Internal Curing Effect and Compressive Strength Calculation of Recycled Clay Brick Aggregate Concrete

Abstract

1. Introduction

2. Materials and Methods

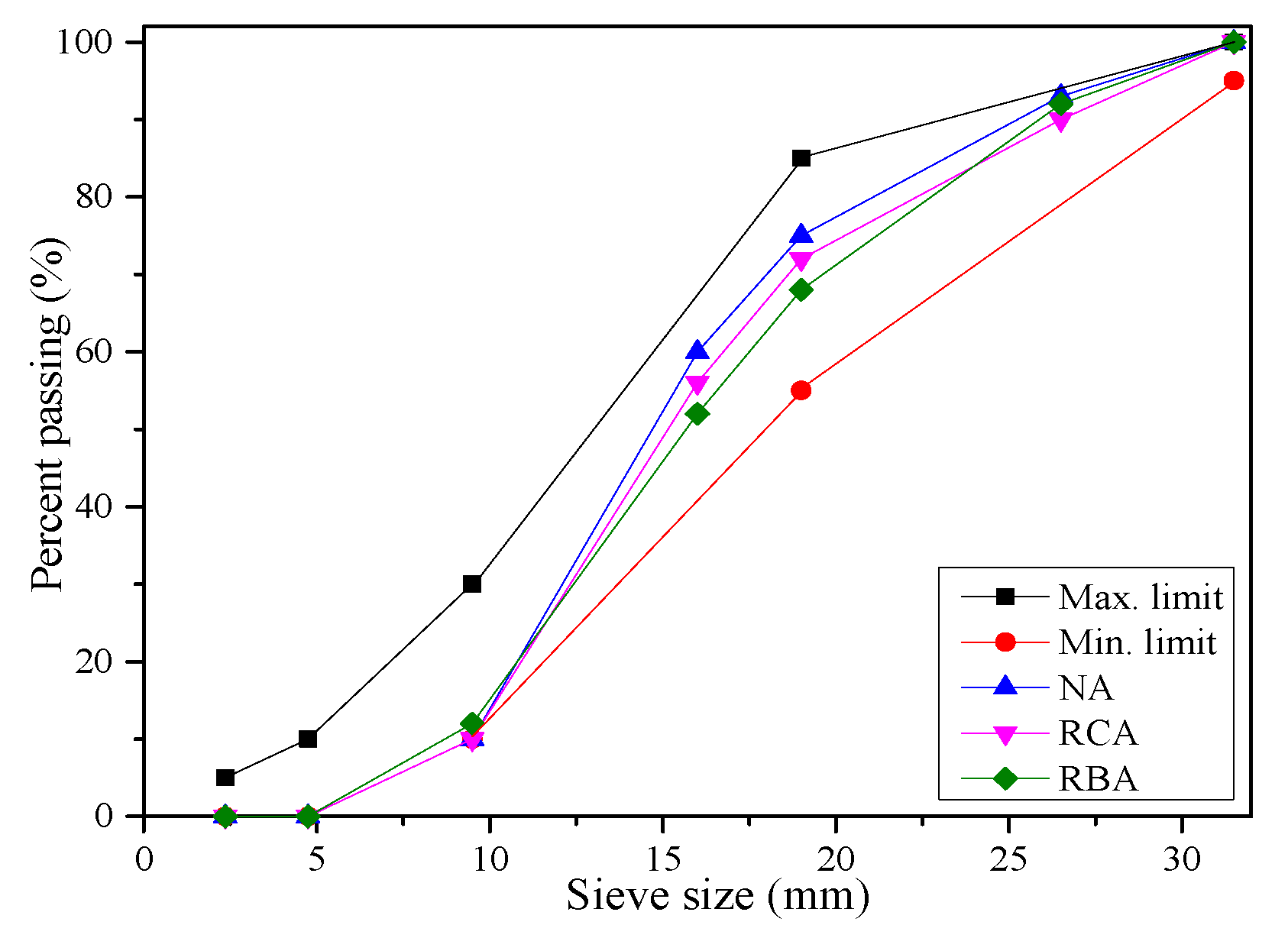

2.1. Materials

2.2. Specimens Design

2.3. Experimental Mode

3. Test Results and Analysis

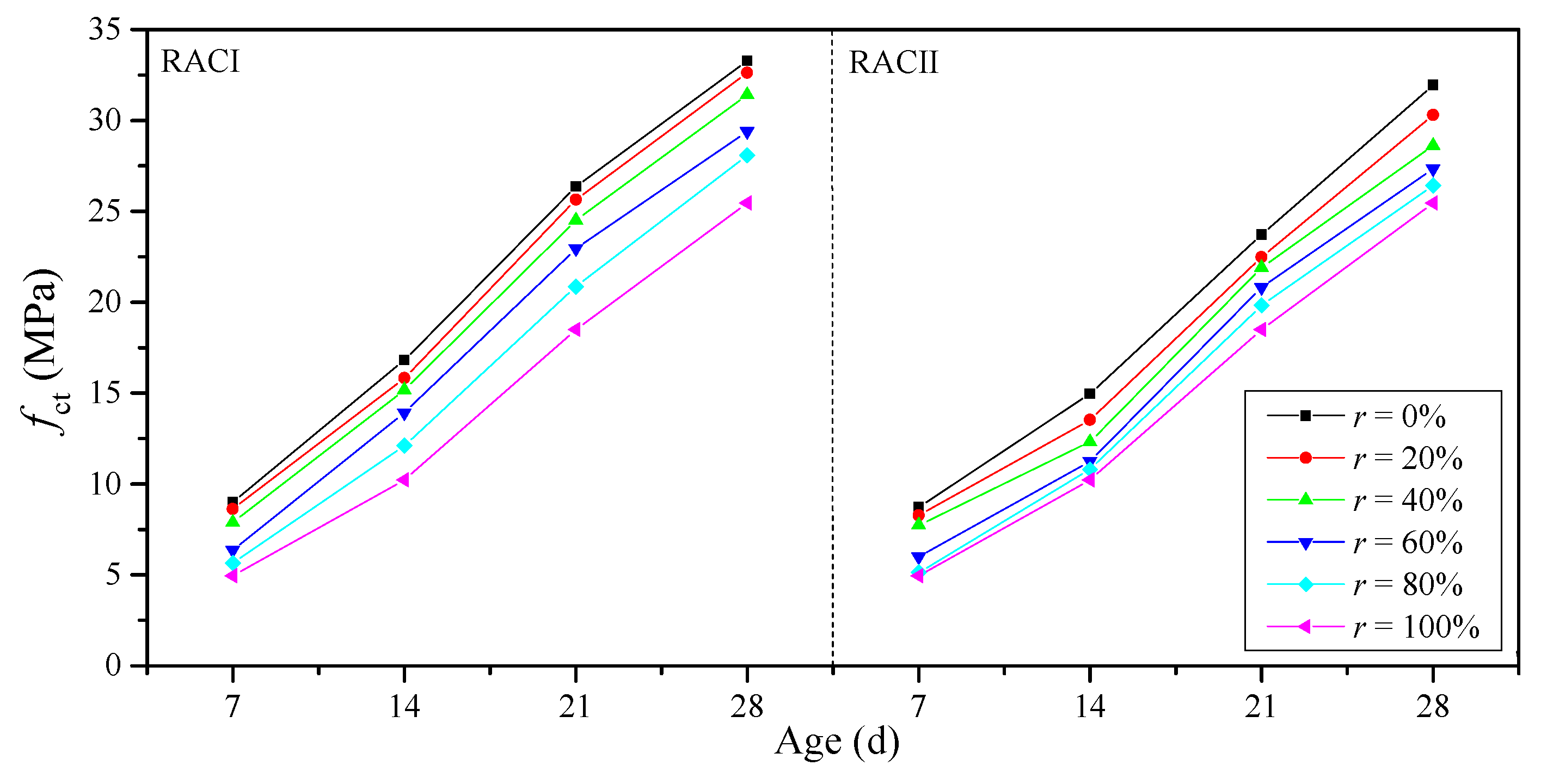

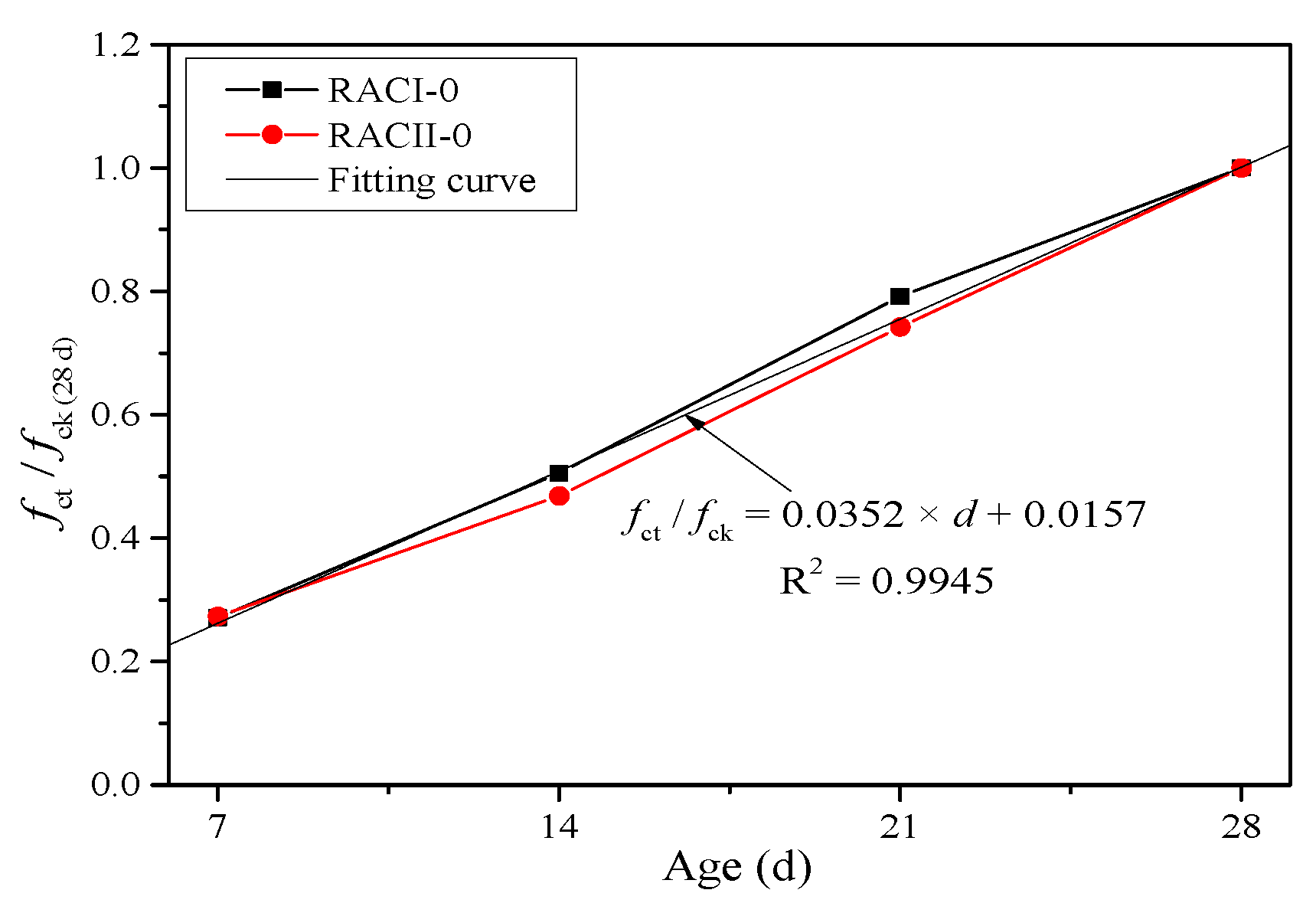

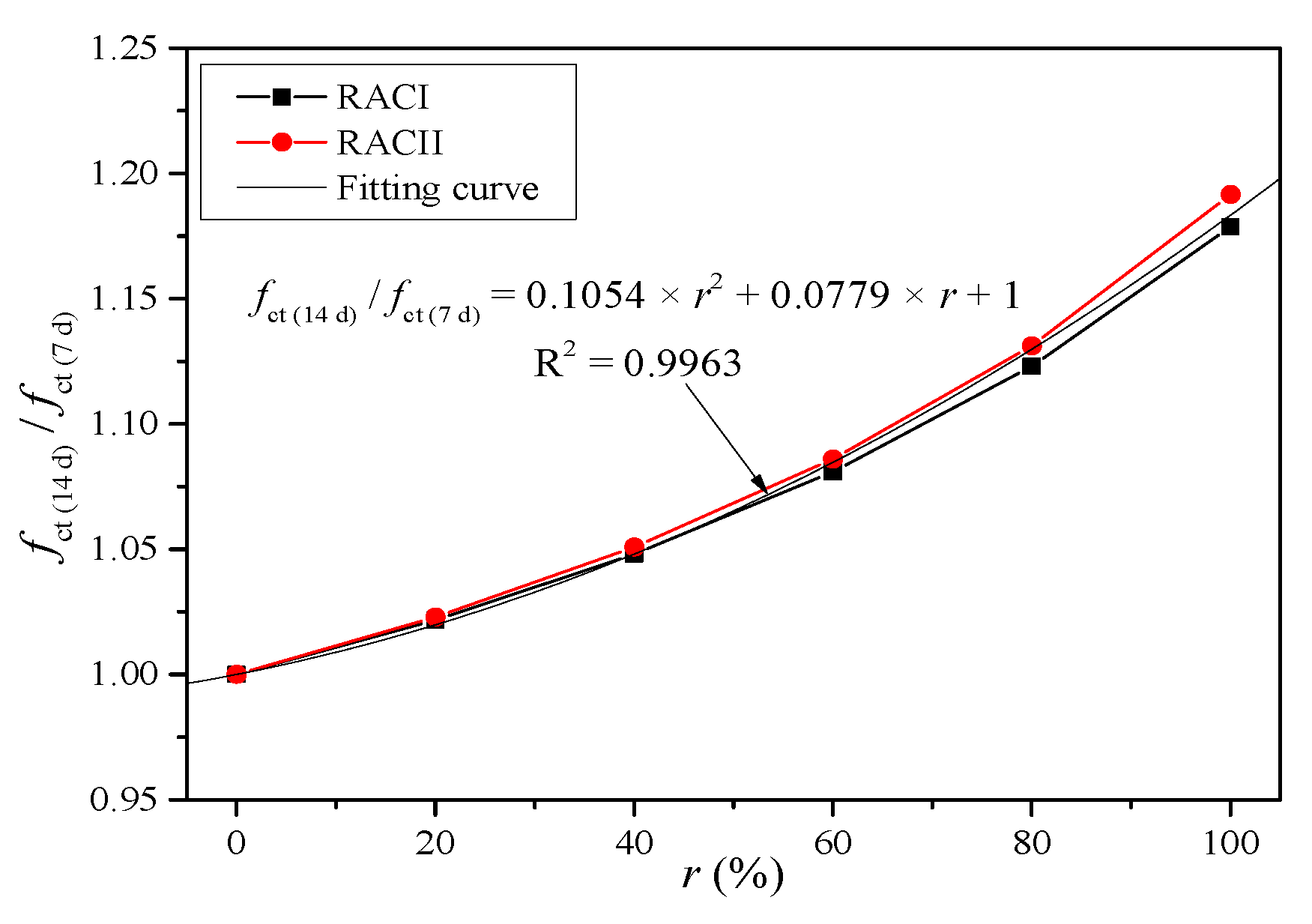

3.1. Curing Age

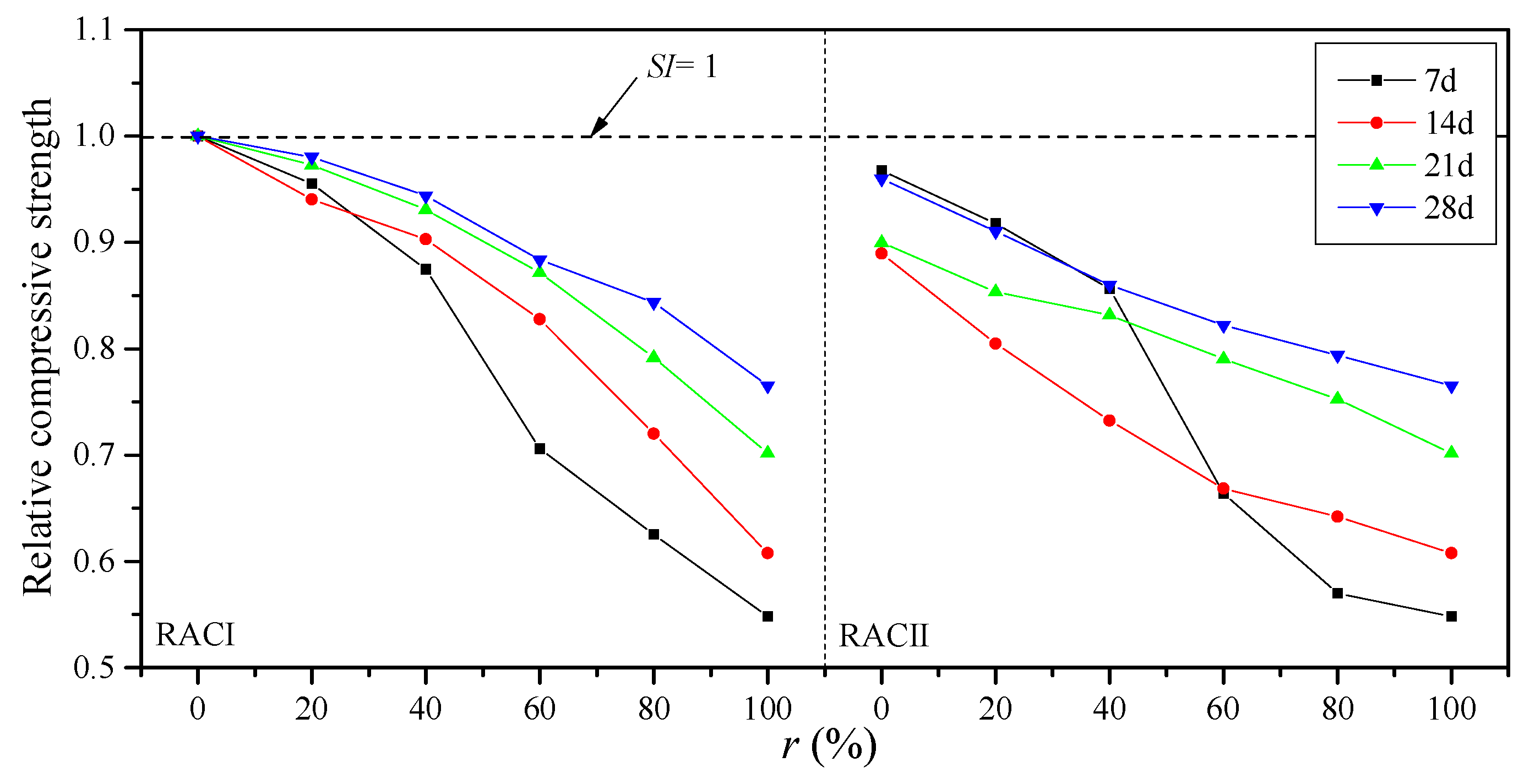

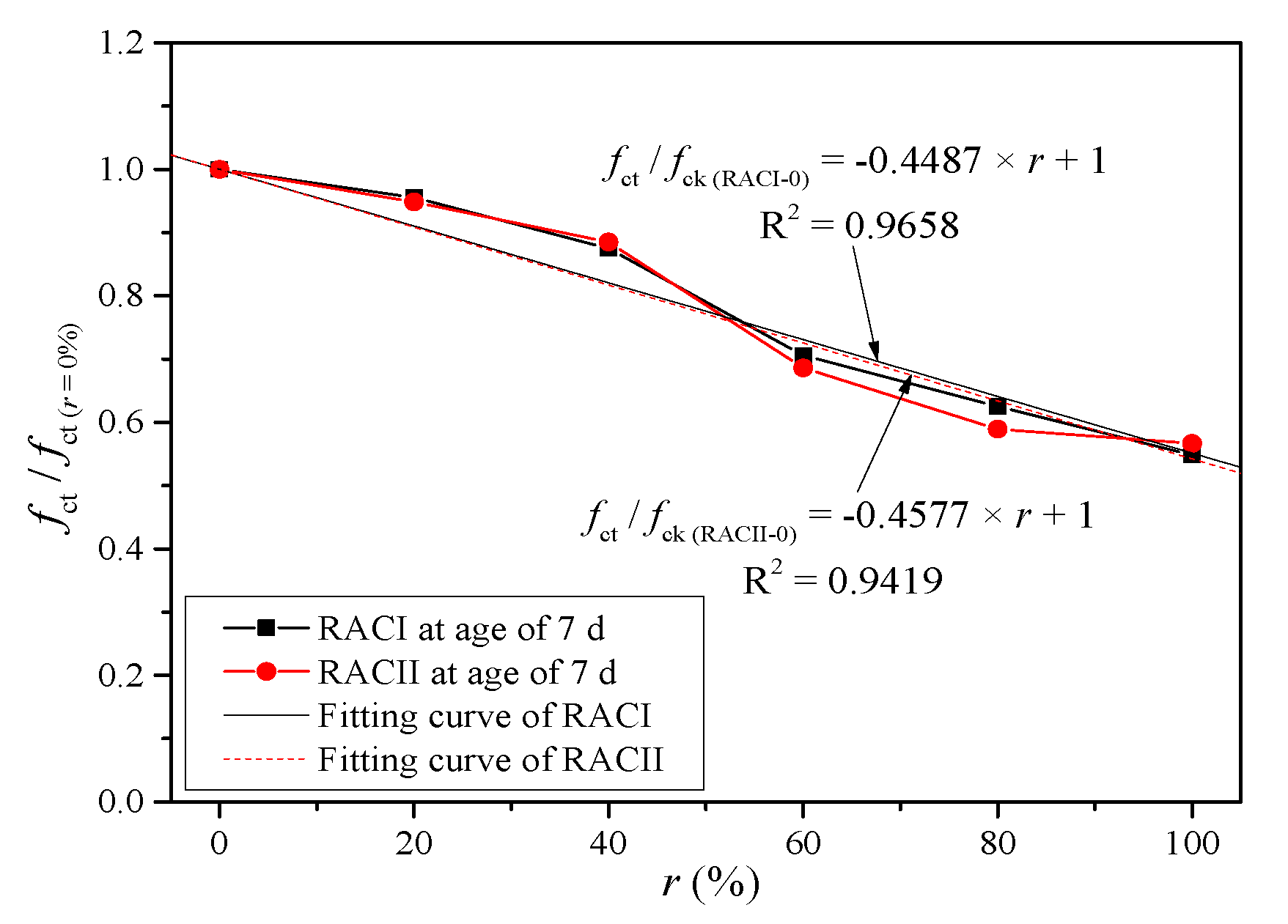

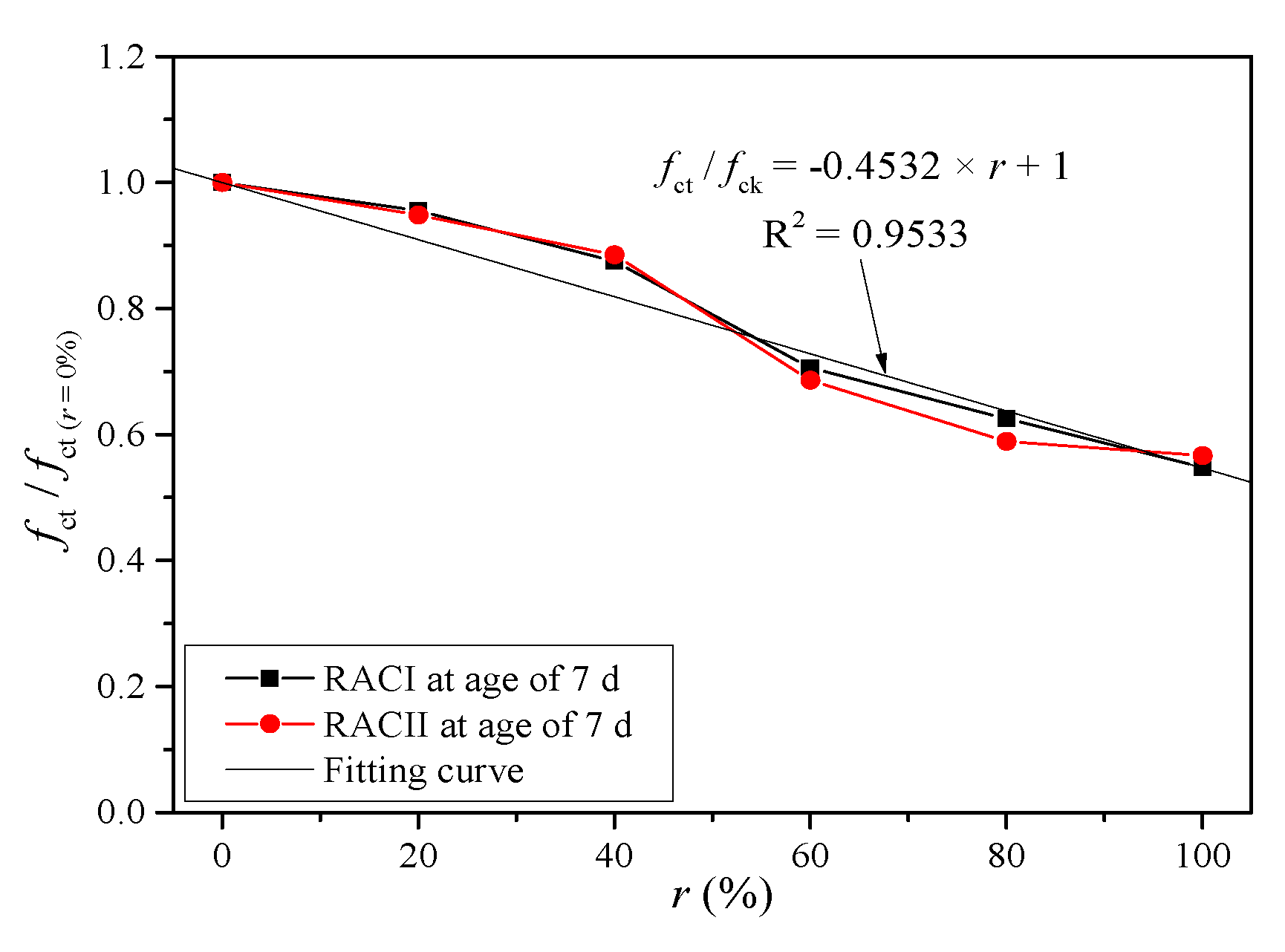

3.2. Replacement Ratio

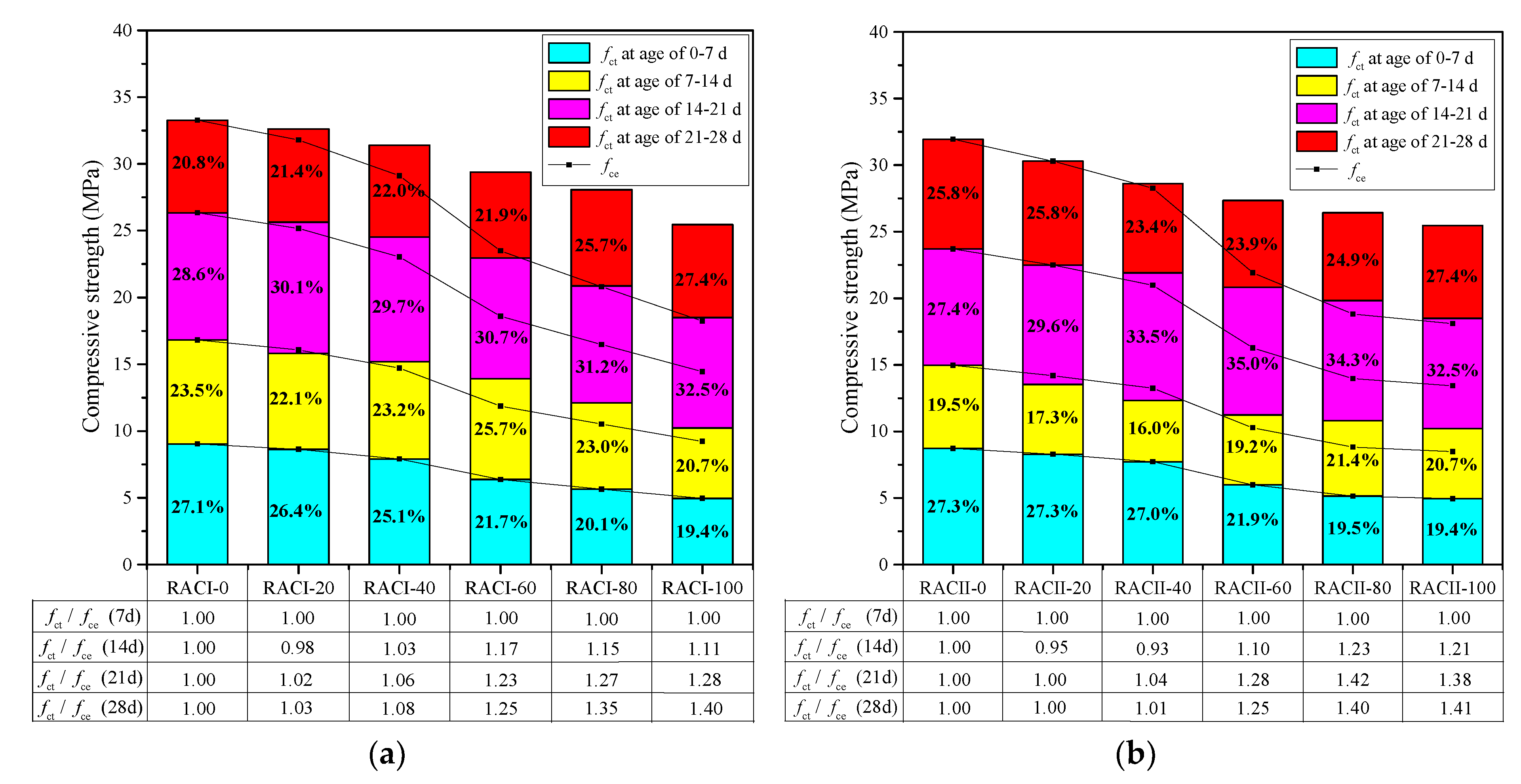

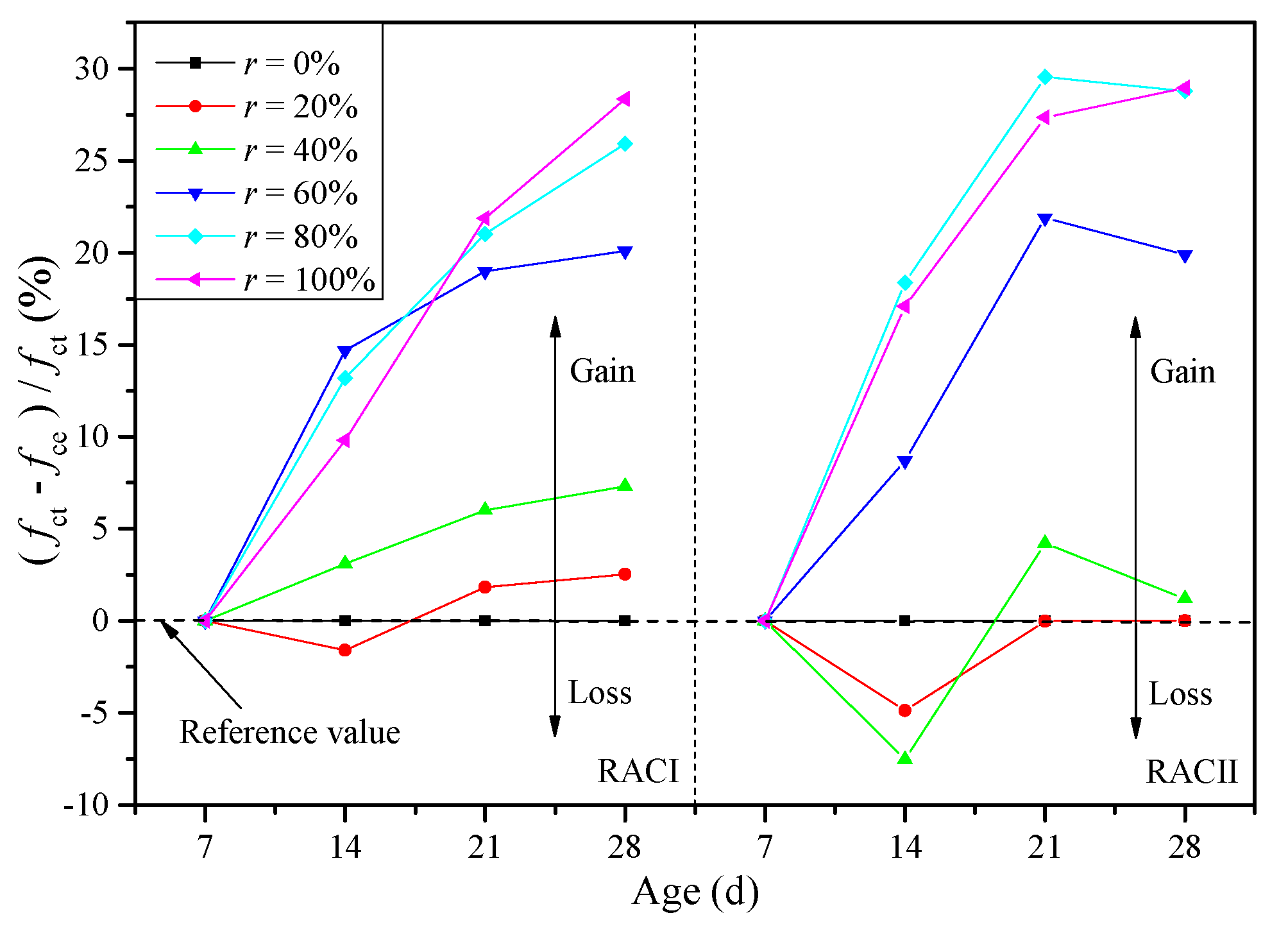

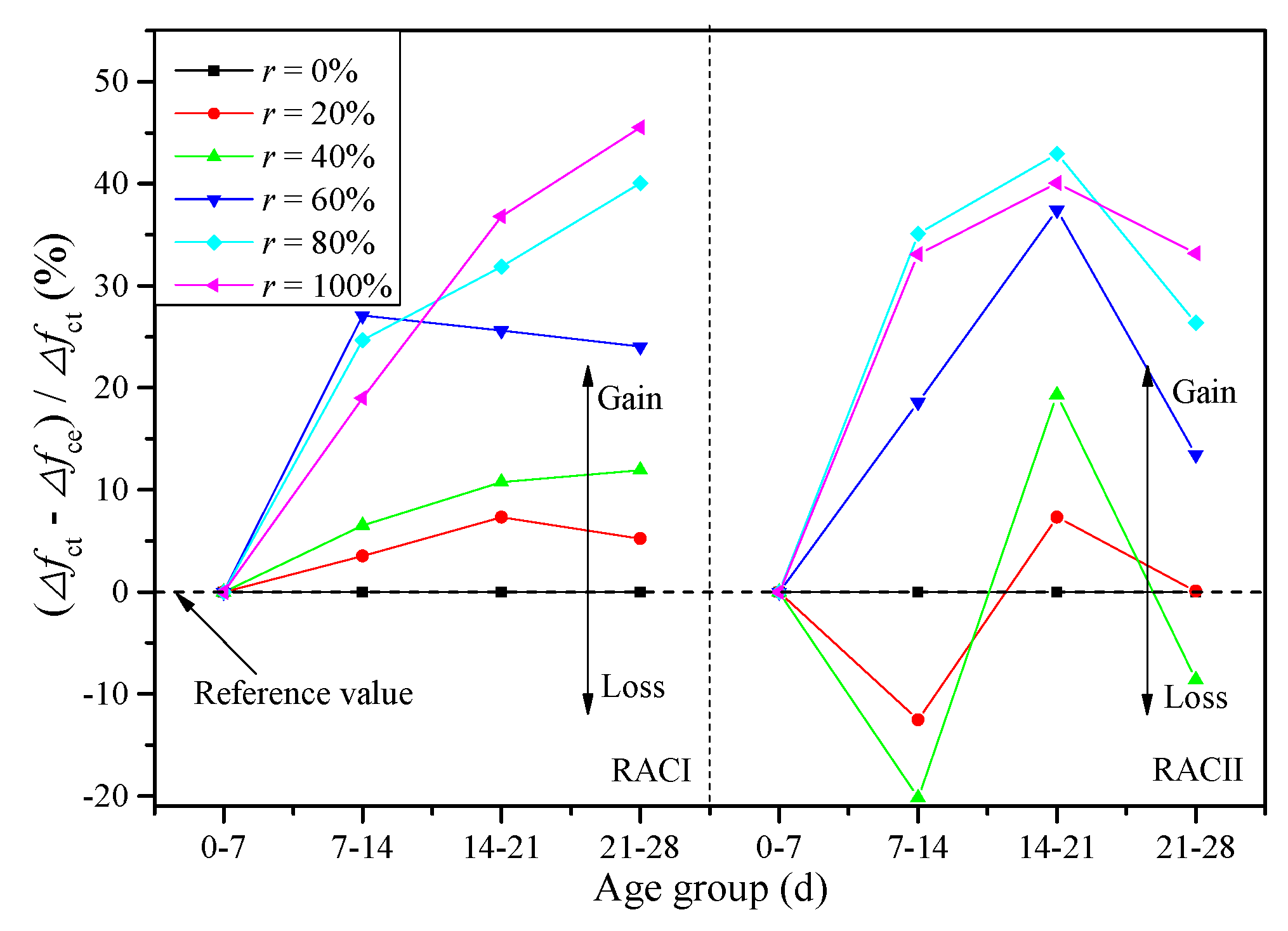

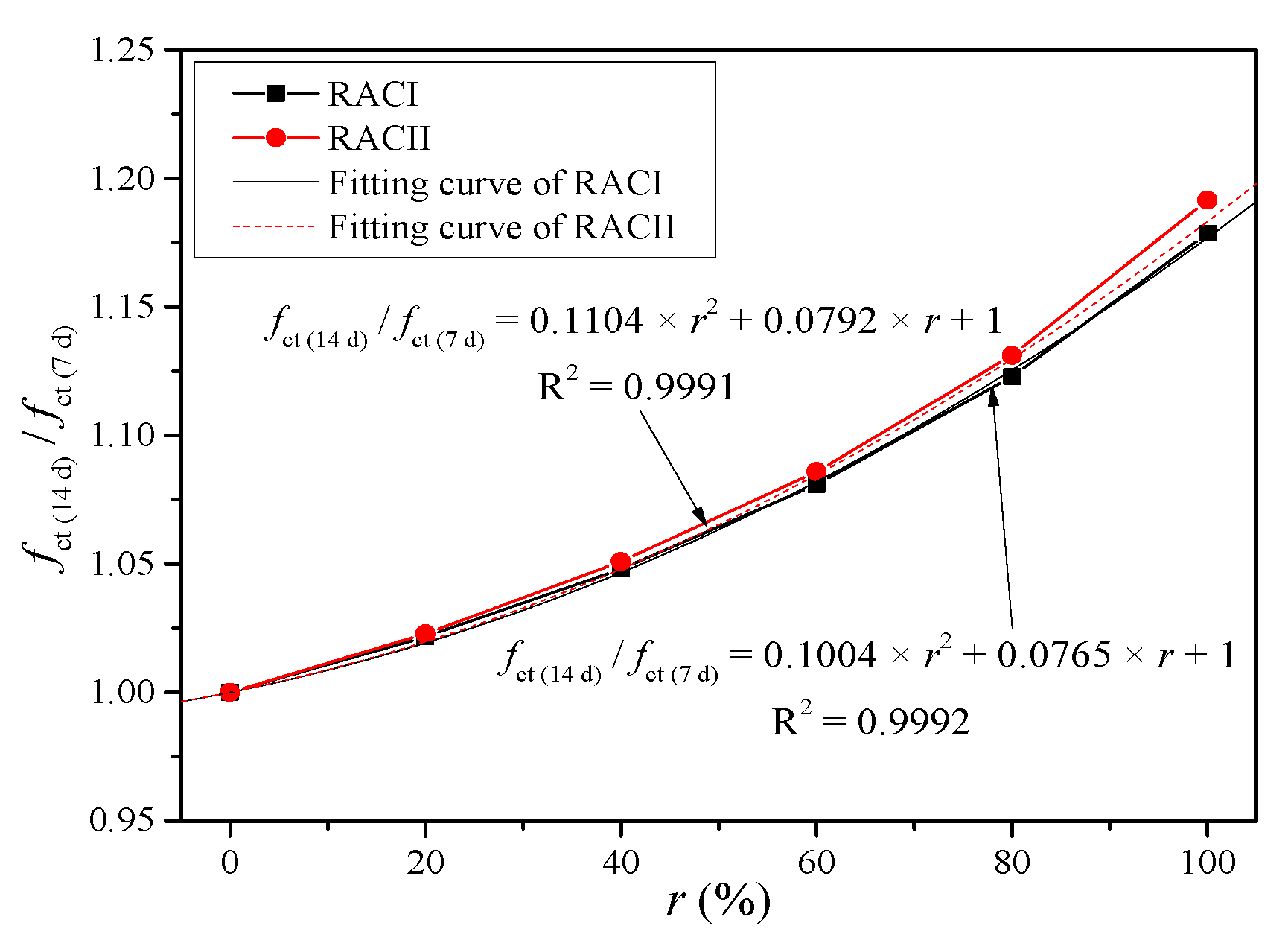

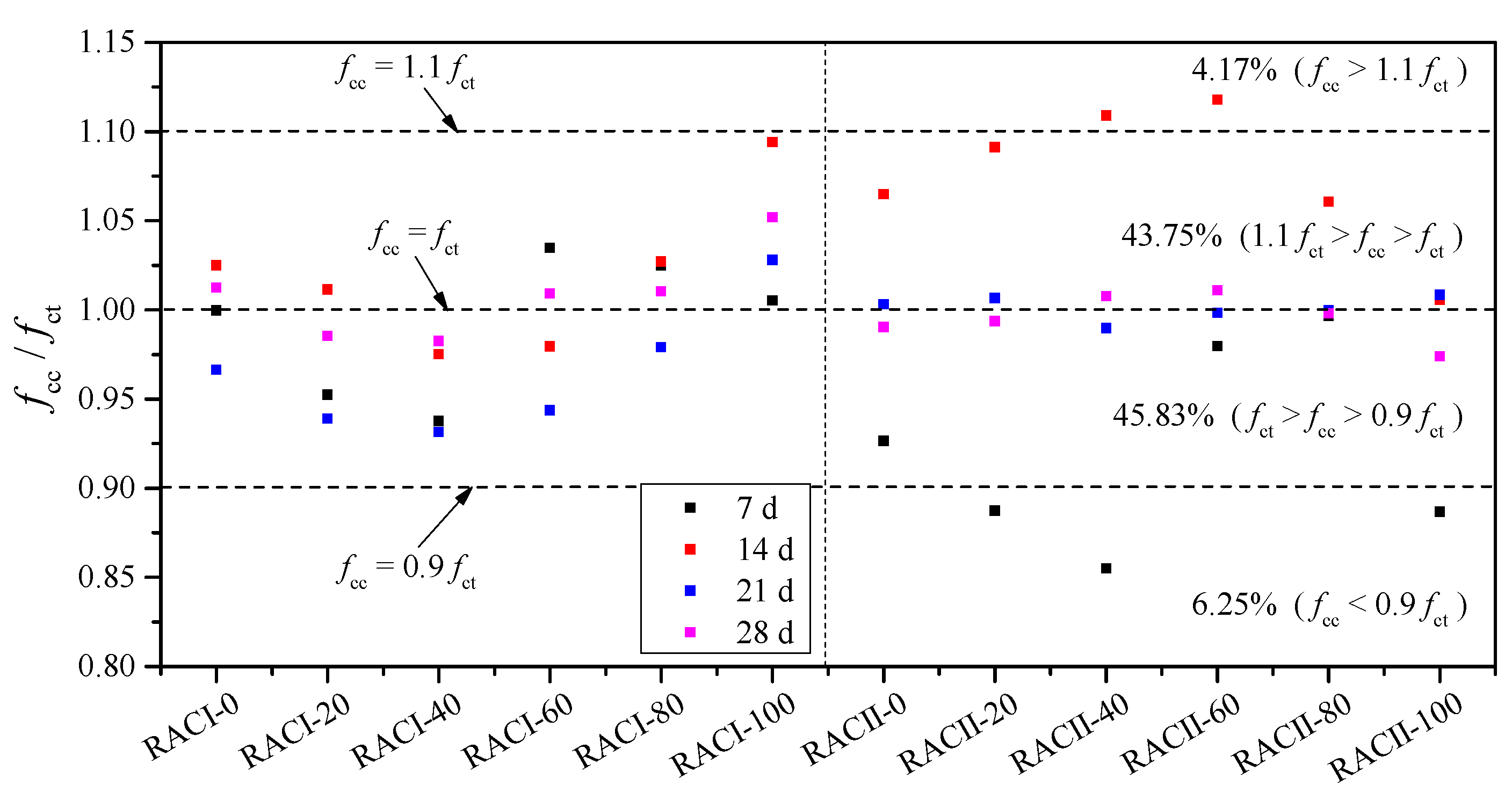

3.3. Internal Curing Effect

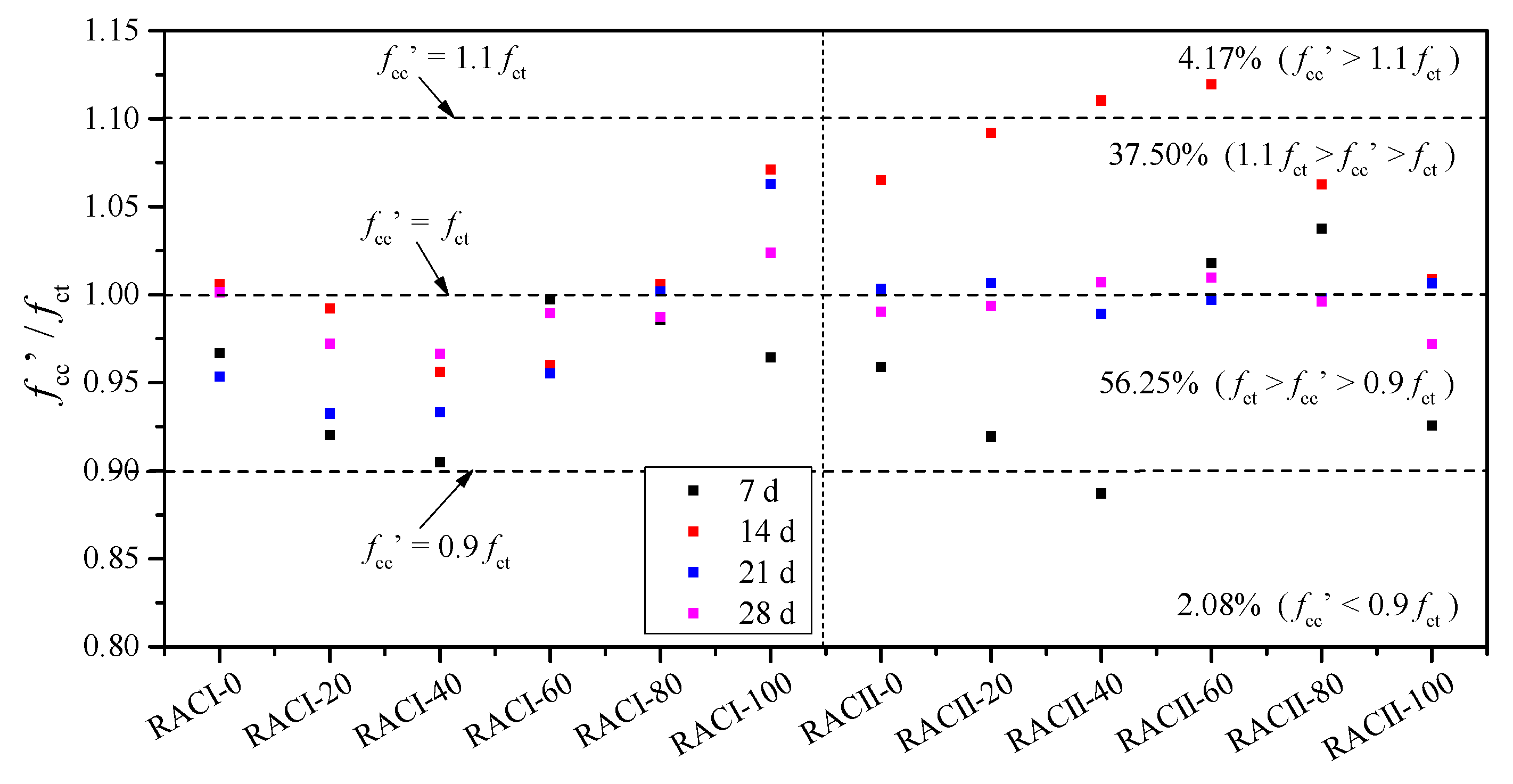

4. Calculation and Discussion

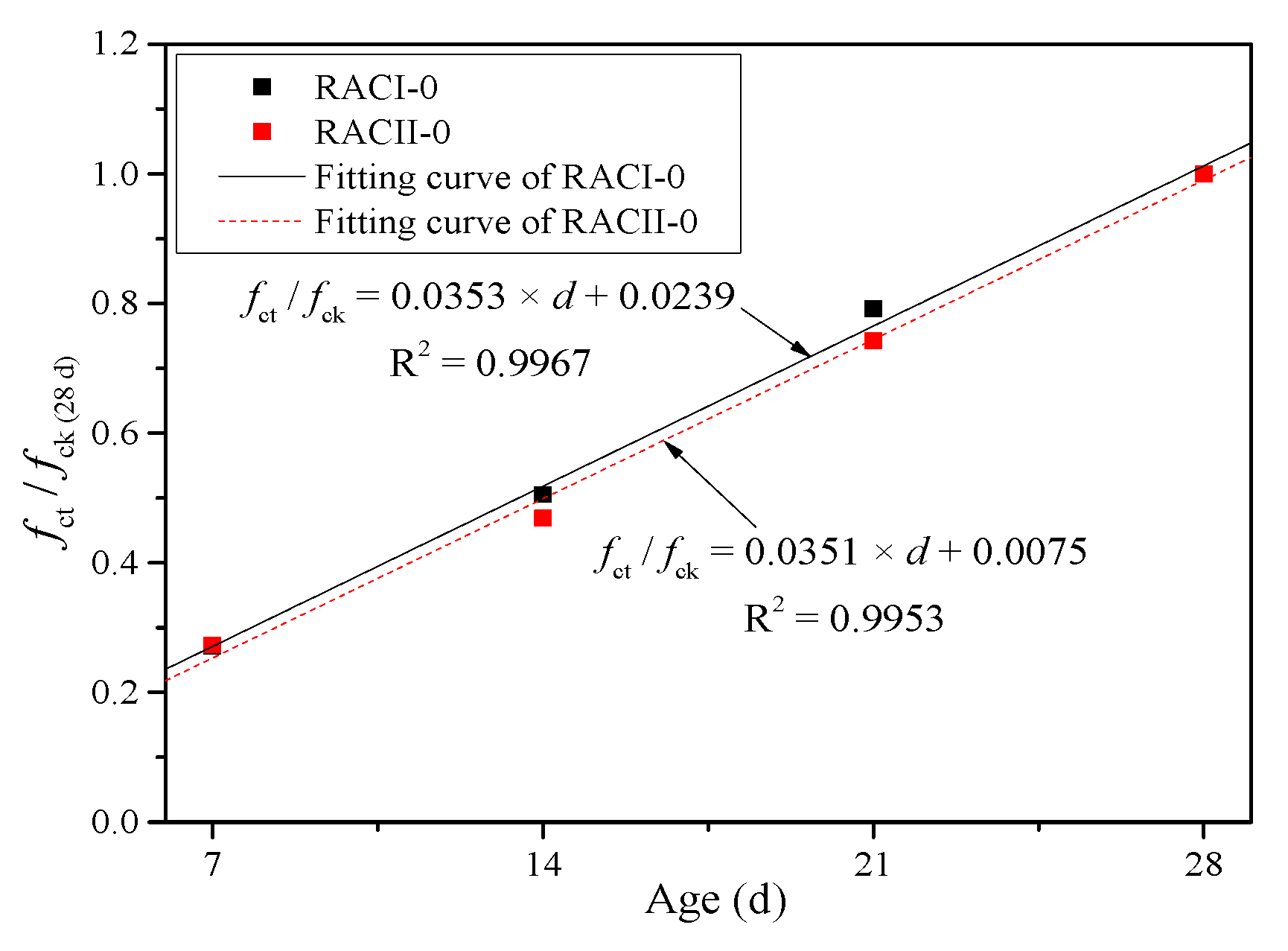

4.1. Calculation of Compressive Strength

4.2. Unified Calculation Method

5. Conclusions

- (1)

- The compressive strength of RAC with RBA or mixed RA gradually increases with the curing age but decreases with the r of RBA. The compressive strength of RACI and RACII decreases steadily when the r is below 40%; then, there is a significant drop once the r is higher than 60%.

- (2)

- The internal curing effect of RAC with a low RBA ratio is mainly reflected at the curing period of 14–21 days, and that of the RAC with a high RBA ratio appears at the curing period of 7–14 days, then becomes obvious after 14 days. The actual tested compressive strength of RAC replaced by 100% RBA exceeds around 40% of the expected compressive strength at the age of 28 days.

- (3)

- When the age of RACI-100 and RACII-100 is 28 days, the compressive strength caused by the internal curing effect accounts for 28.4% and 28.9% of the actual tested compressive strength. The internal curing proportion gradually increases with the age period for RACI, while it reaches its peak at the period of 14–21 days for RACII.

- (4)

- In order to ensure the performance of RAC while using as much RA as possible, a mixture with 40–60% RBA by volume is the most appropriate for RAC. From the viewpoint of compressive strength, it is feasible to completely replace NA with mixed RA.

- (5)

- The equations of compressive strength for RACI and RACII are presented in this investigation according to the curing age and replacement ratio, also considering the internal curing effect of RBA. Further, the unified equation presented is considered more suitable and can increase the convenience of the calculation.

6. Notations

| Abbreviation | Full Name |

| d | Curing age (d) |

| fcc | Calculated compressive strength of RAC (MPa) |

| fcc′ | Unified calculated compressive strength of RAC (MPa) |

| fce | Expected compressive strength without considering the internal curing effect (MPa) |

| fck | Compressive strength of ordinary concrete or RAC without RBA at 28 d (MPa) |

| fct | Compressive strengths of cylindrical specimens converted by the tested Compressive strengths of cubic specimens (MPa) |

| NA | Natural aggregate |

| r | Replacement ratio of recycled coarse aggregate (%) |

| RA | Recycled aggregate |

| RAC | Recycled aggregate concrete |

| RACI | RAC with NA as basic aggregate and RBA as RA |

| RACII | RAC with RCA as basic aggregate and RBA as RA |

| RBA | Recycled brick aggregate |

| RCA | Recycled concrete aggregate |

| w/c | Water / cement (-) |

| SI | A strength index (-) |

| α | Coefficient of curing age (-) |

| α′ | Unified coefficient of curing age (-) |

| β | Coefficient of replacement ratio (-) |

| β′ | Unified coefficient of replacement ratio (-) |

| γ | Coefficient of aggregate type or internal curing effect (-) |

| ρc | Apparent density of cement (kg/m3) |

| ρs | Apparent density of sand (kg/m3) |

| Δfce | Expected compressive strength within each age period (MPa) |

Author Contributions

Funding

Conflicts of Interest

References

- Debieb, F.; Kenai, S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Tanja, K.Š.; Ivana, M.; Rafat, S. Model for mix design of brick aggregate concrete based on neural network modelling. Constr. Build. Mater. 2017, 148, 757–769. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. The influence of the use of recycled aggregates on the compressive strength of concrete: A review. Eur. J. Environ. Civ. Eng. 2015, 19, 825–849. [Google Scholar] [CrossRef]

- Xu, J.J.; Zhao, X.Y.; Yu, Y.; Xie, T.Y.; Yang, G.S.; Xue, J.Y. Parametric sensitivity analysis and modelling of mechanical properties of normal- and high-strength recycled aggregate concrete using grey theory, multiple nonlinear regression and artificial neural networks. Constr. Build. Mater. 2019, 211, 479–491. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B.; Bouziani, T.; Chaid, R. Valorization of brick wastes in the fabrication of concrete blocks. Mater. Tehnol. 2016, 50, 911–916. [Google Scholar] [CrossRef]

- Miličević, I.; Bjegović, D.; Siddique, R. Experimental research of concrete floor blocks with crushed bricks and tiles aggregate. Constr. Build. Mater. 2015, 94, 775–783. [Google Scholar] [CrossRef]

- Baradaran-Nasiri, A.; Nematzadeh, M. The effect of elevated temperatures on the mechanical properties of concrete with fine recycled refractory brick aggregate and aluminate cement. Constr. Build. Mater. 2017, 147, 865–875. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Hasnat, A.; Awal, M.A.; Bosunia, S.Z. Recycling of brick aggregate concrete as coarse aggregate. J. Mater. Civil. Eng. 2014, 27, B4014005. [Google Scholar] [CrossRef]

- Guerra-Romero, M.I.; Rodríguez-Robles, D.; García-González, J.; Juan-Valdés, A.; Pozo, M.D. Effect of mixed recycled aggregates on mechanical properties of recycled concrete. Mag. Concrete. Res. 2015, 67, 247–256. [Google Scholar] [CrossRef]

- Martínez-Lage, I.; Martínez-Abella, F.; Vázquez-Herrero, C.; Pérez-Ordóñez, J.L. Properties of plain concrete made with mixed recycled coarse aggregate. Constr. Build. Mater. 2012, 37, 171–176. [Google Scholar] [CrossRef]

- Gonzalez-Corominas, A.; Etxeberria, M.; Poon, C.S. Influence of the quality of recycled aggregates on the mechanical and durability properties of high performance concrete. Waste. Biomass. Valori. 2017, 8, 1421–1432. [Google Scholar] [CrossRef]

- Gesoglu, M.; Özturan, T.; Güneyisi, E. Shrinkage cracking of lightweight concrete made with cold-bonded fly ash aggregate. Cem. Concr. Res. 2004, 34, 1121–1130. [Google Scholar] [CrossRef]

- Cusson, D.; Hoogeveen, T. Internal curing of high-performance concrete with pre-soaked fine lightweight aggregate for prevention of autogenous shrinkage cracking. Cem. Concr. Res. 2008, 38, 757–765. [Google Scholar] [CrossRef]

- Ondova, M.; Sicakova, A. Evaluation of the influence of specific surface treatments of RBA on a set of properties of concrete. Materials 2016, 9, 156. [Google Scholar] [CrossRef] [PubMed]

- Bentur, A.; Igarashi, S.; Kovler, K. Prevention of autogenous shrinkage in high strength concrete by internal curing using wet lightweight aggregates. Cem. Concr. Res. 2001, 31, 1587–1591. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K.; Bentur, A. Influence of cement paste matrix properties on the autogenous curing of high-performance concrete. Cem. Concr. Compos. 2004, 26, 499–507. [Google Scholar] [CrossRef]

- Durán-Herrera, A.; Aïtcin, P.C.; Petrov, N. Effect of saturated lightweight sand substitution on shrinkage in 0.35 w/b concrete. ACI Mater. J. 2007, 104, 48–52. [Google Scholar] [CrossRef]

- Bentz, D.P. Internal curing of high-performance blended cement mortars. ACI Mater. J. 2007, 104, 408–414. [Google Scholar]

- Ge, Z.; Wang, Y.; Sun, R.; Wu, X.; Guan, Y. Influence of ground waste clay brick on properties of fresh and hardened concrete. Constr. Build. Mater. 2015, 98, 128–136. [Google Scholar] [CrossRef]

- Lei, J.Q.; Chen, A.L. Study on mechanical properties of recycled brick aggregate concrete. In Proceedings of the 14th International Symposium on Structural Engineering (ISSE-14), Beijing, China, 12–15 October 2016; Yang, Q., Yang, Y., Ru, J., Eds.; pp. 1711–1717. [Google Scholar]

- Xiao, J.Z.; Li, W.G.; Poon, C.S. Recent studies on mechanical properties of recycled aggregate concrete in China-A review. Sci. China Technol. Sci. 2012, 55, 1463–1480. [Google Scholar] [CrossRef]

- Pebble and Crushed Stone for Building; China Building Industry Press: Beijing, China, 2011; GB/T 14685-2011.

- Standard for Technical Requirements and Test. Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete; China Building Industry Press: Beijing, China, 2007; JGJ 52-2006. [Google Scholar]

- Lightweight Aggregates and Its Test. Methods, II: Lightweight aggregate test method; China Building Industry Press: Beijing, China, 2010; GB/T 17431.2-2010. [Google Scholar]

- Technical Specification for Testing Concrete Strength with Drilled Core Method; China Building Industry Press: Beijing, China, 2016; JGJ T 384-2016.

- Laserna, S.; Montero, J. Influence of natural aggregates typology on recycled concrete strength properties. Constr. Build. Mater. 2016, 115, 78–86. [Google Scholar] [CrossRef]

- Specification Foe Mis Proportion Design of Ordinary Concrete; China Building Industry Press: Beijing, China, 2011; JGJ 55-2011.

- Standard for Test. Method of Mechanical Properties on Ordinary Concrete; China Building Industry Press: Beijing, China, 2002; GB/T 50081-2002.

- Code for Design of Concrete Structures; China Building Industry Press: Beijing, China, 2010; GB 50010-2010.

- Wu, K.; Chen, F.; Xu, C.; Lin, S.Q.; Nan, Y. Internal curing effect on strength of recycled concrete and its enhancement in concrete-filled thin-wall steel tube. Constr. Build. Mater. 2017, 153, 824–834. [Google Scholar] [CrossRef]

| Aggregate Type | Continuous Grading (mm) | Bulk Density (kg/m3) | Apparent Density (kg/m3) | Water Absorption (%) | Crushing Index (%) | Random Core Drilling (MPa) |

|---|---|---|---|---|---|---|

| NA | 10~30 | 1450 | 2800 | 0.3 | 1.5 | |

| RCA | 10~30 | 1389 | 2452 | 3.1 | 7.0 | 38~42 |

| RBA | 10~30 | 1280 | 1967 | 14.6 | 45.0 | 12 |

| Specimen Group | Coarse Aggregates and Replacement Ratio | Water (kg/m3) | Cement (kg/m3) | Sand (kg/m) | NA (kg/m3) | RBA (kg/m3) | RCA (kg/m3) | Absorption (%) |

|---|---|---|---|---|---|---|---|---|

| RACI-0 | RBA(0%), NA(100%) | 185.00 | 420.45 | 574.01 | 1295.73 | 0.00 | 0.00 | 0.3 |

| RACI-20 | RBA(20%), NA(80%) | 185.00 | 420.45 | 550.22 | 1056.63 | 185.57 | 0.00 | 3.0 |

| RACI-40 | RBA(40%), NA(60%) | 185.00 | 420.45 | 525.64 | 808.10 | 378.46 | 0.00 | 5.7 |

| RACI-60 | RBA(60%), NA(40%) | 185.00 | 420.45 | 500.00 | 549.57 | 579.11 | 0.00 | 8.5 |

| RACI-80 | RBA(80%), NA(20%) | 185.00 | 420.45 | 473.31 | 280.43 | 788.00 | 0.00 | 11.3 |

| RACI-100 | RBA(100%), NA(0%) | 185.00 | 420.45 | 445.50 | 0.00 | 1005.64 | 0.00 | 14.0 |

| RACII-0 | RBA(0%), RCA(100%) | 185.00 | 420.45 | 523.41 | 0.00 | 0.00 | 1181.51 | 3.1 |

| RACII-20 | RBA(20%), RCA(80%) | 185.00 | 420.45 | 508.55 | 0.00 | 191.77 | 956.21 | 5.3 |

| RACII-40 | RBA(40%), RCA(60%) | 185.00 | 420.45 | 493.35 | 0.00 | 388.05 | 725.60 | 7.5 |

| RACII-60 | RBA(60%), RCA(40%) | 185.00 | 420.45 | 477.78 | 0.00 | 589.01 | 489.49 | 9.6 |

| RACII-80 | RBA(80%), RCA(20%) | 185.00 | 420.45 | 461.83 | 0.00 | 794.81 | 247.70 | 11.8 |

| RACII-100 | RBA(100%), RCA(0%) | 185.00 | 420.45 | 445.50 | 0.00 | 1005.64 | 0.00 | 14.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Wu, K.; Ren, L.; Xu, J.; Zheng, H. Internal Curing Effect and Compressive Strength Calculation of Recycled Clay Brick Aggregate Concrete. Materials 2019, 12, 1815. https://doi.org/10.3390/ma12111815

Chen F, Wu K, Ren L, Xu J, Zheng H. Internal Curing Effect and Compressive Strength Calculation of Recycled Clay Brick Aggregate Concrete. Materials. 2019; 12(11):1815. https://doi.org/10.3390/ma12111815

Chicago/Turabian StyleChen, Feng, Kai Wu, Lijian Ren, Jianan Xu, and Huiming Zheng. 2019. "Internal Curing Effect and Compressive Strength Calculation of Recycled Clay Brick Aggregate Concrete" Materials 12, no. 11: 1815. https://doi.org/10.3390/ma12111815

APA StyleChen, F., Wu, K., Ren, L., Xu, J., & Zheng, H. (2019). Internal Curing Effect and Compressive Strength Calculation of Recycled Clay Brick Aggregate Concrete. Materials, 12(11), 1815. https://doi.org/10.3390/ma12111815