Hydrogen Embrittlement Evaluation of Micro Alloyed Steels by Means of J-Integral Curve

Abstract

1. Introduction

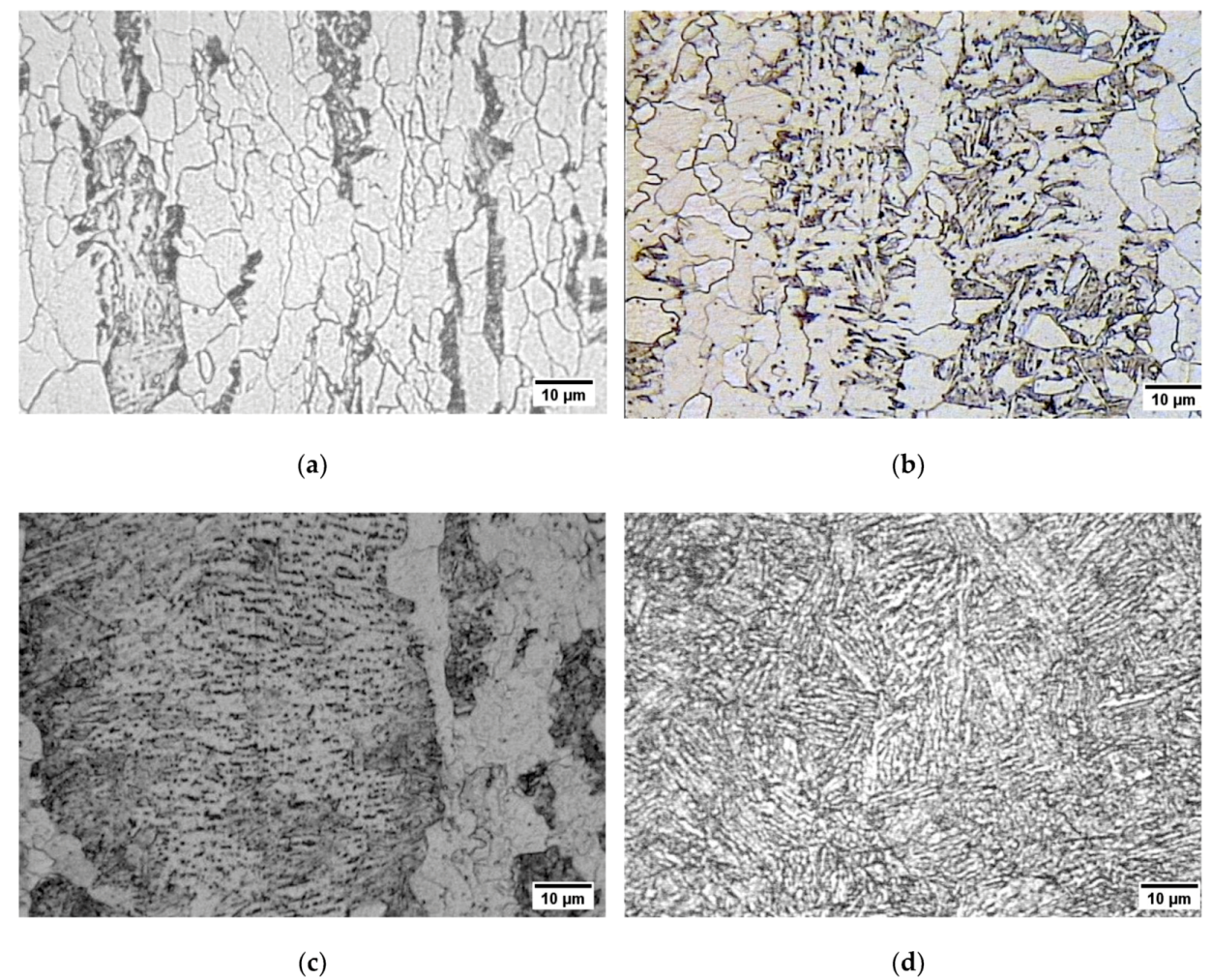

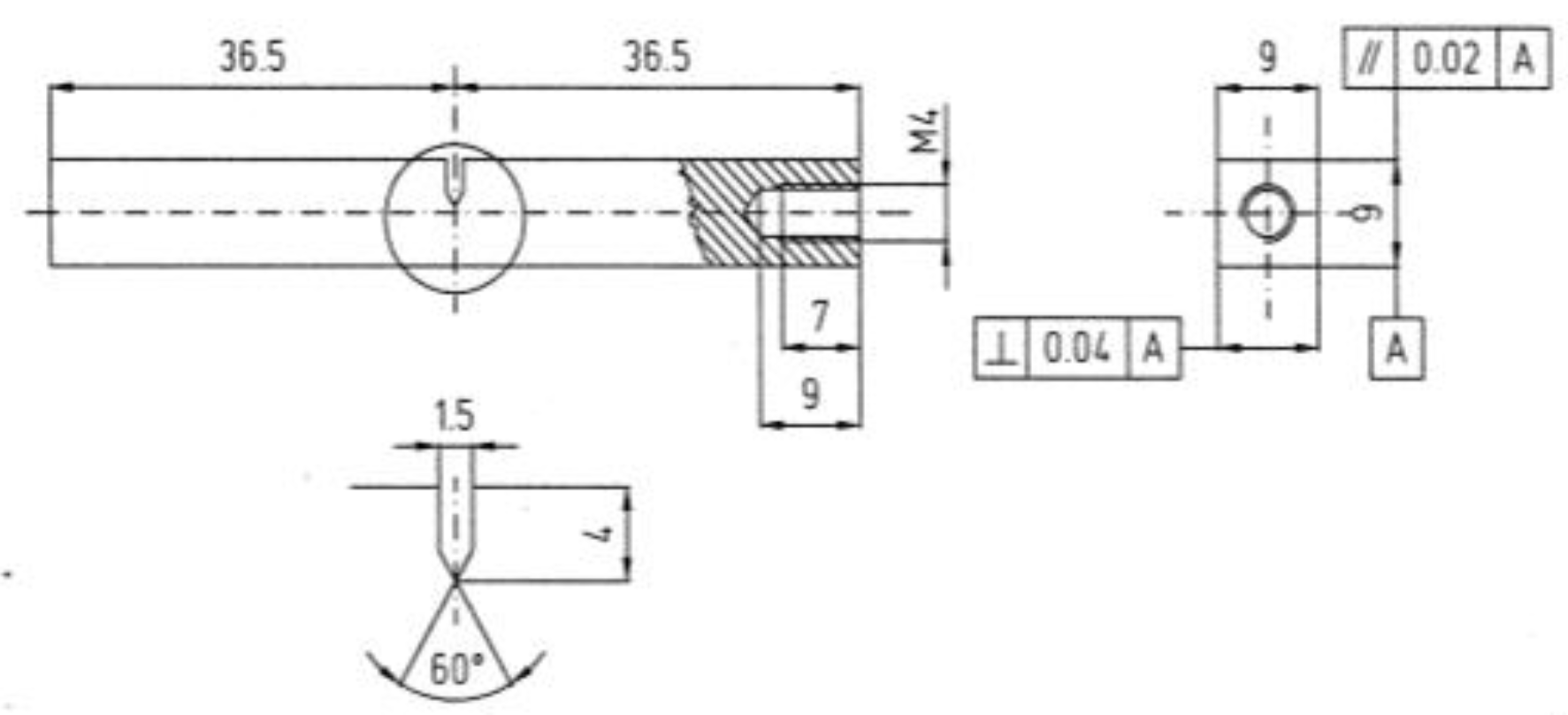

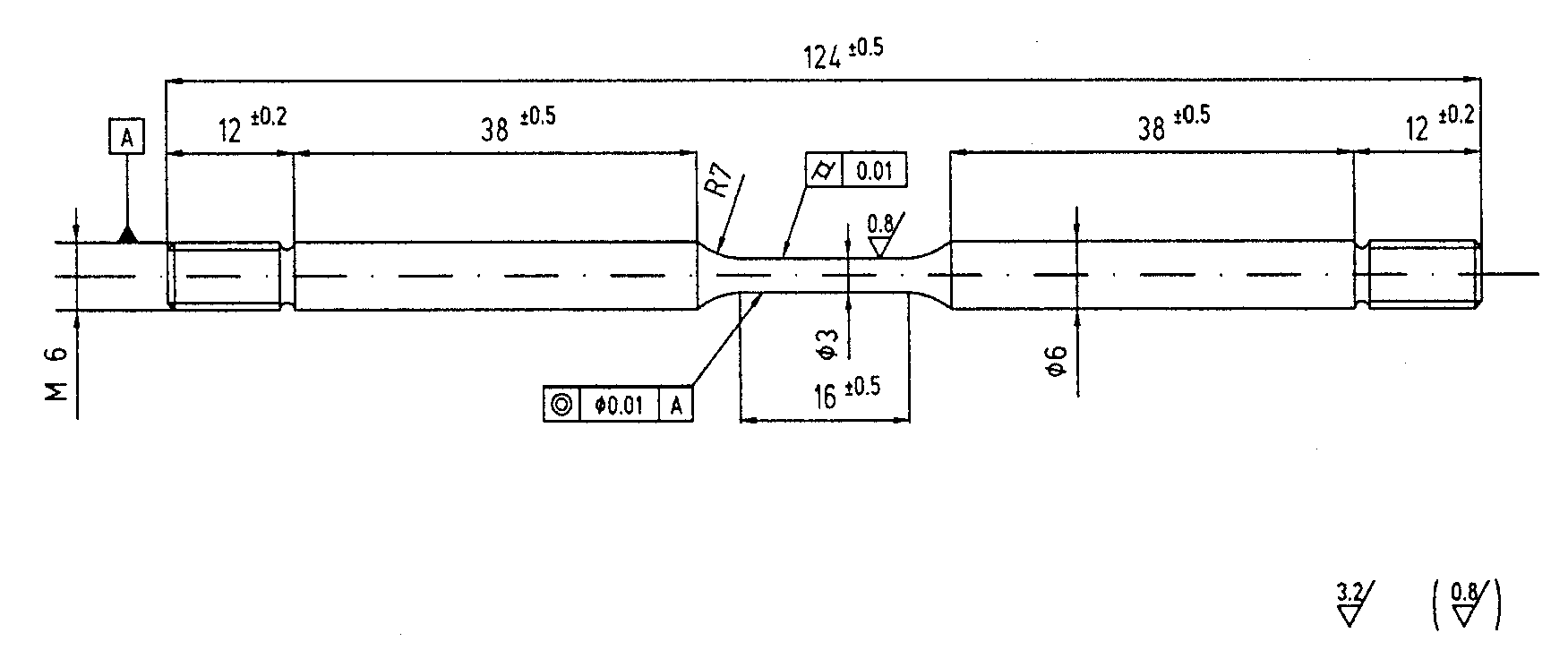

2. Materials and Methods

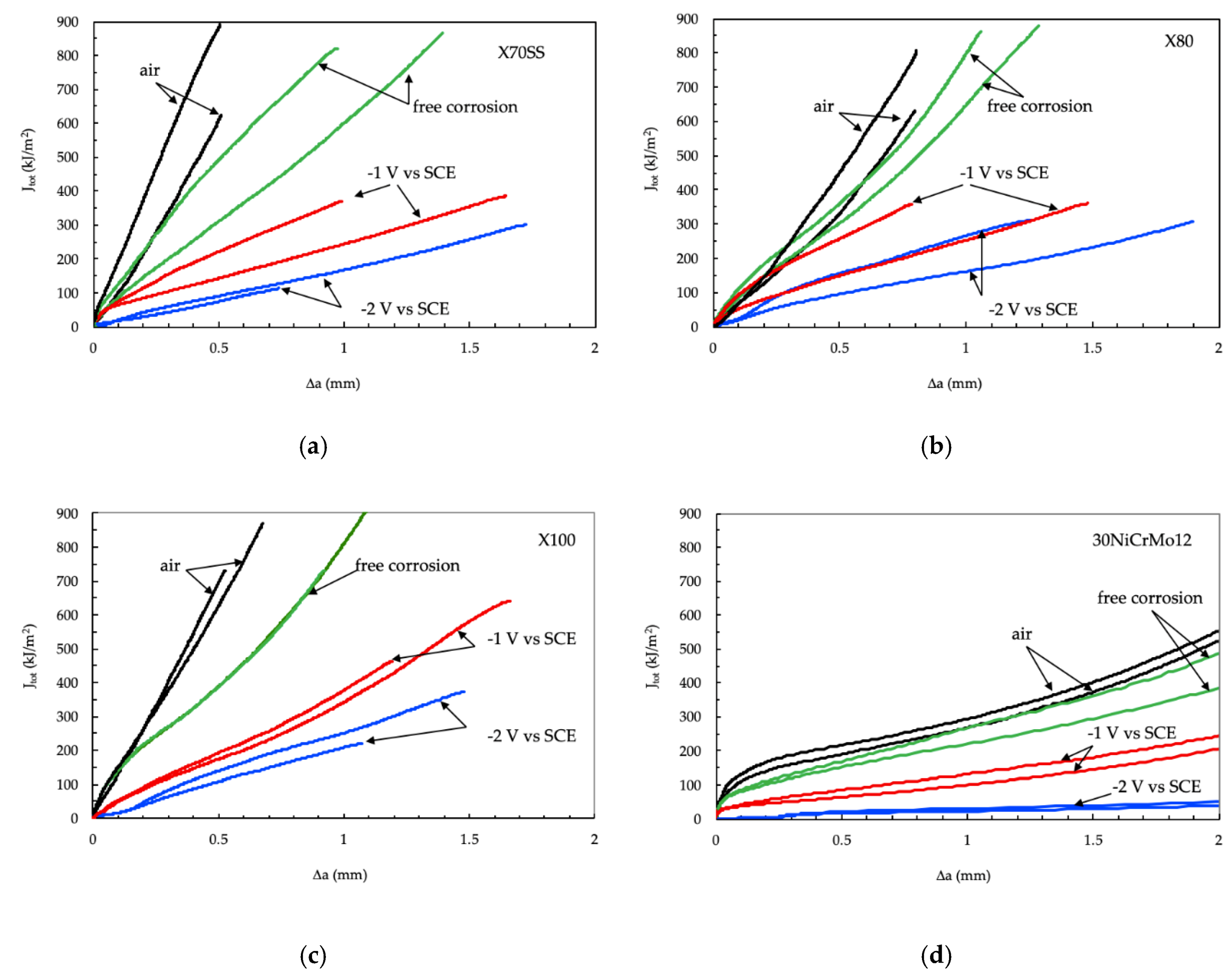

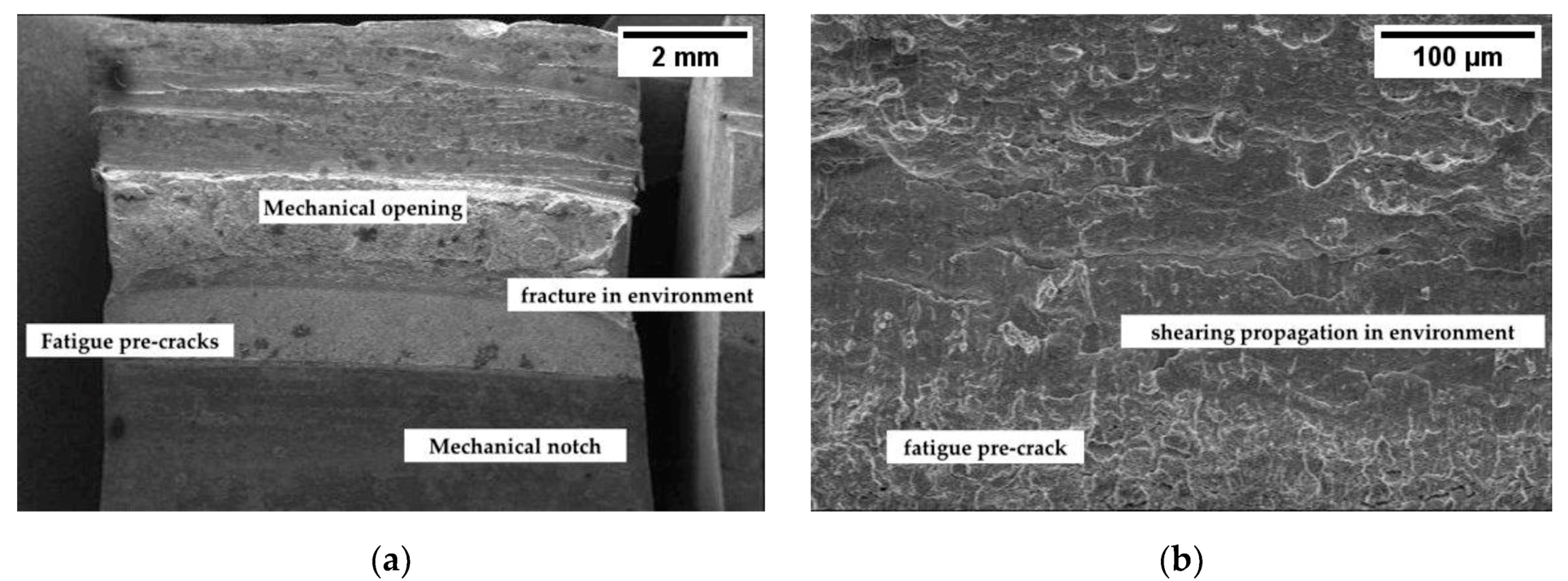

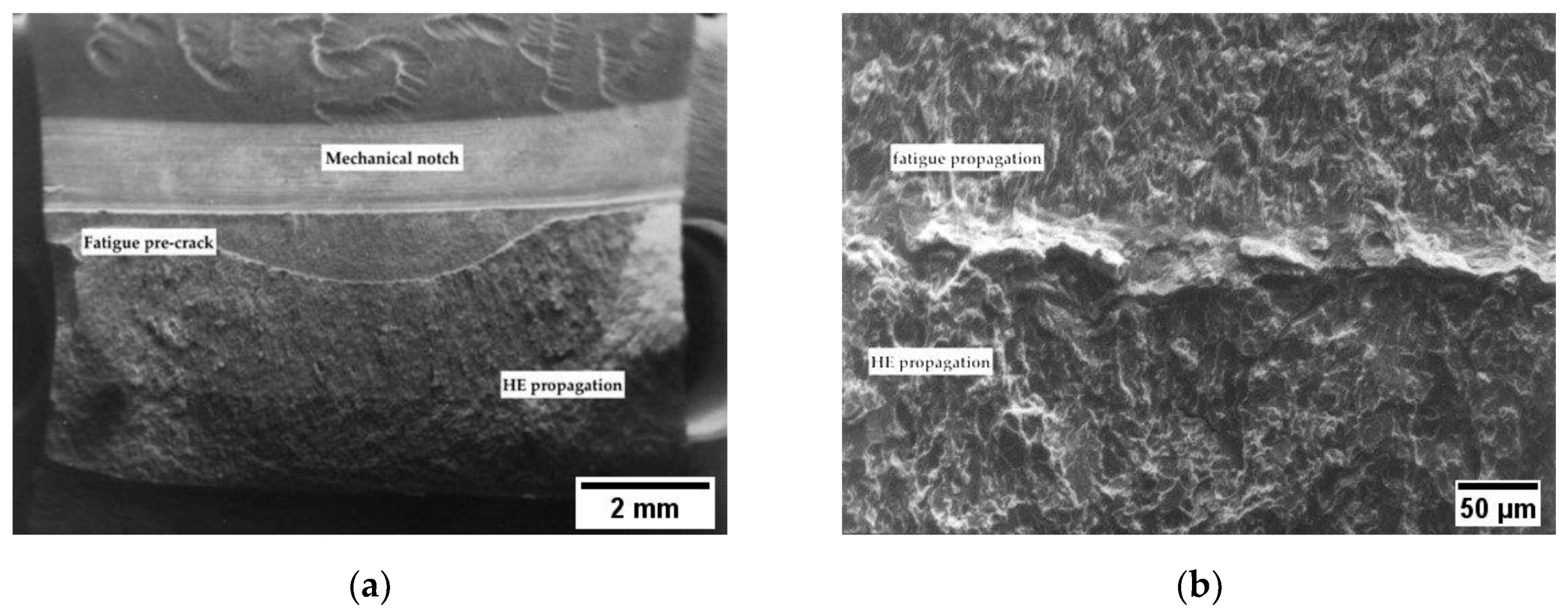

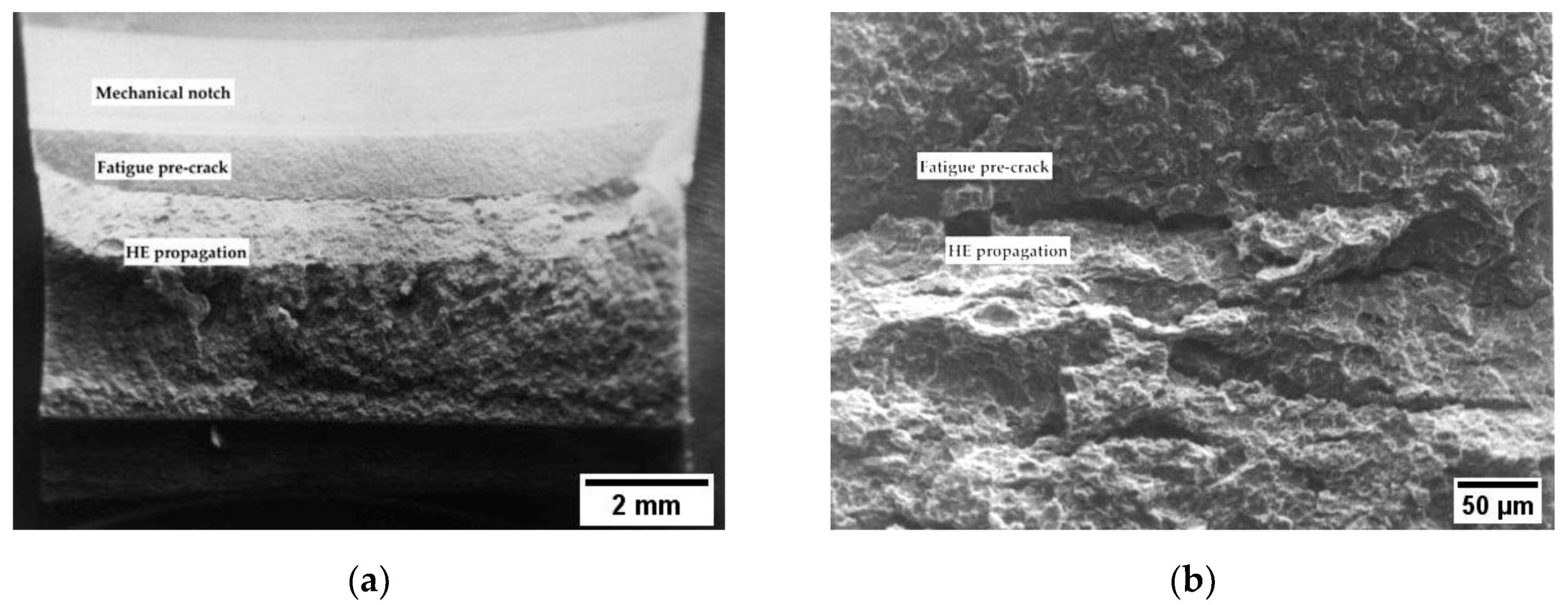

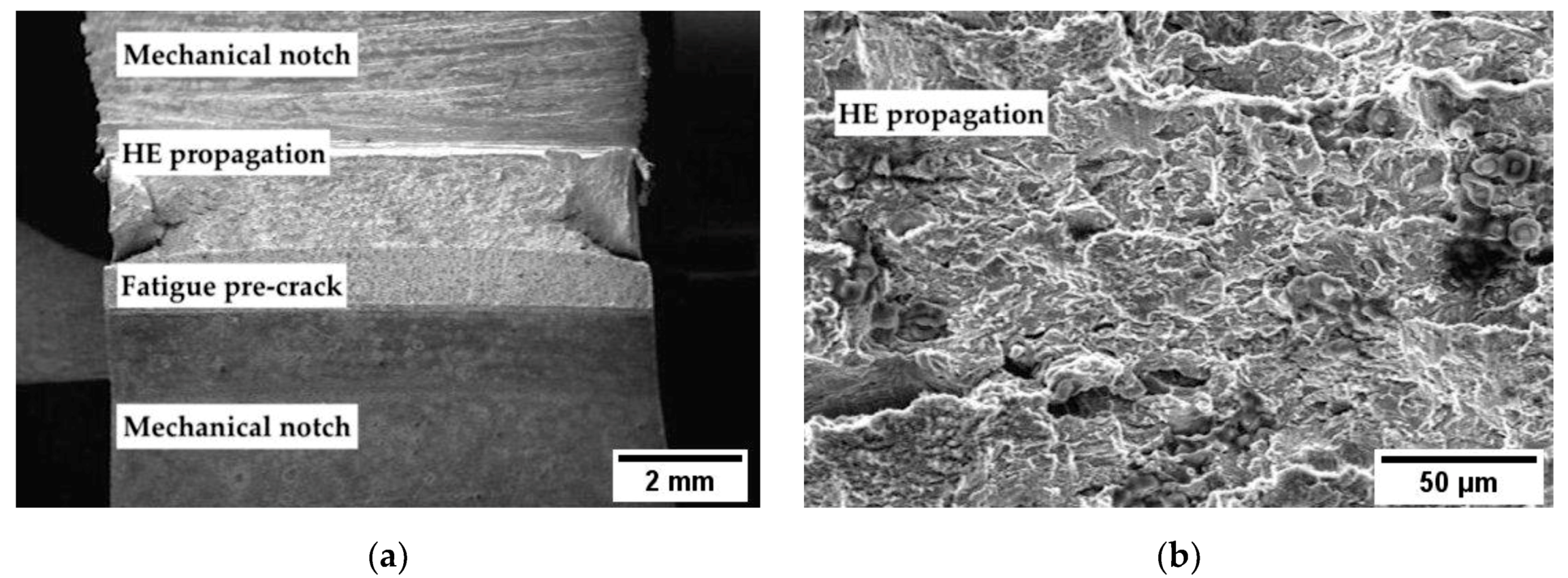

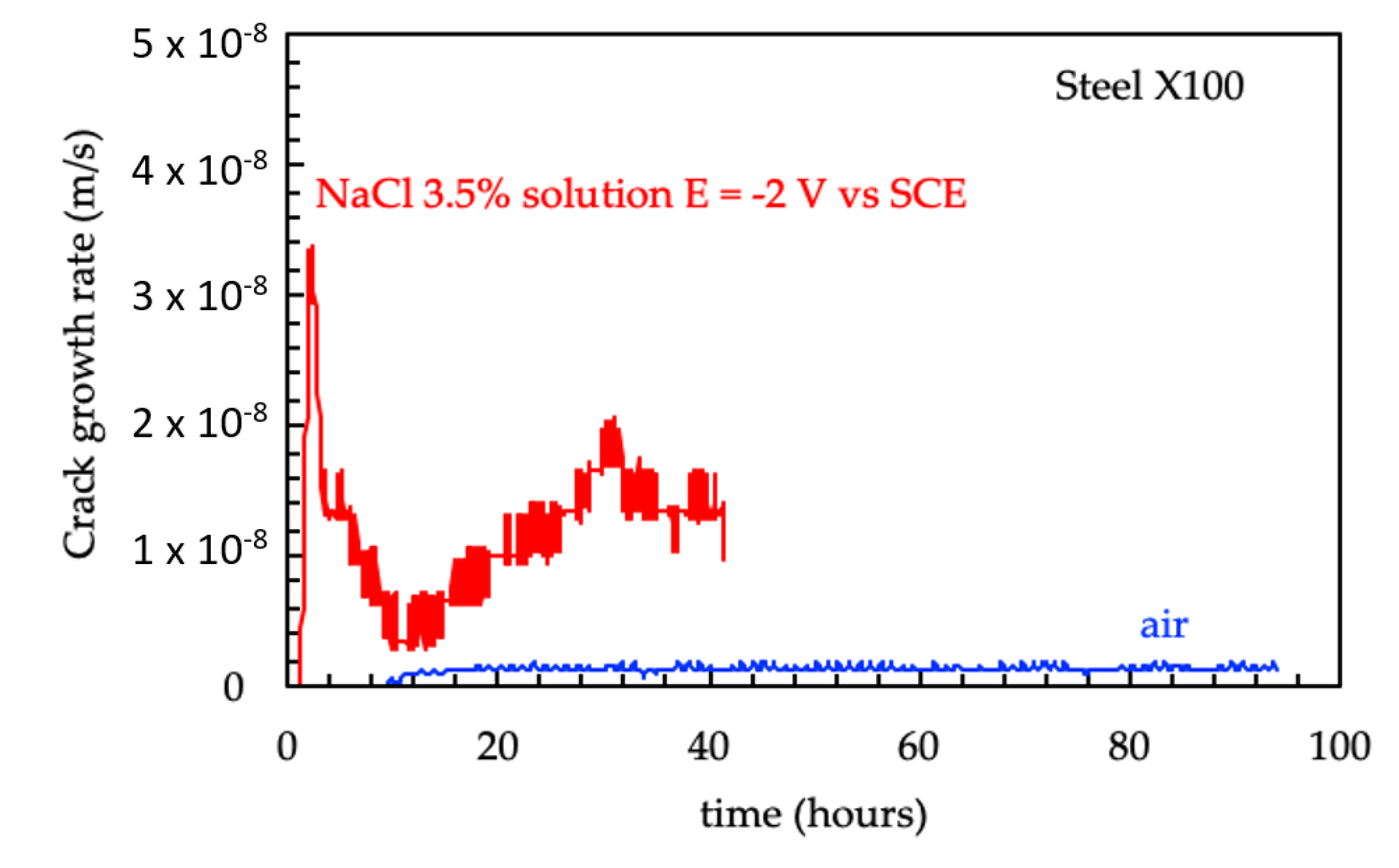

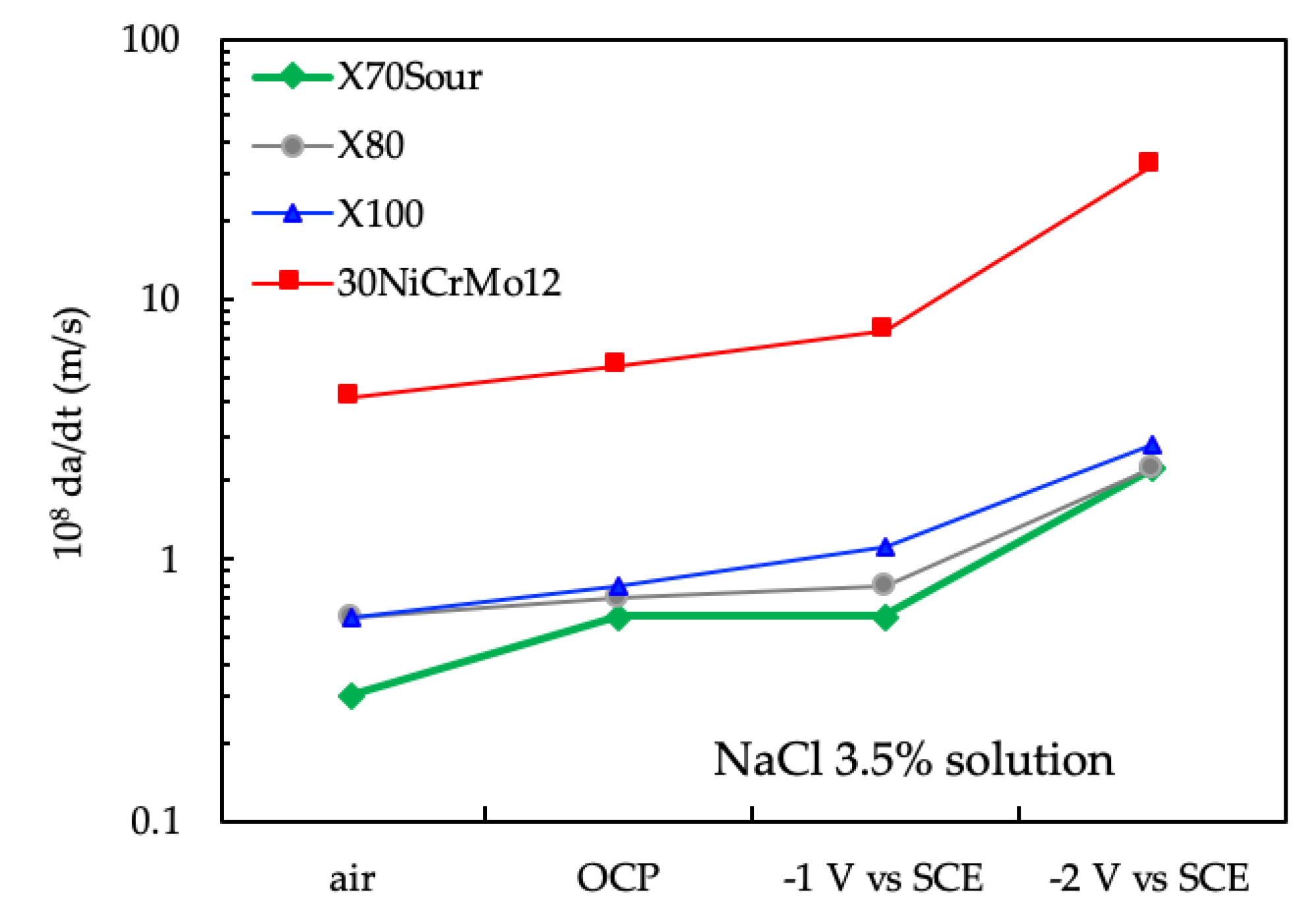

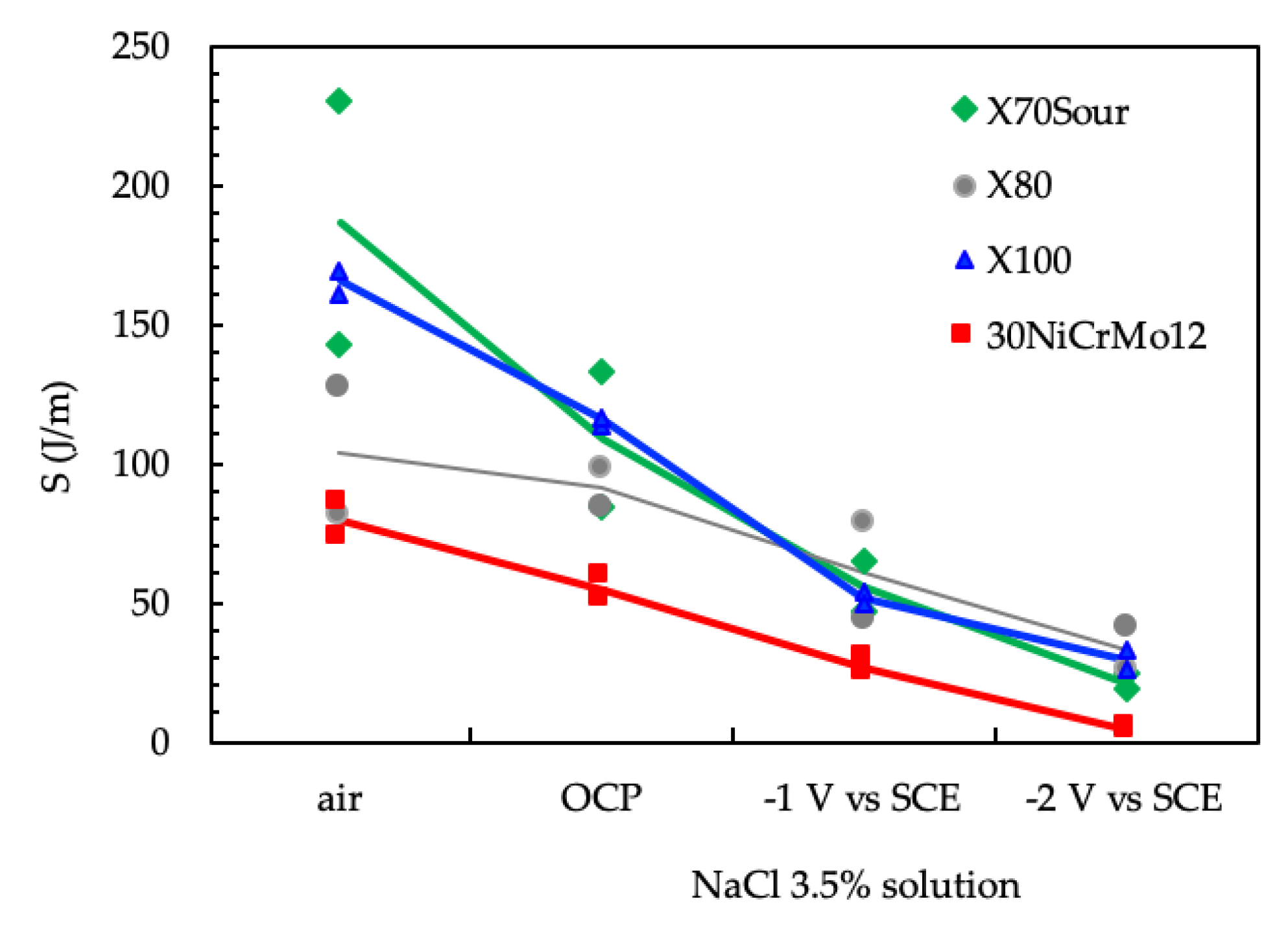

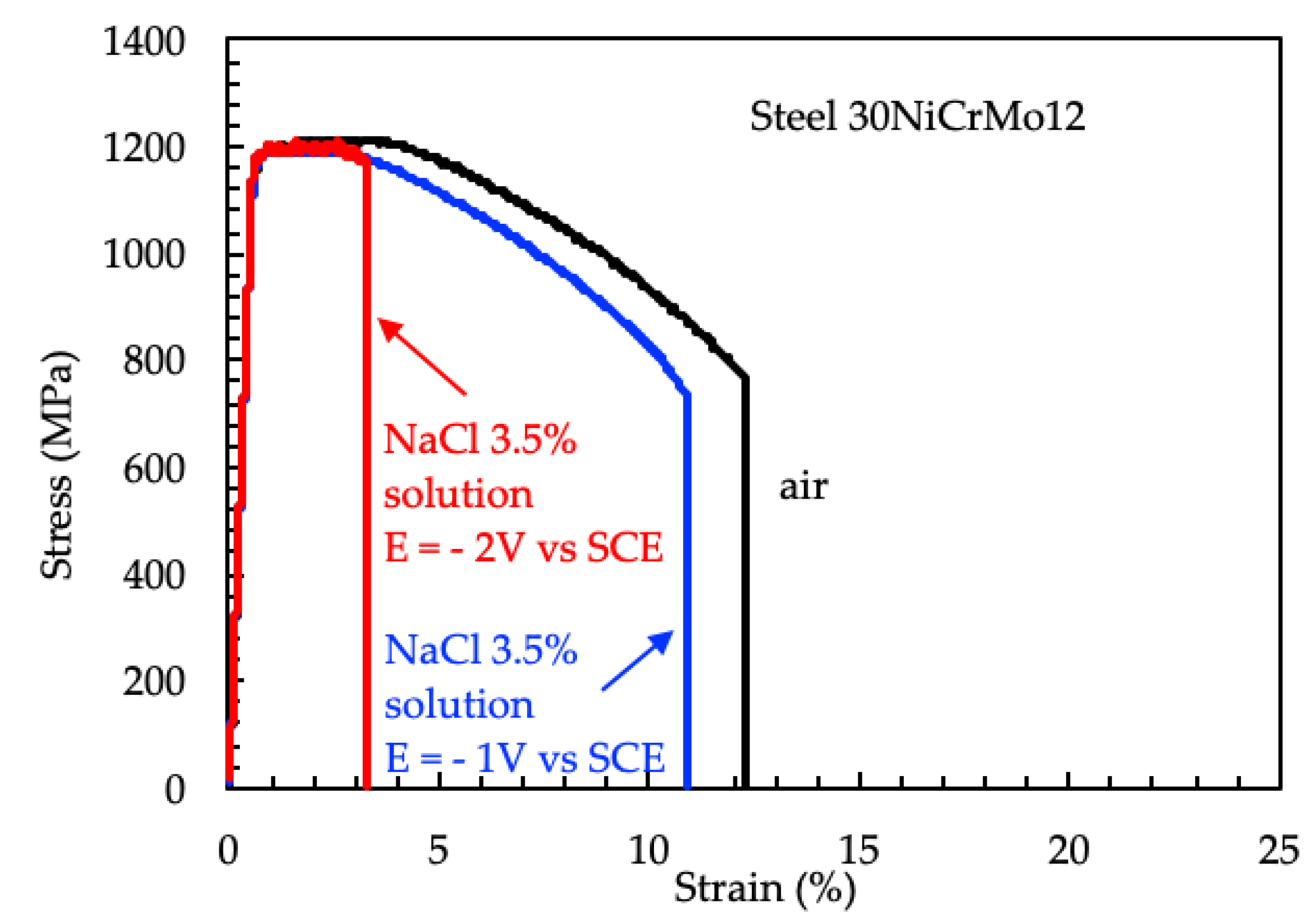

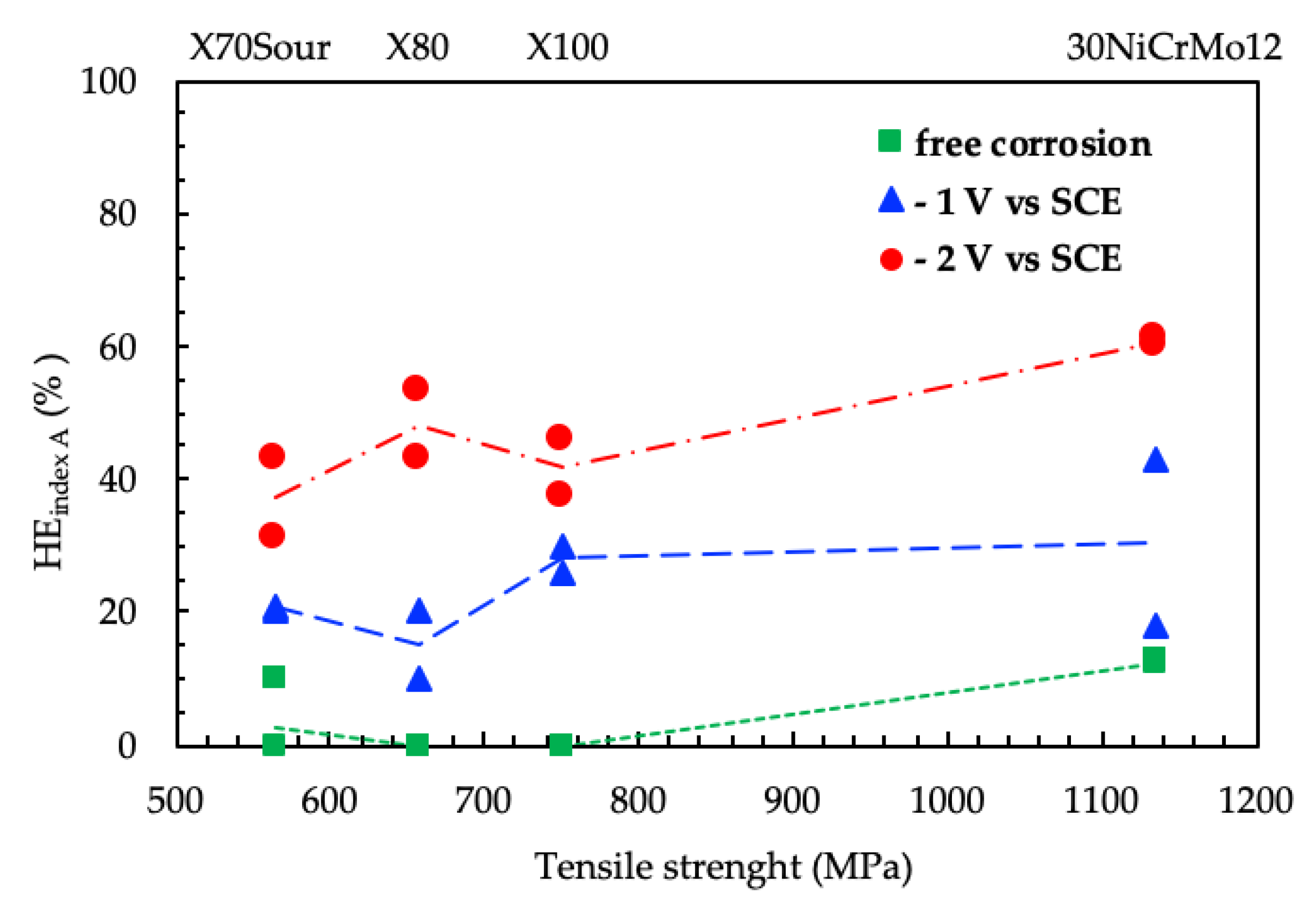

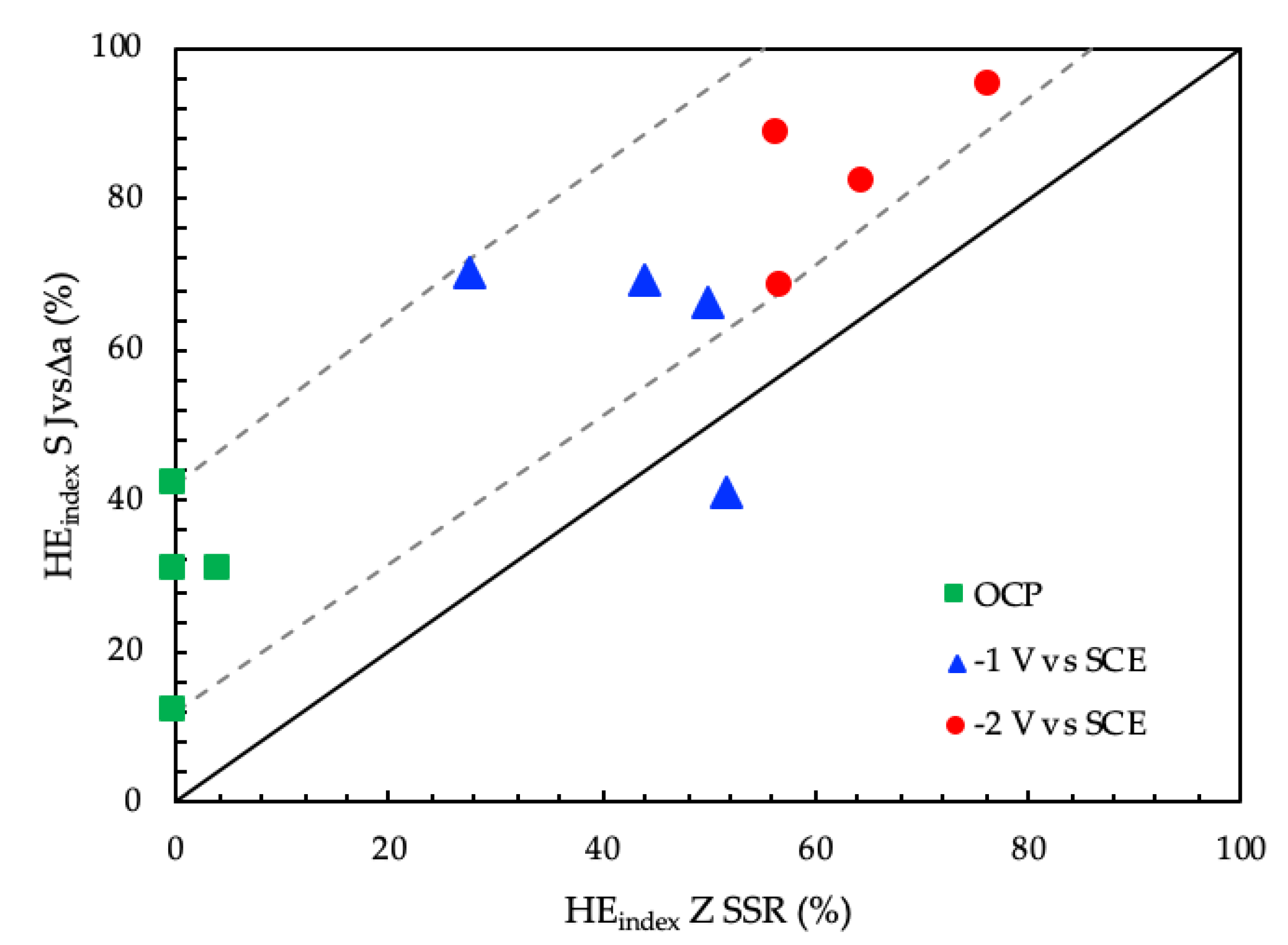

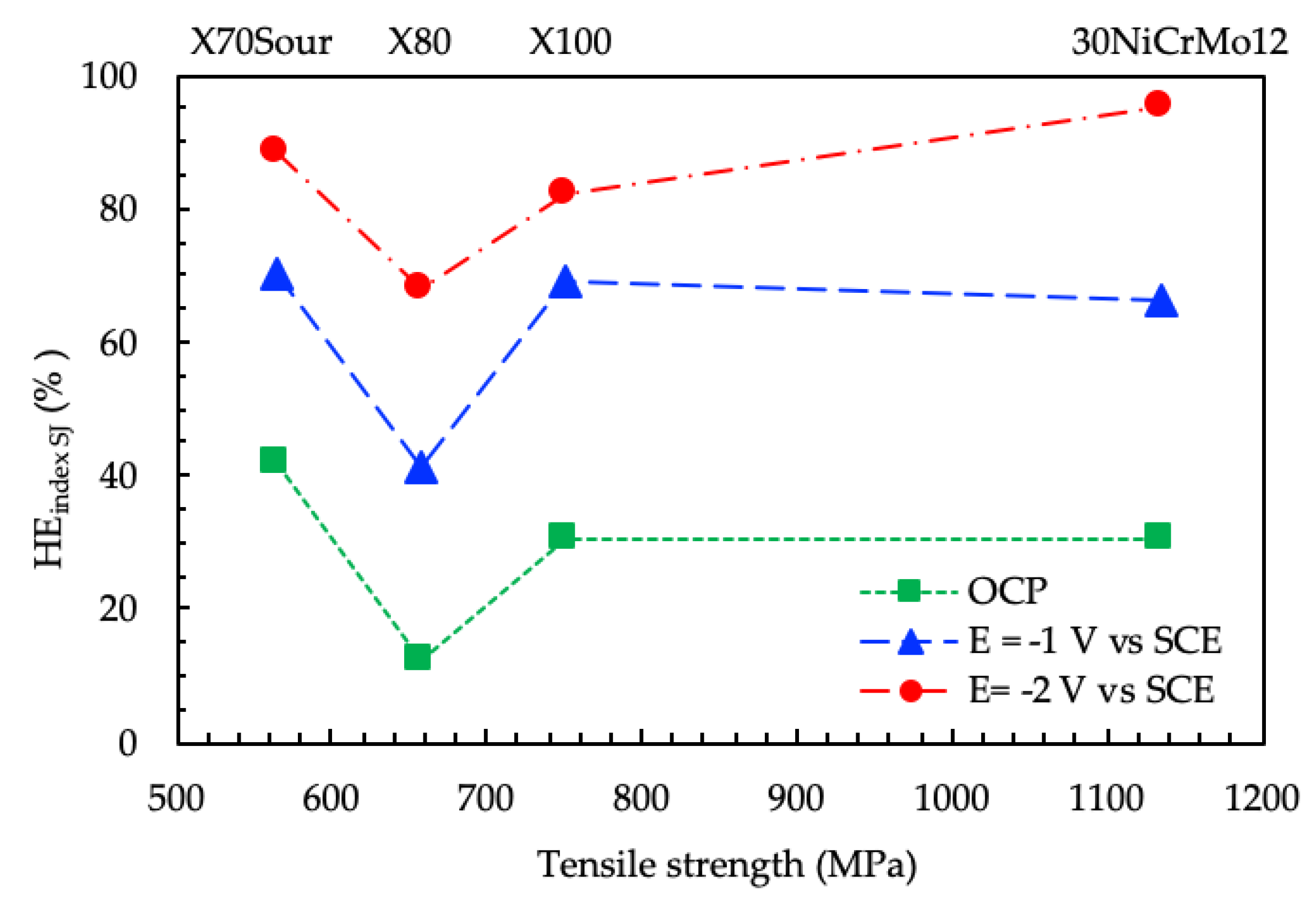

3. Results and Discussion

4. Conclusions

- The J-integral vs. Δa determination is a suitable technique to characterize pipeline steels, which are not susceptible to hydrogen embrittlement under static loading conditions, but can exhibit HE susceptibility under almost-static loading conditions, such as in Slow Strain Rate tests.

- The ratio of the areas under the J-Δa curve in the environment and in air was chosen as a parameter for characterizing the hydrogen embrittlement of the different steels.

- The X80 steel showed the highest hydrogen embrittlement resistance, while X70SS, X100 and 30CrNiMo had similar behaviors.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shipilov, A.; May, I. Structural integrity of aging buried pipelines having cathodic protection. Eng. Failure Anal. 2006, 13, 1159–1176. [Google Scholar] [CrossRef]

- Baker, M.; Fessler, R. Pipeline Corrosion; Final Report; Integrity Management Program Under Delivery OrderDTRS56-02-D-70036; US Department of Transportation Pipeline and Hazardous Materials Safety Administration Office of Pipeline Safety: Washington, DC, USA, November 2008.

- Fessler, R.; Groeneveld, T.; Elsea, A. Stress-corrosion and hydrogen-stress cracking in buried pipelines. In Stress Corrosion Cracking and Hydrogen Embrittlement of Iron Base Alloys; International Corrosion Conference Series; NACE: Huston, TX, USA, 1977. [Google Scholar]

- Carter, C.; Hyatt, M. Review of stress corrosion cracking in low alloy steels with yield strength below 150 ksi. In Stress Corrosion Cracking and Hydrogen Embrittlement of Iron Base Alloys; NACE: Huston, TX, USA, 1977; pp. 524–600. [Google Scholar]

- Hirth, J.P. Effects of hydrogen on the properties of iron and steel. Metall. Trans. A 1980, 11, 861–890. [Google Scholar] [CrossRef]

- Kim, W.; Koh, S.; Yang, B.; Kim, K. Effect of environmental and metallurgical factors on hydrogen induced cracking of HSLA steels. Corrosion Sci. 2008, 50, 3336–3342. [Google Scholar] [CrossRef]

- Razzini, G.; Cabrini, M.; Maffi, S.; Mussati, G.; Peraldo Bicelli, L. Effect of heat-affected zones on hydrogen permeation and embrittlement of low carbon steels. In Materials Science Forum; Bonora, P.L., Deflorian, F., Eds.; Trans Tech Publications: Zurich, Switzerland, 1998; Volume 289–292, pp. 1257–1266. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Pellegrini, S.; Pastore, T. Environmentally assisted cracking and hydrogen diffusion in traditional and high-strength pipeline steels. Corrosion Rev. 2015, 33, 529–545. [Google Scholar] [CrossRef]

- Kennelley, K.; Bone, L.; Orazem, M. Current and Potential Distribution on a Coated Pipeline with Holidays Part I–Model and Experimental Verification. Corrosion 1993, 49, 199–210. [Google Scholar] [CrossRef]

- Punter, A.; Fikkers, A.T.; Vanstaen, G. Hydrogen-induced stress corrosion cracking on a pipeline. Mater. Perform. 1992, 31, 24–28. [Google Scholar]

- Cabrini, M.; Pistone, V.; Sinigaglia, E.; Tarenzi, M. Unique Hsc Scenario Leads To Gas Line Failure. Oil Gas J. 2000, 6, 61–65. [Google Scholar]

- Shanmugam, S.; Ramisetti, N.; Misra, R.; Hartmann, J.; Jansto, S. Microstructure and high strength–toughness combination of a new 700 MPa Nb-microalloyed pipeline steel. Mater. Sci. Eng. A 2008, 478, 26–37. [Google Scholar] [CrossRef]

- Hardie, D.; Charles, E.; Lopez, A. Hydrogen embrittlement of high strength pipeline steels. Corros. Sci. 2006, 48, 4378–4385. [Google Scholar] [CrossRef]

- Demofonti, G.; Cabrini, M.; Marchesani, F.; Spinelli, C. Eni tap project mechanical damage and environmental assisted cracking-full scale methodology Overview. In New Developments on Metallurgy and Applications of High Strength Steels, Proc. Int. Conf. New Developments on Metallurgy and Applications of High Strength Steels; Plenary Lectures Automotive Applications High Temperature Applications Oils and Gas Applications; John Wiley & Sons: Buenos Aires, Argentina, 2008; Volume 1, pp. 611–624. ISBN 97808733972921. [Google Scholar]

- Payer, J.; Berry, W.; Boyd, W. Constant strain rate technique for assessing stress-corrosion susceptibility. In Stress Corrosion–New Approaches; ASTM STP 610; ASTM: Philadelphia, PA, USA, 1976; pp. 82–93. [Google Scholar] [CrossRef]

- Kasahara, K.; Isowaki, T.; Adachi, H. Study on Hydrogen-Stress Cracking Susceptibilities of Line Pipe Steels; Metallic corrosion Frankfurt/Main; Dechema: Frankfurt, Germany, 1981; Volume 1, pp. 394–399. [Google Scholar]

- Hinton, B.R.W.; Procter, R.P.M. The effect of strain-rate and cathodic potential on the tensile ductility of X-65 pipeline steel. Corros. Sci. 1983, 23, 101–123. [Google Scholar] [CrossRef]

- Rebak, R.B.; Xia, Z.; Safruddin, R.; Szklarska-Smialowska, Z. Effect of Solution Composition and Electrochemical Potential on Stress Corrosion Cracking of X-52 Pipeline Steel. Corrosion 1996, 52, 396–405. [Google Scholar] [CrossRef]

- Gu, B.; Luo, J.; Mao, X. Hydrogen-facilitated anodic dissolution-type stress corrosion cracking of pipeline steels in near-neutral pH solution. Corrosion 1999, 55, 96–106. [Google Scholar] [CrossRef]

- Trasatti, S. Susceptibility on hydrogen embrittlement of an X80 steel for pipelines. In Hydrogen Effects on Materials Behavior and Corrosion Deformation Interactions; Moody, N.R., Thompson, A.W., Ricker, R.E., Was, G.S., Jones, R.H., Eds.; TMS: Warrendale, PA, USA, 2003; Volume 1, pp. 959–968. ISBN 0-87339-501. [Google Scholar]

- Zielinski, A.; Domzalicki, P. Hydrogen degradation of high-strength low-alloyed steels. J. Mater. Process. Technol. 2003, 133, 230–235. [Google Scholar] [CrossRef]

- Bosch, C.; Bayle, B.; Magnin, T.; Longaygue, X. Proposal for a critical test to classify the SCC resistance of materials. In Hydrogen Effects on Materials Behavior and Corrosion Deformation Interactions; Moody, N.R., Thompson, A.W., Ricker, R.E., Was, G.S., Jones, R.H., Eds.; TMS: Warrendale, PA, USA, 2003; pp. 587–596. ISBN 0-87339-501. [Google Scholar]

- Dong, C.; Liu, Z.; Li, X.; Cheng, Y. Effects of hydrogen-charging on the susceptibility of X100 pipeline steel to hydrogen-induced cracking. Int. J. Hydrog. Energy 2009, 34, 9879–9884. [Google Scholar] [CrossRef]

- Fassina, P.; Bolzoni, F.; Fumagalli, G.; Lazzari, L.; Vergani, L.; Sciuccati, A. Effect of hydrogen and low temperature on fatigue crack growth of pipeline steels. Eng. Fract. Mech. 2013, 103, 10–25. [Google Scholar] [CrossRef]

- Fassina, P.; Bolzoni, F.M.; Fumagalli, G.; Lazzari, L.; Vergani, L.; Sciuccati, A. Influence of hydrogen and low temperature on mechanical behaviour of two pipeline steels. Eng. Fract. Mech. 2012, 81, 43–55. [Google Scholar] [CrossRef]

- Capelle, J.; Dmytrakh, I.; Pluvinage, G. Comparative assessment of electrochemical hydrogen absorption by pipeline steels with different strength. Corros. Sci. 2010, 52, 554–1559. [Google Scholar] [CrossRef]

- Bolzoni, F.M.; Cabrini, M.; Spinelli, C. Hydrogen diffusion and hydrogen embrittlement behaviour of two high strength pipeline steels. In Proceedings of the Eurocorr 2001 (AIM), Lake Garda, Italy, 30 September–4 October 2001. [Google Scholar]

- Cabrini, M.; Lorenzi, S.; Marcassoli, P.; Pastore, T. Hydrogen embrittlement behavior of HSLA line pipe steel under cathodic protection. Corros. Rev. 2011, 29, 261–270. [Google Scholar] [CrossRef]

- Troiano, A.R. The role of hydrogen and other interstitials in the mechanical behaviour of metals. Trans. ASM 1960, 52, 54–80. [Google Scholar]

- Oriani, R. Mechanicistic Theory of Hydrogen Embrittlement of Steels. In Berichte Der Bunsen-Gesellschaft Fur Physikalische Chemie; Wiley: Weinheim, Germany, 1972; Volume 76, pp. 848–857. [Google Scholar] [CrossRef]

- Ayas, C.; Deshpande, V.; Fleck, N. A fracture criterion for the notch strength of high strength steels in the presence of hydrogen. J. Mech. Phys. Solids 2014, 63, 80–93. [Google Scholar] [CrossRef]

- Nagumo, M. Hydrogen related failure of steels—A new aspect. Mater. Sci. Technol. 2004, 20, 940–950. [Google Scholar] [CrossRef]

- Srinivasan, R.; Neeraj, T. Hydrogen embrittlement of ferritic steels: Deformation and failure mechanisms and challenges in the oil and gas industry. JOM 2014, 66, 1377–1382. [Google Scholar] [CrossRef]

- Lynch, S. Mechanisms of hydrogen assisted cracking-a review. In Hydrogen Effects on Materials Behavior and Corrosion Deformation Interactions; Moody, N.R., Thompson, A.W., Ricker, R.E., Was, G.S., Jones, R.H., Eds.; TMS: Warrendale, PA, USA, 2003; pp. 449–466. ISBN 0-87339-501. [Google Scholar]

- Cabrini, M.; Migliardi, L.; Pastore, T.; Spinelli, C. Effect of cathodic potential and strain rate on hydrogen embrittlement of HSLA steels. In Hydrogen Effects on Materials Behavior and Corrosion Deformation Interactions; Moody, N.R., Thompson, A.W., Ricker, R.E., Was, G.S., Jones, R.H., Eds.; TMS: Warrendale, PA, USA, 2003; Volume 1, pp. 979–988. ISBN 0-87339-501. [Google Scholar]

- Cabrini, M.; D’Urso, G.; Pastore, T. Evaluation of the resistance to hydrogen embrittlement by slow Bending test. In Environment-Induced Cracking of Materials-Prediction, Industrial Developments and Evaluation; Shipilov, S., Jones, R., Olive, J.-M., Rebak, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; Volume 2, pp. 493–502. ISBN 9780080559445. [Google Scholar]

- Cabrini, M.; Lorenzi, S.; Marcassoli, P.; Pastore, T. Hydrogen embrittlement resistance of plastically strained pipeline steels. Metall. Ital. 2007, 99, 25–32. [Google Scholar]

- Wang, R. Effects of hydrogen on the fracture toughness of a X70 pipeline steel. Corros. Sci. 2009, 51, 2803–2810. [Google Scholar] [CrossRef]

- Li, Y.; Gong, B.; Li, X.; Deng, C.; Wang, D. Specimen thickness effect on the property of hydrogen embrittlement in single edge notch tension testing of high strength pipeline steel. Int. J. Hydrog. Energy 2018, 43, 15575–15585. [Google Scholar] [CrossRef]

- Tsay, L.; Chi, M.; Wu, Y.; Wu, J.; Lin, D. Hydrogen embrittlement susceptibility and permeability of two ultra-high strength steels. Corros. Sci. 2006, 48, 1926–1938. [Google Scholar] [CrossRef]

- Toribio, J.; Lancha, A.; Elices, M. Macroscopic variables governing the microscopic fracture of pearlitic steels. Mater. Sci. Eng. A 1991, 145, 167–177. [Google Scholar] [CrossRef]

- Toribio, J. Role of hydrostatic stress in hydrogen diffusion in pearlitic steel. J. Mater. Sci. 1993, 28, 2289–2298. [Google Scholar] [CrossRef]

- Yokobori, A.J.; Nemoto, T.; Satoh, K.; Yamada, T. Numerical analysis on hydrogen diffusion and concentration in solid with emission around the crack tip. Eng. Fract. Mech. 1996, 55, 47–60. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Marcassoli, P.; Pastore, T. Effect of hydrogen diffusion on environmental assisted cracking of pipeline steels under cathodic protection. Metall. Ital. 2008, 100, 15–22. [Google Scholar]

- Beck, W.; Bokris, J.O.M.; McBreen, J.; Nanis, L. Hydrogen permeation in metals as a function of stress, temperature and dissolved hydrogen concentration. Proc. R. Soc. 1966, 290, 220–235. [Google Scholar]

- Cabrini, M.; Cogliati, O.; Maffi, S. Effect of microctructure on hydrogen diffusion in carbon steels. Metall. Ital. 2003, 95, 13–20. [Google Scholar]

- Blundy, R.; Royce, R.; Poole, P.; Shreir, L. Effect of pressure and stress on permeation of hydrogen through steel. In Stress Corrosion Cracking and Hydrogen Embrittlement of Iron Base Alloys; NACE: Houston, TX, USA, 1977; Volume 5, pp. 636–647. [Google Scholar]

- Bockris, J.O.; McBreen, J.; Nanis, L. The Hydrogen Evolution Kinetics and Hydrogen Entry into a-Iron. J. Electrochem. Soc. 1965, 112, 1025–1031. [Google Scholar] [CrossRef]

- Taha, A.; Sofronis, P. A micromechanics approach to the study of hydrogen transport and embrittlement. Eng. Fract. Mech. 2001, 68, 803–837. [Google Scholar] [CrossRef]

- Sofronis, P.; Taha, A. Micromechanical Modeling of Hydrogen Transport—A review. In Environmentally Assisted Cracking: Predictive Methods for Risk Assestment and Evaluation of Materials, Equipment and Structures; American Society for Testing and Materials: Philadelphia, PA, USA, 2000; Volume 1401, pp. 7–103. [Google Scholar]

- Krom, A.; Bakker, A. Hydrogen Trapping Models in Steel. Metall. Mater. Trans. B 2000, 31, 1475–1482. [Google Scholar] [CrossRef]

- Olden, V.; Senumstad Hauge, A.; Magne Akselsen, O. The Influence of Plastic Strain on the Effective Hydrogen Diffusion Coefficient and Trapping in Base Metal and Weld Simulated Heat Affected Zone of an X70 Pipeline Steel. In Proceedings of the Twenty-second (2012) International Offshore and Polar Engineering Conference, Rhodes, Greece, 17–22 June 2012. [Google Scholar]

- Sofronis, P.; Liang, Y.; Aravas, N. Hydrogen induced shear localization of the plastic flow in metals and alloys. Eur. J. Mech. A Solids 2001, 20, 857–872. [Google Scholar] [CrossRef]

- Hashimoto, M.; Latanision, R.M. Experimental study of hydrogen transport during plastic deformation in iron. Metall. Trans. A 1988, 19, 2789. [Google Scholar] [CrossRef]

- Frankel, G.S.; Latanision, R.M. Hydrogen Transport during Deformation in Nickel: Part I. Polycrystalline Nickel. Metall. Trans. A 1986, 17, 861–867. [Google Scholar] [CrossRef]

- Zhu, X.-K.; Joyce, J. Review of fracture toughness (G, K, J, CTOD, CTOA) testing and standardization. Eng. Fract. Mech. 2012, 85, 1–46. [Google Scholar] [CrossRef]

- Park, S.-J.; Seo, M.-K. Interface Science Technology; Chapter 4-Solid-Solid Interfaces; Elsevier: Amsterdam, The Netherlands, 2011; Volume 18, pp. 253–331. [Google Scholar]

- Krompholz, K.; Ullrich, G. Determination Of J-integral R Curves For The Pressure Vessel Material A533 Bl Using The Potential-Drop Technique And The Multispecimen Method. Eng. Fract. Mech. 1986, 23, 803–820. [Google Scholar] [CrossRef]

- Abramson, G.; Evans, J.; Parkins, R.N. Investigation of Stress Corrosion Crack Growth in Mg Alloys Using J-integral Estimations. Metall. Trans. A 1985, 16, 101–108. [Google Scholar] [CrossRef]

- Bakker, A. A DC Potential Drop Procedure for Crack Initiation and R-Curve Measurements During Ductile Fracture Tests. In Elastic-Plastic Fracture Test Methods: The User’s Experience; ASTM STP 856; American Society for Testing and Materials: Philadelphia, PA, USA, 1985; pp. 394–410. [Google Scholar]

- Johnson, H.H. Calibrating the Electrical Potential Method for Studying Slow Crack Growth. Mater. Res. Stand. 1965, 5, 442–445. [Google Scholar]

- Chen, X.F.; Nanstad, R.K.; Sokolov, M.A. Application of Direct Current Potential Drop for the J-integral vs. Crack Growth Resistance Curve Characterization. In Evaluation of Existing and New Sensor Technologies for Fatigue, Fracture and Mechanical Testing; STP1584; ASTM International: Philadelphia, PA, USA, 2015; pp. 97–113. [Google Scholar]

- Turner, C.E. The Eta Factor. Post Yield Fracture Mechanics; Elsevier Applied Science Publishers: London, UK; New York, NY, USA, 1984; p. 451. [Google Scholar] [CrossRef]

- Chattopadhyay, J.; Dutta, B.K.; Kushwaha, H.S. New ‘ηpl’ and ‘γ’ functions to evaluate J–R curve from cracked pipes and elbows. Part I: Theoretical derivation. Eng. Fract. Mech. 2004, 71, 2635–2660. [Google Scholar] [CrossRef]

- Johnson, L.W.; Riess, R.D. Numerical Analysis; Addison-Wesley: Reading, MA, USA; New York, NY, USA, 1982. [Google Scholar] [CrossRef]

- Gutman, E. Mechanochemistry of Materials; Cambridge International Science Publishing: Cambridge, UK, 1998; ISBN 1898326320. [Google Scholar]

- Xu, L.Y.; Cheng, Y.F. An experimental investigation of corrosion of X100 pipeline steel under uniaxial elastic stress in a near-neutral pH solution. Corrosion Sci. 2012, 59, 103–109. [Google Scholar] [CrossRef]

- Xu, L.Y.; Cheng, Y.Y. Corrosion of X100 pipeline steel under plastic strain in a neutral pH bicarbonate solution. Corros. Sci. 2012, 64, 145–152. [Google Scholar] [CrossRef]

- Cui, Z.; Liu, Z.; Wang, L.; Li, X.; Du, C.; Wang, X. Effect of plastic deformation on the electrochemical and stress corrosion cracking behavior of X70 steel in near-neutral pH environment. Mater. Sci. Eng. A 2016, 677, 259–273. [Google Scholar] [CrossRef]

- Murtaza, G.; Akid, R. Empirical corrosion fatigue life prediction models of a high strength steel. Eng. Fract. Mech. 2000, 67, 461–474. [Google Scholar] [CrossRef]

- Koh, S.U.; Kim, J.; Yang, B.; Kim, K. Effect of Line Pipe Steel Microstructure on Susceptibility to Sulfide Stress Cracking. Corrosion 2004, 60, 244–253. [Google Scholar] [CrossRef]

- Huang, F.; Li, X.; Liu, J.; Qu, Y.; Jia, J.; Du, C. Hydrogen-induced cracking susceptibility and hydrogen trapping efficiency of different microstructure X80 pipeline steel. J. Mater. Sci. 2011, 46, 715–722. [Google Scholar] [CrossRef]

- Park, G.T.; Koh, S.; Jung, H.; Kim, K. Effect of microstructure on the hydrogen trapping efficiency and hydrogen induced cracking of linepipe steel. Corros. Sci. 2008, 50, 1865–1871. [Google Scholar] [CrossRef]

- Zhao, M.C.; Liu, M.; Atrens, A.; Shan, Y.-Y.; Yan, K. Effect of applied stress and microstructure on sulfide stress cracking resistance of pipeline steels subject to hydrogen sulfide. Mater. Sci. Eng. 2008, 478, 43–47. [Google Scholar] [CrossRef]

- Liao, C.M.; Lee, J.L. Effect of molybdenum on sulfide stress cracking resistance of low-alloy steels. Corrosion 1994, 50, 695–704. [Google Scholar] [CrossRef]

| Steel | C (%) | Mn (%) | Si (%) | P (%) | S (%) | Cr (%) | Ni (%) | Mo (%) | Nb (%) | Cu (%) | Ti (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X70SS | 0.1 | 1.04 | 0.31 | 0.028 | 0.008 | 0.01 | 0.17 | 0.01 | 0.05 | 0.25 | 0.027 | 0.03 |

| X80 | 0.07 | 1.84 | 0.35 | 0.03 | 0.008 | 0.02 | 0.27 | 0.01 | 0.037 | 0.01 | 0.018 | 0.03 |

| X100 | 0.07 | 1.96 | 0.34 | 0.035 | 0.007 | 0.03 | 0.31 | 0.18 | 0.06 | 0.2 | 0.02 | 0.04 |

| 30 NiCrMo12 | 0.3 | 0.56 | 0.24 | 0.035 | 0.03 | 0.73 | 2.69 | 0.37 | 0.005 | 0.02 | 0 | 0.03 |

| Steel | TYS0.2 1 (MPa) | UTS 2 (MPa) | YS/UTS | Total Elongation(%) | Charpy Energy at Temperature (J/cm2) | |||

|---|---|---|---|---|---|---|---|---|

| 20 °C | 0 °C | −5 °C | −20 °C | |||||

| X70SS | 457 | 566 | 0.81 | 23.5 | - | - | 270 | - |

| X80 | 587 | 659 | 0.89 | 20 | 260 | 250 | - | 220 |

| X100 | 663 | 750 | 0.88 | 19 | - | - | 344 | 320 |

| 30 NiCrMo12 | 1097 | 1135 | 0.97 | 8.7 | 66 | 64 | - | 63 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabrini, M.; Sinigaglia, E.; Spinelli, C.; Tarenzi, M.; Testa, C.; Bolzoni, F.M. Hydrogen Embrittlement Evaluation of Micro Alloyed Steels by Means of J-Integral Curve. Materials 2019, 12, 1843. https://doi.org/10.3390/ma12111843

Cabrini M, Sinigaglia E, Spinelli C, Tarenzi M, Testa C, Bolzoni FM. Hydrogen Embrittlement Evaluation of Micro Alloyed Steels by Means of J-Integral Curve. Materials. 2019; 12(11):1843. https://doi.org/10.3390/ma12111843

Chicago/Turabian StyleCabrini, Marina, Ennio Sinigaglia, Carlo Spinelli, Marco Tarenzi, Cristian Testa, and Fabio Maria Bolzoni. 2019. "Hydrogen Embrittlement Evaluation of Micro Alloyed Steels by Means of J-Integral Curve" Materials 12, no. 11: 1843. https://doi.org/10.3390/ma12111843

APA StyleCabrini, M., Sinigaglia, E., Spinelli, C., Tarenzi, M., Testa, C., & Bolzoni, F. M. (2019). Hydrogen Embrittlement Evaluation of Micro Alloyed Steels by Means of J-Integral Curve. Materials, 12(11), 1843. https://doi.org/10.3390/ma12111843