Investigation of the In-Plane Mechanical Anisotropy of Magnesium Alloy AZ31B-O by VPSC–TDT Crystal Plasticity Model

Abstract

1. Introduction

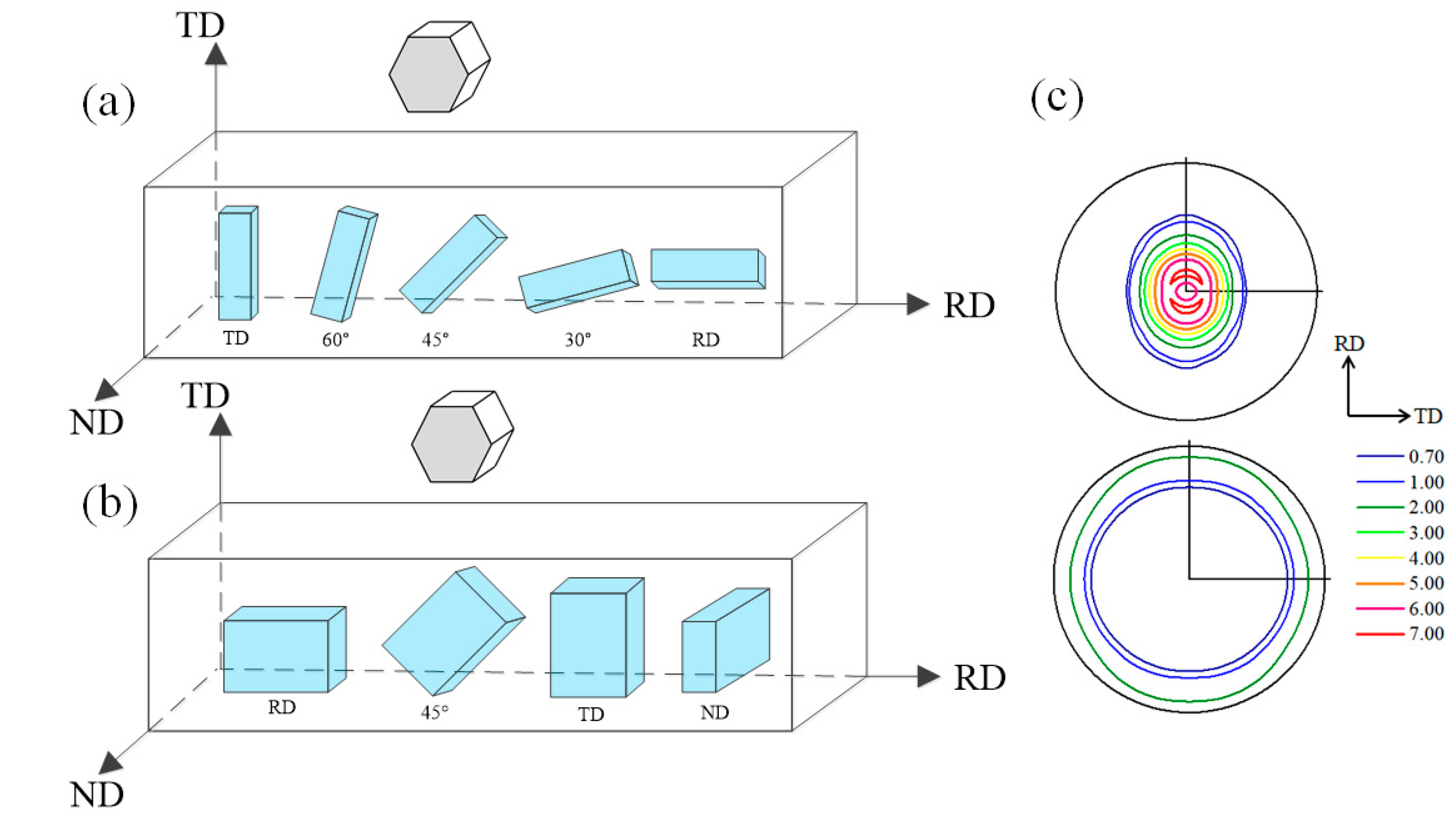

2. Experiment

3. VPSC–TDT Model

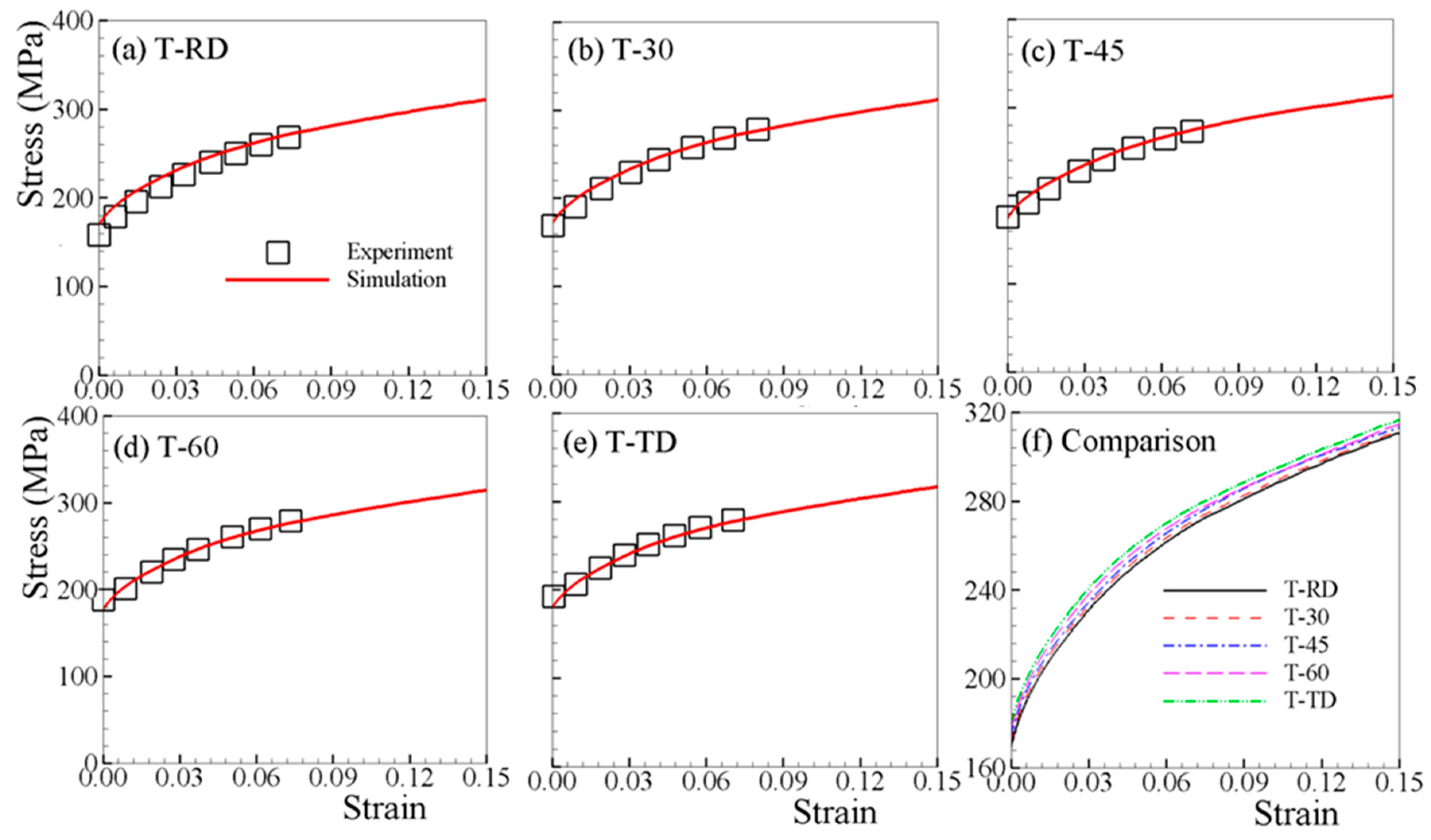

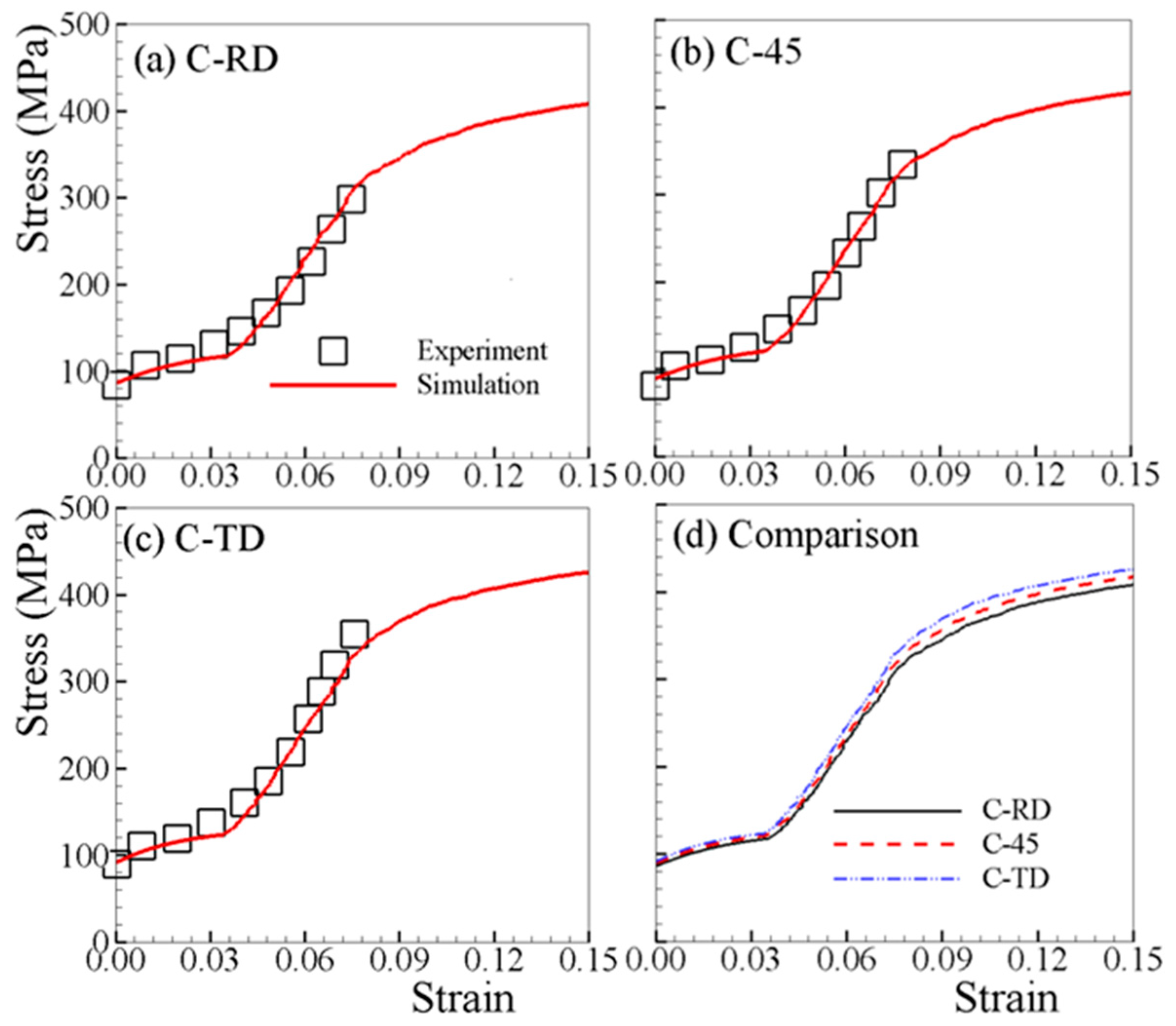

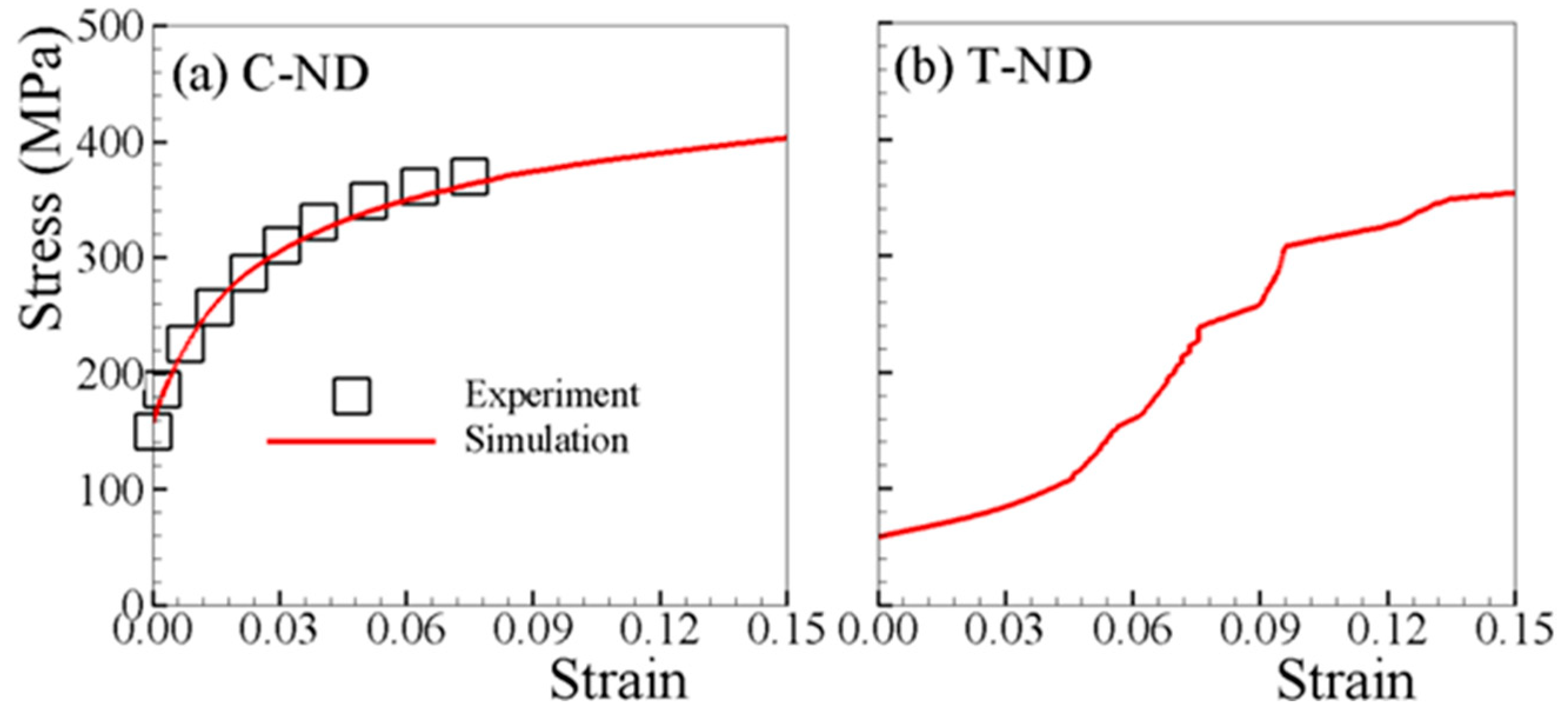

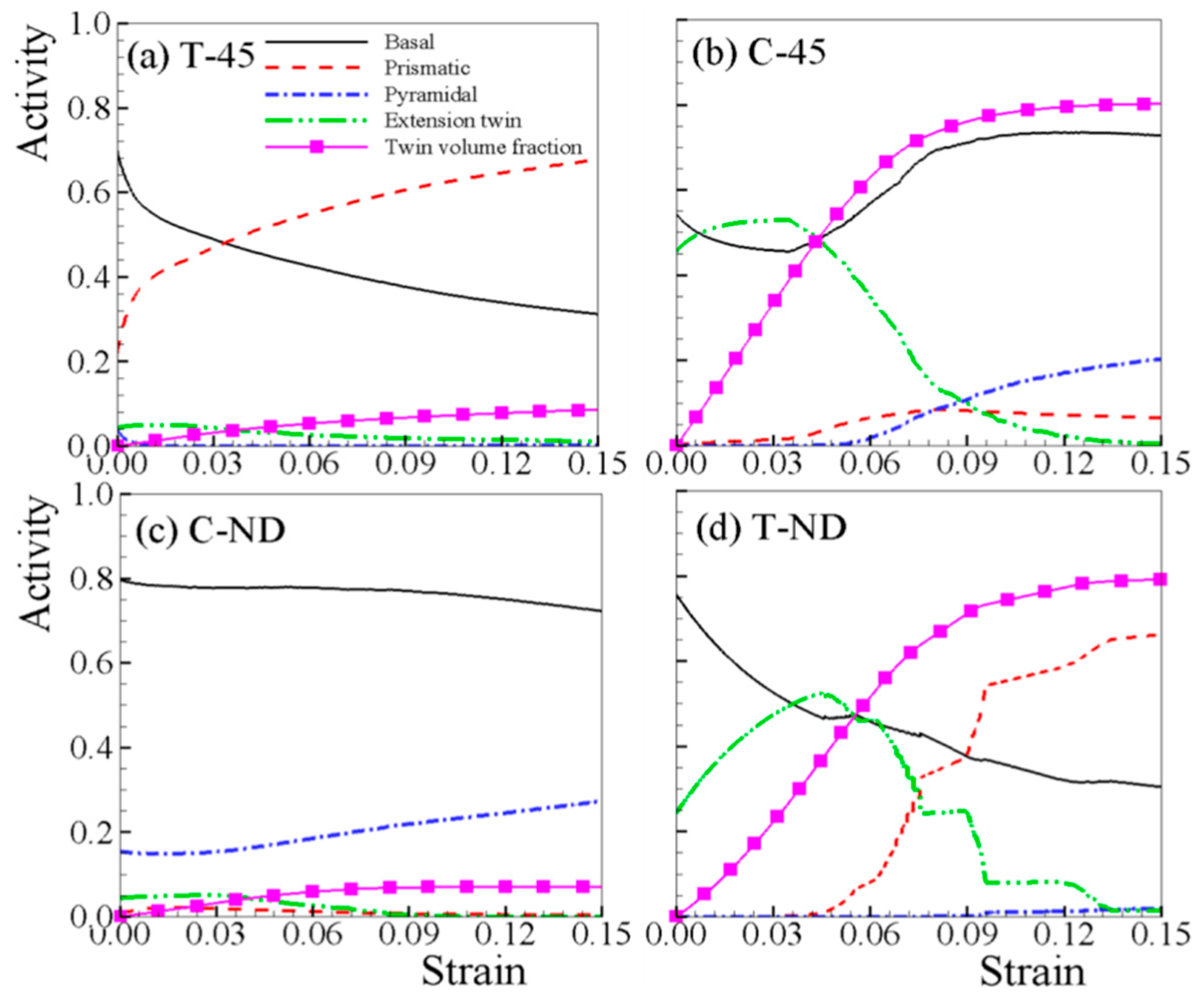

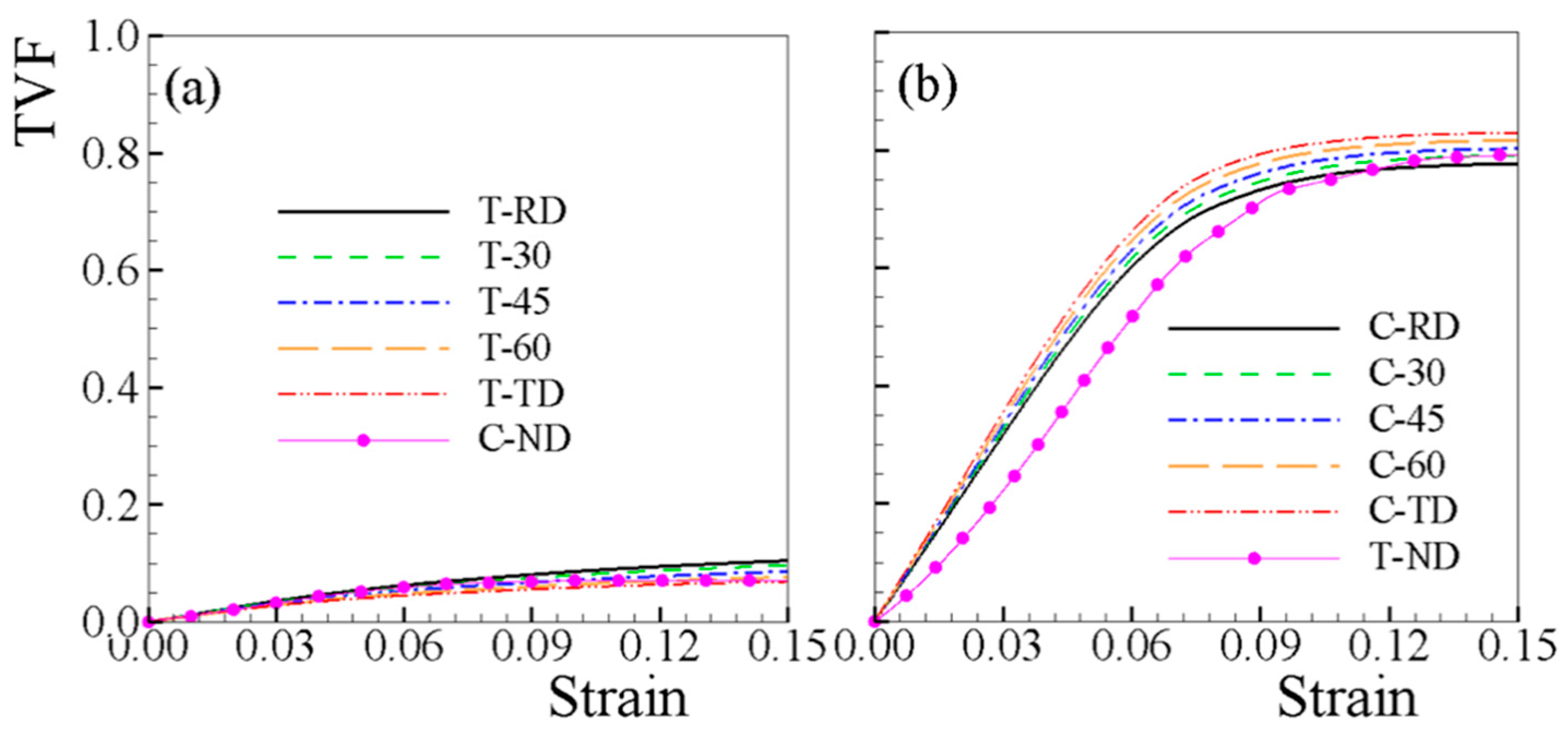

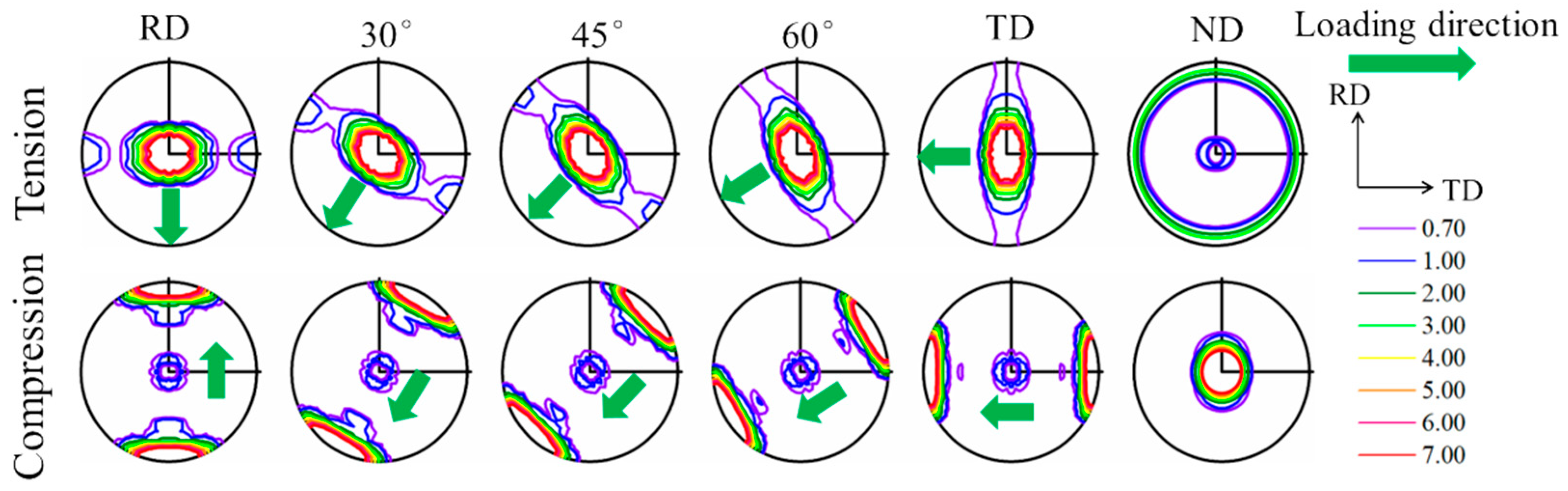

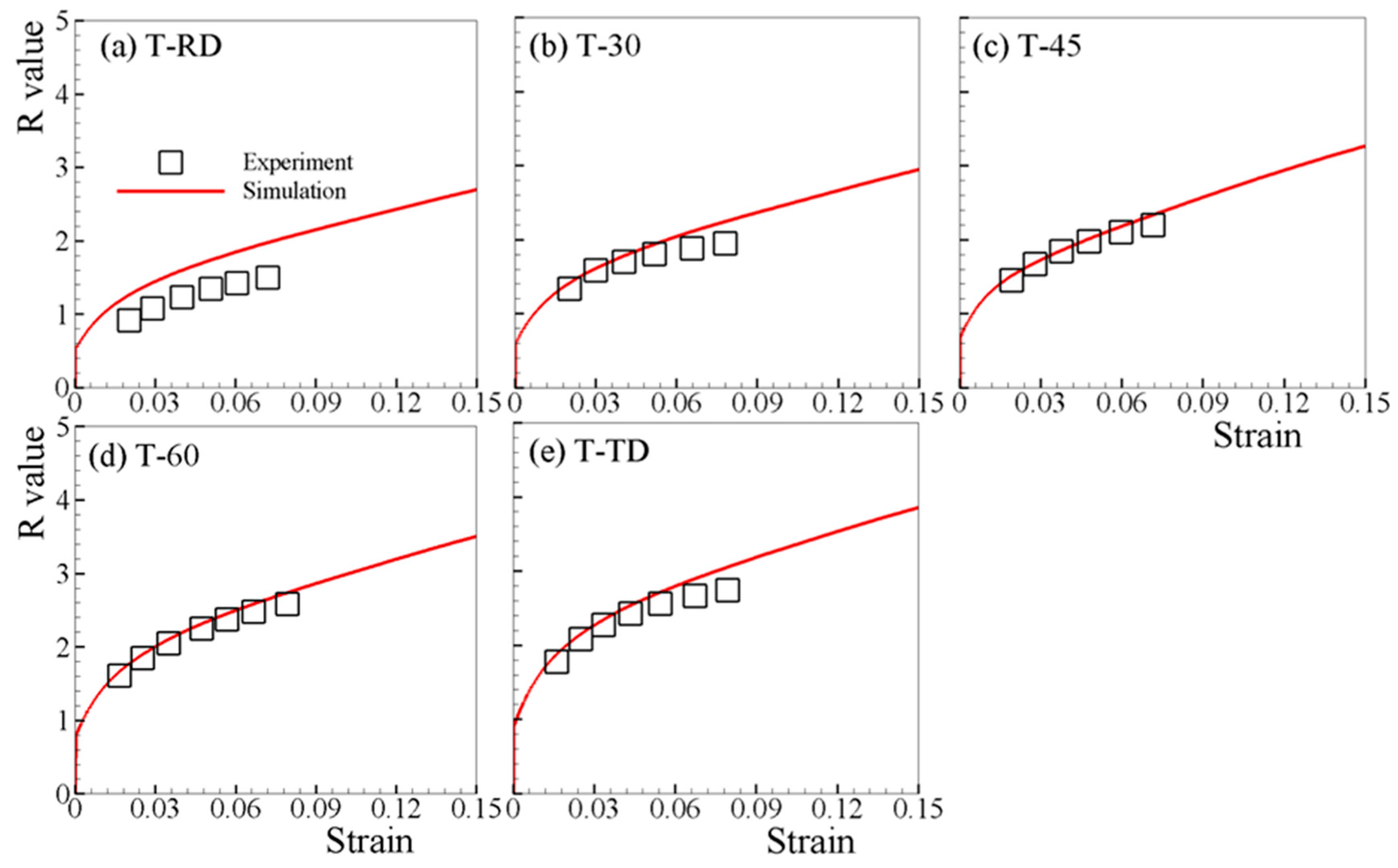

4. Results and Discussions

4.1. Mechanical Behavior

4.2. Texture Evolution

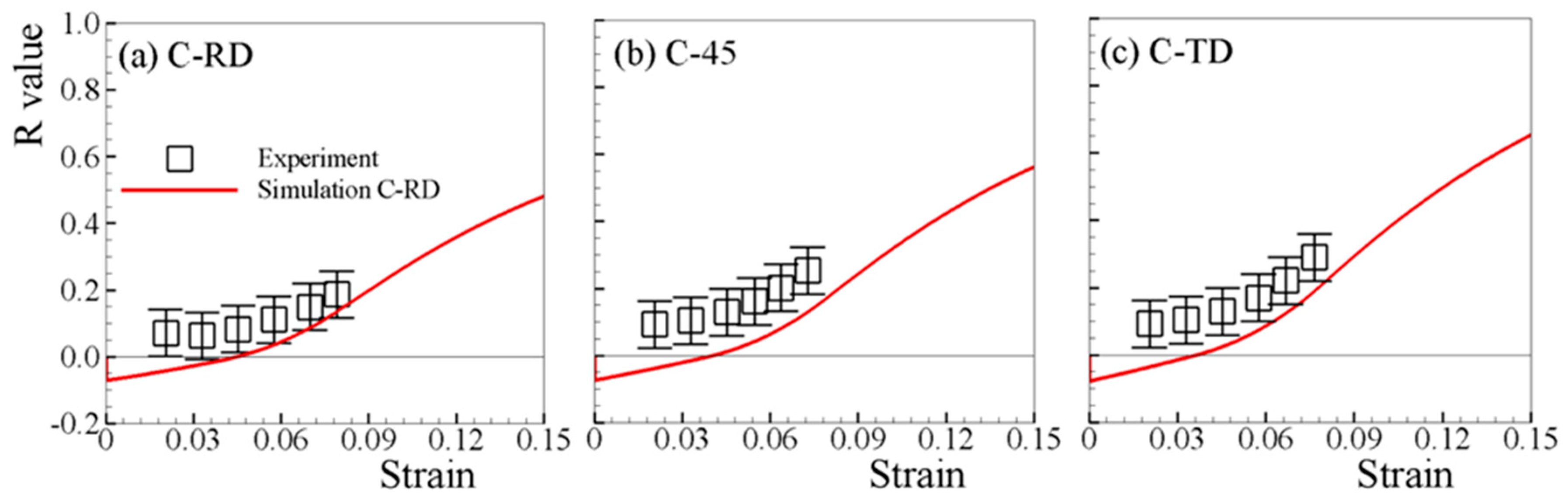

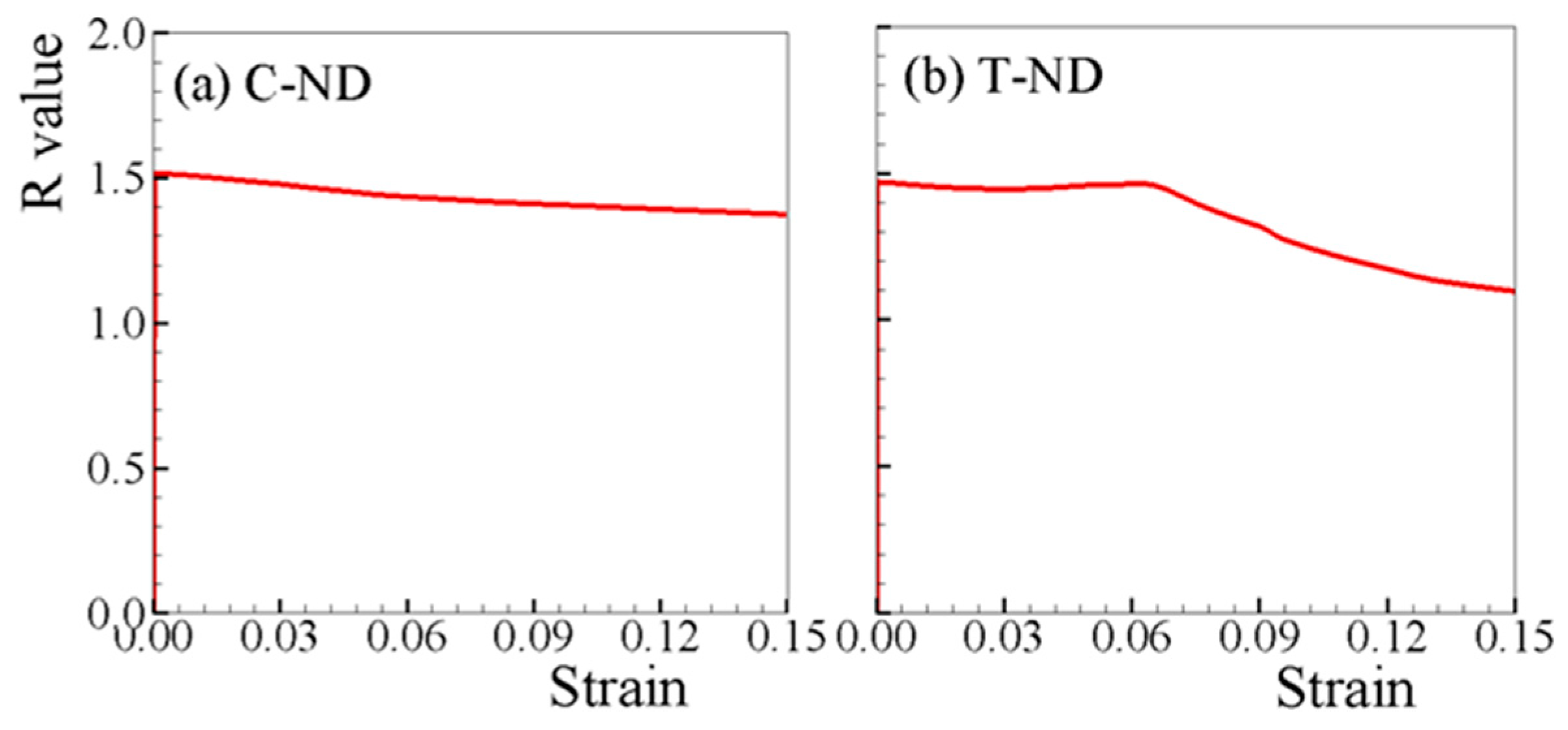

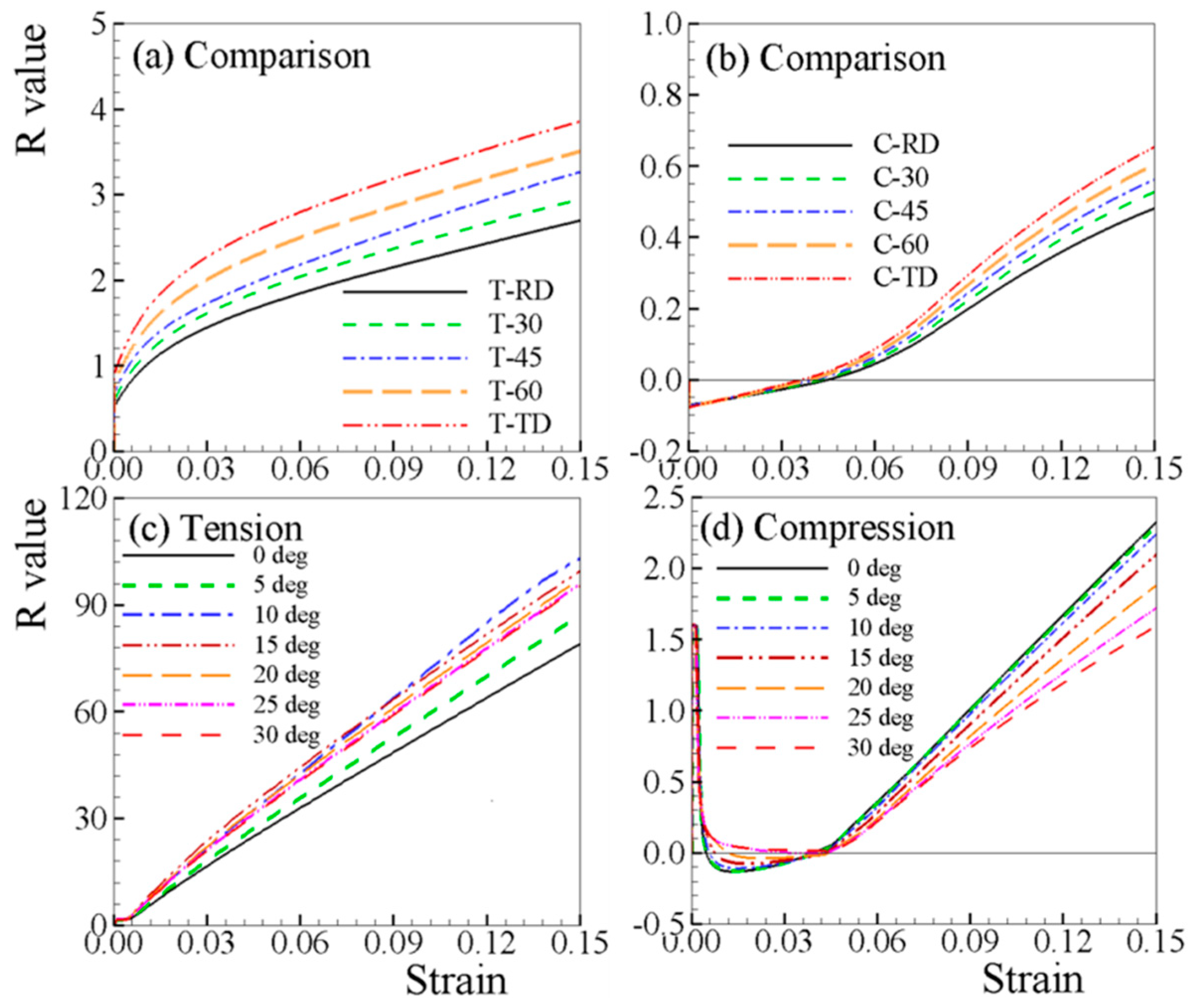

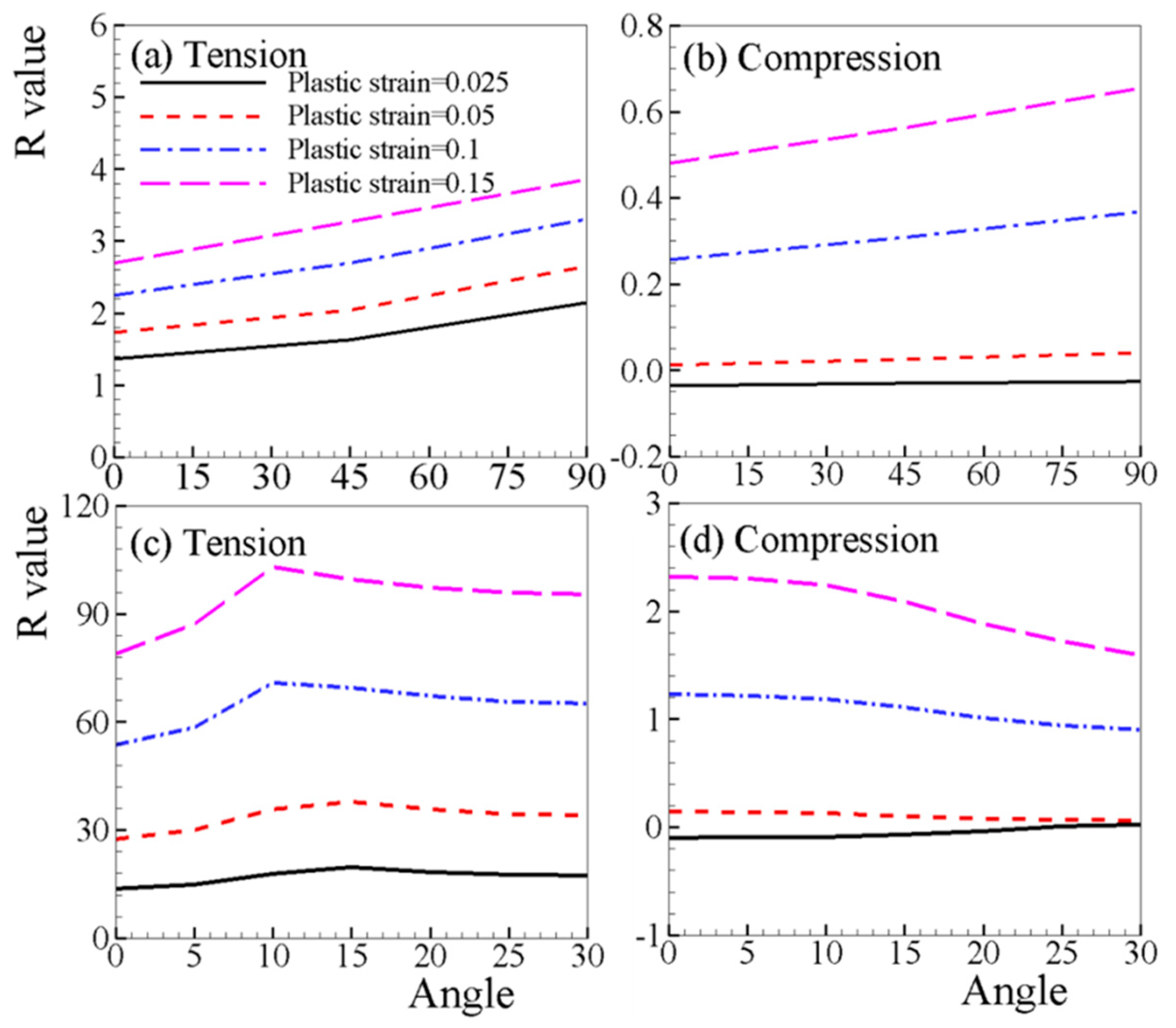

4.3. R-Value Evolution

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, H.; Wu, P.D.; Wang, J.; Tome, C.N. A physics-based crystal plasticity model for hexagonal close packed (HCP) crystals including both twinning and de-twinning mechanisms. Int. J. Plast. 2013, 49, 36–52. [Google Scholar] [CrossRef]

- Wu, P.D.; Guo, X.Q.; Qiao, H.; Agnew, S.R.; Lloyd, D.J.; Embury, J.D. On the rapid hardening and exhaustion of twinning in magnesium alloy. Acta Mater. 2017, 122, 369–377. [Google Scholar] [CrossRef]

- Balik, J.; Dobron, P.; Chmelik, F.; Kuzel, R.; Drozdenko, D.; Bohlen, J.; Letzig, D.; Lukac, P. Modeling of the work hardening in magnesium alloy sheets. Int. J. Plast. 2015, 76, 166–185. [Google Scholar] [CrossRef]

- Barnett, M.R.; Ghaderi, A.; Quinta da Fonseca, J.; Robson, J.D. Influence of orientation on twin nucleation and growth at low strains in a magnesium alloy. Acta Mater. 2014, 80, 380–391. [Google Scholar] [CrossRef]

- Wu, L.; Jain, A.; Brown, D.W.; Stoica, G.M.; Agnew, S.R.; Clausen, B.; Fielden, D.E.; Liaw, P.K. Twinning–detwinning behavior during the strain-controlled low-cycle fatigue testing of a wrought magnesium alloy, ZK60A. J. Alloy. Acta Mater. 2008, 56, 688–695. [Google Scholar] [CrossRef]

- Ulacia, I.; Salisbury, C.P.; Hurtado, I.; Worswick, M.J. Tensile characterization and constitutive modeling of AZ31B magnesium alloy sheet over wide range of strain rates and temperatures. J. Mater. Process. Technol. 2011, 211, 830–839. [Google Scholar] [CrossRef]

- Ulacia, I.; Dudamell, N.; Gálvez, F.; Yi, S.; Pérez-Prado, M.; Hurtado, I. Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates. Acta Mater. 2010, 58, 2988–2998. [Google Scholar] [CrossRef]

- Kurukuri, S.; Worswick, M.J.; Ghaffari Tari, D.; Mishra, R.K.; Carter, J.T. Rate sensitivity and tension-compression asymmetry in AZ31B magnesium alloy sheet. Philos. Trans. A Math. Phys. Eng. Sci. 2014, 372, 20130216. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.D.; Wang, J. Modelling the role of slips and twins in magnesium alloys under cyclic shear. Comput. Mater. Sci. 2015, 96, 214–218. [Google Scholar] [CrossRef]

- Qiao, H.; Agnew, S.R.; Wu, P.D. Modeling twinning and detwinning behavior of Mg alloy ZK60A during monotonic and cyclic loading. Int. J. Plast. 2015, 65, 61–84. [Google Scholar] [CrossRef]

- Agnew, S.R.; Duygulu, O. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast. 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Oppedal, A.L.; Kadiri, H.E.; Tomé, C.N.; Vogel, S.C.; Horstemeyer, M.F. Anisotorpy in hexagonal close-packed structures: Improvements crystals plasticity approaches applied to magnesium alloy. Philos. Mag. 2013, 93, 4311–4330. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Tomé, C.N. A self-consistent anisotropic approach for the simulation of plastic-deformation and texture development of polycrystals-application to zirconium alloys. Acta Metall. Mater. 1993, 41, 2611–2624. [Google Scholar] [CrossRef]

- Barlat, F.; Maeda, Y.; Chung, K.; Yanagawa, M.; Brem, J.C.; Hayashida, Y.; Lege, D.J.; Matsui, K.; Murtha, S.J.; Hattori, S.; et al. Yield function development for aluminum alloy sheets. J. Mech. Phys. Solids 1997, 45, 1727–1763. [Google Scholar] [CrossRef]

- Plunkett, B.; Cazacu, O.; Barlat, F. Orthotropic yield criteria for description of the anisotropy in tension and compression of sheet metals. Int. J. Plast. 2008, 24, 847–866. [Google Scholar] [CrossRef]

- Jain, A.; Agnew, S.R. Modeling the temperature dependent effect of twinning on the behavior of magnesium alloy AZ31B sheet. Mater. Sci. Eng. A 2007, 462, 29–36. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, G.; Kong, D.; Sang, G.; Song, B. Influence of initial texture on formability of AZ31B magnesium alloy sheets at different temperatures. J. Mater. Process. Technol. 2011, 211, 1575–1580. [Google Scholar] [CrossRef]

- Lin, P.; Sun, Y.; Chi, C.; Wang, W. Effect of plastic anisotropy of ZK60 magnesium alloy sheet on its forming characteristics during deep drawing process. Int. J. Adv. Manuf. Technol. 2016, 88, 1–9. [Google Scholar] [CrossRef]

- Tari, D.G.; Worswick, M.J.; Ali, U.; Gharghouri, M.A. Mechanical response of AZ31B magnesium alloy: Experimental characterization and material modeling considering proportional loading at room temperature. Int. J. Plast. 2014, 55, 247–267. [Google Scholar] [CrossRef]

- Wang, H.; Raeisinia, B.; Wu, P.D.; Agnew, S.R.; Tomé, C.N. Evaluation of self-consistent polycrystal plasticity models for magnesium alloy AZ31B sheet. Int. J. Solids Struct. 2010, 47, 2905–2917. [Google Scholar] [CrossRef]

- Chun, Y.B.; Davies, C.H.J. Negative lateral strain ratio induced by deformation twinning in magnesium alloy AZ31. Mater. Sci. Eng. A 2011, 528, 4941–4946. [Google Scholar] [CrossRef]

- Sachs, G. Plasticity problems in metals. Zeitschrift Verein Deutcher Ingenieur 1928, 72, 734–736. [Google Scholar] [CrossRef]

- Taylor, G.I. Plastic strain in metals. J. Inst. Met. 1938, 62, 307–324. [Google Scholar]

- Bishop, J.W.F.; Hill, R. A theoretical deviation of the plastic properties of a polycrystalline face centered metal. Philos. Mag. Ser. 1951, 42, 1298–1307. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Elastic-plastic behavior of polycrystalline metals hardening accounting to Taylor rule. Proc. R. Soc. Lond. A 1970, 319, 247–272. [Google Scholar] [CrossRef]

- Agnew, S.R.; Brown, D.W.; Tomé, C.N. Validating a polycrystal model for the elastoplastic response of magnesium alloy AZ31 using in situ neutron diffraction. Acta Mater. 2006, 54, 4841–4852. [Google Scholar] [CrossRef]

- Muransky, O.; Carr, D.G.; Barnett, M.R.; Oliver, E.C.; Sittner, P. Investigation of deformation mechanisms involved in the plasticity of AZ31 Mg alloy: In situ neutron diffraction and EPSC modelling. Mater. Sci. Eng. A 2008, 496, 14–24. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.D.; Gharghouri, M.A. Effects of basal texture on mechanical behaviour of magnesium alloy AZ31B sheet. Mater. Sci. Eng. A 2010, 527, 3588–3594. [Google Scholar] [CrossRef]

- Turner, P.A.; Tomé, C.N. A study of residual stresses in Zircaloy-2 with rod texture. Acta Metall. Mater. 1994, 42, 4143–4153. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.D.; Tomé, C.N.; Huang, Y.A. Finite strain elastic-viscoplastic self-consistent model for polycrystalline materials. J. Mech. Phys. Solids 2010, 58, 594–612. [Google Scholar] [CrossRef]

- Roberts, C.S. Magnesium and its Alloys; John Wiley & Sons, Inc.: New York, NY, USA, 1960. [Google Scholar]

- Tomé, C.N.; Lebensohn, R.A.; Kocks, U.F. A model for texture development dominated by deformation twinning-application to zirconium alloys. Acta Metall. Mater. 1991, 39, 2667–2680. [Google Scholar] [CrossRef]

- Kalidindi, S.R. Incorporation of deformation twinning in crystal plasticity models. J. Mech. Phys. Solids 1998, 46, 267–290. [Google Scholar] [CrossRef]

- Proust, G.; Tomé, C.N.; Kaschner, G.C. Modeling texture, twinning and hardening evolution during deformation of hexagonal materials. Acta Mater. 2007, 55, 2137–2148. [Google Scholar] [CrossRef]

- Proust, G.; Tomé, C.N.; Jain, A.; Agnew, S.R. Modeling the effect of twinning and detwinning during strain-path changes of magnesium alloy AZ31. Int. J. Plast. 2009, 25, 861–880. [Google Scholar] [CrossRef]

- Wu, X.; Kalidindi, S.R.; Necker, C.; Salem, A.A. Prediction of crystallographic texture evolution and anisotropic stress–strain curves during large plastic strains in high purity α-titanium using a Taylor-type crystal plasticity model. Acta Mater. 2007, 55, 423–432. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.D.; Tomé, C.N.; Wang, J. A constitutive model of twinning and detwinning for hexagonal close packed polycrystals. Mater. Sci. Eng. A 2012, 555, 93–98. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.D.; Wang, J. Modeling inelastic behavior of magnesium alloys during cyclic loading–unloading. Int. J. Plast. 2013, 47, 49–64. [Google Scholar] [CrossRef]

- Guo, X.Q.; Chapuis, A.; Wu, P.D.; Agnew, S.R. On twinning and anisotropy in rolled Mg alloy AZ31 under uniaxial compression. Int. J. Solids Struct. 2015, 64–65, 42–50. [Google Scholar] [CrossRef]

- Ma, C.; Chapuis, A.; Guo, X.Q.; Zhao, L.Y.; Wu, P.D. Modeling the deformation behavior of a rolled Mg alloy with the EVPSC-TDT model. Mater. Sci. Eng. A 2017, 682, 332–340. [Google Scholar] [CrossRef]

- Guo, X.Q.; Chapuis, A.; Wu, P.D.; Liu, Q.; Mao, X. Experimental and numerical investigation of anisotropic and twinning behavior in Mg alloy under uniaxial tension. Mater. Des. 2016, 98, 333–343. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.D.; Kurukuri, S.; Worswick, M.J.; Peng, Y.H.; Tang, D.; Li, D.Y. Strain rate sensitivities of different deformation mechanisms of magnesium alloys. Int. J. Plast. 2018, 107, 207–222. [Google Scholar] [CrossRef]

- Qiao, H.; Guo, X.Q.; Hong, S.G.; Wu, P.D. Modeling of {10-12}-{10-12} secondary twinning in pre-compressed Mg alloy AZ31. J. Alloy. Compd. 2017, 725, 96–107. [Google Scholar] [CrossRef]

- Simmons, G.; Wang, H. Single Crystal Elastic Constants and Calculated Polycrystal Properties; MIT Press: Cambridge, MA, USA, 1971. [Google Scholar]

- Chapuis, A.; Wang, B.; Liu, Q. A comparative study between uniaxial compression and plane strain compression of Mg-3Al-1Zn alloy using experiments and simulations. Mater. Sci. Eng. A 2014, 597, 349–358. [Google Scholar] [CrossRef]

- Kabirian, F.; Khan, A.S.; Gnäupel-Herlod, T. Visco-plastic modeling of mechanical responses and texture evolution in extruded AZ31 magnesium alloy for various loading conditions. Int. J. Plast. 2015, 68, 1–20. [Google Scholar] [CrossRef]

- Zhou, G.W.; Jain, M.K.; Wu, P.D.; Shao, Y.C.; Li, D.Y.; Peng, Y.H. Experiment and crystal plasticity analysis on plastic deformation of AZ31B Mg alloy sheet under intermediate temperatures: How deformation mechanisms evolve. Int. J. Plast. 2016, 79, 19–47. [Google Scholar] [CrossRef]

- Barlat, F.; Aretz, H.; Yoon, J.W.; Karabin, M.E.; Brem, J.C.; Dick, R.E. Linear transformation-based anisotropic yield functions. Int. J. Plast. 2005, 21, 1009–1039. [Google Scholar] [CrossRef]

- Avery, D.H.; Hosford, W.F.; Backofen, W.A. Plastic anisotropy in magnesium alloy sheets. Trans. Met. Soc. Aime 1965, 233, 71–78. [Google Scholar]

- Kaiser, F.; Letzig, D.; Bohlen, J.; Styczynski, A.; Hartig, C.; Kainer, K.U. Anisotropic properties of magnesium sheet AZ31. Mater. Sci. Forum 2003, 315–320. [Google Scholar] [CrossRef]

- Hartig, Ch.; Styczynski, A.; Kaiser, F.; Letzig, D. Plastic anisotropy and texture evolution of rolled AZ31 magnesium alloys. Mater. Sci. Forum 2005, 495–497, 1615–1620. [Google Scholar] [CrossRef]

- Lou, X.Y.; Li, M.; Boger, R.K.; Agnew, S.R.; Wagoner, R.H. Hardening evolution of AZ31B Mg sheet. Int. J. Plast. 2007, 23, 44–86. [Google Scholar] [CrossRef]

- Del Valle, J.A.; Ruano, O.A. Effect of annealing treatments on the anisotropy of a magnesium alloy sheet processed by severe rolling. Mater. Lett. 2009, 63, 1551–1554. [Google Scholar] [CrossRef]

| Al | Zn | Mn | Cu | Fe | Ni | Si | Mg |

|---|---|---|---|---|---|---|---|

| 2.9 | 0.25 | 0.94 | 0.001 | 0.004 | 0.005 | 0.005 | Bal |

| Mode | τ0 (MPa) | τ1 (MPa) | h0 (MPa) | h1 (MPa) | hαβ | A1 | A2 |

|---|---|---|---|---|---|---|---|

| Basal | 5 | 7 | 150 | 25 | 2.0 | – | – |

| Prismatic | 95 | 30 | 350 | 25 | 1.0 | – | – |

| Pyramidal | 105 | 110 | 3000 | 0 | 1.5 | – | – |

| Extension twin | 37 | 0 | 0 | 0 | 1.0 | 0.65 | 0.55 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Li, S.; Wang, H.; Tang, W.; Jiang, Y.; Wu, P. Investigation of the In-Plane Mechanical Anisotropy of Magnesium Alloy AZ31B-O by VPSC–TDT Crystal Plasticity Model. Materials 2019, 12, 1590. https://doi.org/10.3390/ma12101590

Zhang B, Li S, Wang H, Tang W, Jiang Y, Wu P. Investigation of the In-Plane Mechanical Anisotropy of Magnesium Alloy AZ31B-O by VPSC–TDT Crystal Plasticity Model. Materials. 2019; 12(10):1590. https://doi.org/10.3390/ma12101590

Chicago/Turabian StyleZhang, Bo, Shuangming Li, Huamiao Wang, Weiqin Tang, Yaodong Jiang, and Peidong Wu. 2019. "Investigation of the In-Plane Mechanical Anisotropy of Magnesium Alloy AZ31B-O by VPSC–TDT Crystal Plasticity Model" Materials 12, no. 10: 1590. https://doi.org/10.3390/ma12101590

APA StyleZhang, B., Li, S., Wang, H., Tang, W., Jiang, Y., & Wu, P. (2019). Investigation of the In-Plane Mechanical Anisotropy of Magnesium Alloy AZ31B-O by VPSC–TDT Crystal Plasticity Model. Materials, 12(10), 1590. https://doi.org/10.3390/ma12101590