Influence of Processing Parameters on the Thread and Spline Synchronous Rolling Process: An Experimental Study

Abstract

:1. Introduction

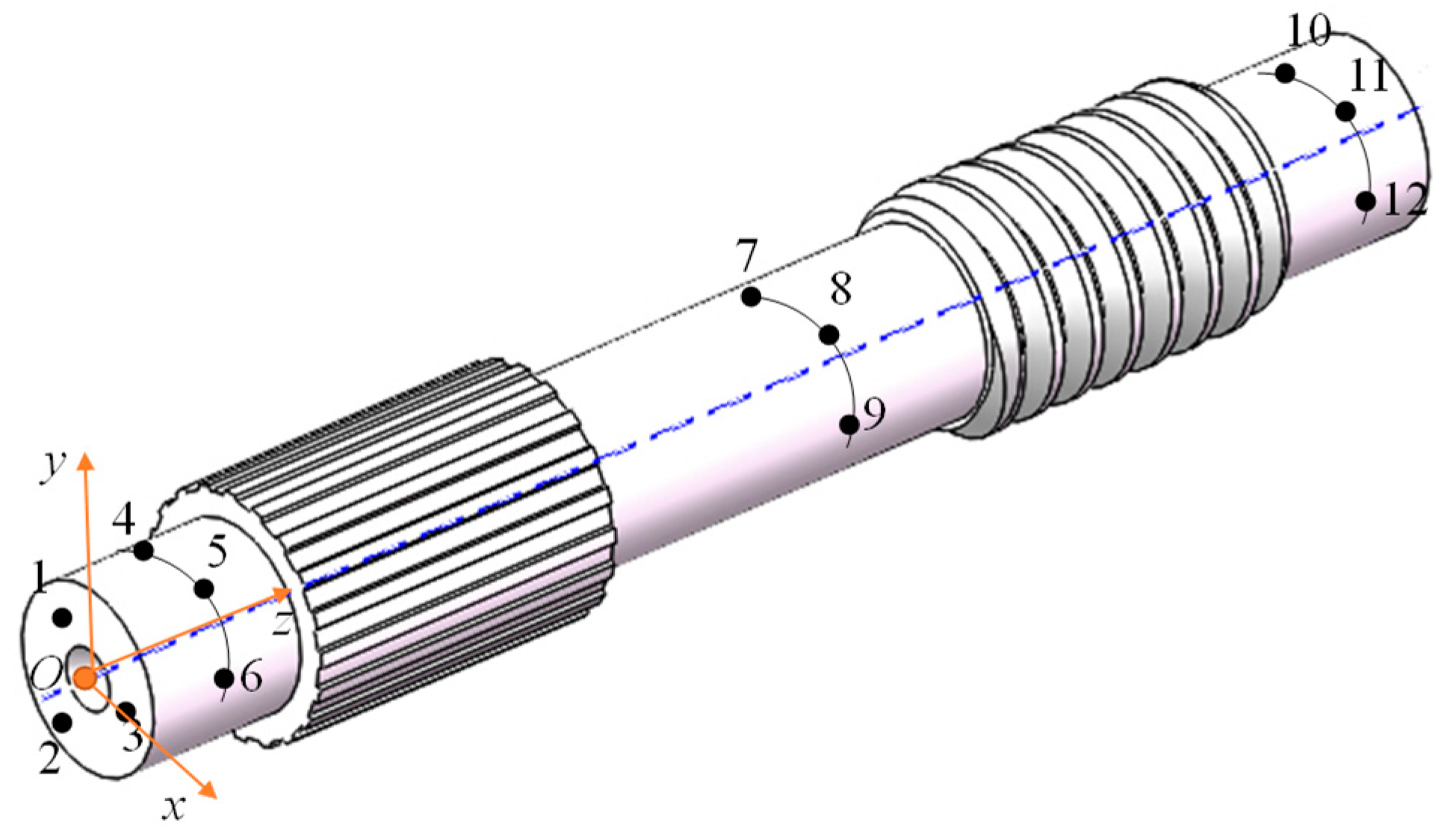

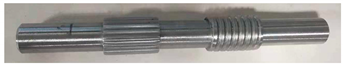

2. Thread and Spline Synchronous Rolling Process

2.1. Description of Synchronous Rolling Process

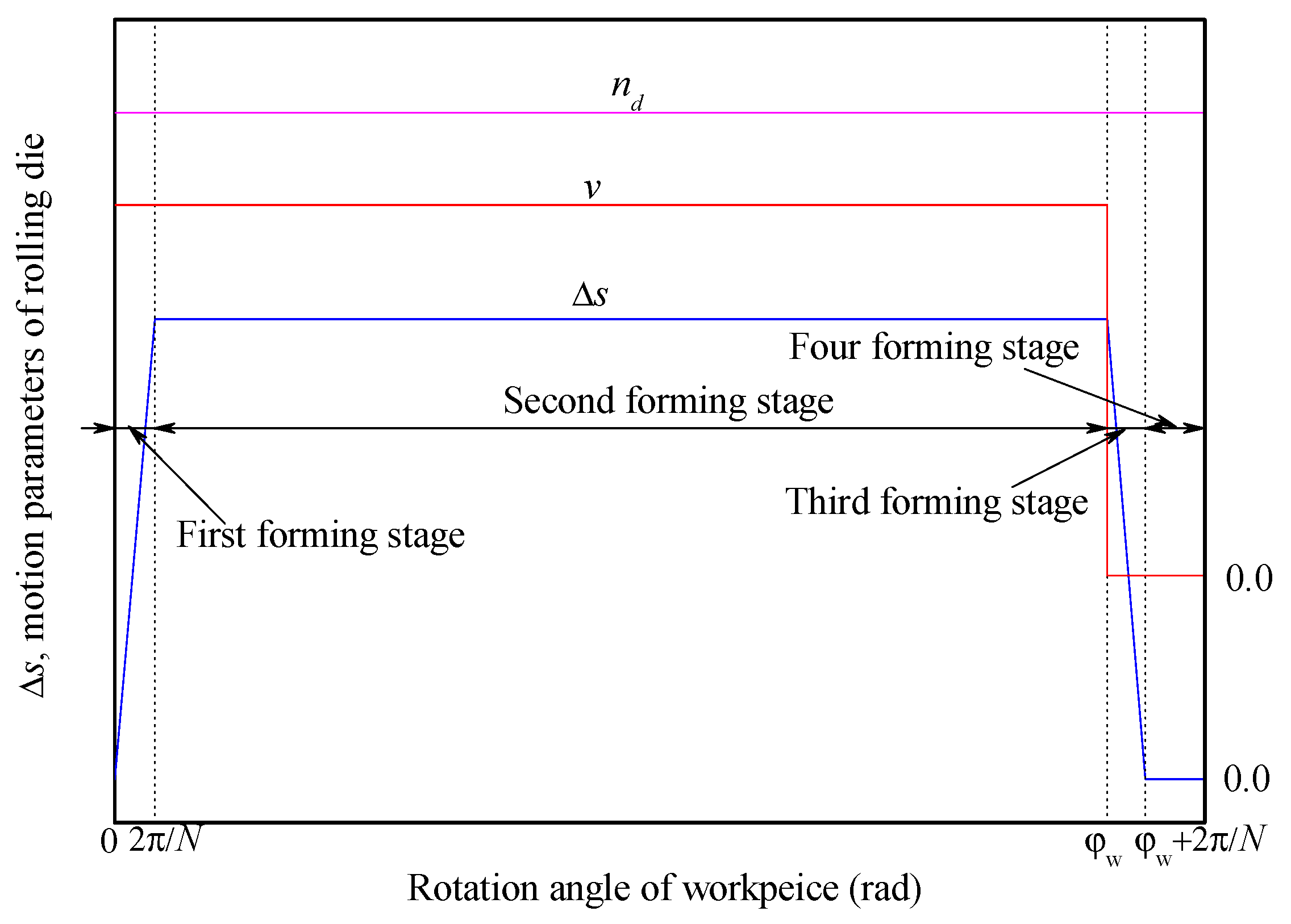

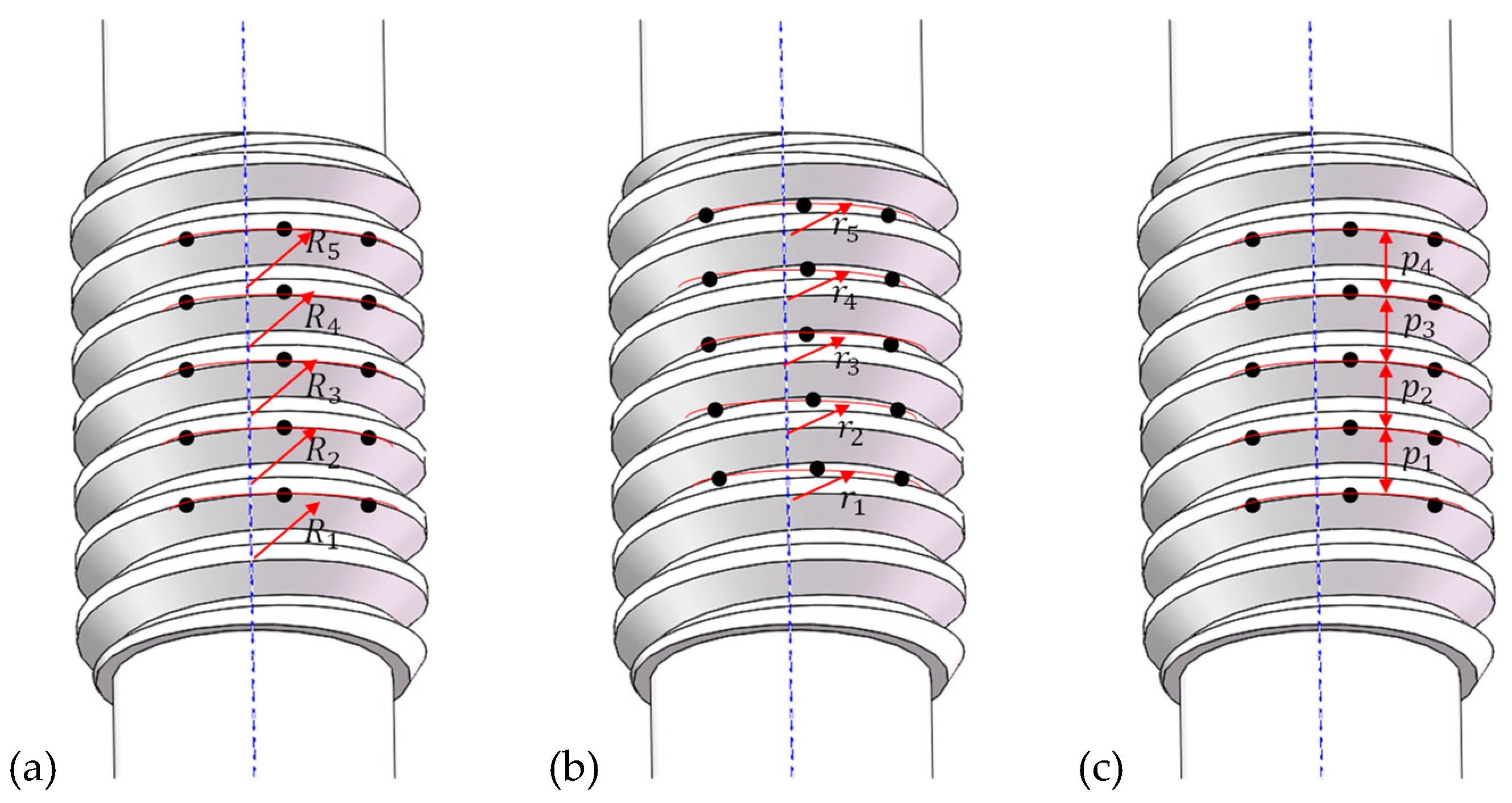

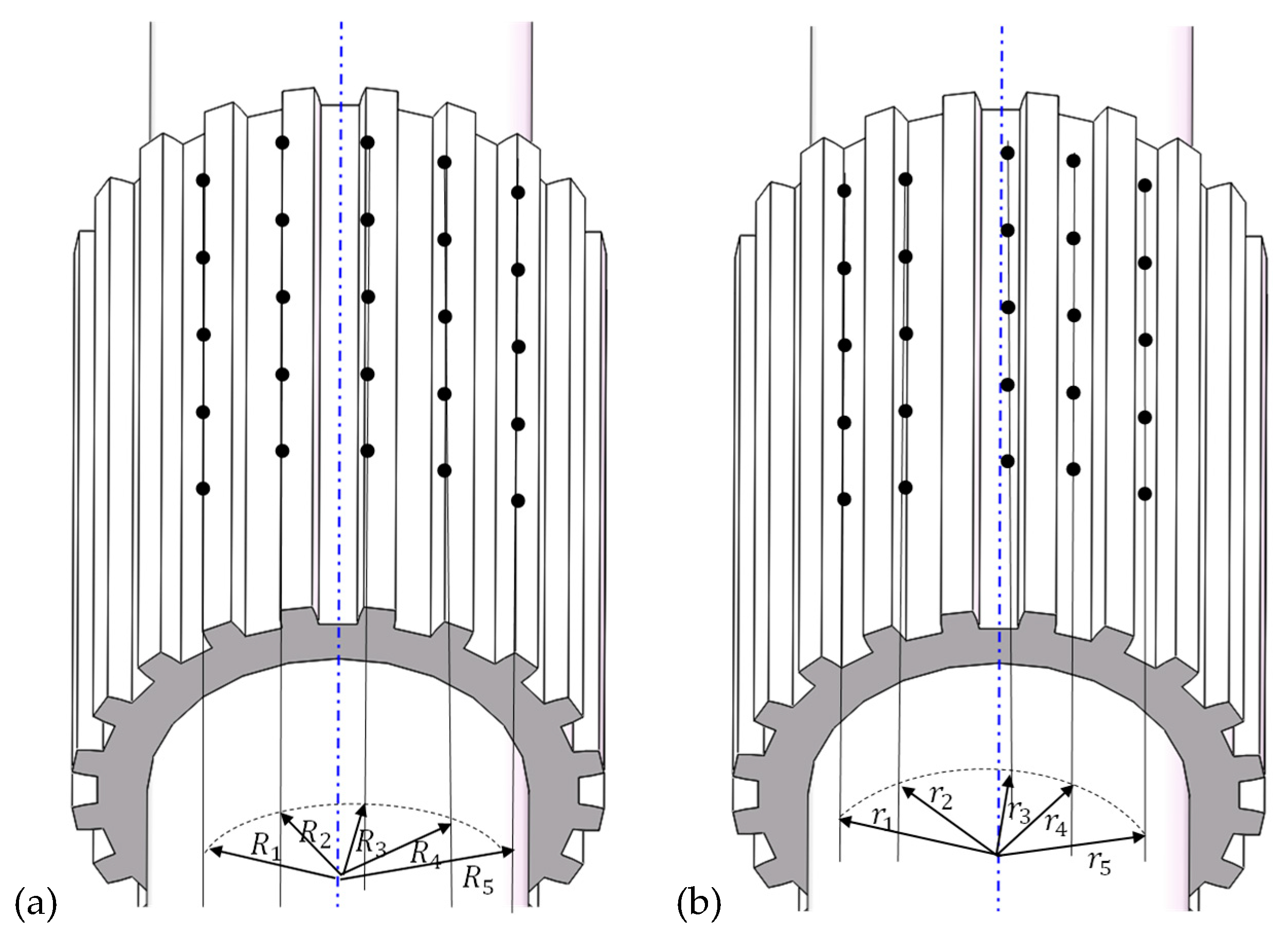

2.1.1. Processing Principle

2.1.2. Characteristic of the Process

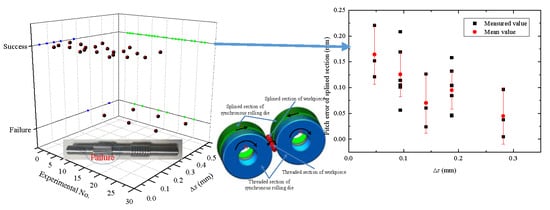

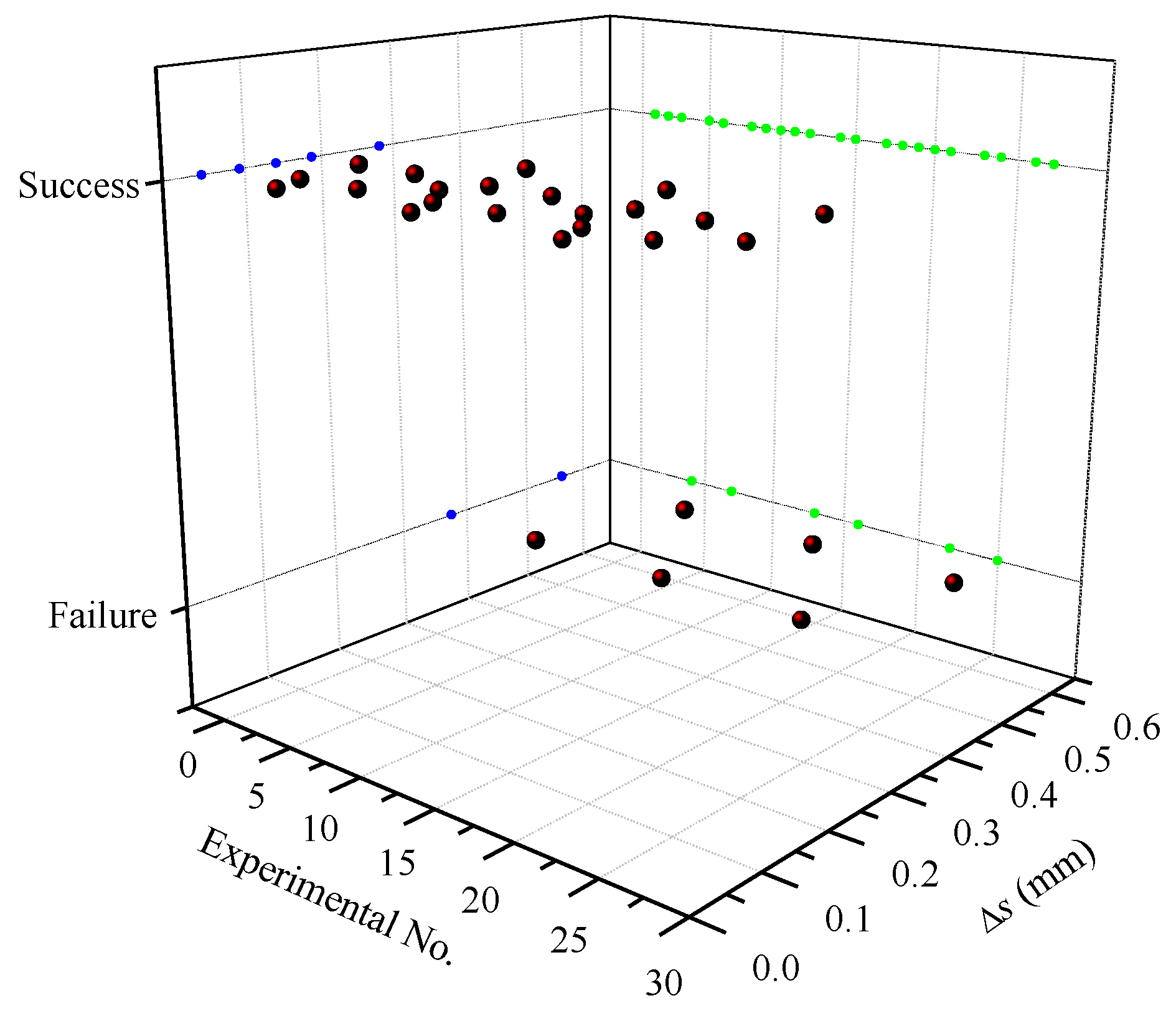

2.2. Experimental Scheme and Experimental Result

2.2.1. Design of Experimental Scheme

2.2.2. Experiment of Synchronous Rolling Process

2.2.3. Experimental Results

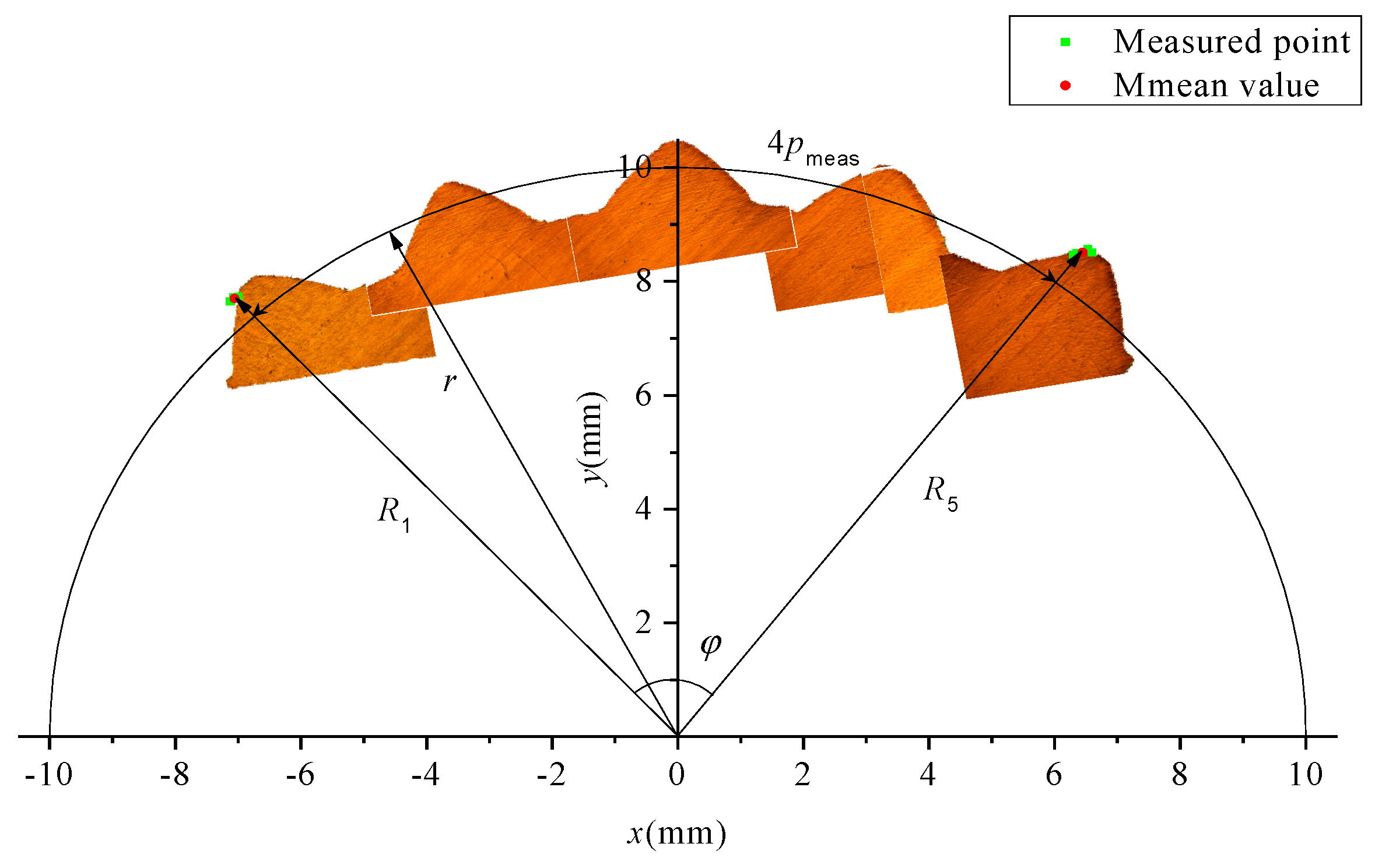

3. Measuring Instrument and Data Processing

4. Results and Discussion

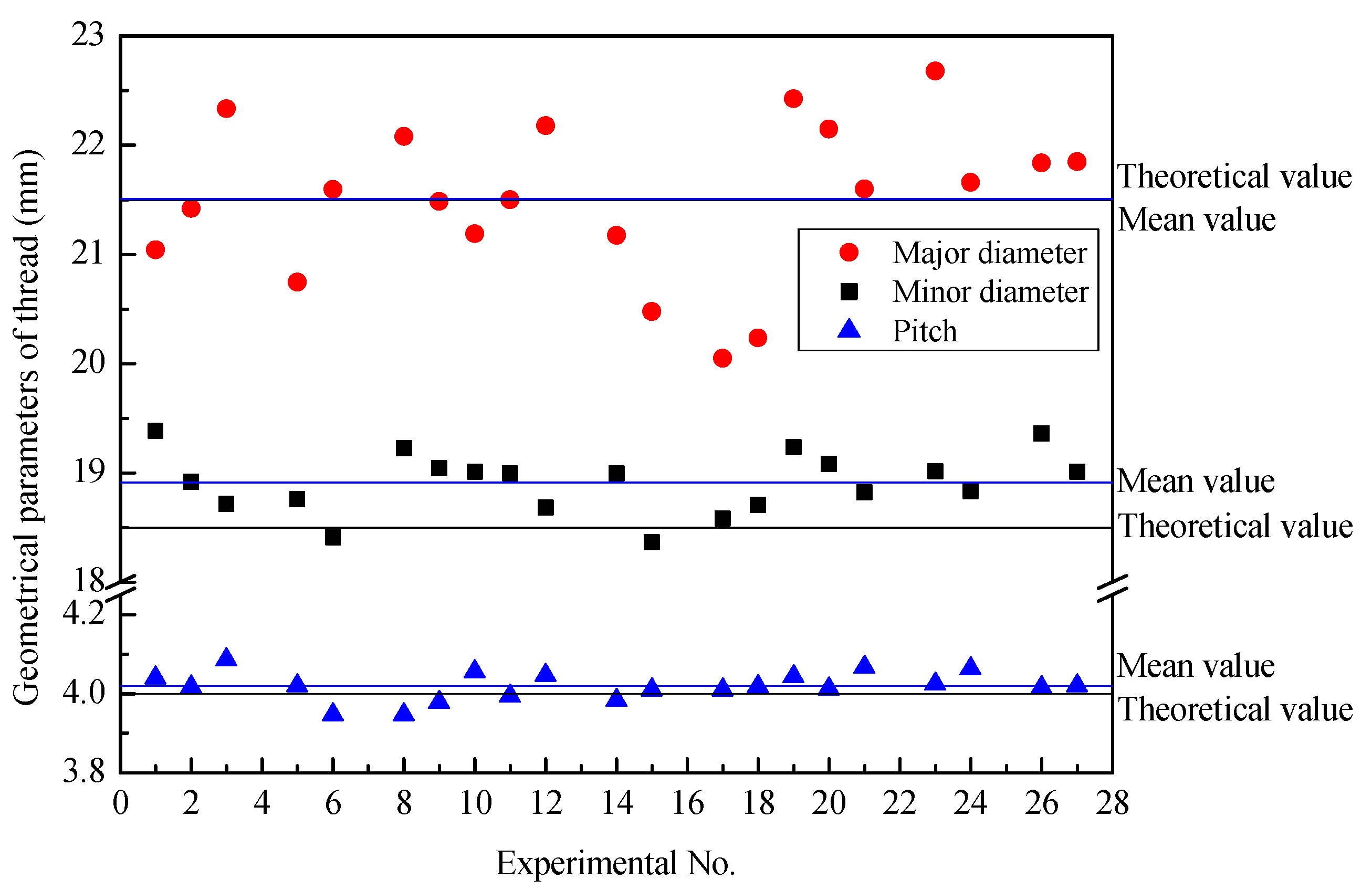

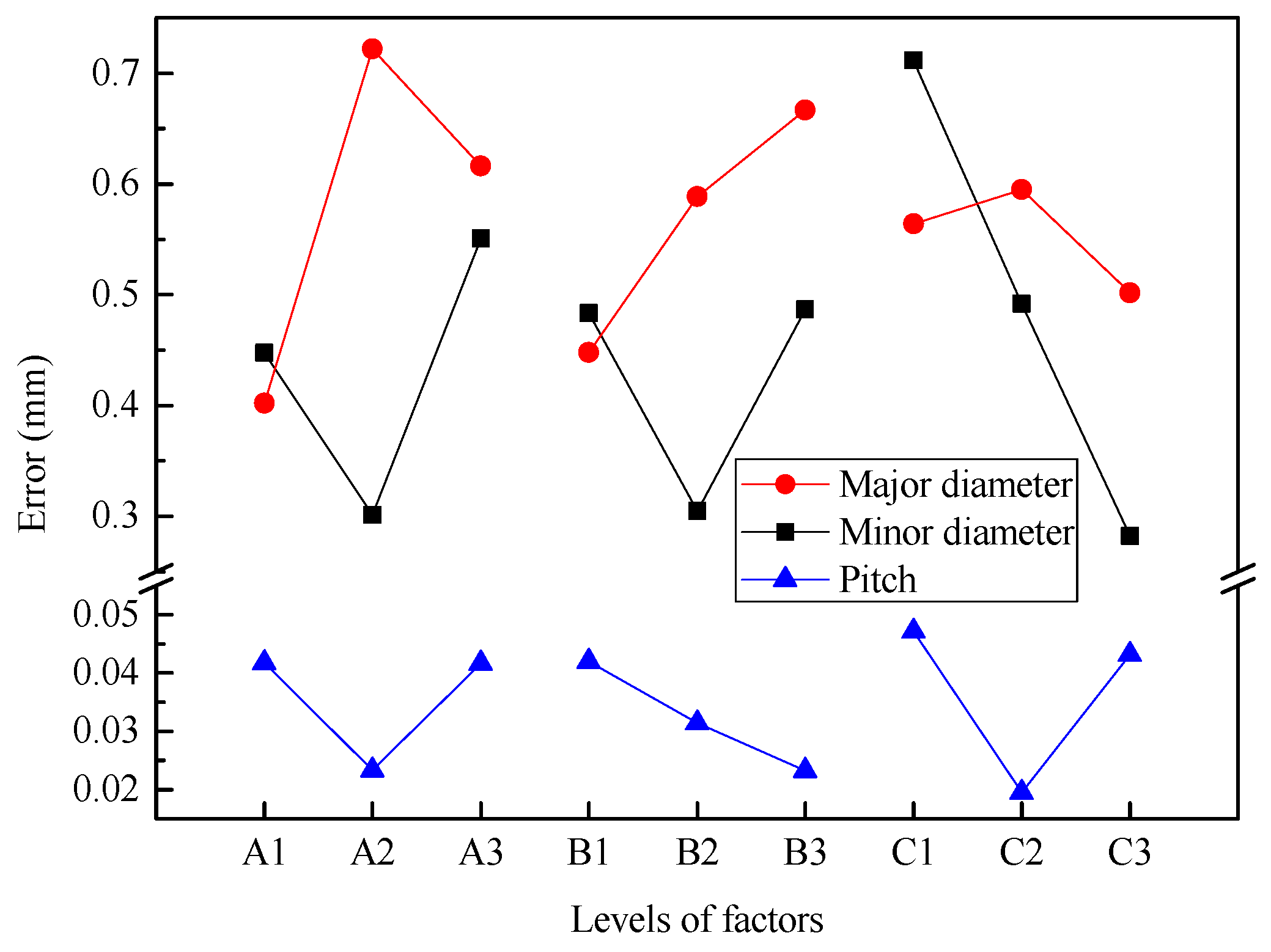

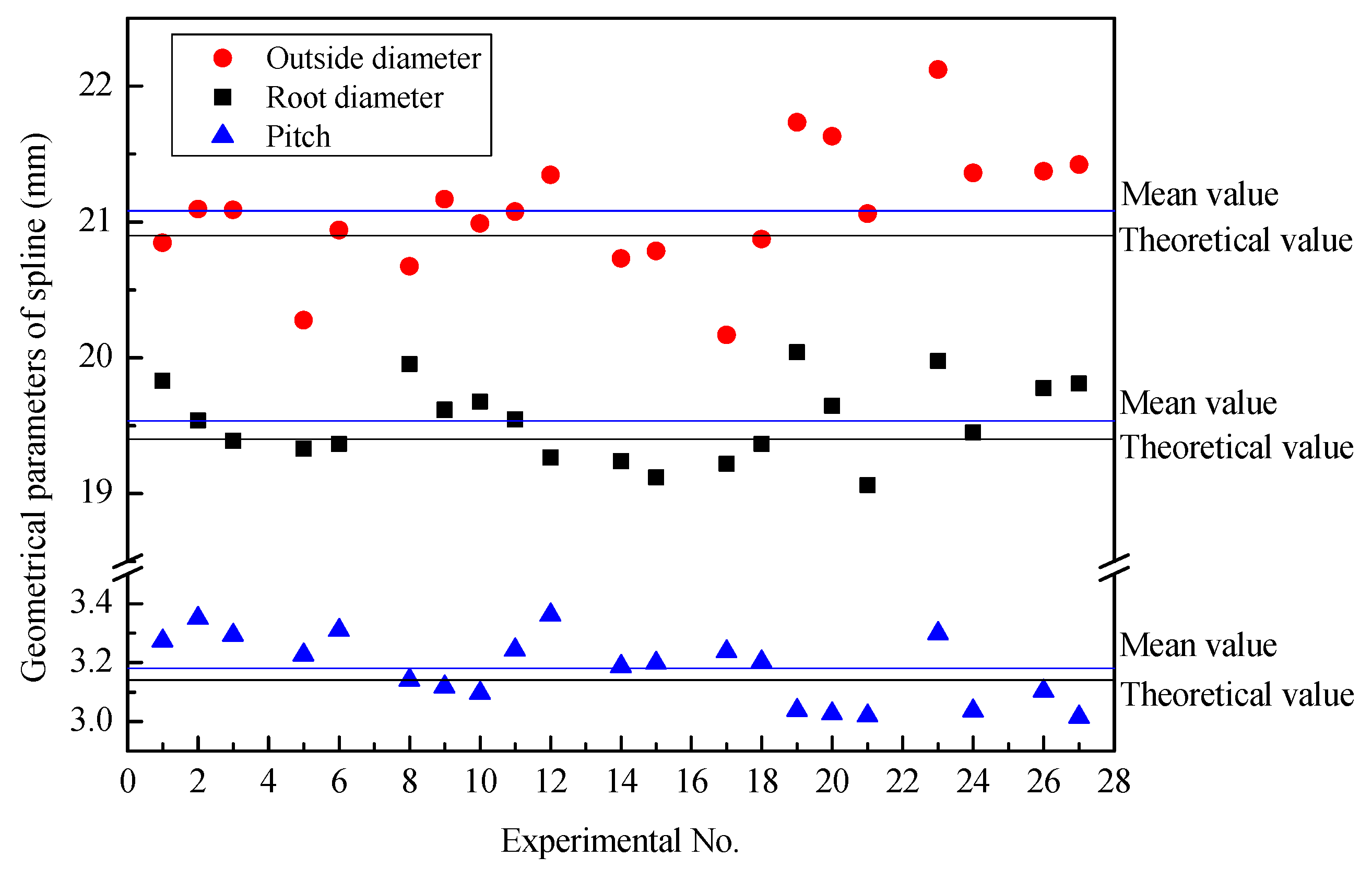

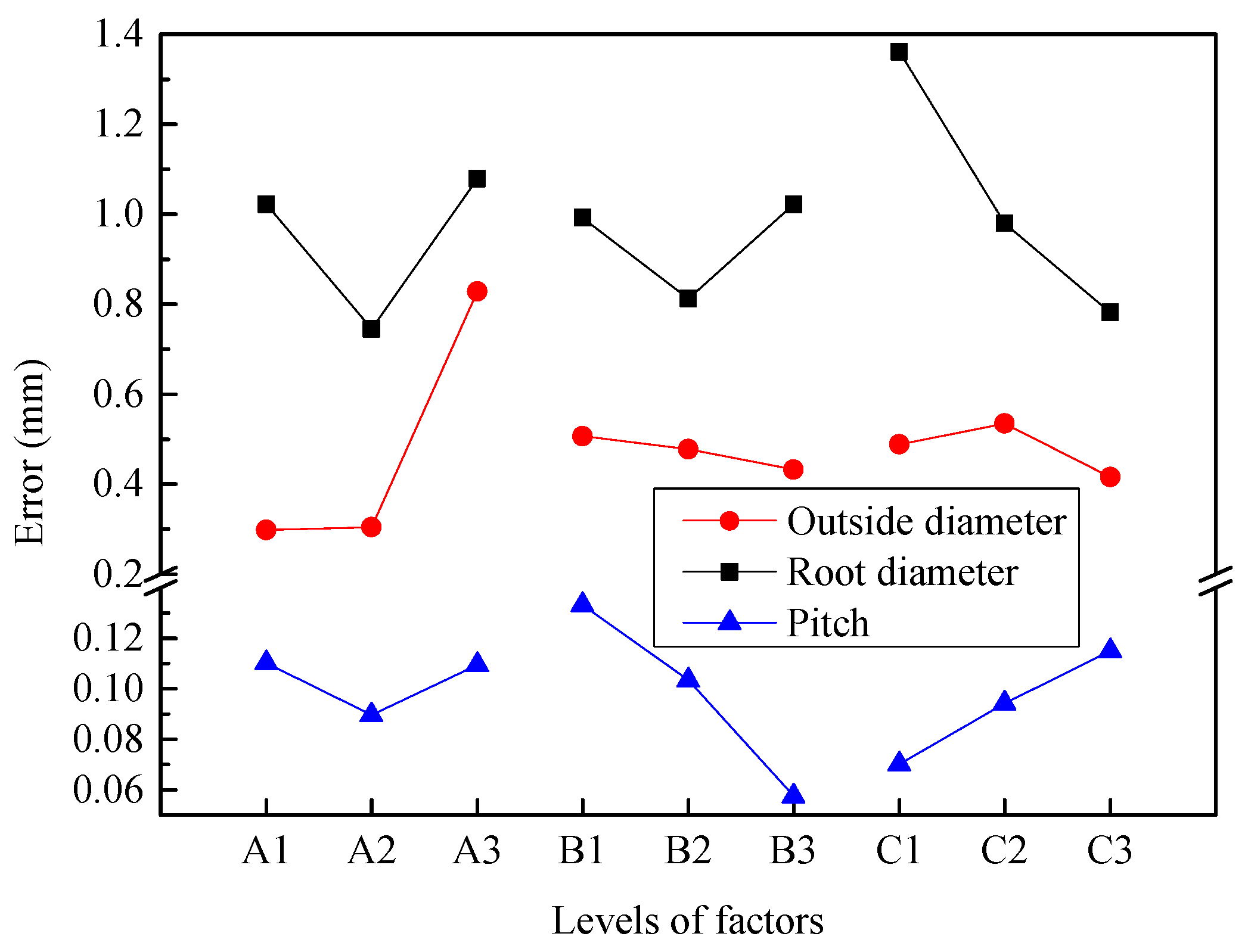

4.1. Basis Parameters of Threaded Section

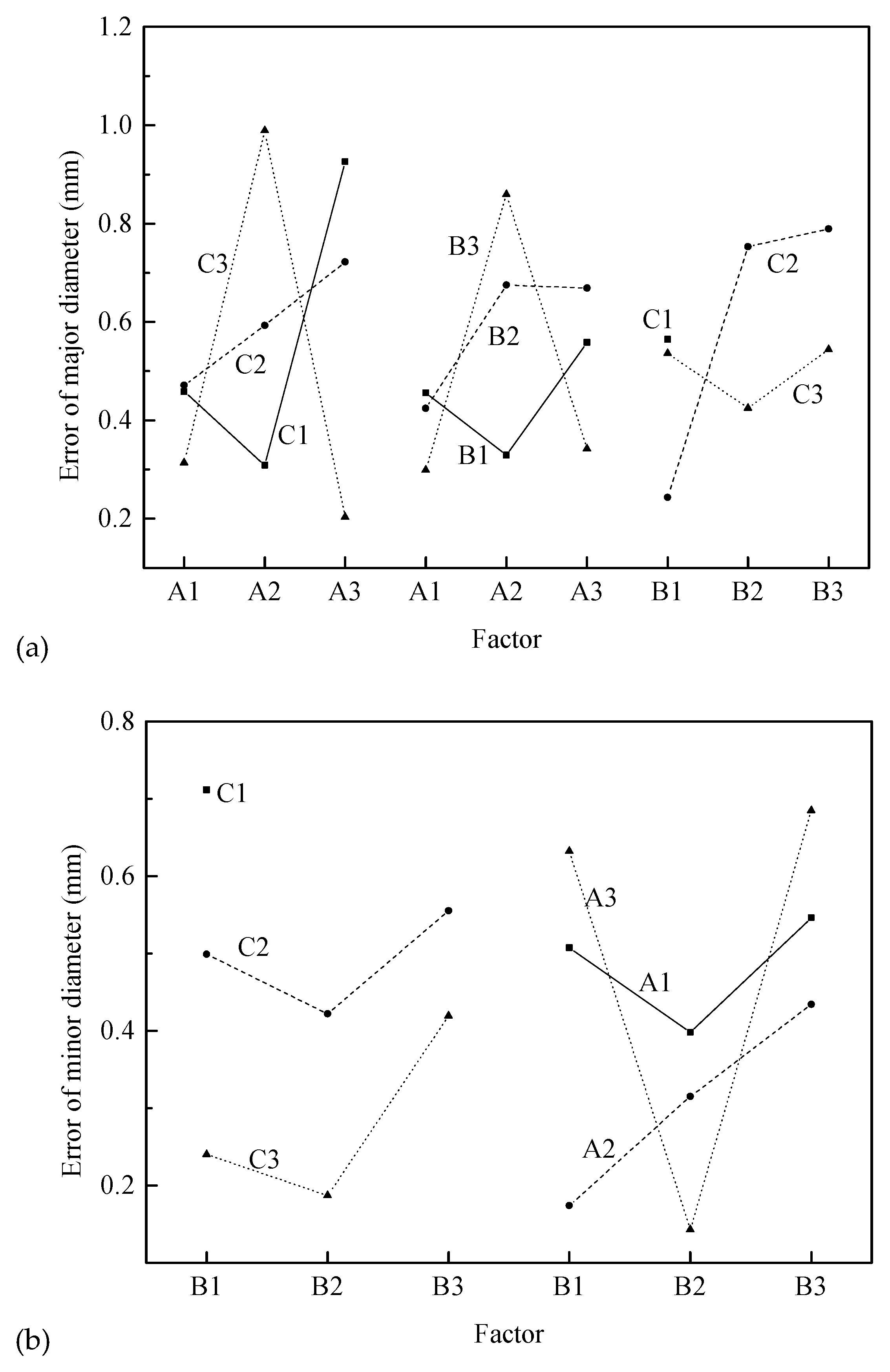

4.1.1. Major Diameter

4.1.2. Minor Diameter

4.1.3. Pitch of Thread

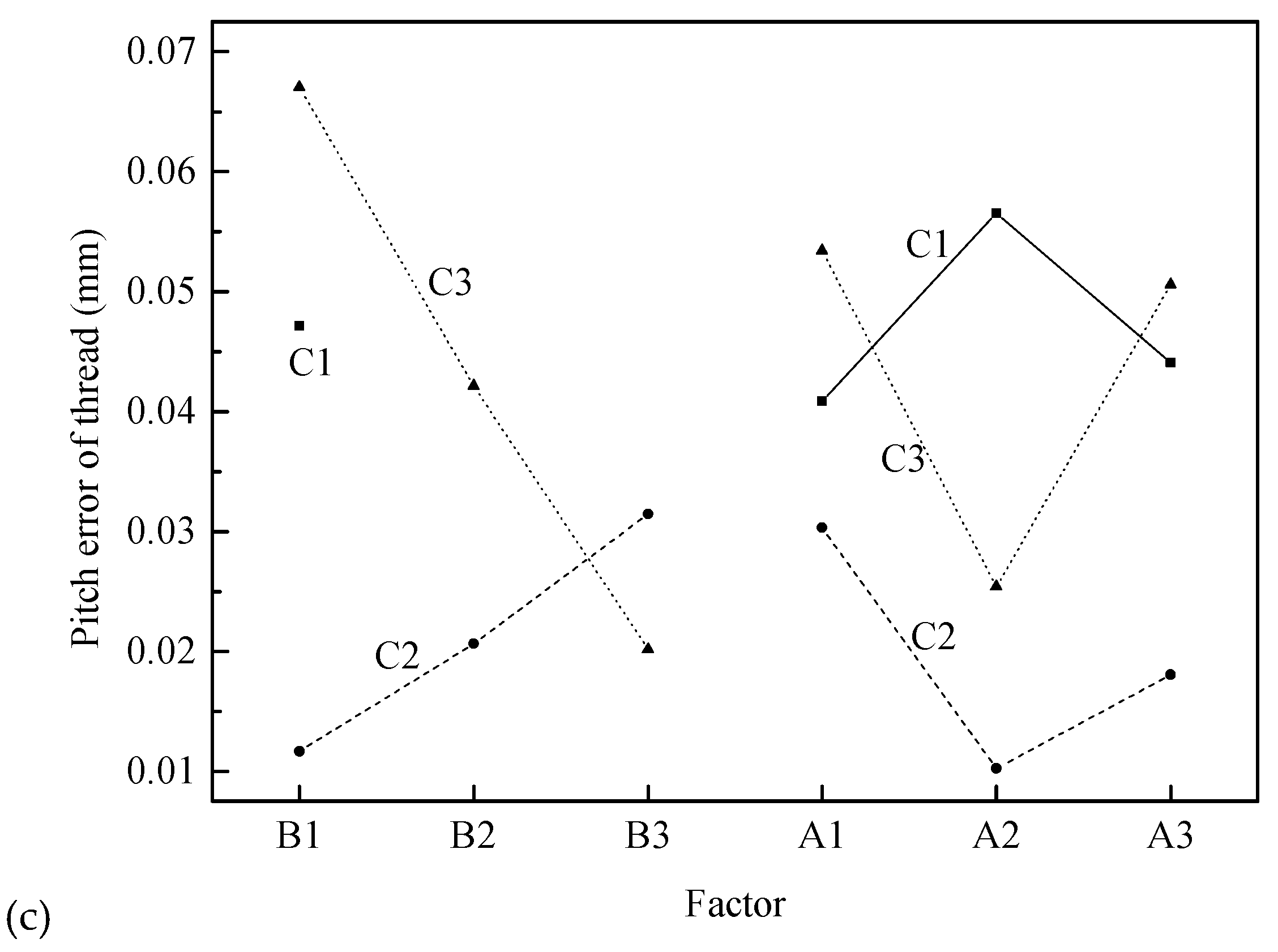

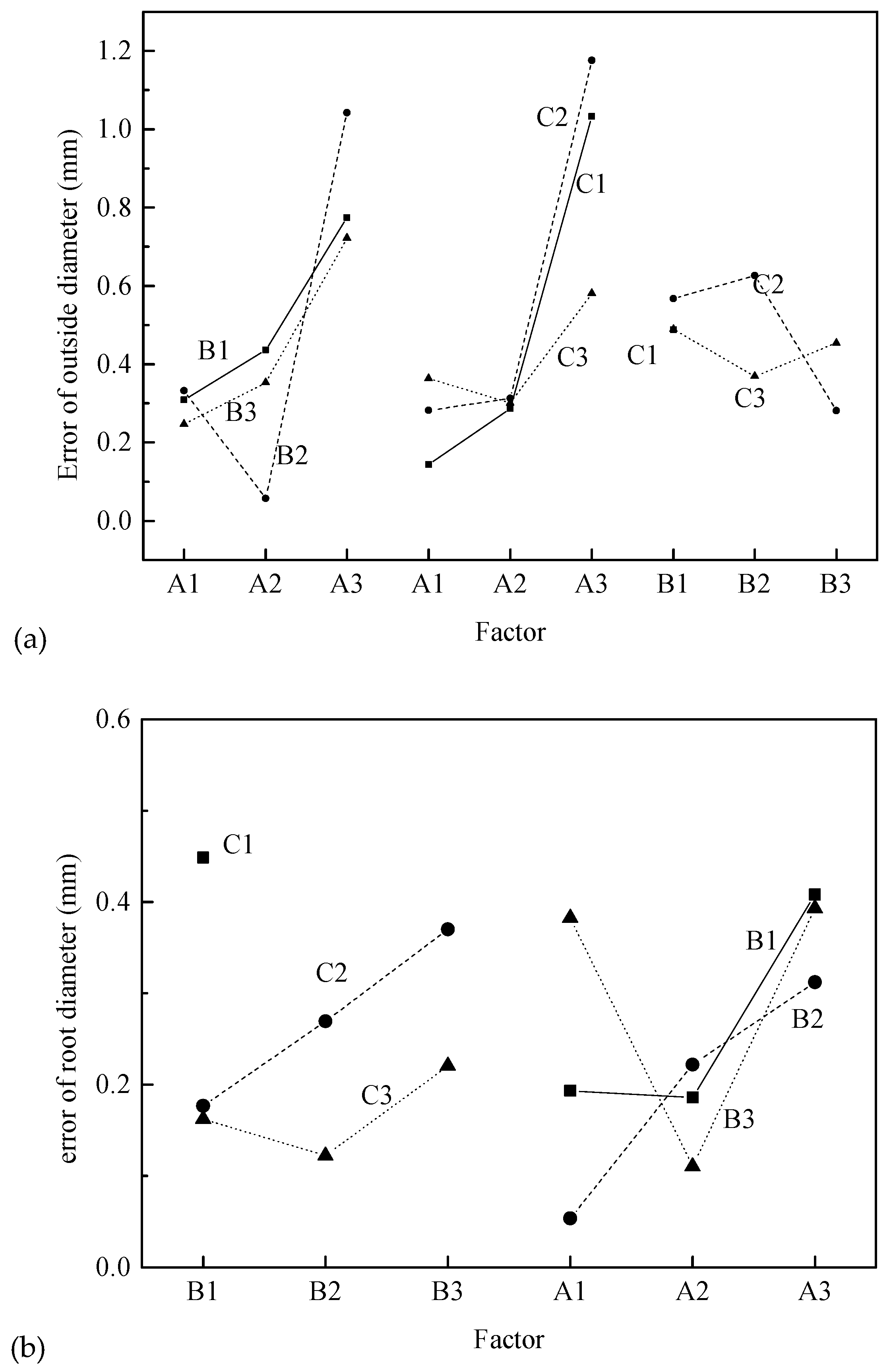

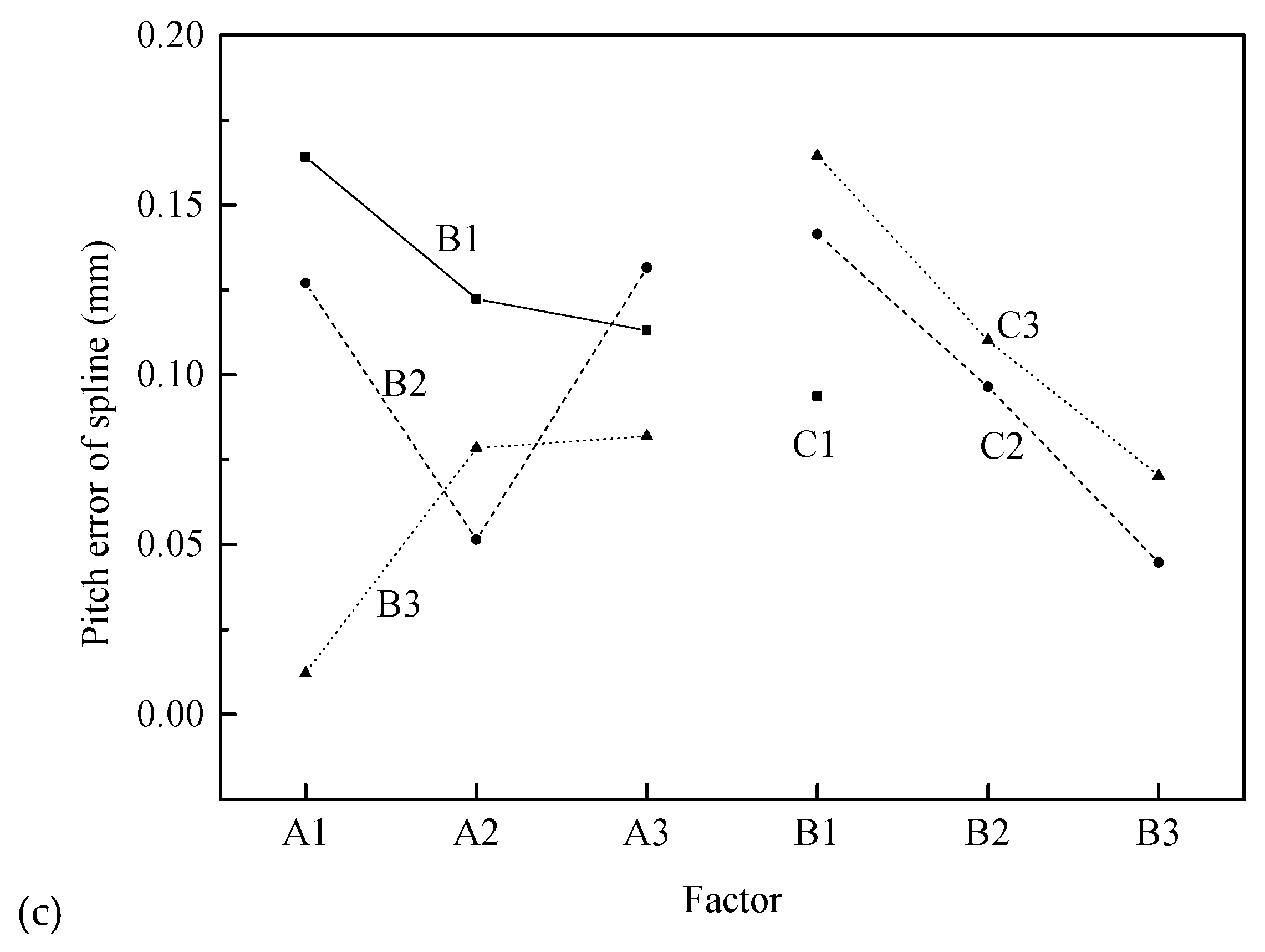

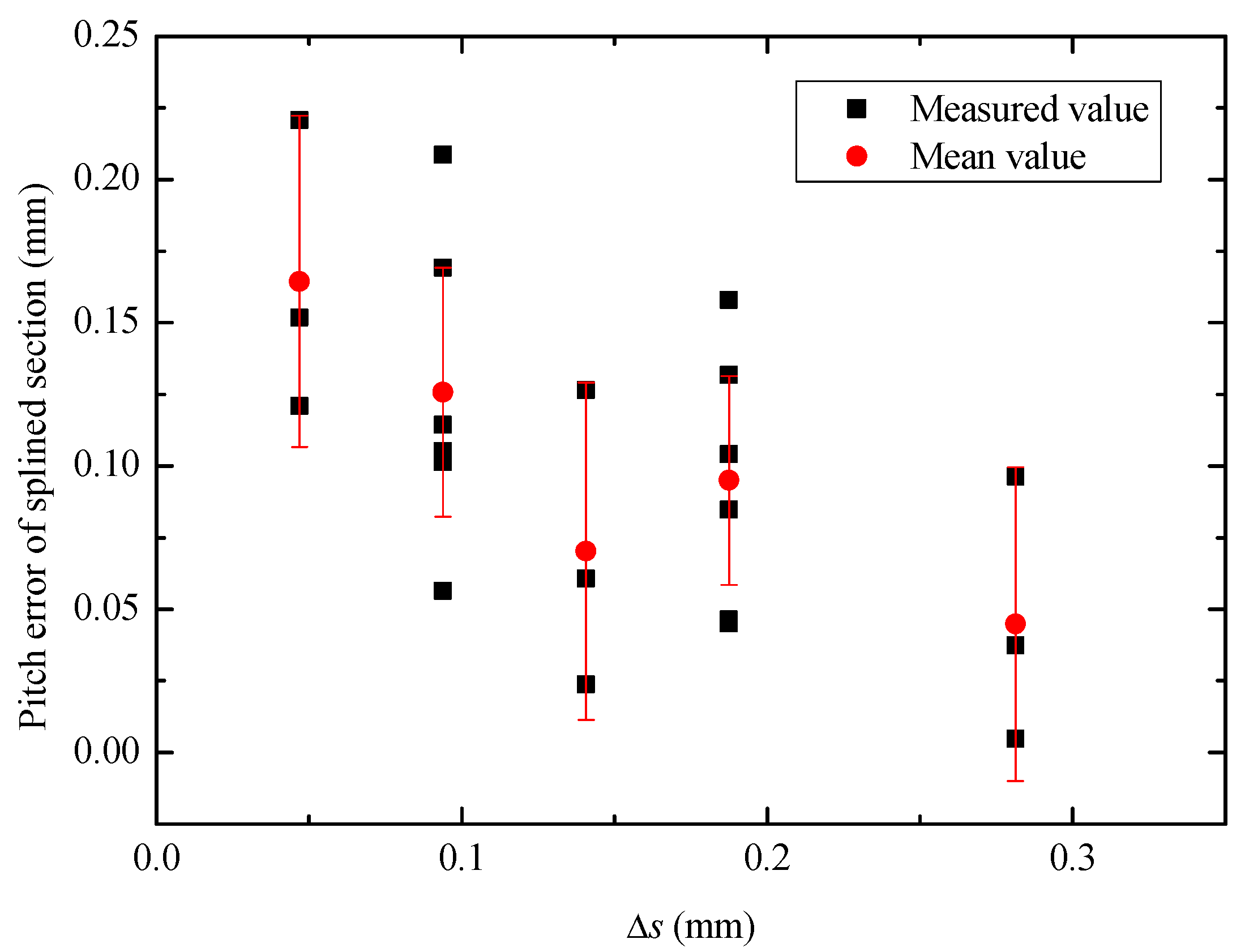

4.2. Basis Parameters of Splined Section

4.2.1. Outside Diameter

4.2.2. Root Diameter

4.2.3. Pitch of Spline

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, D.W.; Zhao, S.D. New method for forming shaft having thread and spline by rolling with round dies. Int. J. Adv. Manuf. Technol. 2014, 70, 1455–1462. [Google Scholar] [CrossRef]

- Zhang, D.W.; Zhao, S.D.; Wu, S.B.; Zhang, Q.; Fan, S.Q.; Li, J.X. Phase characteristic between dies before rolling for thread and spline synchronous rolling process. Int. J. Adv. Manuf. Technol. 2015, 81, 513–528. [Google Scholar] [CrossRef]

- Velinsky, S.A.; Chu, B.; Lasky, T.A. Kinematics and efficiency analysis of planetary roller screw mechanism. J. Mech. Design 2009, 131, 011016. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Tong, R.T.; Ma, S.J.; Lin, T.C. A nonlinear six degrees of freedom dynamic model of planetary roller screw mechanism. Mech. Mach. Theor. 2018, 119, 22–36. [Google Scholar] [CrossRef]

- Song, J.L.; Liu, Z.Q.; Li, Y.T. Cold Rolling Precision Forming of Shaft Parts: Theory and Technologies; Springer: Berlin, Germany, 2017. [Google Scholar]

- Zhang, D.W.; Liu, B.K.; Xu, F.F.; Wang, Q.; Zhao, S.D. A note on phase characteristic among rollers before thread or spline rolling. Int. J. Adv. Manuf. Technol. 2019, 100, 391–399. [Google Scholar] [CrossRef]

- Zhang, D.W. Die structure and its trial manufacture for thread and spline synchronous rolling process. Int. J. Mach. Tool Manuf. 2018, 96, 319–325. [Google Scholar] [CrossRef]

- Zhang, D.W.; Zhao, S.D.; Ou, H.A. Analysis of motion between rolling die and workpiece in thread rolling process with round dies. Mech. Mach. Theor. 2016, 105, 471–494. [Google Scholar] [CrossRef]

- Zhang, D.W.; Zhao, S.D.; Ou, H.A. Motion Characteristic between die and workpiece in spline rolling process with round dies. Adv. Mech. Eng. 2016, 8, 1–12. [Google Scholar] [CrossRef]

- Zhang, D.W.; Zhao, S.D.; Bi, Y.D. Analysis of forming error during thread and spline synchronous rolling process based on motion characteristic. Int. J. Adv. Manuf. Technol. 2019, 102, 915–928. [Google Scholar] [CrossRef]

- Zhang, D.W.; Zhao, S.D.; Li, Y.T. Rotatory condition at initial stage of external spline rolling. Math. Prob. Eng. 2014, 2014, 363184. [Google Scholar] [CrossRef]

- Zhang, D.W.; Li, Y.T.; Fu, J.H.; Zheng, Q.G. Rolling force and rolling moment in spline cold rolling using slip-line field method. Chin. J. Mech. Eng. 2009, 22, 688–695. [Google Scholar] [CrossRef]

- Zhang, D.W.; Zhao, S.D. Deformation characteristic of thread and spline synchronous rolling process. Int. J. Adv. Manuf. Technol. 2016, 87, 835–851. [Google Scholar] [CrossRef]

- He, W.; Xue, W.D.; Tang, B. Experiment Optimization Design Method and Data Analyzing; Chemical Industry Press: Beijing, China, 2012. (In Chinese) [Google Scholar]

- Pan, J.M. Handbook of Chemical Composition and Mechanical Properties for Metal Materials; Machinery Industry Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Zhang, D.W.; Cui, M.C.; Cao, M.; Ben, N.Y.; Zhao, S.D. Determination of friction conditions in cold-rolling process of shaft part by using incremental ring compression test. Int. J. Adv. Manuf. Technol. 2017, 91, 3823–3831. [Google Scholar] [CrossRef]

| Level Rank | A ( (mm)) | B (v (mm/s)) | C ( (r/min)) |

|---|---|---|---|

| 1 | 20.00 | 0.5 | 8 |

| 2 | 20.25 | 1.0 | 16 |

| 3 | 20.50 | 1.5 | 32 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A × B | A × B | C | A × C | A × C | B × C | B × C | |||||

| 1 | 1 (20 mm) | 1 (0.5 mm/s) | 1 | 1 | 1 (8 r/min) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 1 (20 mm) | 1 (0.5 mm/s) | 1 | 1 | 2 (16 r/min) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 3 | 1 (20 mm) | 1 (0.5 mm/s) | 1 | 1 | 3 (32 r/min) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| 4 | 1 (20 mm) | 2 (1 mm/s) | 2 | 2 | 1 (8 r/min) | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 3 |

| 5 | 1 (20 mm) | 2 (1 mm/s) | 2 | 2 | 2 (16 r/min) | 2 | 2 | 3 | 3 | 3 | 1 | 1 | 1 |

| 6 | 1 (20 mm) | 2 (1 mm/s) | 2 | 2 | 3 (32 r/min) | 3 | 3 | 1 | 1 | 1 | 2 | 2 | 2 |

| 7 | 1 (20 mm) | 3 (1.5 mm/s) | 3 | 3 | 1 (8 r/min) | 1 | 1 | 3 | 3 | 3 | 2 | 2 | 2 |

| 8 | 1 (20 mm) | 3 (1.5 mm/s) | 3 | 3 | 2 (16 r/min) | 2 | 2 | 1 | 1 | 1 | 3 | 3 | 3 |

| 9 | 1 (20 mm) | 3 (1.5 mm/s) | 3 | 3 | 3 (32 r/min) | 3 | 3 | 2 | 2 | 2 | 1 | 1 | 1 |

| 10 | 2 (20.25 mm) | 1 (0.5 mm/s) | 2 | 3 | 1 (8 r/min) | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| 11 | 2 (20.25 mm) | 1 (0.5 mm/s) | 2 | 3 | 2 (16 r/min) | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 |

| 12 | 2 (20.25 mm) | 1 (0.5 mm/s) | 2 | 3 | 3 (32 r/min) | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 |

| 13 | 2 (20.25 mm) | 2 (1 mm/s) | 3 | 1 | 1 (8 r/min) | 2 | 3 | 2 | 3 | 1 | 3 | 1 | 2 |

| 14 | 2 (20.25 mm) | 2 (1 mm/s) | 3 | 1 | 2 (16 r/min) | 3 | 1 | 3 | 1 | 2 | 1 | 2 | 3 |

| 15 | 2 (20.25 mm) | 2 (1 mm/s) | 3 | 1 | 3 (32 r/min) | 1 | 2 | 1 | 2 | 3 | 2 | 3 | 1 |

| 16 | 2 (20.25 mm) | 3 (1.5 mm/s) | 1 | 2 | 1 (8 r/min) | 2 | 3 | 3 | 1 | 2 | 2 | 3 | 1 |

| 17 | 2 (20.25 mm) | 3 (1.5 mm/s) | 1 | 2 | 2 (16 r/min) | 3 | 1 | 1 | 2 | 3 | 3 | 1 | 2 |

| 18 | 2 (20.25 mm) | 3 (1.5 mm/s) | 1 | 2 | 3 (32 r/min) | 1 | 2 | 2 | 3 | 1 | 1 | 2 | 3 |

| 19 | 3 (20.5 mm) | 1 (0.5 mm/s) | 3 | 2 | 1 (8 r/min) | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 2 |

| 20 | 3 (20.5 mm) | 1 (0.5 mm/s) | 3 | 2 | 2 (16 r/min) | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3 |

| 21 | 3 (20.5 mm) | 1 (0.5 mm/s) | 3 | 2 | 3 (32 r/min) | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1 |

| 22 | 3 (20.5 mm) | 2 (1 mm/s) | 1 | 3 | 1 (8 r/min) | 3 | 2 | 2 | 1 | 3 | 3 | 2 | 1 |

| 23 | 3 (20.5 mm) | 2 (1 mm/s) | 1 | 3 | 2 (16 r/min) | 1 | 3 | 3 | 2 | 1 | 1 | 3 | 2 |

| 24 | 3 (20.5 mm) | 2 (1 mm/s) | 1 | 3 | 3 (32 r/min) | 2 | 1 | 1 | 3 | 2 | 2 | 1 | 3 |

| 25 | 3 (20.5 mm) | 3 (1.5 mm/s) | 2 | 1 | 1 (8 r/min) | 3 | 2 | 3 | 2 | 1 | 2 | 1 | 3 |

| 26 | 3 (20.5 mm) | 3 (1.5 mm/s) | 2 | 1 | 2 (16 r/min) | 1 | 3 | 1 | 3 | 2 | 3 | 2 | 1 |

| 27 | 3 (20.5 mm) | 3 (1.5 mm/s) | 2 | 1 | 3 (32 r/min) | 2 | 1 | 2 | 1 | 3 | 1 | 3 | 2 |

| Threaded Section | Splined Section | ||||

|---|---|---|---|---|---|

| Parameter | Unit | Value | Parameter | Unit | Value |

| Pitch diameter | mm | 200 | Module | mm | 1 |

| Pitch | mm | 4 | Teeth of spline | — | 200 |

| Starts of thread | — | 10 | Pressure angle | 45 | |

| Half of thread angle | 45 | ||||

| C | Si | Mn | P | S | Cr | Ni | Cu | |

|---|---|---|---|---|---|---|---|---|

| wt% | 0.42~0.50% | 0.17~0.37% | 0.50~0.80% | ≤0.035% | ≤0.035% | ≤0.25% | ≤0.30% | ≤0.25% |

| No. | (mm) | v (mm/s) | (r/min) | Photo of Failed Workpiece |

|---|---|---|---|---|

| 4 | 20 | 1 | 8 |  |

| 7 | 20 | 1.5 | 8 |  |

| 13 | 20.25 | 1 | 8 |  |

| 16 | 20.25 | 1.5 | 8 |  |

| 22 | 20.5 | 1 | 8 |  |

| 25 | 20.5 | 1.5 | 8 |  |

| No. | Threaded Section | Splined Section | ||||

|---|---|---|---|---|---|---|

| Major Diameter | Minor Diameter | Pitch | Outside Diameter | Root Diameter | Pitch | |

| 1 | 21.0422 | 19.3853 | 4.0409 | 20.8442 | 19.8314 | 3.2733 |

| 2 | 21.4201 | 18.9179 | 4.0173 | 21.0952 | 19.5378 | 3.3503 |

| 3 | 22.3316 | 18.7173 | 4.0867 | 21.0866 | 19.3890 | 3.2934 |

| 4 | - | - | - | - | - | - |

| 5 | 20.7475 | 18.7574 | 4.0210 | 20.2745 | 19.3302 | 3.2264 |

| 6 | 21.5946 | 18.4086 | 3.9472 | 20.9393 | 19.3629 | 3.3108 |

| 7 | - | - | - | - | - | - |

| 8 | 22.0808 | 19.2226 | 3.9474 | 20.6734 | 19.9513 | 3.1421 |

| 9 | 21.4837 | 19.0415 | 3.9793 | 21.1668 | 19.61393 | 3.1179 |

| 10 | 21.1908 | 19.0125 | 4.0565 | 20.9868 | 19.67483 | 3.0965 |

| 11 | 21.4995 | 18.9975 | 3.9950 | 21.0757 | 19.54573 | 3.2428 |

| 12 | 22.1765 | 18.6828 | 4.0467 | 21.3448 | 19.2631 | 3.3623 |

| 13 | - | - | - | - | - | - |

| 14 | 21.1733 | 18.9931 | 3.9846 | 20.7290 | 19.2369 | 3.1880 |

| 15 | 20.4775 | 18.3627 | 4.0102 | 20.7856 | 19.1195 | 3.1980 |

| 16 | - | - | - | - | - | - |

| 17 | 20.0485 | 18.5816 | 4.0103 | 20.1654 | 19.2169 | 3.2380 |

| 18 | 20.2333 | 18.7051 | 4.0192 | 20.8717 | 19.3623 | 3.2022 |

| 19 | 22.4258 | 19.2364 | 4.0441 | 21.7333 | 20.0394 | 3.0376 |

| 20 | 22.1495 | 19.0812 | 4.0127 | 21.6307 | 19.6463 | 3.0273 |

| 21 | 21.6000 | 18.8209 | 4.0677 | 21.0592 | 19.0616 | 3.0207 |

| 22 | - | - | - | - | - | - |

| 23 | 22.6790 | 19.0141 | 4.0255 | 22.1221 | 19.9752 | 3.2996 |

| 24 | 21.6583 | 18.8334 | 4.0635 | 21.3612 | 19.4491 | 3.0364 |

| 25 | - | - | - | - | - | - |

| 26 | 21.8360 | 19.3610 | 4.0160 | 21.3720 | 19.7760 | 3.1042 |

| 27 | 21.8495 | 19.0096 | 4.0205 | 21.4219 | 19.8097 | 3.0151 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.-W.; Liu, B.-K.; Zhao, S.-D. Influence of Processing Parameters on the Thread and Spline Synchronous Rolling Process: An Experimental Study. Materials 2019, 12, 1716. https://doi.org/10.3390/ma12101716

Zhang D-W, Liu B-K, Zhao S-D. Influence of Processing Parameters on the Thread and Spline Synchronous Rolling Process: An Experimental Study. Materials. 2019; 12(10):1716. https://doi.org/10.3390/ma12101716

Chicago/Turabian StyleZhang, Da-Wei, Bing-Kun Liu, and Sheng-Dun Zhao. 2019. "Influence of Processing Parameters on the Thread and Spline Synchronous Rolling Process: An Experimental Study" Materials 12, no. 10: 1716. https://doi.org/10.3390/ma12101716

APA StyleZhang, D.-W., Liu, B.-K., & Zhao, S.-D. (2019). Influence of Processing Parameters on the Thread and Spline Synchronous Rolling Process: An Experimental Study. Materials, 12(10), 1716. https://doi.org/10.3390/ma12101716