Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template Compression

Abstract

1. Introduction

2. Methods

2.1. Material Preparation and Characterization

2.2. Flexible Template Preparation

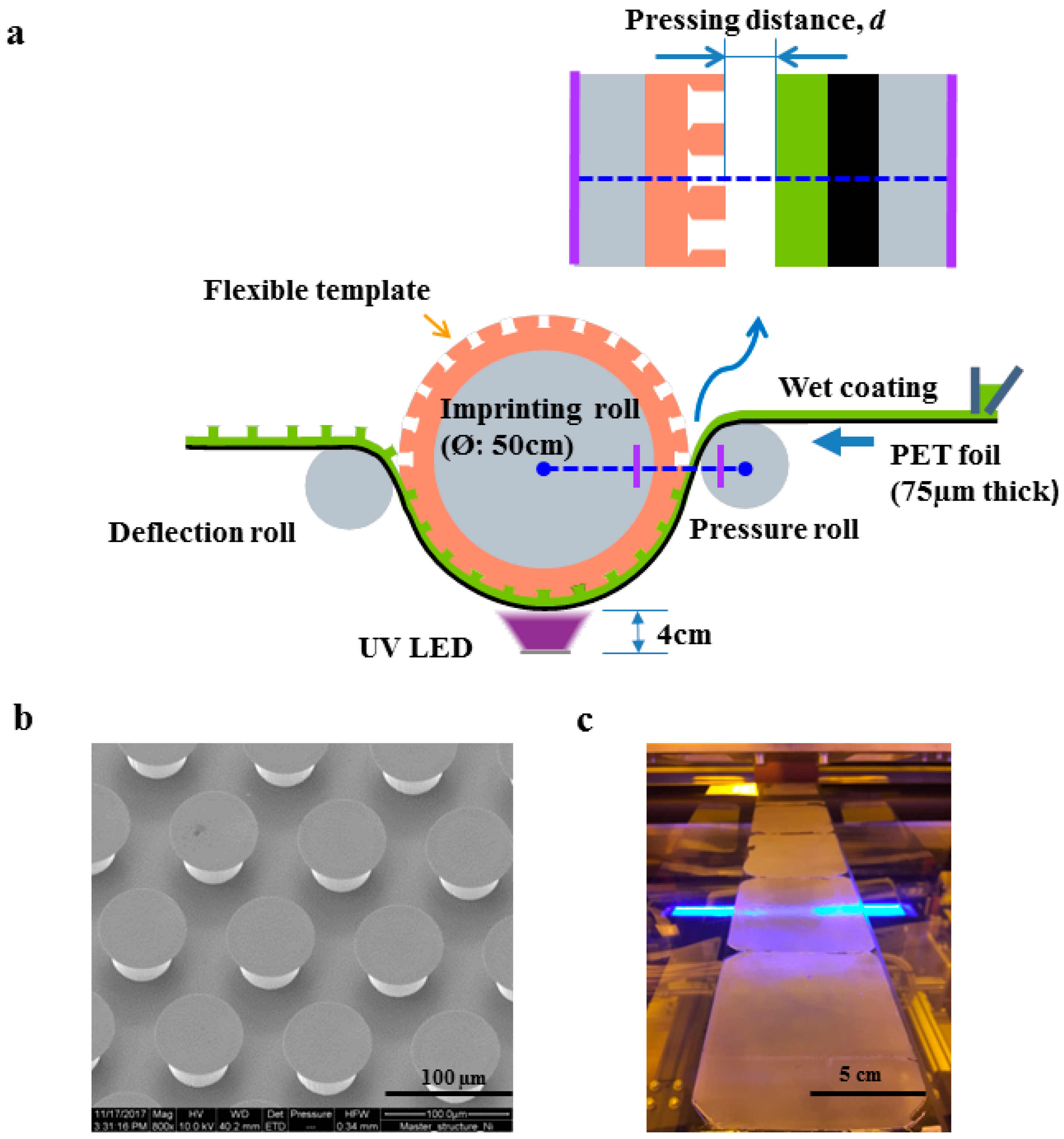

2.3. Micropattern Fabrication by a Roll-to-Roll Process

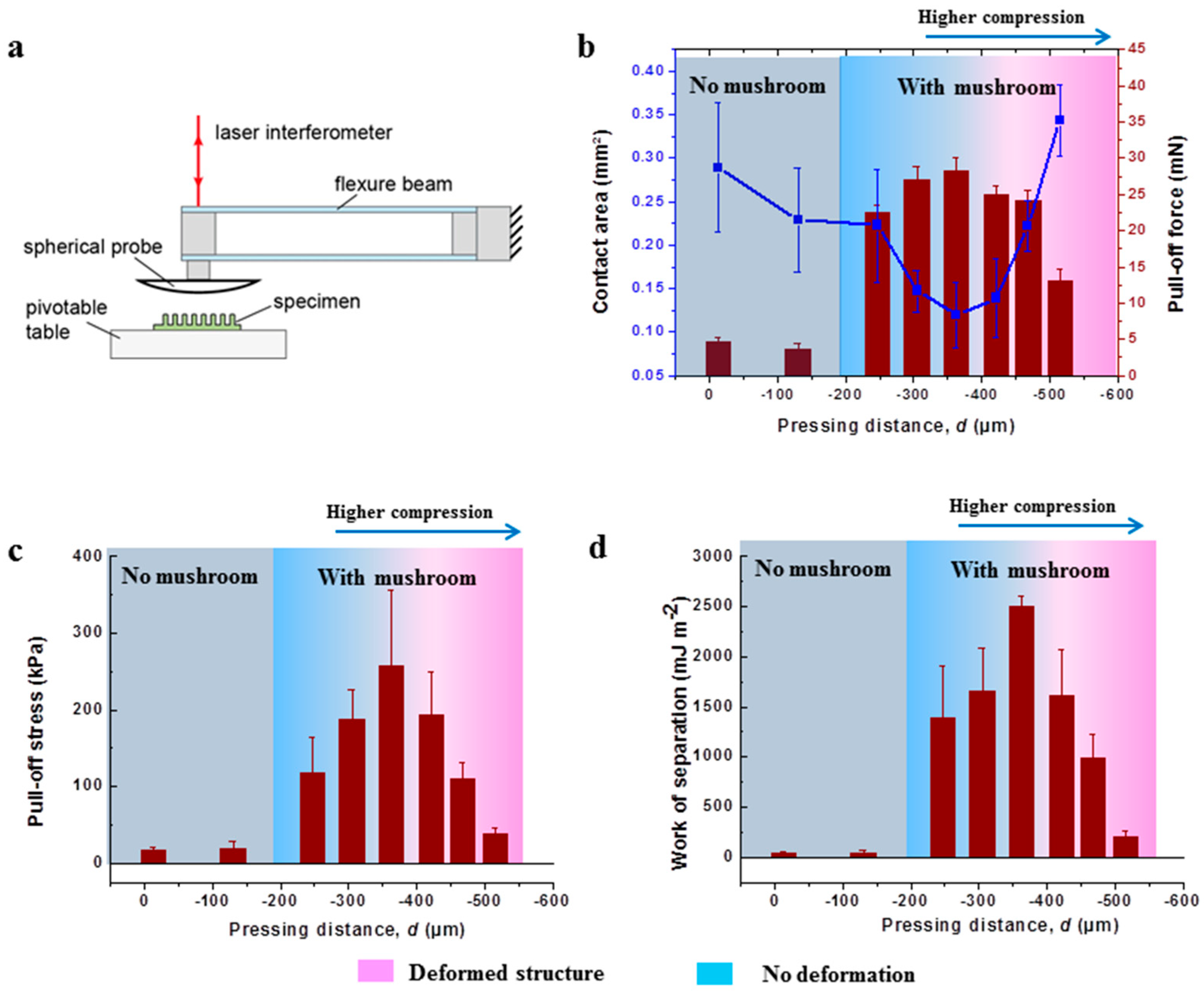

2.4. Adhesion Measurement

3. Results

3.1. Microstructure Results

- “No mushroom” range ( in the range of to At low compression of the template, micropillars without mushroom tip were formed (Figure 2a,b). Instead, the “no mushroom” pillars exhibited concave tip faces. The pillar heights were only and for and , respectively, which is below the original height of the cavities with a depth of .

- “Mushroom” range ( in the range of to : With sufficient compression, microstructures with mushroom caps were generated (Figure 2c–h).

3.2. Adhesion Results

4. Discussion

5. Conclusions

- Fabrication of mushroom-shaped microstructures exhibiting re-entrant features is possible by utilization of flexible templates.

- Compression between the template and the wet coating is required to fill the cavities of the silicone-based mold. Insufficient compression leads to microstructures without mushrooms accompanied by low-adhesion performance.

- The compression could be controlled by the distance between the flexible template and the wet coating. Variations of the distance result in variations of the morphology, which in turn control the adhesion performance. Best adhesion results were obtained for microstructures generated using the shortest distance before they were distorted due to template deformation.

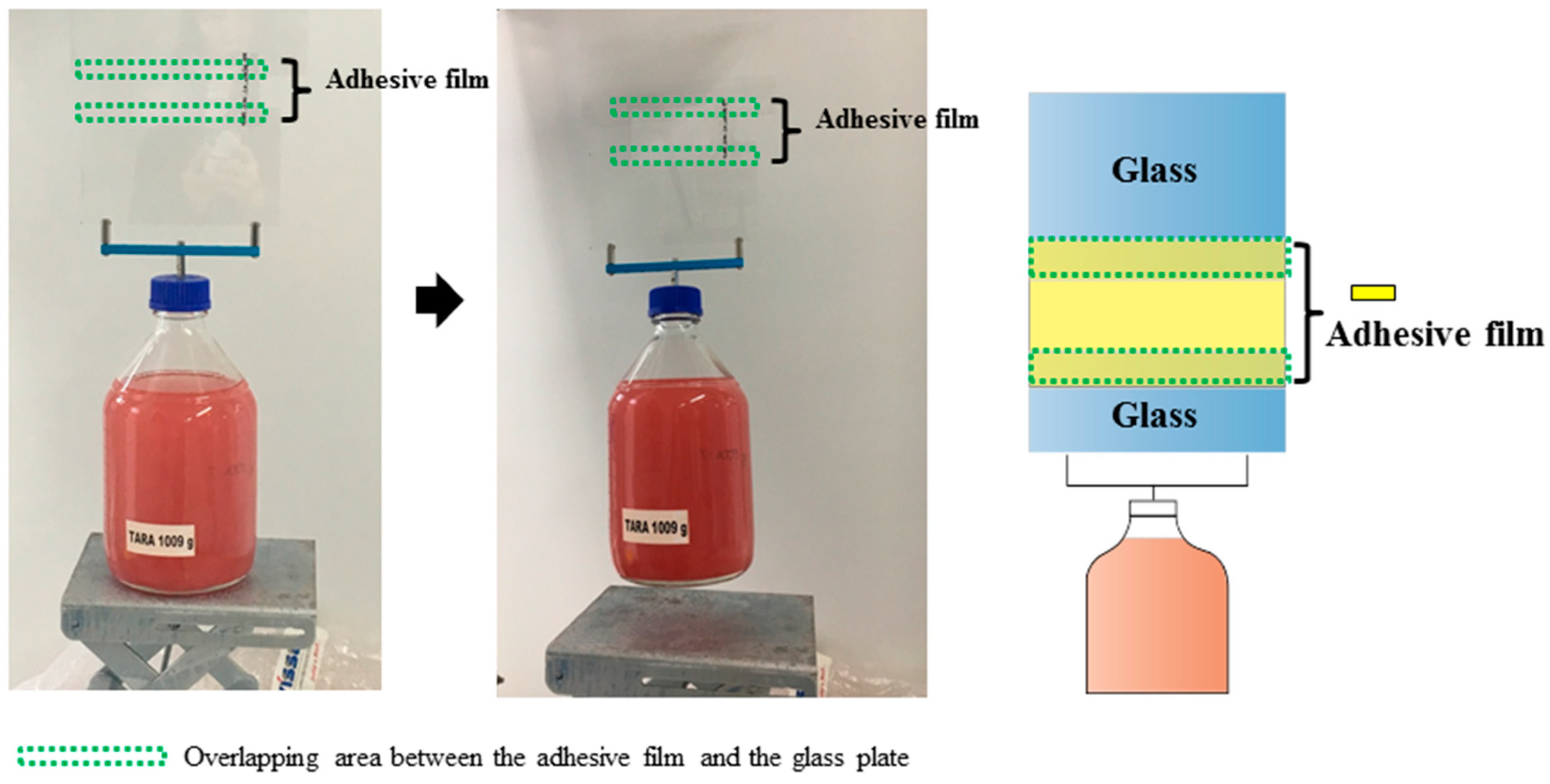

- In addition to normal adhesion, the micropatterned dry adhesive film exhibited remarkable shear adhesion, demonstrating its high potential for applications where normal and shear adhesion are required.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arzt, E.; Gorb, S.; Spolenak, R. From micro to nano contacts in biological attachment devices. Proc. Natl. Acad. Sci. USA 2003, 100, 10603–10606. [Google Scholar] [CrossRef]

- Kamperman, M.; Kroner, E.; del Campo, A.; McMeeking, R.M.; Arzt, E. Functional Adhesive Surfaces with “Gecko” Effect: The Concept of Contact Splitting. Adv. Eng. Mater. 2010, 12, 335–348. [Google Scholar] [CrossRef]

- Hensel, R.; Moh, K.; Arzt, E. Engineering Micropatterned Dry Adhesives: From Contact Theory to Handling Applications. Adv. Funct. Mater. 2018, 28, 1800865. [Google Scholar] [CrossRef]

- Cheung, E.; Sitti, M. Adhesion of Biologically Inspired Polymer Microfibers on Soft Surfaces. Langmuir 2009, 25, 6613–6616. [Google Scholar] [CrossRef]

- Castellanos, G.; Arzt, E.; Kamperman, M. Effect of Viscoelasticity on Adhesion of Bioinspired Micropatterned Epoxy Surfaces. Langmuir 2011, 27, 7752–7759. [Google Scholar] [CrossRef]

- Khaderi, S.N.; Fleck, N.A.; Arzt, E.; McMeeking, R.M. Detachment of an adhered micropillar from a dissimilar substrate. J. Mech. Phys. Solids 2015, 75, 159–183. [Google Scholar] [CrossRef]

- Lakhera, N.G.A.; Schneider, A.S.; Kroner, E. Adhesion behavior of polymer networks with tailored mechanical properties using spherical and flat contacts. MRS Commun. 2013, 3, 73–77. [Google Scholar] [CrossRef]

- Boesel, L.F.; Greiner, C.; Arzt, E.; del Campo, A. Gecko-Inspired Surfaces: A Path to Strong and Reversible Dry Adhesives. Adv. Mater. 2010, 22, 2125–2137. [Google Scholar] [CrossRef]

- Murphy, M.P.; Aksak, B.; Sitti, M. Gecko-Inspired Directional and Controllable Adhesion. Small 2008, 5, 170–175. [Google Scholar] [CrossRef]

- Sameoto, D.; Menon, C. Direct molding of dry adhesives with anisotropic peel strength using an offset lift-off photoresist mold. J. Micromech. Microeng. 2009, 19, 115026. [Google Scholar] [CrossRef]

- Kwak, M.K.; Jeong, H.E.; Bae, W.G.; Jung, H.-S.; Suh, K.Y. Anisotropic Adhesion Properties of Triangular-Tip-Shaped Micropillars. Small 2011, 7, 2296–2300. [Google Scholar] [CrossRef]

- Del Campo, A.; Greiner, C.; Álvarez, I.; Arzt, E. Patterned Surfaces with Pillars with Controlled 3D Tip Geometry Mimicking Bioattachment Devices. Adv. Mater. 2007, 19, 1973–1977. [Google Scholar] [CrossRef]

- Kim, S.; Sitti, M. Biologically inspired polymer microfibers with spatulate tips as repeatable fibrillar adhesives. Appl. Phys. Lett. 2006, 89, 261911. [Google Scholar] [CrossRef]

- Seo, S.; Lee, J.; Kim, K.-S.; Ko, K.H.; Lee, J.H.; Lee, J. Anisotropic Adhesion of Micropillars with Spatula Pads. ACS Appl. Mater. Interfaces 2014, 6, 1345–1350. [Google Scholar] [CrossRef]

- Del Campo, A.; Greiner, C.; Arzt, E. Contact shape controls adhesion of bioinspired fibrillar surfaces. Langmuir 2007, 23, 10235–10243. [Google Scholar] [CrossRef]

- Spuskanyuk, A.V.; McMeeking, R.M.; Deshpande, V.S.; Arzt, E. The effect of shape on the adhesion of fibrillar surfaces. Acta Biomaterialia 2008, 4, 1669–1676. [Google Scholar] [CrossRef]

- Carbone, G.; Pierro, E. Sticky Bio-inspired Micropillars: Finding the Best Shape. Small 2012, 8, 1449–1454. [Google Scholar] [CrossRef]

- Aksak, B.; Sahin, K.; Sitti, M. The optimal shape of elastomer mushroom-like fibers for high and robust adhesion. Beilstein J. Nanotechnol. 2014, 5, 630–638. [Google Scholar] [CrossRef]

- Balijepalli, R.G.; Begley, M.R.; Fleck, N.A.; McMeeking, R.M.; Arzt, E. Numerical simulation of the edge stress singularity and the adhesion strength for compliant mushroom fibrils adhered to rigid substrates. Int. J. Solids Struct. 2016, 85–86, 160–171. [Google Scholar] [CrossRef]

- Dumond, J.J.; Yee Low, H. Recent developments and design challenges in continuous roller micro- and nanoimprinting. J. Vac. Sci. Technol. B Microelectron. Process. Phenom. 2012, 30, 010801. [Google Scholar] [CrossRef]

- Leitgeb, M.; Nees, D.; Ruttloff, S.; Palfinger, U.; Götz, J.; Liska, R.; Belegratis, M.R.; Stadlober, B. Multilength Scale Patterning of Functional Layers by Roll-to-Roll Ultraviolet-Light-Assisted Nanoimprint Lithography. ACS Nano 2016, 10, 4926–4941. [Google Scholar] [CrossRef]

- Kooy, N.; Mohamed, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale Res. Lett. 2014, 9, 320. [Google Scholar] [CrossRef]

- Ahn, S.H.; Guo, L.J. High-Speed Roll-to-Roll Nanoimprint Lithography on Flexible Plastic Substrates. Adv. Mater. 2008, 20, 2044–2049. [Google Scholar] [CrossRef]

- Ahn, S.H.; Guo, L.J. Large-Area Roll-to-Roll and Roll-to-Plate Nanoimprint Lithography: A Step toward High-Throughput Application of Continuous Nanoimprint. ACS Nano 2009, 3, 2304–2310. [Google Scholar] [CrossRef]

- Jeong, H.E.; Suh, K.Y. Nanohairs and nanotubes: Efficient structural elements for gecko-inspired artificial dry adhesives. Nano Today 2009, 4, 335–346. [Google Scholar] [CrossRef]

- Jeong, H.E.; Lee, J.K.; Kim, H.N.; Moon, S.H.; Suh, K.Y. A nontransferring dry adhesive with hierarchical polymer nanohairs. Proc. Natl. Acad. Sci. USA 2009, 106, 5639–5644. [Google Scholar] [CrossRef]

- Jeong, H.E.; Lee, J.-K.; Kwak, M.K.; Moon, S.H.; Suh, K.Y. Effect of leaning angle of gecko-inspired slanted polymer nanohairs on dry adhesion. Appl. Phys. Lett. 2010, 96, 043704. [Google Scholar] [CrossRef]

- Kim, T.-I.; Jeong, H.E.; Suh, K.Y.; Lee, H.H. Stooped Nanohairs: Geometry-Controllable, Unidirectional, Reversible, and Robust Gecko-like Dry Adhesive. Adv. Mater. 2009, 21, 2276–2281. [Google Scholar] [CrossRef]

- Yi, H.; Hwang, I.; Lee, J.H.; Lee, D.; Lim, H.; Tahk, D.; Sung, M.; Bae, W.-G.; Choi, S.-J.; Kwak, M.K.; et al. Continuous and Scalable Fabrication of Bioinspired Dry Adhesives via a Roll-to-Roll Process with Modulated Ultraviolet-Curable Resin. ACS Appl. Mater. Interfaces 2014, 6, 14590–14599. [Google Scholar] [CrossRef]

- Lee, S.H.; Yi, H.; Park, C.W.; Jeong, H.E.; Kwak, M.K. Continuous tip widening technique for roll-to-roll fabrication of dry adhesives. Coatings 2018, 8, 349–355. [Google Scholar] [CrossRef]

- Wu, S. Polar and Nonpolar Interactions in Adhesion. J. Adhes. 1973, 5, 39–55. [Google Scholar] [CrossRef]

- Barreau, V.; Hensel, R.; Guimard, N.K.; Ghatak, A.; McMeeking, R.M.; Arzt, E. Fibrillar Elastomeric Micropatterns Create Tunable Adhesion Even to Rough Surfaces. Adv. Funct. Mater. 2016, 26, 4687–4694. [Google Scholar] [CrossRef]

- Kroner, E.; Arzt, E. Single macropillars as model systems for tilt angle dependent adhesion measurements. Int. J. Adhes. Adhes. 2012, 36, 32–38. [Google Scholar] [CrossRef]

- Koo, N.; Plachetka, U.; Otto, M.; Bolten, J.; Jeong, J.-H.; Lee, E.-S.; Kurz, H. The fabrication of a flexible mold for high resolution soft ultraviolet nanoimprint lithography. Nanotechnology 2008, 19, 225304. [Google Scholar] [CrossRef]

- Fischer, S.C.L.; Groß, K.; Torrents Abad, O.; Becker, M.M.; Park, E.; Hensel, R.; Arzt, E. Funnel-Shaped Microstructures for Strong Reversible Adhesion. Adv. Mater. Interfaces 2017, 4, 1700292. [Google Scholar] [CrossRef]

- Barreau, V.; Yu, D.; Hensel, R.; Arzt, E. Elevated temperature adhesion of bioinspired polymeric micropatterns to glass. J. Mech. Behav. Biomed. Mater. 2017, 76, 110–118. [Google Scholar] [CrossRef]

- Choi, S.-J.; Kim, H.N.; Bae, W.G.; Suh, K.-Y. Modulus- and surface energy-tunable ultraviolet-curable polyurethane acrylate: Properties and applications. J. Mater. Chem. 2011, 21, 14325–14335. [Google Scholar] [CrossRef]

- Spolenak, R.; Gorb, S.; Arzt, E. Adhesion design maps for bio-inspired attachment systems. Acta Biomaterialia 2005, 1, 5–13. [Google Scholar] [CrossRef]

- Lamblet, M.; Verneuil, E.; Vilmin, T.; Buguin, A.; Silberzan, P.; Léger, L. Adhesion Enhancement through Micropatterning at Polydimethylsiloxane-Acrylic Adhesive Interfaces. Langmuir 2007, 23, 6966–6974. [Google Scholar] [CrossRef]

- Bacca, M.; Booth, J.A.; Turner, K.L.; McMeeking, R.M. Load sharing in bioinspired fibrillar adhesives with backing layer interactions and interfacial misalignment. J. Mech. Phys. Solids 2016, 96, 428–444. [Google Scholar] [CrossRef]

- Paretkar, D.; Kamperman, M.; Martina, D.; Zhao, J.; Creton, C.; Lindner, A.; Jagota, A.; McMeeking, R.; Arzt, E. Preload-responsive adhesion: Effects of aspect ratio, tip shape and alignment. J. R. Soc. Interface 2013, 10, 20130171. [Google Scholar] [CrossRef] [PubMed]

- Tinnemann, V.; Arzt, E.; Hensel, R. Switchable double-sided micropatterned adhesives for selective fixation and detachment. J. Mech. Phys. Solids 2018, in press. [Google Scholar] [CrossRef]

| Material | Description | Young’s Modulus (MPa) | Elongation at Break (%) | Surface Free Energy (mJ m−2) | Viscosity at 25 °C (Pa s) |

|---|---|---|---|---|---|

| UA16 | Aliphatic urethane diacrylate oligomer | 359 | 326 | 40.26 | 13.7 |

| ePDMS | Elastosil M4601 | 0.76 | 700 | 25.82 | -- |

| (µm) | (µm) | h (µm) | |

|---|---|---|---|

| −13 | 45.7 | >90 | 45.7 |

| −130 | 44.7 | >90 | 41.2 |

| −247 | 45.4 | >90 | 37.5 |

| −305 | 45.1 | >90 | 34.6 |

| −363 | 40.8 | <90 | 31.2 |

| −422 | 37.7 | <90 | 28.6 |

| −468 | 32.7 | <90 | 19.6 |

| −515 | 32.4 | <90 | 15.8 |

| On Ni shim | 45.9 | >90 | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, D.; Beckelmann, D.; Opsölder, M.; Schäfer, B.; Moh, K.; Hensel, R.; De Oliveira, P.W.; Arzt, E. Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template Compression. Materials 2019, 12, 97. https://doi.org/10.3390/ma12010097

Yu D, Beckelmann D, Opsölder M, Schäfer B, Moh K, Hensel R, De Oliveira PW, Arzt E. Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template Compression. Materials. 2019; 12(1):97. https://doi.org/10.3390/ma12010097

Chicago/Turabian StyleYu, Dan, Dirk Beckelmann, Michael Opsölder, Bruno Schäfer, Karsten Moh, René Hensel, Peter William De Oliveira, and Eduard Arzt. 2019. "Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template Compression" Materials 12, no. 1: 97. https://doi.org/10.3390/ma12010097

APA StyleYu, D., Beckelmann, D., Opsölder, M., Schäfer, B., Moh, K., Hensel, R., De Oliveira, P. W., & Arzt, E. (2019). Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template Compression. Materials, 12(1), 97. https://doi.org/10.3390/ma12010097