Effects of Pumice-Based Porous Material on Hydration Characteristics and Persistent Shrinkage of Ultra-High Performance Concrete (UHPC)

Abstract

1. Introduction

2. Materials and Methods

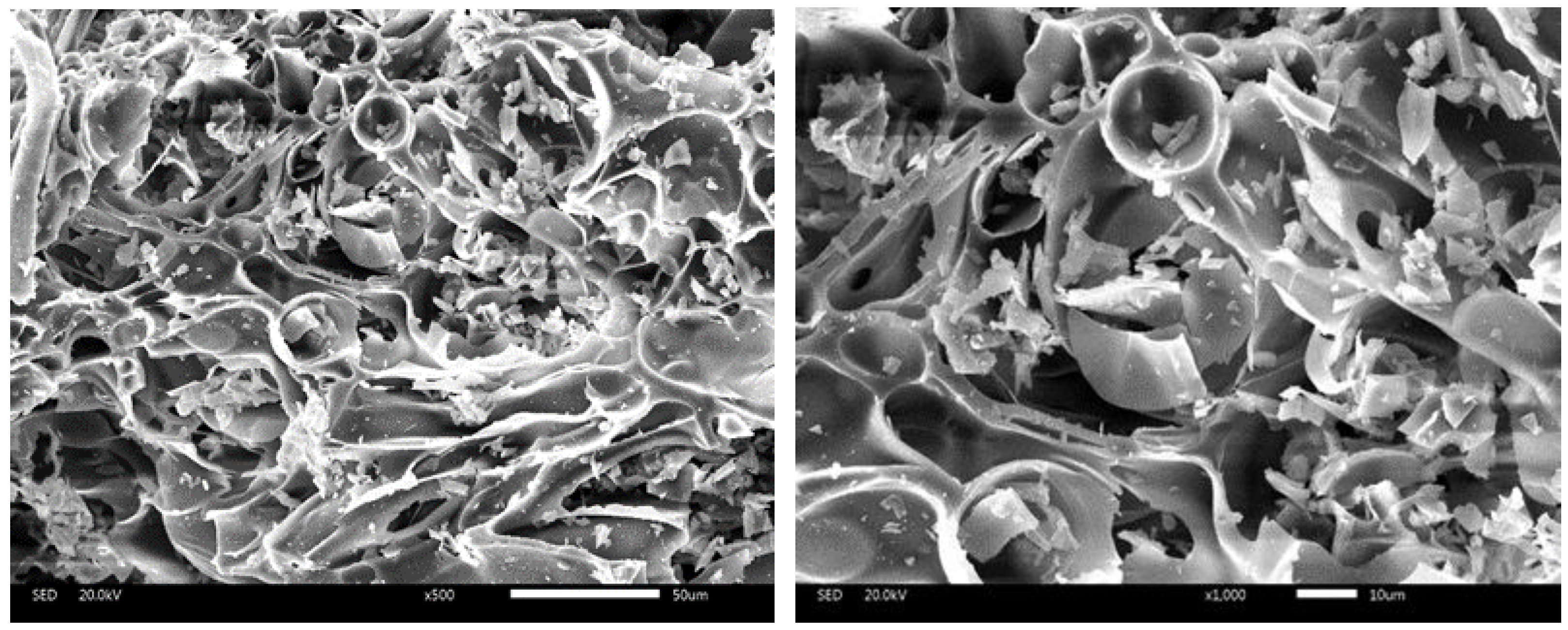

2.1. Materials

2.2. Experimental Methodology

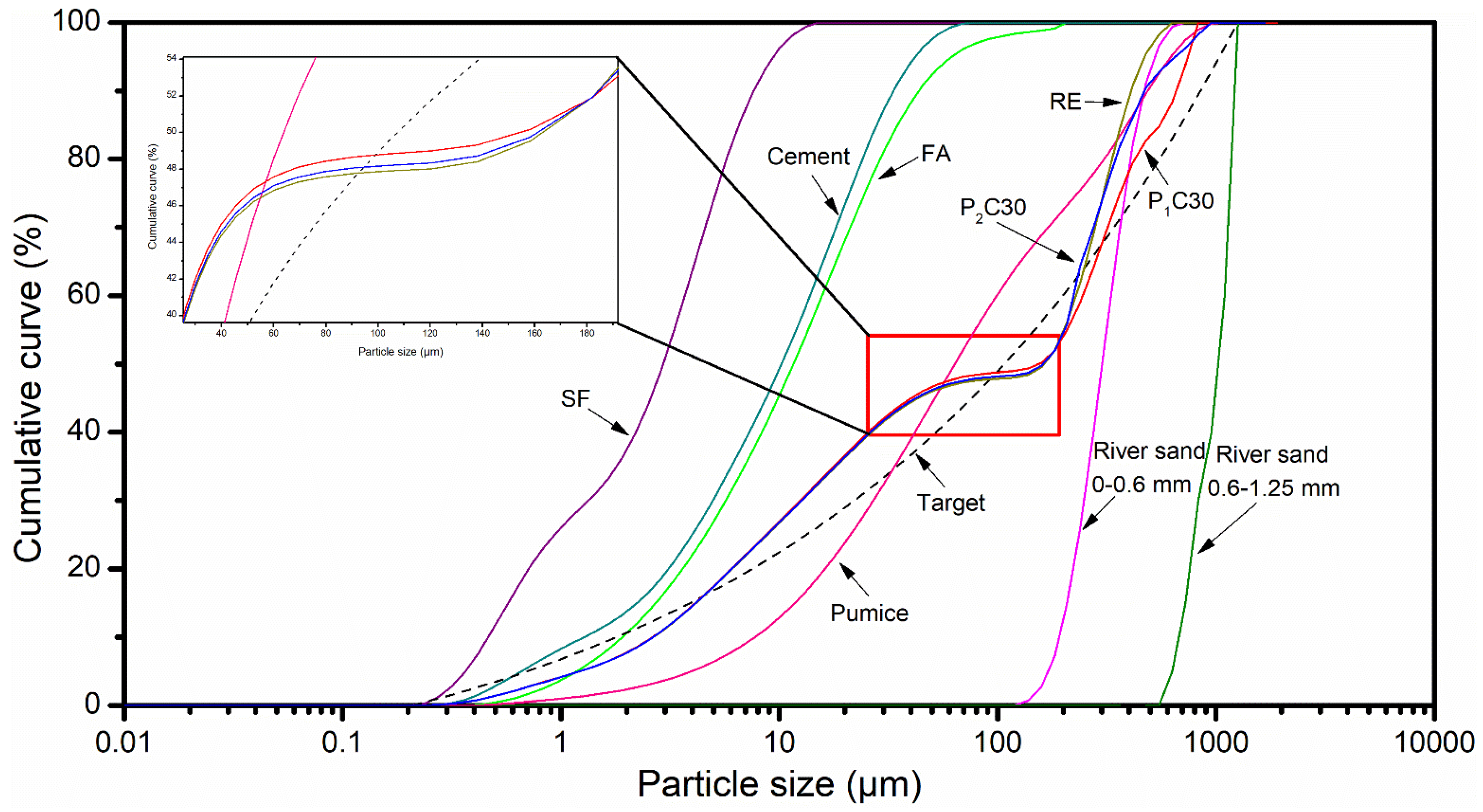

2.2.1. Design Method

2.2.2. Flowability

2.2.3. Mechanical Properties

2.2.4. Drying Shrinkage

2.2.5. Hydration Process

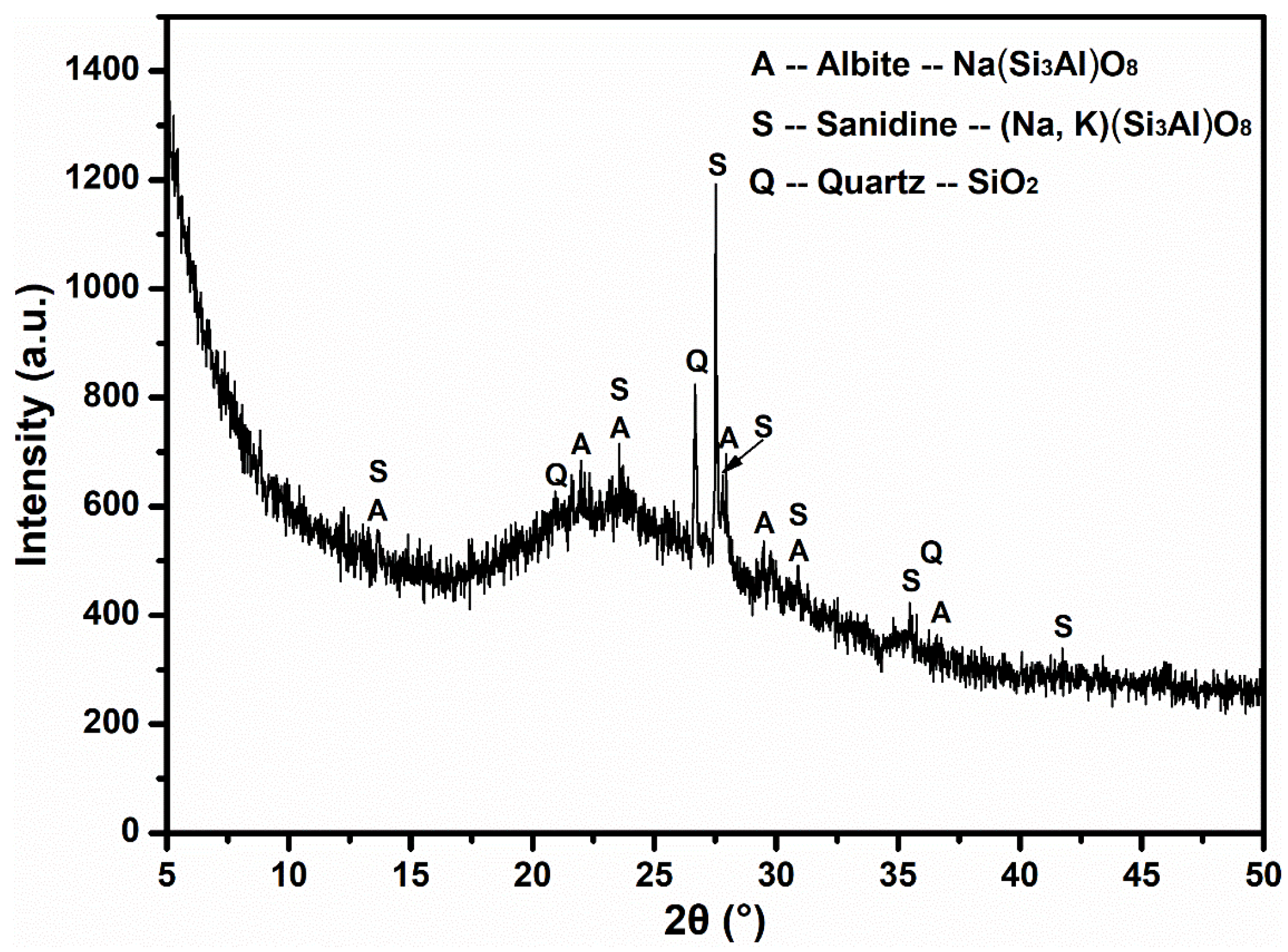

2.2.6. XRD

2.2.7. DTG

2.2.8. ESEM-EDS

3. Results and Discussion

3.1. Fresh Behaviors

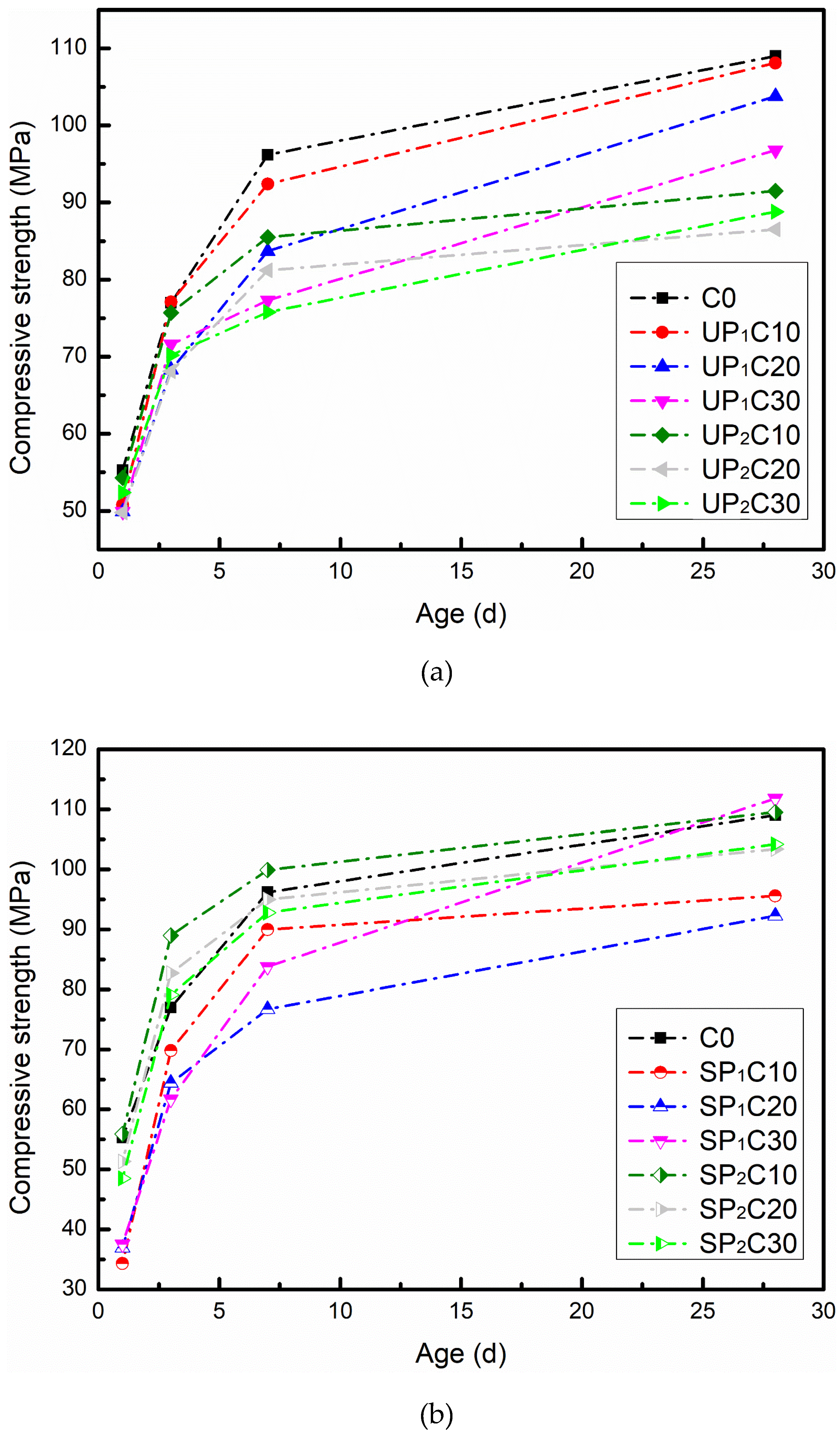

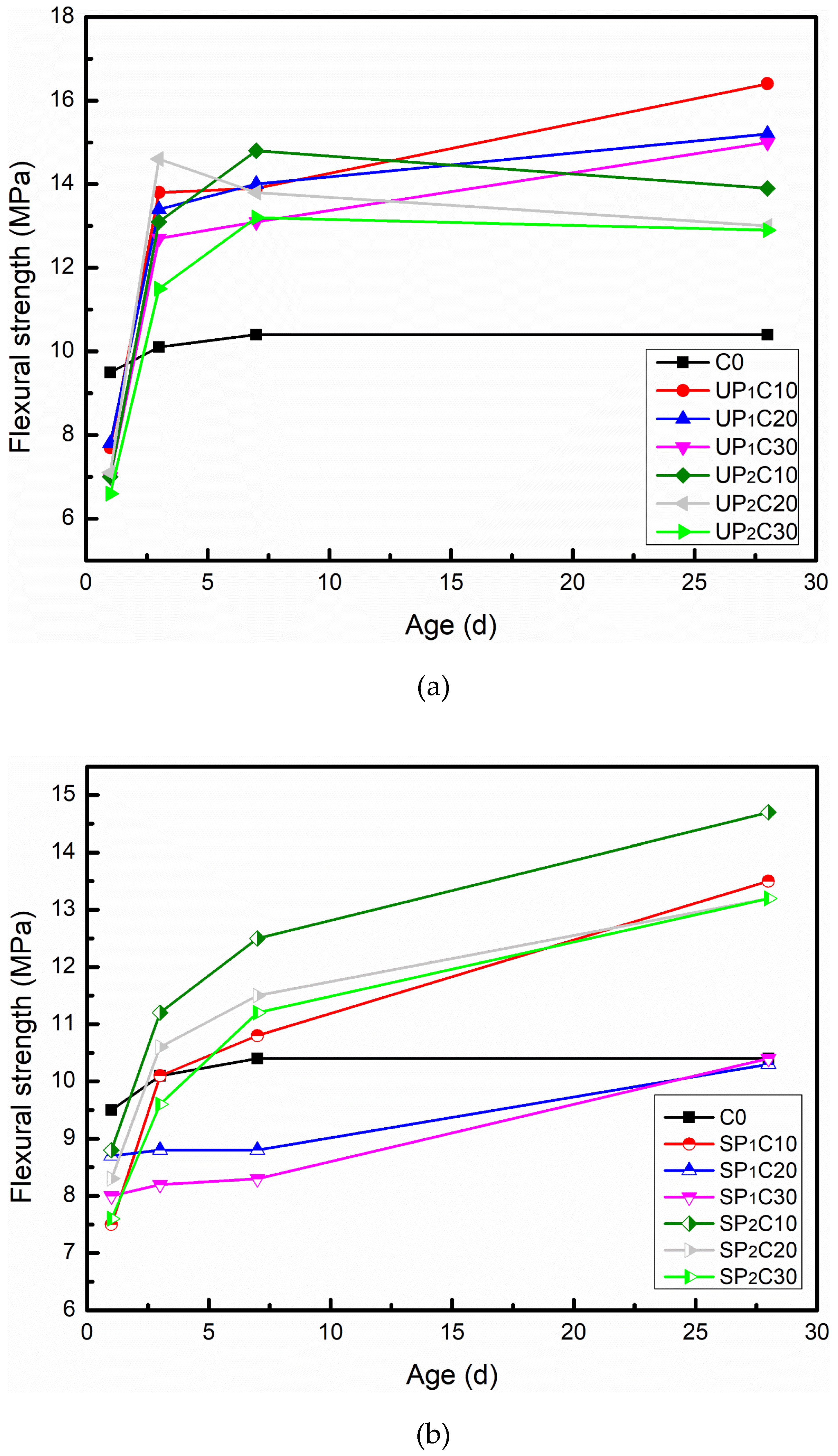

3.2. Mechanical Properties

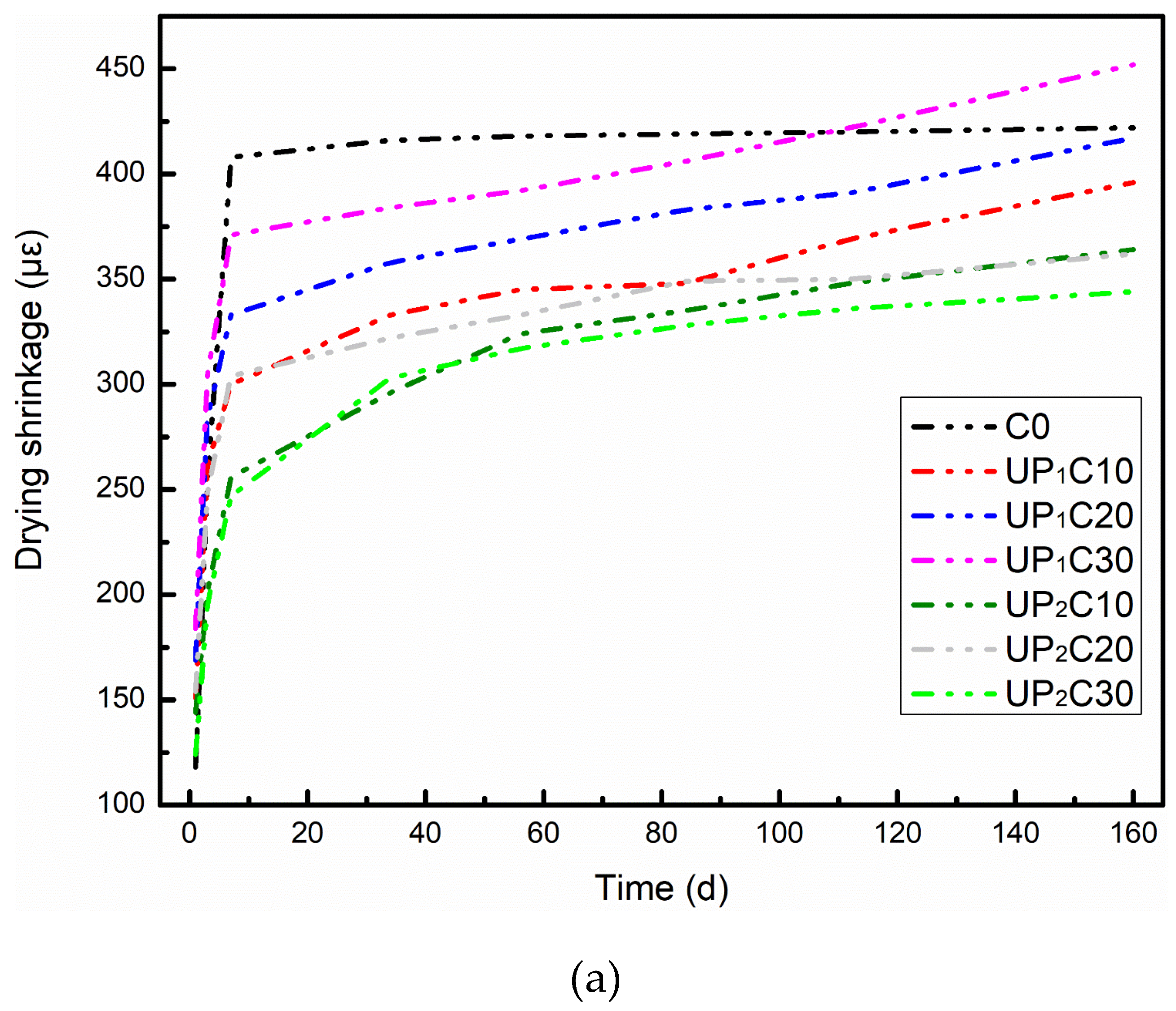

3.3. Persistent Shrinkage Deformation

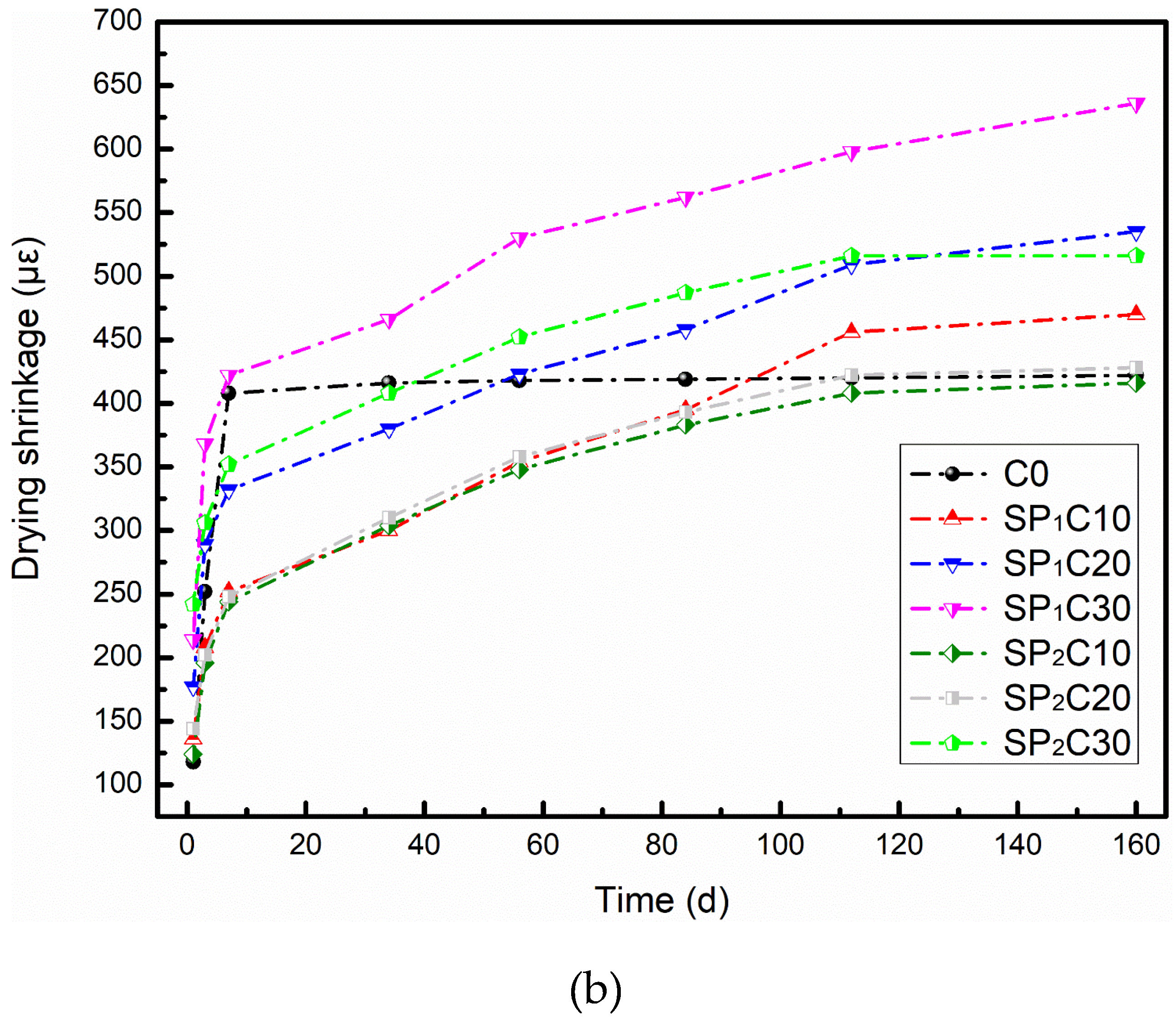

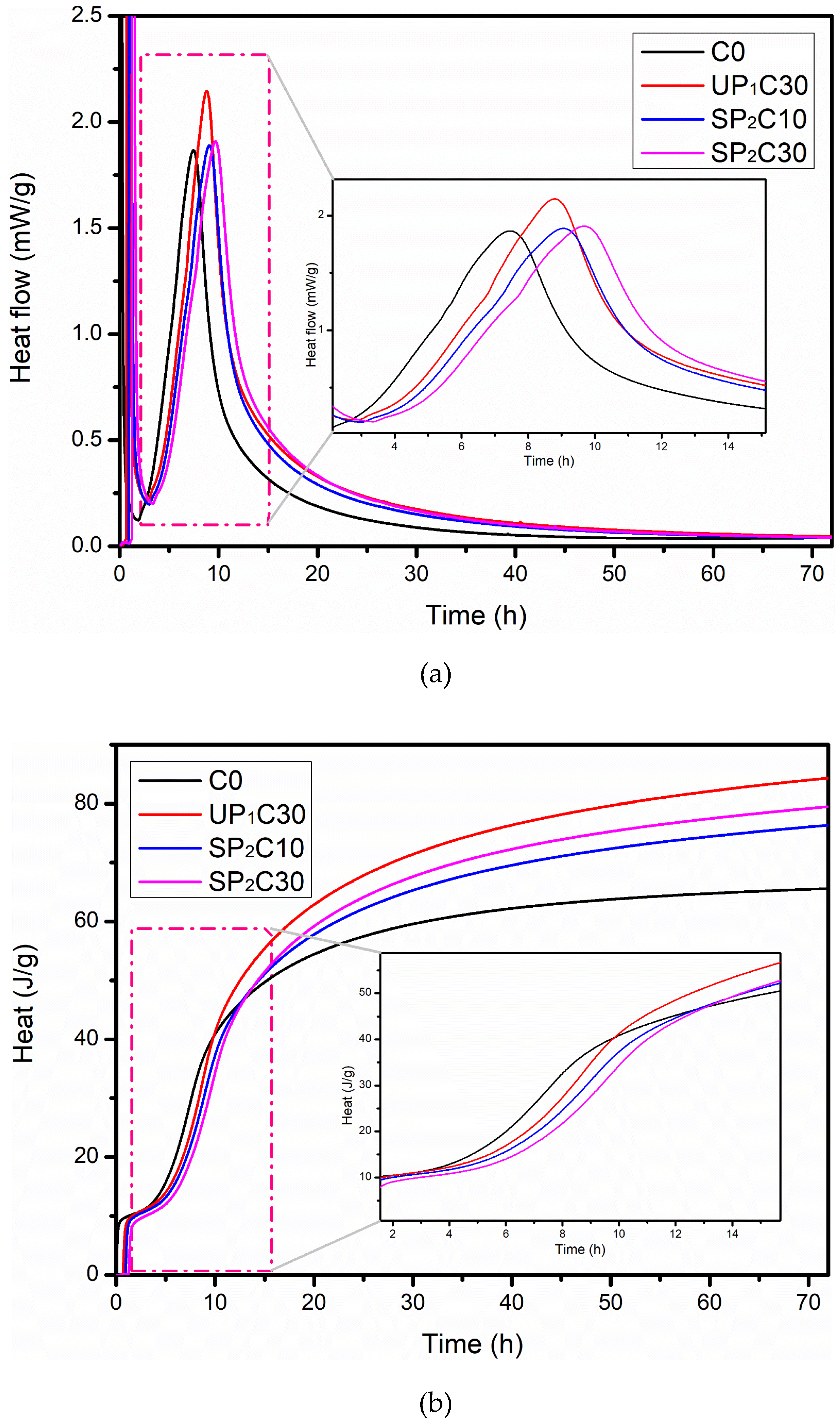

3.4. Hydration Process Analysis

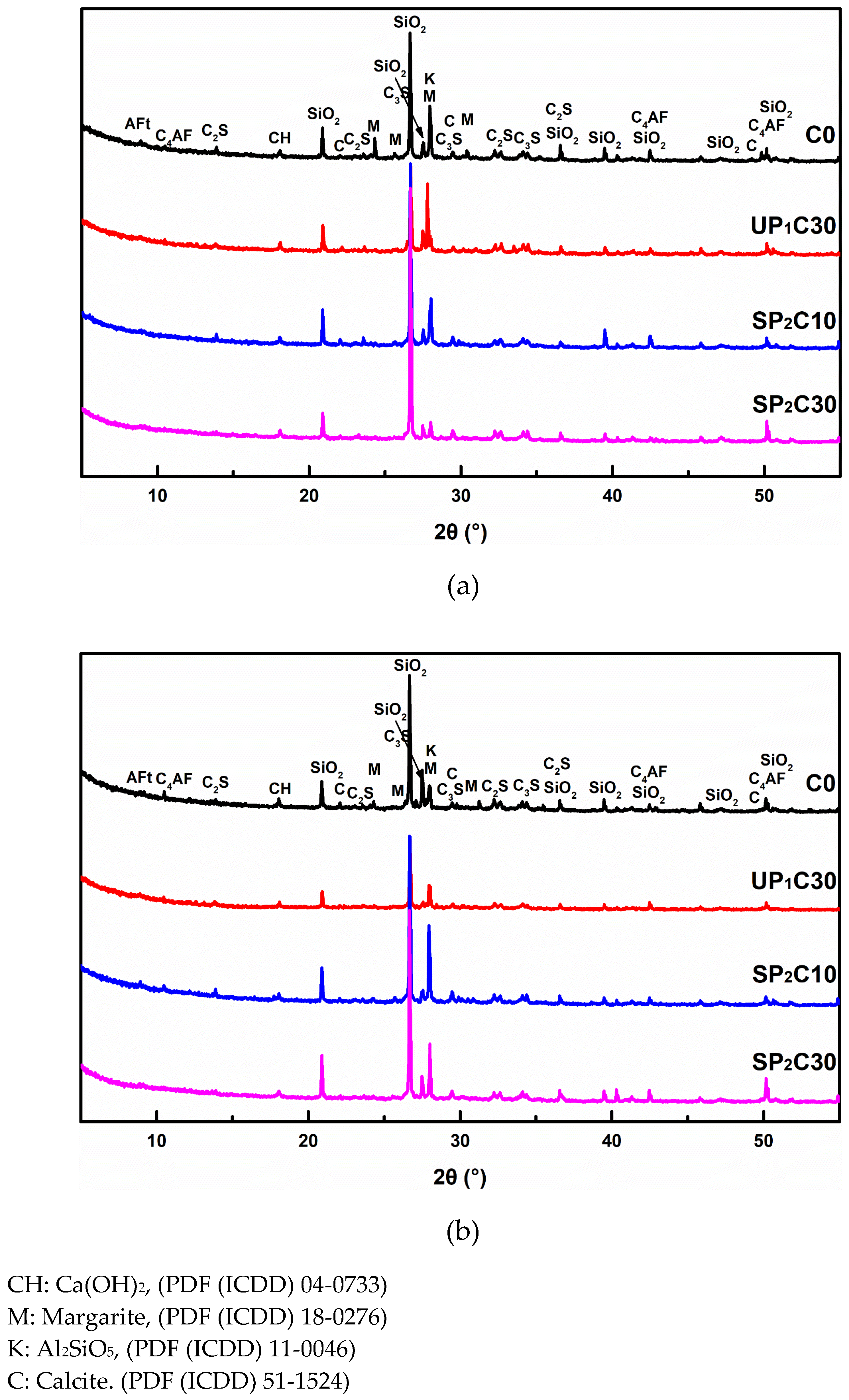

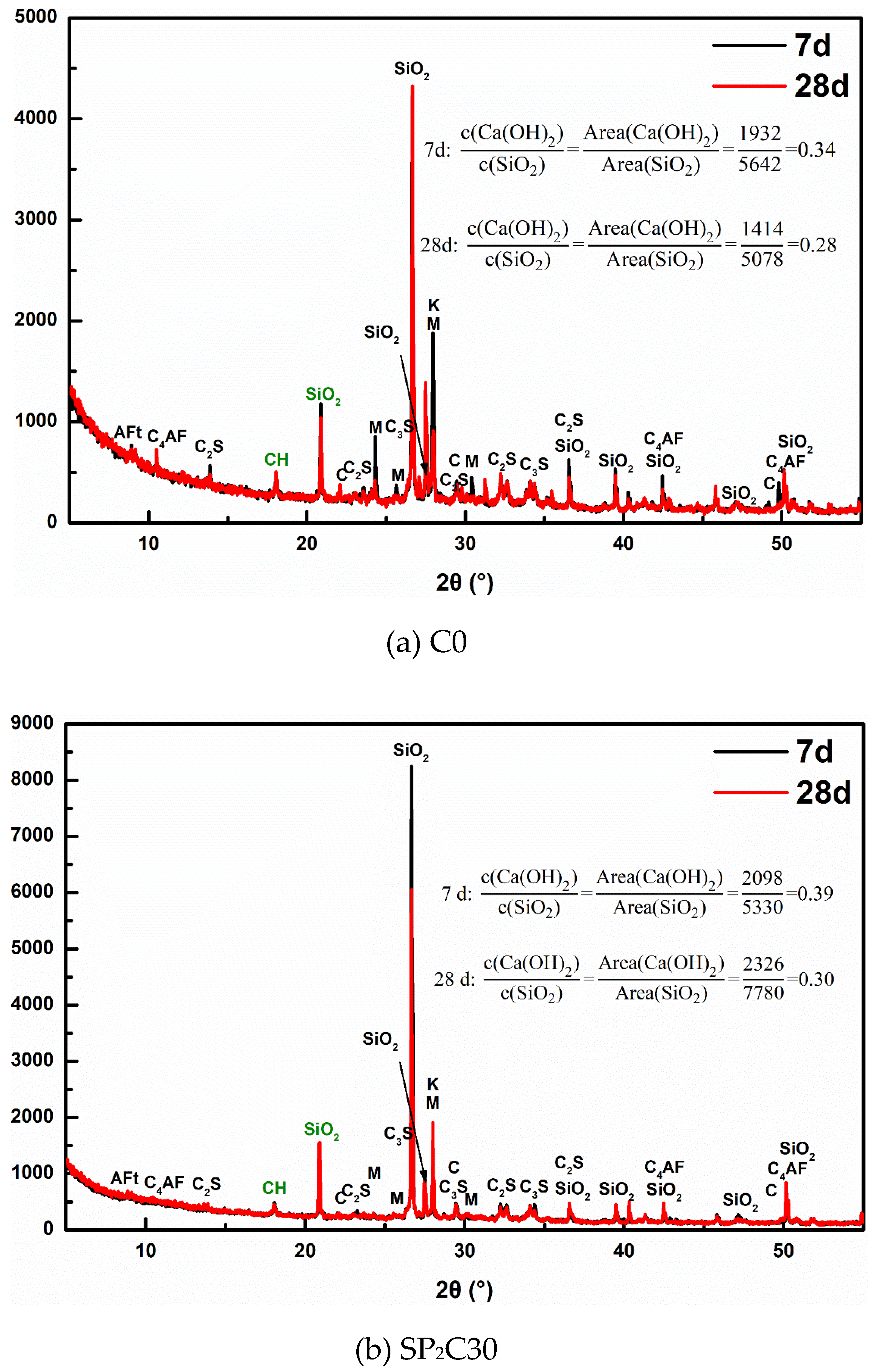

3.5. XRD

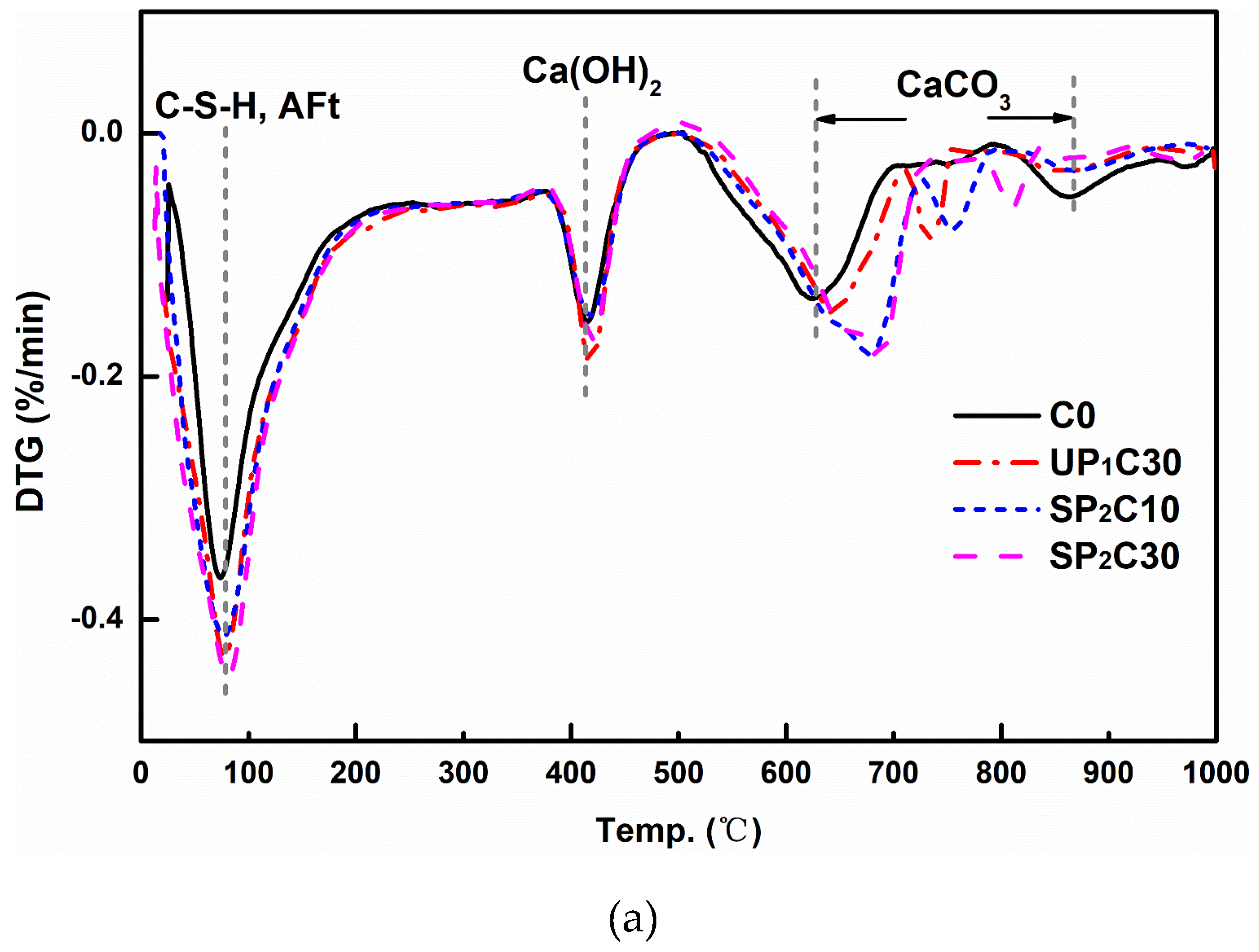

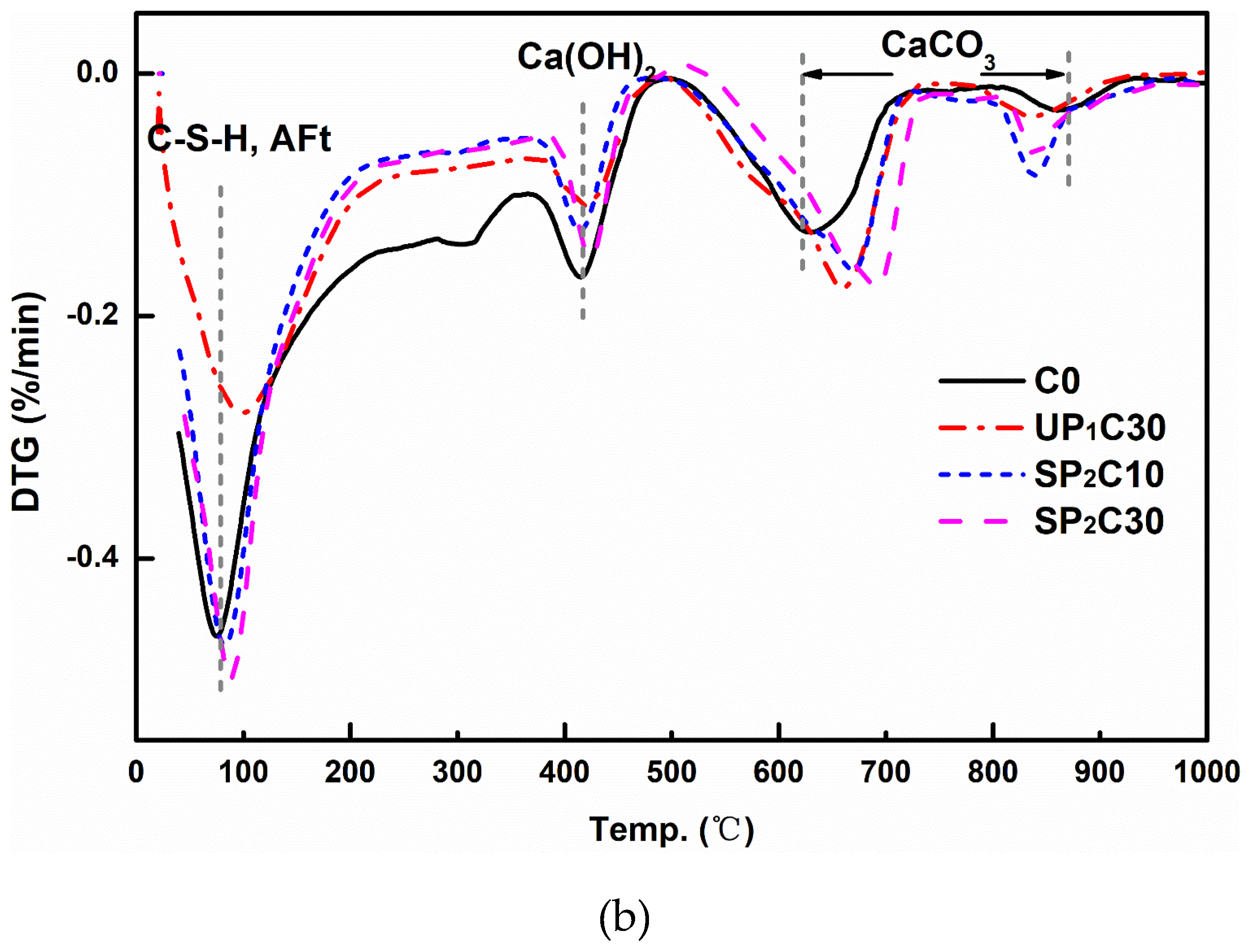

3.6. DTG

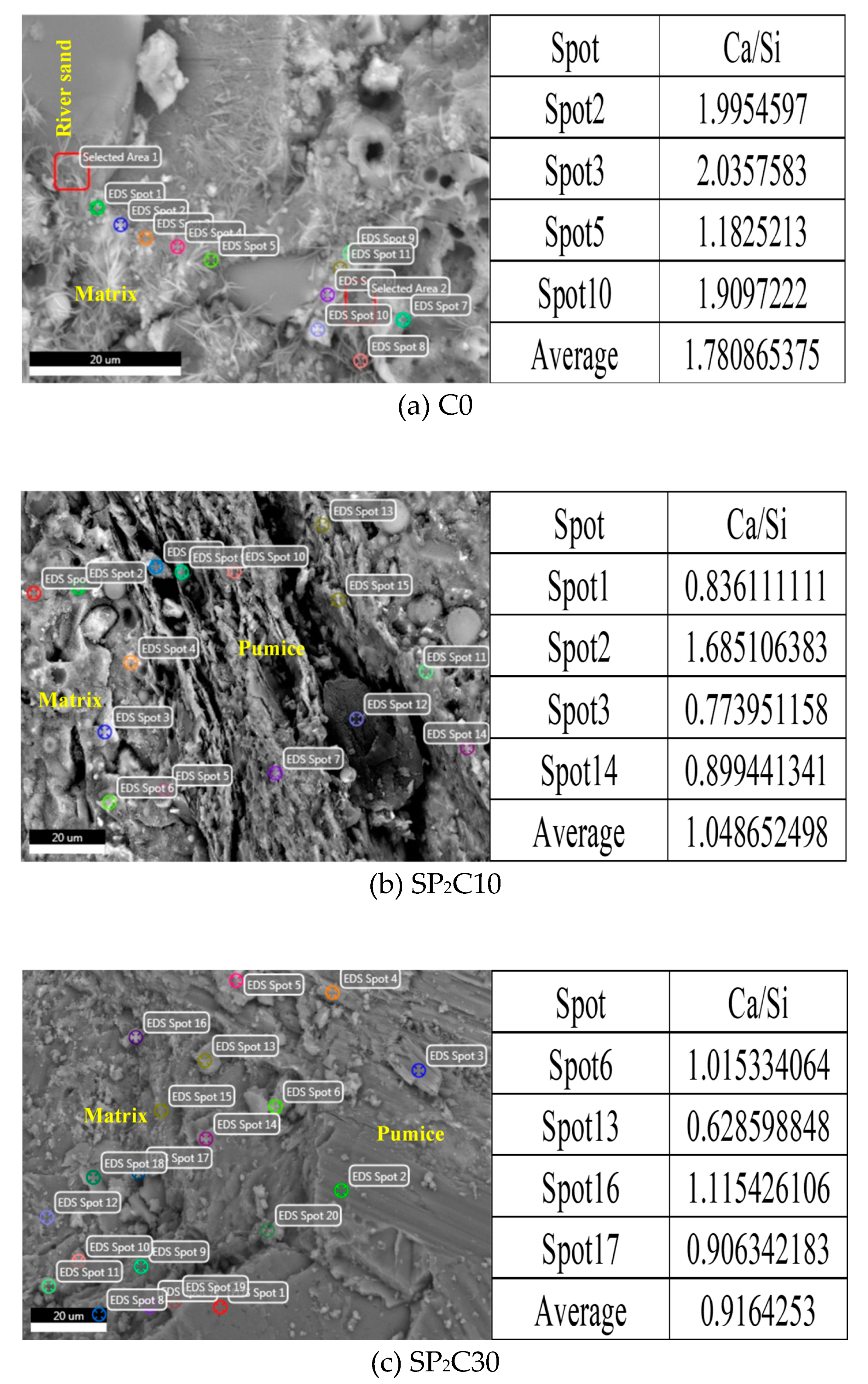

3.7. ESEM-EDS

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Habel, K.; Viviani, M.; Denarié, E.; Brühwiler, E. Development of the mechanical properties of an Ultra-High Performance Fiber Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2006, 36, 1362–1370. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Rahman, S.; Molyneaux, T.; Patnaikuni, I. Ultra high performance concrete: Recent applications and research. Aust. J. Civ. Eng. 2005, 2, 13–20. [Google Scholar] [CrossRef]

- Yu, R. Development of Sustainable Protective Ultra-High Performance Fibre Reinforced Concrete (UHPFRC): Design, Assessment and Modeling. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2015. [Google Scholar]

- Bărbos, G.-A. Long-term Behavior of Ultra-High Performance Concrete (UHPC) Bended Beams. Procedia Technol. 2016, 22, 203–210. [Google Scholar]

- Yoo, D.Y.; Yoon, Y.S. A Review on Structural Behavior, Design, and Application of Ultra-High-Performance Fiber-Reinforced Concrete. Int. J. Concr. Struct. Mater. 2016, 10, 125–142. [Google Scholar] [CrossRef]

- Zhou, M.; Lu, W.; Song, J.W.; Lee, G.C. Application of Ultra-High Performance Concrete in bridge engineering. Constr. Build. Mater. 2018, 186, 1256–1267. [Google Scholar] [CrossRef]

- Ren, L.; Fang, Z.; Wang, K. Design and behavior of super-long span cable-stayed bridge with CFRP cables and UHPC members. Compos. Part B Eng. 2018. [Google Scholar] [CrossRef]

- Azmee, N.M.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018. [Google Scholar] [CrossRef]

- Lura, P.; Jensen, O.M.; van Breugel, K. Autogenous shrinkage in high-performance cement paste: An evaluation of basic mechanisms. Cem. Concr. Res. 2003, 33, 223–232. [Google Scholar] [CrossRef]

- Garas, V.Y.; Kahn, L.F.; Kurtis, K.E. Short-term tensile creep and shrinkage of ultra-high performance concrete. Cem. Concr. Compos. 2009, 31, 147–152. [Google Scholar] [CrossRef]

- Xie, T.; Fang, C.; Ali, M.S.M.; Visintin, P. Characterizations of autogenous and drying shrinkage of ultra-high performance concrete (UHPC): An experimental study. Cem. Concr. Compos. 2018, 91, 156–173. [Google Scholar] [CrossRef]

- Justs, J.; Wyrzykowski, M.; Bajare, D.; Lura, P. Internal curing by superabsorbent polymers in ultra-high performance concrete. Cem. Concr. Res. 2015, 76, 82–90. [Google Scholar] [CrossRef]

- Sensale, G.R.D.; Goncalves, A.F. Effects of Fine LWA and SAP as Internal Water Curing Agents. Int. J. Concr. Struct. Mater. 2014, 8, 229–238. [Google Scholar] [CrossRef]

- Van, V.T.A.; Rößler, C.; Bui, D.D.; Ludwig, H.-M. Rice husk ash as both pozzolanic admixture and internal curing agent in ultra-high performance concrete. Cem. Concr. Compos. 2014, 53, 270–278. [Google Scholar] [CrossRef]

- Liu, J.; Ou, Z.; Mo, J.; Chen, Y.; Guo, T.; Deng, W. Effectiveness of Saturated Coral Aggregate and Shrinkage Reducing Admixture on the Autogenous Shrinkage of Ultrahigh Performance Concrete. Adv. Mater. Sci. Eng. 2017, 2017, 1–11. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K. Effects of saturated lightweight sand content on key characteristics of ultra-high-performance concrete. Cem. Concr. Res. 2017, 101, 46–54. [Google Scholar] [CrossRef]

- Sun, W.; Chen, H.; Luo, X.; Qian, H. The effect of hybrid fibers and expansive agent on the shrinkage and permeability of high-performance concrete. Cem. Concr. Res. 2001, 31, 595–601. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Nardinocchi, A.; Donnini, J. The influence of expansive agent on the performance of fibre reinforced cement-based composites. Constr. Build. Mater. 2015, 91, 171–179. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effects of shrinkage reducing admixture and wollastonite microfiber on early-age behavior of ultra-high performance concrete. Cem. Concr. Compos. 2014, 46, 81–89. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N.; Yoon, Y.S. Effectiveness of shrinkage-reducing admixture in reducing autogenous shrinkage stress of ultra-high-performance fiber-reinforced concrete. Cem. Concr. Compos. 2015, 64, 27–36. [Google Scholar] [CrossRef]

- Ghafari, E.; Ghahari, S.A.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. Effect of supplementary cementitious materials on autogenous shrinkage of ultra-high performance concrete. Constr. Build. Mater. 2016, 127, 43–48. [Google Scholar] [CrossRef]

- Li, W.; Huang, Z.; Hu, G.; Duan, W.; Shah, S.P. Early-age shrinkage development of ultra-high-performance concrete under heat curing treatment. Constr. Build. Mater. 2017, 131, 767–774. [Google Scholar] [CrossRef]

- Shen, P.; Lu, L.; He, Y.; Rao, M.; Fu, Z.; Wang, F.; Hu, S. Experimental investigation on the autogenous shrinkage of steam cured ultra-high performance concrete. Constr. Build. Mater. 2018, 162, 512–522. [Google Scholar] [CrossRef]

- Rajabipour, F.; Sant, G.; Weiss, J. Interactions between shrinkage reducing admixtures (SRA) and cement paste’s pore solution. Cem. Concr. Res. 2008, 38, 606–615. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effect of partially hydrated cementitious materials and superabsorbent polymer on early-age shrinkage of UHPC. Constr. Build. Mater. 2013, 41, 270–275. [Google Scholar] [CrossRef]

- Kang, S.H.; Hong, S.G.; Moon, J. Shrinkage characteristics of heat-treated ultra-high performance concrete and its mitigation using superabsorbent polymer based internal curing method. Cem. Concr. Compos. 2018, 89, 130–138. [Google Scholar] [CrossRef]

- Philleo, R. Concrete Science and Reality. In Materials Science of Concrete II; American Ceramic Society: Westerville, OH, USA, 1991; pp. 1–8. [Google Scholar]

- Bentz, D.P.; Snyder, K.A. Protected paste volume in concrete: Extension to internal curing using saturated lightweight fine aggregate. Cem. Concr. Res. 1999, 29, 1863–1867. [Google Scholar] [CrossRef]

- Bentz, D.P.; Lura, P.; Roberts, J.W. Mixture Proportioning for Internal Curing. Concr. Int. 2005, 27, 35–40. [Google Scholar]

- Bentz, D.P. A review of early-age properties of cement-based materials. Cem. Concr. Res. 2008, 38, 196–204. [Google Scholar] [CrossRef]

- Bentur, A.; Igarashi, S.I.; Kovler, K. Prevention of autogenous shrinkage in high-strength concrete by internal curing using wet lightweight aggregates. Cem. Concr. Res. 2001, 31, 1587–1591. [Google Scholar] [CrossRef]

- Akcay, B.; Tasdemir, M.A. Optimisation of using lightweight aggregates in mitigating autogenous deformation of concrete. Constr. Build. Mater. 2009, 23, 353–363. [Google Scholar] [CrossRef]

- Akcay, B.; Tasdemir, M.A. Effects of distribution of lightweight aggregates on internal curing of concrete. Cem. Conc. Compos. 2010, 32, 611–616. [Google Scholar] [CrossRef]

- Henkensiefken, R.; Nantung, T.; Weiss, J. Internal Curing-From the Laboratory to Implementation. In Proceedings of the International Bridge Conference on Lightweight Aggregate Concrete Bridges Workshop, Pittsburgh, PA, USA, 14–17 June 2009. [Google Scholar]

- Henkensiefken, R.; Bentz, D.; Nantung, T.; Weiss, J. Volume change and cracking in internally cured mixtures made with saturated lightweight aggregate under sealed and unsealed conditions. Cem. Concr. Compos. 2009, 31, 427–437. [Google Scholar] [CrossRef]

- Lura, P.; Wyrzykowski, M.; Tang, C.; Lehmann, E. Internal curing with lightweight aggregate produced from biomass-derived waste. Cem. Concr. Res. 2014, 59, 24–33. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K.; Bentur, A. Efficiency of lightweight aggregates for internal curing of high strength concrete to eliminate autogenous shrinkage. Mater. Struct. 2002, 35, 97–101. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K.; Bentur, A. Influence of cement paste matrix properties on the autogenous curing of high-performance concrete. Cem. Concr. Compos. 2004, 26, 499–507. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K. Effect of internal curing on durability-related properties of high performance concrete. Cem. Concr. Res. 2012, 42, 20–26. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials—I. Principles and theoretical background. Cem. Concr. Res. 2001, 31, 647–654. [Google Scholar] [CrossRef]

- Craeye, B.; Schutter, G.D. Experimental evaluation of mitigation of autogenous shrinkage by means of a vertical dilatometer for concrete. In Proceedings of the Conference on Volume Changes of Hardening Concrete: Testing and Mitigation, Lyngby, Denmark, 20–23 August 2006; RILEM Publications SARL: UGent, Belgium, 2006; pp. 21–30. [Google Scholar]

- Cusson, D.; Hoogeveen, T. Internal curing of high-performance concrete with pre-soaked fine lightweight aggregate for prevention of autogenous shrinkage cracking. Cem. Concr. Res. 2008, 38, 757–765. [Google Scholar] [CrossRef]

- Paul, A.; Lopez, M. Assessing Lightweight Aggregate Efficiency for Maximizing Internal Curing Performance. ACI Mater. J. 2011, 108, 385–393. [Google Scholar]

- Castro, J.; Keiser, L.; Golias, M.; Weiss, J. Absorption and desorption properties of fine lightweight aggregate for application to internally cured concrete mixtures. Cem. Concr. Compos. 2011, 33, 1001–1008. [Google Scholar] [CrossRef]

- Internal Curing of Concrete, State-of-the-Art Report of RILEM Technical Committee 196-ICC (RILEM TC 196-ICC); RILEM Publications S.A.R.L.: Bagneux, France, 2007.

- Suzuki, M.; Meddah, M.S.; Sato, R.; Kawabata, T. Long-term shrinkage and stress in ultra high strength concrete using porous ceramic waste for internal curing. In Proceedings of the International RILEM Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, Technical University of Denmark, Lyngby, Denmark, 15–18 August 2010. [Google Scholar]

- Wang, X.P.; Yu, R.; Shui, Z.; Songa, Q.; Zhang, Z. Mix design and characteristics evaluation of an eco-friendly Ultra-High Performance Concrete incorporating recycled coral based materials. J. Clean. Prod. 2017, 165, 70–80. [Google Scholar] [CrossRef]

- Klug, C.; Cashman, K.; Bacon, C. Structure and physical characteristics of pumice from the climactic eruption of Mount Mazama (Crater Lake), Oregon. Bull. Volcanol. 2002, 64, 486–501. [Google Scholar]

- Hossain, A.; Khandaker, M. Properties of volcanic pumice based cement and lightweight concrete. Cem. Concr. Res. 2004, 34, 283–291. [Google Scholar] [CrossRef]

- Binici, H. Effect of crushed ceramic and basaltic pumice as fine aggregates on concrete mortars properties. Constr. Build. Mater. 2007, 21, 1191–1197. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Ahmed, S.; Lachemi, M. Lightweight concrete incorporating pumice based blended cement and aggregate: Mechanical and durability characteristics. Constr. Build. Mater. 2011, 25, 1186–1195. [Google Scholar] [CrossRef]

- Castro, J.; Weiss, J.; Henkensiefken, R.; Nantung, T.; Bentz, D.P. LWA Absorption and Desorption: The Influence on the Microstructure and Transport Properties of Internally Cured Mortars. In Proceedings of the International Conference on Concrete Under Severe Conditions: Environment & Loading, Merida, Mexico, 7–9 June 2010; Taylor & Francis Group: London, UK, 2010; pp. 1543–1550. [Google Scholar]

- ASTM C09, C1761: Standard Specification for Lightweight Aggregate for Internal Curing of Concrete; ASTM: West Conshohocken, PA, USA, 2013.

- Hüsken, G. A Multifunctional Design Approach for Sustainable Concrete with Application to Concrete Mass Products. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2010. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra- High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- GB/T 2419-2005. PRC National Standard: Test Method for Fluidity of Cement Mortar; Standards Press of China: Beijing, China, 2005. (In Chinese) [Google Scholar]

- GB/T 17671-1999. PRC National Standard: Method of Testing Cements-Determination of Strength; Standards Press of China: Beijing, China, 1999. (In Chinese) [Google Scholar]

- JC/T 603-2004. PRC Building Materials Industry Standard: Standard Test Method for Drying Shrinkage of Mortar; Standards Press of China: Beijing, China, 2004. (In Chinese) [Google Scholar]

- Aïtcin, P.C. High Performance Concrete; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Lura. Autogenous Deformation and Internal Curing of Concrete. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2003. [Google Scholar]

- Tazawa, E.I.; Miyazawa, S. Experimental study on mechanism of autogenous shrinkage of concrete. Cem. Concr. Res. 1995, 25, 1633–1638. [Google Scholar] [CrossRef]

- Loukili, A.; Khelidj, A.; Richard, P. Hydration kinetics, change of relative humidity, and autogenous shrinkage of ultra-high-strength concrete. Cem. Concr. Res. 1999, 29, 577–584. [Google Scholar] [CrossRef]

- Yiotis, A.G.; Stubos, A.K.; Boudouvis, A.G.; Tsimpanogiannis, I.N.; Yortsos, Y.C. Pore-Network Modeling of Isothermal Drying in Porous Media. Transp. Porous Med. 2005, 58, 63–86. [Google Scholar] [CrossRef]

- Ghourchian, S.; Wyrzykowski, M.; Lura, P.; Shekarchi, M.; Ahmadi, B. An investigation on the use of zeolite aggregates for internal curing of concrete. Constr. Build. Mater. 2013, 40, 135–144. [Google Scholar] [CrossRef]

- Zou, D.; Li, K.; Li, W.; Cao, T. Effects of pore structure and water absorption on internal curing efficiency of porous aggregates. Constr. Build. Mater. 2018, 163, 949–959. [Google Scholar] [CrossRef]

- Lura, P.; Bentz, D.P.; Lange, D.A.; KKovler, o.; Bentur, A.; van Breugel, K. Measurement of water transport from saturated pumice aggregates to hardening cement paste. Mater. Struct. 2006, 39, 861–868. [Google Scholar] [CrossRef]

- Henkensiefken, R.; Nantung, T.; Weiss, J. Saturated lightweight aggregate for internal curing in low w/c mixtures: Monitoring water movement using x-ray absorption. Strain 2011, 47, 432–441. [Google Scholar] [CrossRef]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Havlica, J.; Roztocká, D.; Sahu, S. Hydration kinetics of calciumaluminate phases in the presence of various ratios of Ca2+ and SO42− ions in liquid phase. Cem. Concr. Res. 1993, 23, 294–300. [Google Scholar] [CrossRef]

- Richardson, I.G. The calcium silicate hydrates. Cem. Concr. Res. 2008, 38, 137–158. [Google Scholar] [CrossRef]

- Richardson, I.G. Model structures for C–(A)–S–H(I). Acta Crystallogr. B 2014, 70, 903–923. [Google Scholar] [CrossRef]

- Richardson, I.G. The nature of C–S–H in hardened cements. Cem. Concr. Res. 1999, 29, 1131–1147. [Google Scholar] [CrossRef]

- Chang, J.; Fang, Y. Quantitative analysis of accelerated carbonation products of the synthetic calcium silicate hydrate(C–S–H) by QXRD and TG/MS. J. Therm. Anal. Calorim. 2015, 119, 57–62. [Google Scholar] [CrossRef]

- Richardson, I.G.; Groves, G.W. Microstructure and microanalysis of hardened cement pastes involving ground granulated blast-furnace slag. J. Mater. Sci. 1992, 27, 6204–6212. [Google Scholar] [CrossRef]

- Breugel, K.V. Numerical modelling of volume changes at early ages-Potential, pitfalls and challenges. Mater. Struct. 2001, 34, 293–301. [Google Scholar]

- Juenger, M.C.G.; Jennings, H.M. Examining the relationship between the microstructure of calcium silicate hydrate and drying shrinkage of cement pastes. Cem. Concr. Res. 2002, 32, 289–296. [Google Scholar] [CrossRef]

| Compositions | Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO | Fe2O3 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 0.09 | 1.61 | 4.18 | 19.20 | 0.09 | 3.35 | 0.78 | 64.93 | 3.32 | 2.49 |

| SF | 0.13 | 0.47 | 0.25 | 94.65 | 0.17 | 0.69 | 0.84 | 0.36 | 0.15 | 2.29 |

| FA | 0.33 | 0.23 | 38.01 | 46.44 | 0.06 | 0.69 | 0.88 | 7.50 | 3.12 | 2.79 |

| Group | Cement | FA | SF | River Sand | Damp Pumice | Water | SP | ||

|---|---|---|---|---|---|---|---|---|---|

| 0–0.6 | 0.6–1.25 | 0–0.6 | 0.6–1.25 | ||||||

| C0 | 750 | 200 | 144 | 770 | 220 | 0 | 0 | 175 | 31 |

| UP1C10 | 750 | 200 | 144 | 693 | 220 | 37.08 | 0 | 175 | 31 |

| UP1C20 | 750 | 200 | 144 | 616 | 220 | 74.16 | 0 | 175 | 31 |

| UP1C30 | 750 | 200 | 144 | 539 | 220 | 111.24 | 0 | 175 | 31 |

| UP2C10 | 750 | 200 | 144 | 770 | 198 | 0 | 6.00 | 175 | 31 |

| UP2C20 | 750 | 200 | 144 | 770 | 176 | 0 | 12.00 | 175 | 31 |

| UP2C30 | 750 | 200 | 144 | 770 | 154 | 0 | 18.00 | 175 | 31 |

| SP1C10 | 750 | 200 | 144 | 693 | 220 | 55.43 | 0 | 175 | 31 |

| SP1C20 | 750 | 200 | 144 | 616 | 220 | 110.86 | 0 | 175 | 31 |

| SP1C30 | 750 | 200 | 144 | 539 | 220 | 166.29 | 0 | 175 | 31 |

| SP2C10 | 750 | 200 | 144 | 770 | 198 | 0 | 8.38 | 175 | 31 |

| SP2C20 | 750 | 200 | 144 | 770 | 176 | 0 | 16.76 | 175 | 31 |

| SP2C30 | 750 | 200 | 144 | 770 | 154 | 0 | 25.14 | 175 | 31 |

| Group | Extra Water | w/b | Fluidity (mm) | |

|---|---|---|---|---|

| Free | Total | |||

| C0 | 0 | 0.1826 | 0.1826 | 183 |

| UP1C10 | 5.9 | 0.1880 | 167 | |

| UP1C20 | 11.8 | 0.1934 | 173 | |

| UP1C30 | 17.7 | 0.1988 | 214 | |

| UP2C10 | 0.96 | 0.1835 | 165 | |

| UP2C20 | 1.92 | 0.1844 | 180 | |

| UP2C30 | 2.88 | 0.1853 | 201 | |

| SP1C10 | 24.3 | 0.2048 | 269 | |

| SP1C20 | 48.6 | 0.2271 | 345 | |

| SP1C30 | 72.9 | 0.2493 | 374 | |

| SP2C10 | 3.35 | 0.1857 | 147 | |

| SP2C20 | 6.7 | 0.1888 | 181 | |

| SP2C30 | 10.05 | 0.1918 | 186 | |

| Group | C0 | UP1C30 | SP2C10 | SP2C30 |

|---|---|---|---|---|

| 7 d | 0.387 | 0.517 | 0.506 | 0.550 |

| 28 d | 0.420 | 0.348 | 0.385 | 0.423 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Yu, R.; Shui, Z.; Li, X.; Ling, X.; He, W.; Yi, S.; Wu, S. Effects of Pumice-Based Porous Material on Hydration Characteristics and Persistent Shrinkage of Ultra-High Performance Concrete (UHPC). Materials 2019, 12, 11. https://doi.org/10.3390/ma12010011

Liu K, Yu R, Shui Z, Li X, Ling X, He W, Yi S, Wu S. Effects of Pumice-Based Porous Material on Hydration Characteristics and Persistent Shrinkage of Ultra-High Performance Concrete (UHPC). Materials. 2019; 12(1):11. https://doi.org/10.3390/ma12010011

Chicago/Turabian StyleLiu, Kaizhi, Rui Yu, Zhonghe Shui, Xiaosheng Li, Xuan Ling, Wenhao He, Shuangqin Yi, and Shuo Wu. 2019. "Effects of Pumice-Based Porous Material on Hydration Characteristics and Persistent Shrinkage of Ultra-High Performance Concrete (UHPC)" Materials 12, no. 1: 11. https://doi.org/10.3390/ma12010011

APA StyleLiu, K., Yu, R., Shui, Z., Li, X., Ling, X., He, W., Yi, S., & Wu, S. (2019). Effects of Pumice-Based Porous Material on Hydration Characteristics and Persistent Shrinkage of Ultra-High Performance Concrete (UHPC). Materials, 12(1), 11. https://doi.org/10.3390/ma12010011