Superplasticity of Ti-6Al-4V Titanium Alloy: Microstructure Evolution and Constitutive Modelling

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Microstructure Analysis after Annealing

3.2. Superplastic Characteristics

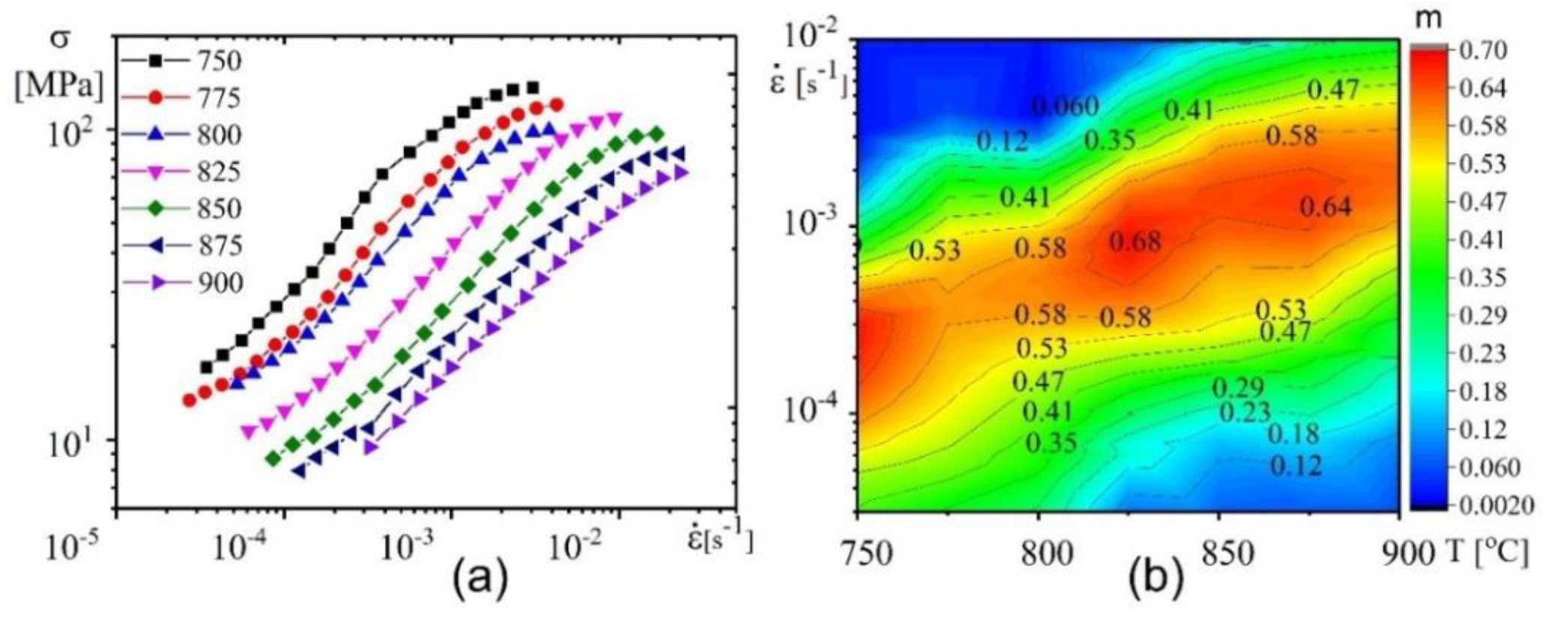

3.2.1. Step-by-Step Reduction of Strain Rate Test

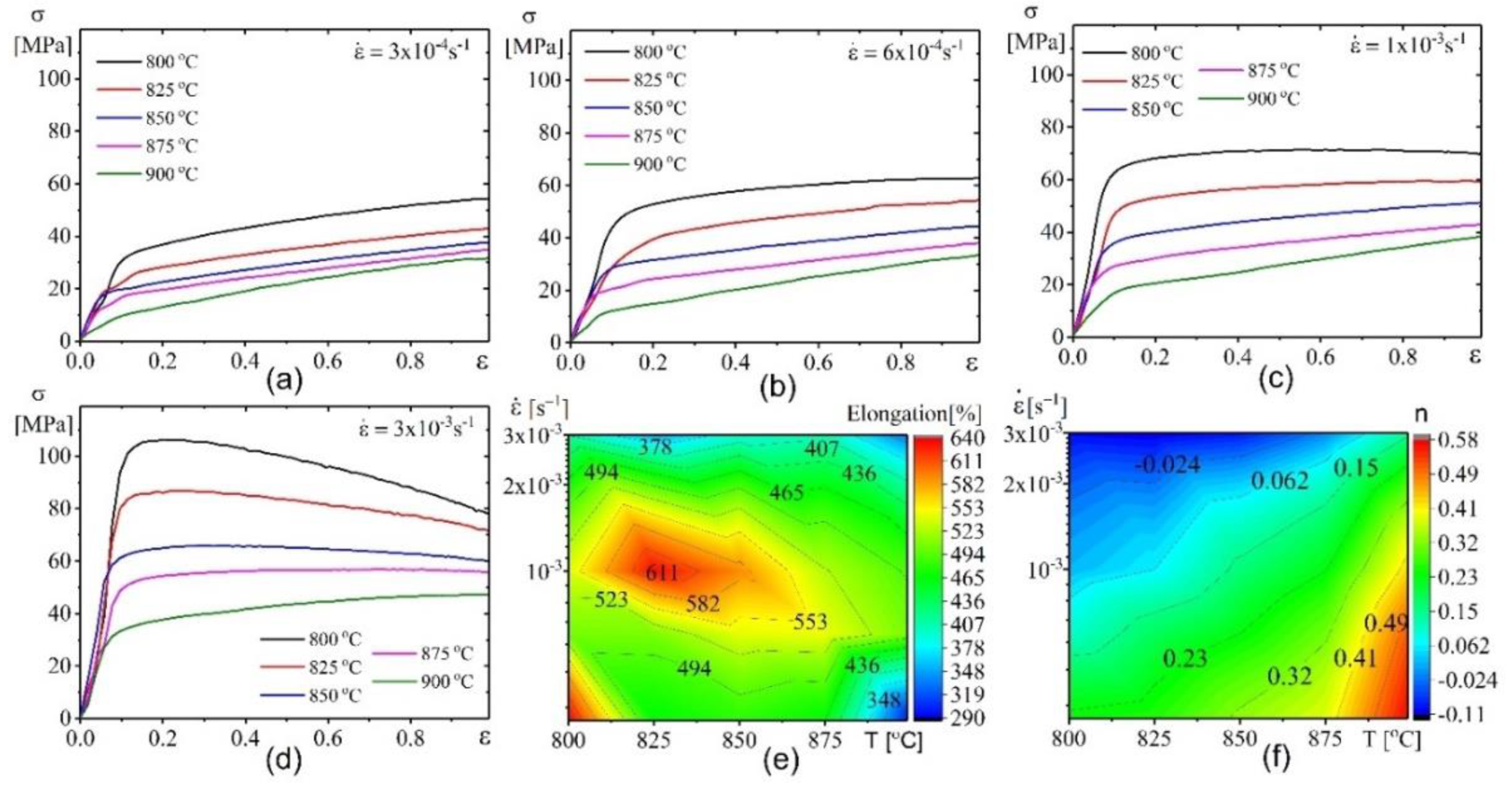

3.2.2. Constant Strain Rate Tests

3.3. Classical Constitutive Equations (CE)

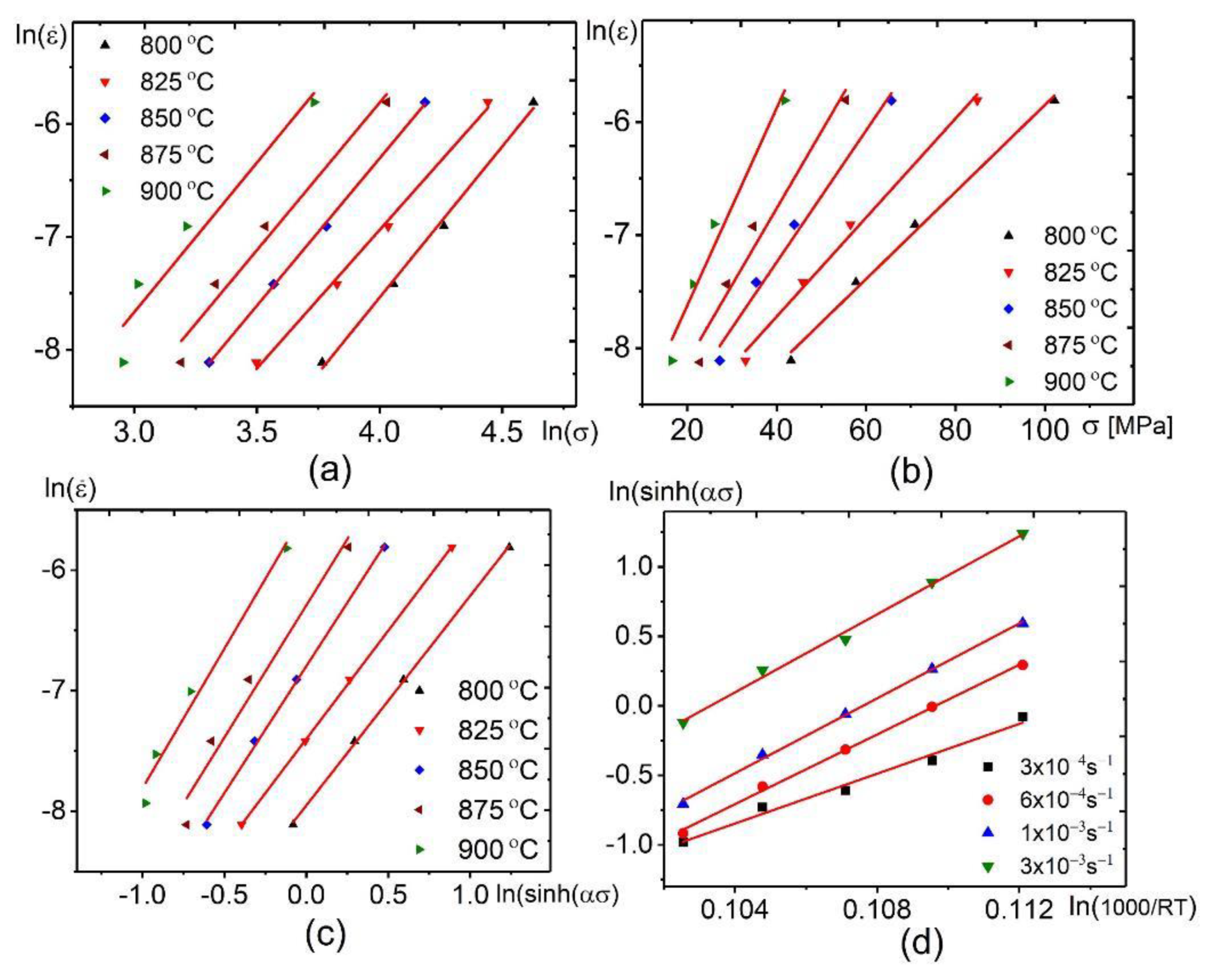

3.3.1. Model Parameters Determination

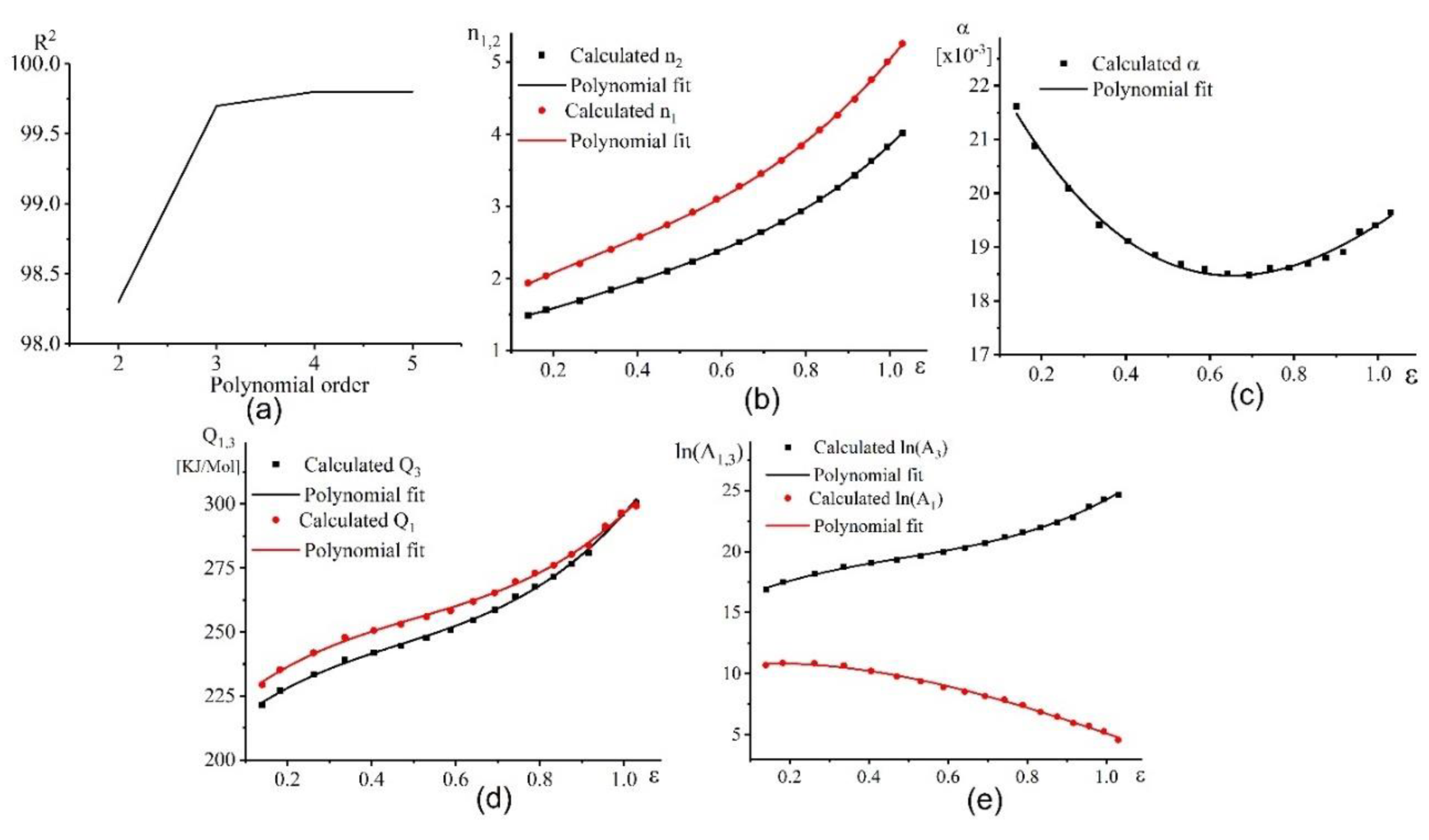

3.3.2. The Strain Dependence of Material Constants

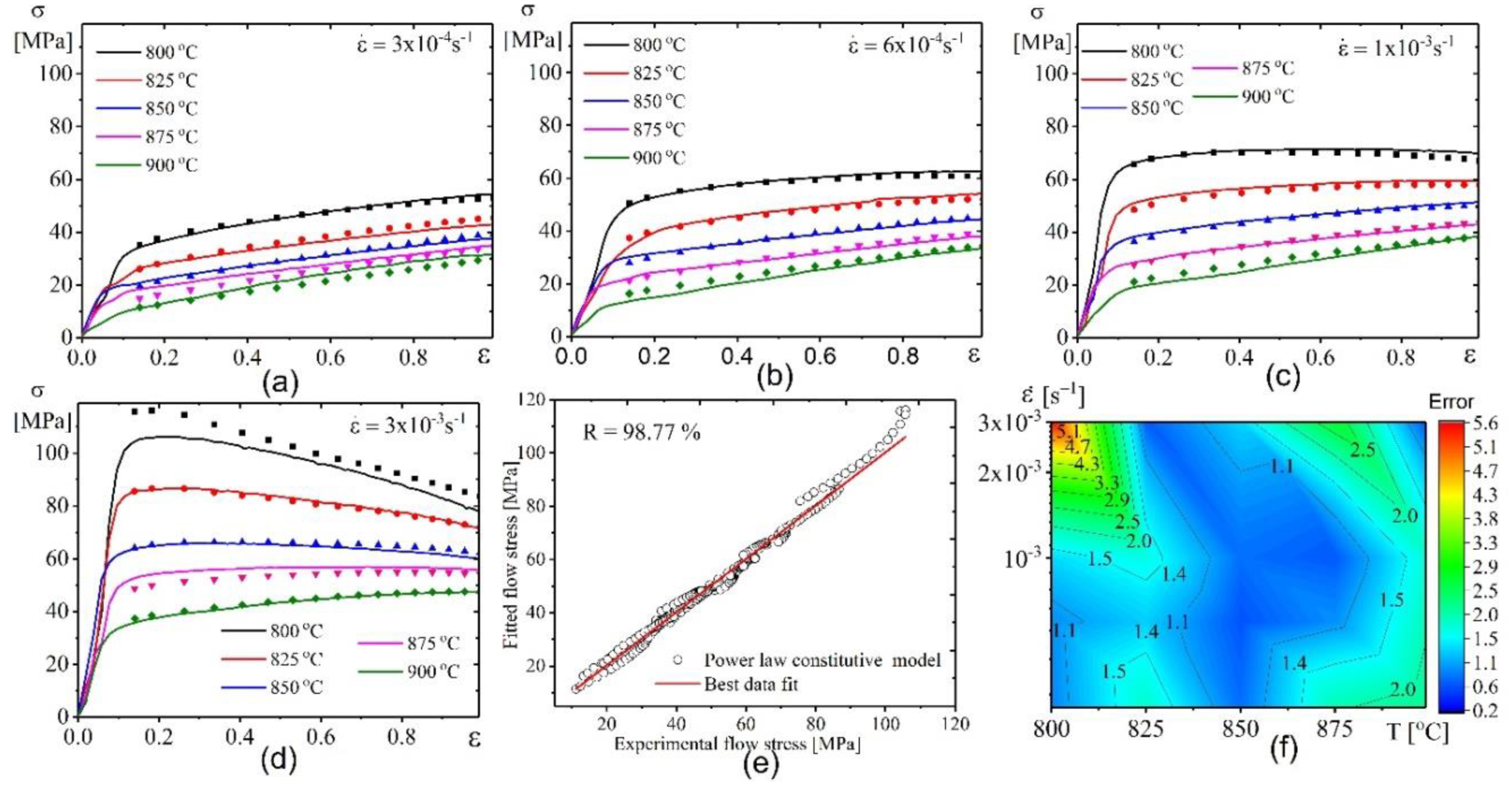

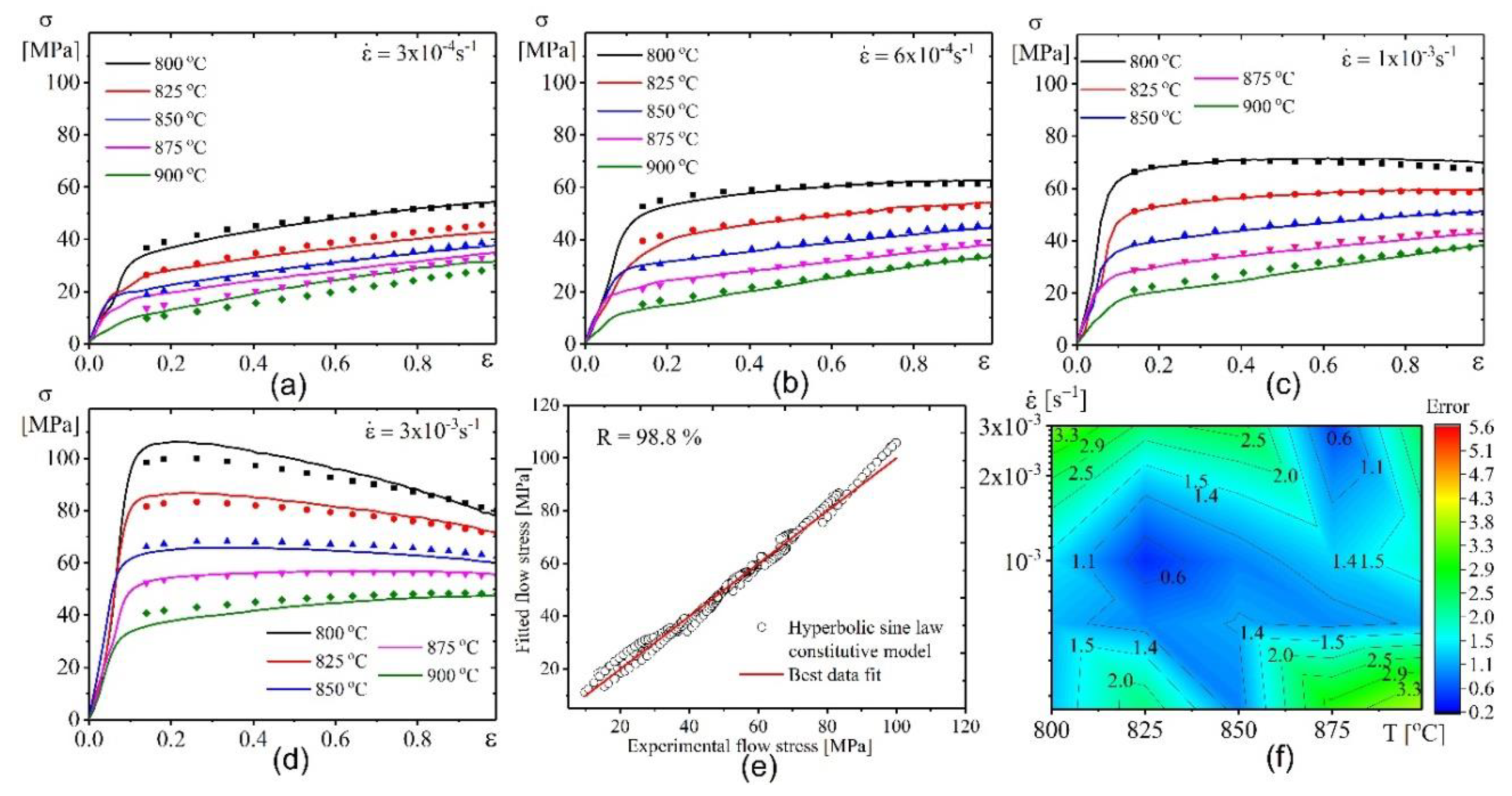

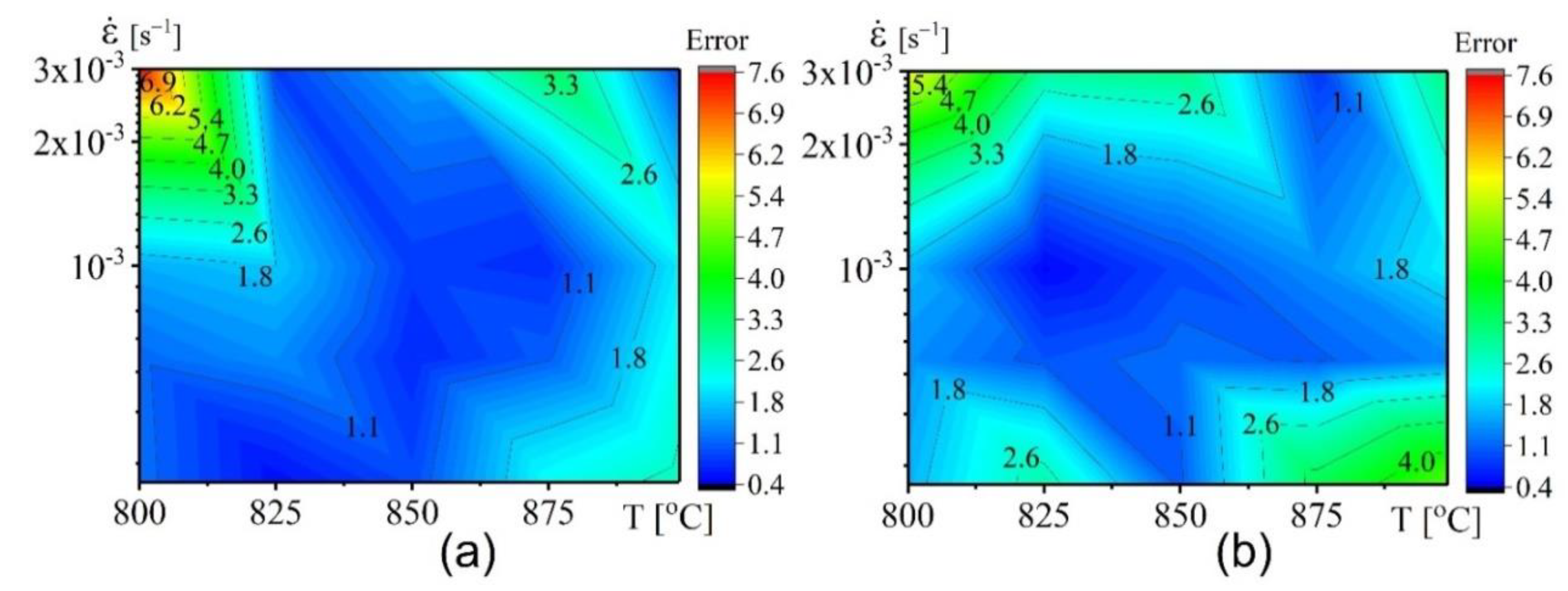

3.3.3. Cross-Approval of the Suggested Models

4. Discussion

5. Conclusions

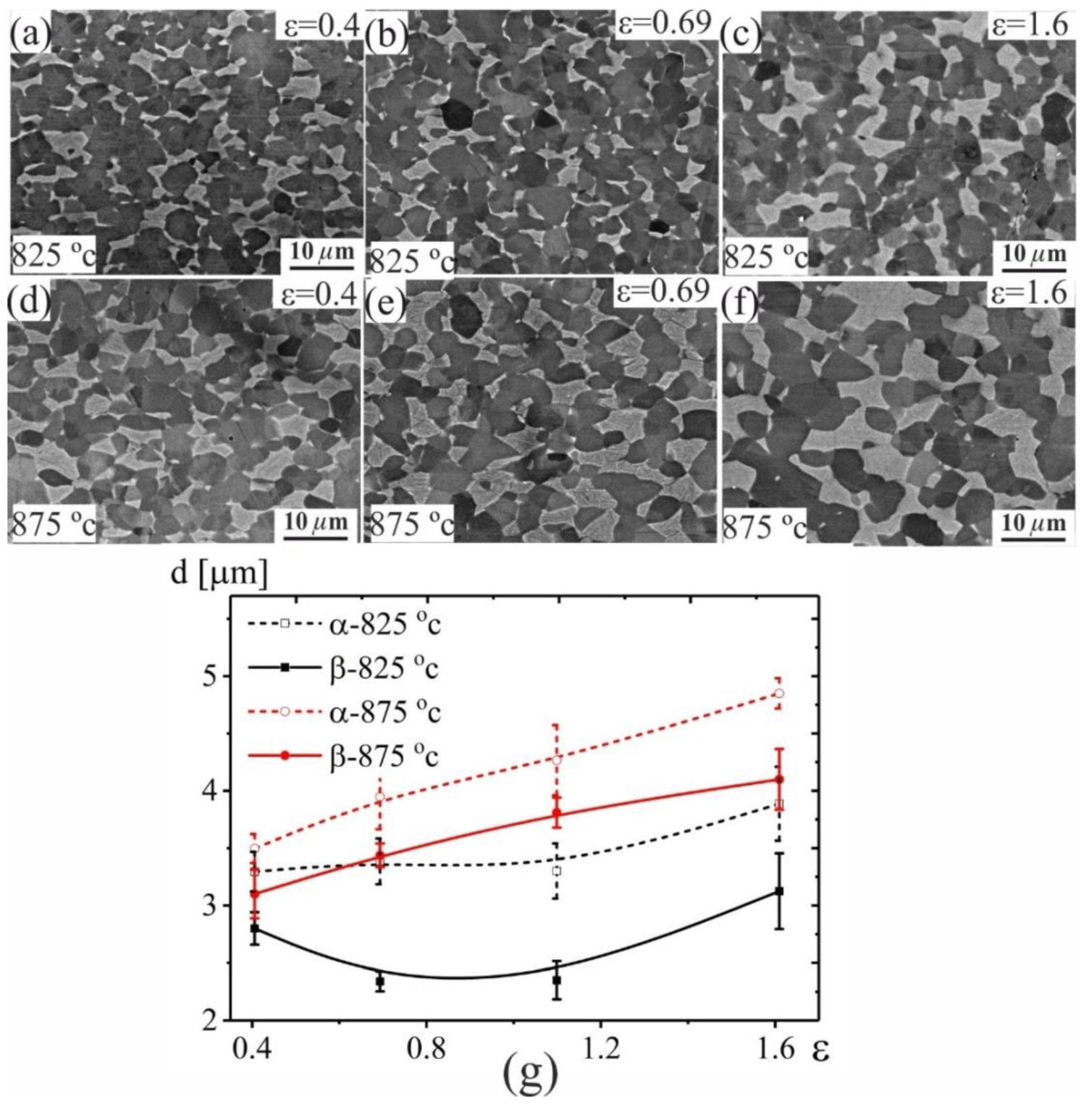

- For the studied alloy composition, the experimental and Thermo-Calc calculated β-phase fraction vs. temperature was in agreement, and the α/β fraction changed from ≈ 80/20 at 750 to ≈ 40/60 at 900 °C. The α-grain size slightly increased from 3.2 ± 0.20 to 3.9 ± 0.25 μm while the β-grains grew significantly from 1.8 ± 0.20 to 4.2 ± 0.20 μm with an increase in annealing temperature from 750 to 900 °C. For the β-grains, a significant temperature-induced grain growth by 2 folds was observed in a temperature range of 850–900 °C.

- The alloy demonstrated superplasticity in a strain rate range of 6 × 10−4–3 × 10−3 s−1 and in a temperature range of 800–900 °C. An elongation-to-failure ˃ 400% and m-value ˃ 0.45 were observed. The considerably low optimal deformation temperature of 825 °C, which provided the maximum superplastic elongation, was established. Due to the fine-structure and its stability during superplastic deformation, a maximum elongation–to-failure of 635% and stable flow with strain hardening coefficient close to zero were achieved at a constant strain rate of 1 × 10−3 s−1 and a temperature of 825 °C. Increasing temperature with decreasing strain rate led to dynamic grain growth and decreased superplastic elongations.

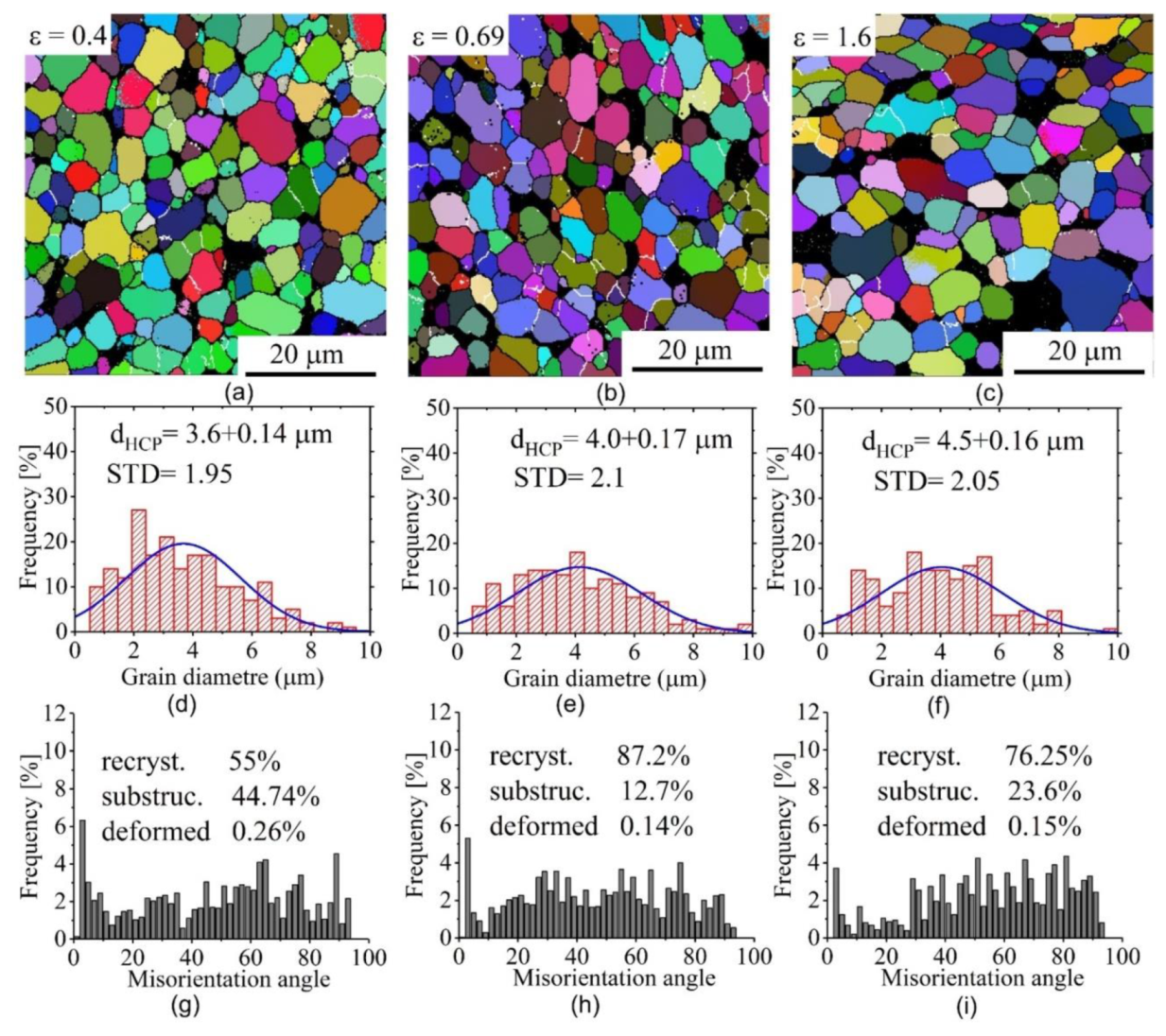

- The recrystallization process was not finished before the superplastic deformation process commenced. Continuous dynamic recrystallization accompanied by decreasing volume fraction of low angle grain boundaries occurred at superplastic deformation, as shown by the EBSD study.

- A comparison of the experimental and approximated flow stresses indicated that, the constitutive models based on both power law and hyperbolic sine equations exhibited high accuracy and good efficiency in fitting and approximating the superplastic deformation behaviour of the studied alloy. The predictability of both developed models was compared using the cross-validation approach. The constitutive model based on the power law equation exhibited excellent predictability of the stress-strain superplastic behaviour of the alloy.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol/Acronym | Full name | Symbol/Acronym | Full name |

| SPF | Superplastic forming | ε | True strain |

| CE | Constitutive equations | Deformation strain rate (s-1) | |

| R | correlation coefficient | T | Deformation temperature (°C) |

| AARE | mean absolute relative error | m | Strain rate sensitivity index |

| RMSE | root mean square error | GBS | Grain boundary sliding |

| ANN | artificial neural network | A, β, n1, n2 and α | Material constants |

| α | Titanium alpha-phase (HCP) | Q | Effective activation energy (kJ/mol) |

| β | Titanium beta phase (BCC) | R | gas constant 8.314 J/(mol·K). |

| SEM | Scanning electron microscope | α′ | Returned beta phase |

| LAGB | low-angle grain boundary | EBSD | Electron backscatter diffraction |

| σ | Flow stress (MPa) | HAGB | high-angle grain boundary |

References

- Langdon, T.G. The physics of superplastic deformation. Mater. Sci. Eng. A 1991, 137, 1–11. [Google Scholar] [CrossRef]

- Kawasaki, M.; Langdon, T.G. Superplasticity in ultrafine-grained materials. Rev. Adv. Mater. Sci. 2018, 54, 46–55. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium an Titanium Alloys, Wiley-VCH: Weinheim, Germany, 2002; ISBN 3527305343.

- Sieniawski, J.; Motyka, M. Superplasticity in titanium alloys. J. Achiev. Mater. Manuf. Eng. 2007, 24, 123–130. [Google Scholar]

- Nieh, T.G.; Wadsworth, J.; Sherby, O.D. Superplasticity in metals and ceramics; Cambridge University Press: New York, NY, USA, 2014; ISBN 9780874216561. [Google Scholar]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer US: Berlin (Deutschland), Germany, 2003; ISBN 1073-5623. [Google Scholar]

- Kaibyshev, O.A. Superplasticity of Alloys, Intermetallides and Ceramics, Springer-Verlag: Berlin/Heidelberg, Germany, 1992; ISBN 978-3-642-84675-5.

- Alabort, E.; Putman, D.; Reed, R.C. Superplasticity in Ti-6A-4V : Characterisation, modelling and applications. Acta Mater. 2015, 95, 428–442. [Google Scholar] [CrossRef]

- Alabort, E.; Kontis, P.; Barba, D.; Dragnevski, K.; Reed, R.C. On the mechanisms of superplasticity in Ti-6Al-4V. Acta Mater. 2016, 105, 449–463. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G.; Prasad, Y.V.R.K. Hot working of commercial Ti–6Al–4V with an equiaxed α–β microstructure: materials modeling considerations. Mater. Sci. Eng. A 2000, 284, 184–194. [Google Scholar] [CrossRef]

- Matsumoto, H.; Nishihara, T.; Velay, V.; Vidal, V. Superplastic Property of the Ti–6Al–4V Alloy with Ultrafine-Grained Heterogeneous Microstructure. Adv. Eng. Mater. 2018, 20, 1–6. [Google Scholar] [CrossRef]

- Xiao, J.; Li, D.S.; Li, X.Q.; Deng, T.S. Constitutive modeling and microstructure change of Ti-6Al-4V during the hot tensile deformation. J. Alloys Compd. 2012, 541, 346–352. [Google Scholar] [CrossRef]

- Ko, Y.G.; Lee, C.S.; Shin, D.H.; Semiatin, S.L. Low-Temperature Superplasticity of Ultra-Fine-Grained Ti-6Al-4V Processed by Equal-Channel Angular Pressing. Metall. Mater. Trans. A 2006, 37, 381–391. [Google Scholar] [CrossRef]

- Gao, F.; Li, W.; Meng, B.; Wan, M.; Zhang, X.; Han, X. Rheological law and constitutive model for superplastic deformation of Ti-6Al-4V. J. Alloys Compd. 2017, 701, 177–185. [Google Scholar] [CrossRef]

- Mosleh, A.O.; Mikhaylovskaya, A.; Kotov, A.D.; AbuShanab, W.; Moustafa, E.; Portnoy, V. Experimental Investigation of the Effect of Temperature and Strain Rate on the Superplastic Deformation Behavior of Ti-Based Alloys in the (α+β) Temperature Field. Metals 2018, 8, 819. [Google Scholar] [CrossRef]

- Vanderhasten, M.; Rabet, L.; Verlinden, B. Deformation mechanisms of Ti-6Al-4V during tensile behavior at low strain rate. J. Mater. Eng. Perform. 2007, 16, 208–212. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Zhao, Q.; Zhao, Y.; Li, R.; Zeng, W. In-situ observations of the tensile deformation and fracture behavior of a fine-grained titanium alloy sheet. J. Alloys Compd. 2018, 740, 660–668. [Google Scholar] [CrossRef]

- Liu, Q.; Hui, S.; Tong, K.; Yu, Y.; Ye, W.; Song, S. yin Investigation of high temperature behavior and processing map of Ti-6Al-4V-0.11Ru titanium alloy. J. Alloys Compd. 2019, 787, 527–536. [Google Scholar] [CrossRef]

- Jha, J.S.; Toppo, S.P.; Singh, R.; Tewari, A.; Mishra, S.K. Flow stress constitutive relationship between lamellar and equiaxed microstructure during hot deformation of Ti-6Al-4V. J. Mater. Process. Technol. 2019, 270, 216–227. [Google Scholar] [CrossRef]

- Tchein, G.J.; Jacquin, D.; Aldanondo, E.; Coupard, D.; Gutierrez-Orrantia, E.; Girot Mata, F.; Lacoste, E. Analytical modeling of hot behavior of Ti-6Al-4V alloy at large strain. Mater. Des. 2019, 161, 114–123. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.; Zhang, W.; Wang, W. A finite-strain thermomechanical model for severe superplastic deformation of Ti-6Al-4V at elevated temperature. J. Alloys Compd. 2019, 787, 1336–1344. [Google Scholar] [CrossRef]

- Zhou, G.; Chen, L.; Liu, L.; Liu, H.; Peng, H.; Zhong, Y. Low-Temperature Superplasticity and Deformation Mechanism of Ti-6Al-4V Alloy. Materials (Basel) 2018, 11, 1212. [Google Scholar] [CrossRef]

- Akihiko, C. Superplasticity of the Ultrafine-Grained Ti-6A Al-4V Alloy with a Metas stable -Single Phase Microstructure. Proc. 13th World Conf. Titan. 2016, 789–792. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Kudryavtsev, E.A.; Salishchev, G.A.; Straumal, B.B.; Semiatin, S.L. Microstructure evolution and mechanical behavior of ultrafine Ti6Al4V during low-temperature superplastic deformation. Acta Mater. 2016, 121, 152–163. [Google Scholar] [CrossRef]

- Yang, P.R.; Cai, M.H.; Wu, C.F.; Su, J.H.; Guo, X.P. Strain-rate dependent hot deformation behavior and mechanism of interphase- precipitated Ti-Mo-xNb steels: Physical modeling and characterization. Mater. Sci. Eng. A 2018, 729, 230–240. [Google Scholar] [CrossRef]

- Wang, X.D.; Pan, Q.L.; Xiong, S.W.; Liu, L.L.; Sun, Y.W.; Wang, W.Y. Prediction on hot deformation behavior of spray-formed 7055 aluminum alloy via phenomenological models. Trans. Nonferrous Met. Soc. China 2018, 28, 1484–1494. [Google Scholar] [CrossRef]

- Cai, J.; Li, F.; Liu, T.; Chen, B.; He, M. Constitutive equations for elevated temperature flow stress of Ti–6Al–4V alloy considering the effect of strain. Mater. Des. 2011, 32, 1144–1151. [Google Scholar] [CrossRef]

- Mosleh, A.O.; Mikhaylovskaya, A.V.; Kotov, A.D.; Portnoy, V.K. Arrhenius-Type Constitutive Equation Model of Superplastic Deformation Behaviour of Different Titanium Based Alloys. Defect Diffus. Forum 2018, 385, 45–52. [Google Scholar] [CrossRef]

- Malinov, S.; Sha, W. Application of artificial neural networks for modelling correlations in titanium alloys. Mater. Sci. Eng. A 2004, 365, 202–211. [Google Scholar] [CrossRef]

- Ji, G.; Li, F.; Li, Q.; Li, H.; Li, Z. A comparative study on Arrhenius-type constitutive model and artificial neural network model to predict high-temperature deformation behaviour in Aermet100 steel. Mater. Sci. Eng. A 2011, 528, 4774–4782. [Google Scholar] [CrossRef]

- He, J.; Zhang, D.; Zhang, W.; Qiu, C.; Zhang, W. Constitutive equation and hot compression deformation behavior of homogenized Al-7.5Zn-1.5Mg-0.2Cu-0.2Zr alloy. Materials 2017, 10, 1193. [Google Scholar] [CrossRef]

- Hu, M.; Dong, L.; Zhang, Z.; Lei, X.; Yang, R.; Sha, Y. A Novel Computational Method of Processing Map for Ti-6Al-4V Alloy and Corresponding Microstructure Study. Materials 2018, 11, 1599. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Porntadawit, J.; Uthaisangsuk, V.; Choungthong, P. Modeling of flow behavior of Ti-6Al-4V alloy at elevated temperatures. Mater. Sci. Eng. A 2014, 599, 212–222. [Google Scholar] [CrossRef]

- Yamanaka, K.; Matsumoto, H.; Chiba, A. A Constitutive Model and Processing Maps Describing the High-Temperature Deformation Behavior of Ti-17 Alloy in the beta-Phase Field. Adv. Eng. Mater. 2018, 1800775, 1–8. [Google Scholar]

- Xiao, Y.; Liu, H.; Yi, D.; Le, J.; Zhou, H.; Jiang, Y.; Zhao, X.; Chen, Z.; Wang, J.; Gao, Q. High-Temperature Deformation Behavior of Ti-6Al-2Sn-4Zr-2Mo Alloy with Lamellar Microstructure Under Plane-Strain Compression. J. Mater. Eng. Perform. 2018, 27, 4941–4954. [Google Scholar] [CrossRef]

- Mosleh, A.; Mikhaylovskaya, A.; Kotov, A.; Pourcelot, T.; Aksenov, S.; Kwame, J.; Portnoy, V. Modelling of the Superplastic Deformation of the Near-α Titanium Alloy (Ti-2.5Al-1.8Mn) Using Arrhenius-Type Constitutive Model and Artificial Neural Network. Metals 2017, 7, 568. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Yang, X.; Guo, H.; Liang, H.; Yao, Z.; Yuan, S. Flow Behavior and Constitutive Equation of Ti-6.5Al-2Sn-4Zr-4Mo-1W-0.2Si Titanium Alloy. J. Mater. Eng. Perform. 2016, 25, 1347–1359. [Google Scholar] [CrossRef]

- Mahmudi, R.; Rezaee-Bazzaz, A.; Banaie-Fard, H.R. Investigation of stress exponent in the room-temperature creep of Sn-40Pb-2.5Sb solder alloy. J. Alloys Compd. 2007, 429, 192–197. [Google Scholar] [CrossRef]

- Langdon, T.G. Identifiying creep mechanisms at low stresses. Mater. Sci. Eng. A 2000, 283, 266–273. [Google Scholar] [CrossRef]

- Zelin, M.; Gershon, B.; Arbel, I. Grain growth during superplastic deformation. Interface Sci. 2002, 10, 37–42. [Google Scholar] [CrossRef]

- Gil, F.J.; Planell, J.A. Behaviour of normal grain growth kinetics in single phase titanium and titanium alloys. Mater. Sci. Eng. A 2000, 283, 17–24. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Mosleh, A.O.; Kotov, A.D.; Kwame, J.S.; Pourcelot, T.; Golovin, I.S.; Portnoy, V.K. Superplastic deformation behaviour and microstructure evolution of near-α Ti-Al-Mn alloy. Mater. Sci. Eng. A 2017, 708, 469–477. [Google Scholar] [CrossRef]

- Imai, H.; Yamane, G.; Matsumoto, H.; Vidal, V.; Velay, V. Superplasticity of metastable ultrafine-grained Ti 6242S alloy: Mechanical flow behavior and microstructural evolution. Mater. Sci. Eng. A 2019, 754, 569–580. [Google Scholar] [CrossRef] [Green Version]

- Despax, L.; Vidal, V.; Delagnes, D.; Dehmas, M.; Geyer, M.; Matsumoto, H.; Velay, V. Superplasticity in fine grain Ti-6Al-4V alloy: Mechanical behavior and microstructural evolution. Defect Diffus. Forum 2018, 385, 137–143. [Google Scholar] [CrossRef]

- Guo, W.; Jia, Q.; Li, R.; Li, W. The Superplastic Deformation Behavior and Phase Evolution of Ti-6Al-4V Alloy at Constant Tensile Velocity. High Temp. Mater. Process. 2017, 36. [Google Scholar] [CrossRef]

- Ghasemi, E.; Jäger, A.; Zarei-Hanzaki, A.; Rezaee, M.; Farabi, E.; Tesař, K. Flow softening and dynamic recrystallization behavior of BT9 titanium alloy: A study using process map development. J. Alloys Compd. 2016, 695, 1706–1718. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhailovskaya, A.V.; Mosleh, A.O.; Pourcelot, T.P. Superplasticity of an Ultrafine-Grained Ti–4% Al–1% V–3% Mo Titanium Alloy. Phys. Met. Metallogr. 2019, 120, 66–74. [Google Scholar] [CrossRef]

- Hémery, S.; Villechaise, P. In situ EBSD investigation of deformation processes and strain partitioning in bi-modal Ti-6Al-4V using lattice rotations. Acta Mater. 2019, 171, 261–274. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Ghosh, A.K. Plastic Flow, Microstructure Evolution, and Defect Formation during Primary Hot Working of Titanium and Titanium Aluminide Alloys with Lamellar Colony Microstructures. Philos. Trans. Math. Phys. Eng. Sci. 2013, 357, 1487–1512. [Google Scholar] [CrossRef]

| Uniaxial Tensile Test Type | Temperature (°C) | Strain Rate (s−1) |

|---|---|---|

| Step-by-step decreasing in strain rate | 750–900 | 10–5 - 10–2 |

| Constant strain rate | 800–900 | 3×10−4 - 3×10−3 |

| ln(A1) | n1/m * | Q1 [KJ/mol] | ln(A2) | β [MPa−1] | Q2 [KJ/mol] | α | ln(A3) | n2 | Q3 [KJ/mol] |

|---|---|---|---|---|---|---|---|---|---|

| 10.22 | 2.5/0.4 | 250.6 | 13.6 | 0.05 | 220.4 | 0.019 | 19 | 1.97 | 242 |

| Parameter | Y0 | B1 | B2 | B3 |

|---|---|---|---|---|

| 0.024 | −0.017 | 0.017 | −0.004 | |

| 1.516 | 3.243 | −2.784 | 3.064 | |

| 1.167 | 2.480 | −2.153 | 2.355 | |

| 10.607 | 3.451 | −12.319 | 3.372 | |

| 15.16 | 15.99 | −21.95 | 15.06 | |

| 212.00 | 159.94 | −218.74 | 143.11 | |

| 204.71 | 154.28 | −217.34 | 154.6 |

| Trial Number | Excluded Conditions | Trial Number | Excluded Conditions | ||

|---|---|---|---|---|---|

| T (°C) | (s−1) | T (°C) | (s−1) | ||

| Trial 1 | 800 | 3 × 10−4 | Trial 11 | 850 | 1 × 10−3 |

| Trial 2 | 800 | 6 × 10−4 | Trial 12 | 850 | 3 × 10−3 |

| Trial 3 | 800 | 1 × 10−3 | Trial 13 | 875 | 3 × 10−4 |

| Trial 4 | 800 | 3 × 10−3 | Trial 14 | 875 | 6 × 10−4 |

| Trial 5 | 825 | 3 × 10−4 | Trial 15 | 875 | 1 × 10−3 |

| Trial 6 | 825 | 6 × 10−4 | Trial 16 | 875 | 3 × 10−3 |

| Trial 7 | 825 | 1 × 10−3 | Trial 17 | 900 | 3 × 10−4 |

| Trial 8 | 825 | 3 × 10−3 | Trial 18 | 900 | 6 × 10−4 |

| Trial 9 | 850 | 3 × 10−4 | Trial 19 | 900 | 1 × 10−3 |

| Trial 10 | 850 | 6 × 10−4 | Trial 20 | 900 | 3 × 10−3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mosleh, A.O.; Mikhaylovskaya, A.V.; Kotov, A.D.; Kwame, J.S.; Aksenov, S.A. Superplasticity of Ti-6Al-4V Titanium Alloy: Microstructure Evolution and Constitutive Modelling. Materials 2019, 12, 1756. https://doi.org/10.3390/ma12111756

Mosleh AO, Mikhaylovskaya AV, Kotov AD, Kwame JS, Aksenov SA. Superplasticity of Ti-6Al-4V Titanium Alloy: Microstructure Evolution and Constitutive Modelling. Materials. 2019; 12(11):1756. https://doi.org/10.3390/ma12111756

Chicago/Turabian StyleMosleh, Ahmed O., Anastasia V. Mikhaylovskaya, Anton D. Kotov, James S. Kwame, and Sergey A. Aksenov. 2019. "Superplasticity of Ti-6Al-4V Titanium Alloy: Microstructure Evolution and Constitutive Modelling" Materials 12, no. 11: 1756. https://doi.org/10.3390/ma12111756

APA StyleMosleh, A. O., Mikhaylovskaya, A. V., Kotov, A. D., Kwame, J. S., & Aksenov, S. A. (2019). Superplasticity of Ti-6Al-4V Titanium Alloy: Microstructure Evolution and Constitutive Modelling. Materials, 12(11), 1756. https://doi.org/10.3390/ma12111756