Development of Hot-Extruded Mg–RE–Zn Alloy Bar with High Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

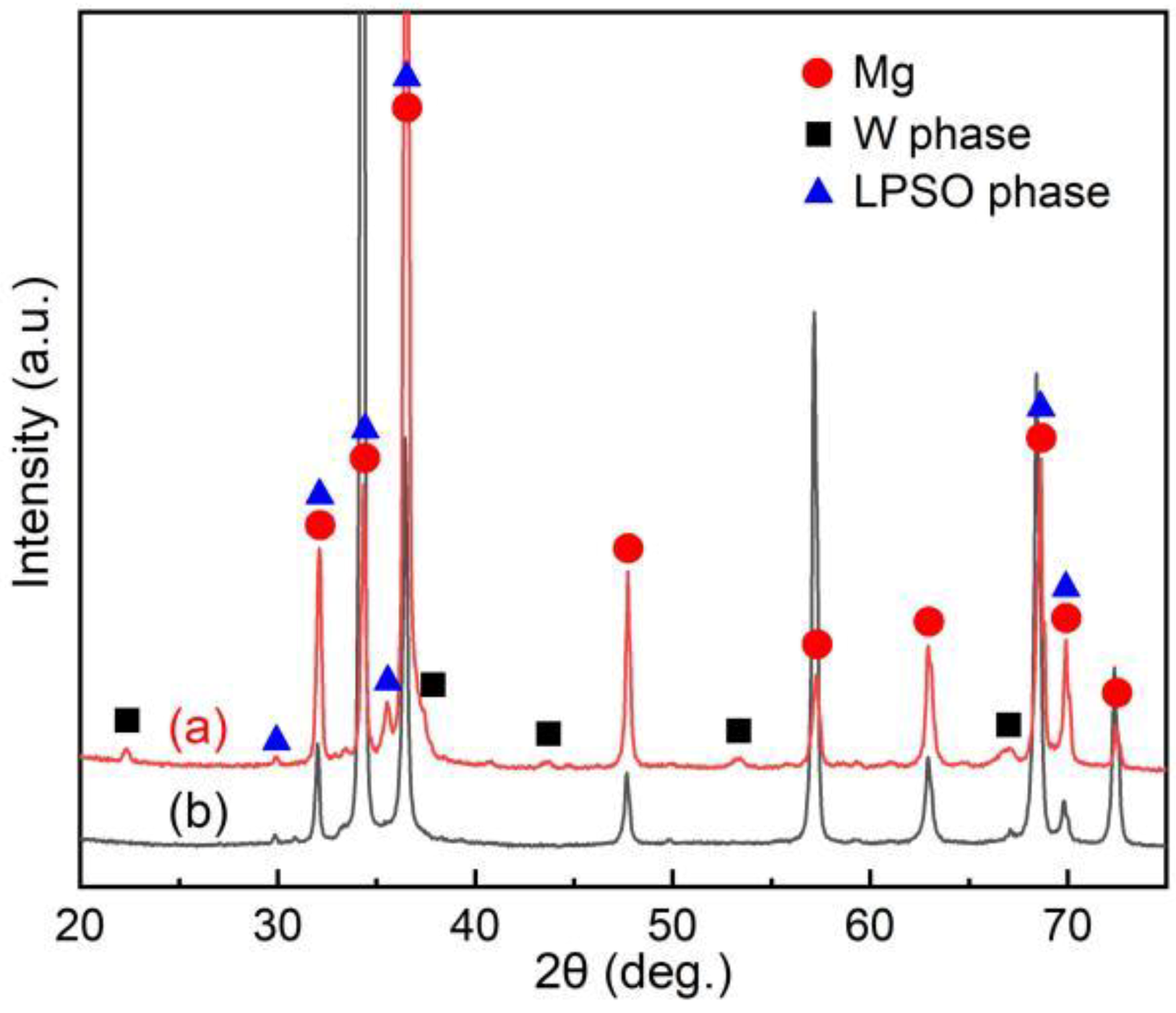

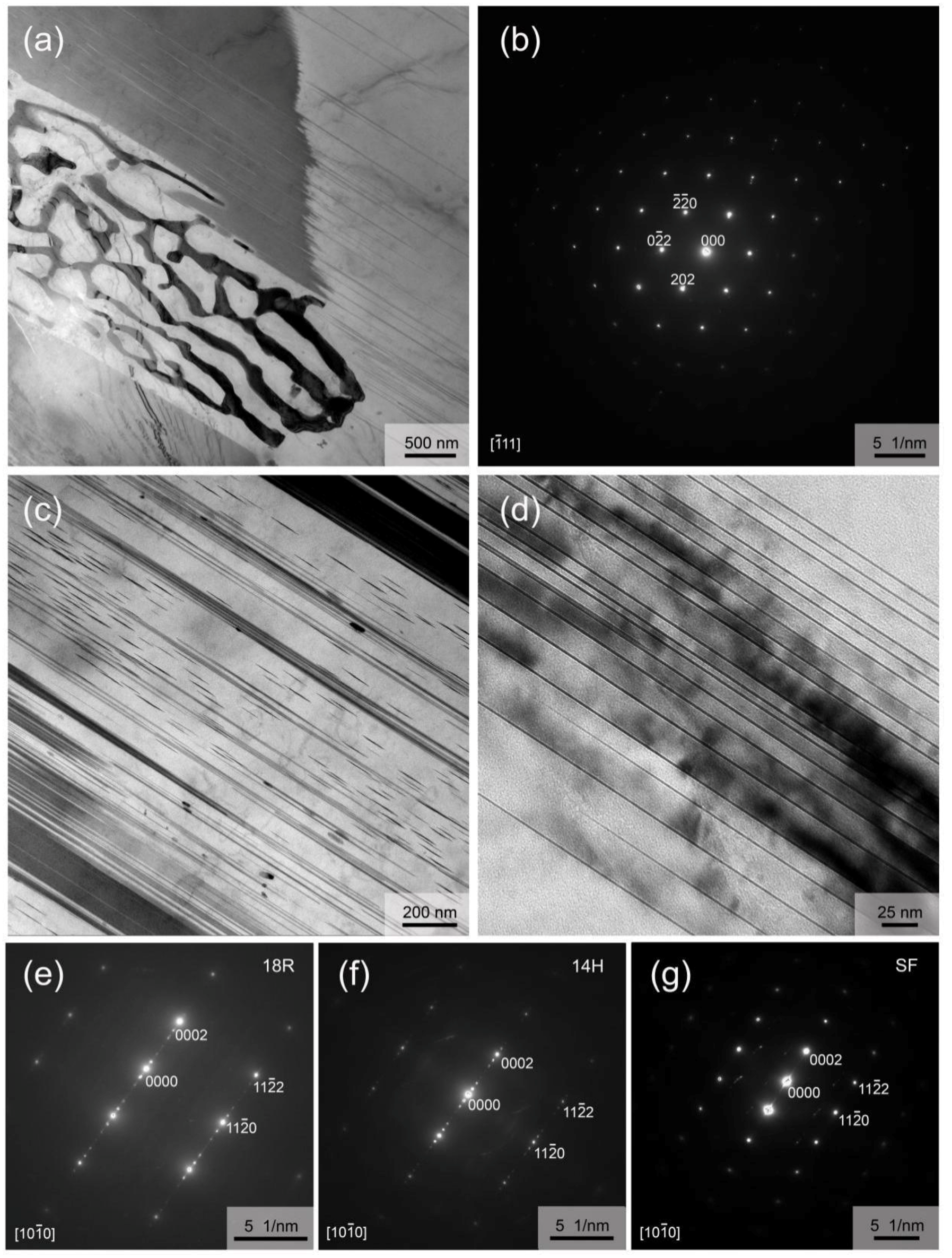

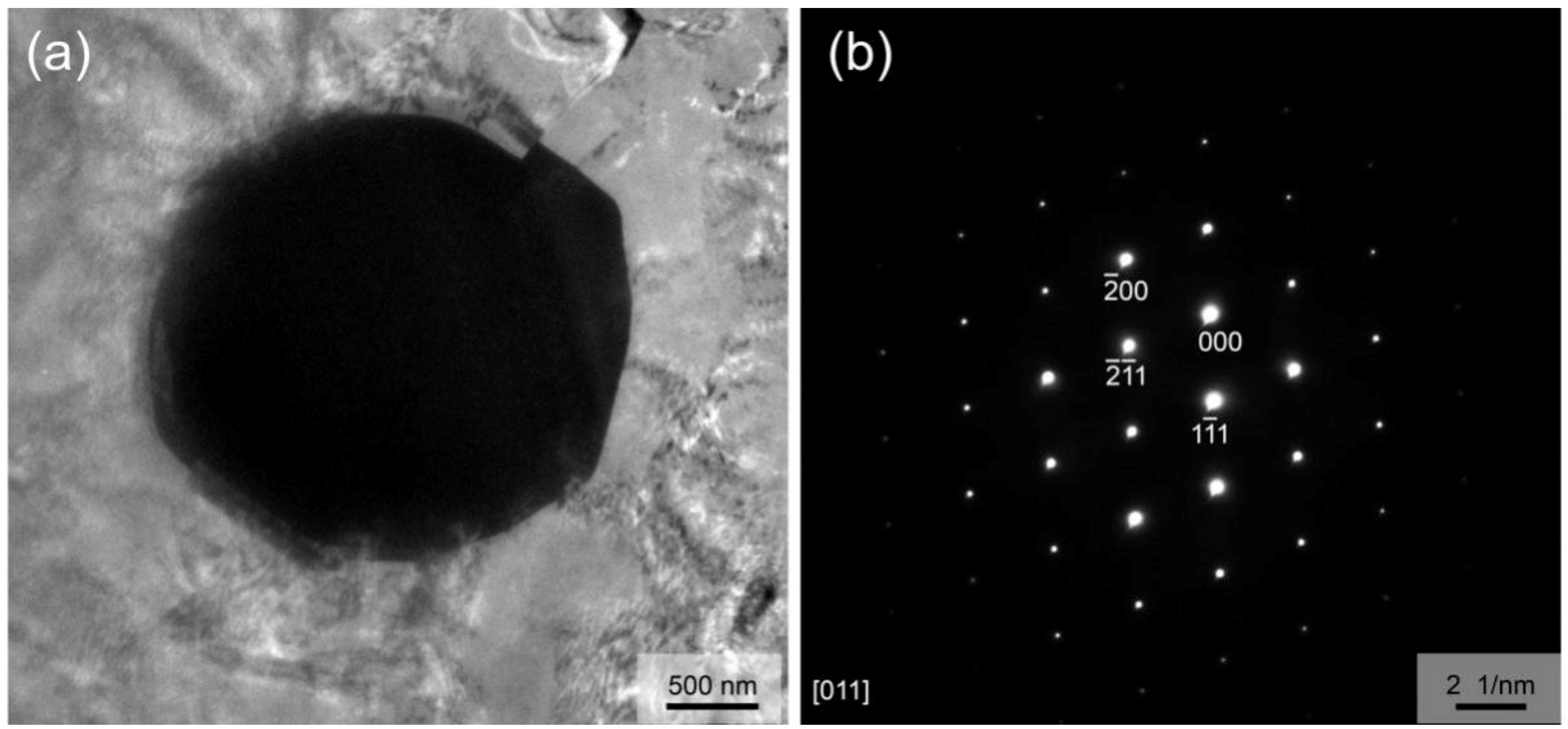

3.1. Microstructure of As-Cast Ingot

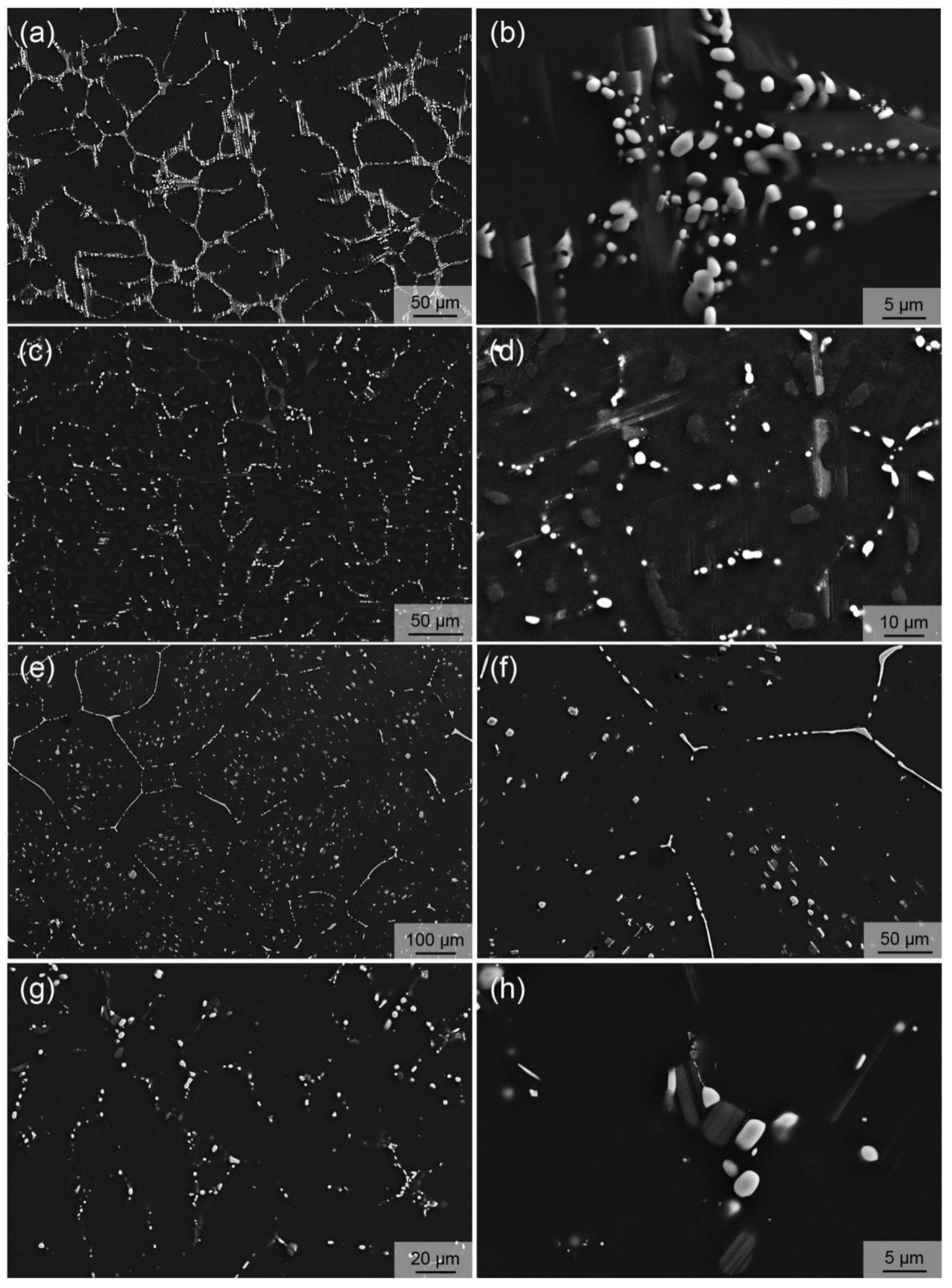

3.2. Microstructure of Solid Solution-Treated Alloys

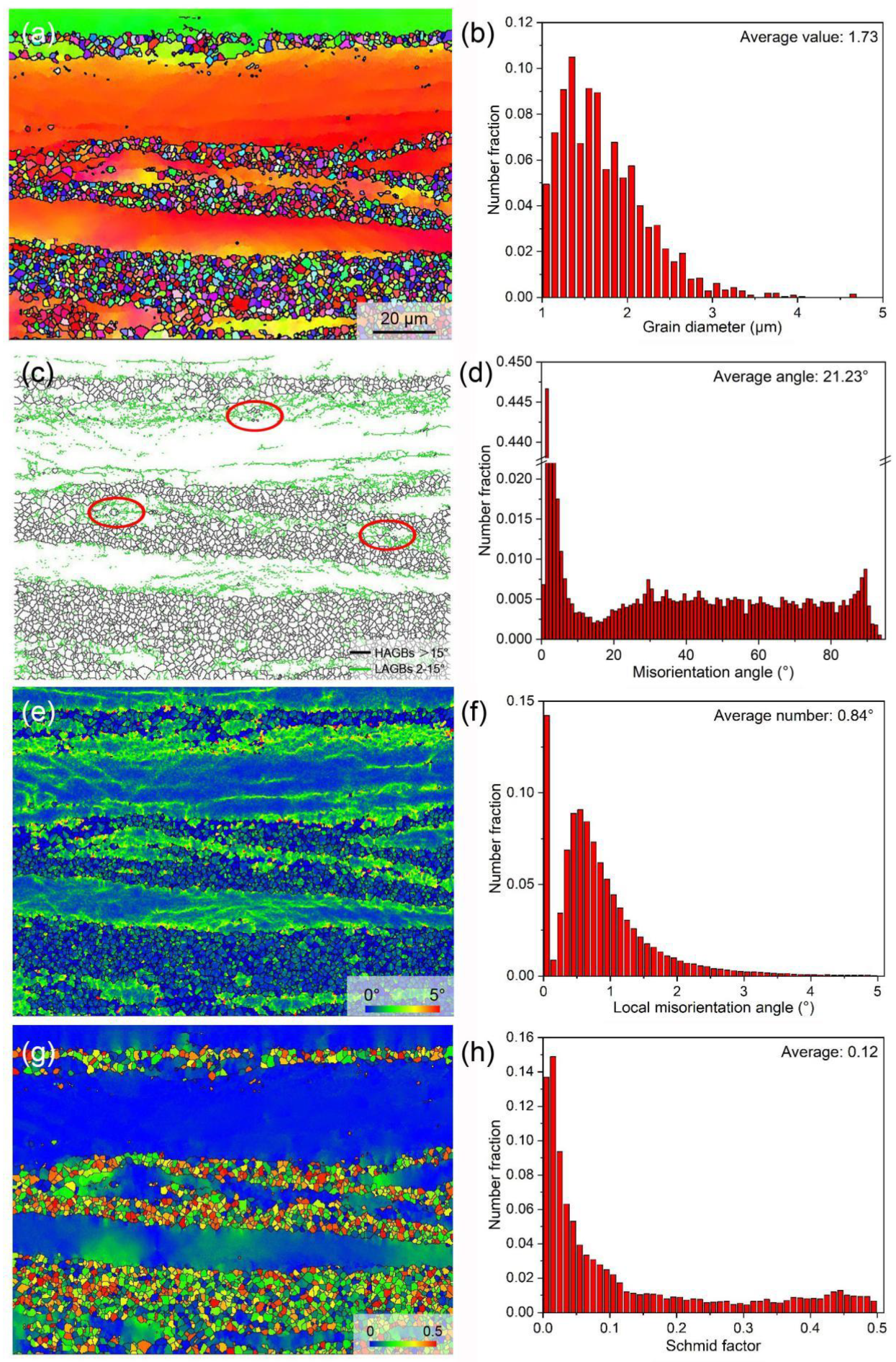

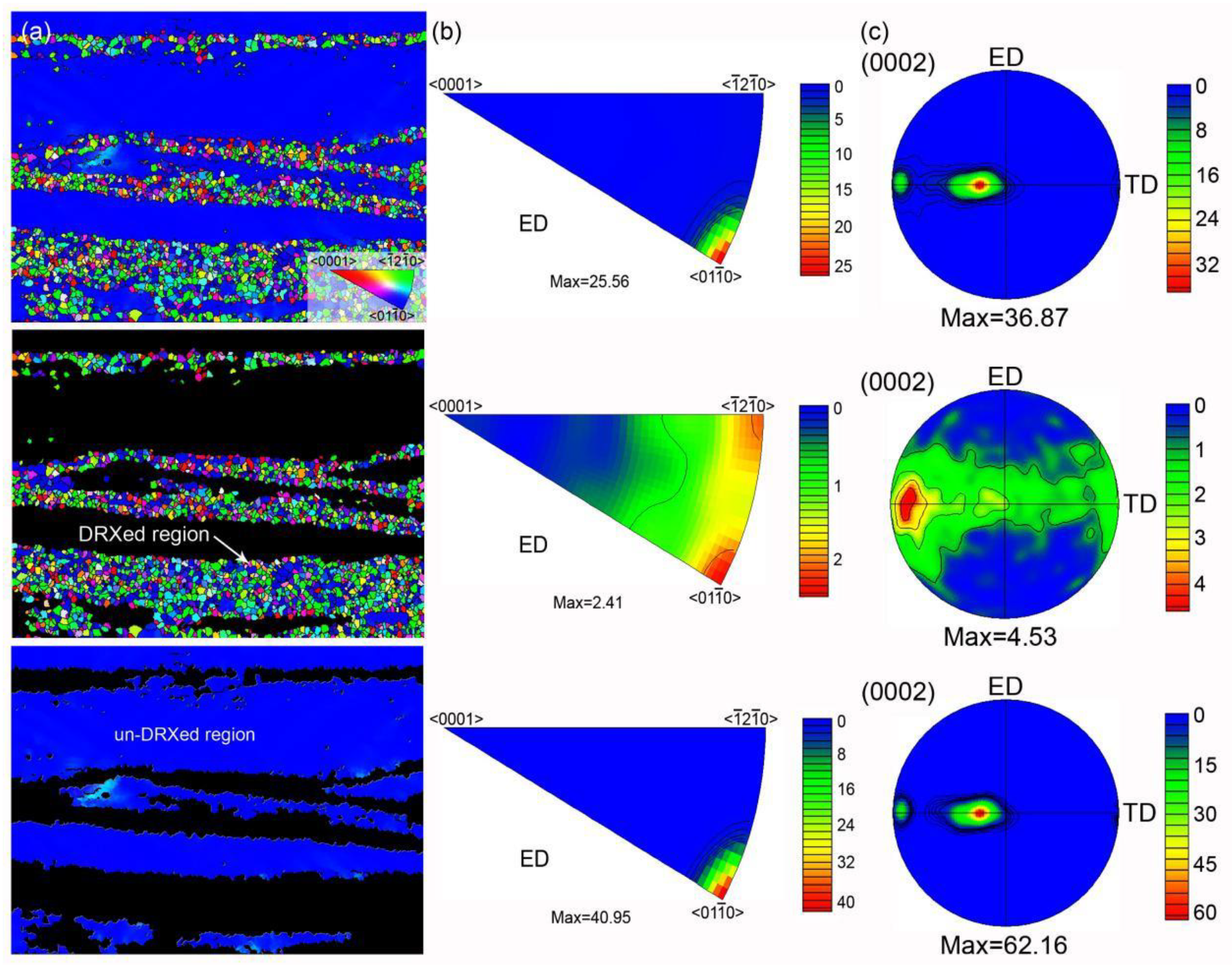

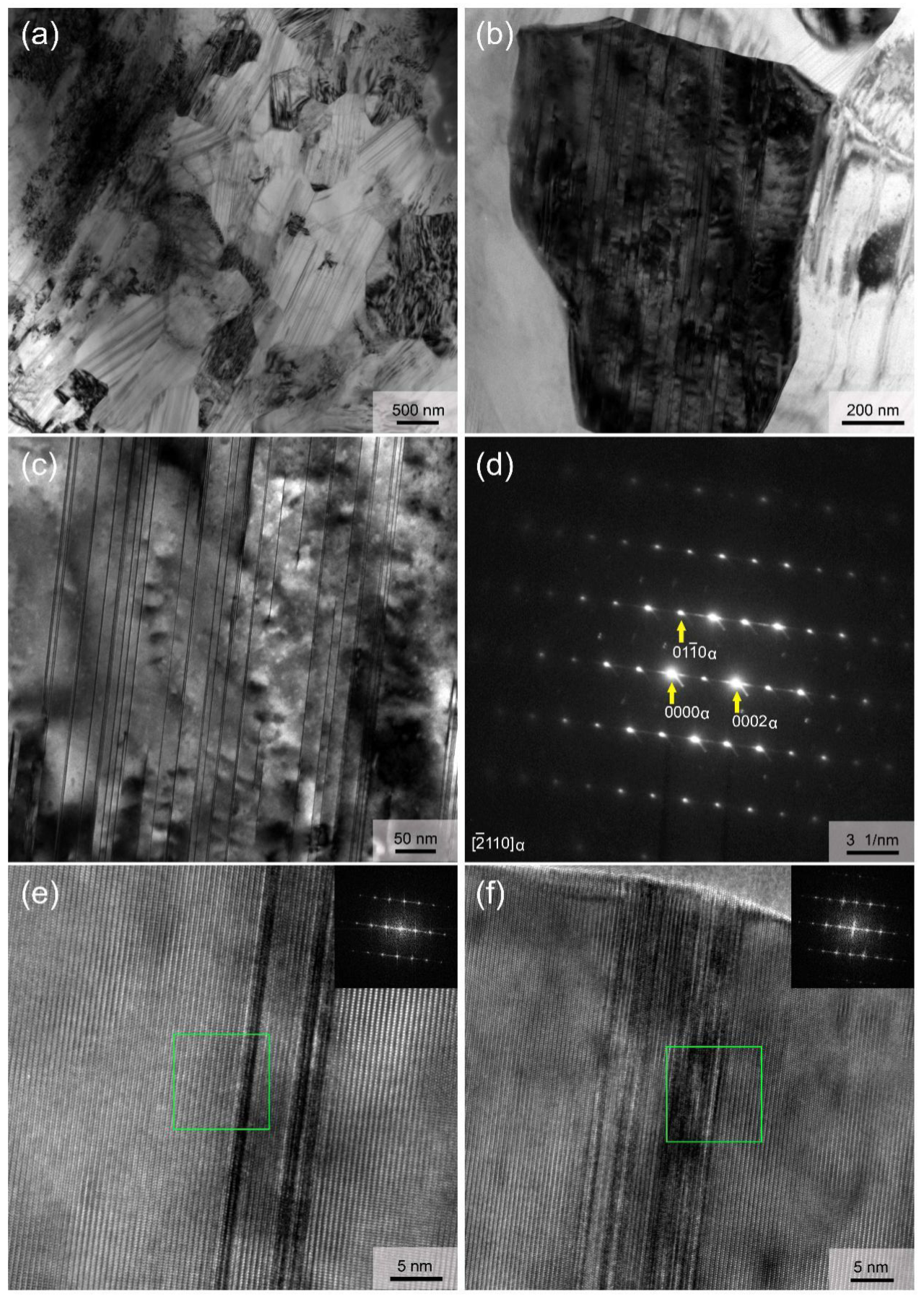

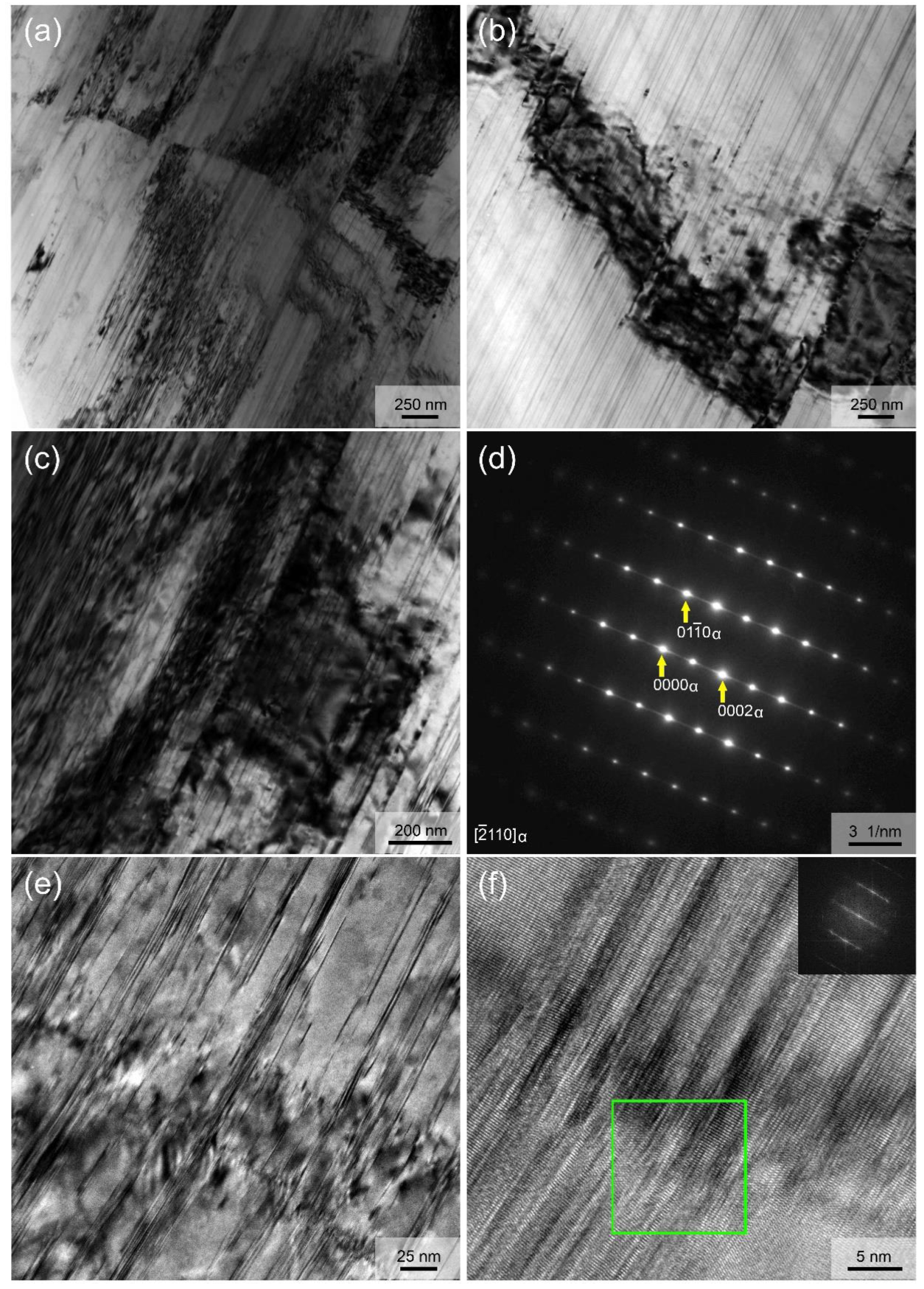

3.3. Microstructure of As-Extruded Alloy

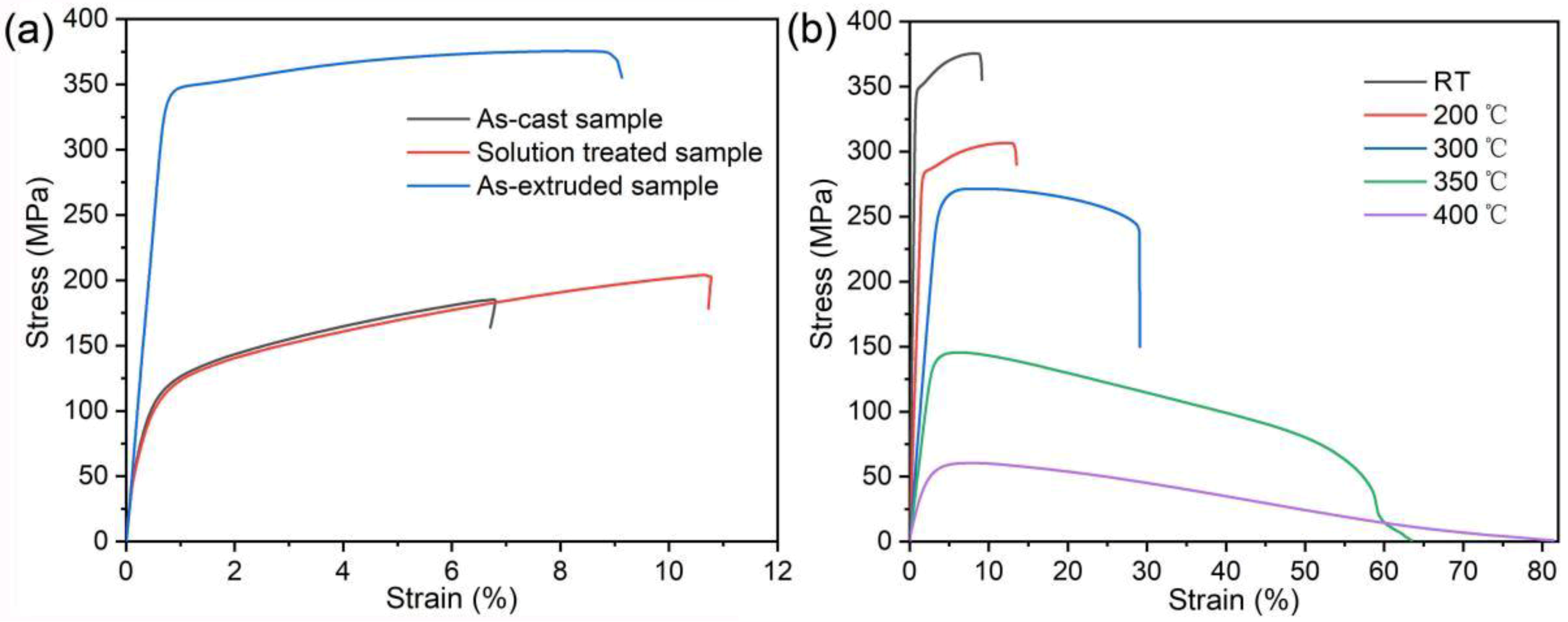

3.4. Mechanical Properties of the Studied Alloy

4. Conclusions

- (1)

- The mixed phases/structures of fcc W phase, 18R-LPSO phase, 14H-LPSO phase and basal plane SFs were formed in the as-cast alloy, mainly based on the alloy component of (Er + Y)/Zn = 1:1 and Er/Y = 1:1 (at %). Heat treatment at 530 °C for 10 h was effective in dissolving the secondary phases into the Mg matrix.

- (2)

- High number-density nanospaced basal plane SFs were formed throughout both the DRXed and un-DRXed grains during hot extrusion at 350 °C for the solid solution-treated alloy. This special feature is the combined effect of appropriate alloy composition and preparation process parameters.

- (3)

- The as-extruded alloy showed superior tensile properties from RT to 300 °C. The UTS and YS could be maintained above 300 MPa at RT, and above 250 MPa even at 300 °C. The excellent elevated-temperature strength is mainly related to the formation of (a) nanospaced basal plane SFs with a large aspect ratio throughout the whole Mg matrix, (b) fine DRXed grains with ~2 μm in size, and (c) strongly basal-textured un-DRXed with numerous substructures.

Author Contributions

Funding

Conflicts of Interest

References

- Fu, X.; Tan, M.; Jarfors, A.; Gupta, M. Processing and properties of amorphous magnesium-based eco-materials. MSF 2011, 695, 186. [Google Scholar] [CrossRef]

- Chen, L.; Xu, J.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.; Mathaudhu, S.; Li, X. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539–543. [Google Scholar] [CrossRef]

- Pollock, T. Weight loss with magnesium alloys. Science 2010, 328, 986–987. [Google Scholar] [CrossRef]

- Mordike, B.; Ebert, T. Magnesium: Properties—Applications—Potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Joost, W.; Krajewski, P. Towards magnesium alloys for high-volume automotive applications. Scr. Mater. 2017, 128, 107–112. [Google Scholar] [CrossRef]

- Wang, X.; Xu, D.; Wu, R.; Chen, X.; Peng, Q.; Jin, L.; Xin, Y.; Zhang, Z.; Liu, Y.; Chen, X.; et al. What is going on in magnesium alloys? J. Mater. Sci. Technol. 2018, 34, 245–247. [Google Scholar] [CrossRef]

- Trang, T.; Zhang, J.; Kim, J.; Zargaran, A.; Hwang, J.; Suh, B.; Kim, N. Designing a magnesium alloy with high strength and high formability. Nat. Commun. 2018, 9. [Google Scholar] [CrossRef]

- Jiang, Z.; Feng, J.; Chen, Q.; Jiang, S.; Dai, J.; Jiang, B.; Pan, F. Preparation and Characterization of Magnesium Alloy Containing Al2Y Particles. Materials 2018, 11, 1748. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Wu, R.; Feng, Y.; Liu, S.; Wang, X.; Jiao, Y.; Yang, Q.; Meng, J. Development of high mechanical properties and moderate thermal conductivity cast Mg alloy with multiple RE via heat treatment. J. Mater. Sci. Technol. 2018, 34, 1076–1084. [Google Scholar] [CrossRef]

- Peng, Q.; Sun, Y.; Ge, B.; Fu, H.; Zu, Q.; Tang, X.; Huang, J. Interactive contraction nanotwins-stacking faults strengthening mechanism of Mg alloys. Acta Mater. 2019, 169, 36–44. [Google Scholar] [CrossRef]

- Pekguleryuz, M.; Kaya, A. Creep Resistant Magnesium Alloys for Powertrain Applications. Adv. Eng. Mater. 2003, 5, 866–878. [Google Scholar] [CrossRef]

- Xu, C.; Nakata, K.; Oh-ishi, K.; Homma, T.; Ozaki, T.; Kamado, S. Improving creep property of Mg–Gd–Zn alloy via trace Ca addition. Scr. Mater. 2017, 139, 34–38. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, C.; Zheng, T.; Pan, F.; Tang, A. Strengthening Effects of Zn Addition on an Ultrahigh Ductility Mg-Gd-Zr Magnesium Alloy. Materials 2018, 11, 1942. [Google Scholar] [CrossRef]

- Amano, T. Rare earth application for heat-resisting alloys. J. Rare Earth 2010, 28, 12–21. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Wu, R.; Sun, J.; Jiao, Y.; Hou, L.; Zhang, J.; Li, X.; Zhang, M. Ambient-temperature mechanical properties of isochronally aged 1420-Sc-Zr aluminum alloy. Mater. Sci. Eng. A 2019, 745, 411–419. [Google Scholar] [CrossRef]

- Czerwinski, F. The reactive element effect on high-temperature oxidation of magnesium. Int. Mater. Rev. 2015, 60, 264–296. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Wu, R.; Hou, L.; Zhang, M. Recent developments in high-strength Mg-RE-based alloys: Focusing on Mg-Gd and Mg-Y systems. J. Magnes. Alloys 2018, 6, 277–291. [Google Scholar] [CrossRef]

- Guan, K.; Meng, F.; Qin, P.; Yang, Q.; Zhang, D.; Li, B.; Sun, W.; Lv, S.; Huang, Y.; Hort, N. Effects of samarium content on microstructure and mechanical properties of Mg-0.5Zn-0.5Zr alloy. J. Mater. Sci. Technol. 2019, 35, 1368–1377. [Google Scholar] [CrossRef]

- Li, B.; Guan, K.; Yang, Q.; Niu, X.; Zhang, D.; Lv, S.; Meng, F.; Huang, Y.; Hort, N.; Meng, J. Microstructures and mechanical properties of a hot-extruded Mg-8Gd-3Yb-1.2Zn-0.5Zr (wt%) alloy. J. Alloys Compd. 2019, 776, 666–678. [Google Scholar] [CrossRef]

- Singh, A.; Nakamura, M.; Watanabe, M.; Kato, A.; Tsai, A. Quasicrystal strengthened Mg–Zn–Y alloys by extrusion. Scr. Mater. 2003, 49, 417–422. [Google Scholar] [CrossRef]

- Jiang, H.; Qiao, X.; Xu, C.; Zheng, M.; Wu, K.; Kamado, S. Ultrahigh strength as-extruded Mg-10.3Zn-6.4Y-0.4Zr-0.5Ca alloy containing W phase. Mater. Des. 2016, 108, 391–399. [Google Scholar] [CrossRef]

- Garces, G.; Cabeza, S.; Barea, R.; Pérez, P.; Adeva, P. Maintaining High Strength in Mg-LPSO Alloys with Low Yttrium Content Using Severe Plastic Deformation. Materials 2018, 11, 733. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, J.; Kong, P.; Zhang, Z.; Jing, Y.; Zhuang, J.; Wang, W.; Zhang, L.; Xu, C.; Wu, R.; et al. Enhancing the performance of Mg-based implant materials by introducing basal plane stacking faults. J. Mater. Chem. B 2015, 3, 7386–7400. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, C.; Jing, Y.; Lv, S.; Liu, S.; Fang, D.; Zhuang, J.; Zhang, M.; Wu, R. New horizon for high performance Mg-based biomaterial with uniform degradation behavior: Formation of stacking faults. Sci. Rep. 2015, 5, 13933. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Geng, L.; Huang, L.; Zhang, X.; Dong, C. Enhanced Mechanical Properties in Fine Grained Mg-1.0Zn-0.5Ca Alloys Prepared by Extrusion at Different Temperatures. Scr. Mater. 2010, 63, 1024–1027. [Google Scholar] [CrossRef]

- Meng, S.; Yu, H.; Fan, S.; Li, Q.; Park, S.; Suh, J.; Kim, Y.; Nan, X.; Bian, M.; Yin, F. Recent Progress and Development in Extrusion of Rare Earth Free Mg Alloys. Acta Met. Sin. 2019, 32, 145–168. [Google Scholar] [CrossRef]

- Kawamura, Y.; Hayashi, K.; Inoue, A.; Masumoto, T. Rapidly solidified powder metallurgy Mg97Zn1Y2 Alloys with excellent tensile yield strength above 600 MPa. Mater. Trans. 2001, 42, 1172–1176. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, J.; Leng, Z.; Liu, S.; Yang, Q.; Wu, R.; Zhang, M. Microstructure and mechanical properties of high-performance Mg-Y-Er-Zn extruded alloy. Mater. Des. 2014, 54, 256–263. [Google Scholar] [CrossRef]

- Gandel, D.; Easton, M.; Gibson, M.; Birbilis, N. CALPHAD simulation of the Mg-(Mn, Zr)-Fe system and experimental comparison with as-cast alloy microstructures as relevant to impurity driven corrosion of Mg-alloys. Mater. Chem. Phys. 2014, 143, 1082–1091. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, X.; Hu, W.; Li, J.; Le, Q.; Bao, L.; Zhu, Z.; Cui, J. Microstructures, mechanical properties and corrosion behaviors of Mg-Y-Zn-Zr alloys with specific Y/Zn mole ratios. J. Alloys Compd. 2015, 624, 116–125. [Google Scholar] [CrossRef]

- Zhu, Y.; Morton, A.; Nie, J. The 18R and 14H long-period stacking ordered structures in Mg-Y-Zn alloys. Acta Mater. 2010, 58, 2936–2947. [Google Scholar] [CrossRef]

- Yamasaki, M.; Sasaki, M.; Nishijima, M.; Hiraga, K.; Kawamura, Y. Formation of 14H long period stacking ordered structure and profuse stacking faults in Mg-Zn-Gd alloys during isothermal aging at high temperature. Acta Mater. 2007, 55, 6798–6805. [Google Scholar] [CrossRef]

- Shao, X.; Yang, Z.; Ma, X. Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure. Acta Mater. 2010, 58, 4760–4771. [Google Scholar] [CrossRef]

- Yu, Z.; Xu, C.; Meng, J.; Zhang, X.; Kamado, S. Effects of pre-annealing on microstructure and mechanical properties of as-extruded Mg-Gd-Y-Zn-Zr alloy. J. Alloys Compd. 2017, 729, 627–637. [Google Scholar] [CrossRef]

- Wu, S.; Oh-ishi, K.; Kamado, S.; Homma, T. Twins, recrystallization and texture evolution of a Mg-5.99Zn-1.76Ca-0.35Mn (wt.%) alloy during indirect extrusion process. Scr. Mater. 2011, 65, 875–878. [Google Scholar]

- Shao, X.; Peng, Z.; Jin, Q.; Ma, X. Atomic-scale segregations at the deformation-induced symmetrical boundary in an Mg-Zn-Y alloy. Acta Mater. 2016, 118, 177–186. [Google Scholar] [CrossRef]

- Xu, C.; Nakata, T.; Qiao, X.; Zheng, M.; Wu, K.; Kamado, S. Effect of LPSO and SFs on microstructure evolution and mechanical properties of Mg-Gd-Y-Zn-Zr alloy. Sci. Rep. 2017, 7, 40846. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Chisholm, M.; Duscher, G.; Ma, X.; Pennycook, S. Direct observation of dislocation dissociation and Suzuki segregation in a Mg-Zn-Y alloy by aberration-corrected scanning transmission electron microscopy. Acta Mater. 2013, 61, 350–359. [Google Scholar] [CrossRef]

- Suzuki, M.; Kimura, T.; Koike, J.; Maruyama, K. Strengthening effect of Zn in heat resistant Mg-Y-Zn solid solution alloys. Scr. Mater. 2003, 48, 997–1002. [Google Scholar] [CrossRef]

- Hou, X.; Cao, Z.; Wang, L.; Xu, S.; Kamado, S.; Wang, L. Microstructure and mechanical properties of extruded Mg–8Gd–2Y–1Nd–0.3Zn–0.6Zr alloy. Mater. Sci. Eng. A 2011, 528, 7805–7810. [Google Scholar] [CrossRef]

- Anyanwu, I.; Kamado, S.; Kojima, Y. Aging characteristics and high temperature tensile properties of Mg-Gd-Y-Zr alloys. Mater. Trans. 2001, 42, 1206–1211. [Google Scholar] [CrossRef]

- Yu, Z.; Huang, Y.; Qiu, X.; Yang, Q.; Sun, W.; Tian, Z.; Zhang, D.; Meng, J. Fabrication of magnesium alloy with high strength and heat-resistance by hot extrusion and ageing. Mater. Sci. Eng. A 2013, 578, 346–353. [Google Scholar] [CrossRef]

- Nodooshan, H.; Wu, G.; Liu, W.; Wei, G.; Li, Y.; Zhang, S. Effect of Gd content on high temperature mechanical properties of Mg–Gd–Y–Zr alloy. Mater. Sci. Eng. 2016, 651, 840–847. [Google Scholar] [CrossRef]

- Leng, Z.; Zhang, J.; Zhang, M.; Liu, X.; Zhan, H.; Wu, R. Microstructure and high mechanical properties of Mg–9RY–4Zn (RY: Y-rich misch metal) alloy with long period stacking ordered phase. Mater. Sci. Eng. A 2012, 540, 38–45. [Google Scholar] [CrossRef]

- Liu, K.; Rokhlin, L.; Elkin, F.; Tang, D.; Meng, J. Effect of ageing treatment on the microstructures and mechanical properties of the extruded Mg–7Y–4Gd–1.5Zn–0.4Zr alloy. Mater. Sci. Eng. A 2010, 527, 828–834. [Google Scholar] [CrossRef]

- Li, B.; Teng, B.; Chen, G. Microstructure evolution and mechanical properties of Mg-Gd-Y-Zn-Zr alloy during equal channel angular pressing. Mater. Sci. Eng. A 2019, 744, 396–405. [Google Scholar] [CrossRef]

- Oh-ishi, K.; Mendis, C.; Homma, T.; Kamado, S.; Ohkubo, T.; Hono, K. Bimodally grained microstructure development during hot extrusion of Mg-2.4 Zn-0.1 Ag-0.1 Ca-0.16 Zr (at.%) alloys. Acta Mater. 2009, 57, 5593–5604. [Google Scholar] [CrossRef]

- Yang, Q.; Xiao, B.; Zhang, Q.; Zheng, M.; Ma, Z. Exceptional high-strain-rate superpl-asticity in Mg-Gd-Y-Zn-Zr alloy with long-period stacking ordered phase. Scr. Mater. 2013, 69, 801–804. [Google Scholar] [CrossRef]

- Yin, D.; Wang, Q.; Gao, Y.; Chen, C.; Zheng, J. Effects of heat treatments on microstructure and mechanical properties of Mg-11Y-5Gd-2Zn-0.5Zr (wt.%) alloy. J. Alloys Compd. 2011, 509, 1696–1704. [Google Scholar] [CrossRef]

| States | UTS (MPa) | YS (MPa) | El (%) |

|---|---|---|---|

| As-cast | 185.3 ± 2.1 | 89.1 ± 2.9 | 6.8 ± 0.8 |

| Solution-treated | 204.0 ± 2.7 | 86.8 ± 2.6 | 10.7 ± 1.0 |

| As-extruded | 375.5 ± 4.3 | 341.4 ± 4.3 | 9.1 ± 1.8 |

| Temperature (°C) | UTS (MPa) | YS (MPa) | El (%) |

|---|---|---|---|

| 25 | 375.5 ± 4.3 | 341.4 ± 4.3 | 9.1 ± 1.8 |

| 200 | 306.6 ± 5.4 | 276.7 ± 5.7 | 13.5 ± 1.9 |

| 300 | 271.3 ± 7.4 | 255.7 ± 4.8 | 29.1 ± 5.8 |

| 350 | 145.5 ± 2.1 | 131.5 ± 3.4 | 63.4 ± 3.7 |

| 400 | 60.5 ± 1.6 | 36.6 ± 2.7 | 81.4 ± 3.1 |

| Alloys (wt %) | Temperature (°C) | UTS (MPa) | YS (MPa) | El (%) | Refs. |

|---|---|---|---|---|---|

| Mg–8Gd–2Y–1Nd–0.3Zn–0.6Zr | RT | 271 | 143 | 18.7 | [40] |

| 300 | 188 | 121 | 44.0 | ||

| Mg–9Gd–4Y–0.6Zr | RT | 330 | 300 | 13.0 | [41] |

| 300 | 190 | 150 | 28.0 | ||

| Mg–11Gd–4.5Y–1Nd–1.5Zn–0.5Zr | RT | 377 | 327 | 3.8 | [42] |

| 300 | 193 | 172 | 54.4 | ||

| Mg–12Gd–3Y–0.5Zr | RT | 360 | 245 | 2.3 | [43] |

| 300 | 200 | 176 | 18.5 | ||

| Mg–9RY–4Zn | RT | 265 | 353 | 9.7 | [44] |

| 300 | 204 | 247 | 29.2 | ||

| Mg–8Gd–3Yb–1.2Zn–0.5Zr | RT | 425 | 413 | 5.5 | [19] |

| 300 | 204 | 191 | 25.5 | ||

| Mg–7Y–4Gd–1.5Zn–0.4Zr | RT | 331 | 228 | 7.3 | [45] |

| 300 | 230 | 123 | 40.0 | ||

| Mg–4Er–2Y–3Zn–0.4Mn | RT | 376 | 341 | 9.1 | This work |

| 300 | 271 | 256 | 29.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhang, J.; Feng, Y.; Xie, J.; Liu, Y.; Liu, S.; Meng, J.; Yang, Q.; Liu, Z.; Wu, R. Development of Hot-Extruded Mg–RE–Zn Alloy Bar with High Mechanical Properties. Materials 2019, 12, 1722. https://doi.org/10.3390/ma12101722

Li Z, Zhang J, Feng Y, Xie J, Liu Y, Liu S, Meng J, Yang Q, Liu Z, Wu R. Development of Hot-Extruded Mg–RE–Zn Alloy Bar with High Mechanical Properties. Materials. 2019; 12(10):1722. https://doi.org/10.3390/ma12101722

Chicago/Turabian StyleLi, Zehua, Jinghuai Zhang, Yan Feng, Jinshu Xie, Yinfu Liu, Shujuan Liu, Jian Meng, Qiang Yang, Zhuang Liu, and Ruizhi Wu. 2019. "Development of Hot-Extruded Mg–RE–Zn Alloy Bar with High Mechanical Properties" Materials 12, no. 10: 1722. https://doi.org/10.3390/ma12101722

APA StyleLi, Z., Zhang, J., Feng, Y., Xie, J., Liu, Y., Liu, S., Meng, J., Yang, Q., Liu, Z., & Wu, R. (2019). Development of Hot-Extruded Mg–RE–Zn Alloy Bar with High Mechanical Properties. Materials, 12(10), 1722. https://doi.org/10.3390/ma12101722