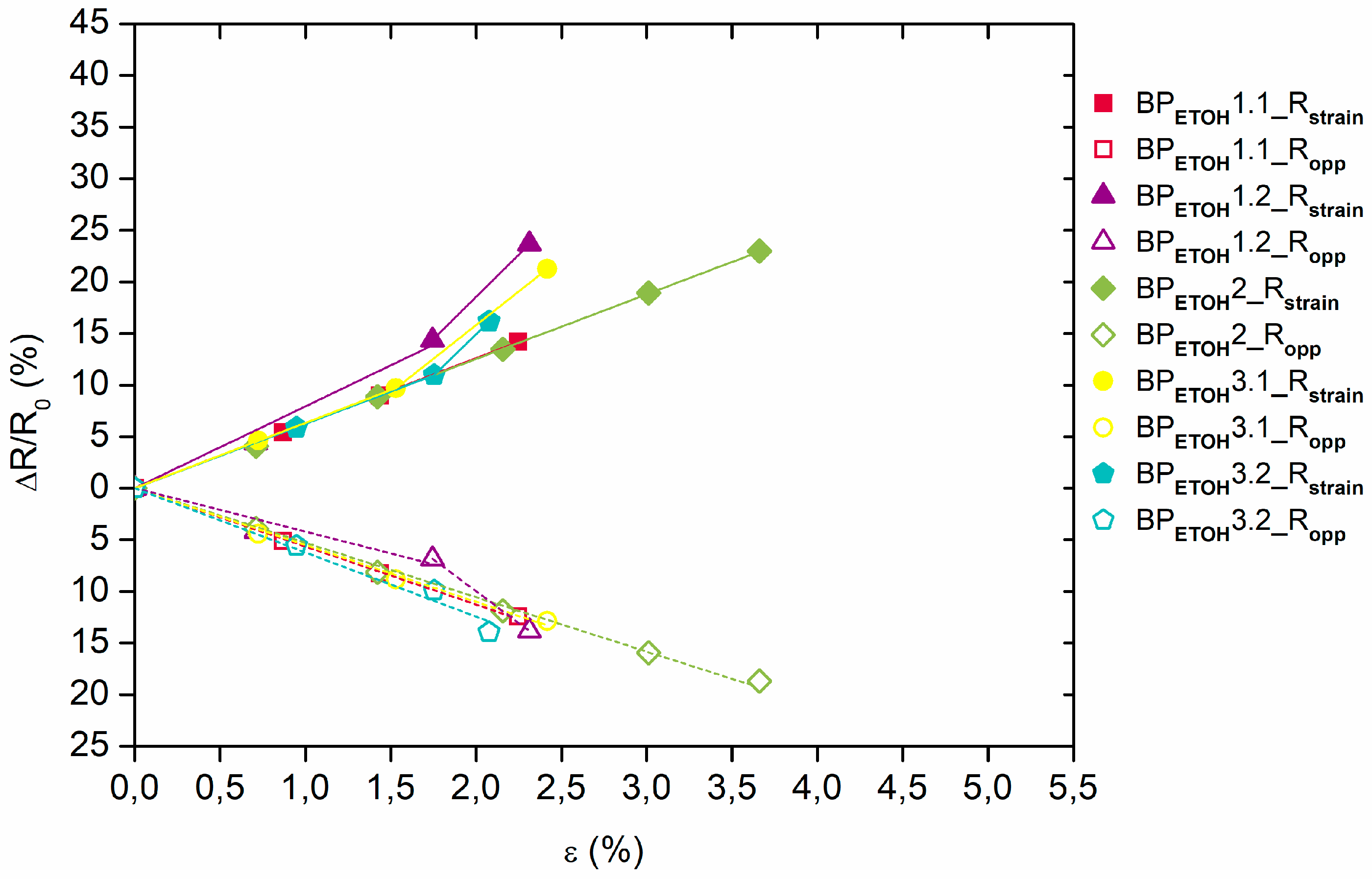

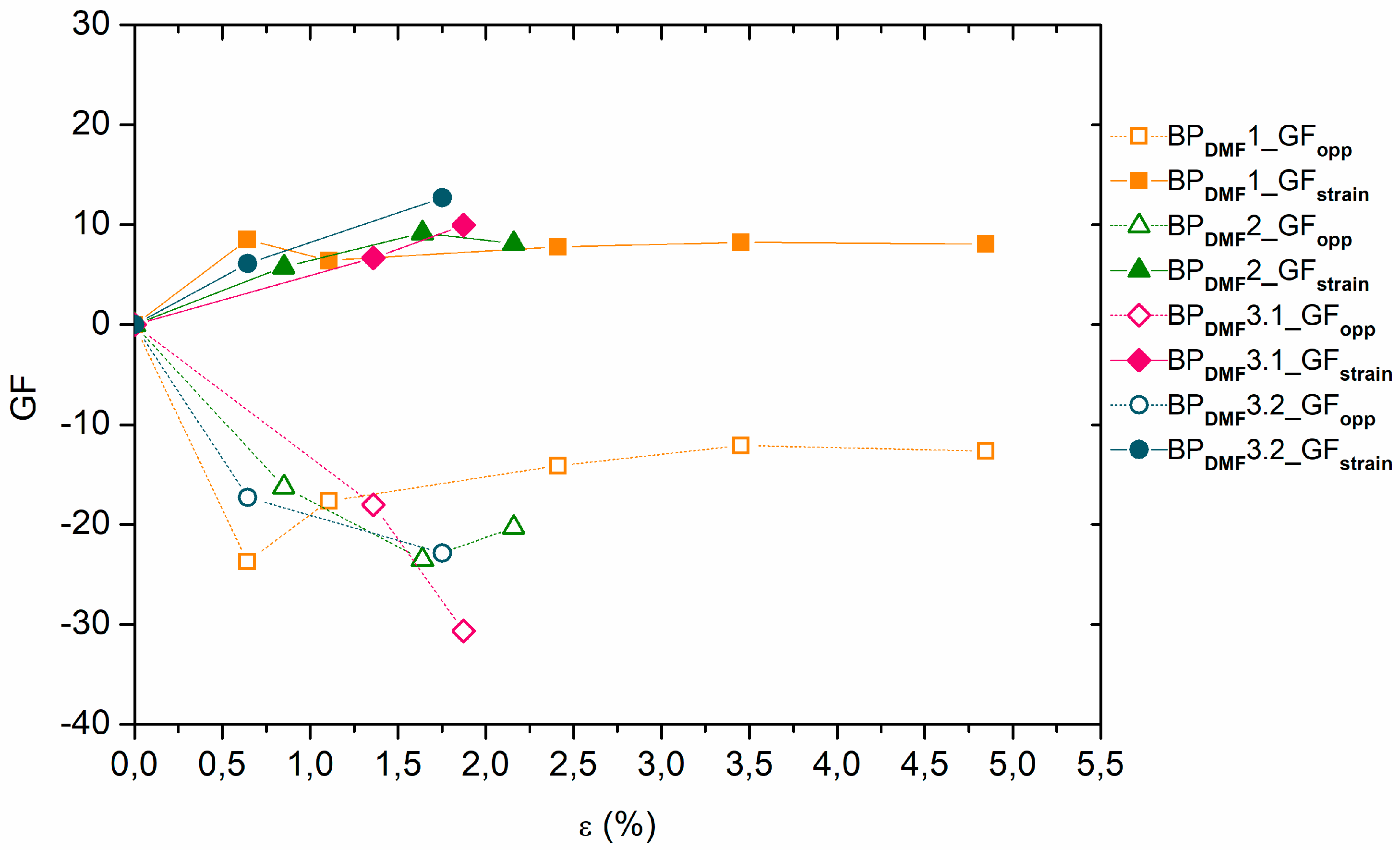

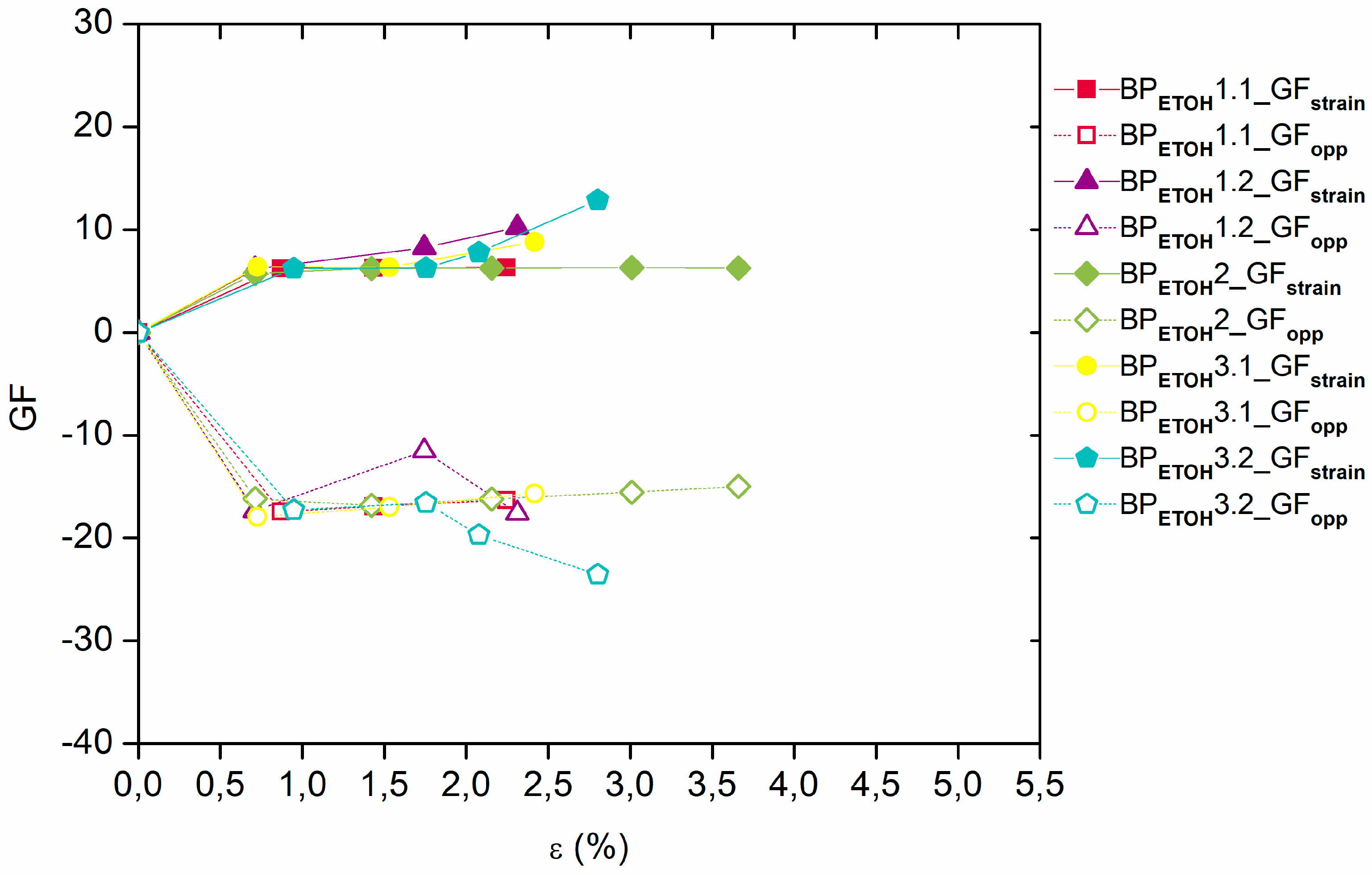

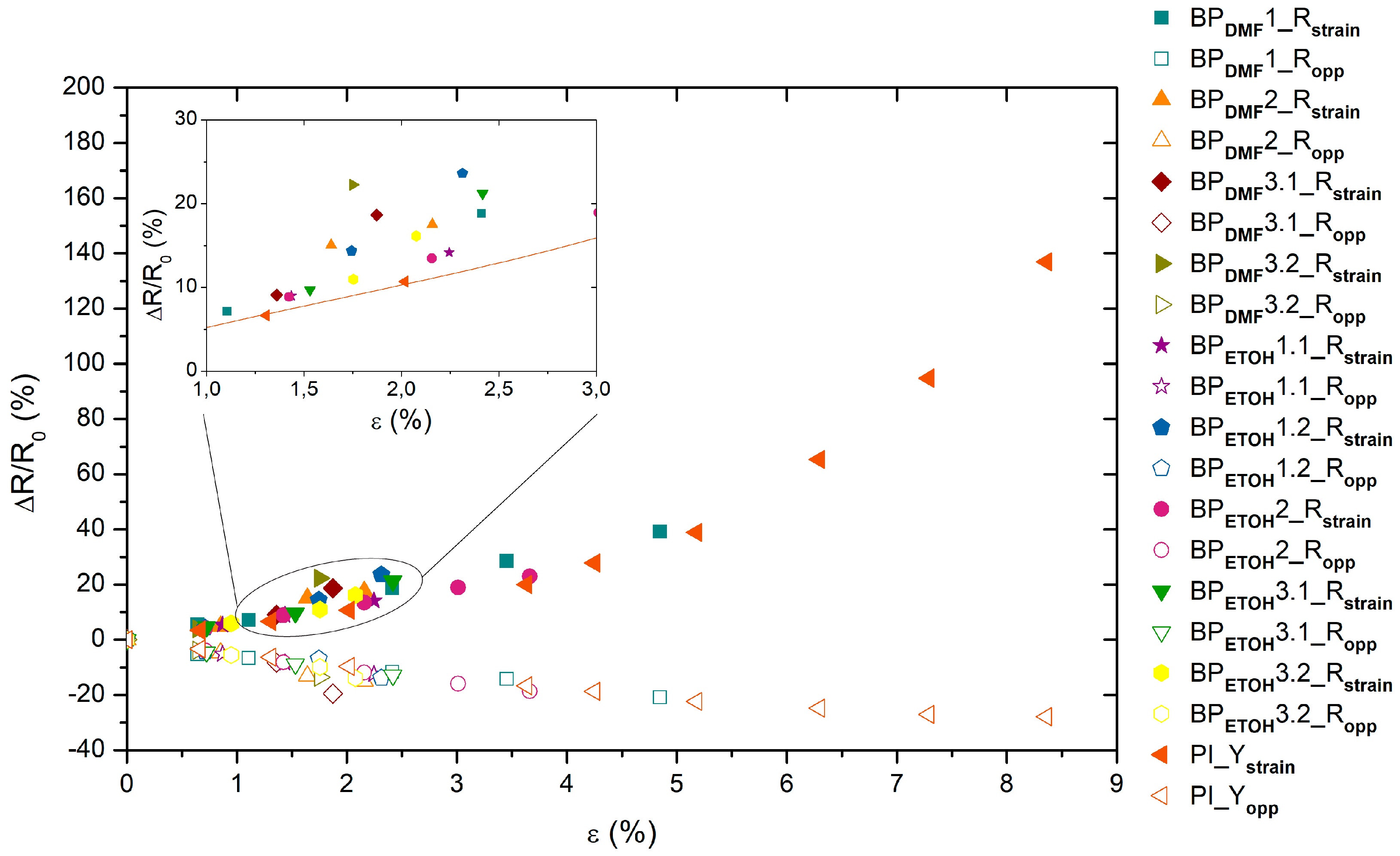

3.2. Electrical Resistivity versus Strain Measurements

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bandaru, P.R. Electrical Properties and Applications of Carbon Nanotube Structures. J. Nanosci. Nanotechnol. 2007, 7, 1239–1267. [Google Scholar] [CrossRef] [PubMed]

- Shearer, C.J.; Cherevan, A.; Eder, D. Application and Future Challenges of Functional Nanocarbon Hybrids. Adv. Mater. 2014, 26, 2296–2318. [Google Scholar] [CrossRef] [PubMed]

- Santos, A.; Amorim, L.; Nunes, J.P.; Rocha, L.A.; Silva, A.F.; Viana, J.C. Aligned carbon nanotube based sensors for strain sensing applications. Sens. Actuators A Phys. 2019, 289, 157–164. [Google Scholar] [CrossRef]

- Bouhamed, A.; Müller, C.; Choura, S.; Kanoun, O. Processing and characterization of MWCNTs/epoxy nanocomposites thin films for strain sensing applications. Sens. Actuators A Phys. 2017, 257, 65–72. [Google Scholar] [CrossRef]

- Selvan, N.T.; Eshwaran, S.B.; Das, A.; Stöckelhuber, K.W.; Wießner, S. Piezoresistive natural rubber-multiwall carbon nanotube nanocomposite for sensor applications. Sens. Actuators A Phys. 2016, 239, 102–113. [Google Scholar] [CrossRef]

- Rein, M.D.; Breuer, O.; Wagner, H.D. Sensors and sensitivity: Carbon nanotube buckypaper films as strain sensing devices. Compos. Sci. Technol. 2011, 71, 373–381. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, G.; Liu, C.; Fan, S. High-Density Carbon Nanotube Buckypapers with Superior Transport and Mechanical Properties. Nano Lett. 2012, 12, 4848–4852. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Bogdanovich, A.E.; Bradford, P.D. Aligned Carbon Nanotube Sheet Piezoresistive Strain Sensors. Smart Mater. Struct. 2015, 24, 095004. [Google Scholar] [CrossRef]

- García, B.E.J.; Hart, A.J.; Wardle, B.L.; Slocum, A.H. Fabrication and Nanocompression Testing of Aligned Carbon-Nanotube—Polymer Nanocomposites. Adv. Mater. 2007, 19, 2151–2156. [Google Scholar] [CrossRef]

- Kamanina, N.V.; Likhomanova, S.V.; Kuzhakov, P.V. Advantages of the surface structuration of KBr materials for spectrometry and sensors. Sensors 2018, 18, 3013. [Google Scholar] [CrossRef]

- Adiloğlu, S. Perspective of the Structuration Process use in the Optoelectronics, Solar Energy, and Biomedicine. In Nanomechanics; IntechOpen: London, UK, 2017; Volume 8, pp. 167–183. [Google Scholar]

- Kanoun, O.; Müller, C.; Benchirouf, A.; Sanli, A.; Dinh, T.; Al-Hamry, A.; Bu, L.; Gerlach, C.; Bouhamed, A. Potential of Flexible Carbon Nanotube Films for High Performance Strain and Pressure Sensors. Nanotechnol. Opt. Sens. 2014, 14, 148–183. [Google Scholar]

- Kanoun, O.; Müller, C.; Benchirouf, A.; Sanli, A.; Dinh, T.N.; Al-Hamry, A.; Bu, L.; Gerlach, C.; Bouhamed, A. Flexible Carbon Nanotube Films for High Performance Strain Sensors. Sensors 2014, 14, 10042–10071. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Kröger, M. A theoretical evaluation of the effects of carbon nanotube entanglement and bundling on the structural and mechanical properties of buckypaper. Carbon 2012, 50, 1793–1806. [Google Scholar] [CrossRef]

- Wang, X.; Lu, S.; Ma, K.; Xiong, X.; Zhang, H.; Xu, M. Tensile strain sensing of buckypaper and buckypaper composites. Mater. Des. 2015, 88, 414–419. [Google Scholar] [CrossRef]

- Li, C.; Zhang, D.; Deng, C.; Wang, P.; Hu, Y.; Bin, Y.; Fan, Z.; Pan, L. High performance strain sensor based on buckypaper for full-range detection of human motions. Nanoscale 2018, 10, 14966–14975. [Google Scholar] [CrossRef] [PubMed]

- Bu, L.; Steiz, J.; Kanoun, O. Influence of processing parameters on properties of strain sensors based on carbon nanotube films. In Proceedings of the 7th International Multi-Conference on Systems, Signals and Devices—Sensors, Circuits & Instrumentation Systems, Amman, Jordan, 27–30 June 2010. [Google Scholar]

- Tan, S.H.; Mariatti, M.; Mohamed, A.R.; Wan Dalina, W.A.D.; Mohd Ishak, Z.A. Fabrication and Properties of Multi-Walled Carbon Nanotubes Buckypaper. Adv. Mater. Res. 2015, 1108, 33–38. [Google Scholar]

- Dinh, T.N.; Steitz, J.; Bu, L.; Kaunoun, O. Influence of the composition of MWCNTs layers on the properties of strain gauges. In Proceedings of the 9th IEEE Conference on Nanotechnology, Genoa, Italy, 26–30 July 2009; pp. 477–480. [Google Scholar]

- Vennerberg, D.; Kessler, M.R. Anisotropic buckypaper through shear-induced mechanical alignment of carbon nanotubes in water. Carbon 2014, 80, 433–439. [Google Scholar] [CrossRef] [Green Version]

- Oh, J.Y.; Yang, S.J.; Park, J.Y.; Kim, T.; Lee, K.; Kim, Y.S.; Han, H.N.; Park, C.R. Easy preparation of self-assembled high-density buckypaper with enhanced mechanical properties. Nano Lett. 2015, 15, 190–197. [Google Scholar] [CrossRef]

- Yu, G.; Cao, A.; Lieber, C.M. Large-area blown bubble films of aligned nanowires and carbon nanotubes. Nat. Nanotechnol. 2007, 2, 372–377. [Google Scholar] [CrossRef]

- Lee, J.; Stein, I.Y.; Kessler, S.S.; Wardle, B.L. Aligned Carbon Nanotube Film Enables Thermally Induced State Transformations in Layered Polymeric Materials. ACS Appl. Mater. Interfaces 2015, 7, 8900–8905. [Google Scholar] [CrossRef] [Green Version]

- Stahl, J.J.; Bogdanovich, A.E.; Bradford, P.D. Carbon nanotube shear-pressed sheet interleaves for Mode i interlaminar fracture toughness enhancement. Compos. Part A Appl. Sci. Manuf. 2016, 80, 127–137. [Google Scholar] [CrossRef]

- Chen, G.; Futaba, D.N.; Hata, K. Interplay of wall number and diameter on the electrical conductivity of carbon nanotube thin films. Carbon 2014, 67, 318–325. [Google Scholar] [CrossRef]

- Hu, N.; Karube, Y.; Arai, M.; Watanabe, T.; Yan, C. Investigation on sensitivity of a polymer/carbon nanotube composite strain sensor. Carbon 2009, 48, 680–687. [Google Scholar] [CrossRef]

- Vertuccio, L.; Guadagno, L.; Spinelli, G.; Lamberti, P.; Tucci, V.; Russo, S. Piezoresistive properties of resin reinforced with carbon nanotubes for health-monitoring of aircraft primary structures. Compos. Part B Eng. 2016, 107, 192–202. [Google Scholar] [CrossRef]

- Pham, G.T.; Park, Y.B.; Liang, Z.; Zhang, C.; Wang, B. Processing and modeling of conductive thermoplastic/carbon nanotube films for strain sensing. Compos. Part B Eng. 2008, 39, 209–216. [Google Scholar] [CrossRef]

- Oliva-Avilés, A.I.; Avilés, F.; Sosa, V. Electrical and piezoresistive properties of multi-walled carbon nanotube/polymer composite films aligned by an electric field. Carbon 2011, 49, 2989–2997. [Google Scholar] [CrossRef]

- Park, M.; Kim, H.; Youngblood, J.P. Strain-dependent electrical resistance of multi-walled carbon nanotube/polymer composite films. Nanotechnology 2008, 19, 055705. [Google Scholar] [CrossRef] [PubMed]

| Sensor Type | εb (%) | ∆R/R0 (%) | GF | GFν * | ||

|---|---|---|---|---|---|---|

| Axial | Transverse | Axial | Transverse | Transverse | ||

| BPDMF/PI | 2.7 ± 1.3 | [17.5; 39.2] | [−20.8; −13.6] | [7.7; 9.4] | [−24.3; −16] | [−8.3; −5.5] |

| BPETOH/PI | 2.5 ± 0.6 | [14.2; 23.7] | [−18.7; −12.4] | [7.2; 8.2] | [−17.9; −15.5] | [−6.1; −5.3] |

| Knocked down VA-CNT/PI | 8.4 | 137 | −27.8 | 16.4 | −9.8 | −3.3 |

| Sensor Type | Fabrication Method | GF | References | |

|---|---|---|---|---|

| Axial | Transverse | |||

| BPDMF/PI | Dispersion; Vacuum filtration | [7.7; 9.4] | [−24.3; −16] | Present work |

| BPETOH/PI | Dispersion; Vacuum filtration | [7.2; 8.2] | [−17.9; −15.5] | Present work |

| Knocked down VA-CNT/PI | CVD; knock down | 16.4 | −9.8 | [3] |

| MWCNT BP/epoxy | Dispersion; Vacuum filtration; incorporation within the matrix | ≈0.85 | [6] | |

| MWCNT/epoxy | Solution mixing; isothermal curing | ≈0.6 | [27] | |

| MWCNT/PMMA | Bulk mixing; melt processing | 15.32 (1 wt.% MWCNT) | [28] | |

| MWCNT/PSF | Solution mixing; mould casting (AC alignment) | 2.68 (0.5 wt.% MWCNT) | [29] | |

| MWCNT/PEO | Solution mixing; mould casting | 50 (2.9 wt.% MWCNT) | [30] | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, A.; Amorim, L.; Nunes, J.P.; Rocha, L.A.; Silva, A.F.; Viana, J.C. A Comparative Study between Knocked-Down Aligned Carbon Nanotubes and Buckypaper-Based Strain Sensors. Materials 2019, 12, 2013. https://doi.org/10.3390/ma12122013

Santos A, Amorim L, Nunes JP, Rocha LA, Silva AF, Viana JC. A Comparative Study between Knocked-Down Aligned Carbon Nanotubes and Buckypaper-Based Strain Sensors. Materials. 2019; 12(12):2013. https://doi.org/10.3390/ma12122013

Chicago/Turabian StyleSantos, Ana, Luís Amorim, João Pedro Nunes, Luís Alexandre Rocha, Alexandre Ferreira Silva, and Júlio César Viana. 2019. "A Comparative Study between Knocked-Down Aligned Carbon Nanotubes and Buckypaper-Based Strain Sensors" Materials 12, no. 12: 2013. https://doi.org/10.3390/ma12122013

APA StyleSantos, A., Amorim, L., Nunes, J. P., Rocha, L. A., Silva, A. F., & Viana, J. C. (2019). A Comparative Study between Knocked-Down Aligned Carbon Nanotubes and Buckypaper-Based Strain Sensors. Materials, 12(12), 2013. https://doi.org/10.3390/ma12122013