Enhanced Molten Salt Resistance by Sidewall Pores Repair during Fs Laser Drilling of a Thermal Barrier-Coated Superalloy

Abstract

:1. Introduction

2. Materials and Methods

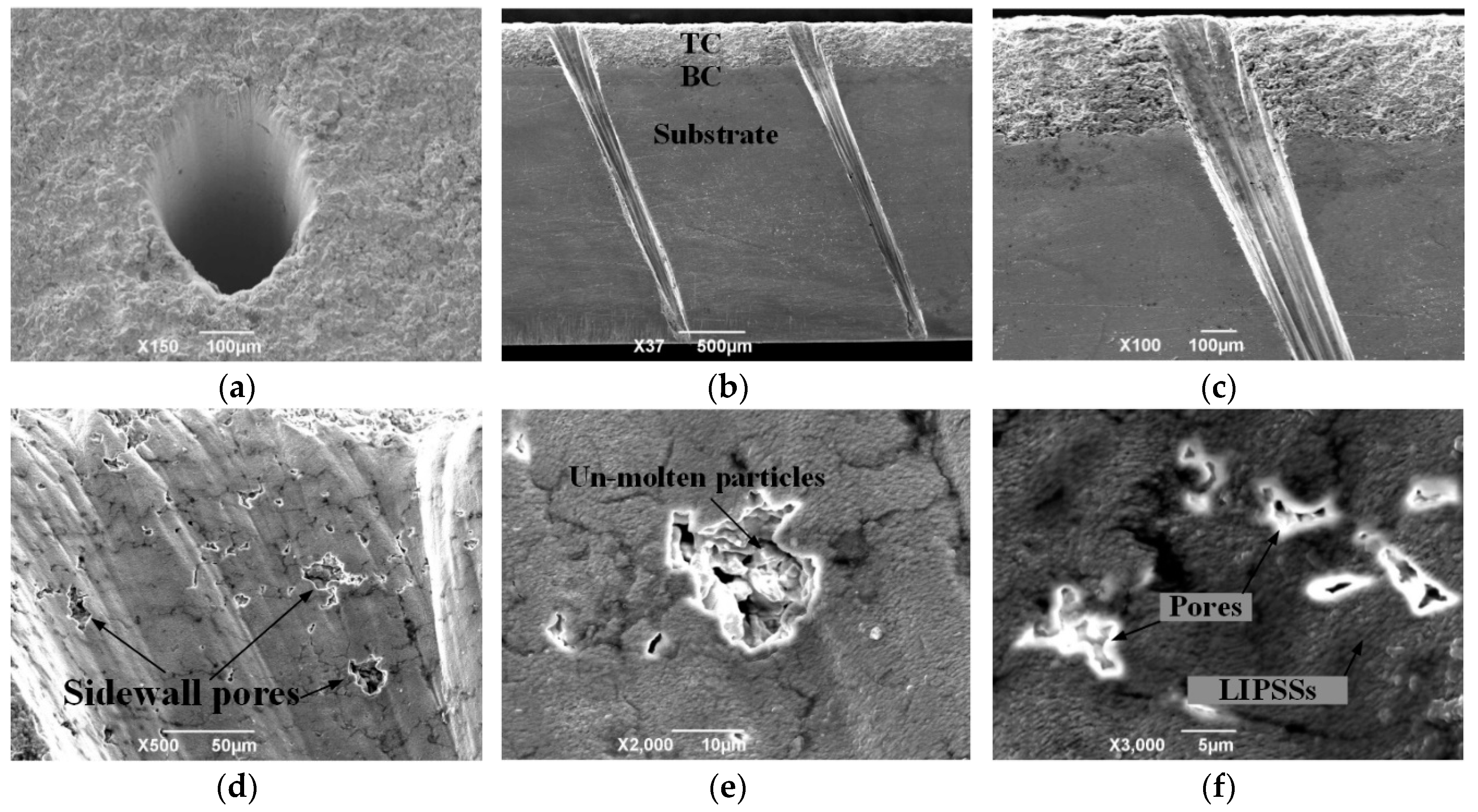

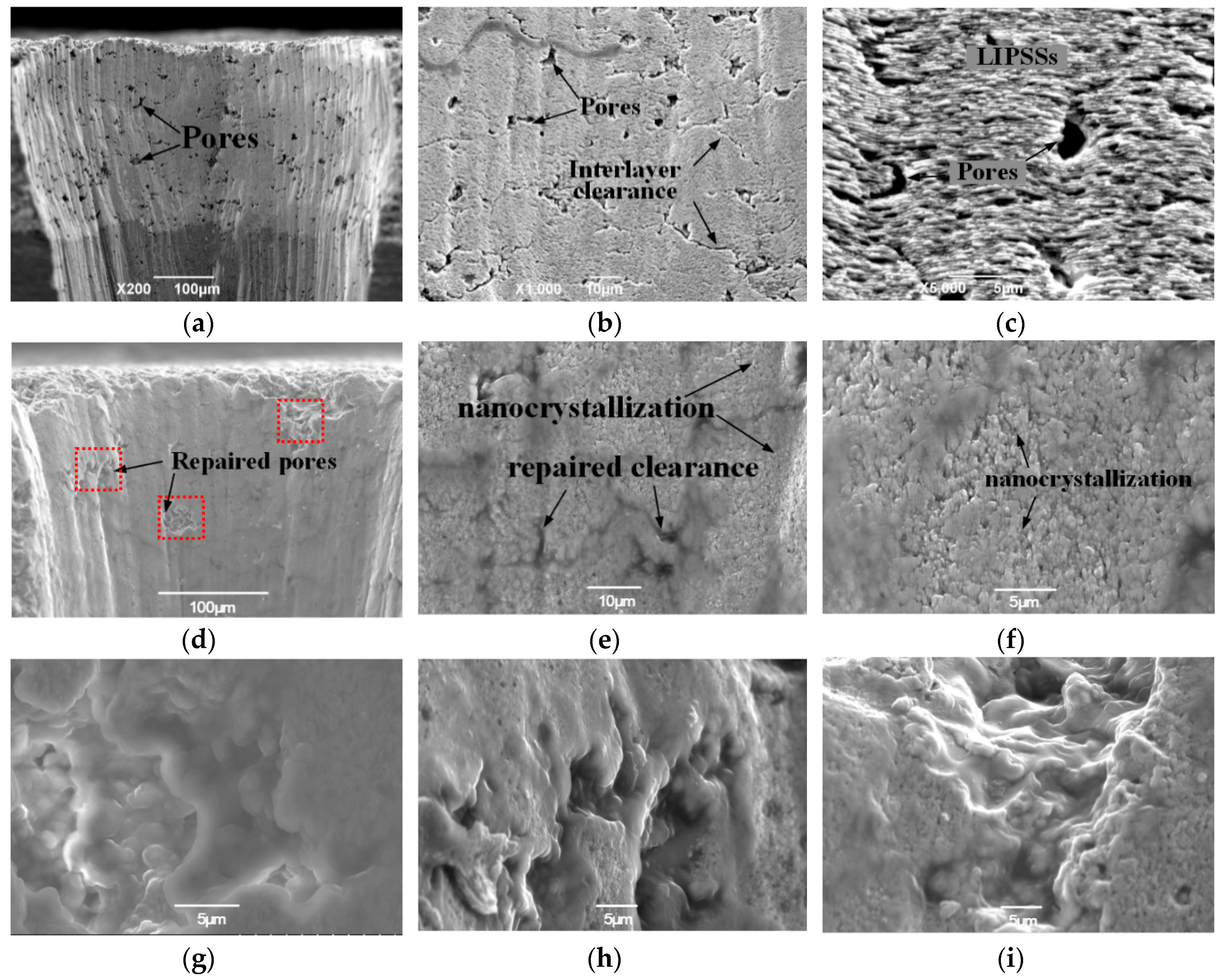

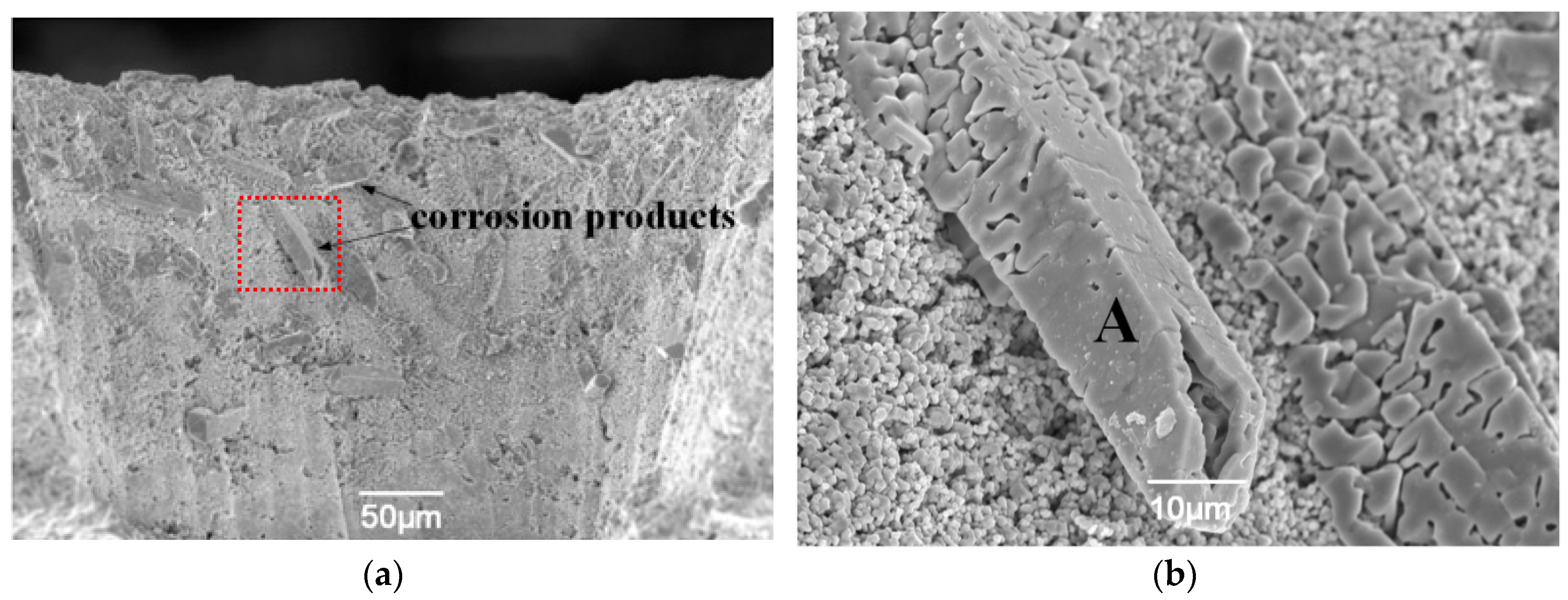

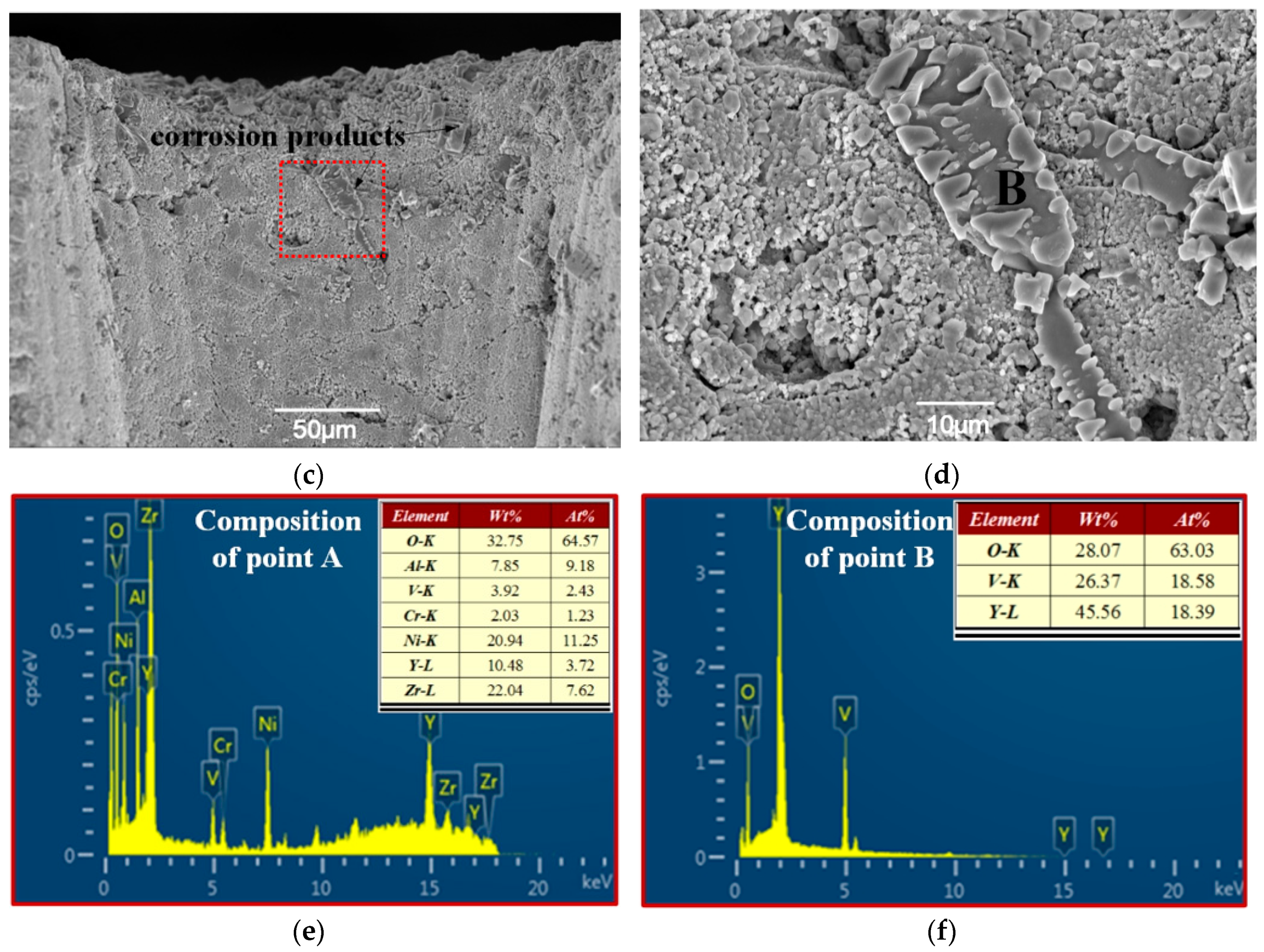

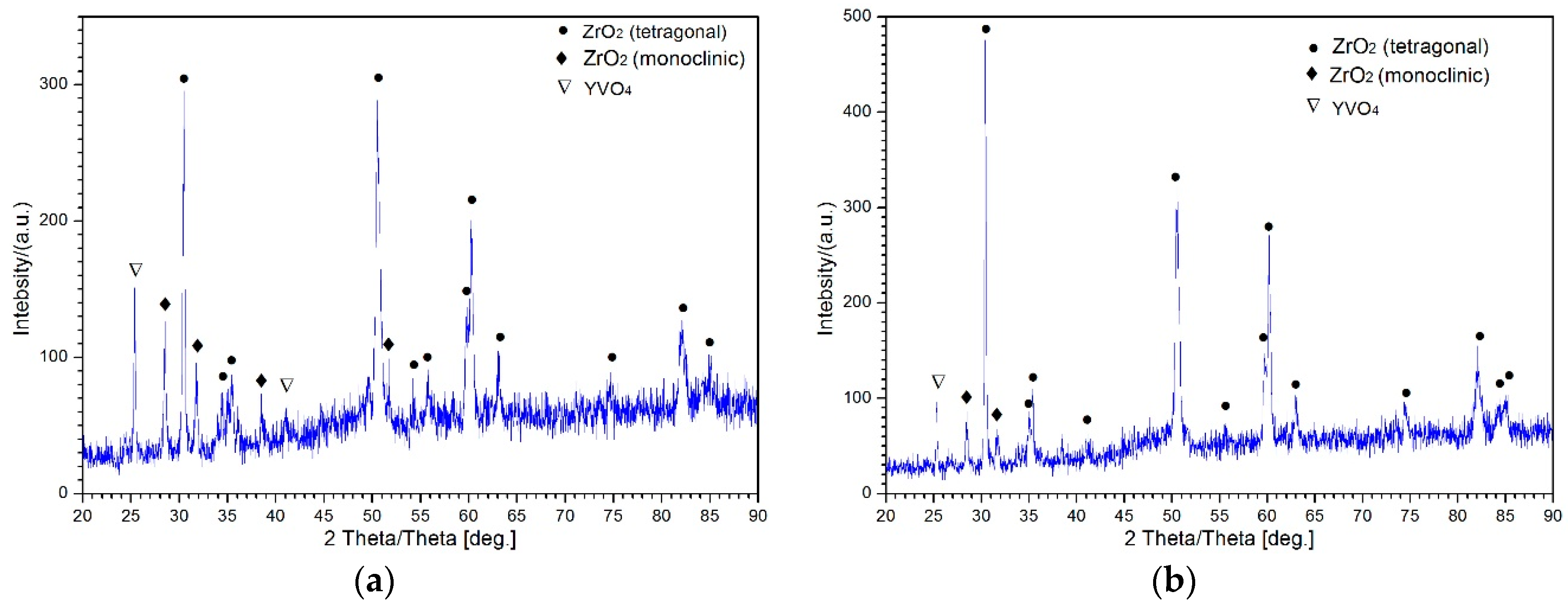

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Das, D.K.; Pollock, T.M. Femtosecond laser machining of cooling holes in thermal barrier coated CMSX4 superalloy. J. Mater. Process. Technol. 2009, 209, 5661–5668. [Google Scholar] [CrossRef]

- Cui, J.; Cheng, Y.; Zhang, J.; Mei, H.; Wang, X. Femtosecond laser irradiation of carbon nanotubes to metal electrodes. Appl. Sci. 2019, 9, 476. [Google Scholar] [CrossRef]

- Wang, R.; Duan, W.; Wang, K.; Dong, X.; Fan, Z.; Mei, X.; Wang, W.; Zhang, S. Computational and experimental study on hole evolution and delamination in laser drilling of thermal barrier coated nickel superalloy. Opt. Lasers Eng. 2018, 107, 161–175. [Google Scholar] [CrossRef]

- Zhai, Z.; Wang, W.; Zhao, J.; Mei, X.; Wang, K.; Wang, F.; Pan, A. Effect of temporal control of air/water environment on laser drilling of nickel-based alloy with thermal barrier coatings. Int. J. Adv. Manuf. Technol. 2018, 97, 3395–3405. [Google Scholar] [CrossRef]

- Corcoran, A.; Sexton, L.; Seaman, B.; Ryan, P.; Byrne, G. The laser drilling of multi-layer aerospace material systems. J. Mater. Process. Technol. 2002, 123, 100–106. [Google Scholar] [CrossRef]

- Sezer, H.K.; Li, L.; Schmidt, M.; Pinkerton, A.J.; Anderson, B.; Williams, P. Effect of beam angle on HAZ, recast and oxide layer characteristics in laser drilling of TBC nickel superalloys. Int. J. Mach. Tools Manuf. 2006, 46, 1972–1982. [Google Scholar] [CrossRef]

- Fan, Z.; Dong, X.; Wang, K.; Duan, W.; Wang, R.; Mei, X.; Wang, W.; Cui, J.; Yuan, X.; Xu, C. Effect of drilling allowance on TBC delamination, spatter and re-melted cracks characteristics in laser drilling of TBC coated superalloys. Int. J. Mach. Tools Manuf. 2016, 106, 1–10. [Google Scholar] [CrossRef]

- Girardot, J.; Schneider, M.; Berthe, L.; Favier, V. Investigation of delamination mechanisms during a laser drilling on a cobalt-base superalloy. J. Mater. Process Technol. 2013, 213, 1682–1691. [Google Scholar] [CrossRef] [Green Version]

- Bathe, R.; Padmanabham, G. Evaluation of laser drilling of holes in thermal barrier coated superalloys. Mater. Sci. Technol. 2014, 30, 1778–1782. [Google Scholar] [CrossRef]

- Sun, X.; Dong, X.; Wang, K.; Wang, R.; Fan, Z.; Duan, W. Experimental investigation on thermal effects in picosecond laser drilling of thermal barrier coated In718. Opt. Lasers Technol. 2019, 113, 150–158. [Google Scholar] [CrossRef]

- Zhao, W.; Yu, Z. Self-cleaning effect in high quality percussion ablating of cooling hole by picosecond ultra-short pulse laser. Opt. Lasers Eng. 2018, 105, 125–131. [Google Scholar] [CrossRef]

- Feng, Q.; Picard, Y.N.; McDonald, J.P.; van Rompay, P.A.; Yalisove, S.M.; Pollock, T.M. Femtosecond laser machining of single-crystal superalloys through thermal barrier coatings. Sci. Eng. A 2006, 430, 203–207. [Google Scholar] [CrossRef]

- Cui, J.; Yang, L.; Zhou, L.; Wang, Y. Nanoscale soldering of axially positioned single-walled carbon nanotubes: A molecular dynamics simulation study. ACS Appl. Mater. Interfaces 2014, 6, 2044–2050. [Google Scholar] [CrossRef] [PubMed]

- Schwingel, D.; Taylor, R.; Haubold, T.; Wigren, J.; Gualco, C. Mechanical and thermophysical properties of thick PYSZ thermal barrier coatings: Correlation with microstructure and spraying parameters. Surf. Coat. Technol. 1998, 108, 99–106. [Google Scholar] [CrossRef]

- Guo, H.B.; Vassen, R.; Stover, D. Thermophysical properties and thermal cycling behavior of plasma sprayed thick thermal barrier coatings. Surf. Coat. Technol. 2005, 192, 48–56. [Google Scholar] [CrossRef]

- Habibi, M.H.; Wang, L.; Guo, S.M. Evolution of hot corrosion resistance of YSZ, Gd2Zr2O7, and Gd2Zr2O7 + YSZ composite thermal barrier coatings in Na2SO4 + V2O5 at 1050 °C. J. Eur. Ceram. Soc. 2012, 32, 1635–1642. [Google Scholar] [CrossRef]

- Lee, E.Y.; Sohn, Y.; Jha, S.K.; Holmes, J.W.; Sisson, R.D. Phase transformations of plasma-sprayed zirconia–ceria thermal barrier coatings. J. Am. Ceram. Soc. 2002, 85, 2065–2071. [Google Scholar] [CrossRef]

- Ghasemi, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H. The influence of laser treatment on thermal shock resistance of plasma-sprayed nanostructured yttria stabilized zirconia thermal barrier coatings. Ceram. Int. 2014, 40, 347–355. [Google Scholar] [CrossRef]

- Pham, K.X.; Tanabe, R.; Ito, Y. Laser-induced periodic surface structures formed on the sidewalls of microholes trepanned by a femtosecond laser. Appl. Phys. A 2012, 102, 485–493. [Google Scholar] [CrossRef]

- Liu, B.; Wang, W.; Jiang, G.; Mei, X.; Wang, Z.; Wang, K.; Cui, J. Study on hierarchical structured PDMS for surface super-hydrophobicity using imprinting with ultrafast laser structured models. Appl. Surf. Sci. 2016, 364, 528–538. [Google Scholar] [CrossRef]

- Aramesh, M.; Mayamei, Y.; Wolff, A.; Ostrikov, K. Superplastic nanoscale pore shaping by ion irradiation. Nat. Commun. 2018, 9, 835. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhang, X.; Li, F.; Zhang, Z.; Li, H.; Wang, Y.; Ren, L.; Liu, M. Effects of selective laser modification and Al deposition on the hot corrosion resistance of ceria and yttria-stabilized zirconia thermal barrier coatings. Coatings 2019, 9, 353. [Google Scholar] [CrossRef]

- Wang, P.; Deng, S.J.; He, Y.D.; Liu, C.X.; Zhang, J. Oxidation and hot corrosion behavior of Al2O3/YSZ coatings prepared by cathode plasma electrolytic deposition. Corros. Sci. 2016, 109, 13–21. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, K.; Dong, X.; Wang, R.; Duan, W.; Mei, X.; Wang, W.; Cui, J.; Zhang, S.; Xu, C. The role of the surface morphology and segmented cracks on the damage forms of laser re-melted thermal barrier coatings in presence of a molten salt (Na2SO4 + V2O5). Corros. Sci. 2017, 115, 56–67. [Google Scholar] [CrossRef]

- Ghasemi, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H.; Hajizadeh-Oghaz, M.; Ahmadi-Pidani, R. The influence of laser treatment on hot corrosion behavior of plasma-sprayed nanostructured yttria stabilized zirconia thermal barrier coatings. J. Eur. Ceram. Soc. 2014, 34, 2013–2021. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Sun, X.; Mei, X.; Wang, R. Enhanced Molten Salt Resistance by Sidewall Pores Repair during Fs Laser Drilling of a Thermal Barrier-Coated Superalloy. Materials 2019, 12, 1905. https://doi.org/10.3390/ma12121905

Fan Z, Sun X, Mei X, Wang R. Enhanced Molten Salt Resistance by Sidewall Pores Repair during Fs Laser Drilling of a Thermal Barrier-Coated Superalloy. Materials. 2019; 12(12):1905. https://doi.org/10.3390/ma12121905

Chicago/Turabian StyleFan, Zhengjie, Xiaomao Sun, Xuesong Mei, and Rujia Wang. 2019. "Enhanced Molten Salt Resistance by Sidewall Pores Repair during Fs Laser Drilling of a Thermal Barrier-Coated Superalloy" Materials 12, no. 12: 1905. https://doi.org/10.3390/ma12121905