Experimental Study on Shear Behavior of Steel Fiber Reinforced Concrete Beams with High-Strength Reinforcement

Abstract

1. Introduction

2. Experimental Program

2.1. Materials and Mixture Proportions

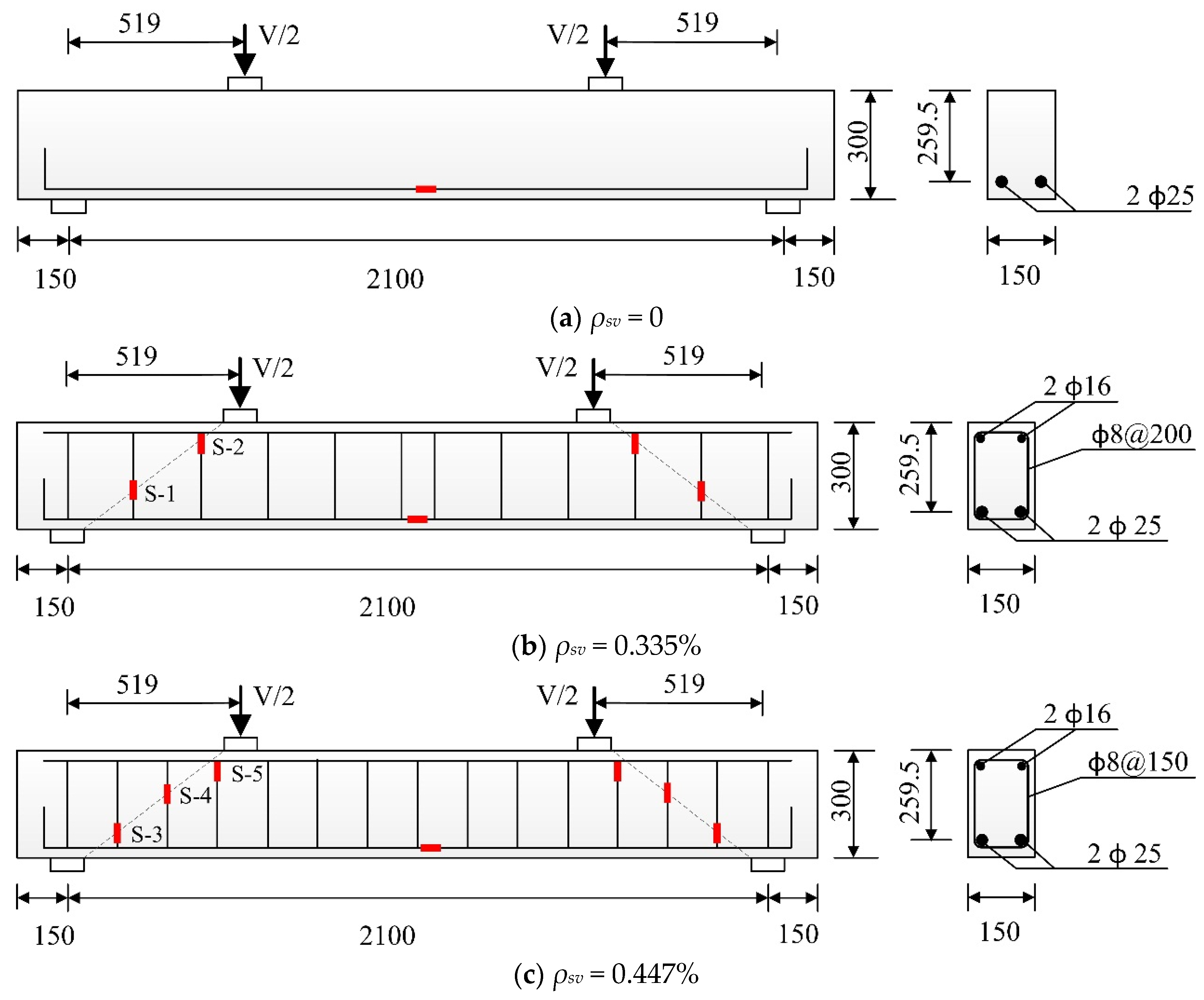

2.2. Details of Experimental Specimen

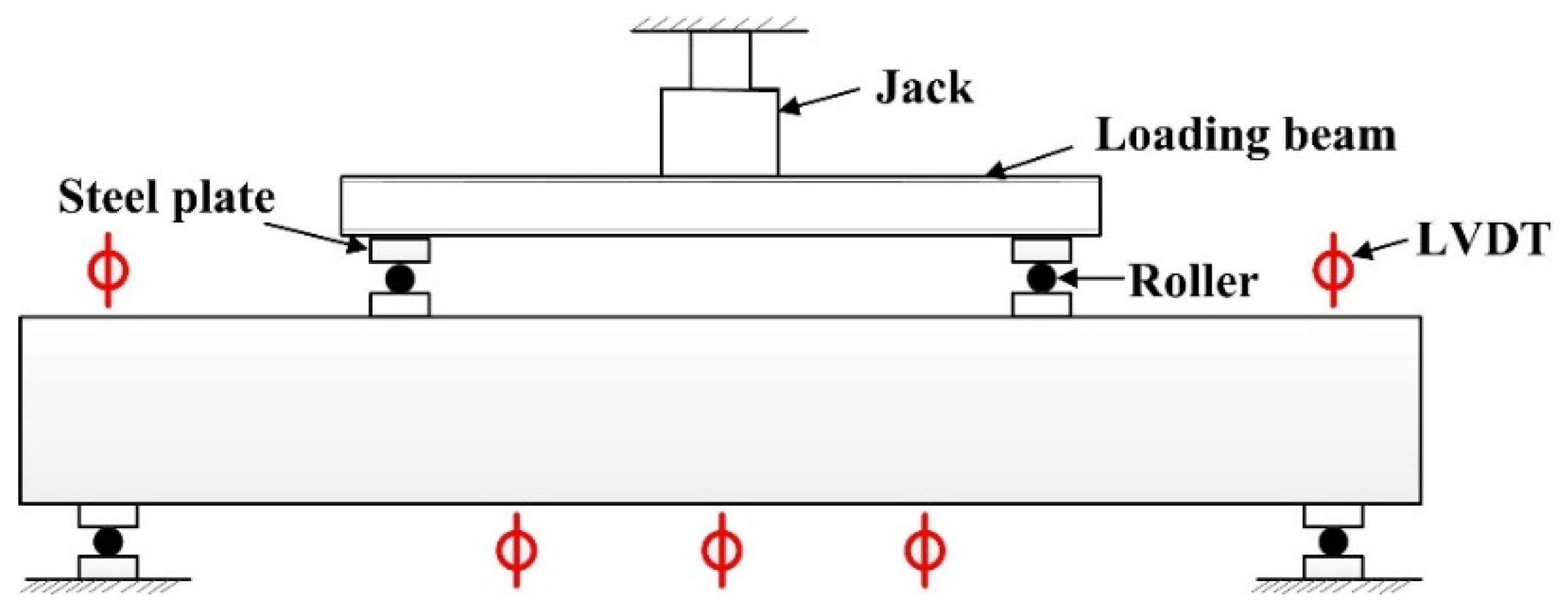

2.3. Test Procedure and Data Collection

3. Experimental Results and Data Analysis

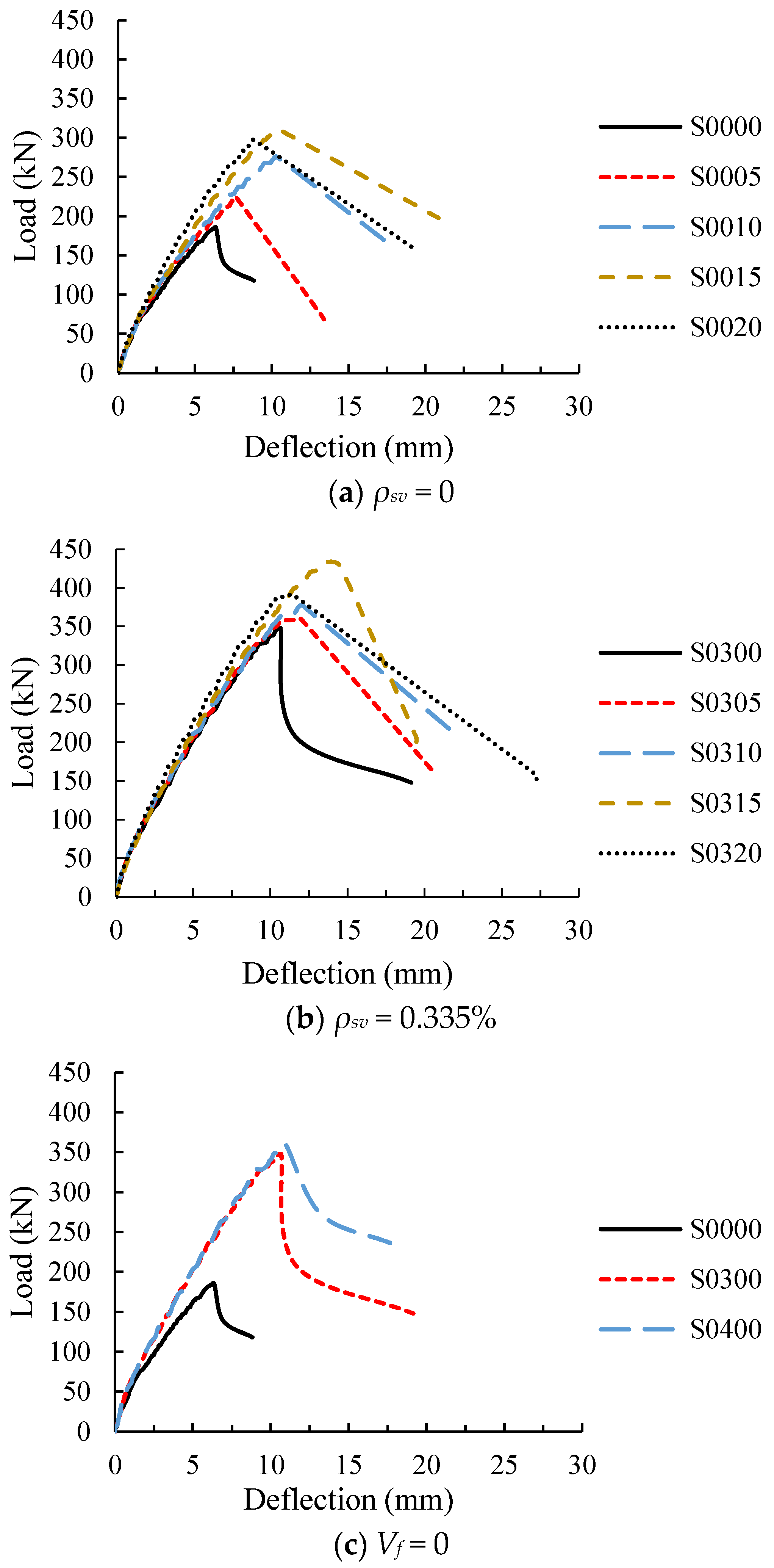

3.1. Load-Deflection Curve

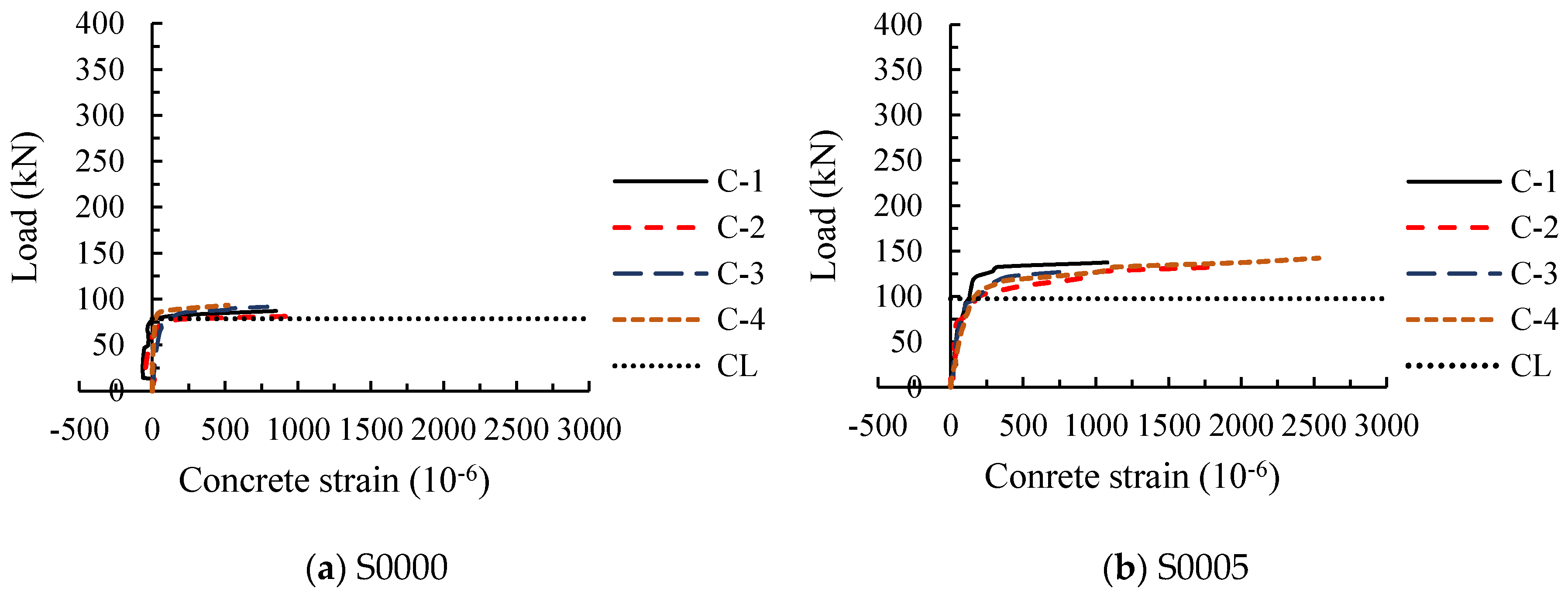

3.2. Tensile Concrete Strain

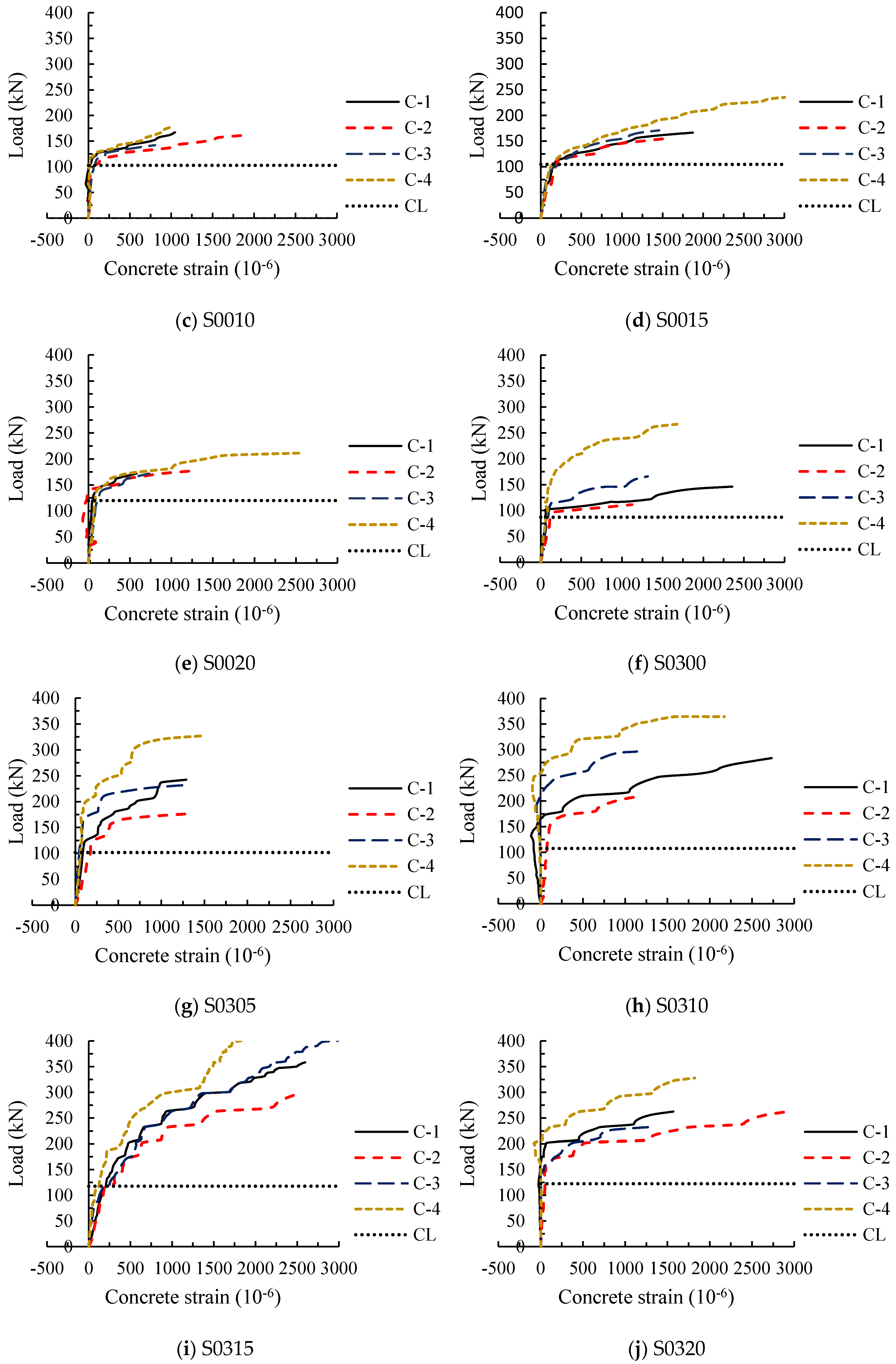

3.3. Stirrup Strain

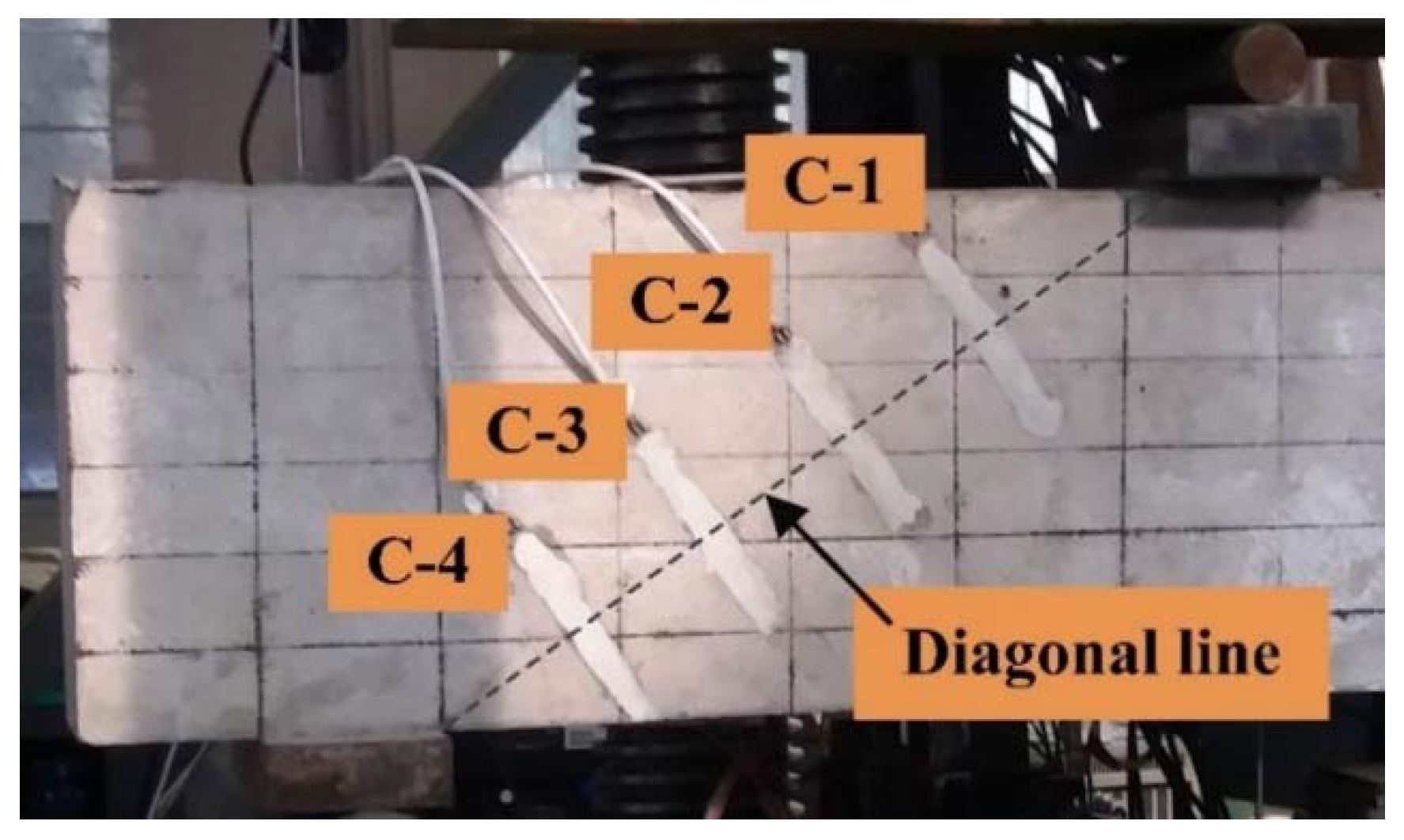

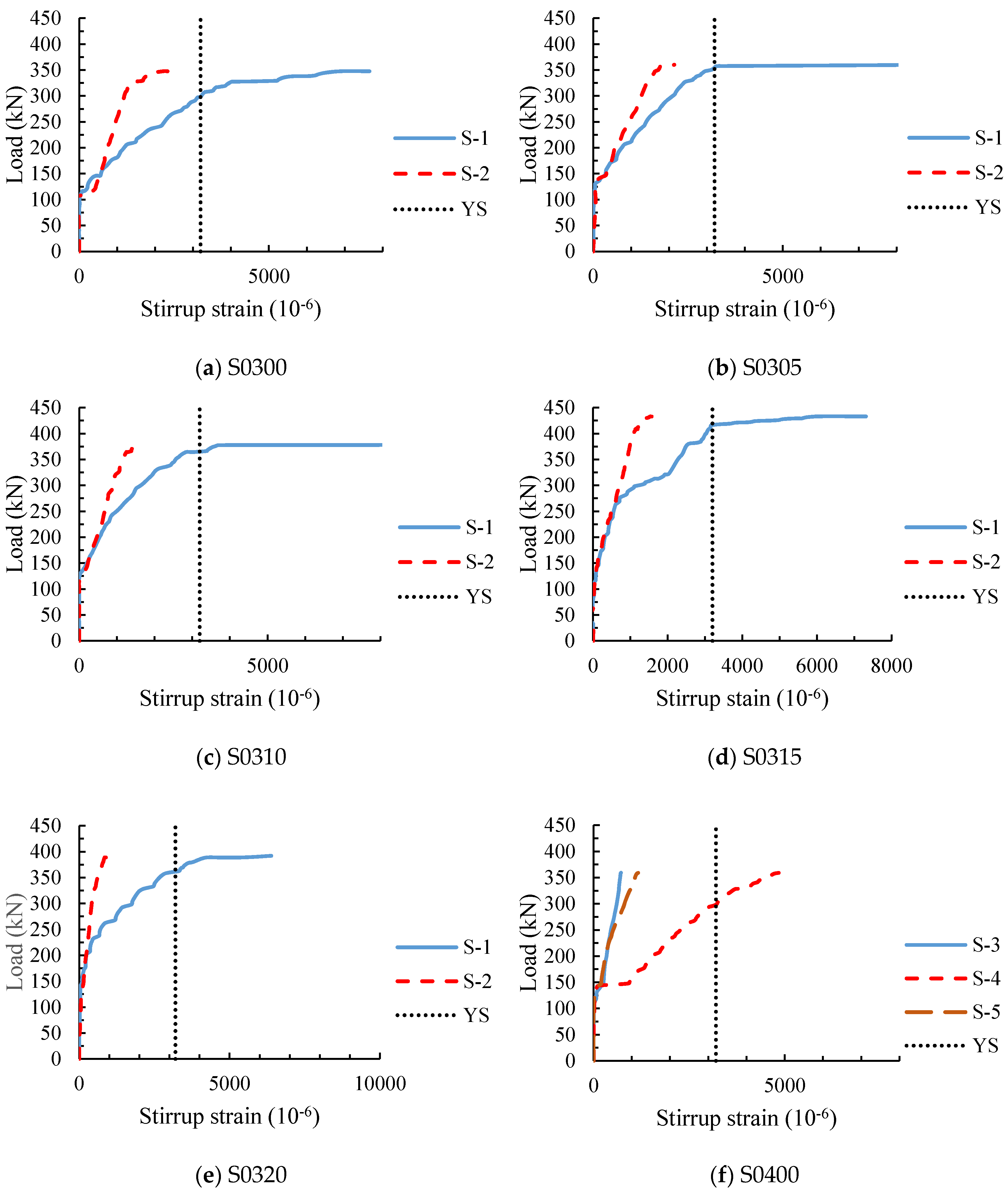

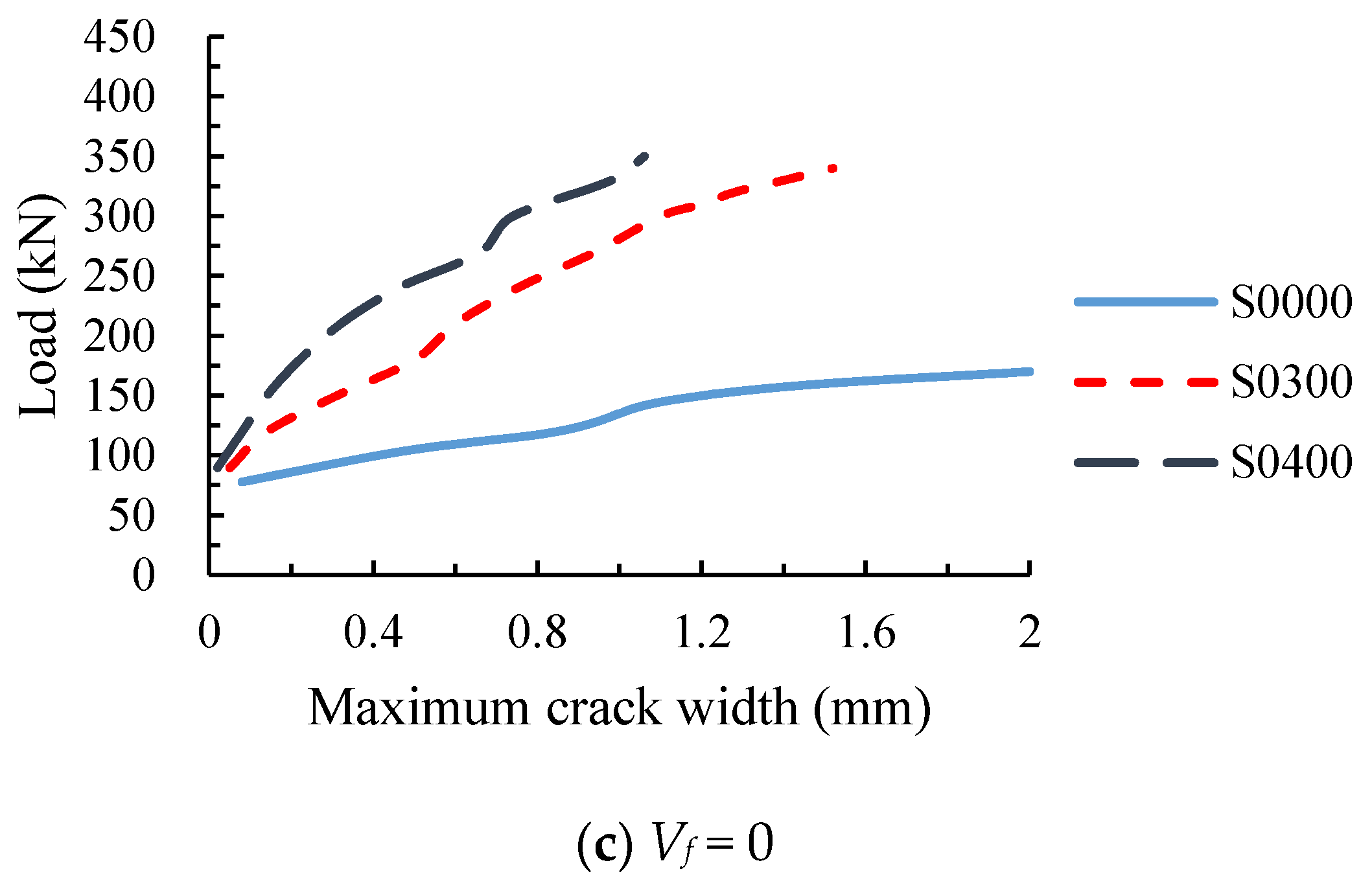

3.4. Diagonal Crack Width

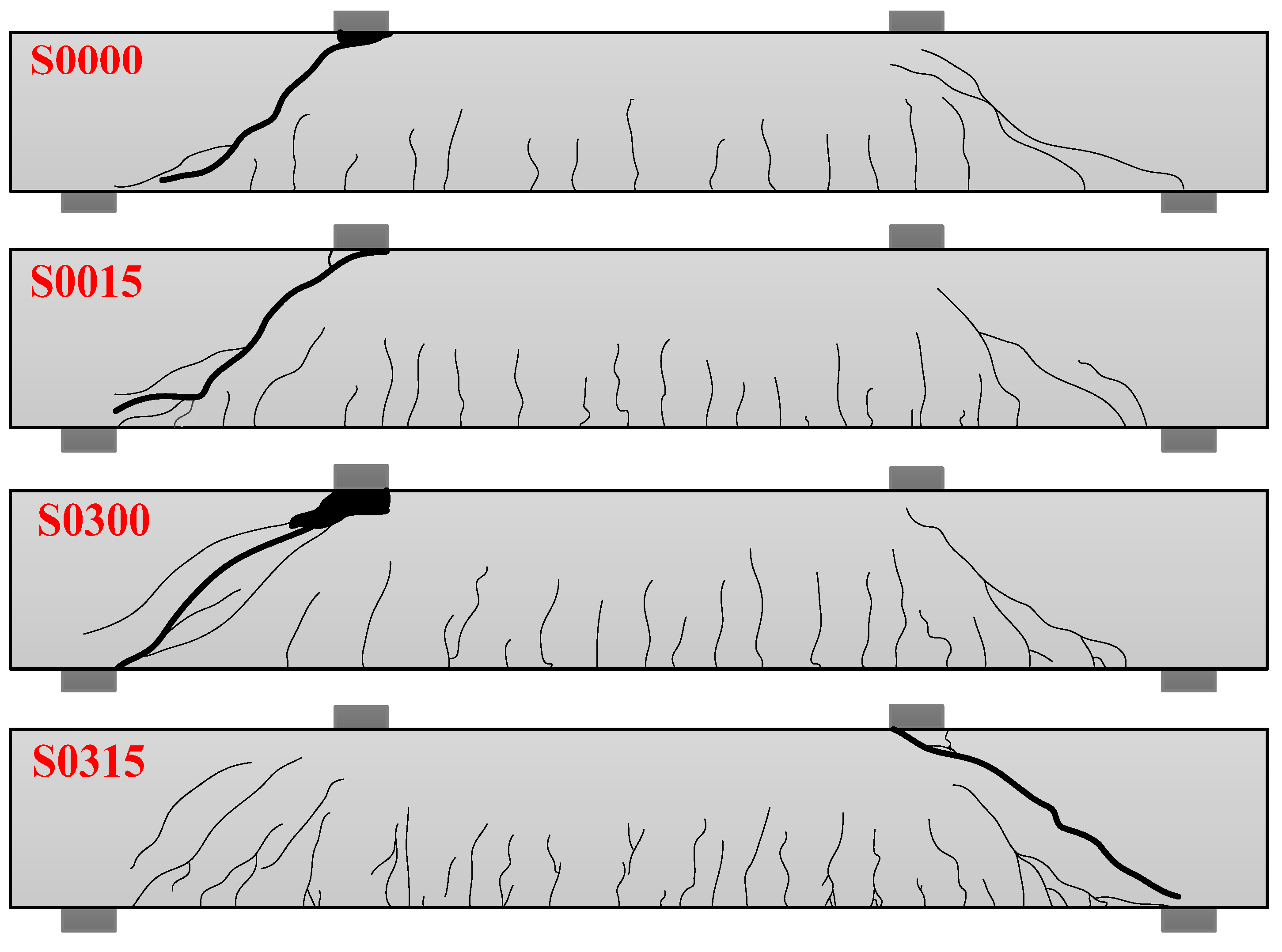

3.5. Failure Modes

4. The Analysis of Shear Capacity

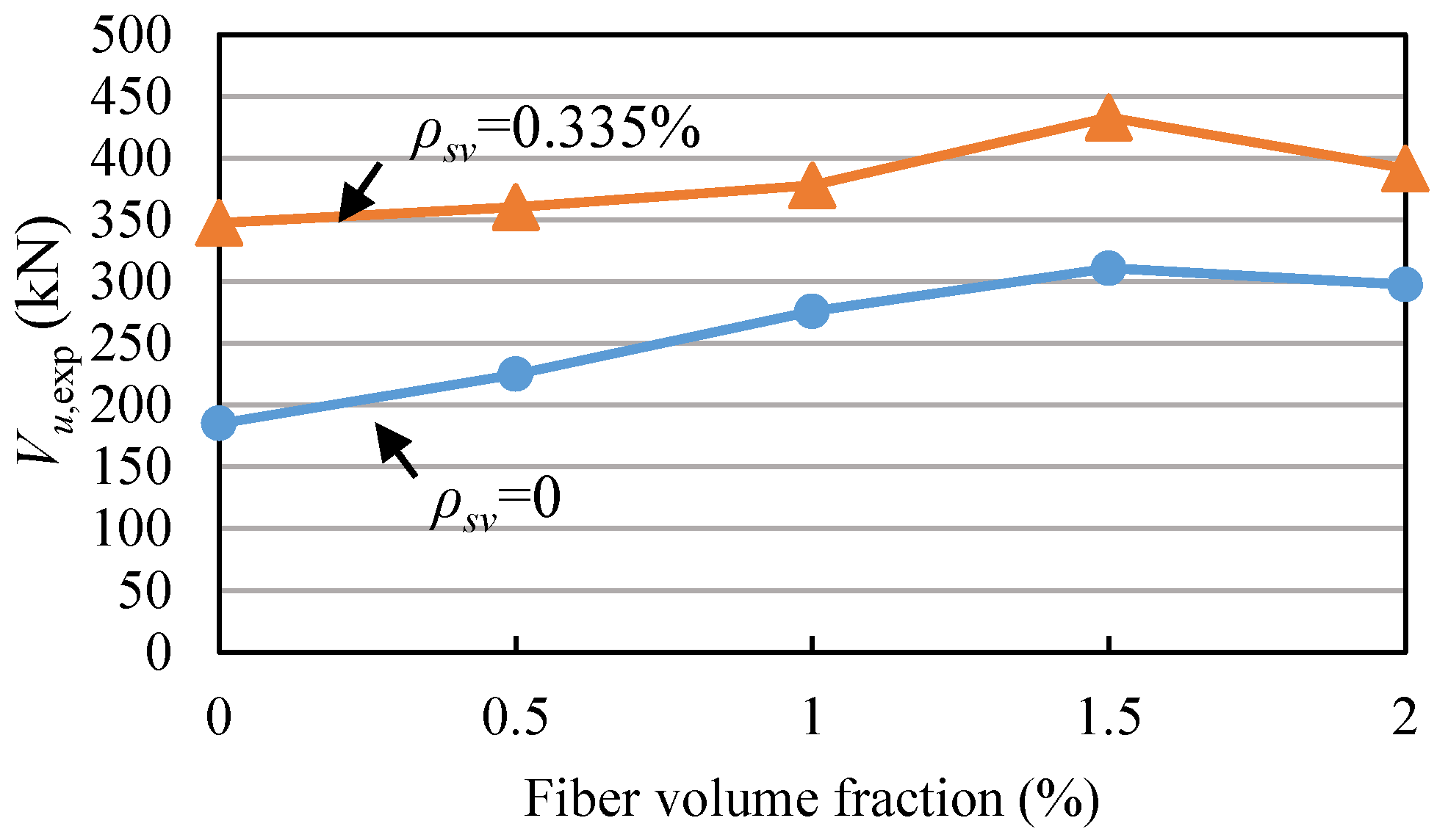

4.1. Effect of Fiber Volume Fraction

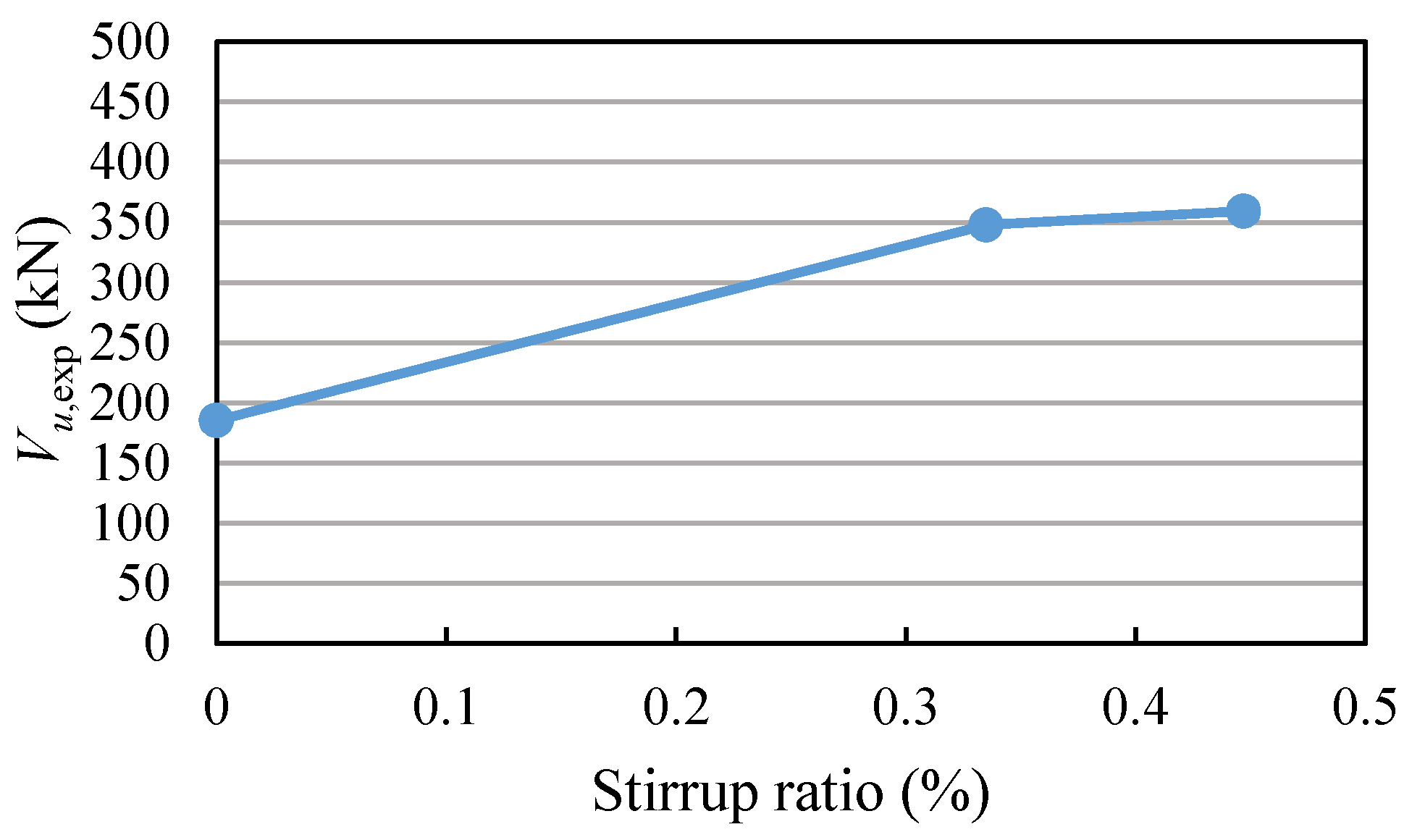

4.2. Effect of Stirrup Ratio

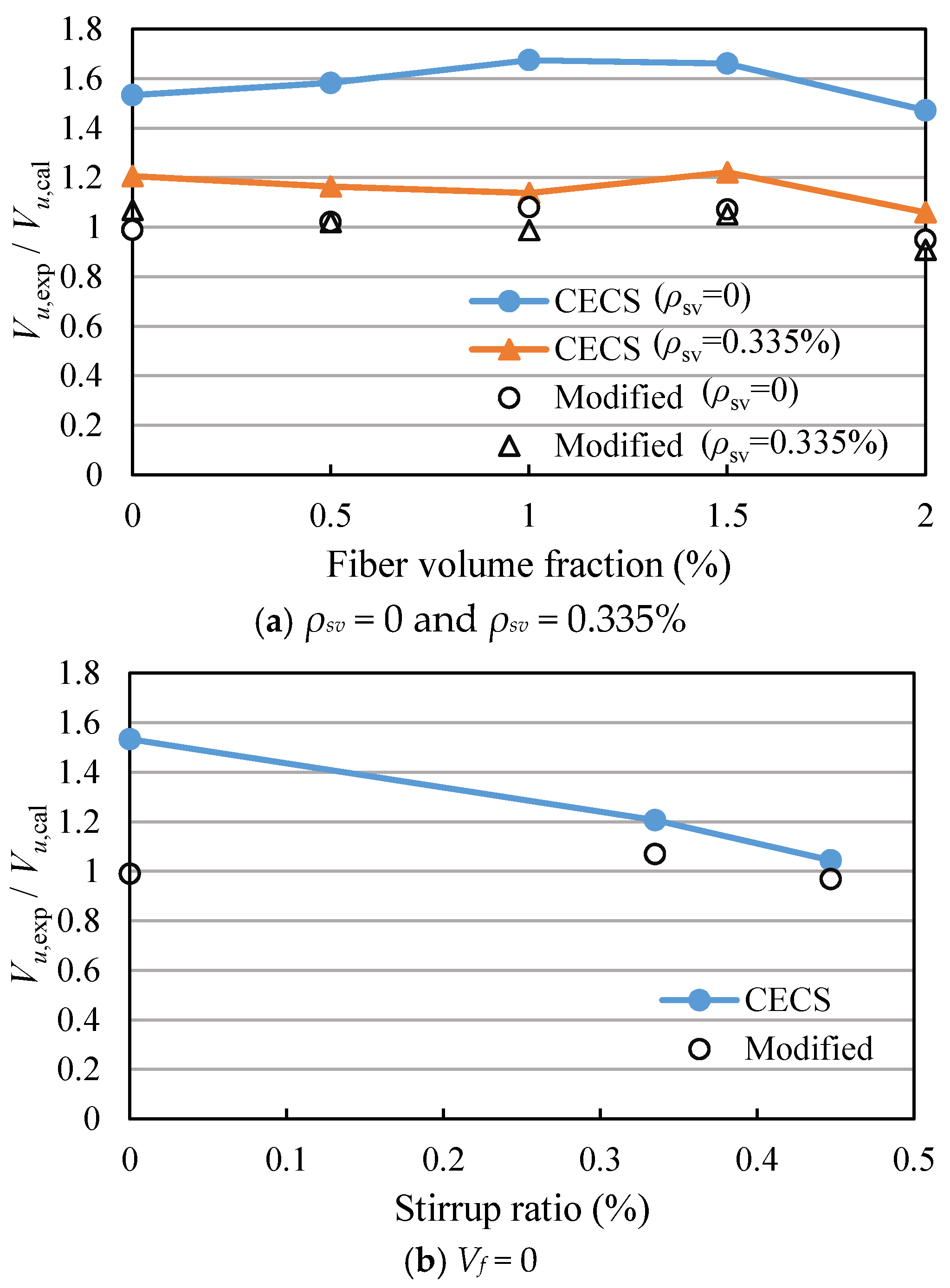

4.3. Comparison between the Measured Values and the Calculated Values of the Codes

4.3.1. Comparison between the Measured Values and Calculated Values of CECS 38:2004

4.3.2. Comparison between the Measured Values and Calculated Values of ACI544.4R

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Notations:

| Vf | volume fraction of steel fiber |

| lf | length of steel fiber |

| df | equivalent diameter of steel fiber |

| λf | characteristic value of fiber content |

| βv | influence coefficient of steel fiber on shear capacity |

| b | width of beam section |

| h0 | effective depth of beam section |

| ρsv | stirrup ratio |

| fc | compression strength of prism specimen at 28 days |

| fts | splitting tensile strength of cylinder specimen at 28 days |

| ft | tensile strength of SFRC without considering the effect of steel fiber |

| Ec | elastic modulus of concrete |

| fyv | yield strength of stirrup |

| Asv | section area of stirrup in shear span |

| s | stirrup spacing |

| λ | shear span ratio |

| Vu,exp | shear capacity measured from the experiment |

| Vu,CECS | shear capacity calculated by CECS38:2004 |

| Vu,ACI | shear capacity calculated by ACI544.4R |

| Vu,Modified | shear capacity calculated by the modified equation of CECS38:2004 |

| Vcf | shear force provided by SFRC |

| Vs | shear force provided by the stirrup |

| α | influence coefficient of stirrup ratio on the Vcf |

References

- Harries, K.A.; Shahrooz, B.M.; Soltani, A. Flexural crack widths in concrete girders with high-strength reinforcement. J. Bridge Eng. 2012, 17, 804–812. [Google Scholar] [CrossRef]

- Soltani, A.; Harries, K.A.; Shahrooz, B.M. Crack opening behavior of concrete reinforced with high strength reinforcing steel. Int. J. Concr. Struct. Mater. 2013, 7, 253–264. [Google Scholar] [CrossRef]

- Hassan, T.K.; Mantawy, A.; Soliman, J.; Sherif, A.; Rizkalla, S.H. Bond characteristics and shear behavior of concrete beams reinforced with high-strength steel reinforcement. Adv. Struct. Eng. 2012, 15, 303–318. [Google Scholar] [CrossRef]

- Munikrishma, A.; Hosny, A.; Rizkalla, S.; Zia, P. Behavior of concrete beams reinforced with ASTM A1035 Grade 100 stirrups under shear. ACI Struct. J. 2011, 108, 34–41. [Google Scholar]

- Munikrishma, A. Shear Behavior of Concrete Beam Reinforced with High Performance Steel Shear Reinforcement. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 12 August 2008. [Google Scholar]

- Lee, J.Y.; Lee, D.H.; Lee, J.E.; Choi, S.H. Shear behavior and diagonal crack width for reinforced concrete beams with high-strength shear reinforcement. ACI Struct. J. 2015, 112, 323–333. [Google Scholar] [CrossRef]

- Sumper, M.S.; Rizkalla, S.H.; Zia, P. Behavior of high-performance steel as shear reinforcement for concrete beams. ACI Struct. J. 2009, 106, 171–177. [Google Scholar]

- Yazıc, Ş.; İnan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Olivito, R.S.; Zuccarello, F.A. An experimental study on the tensile strength of steel fiber reinforced concrete. Compos. Part B-Eng. 2010, 41, 246–255. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Soon, Y.S.; Banthia, N. Flexural response of steel-fiber-reinforced concrete beams: Effects of strength, fiber content, and strain-rate. Cem. Concr. Compos. 2015, 64, 84–92. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Meda, A.; Minelli, F.; Plizzari, G.A. Flexural behavior of RC beams in fibre reinforced concrete. Compos. Part B-Eng. 2012, 43, 2930–2937. [Google Scholar] [CrossRef]

- Biolzi, L.; Cattaneo, S.; Mola, F. Bending-shear response of self-consolidating and high-performance reinforced concrete beams. Eng. Struct. 2014, 59, 339–410. [Google Scholar] [CrossRef]

- Kwak, Y.K.; Eberhard, M.O.; Kim, W.S.; Kim, J. Shear strength of steel fiber-reinforced concrete beams without stirrups. ACI Struct. J. 2003, 99, 530–538. [Google Scholar]

- Amin, A.; Foster, S.J. Shear strength of steel fibre reinforced concrete beams with stirrups. Eng. Struct. 2016, 111, 323–332. [Google Scholar] [CrossRef]

- Biolzi, L.; Cattaneo, S. Response of steel fiber reinforced high strength concrete beams: Experiments and code predictions. Cem. Concr. Compos. 2017, 77, 1–13. [Google Scholar] [CrossRef]

- Gao, D.Y.; Zhao, J.; Zhu, H.T. The experimental research on the shear behavior of partial steel fiber reinforced concrete beams. J. Hydraul. Eng. 1999, 2, 28–32. [Google Scholar]

- Yoo, D.Y.; Yang, J.M. Effects of stirrup, steel fiber, and beam size on shear behavior of high-strength concrete beams. Cem. Concr. Compos. 2018, 87, 137–148. [Google Scholar] [CrossRef]

- Ding, Y.N.; You, Z.G.; Jalali, S. The composite effect of steel fibres and stirrups on the shear behaviour of beams using self-consolidating concrete. Eng. Struct. 2011, 33, 107–117. [Google Scholar] [CrossRef]

- Narayanan, R.; Darwish, I.Y.S. Shear in mortar beams containing fibers and fly ash. J. Struct. Eng. 1988, 114, 84–102. [Google Scholar] [CrossRef]

- Dinh, H.H.; Parra-Montesinos, G.J.; Wight, J.K. Shear behavior of steel fiber-reinforced concrete beams without stirrup reinforcement. ACI Struct. J. 2010, 107, 597–606. [Google Scholar]

- Shoaib, A.; Lubell, A.S.; Bindiganavile, V.S. Shear response of lightweight steel fiber reinforced concrete members without stirrups. Mater. Struct. 2015, 48, 3141–3157. [Google Scholar] [CrossRef]

- Kang, T.H.K.; Kim, W.; Kwak, Y.K.; Hong, S.G. Shear testing of steel fiber-reinforced lightweight concrete beams without web reinforcement. ACI Struct. J. 2011, 108, 553–561. [Google Scholar]

- Tahenni, T.; Chenrouk, M.; Lecompte, T. Effect of steel fibers on the shear behavior of high strength concrete beams. Constr. Build. Mater. 2016, 105, 14–28. [Google Scholar] [CrossRef]

- Meda, A.; Minelli, F.; Plizzari, G.A.; Riva, P. Shear behaviour of steel fibre reinforced concrete beams. Mater. Struct. 2005, 38, 343–351. [Google Scholar] [CrossRef]

- Cucchiara, C.; Mendola, L.L.; Papia, M. Effectiveness of stirrups and steel fibres as shear reinforcement. Cem. Concr. Compos. 2004, 26, 777–786. [Google Scholar] [CrossRef]

- Furlan, S., Jr.; Hanai, J.B.D. Shear behaviour of fiber reinforced concrete beams. Cem. Concr. Compos. 1997, 19, 359–366. [Google Scholar] [CrossRef]

- Ding, Y.N.; Zhang, F.; Torgal, F.; Zhang, Y.L. Shear behaviour of steel fibre reinforced self-consolidating concrete beams based on the modified compression field theory. Compos. Struct. 2012, 94, 2440–2449. [Google Scholar] [CrossRef]

- Lim, W.Y.; Hong, S.G. Shear tests for ultra-high performance fiber reinforced concrete (UHPFRC) beams with shear reinforcement. Int. J. Concr. Struct. Mater. 2016, 10, 177–188. [Google Scholar] [CrossRef]

- China Association for Engineering Construction Standardization. Technical Specification for Fiber Reinforced Concrete Structure; CECS 38:2004; China Planning Press: Beijing, China, 2004; pp. 23–25. (In Chinese) [Google Scholar]

- American Concrete Institute Committee. Design Considerations for Steel Fiber Reinforced Concrete; ACI 544.4R-88, Reapproved 2009; American Concrete Institute: Farmington Hills, MI, USA, 2009; pp. 574–576. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Code for Design of Concrete Structures; GB50010-2002; China Architecture & Building Press: Beijing, China, 2002; pp. 21–27. (In Chinese)

- American Concrete Institute Committee. Building Code Requirements for Reinforced Concrete and Commentary; ACI 318-08; American Concrete Institute: Farmington Hills, MI, USA, 2008; p. 43. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Steel Fiber Reinforced Concrete; JG/T472-2015; Standards Press of China: Beijing, China, 2015; pp. 3–5. (In Chinese)

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard of Test Methods of Concrete Structures; GB/T50152-2012; China Architecture and Building Press: Beijing, China, 2012; pp. 11–25. (In Chinese)

- Ashour, S.A. Effect of compressive strength and tensile reinforcement ratio on flexural behavior of high-strength concrete beams. Eng. Struct. 2000, 22, 413–423. [Google Scholar] [CrossRef]

- Ezeldin, A.S.; Balaguru, P.N. Normal and high-strength fiber reinforced concrete under compression. J. Mater. Civ. Eng. 1992, 4, 415–429. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Dhang, N.; Gupta, A.P. Stress-strain curves for steel-fiber reinforced concrete under compression. Cem. Concr. Compos. 1999, 21, 383–390. [Google Scholar] [CrossRef]

- Swamy, R.N.; Jones, R.; Chiam, A.T.P. Influence of steel fibers on the shear resistance of lightweight concrete I-beams. ACI Struct. J. 1993, 40, 103–114. [Google Scholar]

- Spinella, N. Shear strength of full-scale steel fibre-reinforced concrete beams without stirrups. Comput. Concr. 2013, 11, 365–382. [Google Scholar] [CrossRef]

- Dinh, H.H.; Parra-Montesinos, G.J.; Wight, G.K. Shear strength model for steel fiber reinforced concrete beams without stirrup reinforcement. J. Struct. Eng. 2011, 137, 1039–1051. [Google Scholar] [CrossRef]

- Sharma, A.K. Shear strength of steel fiber reinforced concrete beams. ACI Struct. J. 1986, 83, 624–628. [Google Scholar]

| Mix | W/B | Cement (kg) | Water (kg) | Coarse Aggregate (kg) | Fine Aggregate (kg) | Sand Ratio (%) | Steel Fiber (kg) | Vf (%) |

|---|---|---|---|---|---|---|---|---|

| M-1 | 0.5 | 410 | 205 | 1150 | 735 | 39 | 0 | 0 |

| M-2 | 0.5 | 410 | 205 | 1127 | 746 | 39 | 39.25 | 0.5 |

| M-3 | 0.5 | 410 | 205 | 1104 | 756 | 39 | 78.5 | 1.0 |

| M-4 | 0.5 | 410 | 205 | 1082 | 766 | 39 | 117.75 | 1.5 |

| M-5 | 0.5 | 410 | 205 | 1058 | 777 | 39 | 157 | 2.0 |

| Diameter (mm) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Percent Elongation (%) |

|---|---|---|---|

| 8 | 641.9 | 848.4 | 9.0 |

| 16 | 585.5 | 740.8 | 14.4 |

| 25 | 567.8 | 735.5 | 14.6 |

| Beam ID | Stirrup | ρsv (%) | Vf (%) | fc (MPa) | fts (MPa) | Es (MPa) | Vu,exp (kN) | Vu,CECS (kN) | Vu,ACI (kN) | Vu,exp/Vu,CECS | Vu,exp/Vu,ACI | Vu,exp/Vu,Modified |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S0000 | - | 0 | 0 | 33.03 | 3.72 | 23,713 | 185.20 | 120.80 | 162.35 | 1.53 | 1.14 | 0.99 |

| S0005 | - | 0 | 0.5 | 34.45 | 4.46 | 24,856 | 225.07 | 142.24 | 194.65 | 1.58 | 1.16 | 1.02 |

| S0010 | - | 0 | 1.0 | 36.08 | 5.33 | 25,968 | 276.12 | 164.88 | 232.61 | 1.67 | 1.19 | 1.08 |

| S0015 | - | 0 | 1.5 | 37.13 | 5.85 | 27,211 | 310.90 | 187.24 | 255.31 | 1.66 | 1.22 | 1.07 |

| S0020 | - | 0 | 2.0 | 35.26 | 5.66 | 26,802 | 297.61 | 202.23 | 247.02 | 1.47 | 1.20 | 0.95 |

| S0300 | φ8@200 | 0.335 | 0 | 33.03 | 3.72 | 23,713 | 347.61 | 288.20 | 329.76 | 1.21 | 1.05 | 1.07 |

| S0305 | φ8@200 | 0.335 | 0.5 | 34.45 | 4.46 | 24,856 | 360.45 | 309.65 | 362.05 | 1.16 | 0.99 | 1.02 |

| S0310 | φ8@200 | 0.335 | 1.0 | 36.08 | 5.33 | 25,968 | 378.02 | 332.29 | 400.02 | 1.14 | 0.95 | 0.99 |

| S0315 | φ8@200 | 0.335 | 1.5 | 37.13 | 5.85 | 27,211 | 433.13 | 354.64 | 422.71 | 1.22 | 1.02 | 1.05 |

| S0320 | φ8@200 | 0.335 | 2.0 | 35.26 | 5.66 | 26,802 | 391.79 | 369.64 | 414.72 | 1.06 | 0.95 | 0.91 |

| S0400 | φ8@150 | 0.447 | 0 | 33.03 | 3.72 | 23,713 | 359.10 | 344.01 | 385.56 | 1.04 | 0.93 | 0.97 |

| Average | 1.34 | 1.07 | 1.01 | |||||||||

| Standard deviation | 0.23 | 0.11 | 0.05 | |||||||||

| Coefficient of variation | 0.17 | 0.10 | 0.05 | |||||||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Liang, J.; Chu, L.; Shen, F. Experimental Study on Shear Behavior of Steel Fiber Reinforced Concrete Beams with High-Strength Reinforcement. Materials 2018, 11, 1682. https://doi.org/10.3390/ma11091682

Zhao J, Liang J, Chu L, Shen F. Experimental Study on Shear Behavior of Steel Fiber Reinforced Concrete Beams with High-Strength Reinforcement. Materials. 2018; 11(9):1682. https://doi.org/10.3390/ma11091682

Chicago/Turabian StyleZhao, Jun, Jingchao Liang, Liusheng Chu, and Fuqiang Shen. 2018. "Experimental Study on Shear Behavior of Steel Fiber Reinforced Concrete Beams with High-Strength Reinforcement" Materials 11, no. 9: 1682. https://doi.org/10.3390/ma11091682

APA StyleZhao, J., Liang, J., Chu, L., & Shen, F. (2018). Experimental Study on Shear Behavior of Steel Fiber Reinforced Concrete Beams with High-Strength Reinforcement. Materials, 11(9), 1682. https://doi.org/10.3390/ma11091682