Modeling and Analysis of Single Point Incremental Forming Force with Static Pressure Support and Ultrasonic Vibration

Abstract

1. Introduction

2. Methods

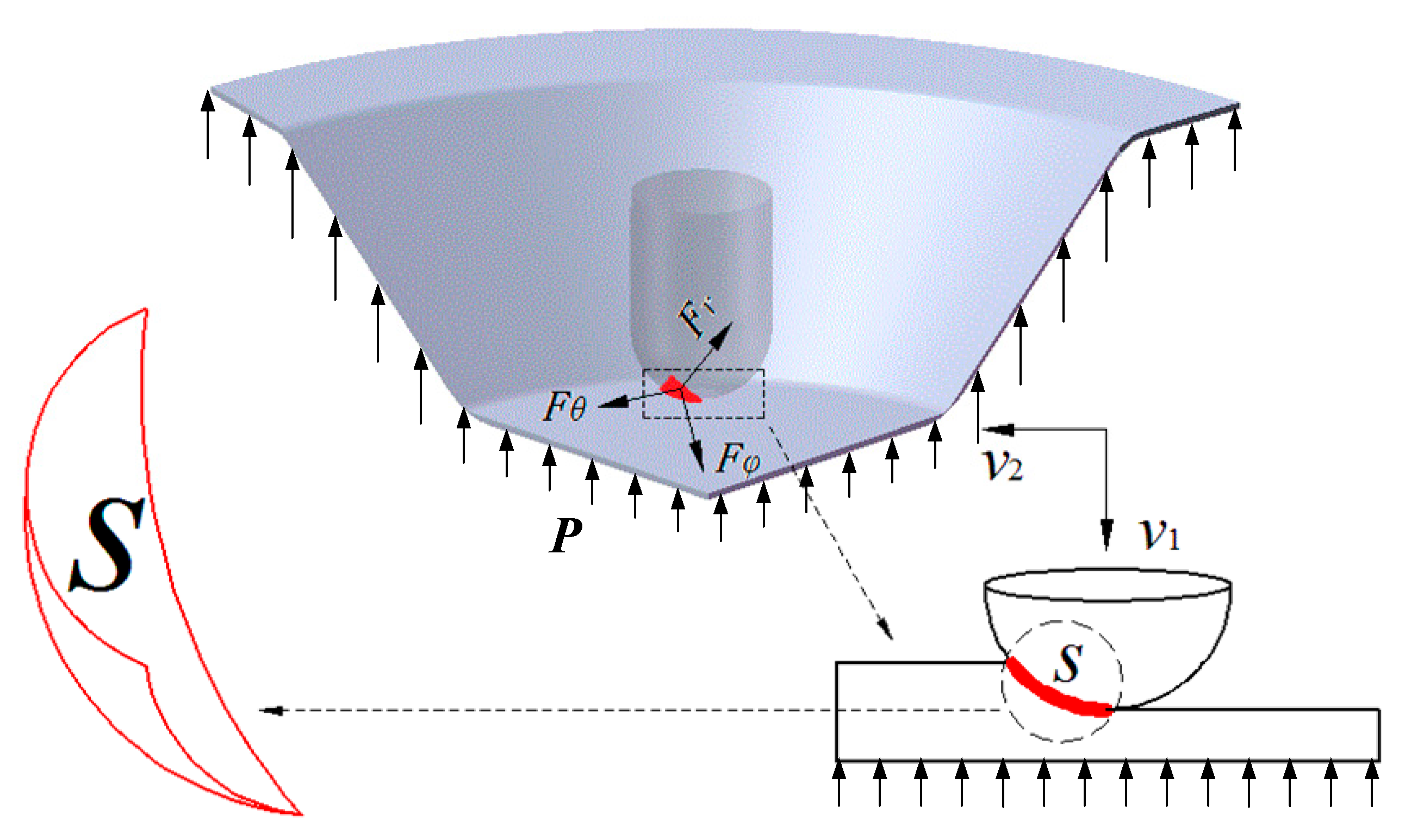

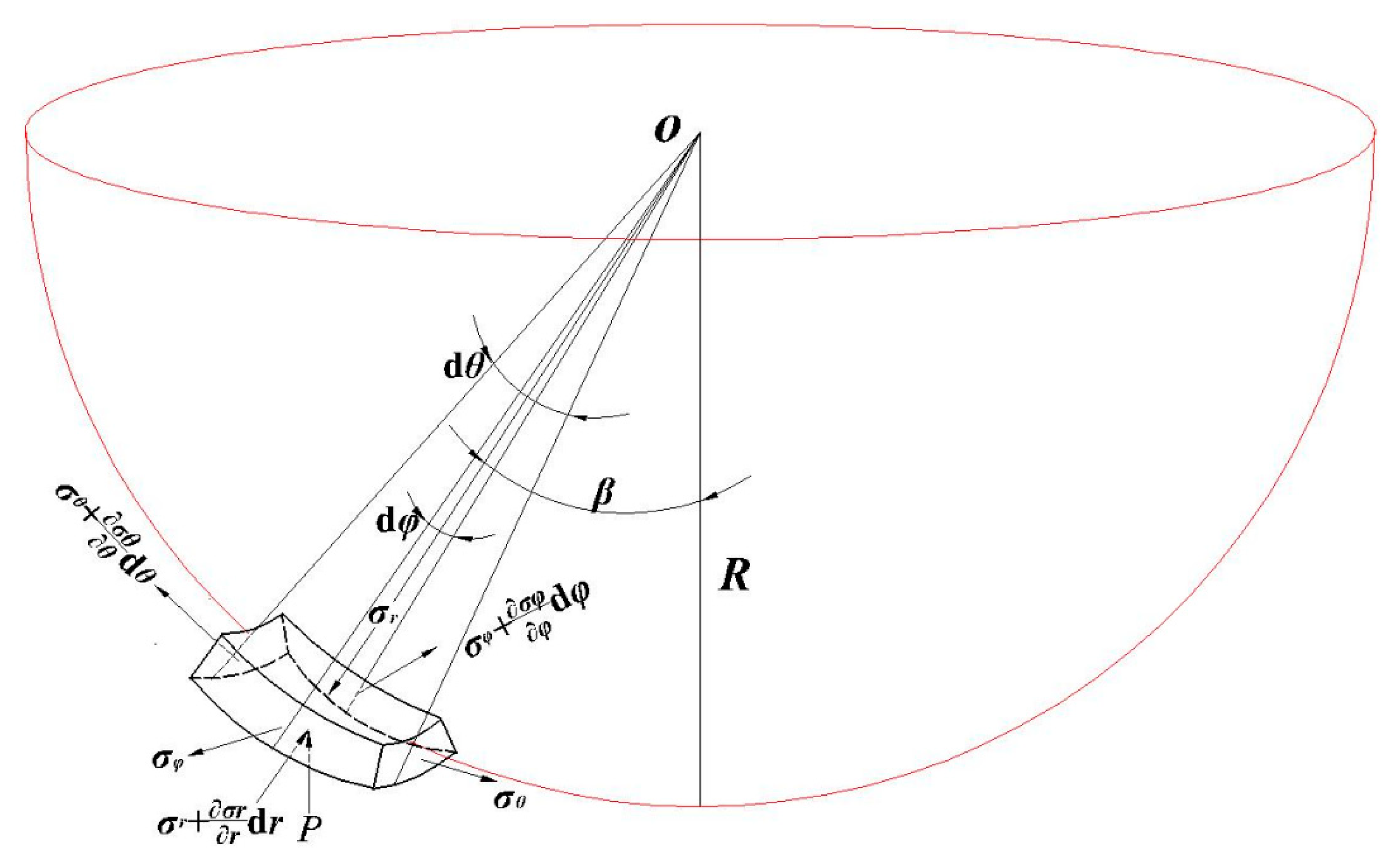

2.1. Mechanical Balance Equation

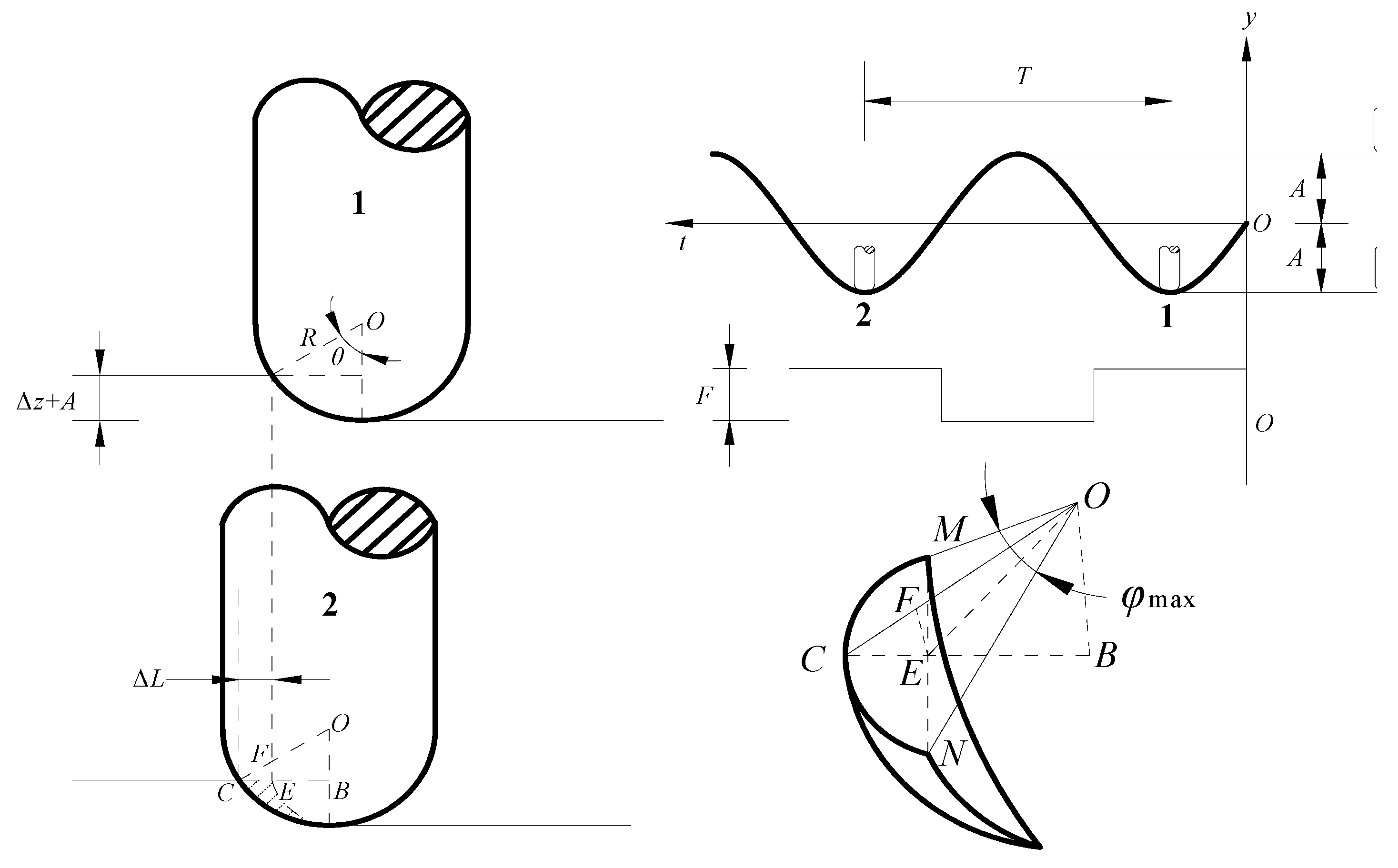

2.2. The Geometric Equation of the Contact Area

2.3. Forming Force Analytical Model and Coordinate Transformation

3. Experiments

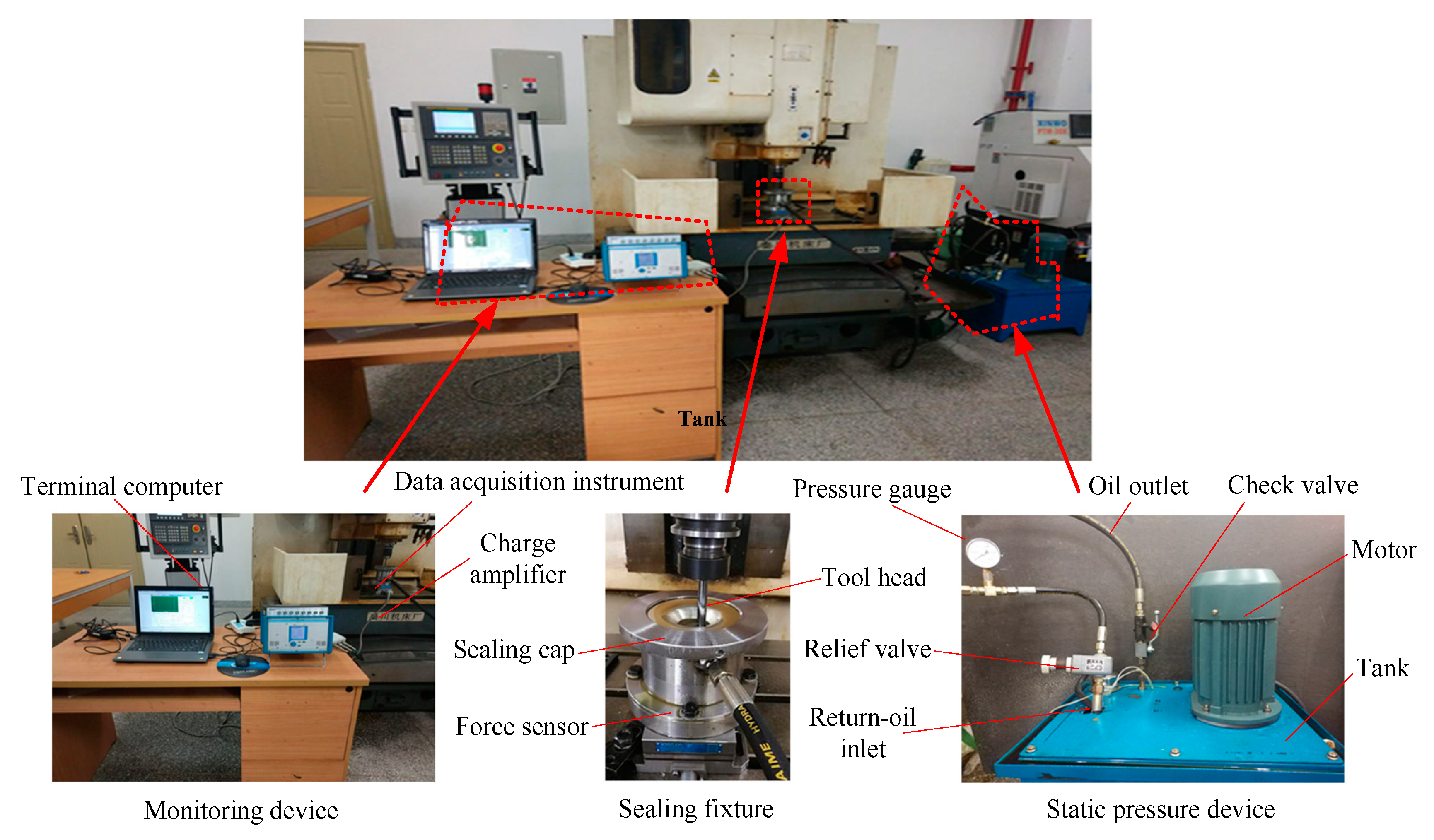

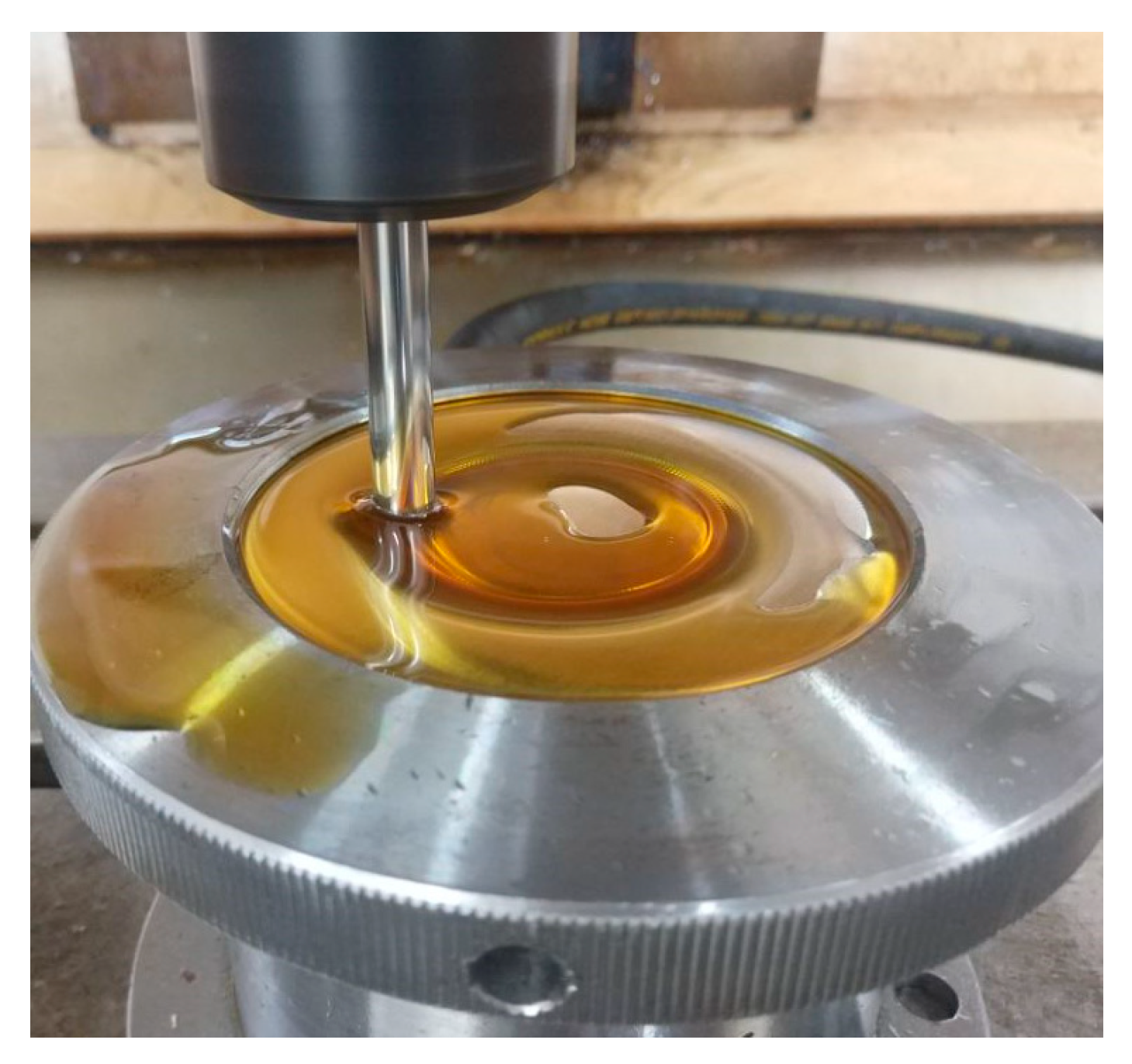

3.1. Experimental Equipment and Materials

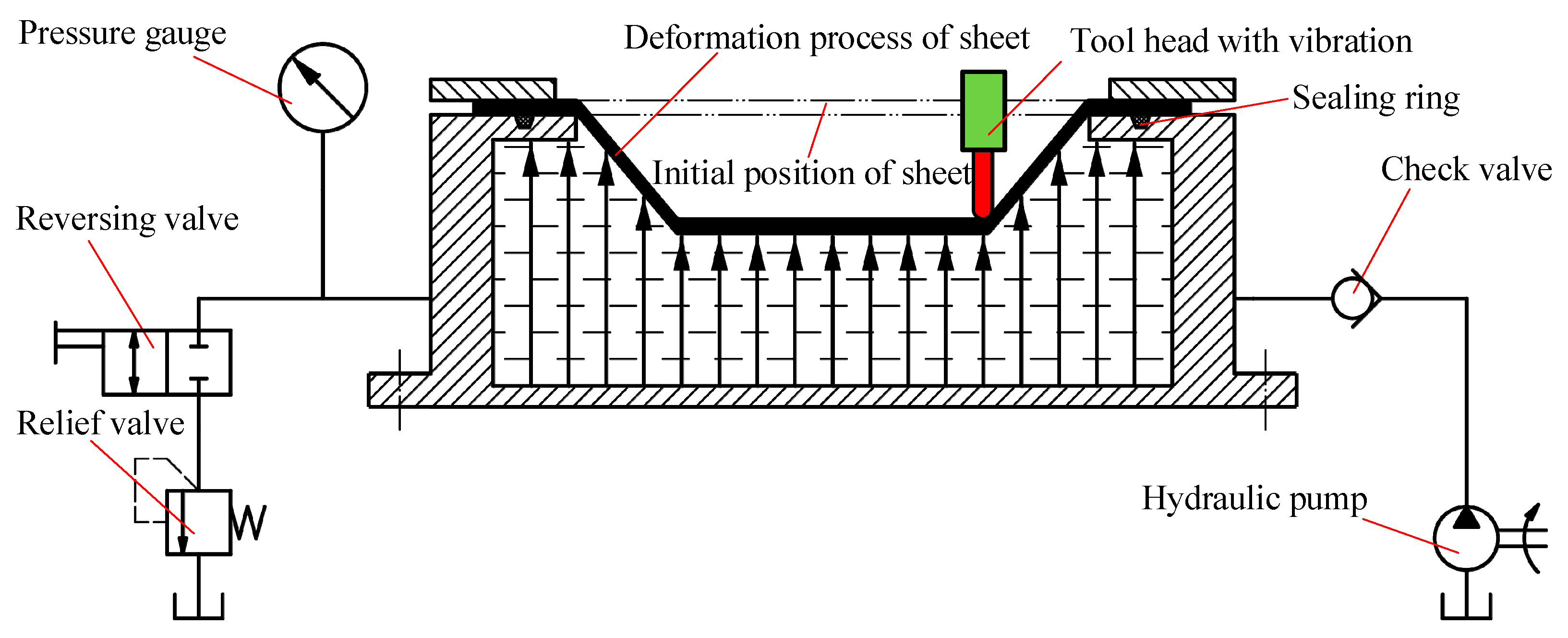

3.2. Static Pressure Support System

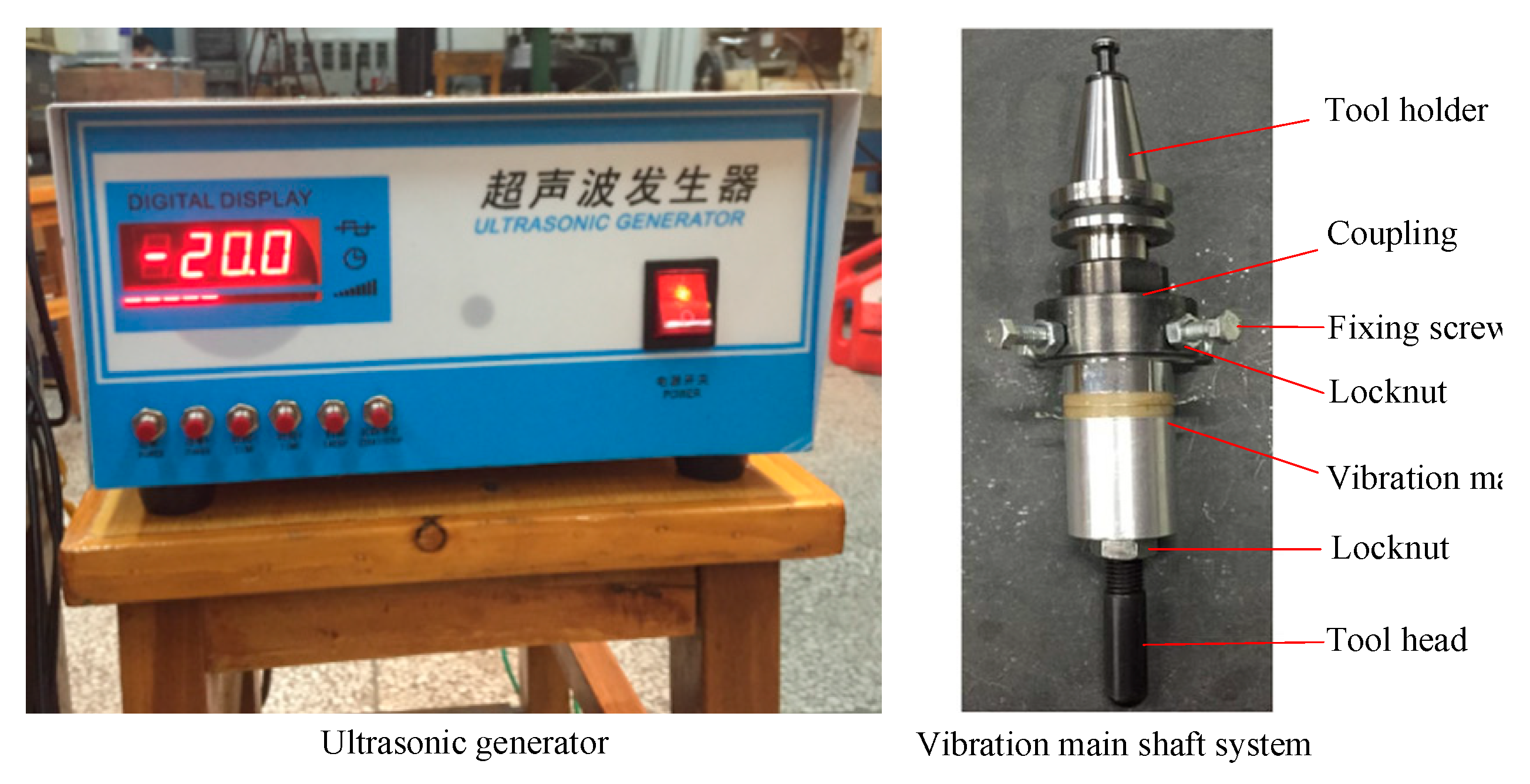

3.3. Ultrasonic Vibration System

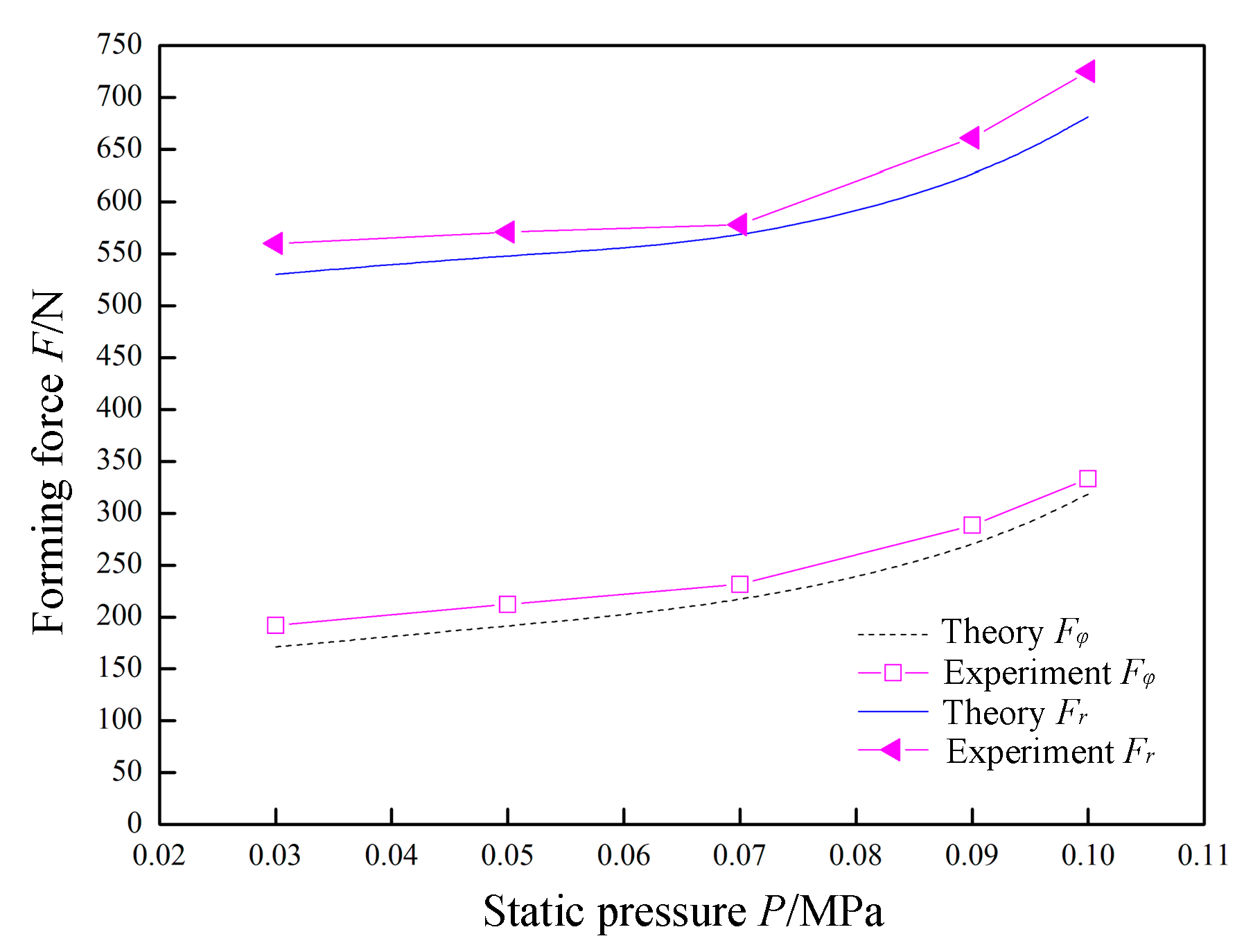

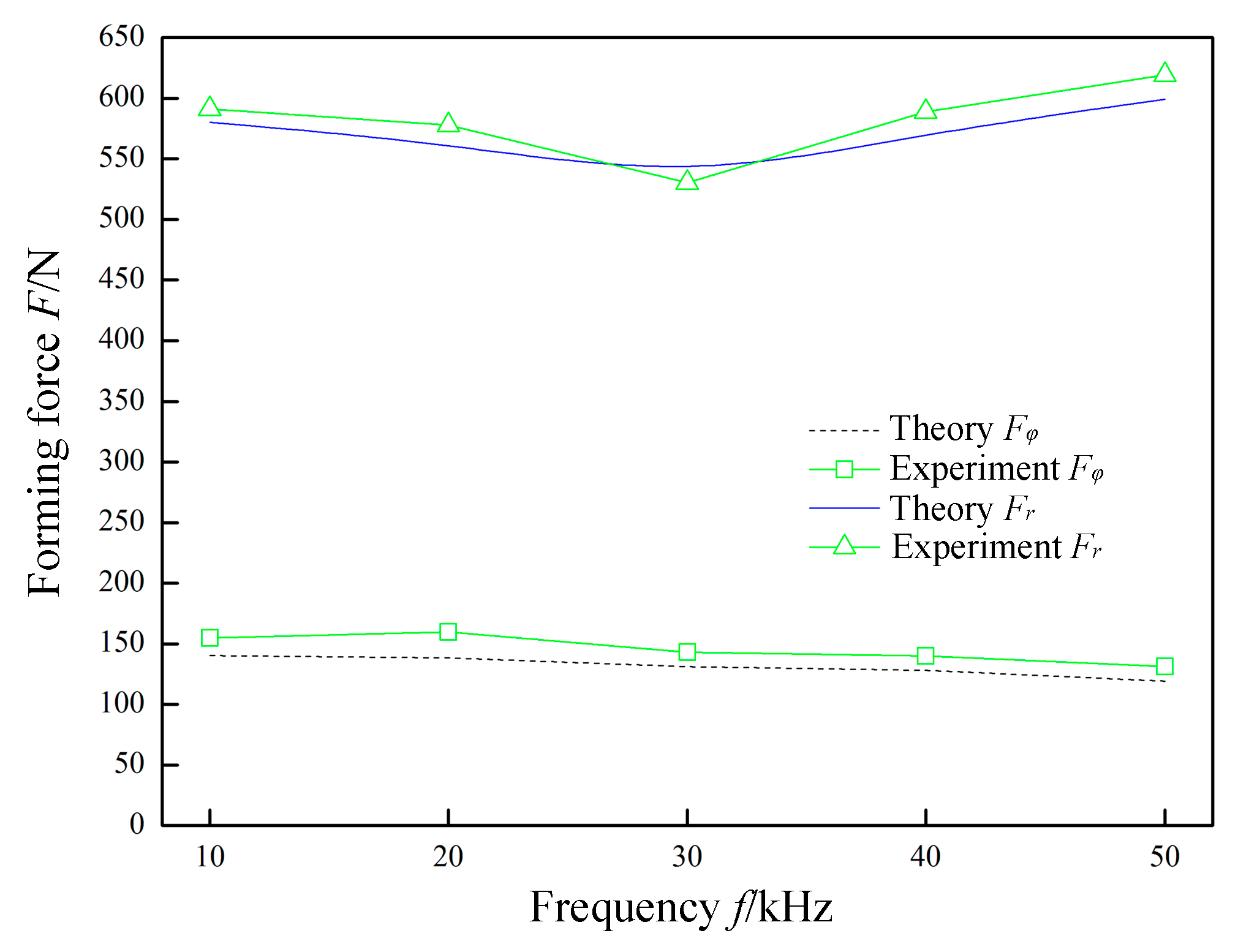

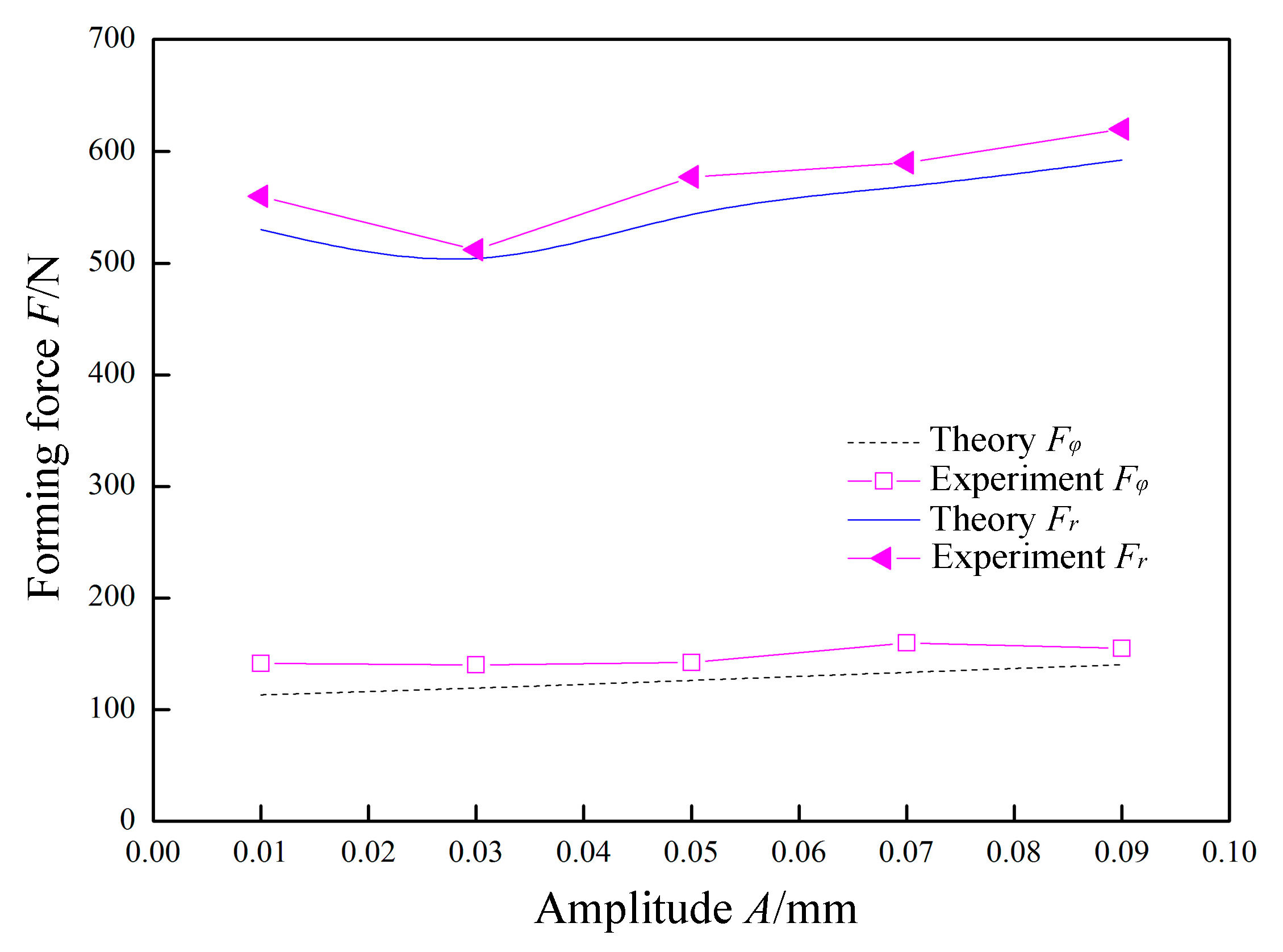

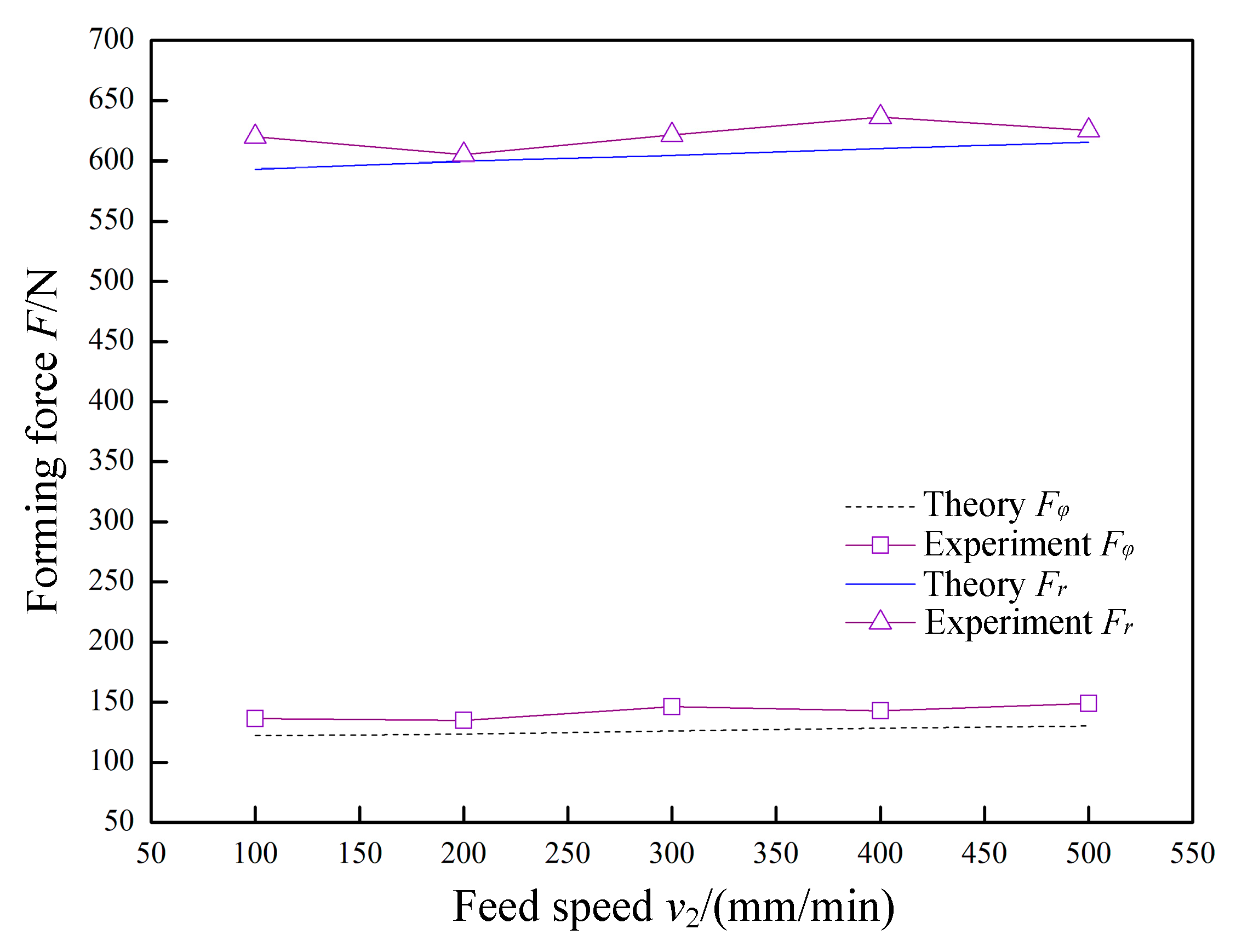

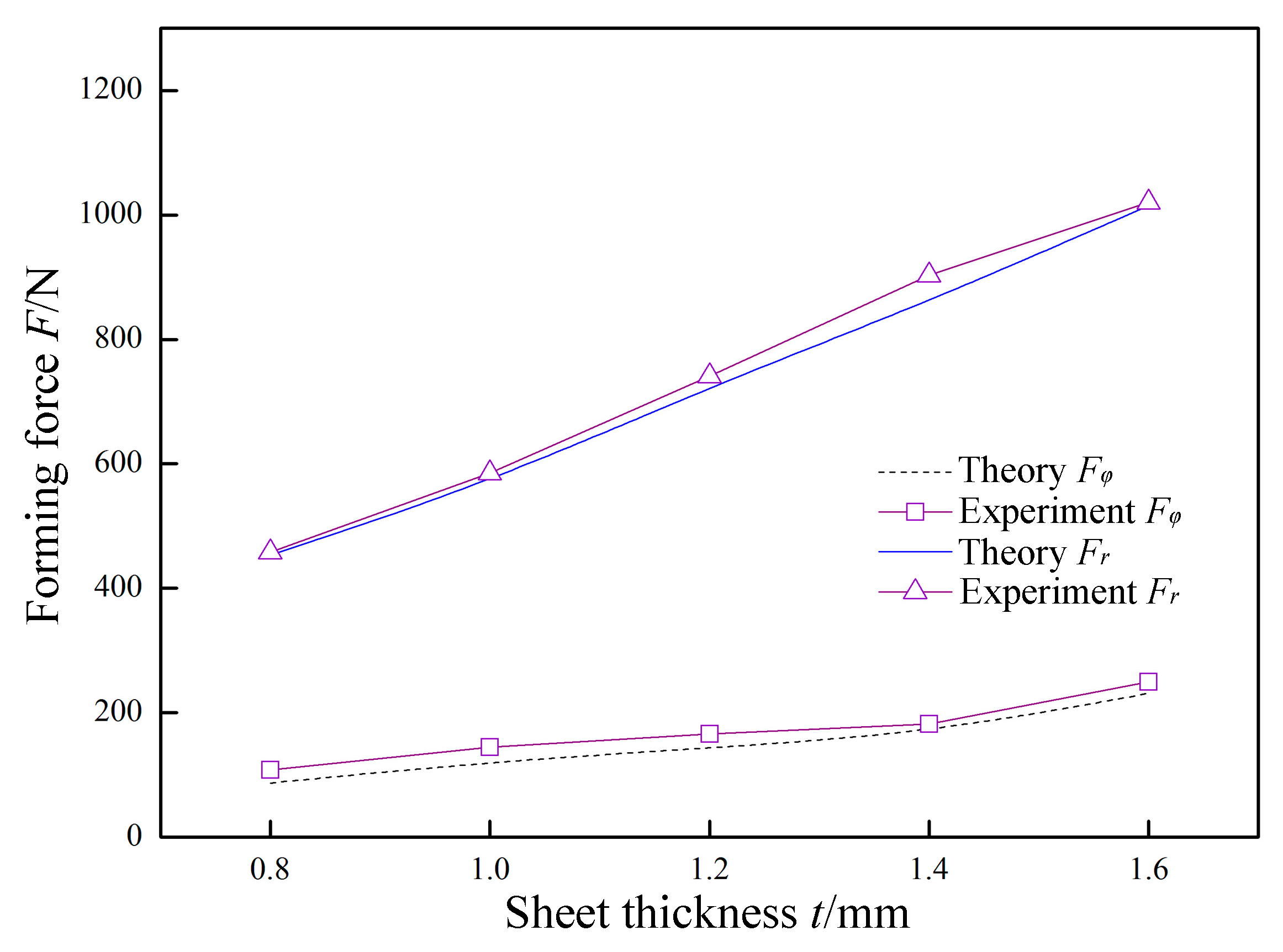

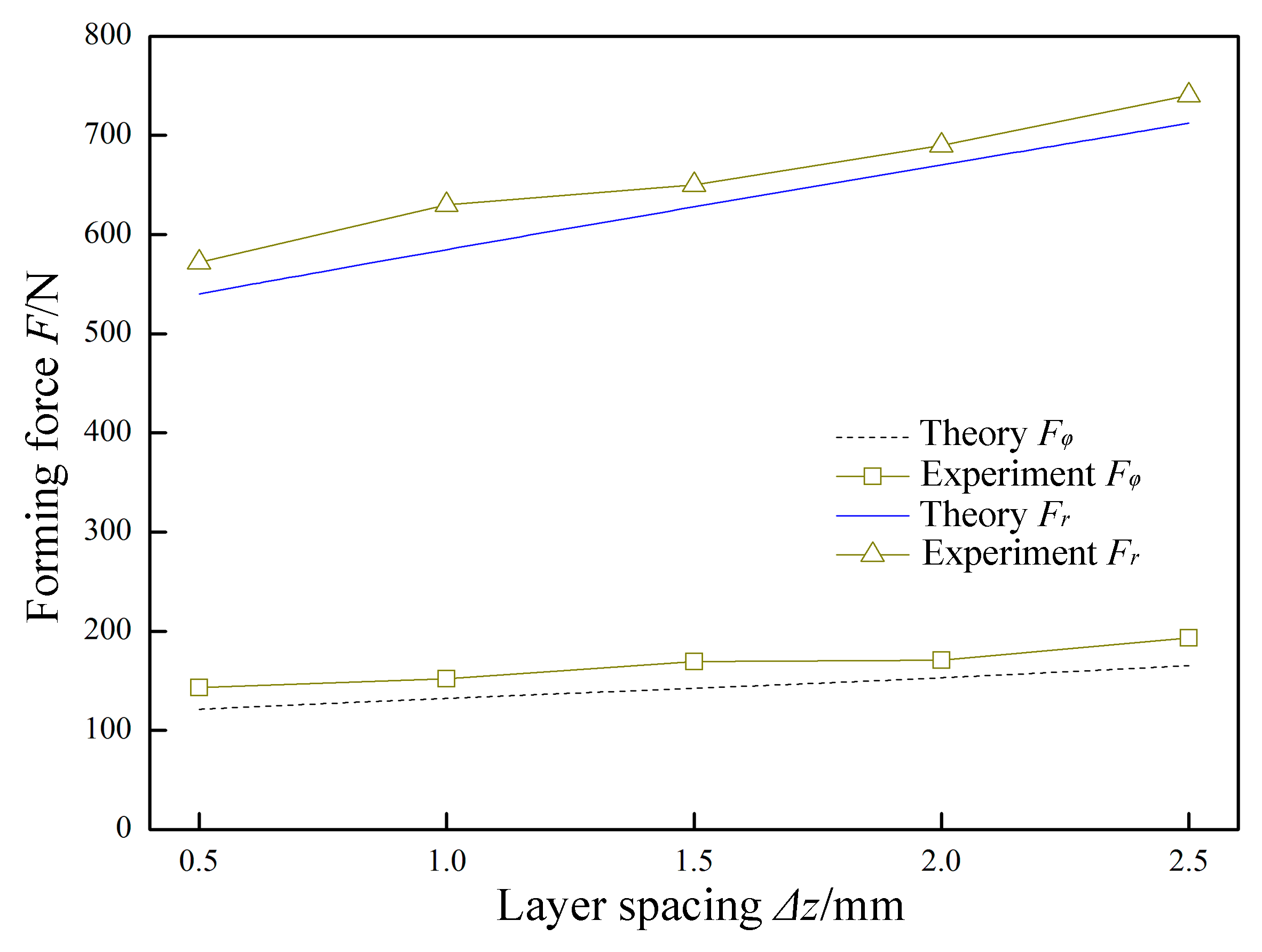

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| SPIF | Single Point Incremental Forming |

| UV | Ultrasonic Vibration |

| SPS | Static Pressure Support |

| SPS-UV-SPIF | Static Pressure Support–Ultrasonic Vibration-Single Point Incremental Forming |

| CNC | Computerized Numerical Control |

| NC | Numerical Control |

| t0 | Initial Thickness of the Sheet |

| t1 | Thickness of the Target Part |

| D | Diameter of Tool Head |

| Δz | Layer Spacing |

| α | Forming Angle of the Target Part |

| S | The Contact Area |

| Fr | Normal Force |

| Fθ | Circumferential Force |

| Fφ | Radial Force |

| P | Static Pressure Support Force |

| v1 | Impact Speed of Tool Head |

| v2 | Feed Speed of Tool Head |

| σr | Normal Stress |

| σθ | Circumferential Stress |

| σφ | Radial Stress |

| dθ | Angle between the Sides of the Micro-Element |

| dφ | Another Angle between the Sides of the Micro-Element |

| β | Declination of the Micro-Element Center Relative to the Tool Head |

| R | Tool Head Radius |

| t | Thickness of the Micro-Element |

| F | Forming Force |

| T | Vibration Period |

| ΔL | Horizontal Displacement of the Tool Head in One Vibration Period |

| βmax | Maximum Values of ∠β |

| φmax | Maximum Values of∠φ |

| Fx | Horizontal Force of the x-y Plane |

| Fy | Horizontal Force of the x-y Plane |

| Fz | Axial Force |

| Ft | Frictional Force |

References

- Behera, A.K.; de Sousa, R.A.; Ingarao, G.; Oleksik, V. Single point incremental forming: An assessment of the progress and technology trends from 2005 to 2015. J. Manuf. Process. 2017, 27, 37–62. [Google Scholar] [CrossRef]

- Duflou, J.R.; Habraken, A.M.; Cao, J.; Malhotra, R.; Bambach, M.; Adams, D.; Vanhove, H.; Mohammadi, A.; Jeswiet, J. Single point incremental forming: State-of-the-art and prospects. Int. J. Mater. Form. 2017, 11, 743–773. [Google Scholar] [CrossRef]

- Shrivastava, P.; Tandon, P. Microstructure and texture based analysis of forming behavior and deformation mechanism of AA1050 sheet during Single Point Incremental Forming. J. Manuf. Process. Technol. 2019, 266, 292–310. [Google Scholar] [CrossRef]

- Edwards, W.L.; Grimm, T.J.; Ragai, I.; Roth, J.T. Optimum Process Parameters for Springback Reduction of Single Point Incrementally Formed Polycarbonate. Procedia Manuf. 2017, 10, 329–338. [Google Scholar] [CrossRef]

- Allwood, J.M.; Braun, D.; Music, O. The effect of partially cut-out blanks on geometric accuracy in incremental sheet forming. J. Manuf. Process. Technol. 2010, 210, 1501–1510. [Google Scholar] [CrossRef]

- Shrivastava, P.; Kumar, P.; Tandon, P.; Pesin, A. Improvement in formability and geometrical accuracy of incrementally formed AA1050 sheets by microstructure and texture reformation through preheating, and their FEA and experimental validation. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 335–350. [Google Scholar] [CrossRef]

- Li, Y.; Lu, H.; Daniel, W.J.; Meehan, P.A. Investigation and optimization of deformation energy and geometric accuracy in the incremental sheet forming process using response surface methodology. Int. J. Adv. Manuf. Technol. 2015, 79, 2041–2055. [Google Scholar] [CrossRef]

- Lu, H.B.; Li, Y.L.; Liu, Z.B.; Liu, S.; Meehan, P.A. Study on Step Depth for Part Accuracy Improvement in Incremental Sheet Forming Process. Adv. Mater. Res. 2014, 939, 274–280. [Google Scholar] [CrossRef]

- Fiorentino, A.; Feriti, G.C.; Giardini, C.; Ceretti, E. Part precision improvement in incremental sheet forming of not axisymmetric parts using an artificial cognitive system. J. Manuf. Syst. 2015, 35, 215–222. [Google Scholar] [CrossRef]

- Bedan, A.S.; Habeeb, H.A. Experimental Study the Effect of Tool Geometry on Dimensional Accuracy in Single Point Incremental Forming (SPIF) Process. Al-Nahrain J. Eng. Sci. 2018, 21, 108–117. [Google Scholar] [CrossRef][Green Version]

- Taherkhani, A.; Basti, A.; Nariman-Zadeh, N.; Jamali, A. Achieving maximum dimensional accuracy and surface quality at the shortest possible time in single-point incremental forming via multi-objective optimization. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018. [Google Scholar] [CrossRef]

- Mundo, D.; Gatti, G.; Ambrogio, G.; Filice, L.; Danieli, G.A. Considerations on Process Performance in Incremental Forming by Inducing High Frequency Vibration. In Proceedings of the EUCOMES 08; Springer: Dordrecht, The Netherlands, 2009; pp. 523–530. [Google Scholar]

- Vahdati, M.; Mahdavinejad, R.; Amini, S. Investigation of the ultrasonic vibration effect in incremental sheet metal forming process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 231, 971–982. [Google Scholar] [CrossRef]

- Amini, S.; Gollo, A.H.; Paktinat, H. An investigation of conventional and ultrasonic-assisted incremental forming of annealed AA1050 sheet. Int. J. Adv. Manuf. Technol. 2017, 90, 1569–1578. [Google Scholar] [CrossRef]

- Obikawa, T.; Hayashi, M. Ultrasonic-Assisted Incremental Microforming of Thin Shell Pyramids of Metallic Foil. Micromachines 2017, 8, 142. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Sun, J.; Li, J.; Zhao, G. Effects of ultrasonic vibration on deformation mechanism of incremental point-forming process. Procedia Eng. 2017, 207, 777–782. [Google Scholar]

- Davarpanah, M.A.; Zhang, Z.; Bansal, S.; Cao, J.; Malhotra, R. Preliminary investigations on Double Sided Incremental Forming of thermoplastics. Manuf. Lett. 2016, 8, 21–26. [Google Scholar] [CrossRef]

- Li, H.; Yang, X.P. Research on Technology of High-Pressure Water Jet Incremental Sheet Metal Forming. Appl. Mech. Mater. 2014, 496, 148–154. [Google Scholar] [CrossRef]

- Liu, R.; Lu, B.; Xu, D.; Chen, J.; Chen, F.; Ou, H.; Long, H. Development of novel tools for electricity-assisted incremental sheet forming of titanium alloy. Int. J. Adv. Manuf. Technol. 2016, 85, 1137–1144. [Google Scholar] [CrossRef]

- Mohammadi, A.; Vanhove, H.; Van Bael, A.; Duflou, J.R. Towards accuracy improvement in single point incremental forming of shallow parts formed under laser assisted conditions. Int. J. Mater. Form. 2016, 9, 339–351. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, L.; Li, J.; Feng, F.; Su, H.; Ma, F.; Zhong, K. Investigation of dynamic deformation behaviour of large-size sheet metal parts under local Lorentz force. J. Manuf. Process. Technol. 2019, 265, 20–33. [Google Scholar] [CrossRef]

- Su, H.; Huang, L.; Li, J.; Ma, F.; Huang, P.; Feng, F. Two-step electromagnetic forming: A new forming approach to local features of large-size sheet metal parts. Int. J. Mach. Tools Manuf. 2018, 124, 99–116. [Google Scholar] [CrossRef]

- Bai, L.; Li, Y.; Yang, M.; Yao, Z.; Yao, Z. Influences of Process Parameters and Vibration Parameters on the Forming Force in the Ultrasonic-Assisted Incremental Forming Process. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef]

| Chemical Element | Al | Cu | Ti | Zn | Si | Mg | Mn | Fe |

|---|---|---|---|---|---|---|---|---|

| Content (%) | 99.63 | 0.03 | 0.02 | 0.03 | 0.12 | 0.02 | 0.01 | 0.14 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, L.; Li, Y.; Yang, M.; Lin, Y.; Yuan, Q.; Zhao, R. Modeling and Analysis of Single Point Incremental Forming Force with Static Pressure Support and Ultrasonic Vibration. Materials 2019, 12, 1899. https://doi.org/10.3390/ma12121899

Bai L, Li Y, Yang M, Lin Y, Yuan Q, Zhao R. Modeling and Analysis of Single Point Incremental Forming Force with Static Pressure Support and Ultrasonic Vibration. Materials. 2019; 12(12):1899. https://doi.org/10.3390/ma12121899

Chicago/Turabian StyleBai, Lang, Yan Li, Mingshun Yang, Yunbo Lin, Qilong Yuan, and Renfeng Zhao. 2019. "Modeling and Analysis of Single Point Incremental Forming Force with Static Pressure Support and Ultrasonic Vibration" Materials 12, no. 12: 1899. https://doi.org/10.3390/ma12121899

APA StyleBai, L., Li, Y., Yang, M., Lin, Y., Yuan, Q., & Zhao, R. (2019). Modeling and Analysis of Single Point Incremental Forming Force with Static Pressure Support and Ultrasonic Vibration. Materials, 12(12), 1899. https://doi.org/10.3390/ma12121899