Testing and Prediction of the Strength Development of Recycled-Aggregate Concrete with Large Particle Natural Aggregate

Abstract

1. Introduction

2. Materials and Methods

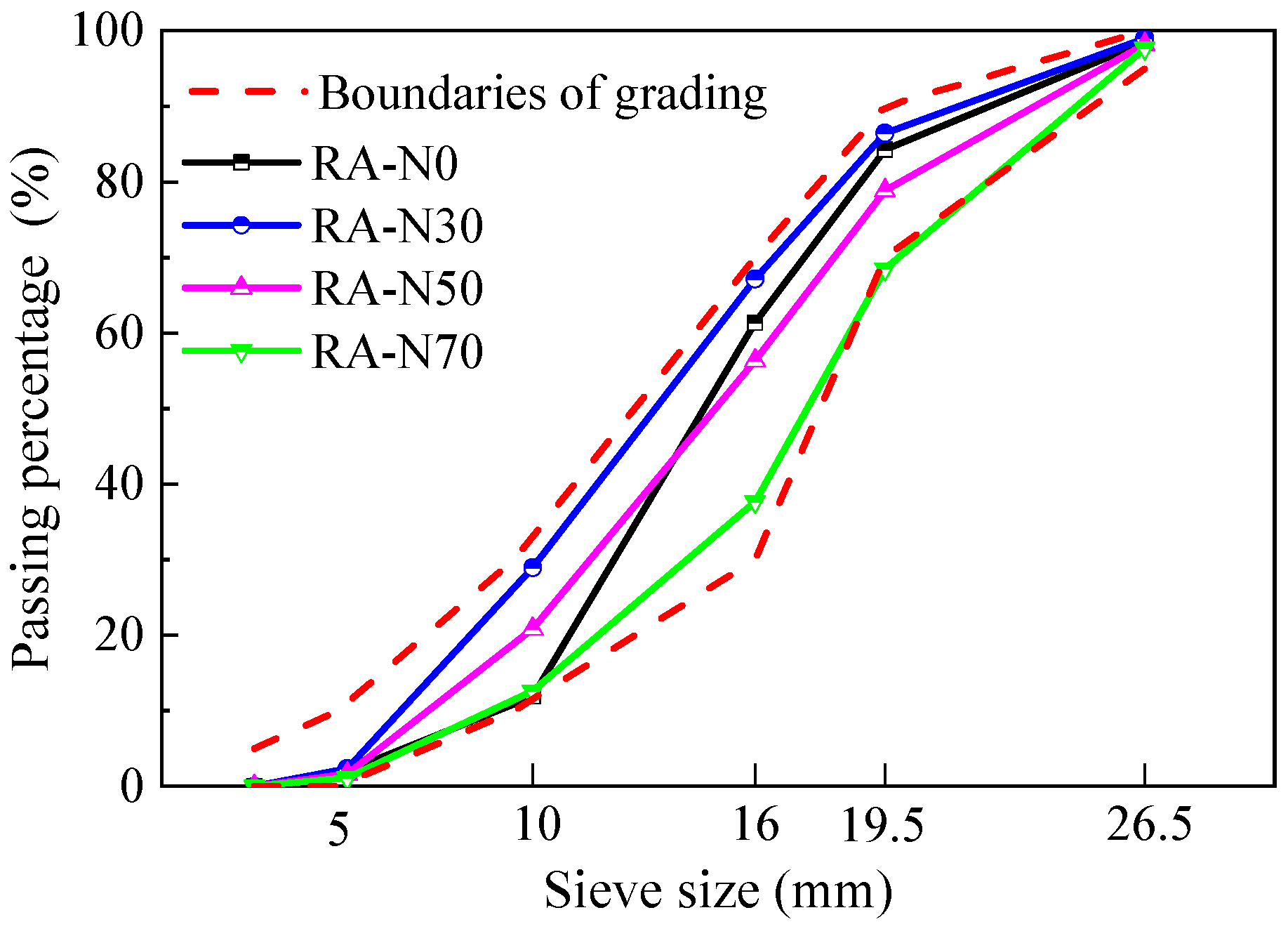

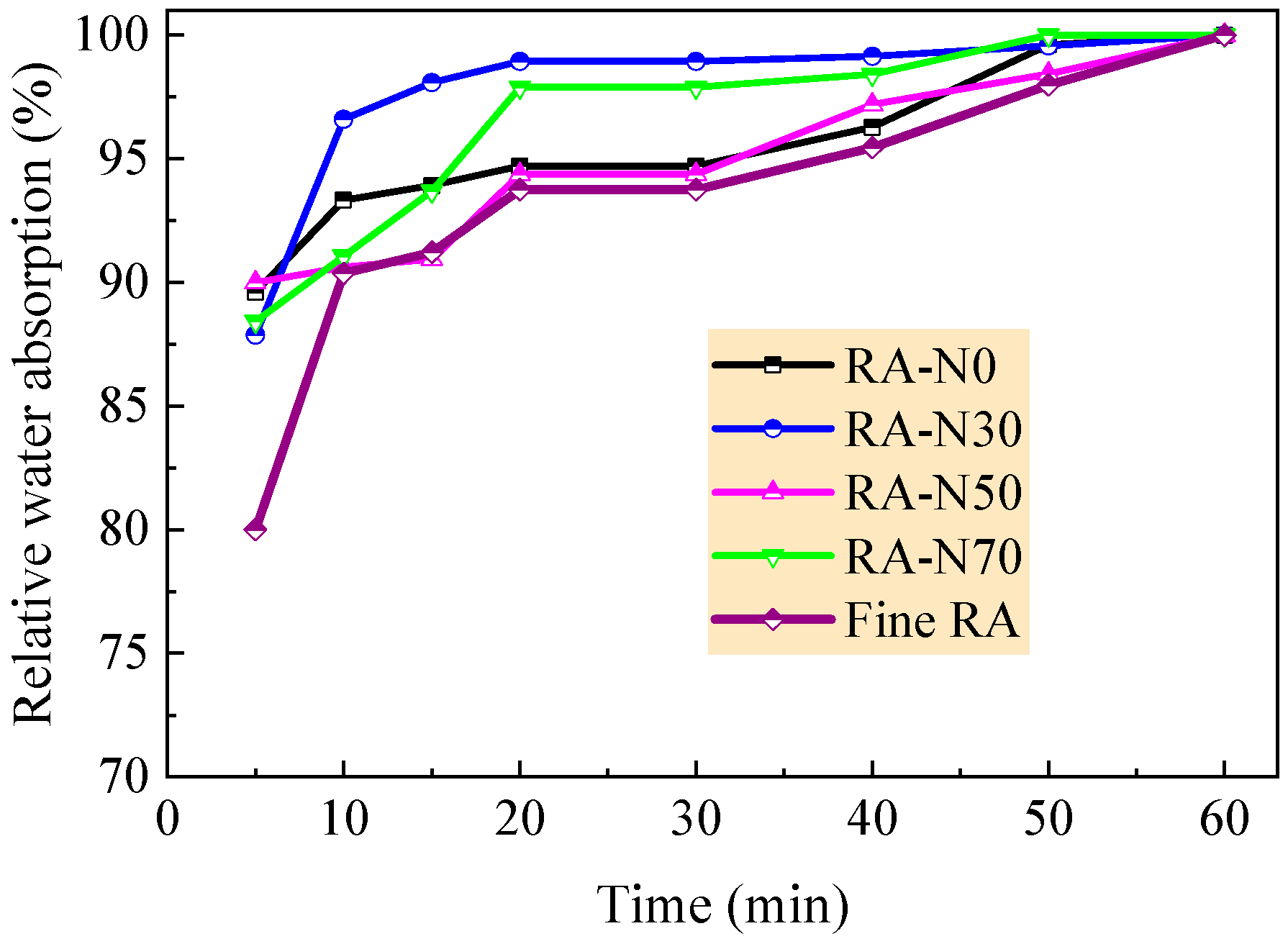

2.1. Raw Materials

2.2. Mix Proportions of RAC

2.3. Specimen Preparation and Testing

3. Results and Discussion

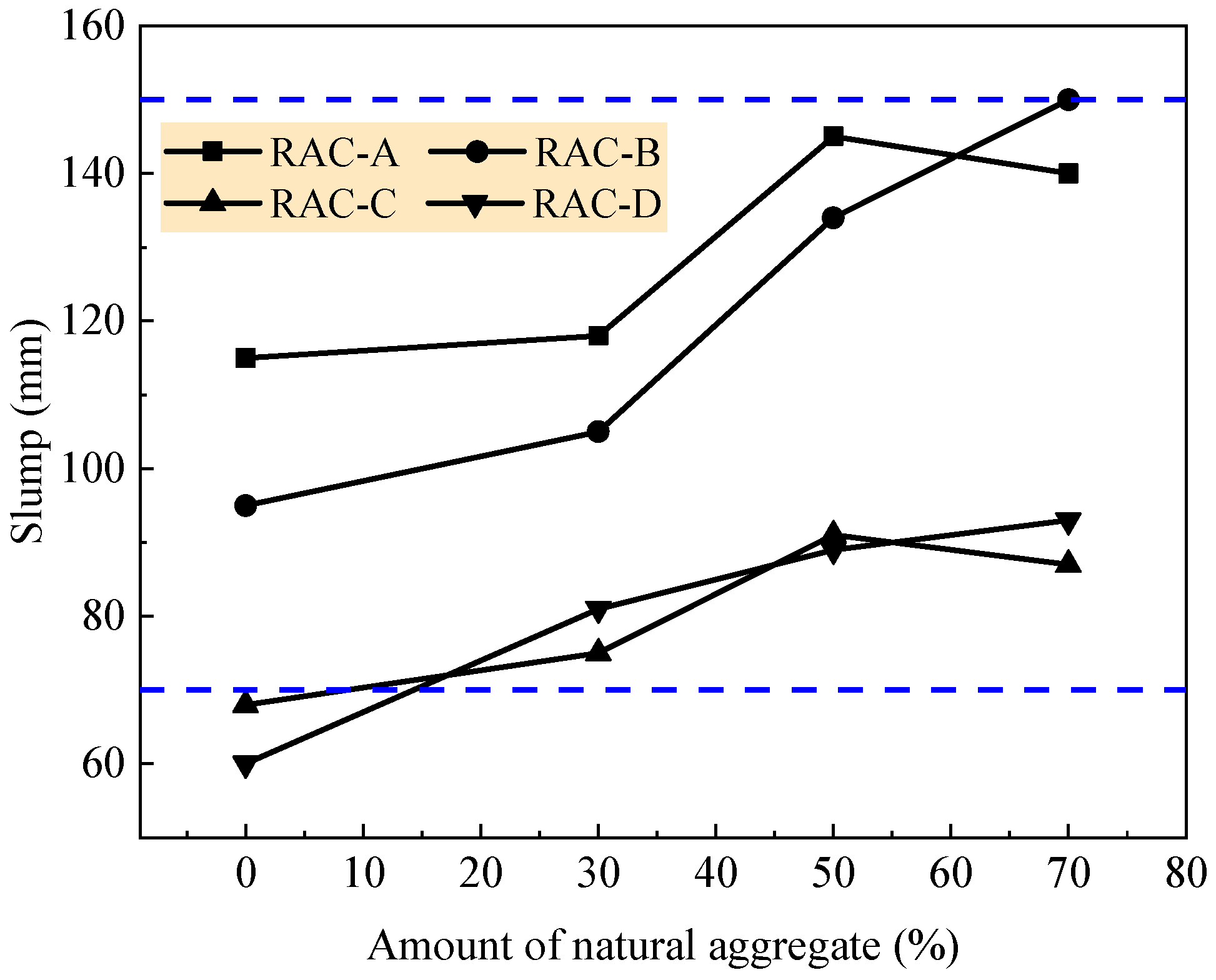

3.1. Properties of Fresh RAC

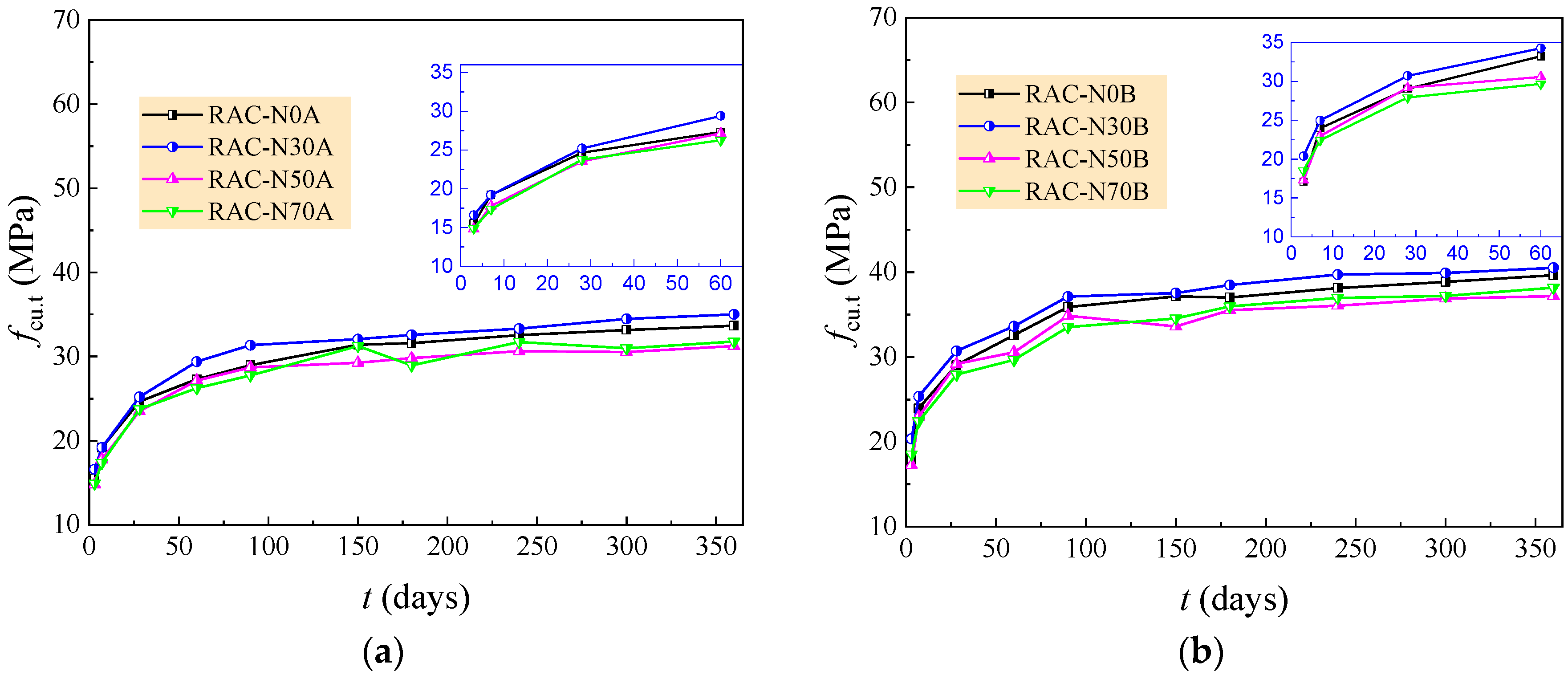

3.2. Development of Compressive Strength

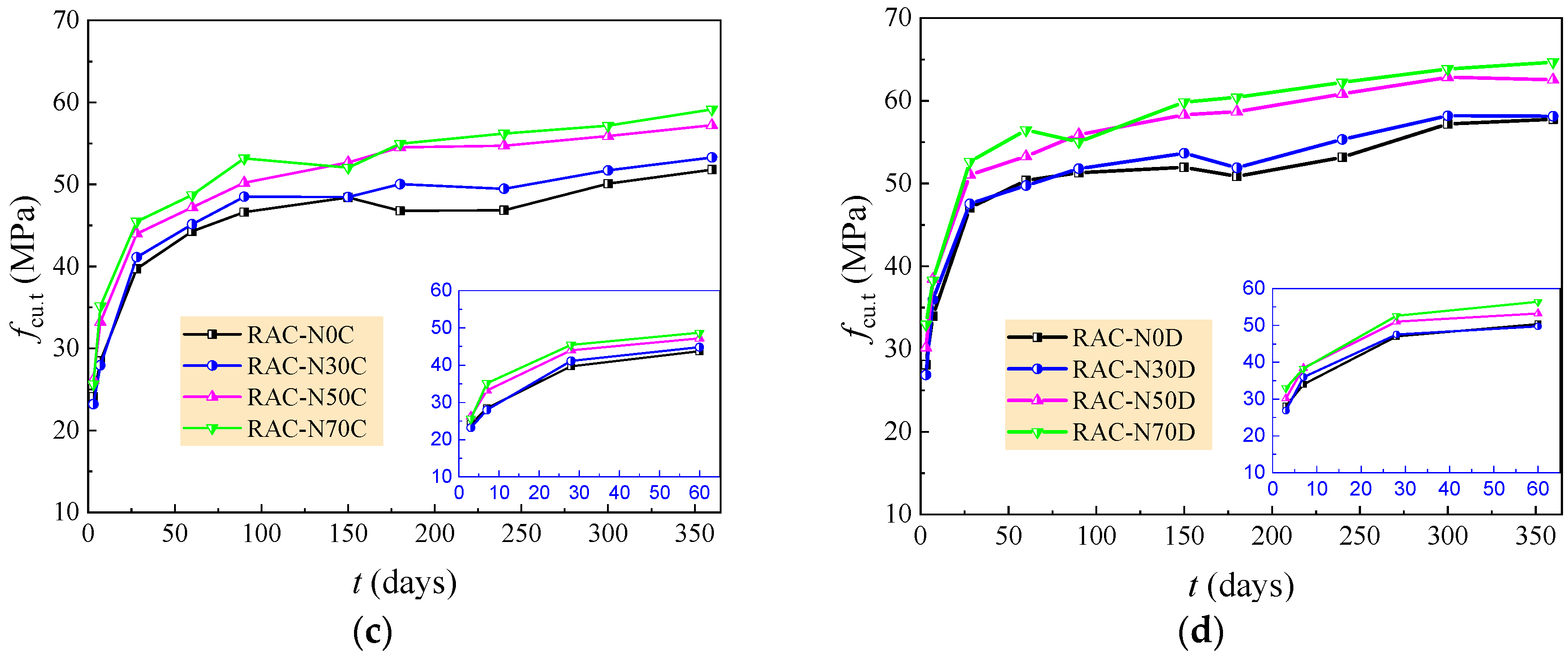

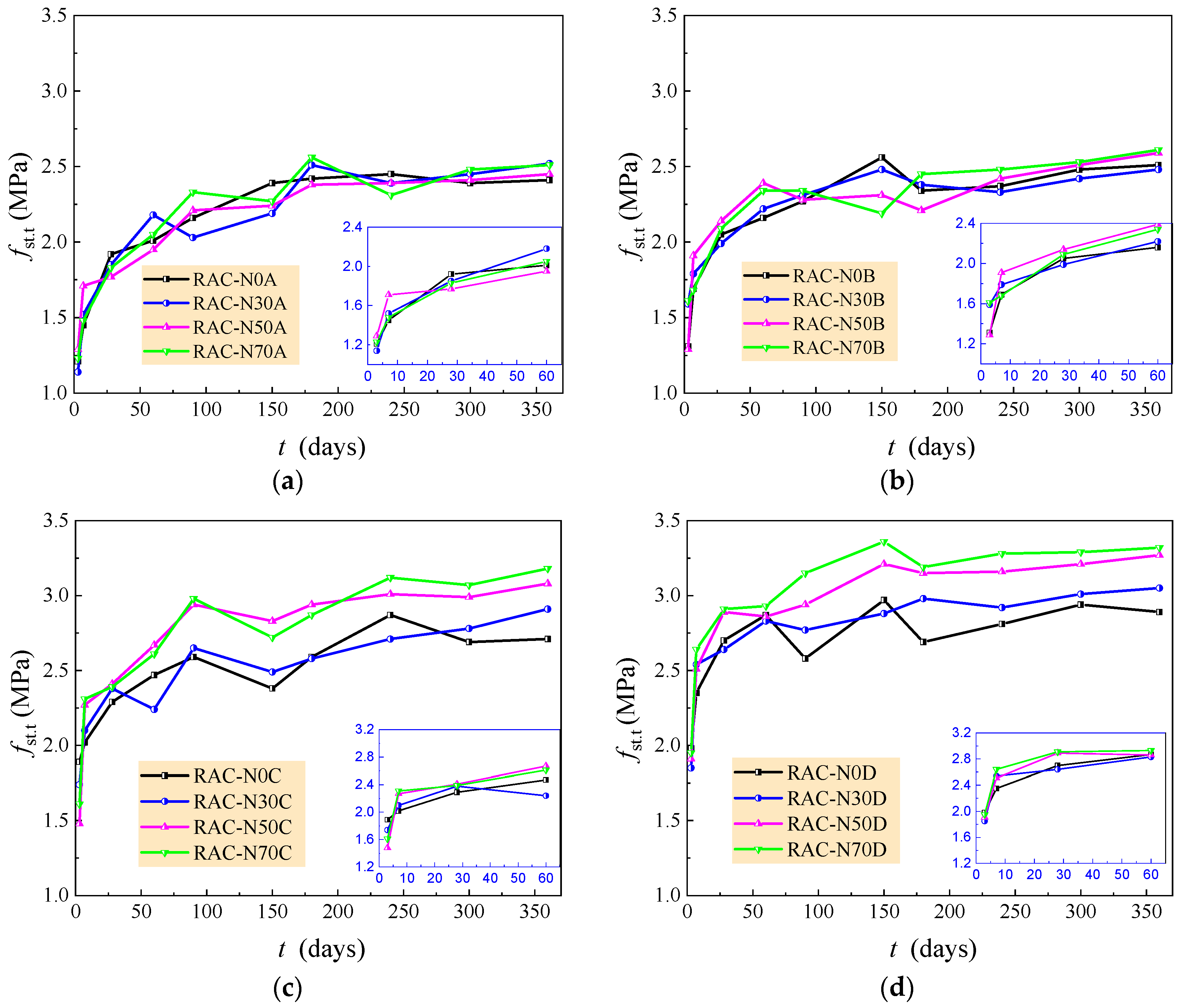

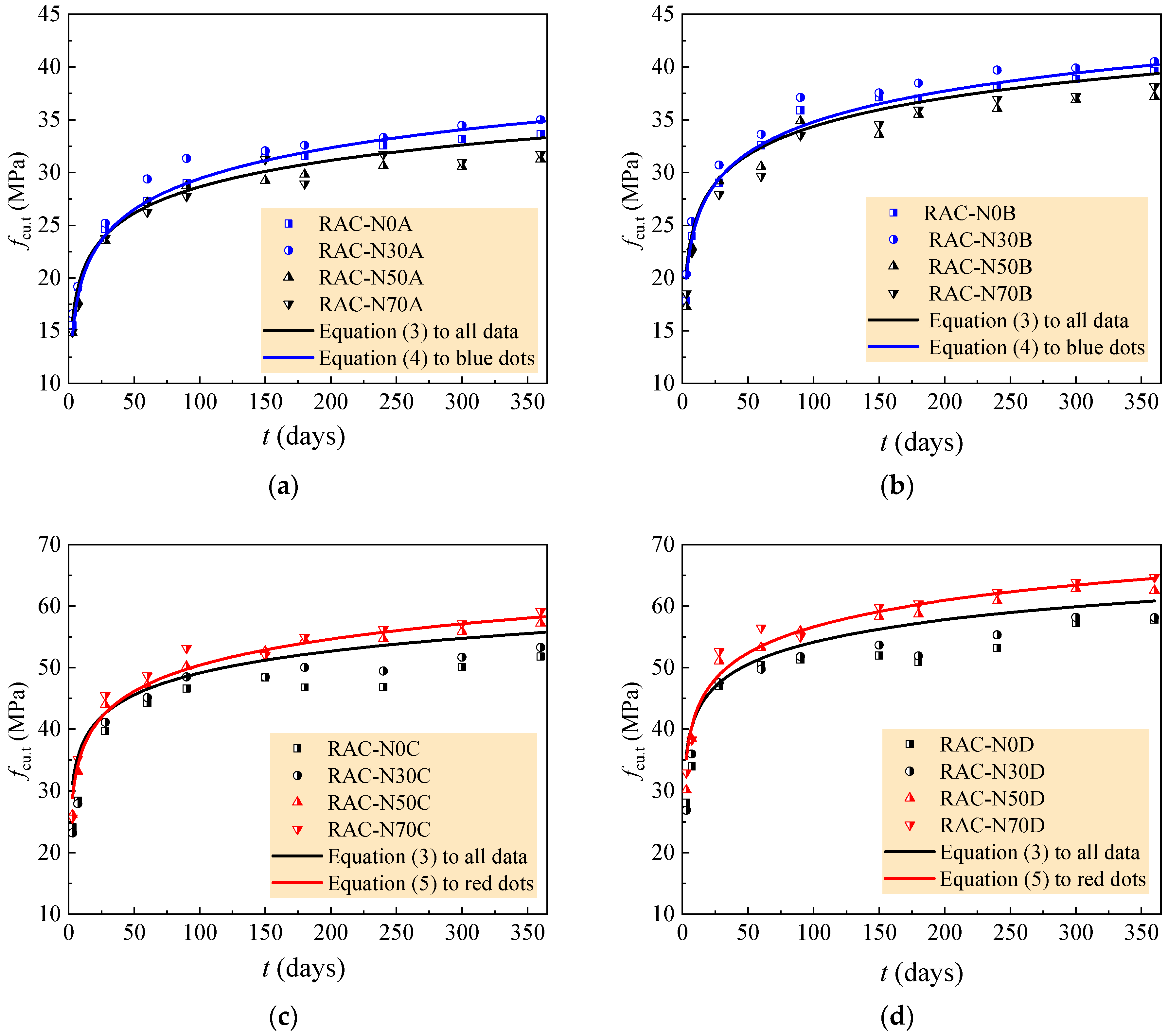

3.3. Development of the Splitting Tensile Strength

4. Prediction of Strength Development

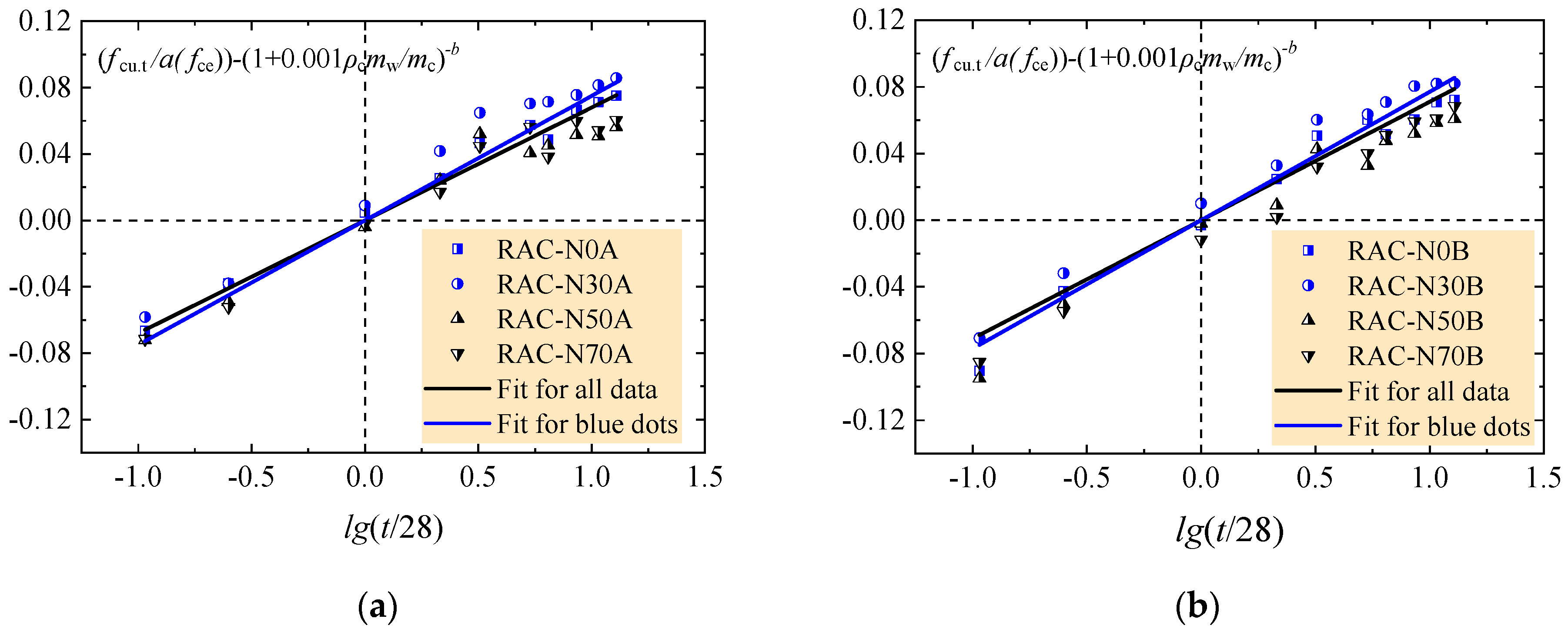

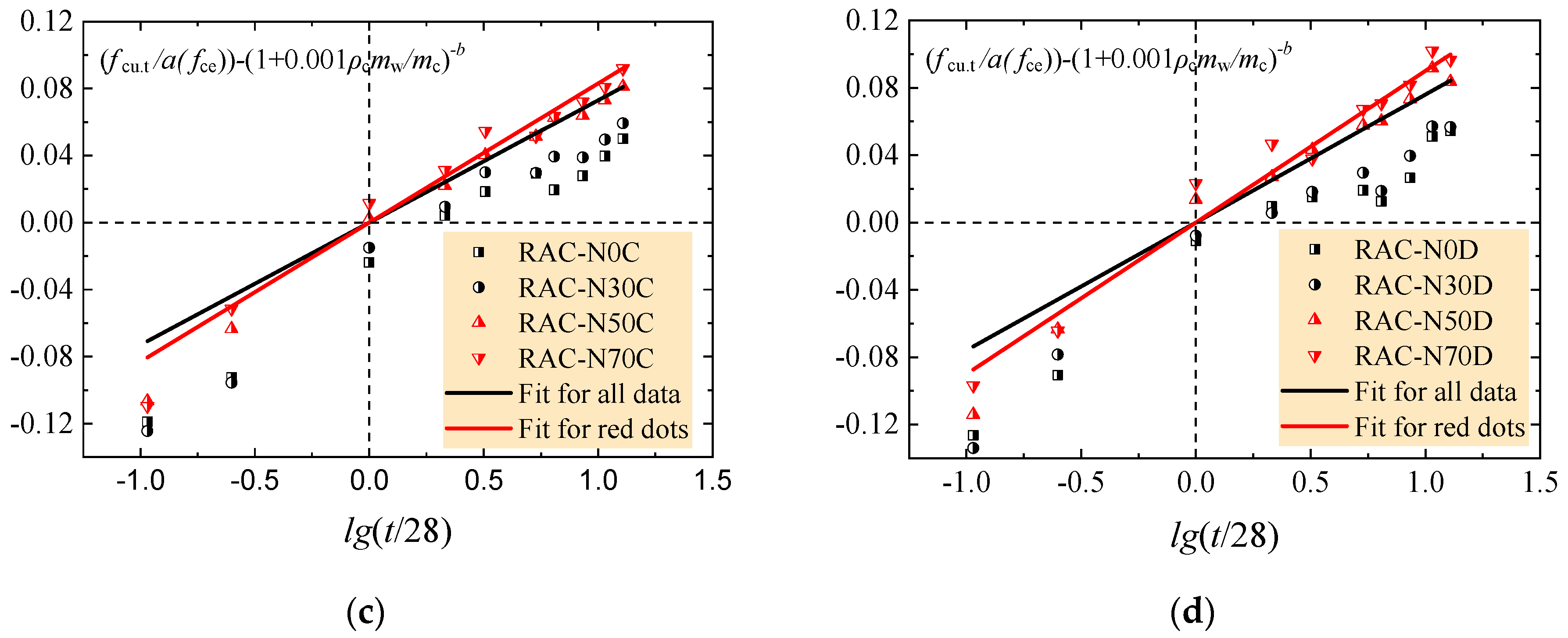

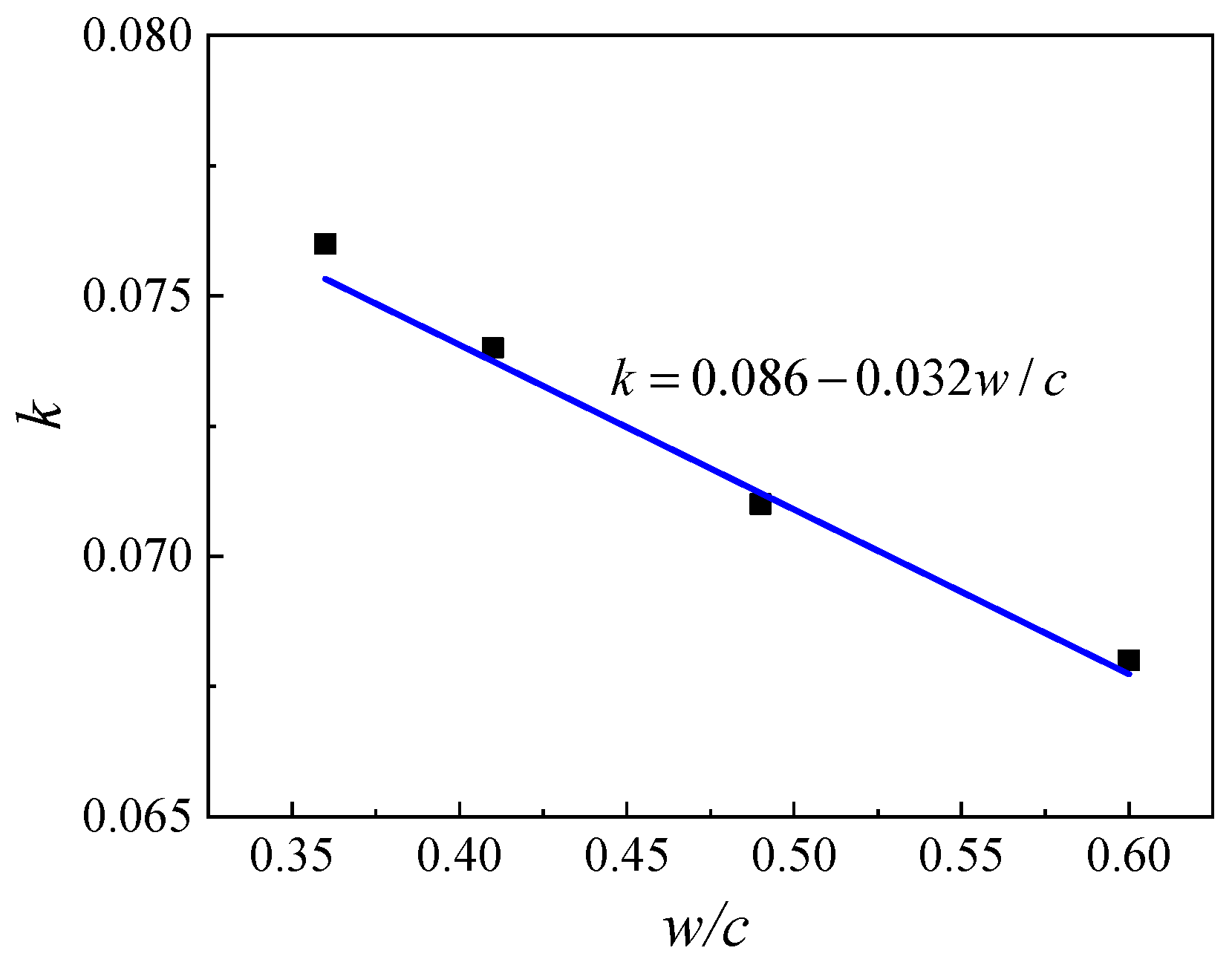

4.1. Compressive Strength

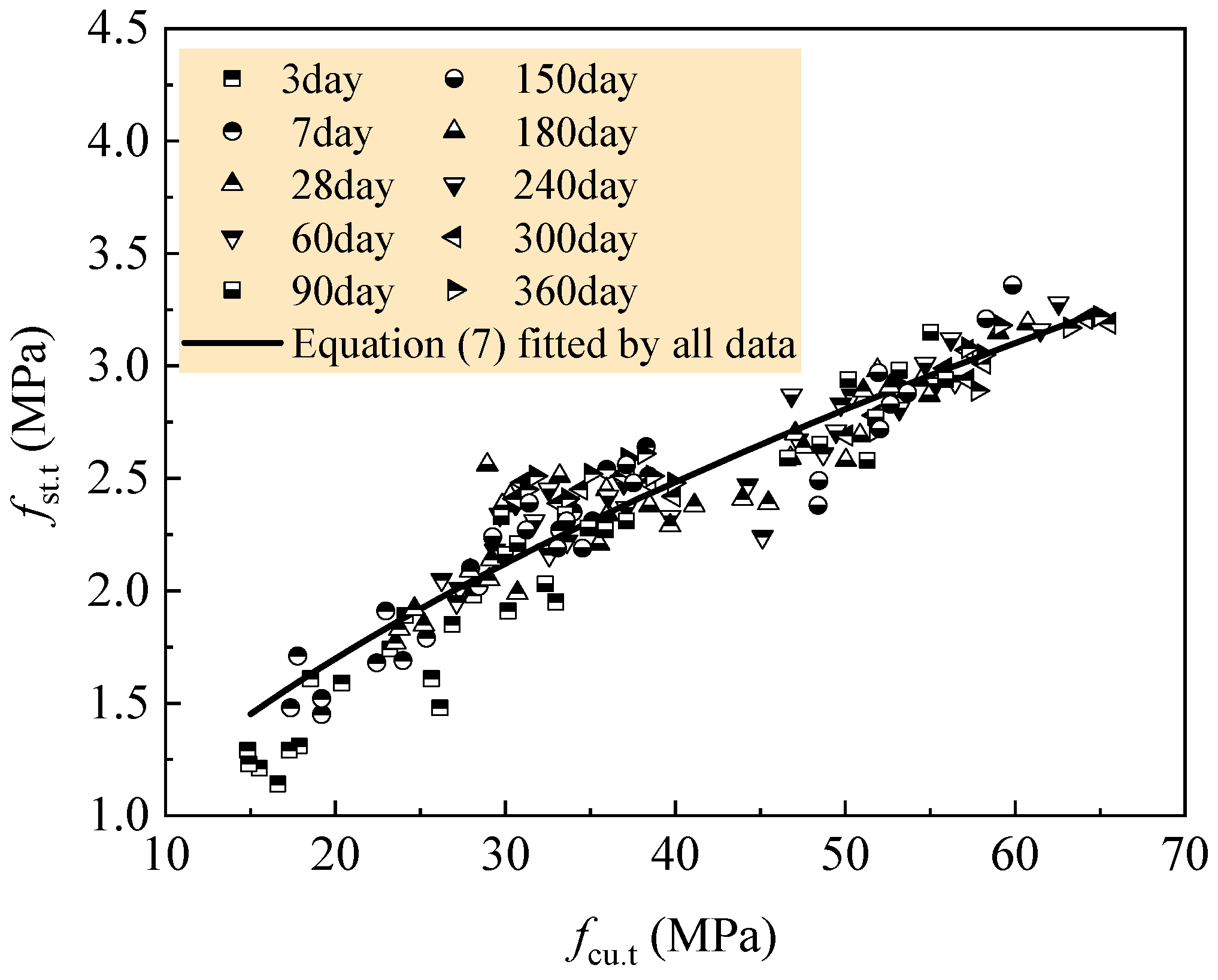

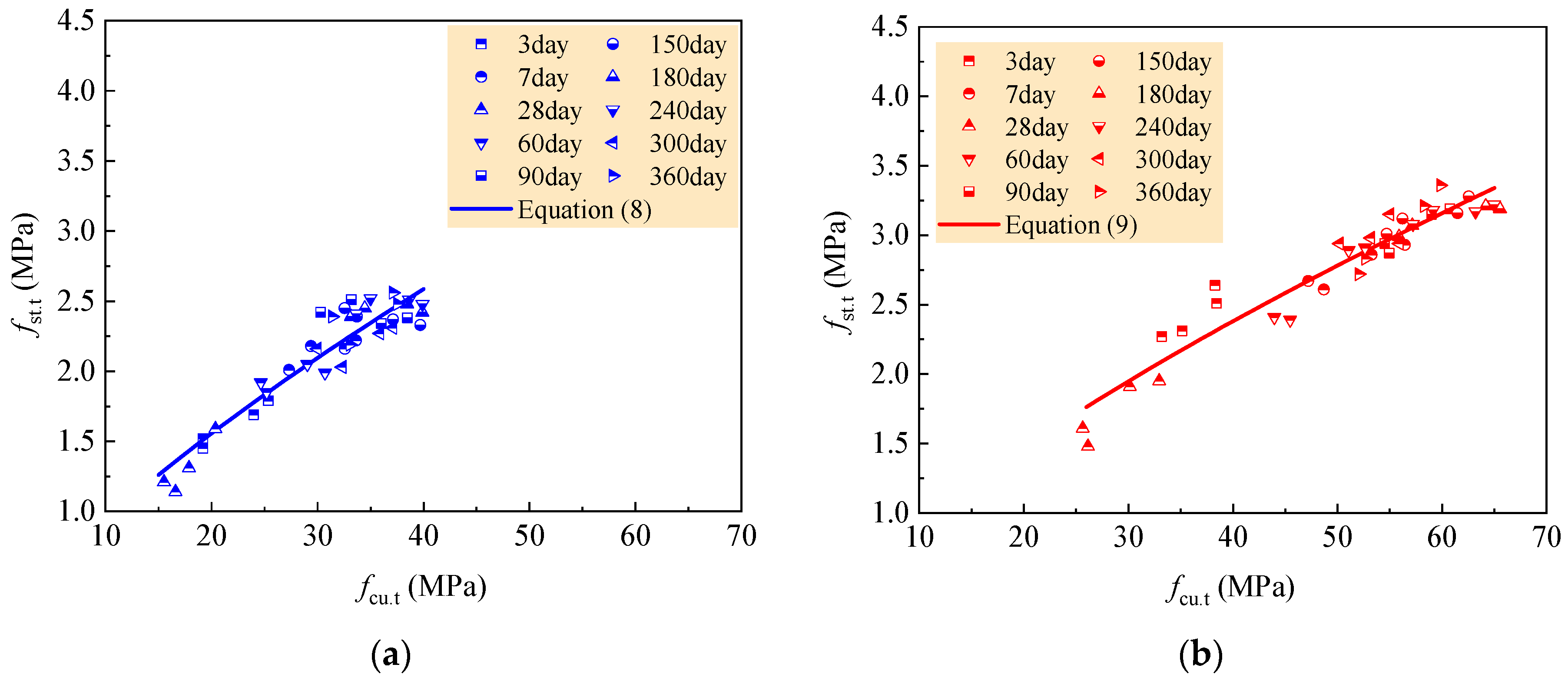

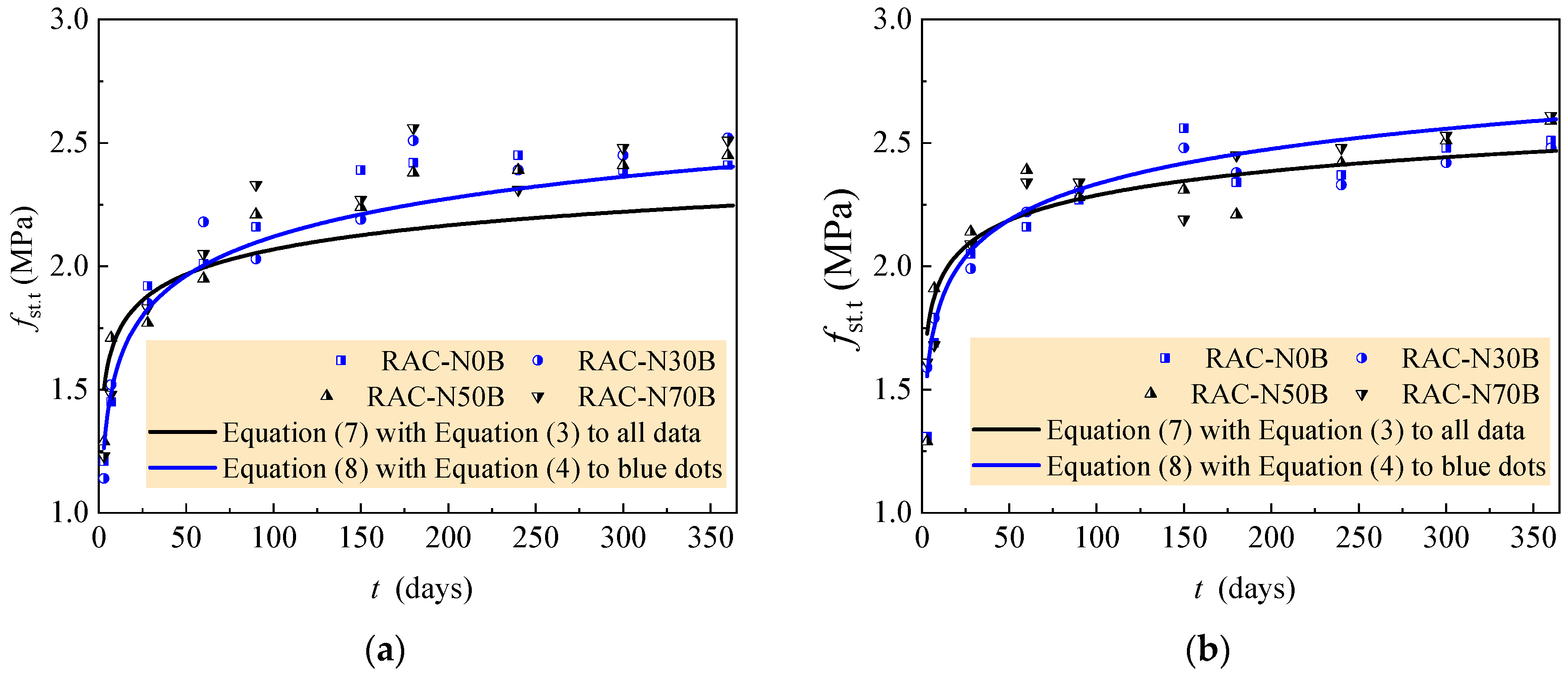

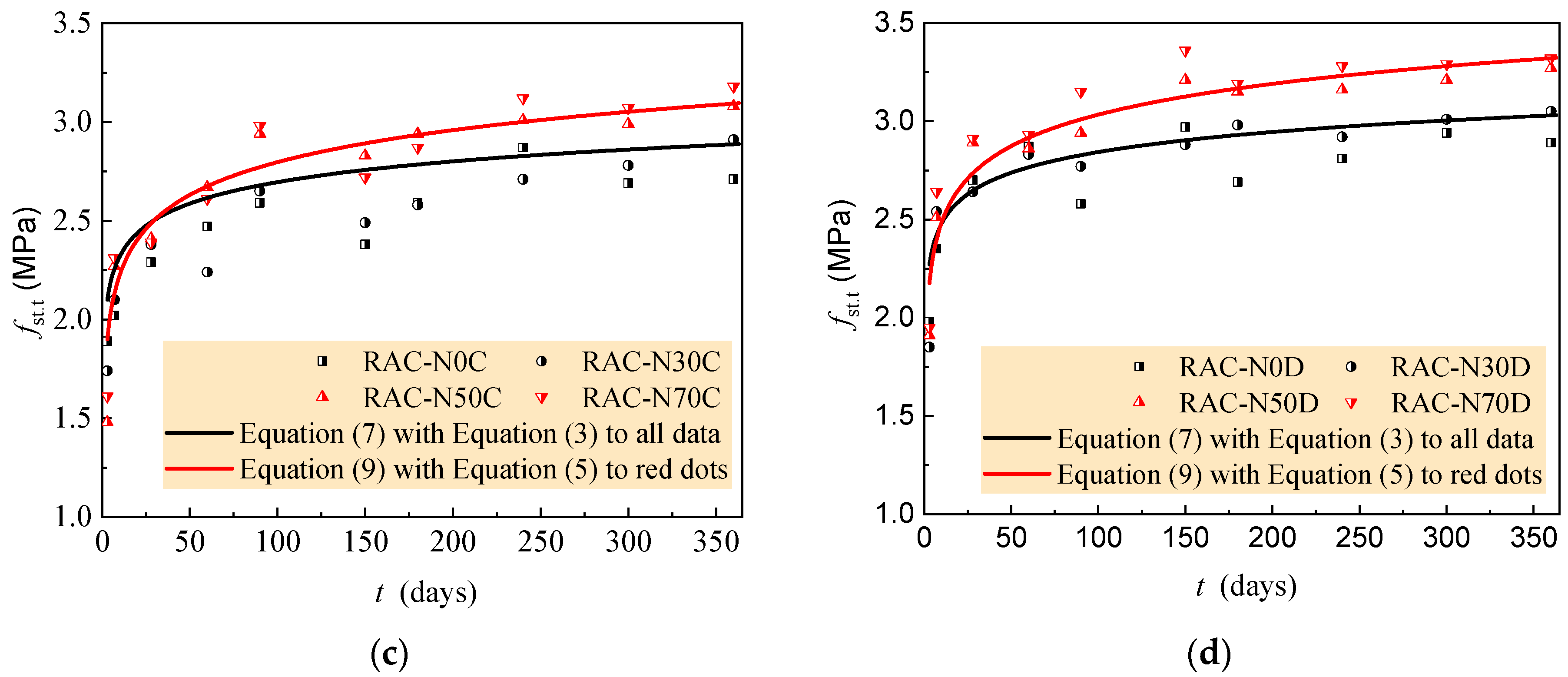

4.2. Splitting Tensile Strength

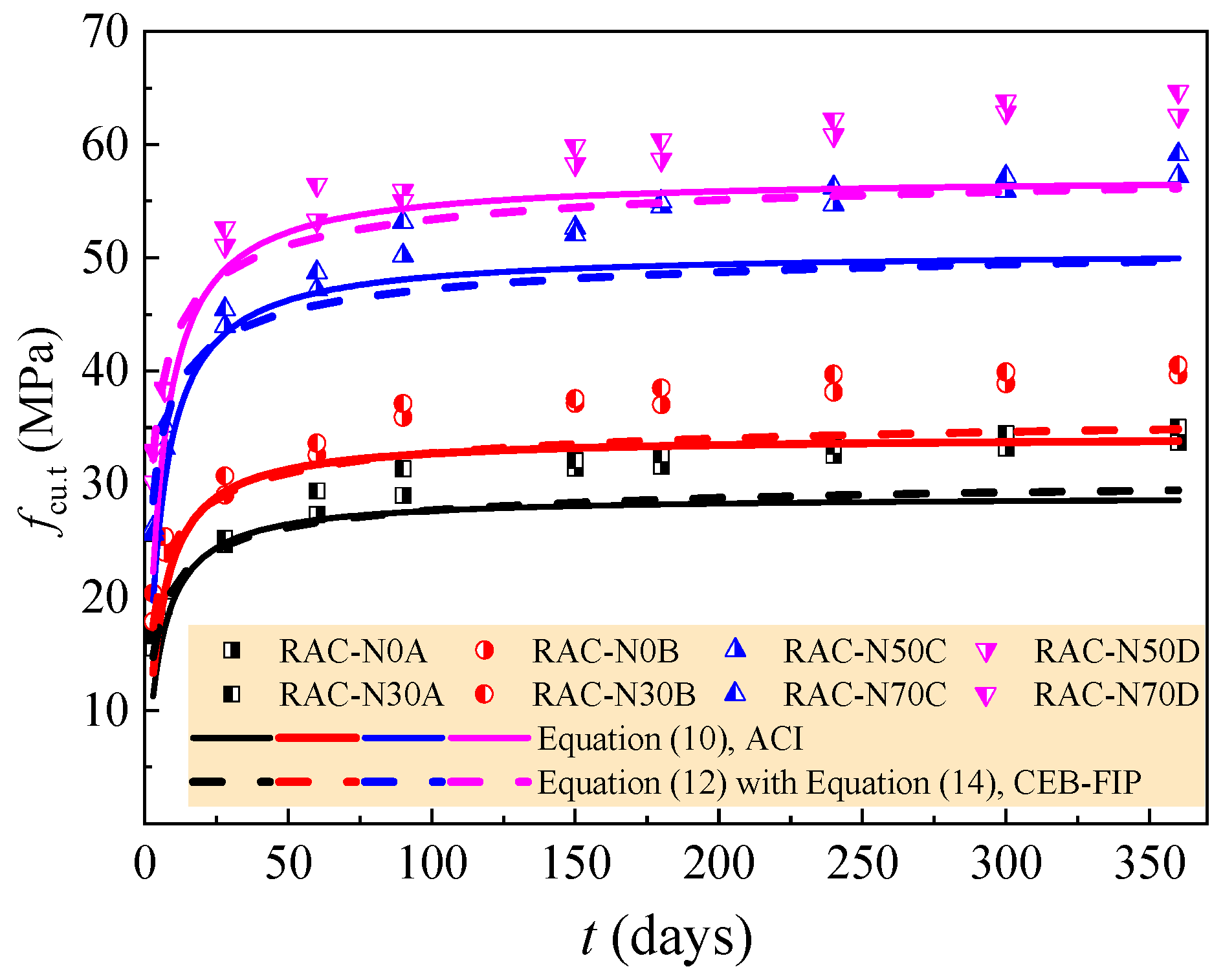

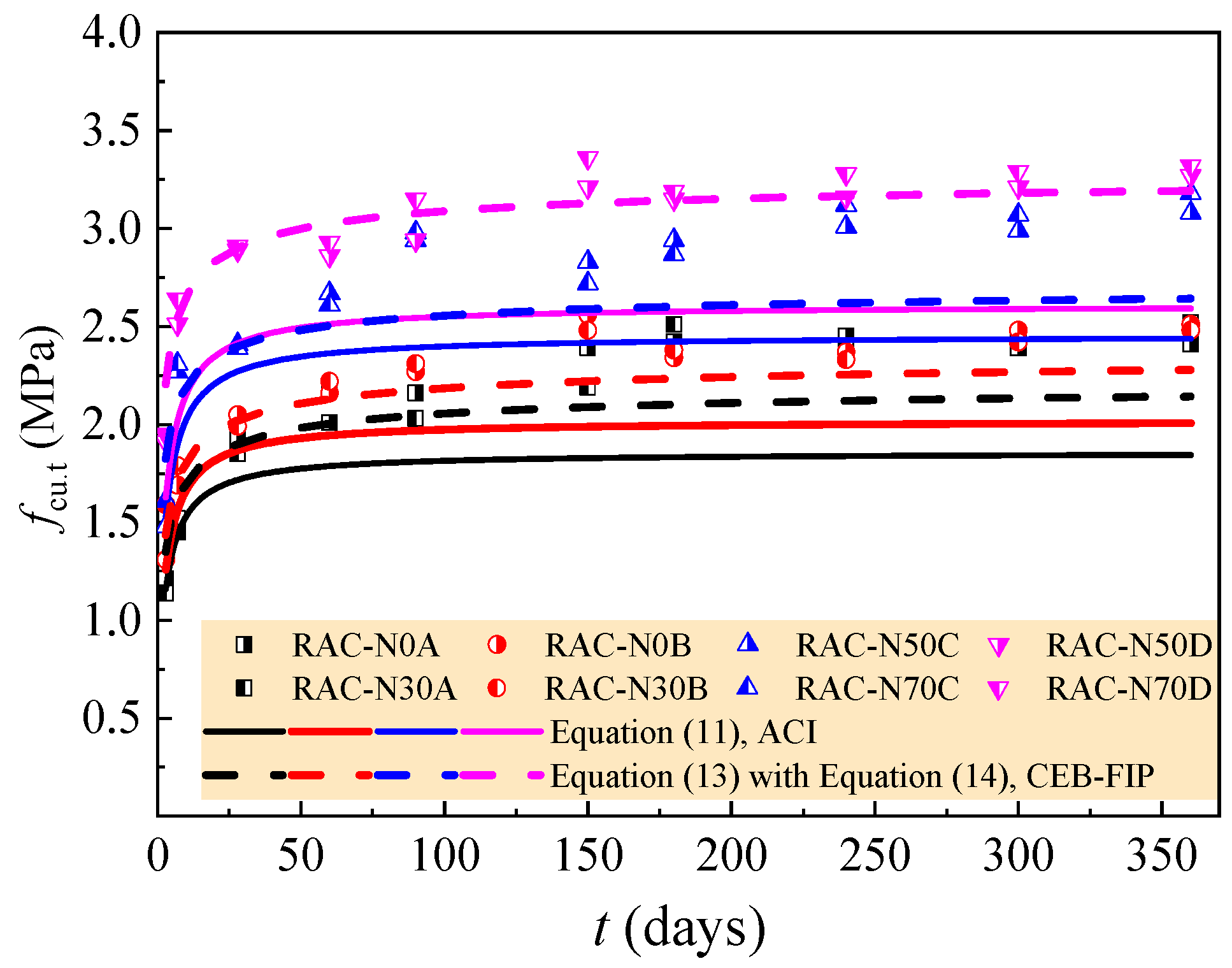

5. Assessment by Commonly Used Models

6. Conclusions

- (1)

- The compressive and tensile strength of the new RAC with large particle natural aggregate grew in trends as rapid, fast to steady with an increase of curing age. This was affected by the water/cement ratio and strength grade of the cement. When w/c = 0.6 and 0.49, the compressive strength was higher for the RAC with 30% natural aggregate, while the tensile strength was not obviously influenced by the amount of natural aggregate. When w/c = 0.41 and 0.36, the compressive and splitting tensile strengths were higher for the RAC with 50% and 70% natural aggregate, while the strengths benefited from 30% natural aggregate. This indicates that the rational amount of large particle natural aggregate existed in the RAC with a different water/cement ratio.

- (2)

- Based on the modification to a predictive model of compressive strength of conventional concrete, the predictive equation of compressive strength of the RAC at any curing age is proposed, in which the main influence factors are the strength and density of cement, the water/cement ratio and the curing age. By introducing the relationship between splitting tensile strength and compressive strength of the RAC at any curing age, the splitting tensile strength can be predicted from the compressive strength at the same curing age. After the fitness analyses, the large prediction can be controlled within 10% over test results. This provides a convenient method for engineering applications.

- (3)

- A rational amount of large particle natural aggregate can be determined to get good strength development. It should be no more than 30% for the RAC in a strength grade no larger than C30 with w/c = 0.60 and 0.49, and no less than 50% for the RAC in a strength grade no less than C40 with w/c = 0.41 and 0.36. Along with the general prediction of the strength development of all tested RAC, the optimal predictive formulas are proposed for the strength development of the RAC with a rational amount of natural aggregate.

- (4)

- The test results of the RAC with a rational amount of natural aggregate are assessed by the commonly used time-dependent models proposed by ACI and CEB-FIP. These models are conservative to predict the strength development of the RAC, except that the CEB-FIP model provides a higher tensile strength at 3 days.

- (5)

- Due to the lack of studies on the safe prediction of the strength development of RAC with different amounts of large particle natural aggregate, the modern design experimental method needs to be used to estimate numerical mechanical characteristics without the need for real tests.

Author Contributions

Funding

Conflicts of Interest

References

- Hendriks, C.F.; Pietersen, H.S. Sustainable raw materials: Construction and demolition waste–state-of-the-art report of RILEM technical committee 165-SRM. RILEM publications: Geneva, Switzerland, 2000. [Google Scholar]

- Li, X.P. Recycling and reuse of waste concrete in China Part I. Material behavior of recycled aggregate concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, W.G.; Fan, Y.H. An overview of study on recycled aggregate concrete in China. Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Lotfi, S.; Eggimann, M.; Wagner, E. Performance of recycled aggregate concrete based on a new concrete recycling technology. Constr. Build. Mater. 2015, 95, 243–256. [Google Scholar] [CrossRef]

- Kim, H.; Goulias, D.G. Shrinkage behavior of sustainable concrete with crushed returned concrete aggregate. J. Mater. Civ. Eng. 2015, 27, 04014204. [Google Scholar] [CrossRef]

- Otsuki, N.; Miyazato, S.; Yodsudjai, W. Influence of recycled aggregate on interfacial transition zone strength, chloride penetration and carbonation of concrete. J. Mater. Civ. Eng. 2003, 15, 443–451. [Google Scholar] [CrossRef]

- Li, J.H.; Xiao, H.N.; Zhou, Y. Influence of coating recycled aggregate surface with pozzolanic powder on properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Ho, N.Y.; Lee, Y.P.K.; Lim, W.F. Efficient utilization of recycled concrete aggregate in structural concrete. J. Mater. Civ. Eng. 2013, 25, 318–327. [Google Scholar] [CrossRef]

- Wai, H.K.; Mahyuddion, R.; Kenn, J.K. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2012, 6, 565–573. [Google Scholar]

- Yao, Y.F.; Jin, B.H.; Zhang, H.G.; Lan, H.W. Influence of replacement rate of recycled coarse aggregate on mechanical properties of recycled concrete. J. Guangxi Univ. (Nat. Sci. Ed) 2016, 4, 1187–1193. (In Chinese) [Google Scholar] [CrossRef]

- Liu, S.X.; Wei, X.G.; Wei, W. Influence of recycled coarse aggregate on recycled concrete performance. Build. Struct. 2014, 14, 17–20. (In Chinese) [Google Scholar]

- Seo, D.S.; Choi, H.B. Effects of the old cement mortar attached to the recycled aggregate surface on the bond characteristics between aggregate and cement mortar. Constr. Build. Mater. 2014, 59, 72–77. [Google Scholar] [CrossRef]

- Zhao, S.B.; Guo, Q.; Li, G.X.; Su, Y.F.; Shao, W.J. Basic mechanical properties of concrete with machine-made sand and recycled coarse aggregate. Appl. Mech. Mater. 2013, 357, 1102–1105. [Google Scholar] [CrossRef]

- Li, C.Y.; Zhao, M.L.; Ren, F.C.; Liang, N.; Li, J.; Zhao, M.S. Bond Properties between full-recycled-aggregate concrete and deformed steel bar. Open Civ. Eng. J. 2017, 11, 685–698. [Google Scholar] [CrossRef]

- Sidorova, A.; Vazquez-Ramonich, E.; Barra-Bizinotto, M. Study of the recycled aggregates natures influence on the aggregate cement paste interface and ITZ. Constr. Build. Mater. 2014, 68, 677. [Google Scholar] [CrossRef]

- Qiao, J.S.; Zang, P.; Huo, W.J. Influence of maximum particle size of coarse aggregate on strength of recycled concrete. J. Hebei United Univ. 2016, 1, 107–110. (In Chinese) [Google Scholar]

- Li, S.S.; Gao, D.Y. Experimental research on the influence of coarse aggregate size on boulder concrete compressive strength. Concrete 2013, 2, 59–63. (In Chinese) [Google Scholar]

- Zhao, S.B.; Liang, N.; Liu, L.X.; Sun, L.; Yang, S. Experimental study on mechanical properties of fine aggregate concrete made after wet-sieving coarse aggregate. Adv. Mater. Res. 2011, 168, 2200–2203. [Google Scholar] [CrossRef]

- Li, X.K.; Guo, Q.; Zhao, S.B.; Li, G.X.; Su, Y.F. Mix design and experimental study of fully recycled aggregate concrete. J. North Chin. Univ. Water Resour. Electric Power 2013, 4, 53–56. (In Chinese) [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Code for Design of Concrete Structures; GB 50010-2010; China Building Industry Press: Beijing, China, 2010. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Code for Durability Design of Concrete Structures; GB/T 50476-2008; China Building Industry Press: Beijing, China, 2008. (In Chinese)

- Butler, L.; West, J.S.; Tighe, S.L. Effect of recycled concrete coarse aggregate from multiple sources on the hardened properties of concrete with equivalent compressive strength. Constr. Build. Mater. 2013, 47, 1292–1301. [Google Scholar] [CrossRef]

- Fathifazl, G.; Razaqpur, A.G.; Isgor, O.B.; Abbas, A.; Fournier, B.; Foo, S. Creep and drying shrinkage characteristics of concrete produced with coarse recycled concrete aggregate. Cem. Concr. Compos. 2011, 33, 1026–1037. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Elhakam, A.A.; Mohamed, A.E.; Awad, E. Influence of self-healing, mixing method and adding silica fume on mechanical properties of recycled aggregates concrete. Constr. Build. Mater. 2012, 35, 421–427. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R.; Salas, A. Initial moisture and mixing effects on higher quality recycled coarse aggregate concrete. Constr. Build. Mater. 2012, 26, 565–573. [Google Scholar] [CrossRef]

- Liang, Y.C.; Ye, Z.M.; Vernerey, F.; Xi, Y.P. Development of processing methods to improve strength of concrete with 100% recycled coarse aggregate. J. Mater. Civ. Eng. 2015, 5, 04014163(9). [Google Scholar] [CrossRef]

- Yildirim, S.T.; Meyer, C.; Herfellner, S. Effects of internal curing on the strength, drying shrinkage and freeze-thaw resistance of concrete containing recycled concrete aggregates. Constr. Build. Mater. 2015, 91, 288–296. [Google Scholar] [CrossRef]

- Cui, H.Z.; Shi, X.; Memon, S.A.; Xing, F.; Tang, W. Experimental study on the influence of water absorption of recycled coarse aggregates on properties of the resulting concretes. J. Mater. Civ. Eng. 2015, 4, 04014138(9). [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Mechanical strength and drying shrinkage properties of concrete containing treated coarse recycled concrete aggregates. Constr. Build. Mater. 2014, 68, 726–739. [Google Scholar] [CrossRef]

- Guedes, M.; Evangelista, L.; de Brito, J.; Ferro, A.C. Microstructural characterization of concrete prepared with recycled aggregates. Microsc. Microanal. 2013, 19, 1222–1230. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Liang, N.; Zhao, S.B.; Zhu, W.W.; Yao, K.Q.; Jin, L.H.; Qian, X.J. Experimental study on shrinkage behavior of full-recycled aggregate concrete. J. North Chin. Univ. Water Resour. Electric Power 2017, 6, 43–48. (In Chinese) [Google Scholar]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 5, 397–401. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Pereira, P.; Evangelista, L.; de Brito, J. The effect of superplasticisers on the workability and compressive strength of concrete made with fine recycled concrete aggregates. Constr. Build. Mater. 2012, 28, 722–729. [Google Scholar] [CrossRef]

- Pan, L.Y.; Liang, N.; Hu, F.J.; Yao, K.Q.; Cheng, D.D.; Pei, S.W. Experimental study and evaluation of mechanical properties of full-recycled coarse aggregate concrete. J. North Chin. Univ. Water Resour. Electric Power 2017, 6, 32–42. (In Chinese) [Google Scholar]

- Yao, K.Q.; Liang, N.; Wu, H.H.; Pei, S.W. Experimental study on strength development of full-recycled-aggregate concrete. Hans J. Civ. Eng. 2017, 5, 498–507. (In Chinese) [Google Scholar] [CrossRef]

- Li, F.L.; Li, J.; Chen, S.; Zhao, W.J. Experiment of basic mechanical properties of concrete mixed with composite aggregate. Adv. Mater. Res. 2011, 168, 2178–2181. [Google Scholar] [CrossRef]

- Santos, S.A.; Da Silva, P.R.; De Brito, J. Mechanical performance evaluation of self-compacting concrete with fine and coarse recycled aggregates from the precast industry. Material 2017, 8, 904. [Google Scholar] [CrossRef] [PubMed]

- Li, C.Y.; Geng, H.B.; Deng, C.H.; Li, B.C.; Zhao, S.B. Experimental investigation on columns of steel fiber reinforced concrete with recycled aggregates under large eccentric compression load. Material 2019, 3, 445. [Google Scholar] [CrossRef]

- Cheng, D.D.; Geng, H.B.; Li, Q.; Li, B.C.; Ma, K. Study on large eccentric compression resistance of steel fiber recycled concrete columns. Hans J. Civ. Eng. 2018, 7, 313–320. (In Chinese) [Google Scholar] [CrossRef]

- Ding, X.X.; Li, C.Y.; Xu, Y.Y.; Li, F.L.; Zhao, S.B. Experimental study on long-term compressive strength development of concrete with manufactured sand. Constr. Build. Mater. 2016, 108, 67–73. [Google Scholar] [CrossRef]

- Zhao, S.B.; Ding, X.X.; Zhao, M.S.; Li, C.Y.; Pei, S.W. Experimental study on tensile strength development of concrete with manufactured sand. Constr. Build. Mater. 2017, 138, 247–253. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Recycled Coarse Aggregate for Concrete; GB/T 25177-2010; China Standard Press: Beijing, China, 2011. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete; JGJ 52-2006; China Building Industry Press: Beijing, China, 2006. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Recycled Fine Aggregate for Concrete; GB/T 25176-2010; China Standard Press: Beijing, China, 2011. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Specification for Mix Proportion Design of Ordinary Concrete; JGJ 55-2011; China Building Industry Press: Beijing, China, 2011. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Method of Mechanical Properties on Ordinary Concrete; GB/T 50081-2002; China Building Industry Press: Beijing, China, 2002. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Method of Performance on Ordinary Fresh Concrete; GB/T 50080-2002; China Building Industry Press: Beijing, China, 2002. (In Chinese)

- Larrard, F.D. Concrete Mixture Proportioning: A Scientific Approach; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Li, X.K.; Ma, X.L.; Zhang, X.Y. Experimental study on mix proportion of fair-faced concrete for urban bridge. Adv. Mater. Res. 2012, 450, 383–386. [Google Scholar] [CrossRef]

- Jin, L.H.; Ma, X.L.; Li, X.K. Experimental study on basic properties of fair-faced concrete for urban bridge. Appl. Mechan. Mater. 2013, 438, 1156–1159. [Google Scholar] [CrossRef]

- ACI committee 209. Prediction of Creep, Shrinkage, and Temperature Effects in Concrete Structures; ACI committee 209: Detroit, MI, USA, 1992. [Google Scholar]

- PN-EN 1992-1-1, Eurocode 2. Design of Concrete Structures: Part 1-1: General Rules and Rules for Buildings; British Standards Institution: London, UK, 2008. [Google Scholar]

- Comite Euro-International Du Beton. CEB-FIP Model Code 2010; Thomas Telford Services Ltd.: Thomas Telford House, London, UK, 2011. [Google Scholar]

| Coarse Aggregate | RA-N0 | RA-N30 | RA-N50 | RA-N70 |

|---|---|---|---|---|

| Natural aggregate (%) | 0 | 30 | 50 | 70 |

| Apparent density (kg/m3) | 2634.1 | 2691.5 | 2732.8 | 2735.1 |

| Bulk density (kg/m3) | 1345.8 | 1410.1 | 1463.2 | 1469.7 |

| Close-compacted density (kg/m3) | 1452.3 | 1512.4 | 1600.2 | 1612.9 |

| Moisture content (%) | 3.2 | 2.1 | 1.7 | 0.9 |

| Water absorption of 24 h (%) | 5.1 | 4.7 | 3.2 | 1.9 |

| Crushed index (%) | 14.7 | 14.1 | 13.5 | 13.2 |

| Silt content (%) | 0.42 | 0.29 | 0.21 | 0.19 |

| Properties | Values |

|---|---|

| Fineness modulus | 3.5 |

| Apparent density (kg/m3) | 2395.7 |

| Bulk density (kg/m3) | 1330 |

| Close-compacted density (kg/m3) | 1470 |

| Moisture content (%) | 5.70 |

| Water absorption of 24 h (%) | 9.45 |

| Crush index (%) | 9.35 |

| Grade | Density (kg/m3) | Water Requirement of Standard Consistency (%) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Initial | Final | 3 days | 28 days | 3 days | 28 days | |||

| 42.5 | 3071 | 26.9 | 168 | 269 | 28.9 | 45.2 | 4.00 | 5.30 |

| 52.5 | 3132 | 29.2 | 142 | 238 | 37.1 | 57.9 | 6.45 | 8.64 |

| Mix | w/c | Natural Aggregate (%) | Cement (kg/m3) | Water (kg/m3) | Fine RA (kg/m3) | Coarse Aggregate (kg/m3) | Additional Water (kg/m3) | |

|---|---|---|---|---|---|---|---|---|

| Natural | Recycled | |||||||

| RAC-N0A | 0.6 | 0 | 332 | 200 | 651 | 0 | 1157 | 54.9 |

| RAC-N30A | 0.6 | 30 | 332 | 200 | 734 | 304 | 710 | 55.6 |

| RAC-N50A | 0.6 | 50 | 332 | 200 | 736 | 508 | 508 | 50.4 |

| RAC-N70A | 0.6 | 70 | 332 | 200 | 737 | 712 | 305 | 45.3 |

| RAC-N0B | 0.49 | 0 | 409 | 200 | 626 | 0 | 1114 | 52.8 |

| RAC-N30B | 0.49 | 30 | 409 | 200 | 708 | 293 | 684 | 53.6 |

| RAC-N50B | 0.49 | 50 | 409 | 200 | 709 | 490 | 490 | 51.1 |

| RAC-N70B | 0.49 | 70 | 409 | 200 | 711 | 687 | 294 | 43.6 |

| RAC-N0C | 0.41 | 0 | 435 | 180 | 608 | 0 | 1119 | 53.1 |

| RAC-N30C | 0.41 | 30 | 435 | 180 | 688 | 310 | 722 | 53.6 |

| RAC-N50C | 0.41 | 50 | 435 | 180 | 689 | 517 | 517 | 48.3 |

| RAC-N70C | 0.41 | 70 | 435 | 180 | 691 | 691 | 311 | 43.6 |

| RAC-N0D | 0.36 | 0 | 503 | 180 | 612 | 0 | 1089 | 51.2 |

| RAC-N30D | 0.36 | 30 | 503 | 180 | 697 | 288 | 674 | 52.8 |

| RAC-N50D | 0.36 | 50 | 503 | 180 | 698 | 482 | 482 | 47.9 |

| RAC-N70D | 0.36 | 70 | 503 | 180 | 700 | 676 | 290 | 42.9 |

| Trial No. | Groups | Designed Curing Age t (days) |

|---|---|---|

| A, B, C, D | 4 × (4 × 10) for compressive strength 4 × (4 × 10) for splitting tensile strength | 3, 7, 28, 60, 90, 150, 180, 240, 300, 360 |

| RAC | 30A/0A | 50A/0A | 70A/0A | 30B/0B | 50B/0B | 70B/0B | 30C/0C | 50C/0C | 70C/0C | 30D/0D | 50D/0D | 70D/0D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Mean ratio | 1.063 | 0.949 | 0.954 | 1.036 | 0.945 | 0.944 | 1.044 | 1.129 | 1.158 | 1.014 | 1.119 | 1.146 |

| Variation coefficient | 0.044 | 0.035 | 0.037 | 0.042 | 0.030 | 0.055 | 0.036 | 0.031 | 0.044 | 0.025 | 0.034 | 0.031 |

| RAC | 30A/0A | 50A/0A | 70A/0A | 30B/0B | 50B/0B | 70B/0B | 30C/0C | 50C/0C | 70C/0C | 30D/0D | 50D/0D | 70D/0D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Mean ratio | 0.998 | 0.979 | 1.010 | 0.993 | 1.008 | 1.017 | 1.007 | 1.111 | 1.112 | 1.029 | 1.094 | 1.125 |

| Variation coefficient | 0.029 | 0.046 | 0.031 | 0.017 | 0.031 | 0.031 | 0.016 | 0.029 | 0.031 | 0.018 | 0.034 | 0.034 |

| RAC trials | A | B | C | D |

|---|---|---|---|---|

| k | 0.068 | 0.071 | 0.074 | 0.076 |

| Correlation coefficient | 0.954 | 0.952 | 0.838 | 0.830 |

| Standard error | 0.005 | 0.006 | 0.002 | 0.005 |

| RAC-N | 0A | 30A | 50A | 70B | 0B | 30B | 50B | 70B |

| Number | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Mean ratio | 1.02 | 1.07 | 0.96 | 0.97 | 1.01 | 1.04 | 0.94 | 0.95 |

| Variation coefficient | 2.01% | 3.32% | 4.52% | 3.91% | 5.24% | 2.05% | 4.21% | 1.89% |

| Correlation coefficient | 0.991 | 0.987 | 0.972 | 0.981 | 0.982 | 0.991 | 0.985 | 0.993 |

| RAC-N | 0C | 30C | 50C | 70C | 0D | 30D | 50D | 70D |

| Number | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Mean ratio | 0.88 | 0.90 | 1.02 | 1.06 | 0.90 | 0.91 | 1.02 | 1.08 |

| Variation coefficient | 5.02% | 7.24% | 4.60% | 5.83% | 5.69% | 6.14% | 5.21% | 4.47% |

| Correlation coefficient | 0.985 | 0.971 | 0.992 | 0.981 | 0.961 | 0.963 | 0.981 | 0.985 |

| RAC-N | 0A | 30A | 0B | 30B | 50C | 70C | 50D | 70D |

|---|---|---|---|---|---|---|---|---|

| Number | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Mean ratio | 0.98 | 1.02 | 0.97 | 1.01 | 0.97 | 1.01 | 0.98 | 1.02 |

| Variation coefficient | 4.21% | 3.72% | 4.94% | 3.11% | 3.51% | 6.18% | 4.66% | 5.62% |

| Correlation coefficient | 0.941 | 0.961 | 0.972 | 0.985 | 0.992 | 0.972 | 0.979 | 0.982 |

| RAC-N | 0A | 30A | 50A | 70B | 0B | 30B | 50B | 70B |

| Number | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Mean ratio | 1.08 | 1.06 | 1.05 | 1.06 | 1.0 | 1.02 | 1.01 | 0.99 |

| Variation coefficient | 9.17% | 10.38% | 6.79% | 9.72% | 7.87% | 3.16% | 8.43% | 4.89% |

| Correlation coefficient | 0.989 | 0.978 | 0.975 | 0.978 | 0.975 | 0.978 | 0.924 | 0.966 |

| RAC-N | 0C | 30C | 50C | 70C | 0D | 30D | 50D | 70D |

| Number | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Mean ratio | 0.89 | 0.92 | 1.02 | 1.04 | 0.96 | 0.95 | 1.05 | 1.06 |

| Variation coefficient | 3.81% | 4.87% | 9.31% | 8.34% | 5.06% | 5.55% | 5.71% | 6.21% |

| Correlation coefficient | 0.942 | 0.944 | 0.959 | 0.951 | 0.893 | 0.933 | 0.954 | 0.933 |

| RAC-N | 0A | 30A | 0B | 30B | 50C | 70C | 50D | 70D |

|---|---|---|---|---|---|---|---|---|

| Number | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Mean ratio | 1.04 | 1.02 | 0.96 | 0.98 | 0.96 | 1.03 | 0.97 | 1.02 |

| Variation coefficient | 8.35% | 9.41% | 6.89% | 3.69% | 8.79% | 9.19% | 9.33% | 7.21% |

| Correlation coefficient | 0.921 | 0.935 | 0.951 | 0.974 | 0.961 | 0.955 | 0.947 | 0.940 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Wang, F.; Deng, X.; Li, Y.; Zhao, S. Testing and Prediction of the Strength Development of Recycled-Aggregate Concrete with Large Particle Natural Aggregate. Materials 2019, 12, 1891. https://doi.org/10.3390/ma12121891

Li C, Wang F, Deng X, Li Y, Zhao S. Testing and Prediction of the Strength Development of Recycled-Aggregate Concrete with Large Particle Natural Aggregate. Materials. 2019; 12(12):1891. https://doi.org/10.3390/ma12121891

Chicago/Turabian StyleLi, Changyong, Fei Wang, Xiangsheng Deng, Yizhuo Li, and Shunbo Zhao. 2019. "Testing and Prediction of the Strength Development of Recycled-Aggregate Concrete with Large Particle Natural Aggregate" Materials 12, no. 12: 1891. https://doi.org/10.3390/ma12121891

APA StyleLi, C., Wang, F., Deng, X., Li, Y., & Zhao, S. (2019). Testing and Prediction of the Strength Development of Recycled-Aggregate Concrete with Large Particle Natural Aggregate. Materials, 12(12), 1891. https://doi.org/10.3390/ma12121891