Influence of Multi-Holes on Fatigue Behaviors of Cast Magnesium Alloys Based on In-Situ Scanning Electron Microscope Technology

Abstract

1. Introduction

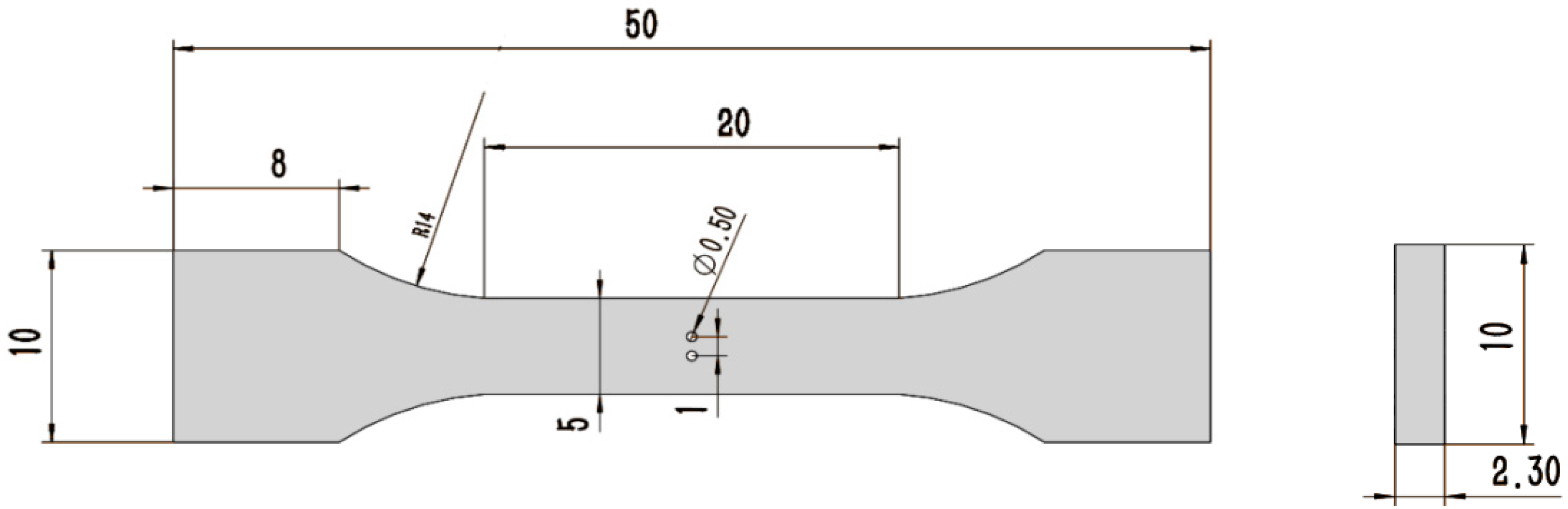

2. Experimental and Material

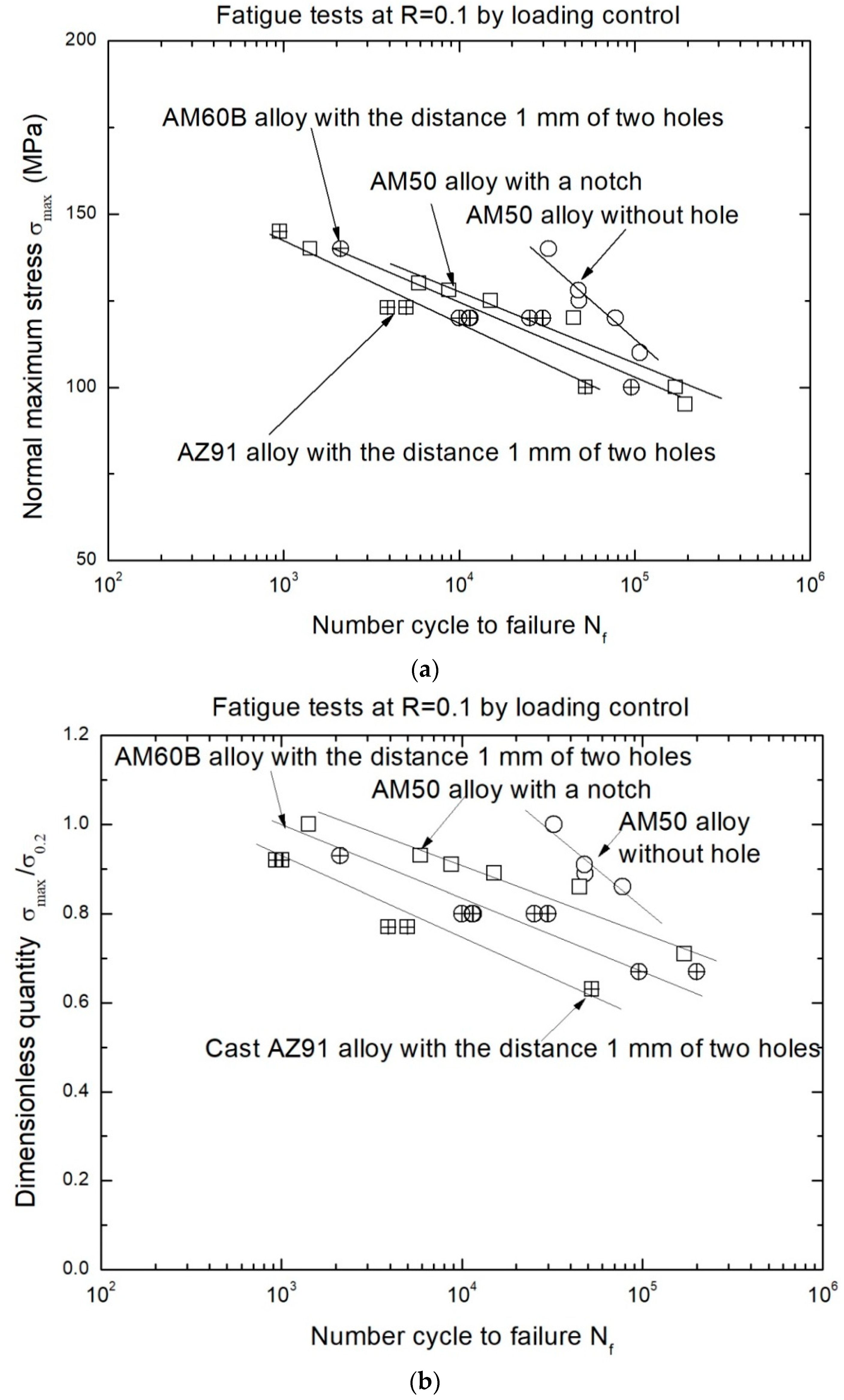

3. Fatigue Experimental Results

4. Analysis and Discussion

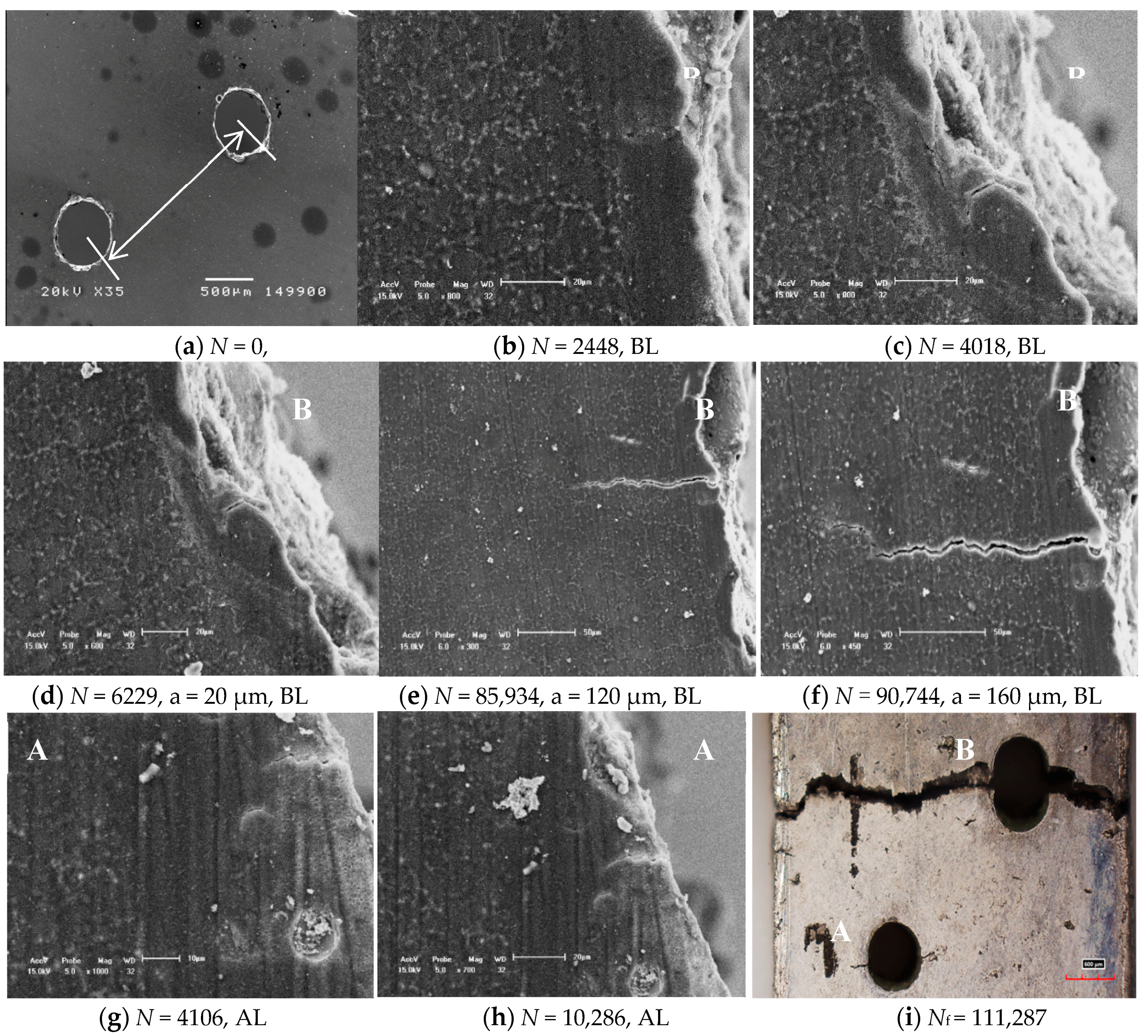

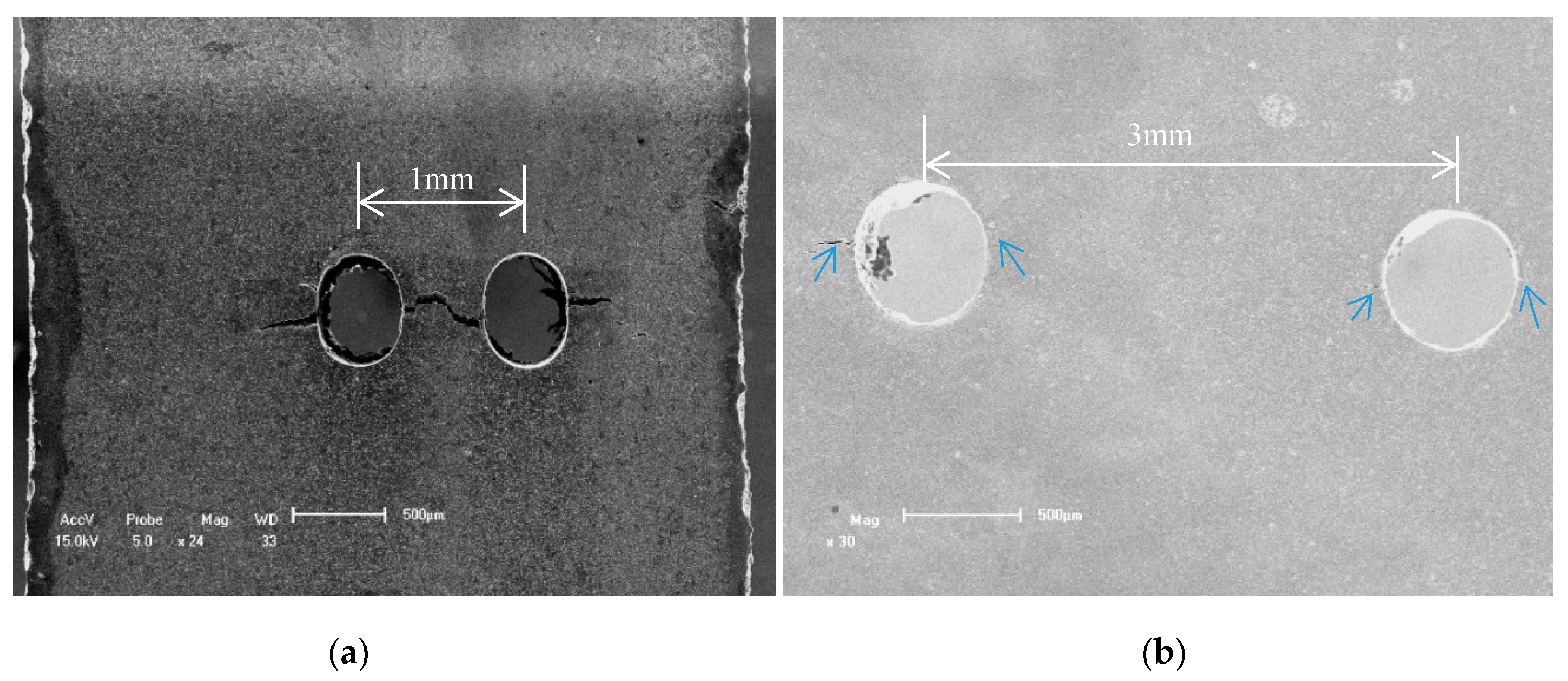

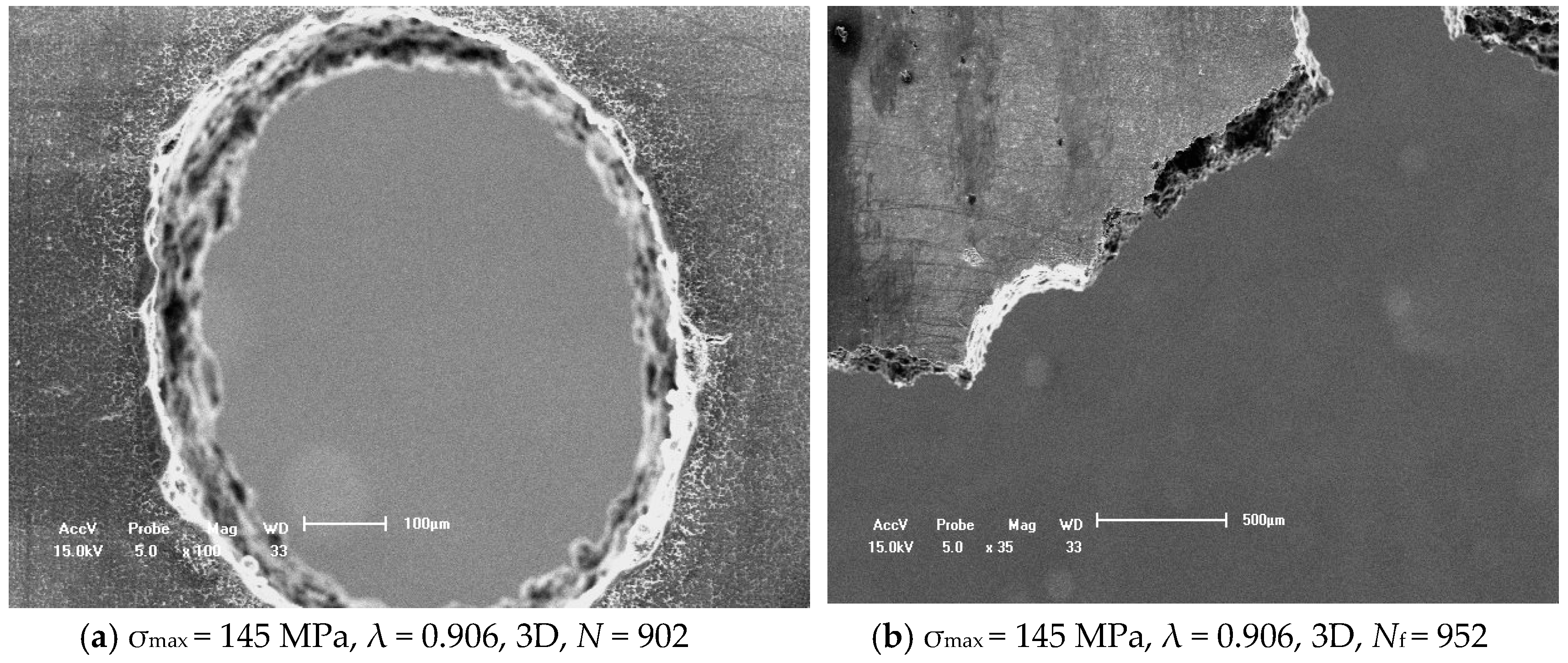

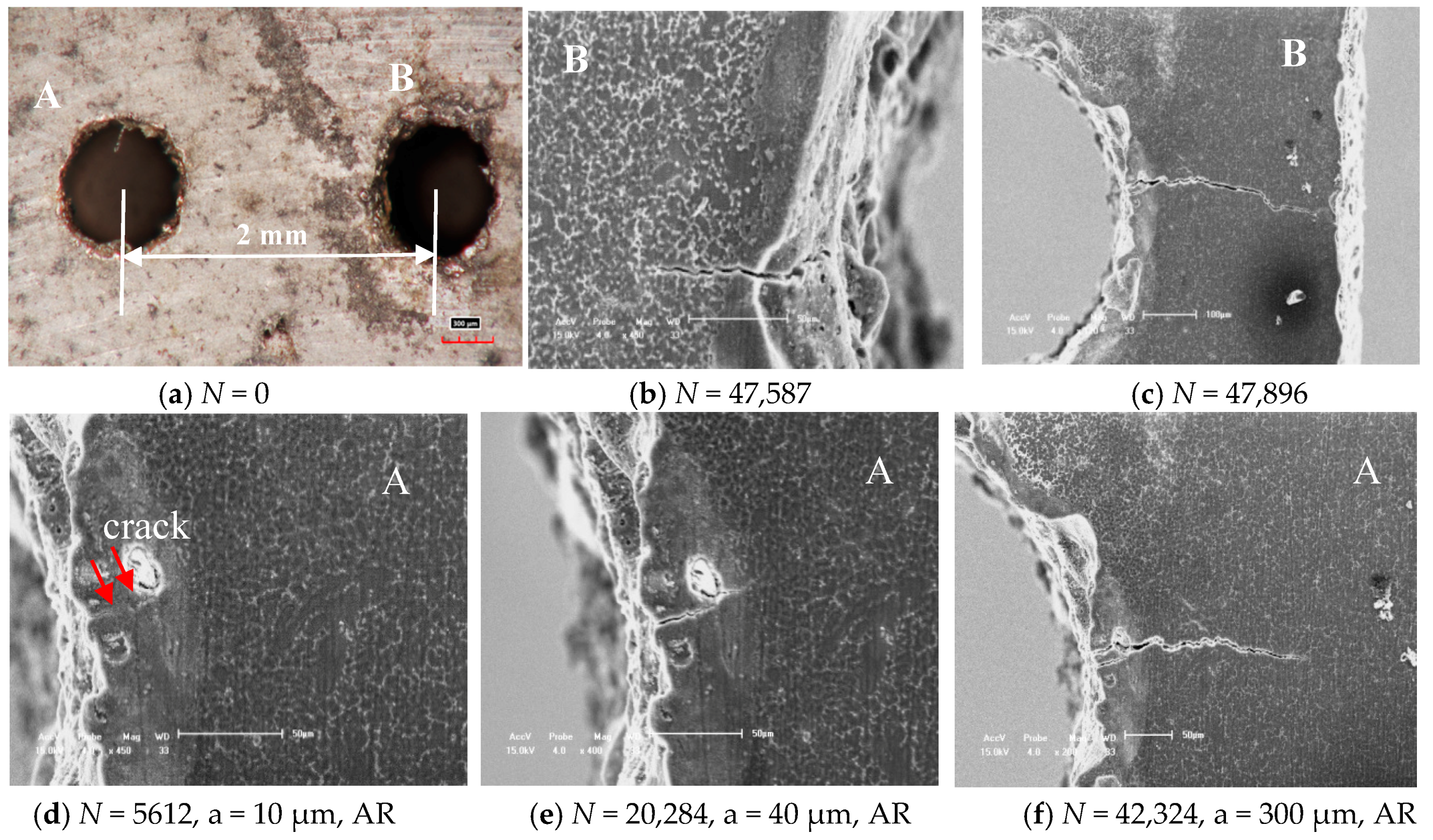

4.1. Effect of Tilted Angles of Multi-holes on Fatigue Behavior of Cast AM60B Alloy

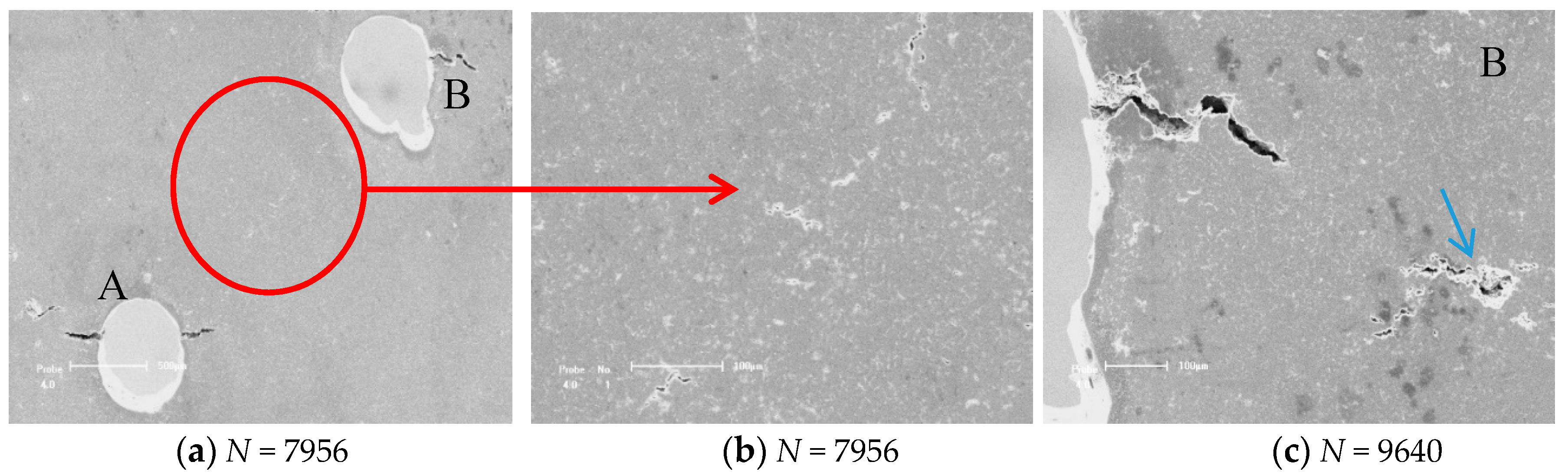

4.2. Effect of Tilted Angles of Multi-holes on Fatigue Behavior of Cast AZ91 Alloy

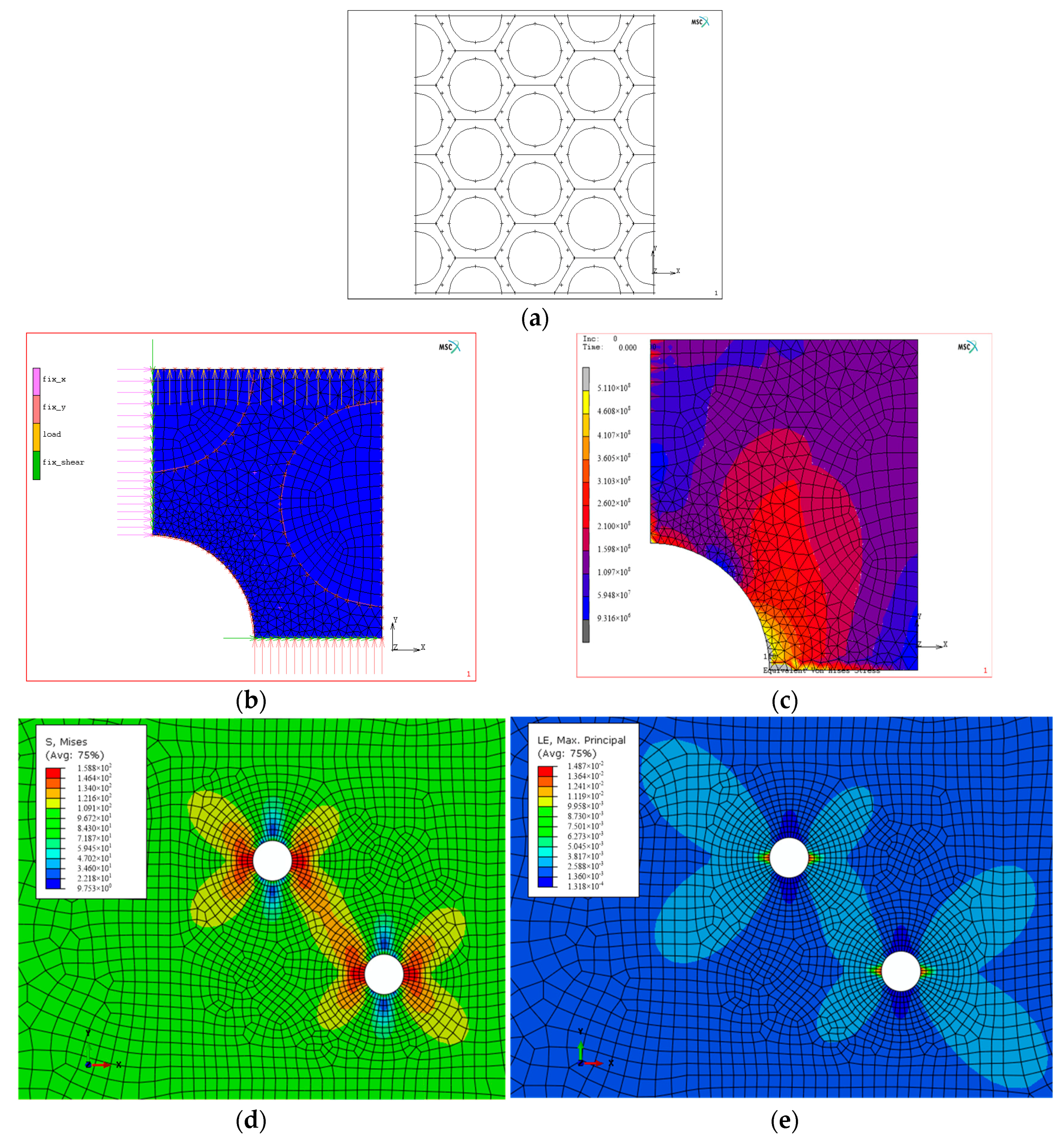

4.3. Validation of Fatigue Behavior by Using Finite Element Method

5. Conclusions

- For cast AZ91 alloy, the fatigue crack propagation behavior is more sensitive to changes in the distance between the two small holes than that of cast AM50 and AM60B alloys. This is because the plastic deformation capability of the former is much lower than that of the latter so that the LCF crack propagation resistance of the former is lower than that of the latter. The low cycle fatigue crack propagation behavior of the former depends strongly on the plastic strain or the maximum stress value but that of the latter depends mainly on the von Mises stress amplitude and its distribution.

- The LCF crack initiation behavior of cast AM60B and AZ91 alloys with tilted 90° and the hole distances indicated that all fatigue crack initiation seats occurred at the edge of hole and LCF crack propagation behavior depends mainly on the distance of two holes, which the LCF crack propagates preferentially between two small through holes when the hole distance is less than λ = 2 mm (4D). Therefore, the correlative effect of the distance of about λ = 2 mm (4D) on the LCF crack propagation can be defined as the critical distance between two small holes when the diameter of hole is about 0.5 mm.

- The LCF crack initiation behavior of cast Mg-Al alloys with tilted angle α = 45° and different hole distances is similar to that of the case with tilted angle α = 90° but the crack propagation behavior depends not only on the distance of two through holes but also on the plastic deformation capability of cast AM60B and AZ91 alloys as well as the applied stress ratio λ parameter (λ = σmax/σ0.2).

- The LCF crack growth rates of the cast AZ91 and AM60B alloys are about 1.38 × 10−8 m/cycle and 0.83 × 10−8 m/cycle, respectively, under the same condition. Therefore, the fatigue life of the former is shorter (just under 2 times) than that of the latter. The results demonstrate a good correlation with S-N curves by using the longitudinal coordinates of the maximum stress amplitude or the λ parameter.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Goodenberger, D.L.; Stephens, R.I. Fatigue of AZ91E-T6 cast magnesium alloy. J. Eng. Mater. Technol. Trans. ASEM 1993, 115, 391–397. [Google Scholar] [CrossRef]

- Stephens, R.I.; Schrader, C.D.; Lease, K.B. Corrosion-fatigue of AZ91E-T6 cast magnesium alloy in A 3.5 percent NaCl aqueous environment. J. Eng. Mater. Technol. Trans. ASEM 1995, 117, 293–298. [Google Scholar] [CrossRef]

- Mordike, B.L.; Ebert, T. Magnesium-properties-applications-potential. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Hu, H.; Yu, A.; Li, N.Y.; Allison, J.E. Potential magnesium alloys for high temperature die cast automotive applications: A review. Mater. Manuf. Process. 2003, 18, 687–717. [Google Scholar] [CrossRef]

- Pantelakis, S.G.; Alexopoulos, N.D.; Chamos, A.N. Mechanical performance evaluation of cast magnesium alloys for automotive and aeronautical applications. J. Eng. Mater. Technol. Trans. ASEM 2006, 129, 422–430. [Google Scholar] [CrossRef]

- Zhu, S.M.; Easton, M.A.; Abbott, T.B.; Nie, J.F.; Dargusch, M.S.; Hort, T.N.; Gibson, M.A. Evaluation of magnesium die-casting alloys for elevated temperature applications: Microstructure, tensile properties and creep resistance. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2015, 46, 3543–3554. [Google Scholar] [CrossRef]

- Chen, Y.S.; Wu, G.H.; Liu, W.C.; Zhang, L.G.; Wang, Q. Effect of mold temperature on microstructure and mechanical properties of rheo-squeeze casting Mg-3Nd-0.2Zn-0.4Zr alloy. J. Mater. Res. 2017, 32, 4206–4218. [Google Scholar] [CrossRef]

- Zhang, H.H.; Zhang, L.; Wu, G.H.; Chen, A.T.; Cui, W.D.; Chen, Y.S.; Wang, Q.; Gao, Z.K. Microstructure and mechanical properties of Mg-3.0Y-2.5Nd-1.0Gd-xZn-0.5Zr alloys produced by metallic and sand mold casting. J. Mater. Res. 2017, 32, 3191–3201. [Google Scholar] [CrossRef]

- Tang, B.; Li, S.S.; Wang, X.S.; Zeng, D.B. An investigation on hot-crack mechanism of Ca addition into AZ91D alloy. J. Mater. Sci. 2005, 40, 2931–2936. [Google Scholar] [CrossRef]

- Tang, B.; Wang, X.S.; Li, S.S.; Zeng, D.B.; Wu, R. Effects of Ca combined with Sr additions on microstructure and mechanical properties of AZ91D magnesium alloy. Mater. Sci. Technol. 2005, 21, 574–578. [Google Scholar] [CrossRef]

- Tang, B.; Li, S.S.; Wang, X.S.; Zeng, D.B.; Wu, R. Effect of Ca/Sr composite addition into AZ91D alloy on hot-crack mechanism. Scr. Mater. 2005, 53, 1077–1082. [Google Scholar] [CrossRef]

- Wang, X.S.; Jin, L.; Li, Y.; Guo, X.W. Effect of equal channel angular extrusion process on deformation behaviors of Mg-3Al-Zn alloy. Mater. Lett. 2008, 62, 1856–1858. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.G.; Yoon, J.; Lee, C.S. Influence of loading direction on the anisotropic fatigue properties of rolled magnesium alloy. Int. J. Fatigue 2016, 87, 210–215. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M.; Liu, Z.H.; Chen, J. Investiguation of uniaxial low-cycle fatigue failure behavior of hot-rolled AZ91 magnesium alloy. Int. J. Fatigue 2012, 48, 122–132. [Google Scholar] [CrossRef]

- Ishihara, S.; Taneguchi, S.; Shibata, H.; Goshima, T.; Saiki, A. Anisotropy of the fatigue behavior of extruded and rolled magnesium alloys. Int. J. Fatigue 2013, 50, 94–100. [Google Scholar] [CrossRef]

- Gall, K.; Biallas, G.; Hans, M.; Horstemeyer, M.E.; McDowell, D.L. Environmentally influenced microstructurally small fatigue crack growth in cast magnesium. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2005, 396, 143–154. [Google Scholar] [CrossRef]

- Wang, X.S.; Fan, J.H. SEM online investigation of fatigue crack initiation and propagation in notched cast magnesium alloy. J. Mater. Sci. 2004, 39, 2617–2620. [Google Scholar] [CrossRef]

- Wang, X.S.; Fan, J.H. An evaluation on the growth rate of small fatigue cracks in cast AM50 magnesium alloy at different temperatures in vacuum conditions. Int. J. Fatigue 2006, 28, 79–86. [Google Scholar] [CrossRef]

- Wang, X.S.; Liang, F.; Fan, J.H.; Zhang, F.H. Low-cycle fatigue small crack initiation and propagation mechanism of cast magnesium alloys based on in-situ SEM observations. Philos. Mag. 2006, 86, 1581–1596. [Google Scholar] [CrossRef]

- Li, Z.M.; Wang, Q.G.; Luo, A.A.; Fu, P.H.; Peng, L.M. Fatigue strength dependence on the ultimate tensile strength and hardness in magnesium alloys. Int. J. Fatigue 2015, 80, 468–476. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Yang, N.; Zettl, B.; McDowell, D.L.; Fan, J.H.; Gullett, P.M. High cycle fatigue of a die cast AZ91E-T4 magnesium alloy. Acta Meter. 2004, 52, 1327–1336. [Google Scholar] [CrossRef]

- EI Kadiri, H.; Xue, Y.B.; Horstemeyer, M.F.; Jordon, J.B.; Wang, P.T. Identification and modeling of fatigue crack growth mechanisms in a die-cast AM50 magnesium alloy. Acta Meter. 2006, 54, 5061–5076. [Google Scholar] [CrossRef]

- Mayer, H.; Papakyriacou, M.; Zettle, B.; Stanzl, S.E. Influence of porosity on the fatigue limit of die cast magnesium and aluminum alloys. Int. J. Fatigue 2003, 25, 245–256. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, W.C.; Wu, G.H.; Chen, X.J.; Zhang, H.H. Influence of heat treatment on cyclic deformation and low-cycle fatigue behavior of sand-cast Mg-10Gd-3Y-0.5Zr magnesium alloy. J. Mater. Res. 2017, 32, 2179–2187. [Google Scholar] [CrossRef]

- Preciado, M.; Bravo, P.M.; Cardenas, D. Influence of porosity in the fatigue behavior of the high-pressure die-casting AZ91 magnesium alloys. J. Eng. Mater. Technol. Trans. ASEM 2016, 138, 041006. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Yang, N.; Gall, K.; McDowell, D.; Fan, J.H.; Gullett, P.M. High cycle fatigue mechanics in a cast AM60B magnesium alloy. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 1045–1056. [Google Scholar] [CrossRef]

- Lu, Y.; Taheri, F.; Gharghouri, M. Study of fatigue crack incubation and propagation mechanisms in a HPDC AM60B magnesium alloy. J. Alloy Compd. 2008, 466, 214–227. [Google Scholar] [CrossRef]

- Murugan, G.; Raghukandan, K.; Pillai, U.T.S.; Pai, B.C.; Mahadevan, K. Statistical analysis of high cycle fatigue investigations of cast magnesium alloys under transverse load. Trans. Indian Inst. Met. 2010, 63, 511–514. [Google Scholar] [CrossRef]

- Mohd, S.; Mutoh, Y.; Otsuka, Y.; Miyashita, Y.; Koike, T.; Suzuki, T. Scatter analysis of fatigue life and pore size data of die-cast AM60B magnesium alloy. Eng. Fail. Anal. 2012, 22, 64–72. [Google Scholar] [CrossRef]

- Hu, X.F.; Bui, T.Q.; Wang, J.N.; Yao, W.A.; Ton, L.H.T.; Singh, I.V. A new cohesive crack tip symplectic analytical singular element involving plastic zone length for fatigue crack growth prediction under variable amplitude cyclic loading. Eur. J. Mech. A-Solids 2017, 65, 79–90. [Google Scholar] [CrossRef]

- Yu, T.T.; Bui, T.Q. Numerical simulation of 2-D weak and strong discontinuities by a novel approach based on XFEM with local mesh refinement. Comput. Struct. 2018, 196, 112–133. [Google Scholar] [CrossRef]

- Wu, C.T.; Bui, T.Q.; Wu, Y.C.; Luo, T.L.; Wang, M.; Liao, C.C.; Chen, P.Y.; Lai, Y.S. Numerical and experimental validation of a particle Galerkin method for metal grinding simulation. Comput. Mech. 2018, 61, 365–385. [Google Scholar] [CrossRef]

- Wang, X.S.; Fan, J.H.; Wu, B.S.; Li, Y. Effects of distance and alignment holes on fatigue crack behaviors of cast magnesium alloys. Adv. Mater. Res. 2008, 33, 13–18. [Google Scholar] [CrossRef]

| Materials | Al | Mn | Si | Zn | Cu | Mg | σ0.2 (MPa) | σb (MPa) | Δ (%) |

|---|---|---|---|---|---|---|---|---|---|

| AM50 | 2.50 | 0.2 | 1.20 | 0.25 | 0.080 | Bal. | 140 | 200 | 15.0 |

| AM60B | 5.99 | 0.2 | 1.20 | 0.25 | 0.008 | Bal. | 150 | 160 | 10.0 |

| AZ91 | 8.97 | - | 0.05 | 0.45 | 0.025 | Bal. | 160 | 240 | 3.5 |

| Materials | E (GPa) | υ | Micro Hardness (MPa) | Crystal Particle Size (μm) | FE Mesh |

|---|---|---|---|---|---|

| α-Mg | 43 | 0.35 | 66.86 | 10 | hexagon |

| β-Mg17Al12 | 58 | 0.30 | 88.34 | 15 | hexagon |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.-S.; Tan, C.-H.; Ma, J.; Zhu, X.-D.; Wang, Q.-Y. Influence of Multi-Holes on Fatigue Behaviors of Cast Magnesium Alloys Based on In-Situ Scanning Electron Microscope Technology. Materials 2018, 11, 1700. https://doi.org/10.3390/ma11091700

Wang X-S, Tan C-H, Ma J, Zhu X-D, Wang Q-Y. Influence of Multi-Holes on Fatigue Behaviors of Cast Magnesium Alloys Based on In-Situ Scanning Electron Microscope Technology. Materials. 2018; 11(9):1700. https://doi.org/10.3390/ma11091700

Chicago/Turabian StyleWang, Xi-Shu, Chang-Hao Tan, Juan Ma, Xiao-Dong Zhu, and Qing-Yuan Wang. 2018. "Influence of Multi-Holes on Fatigue Behaviors of Cast Magnesium Alloys Based on In-Situ Scanning Electron Microscope Technology" Materials 11, no. 9: 1700. https://doi.org/10.3390/ma11091700

APA StyleWang, X.-S., Tan, C.-H., Ma, J., Zhu, X.-D., & Wang, Q.-Y. (2018). Influence of Multi-Holes on Fatigue Behaviors of Cast Magnesium Alloys Based on In-Situ Scanning Electron Microscope Technology. Materials, 11(9), 1700. https://doi.org/10.3390/ma11091700