Tribological Performance of Microhole-Textured Carbide Tool Filled with CaF2

Abstract

:1. Introduction

2. Experimental Procedures

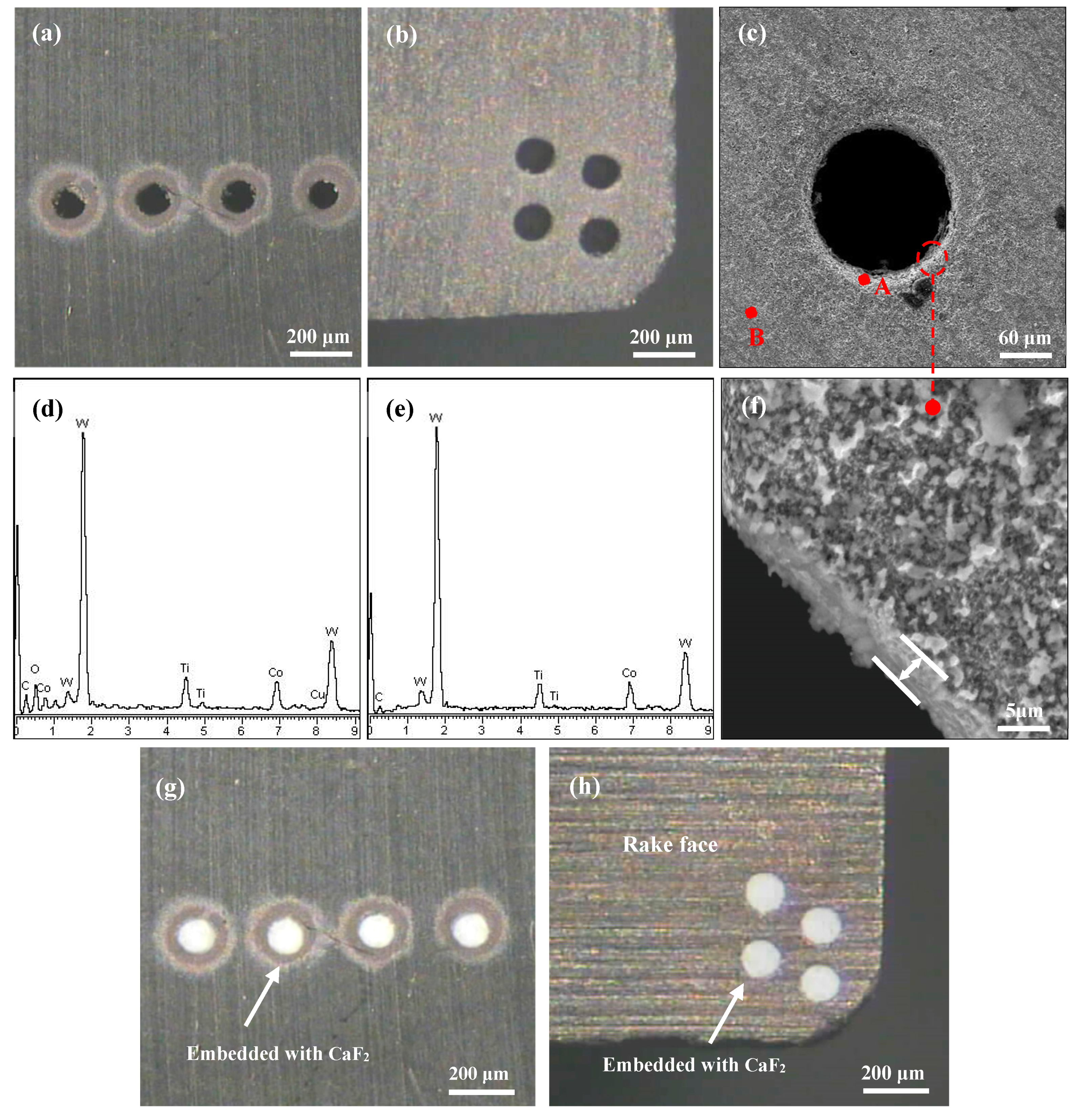

2.1. Fabrication of the Microhole-Textured Tool Filled with CaF2

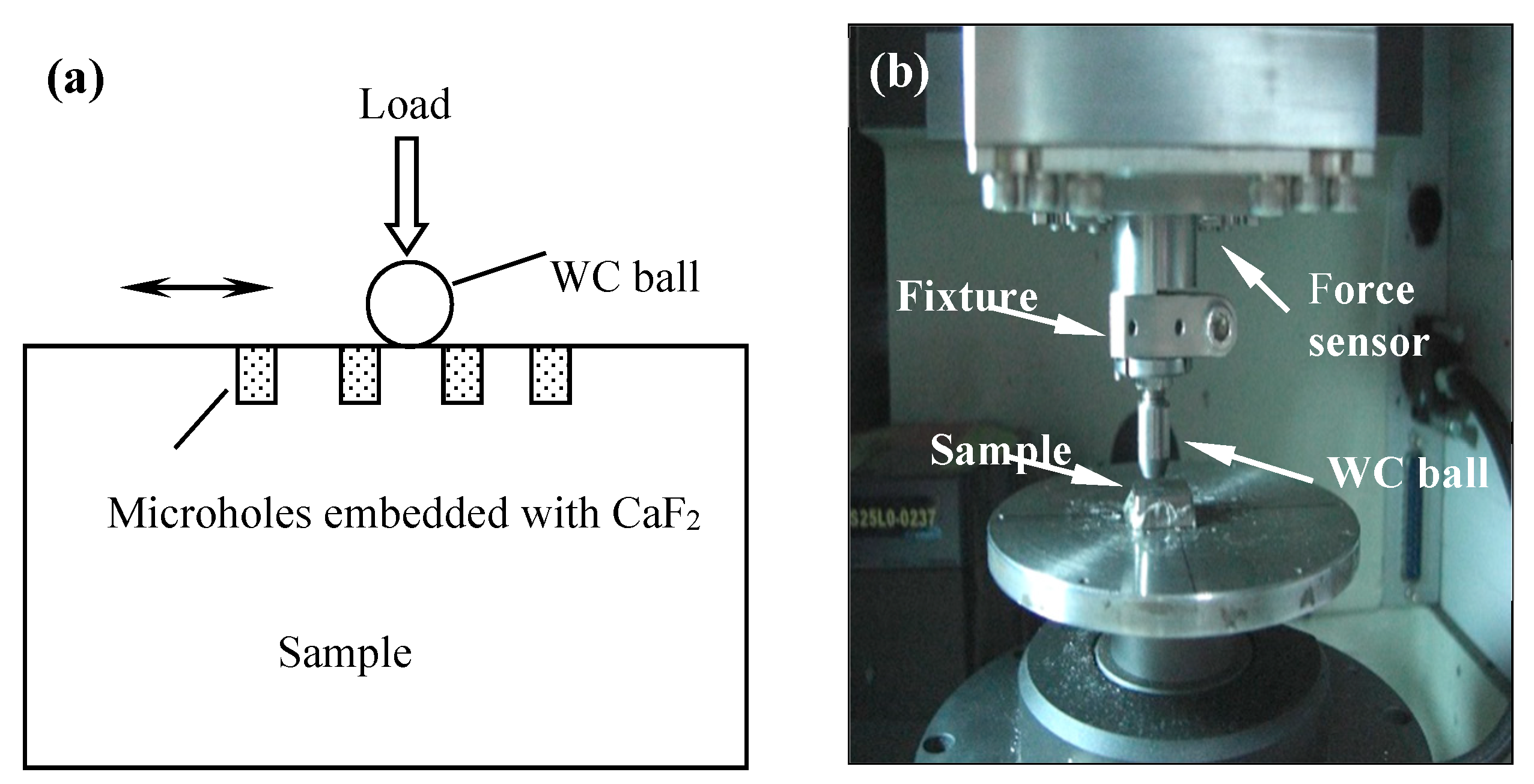

2.2. Friction Tests

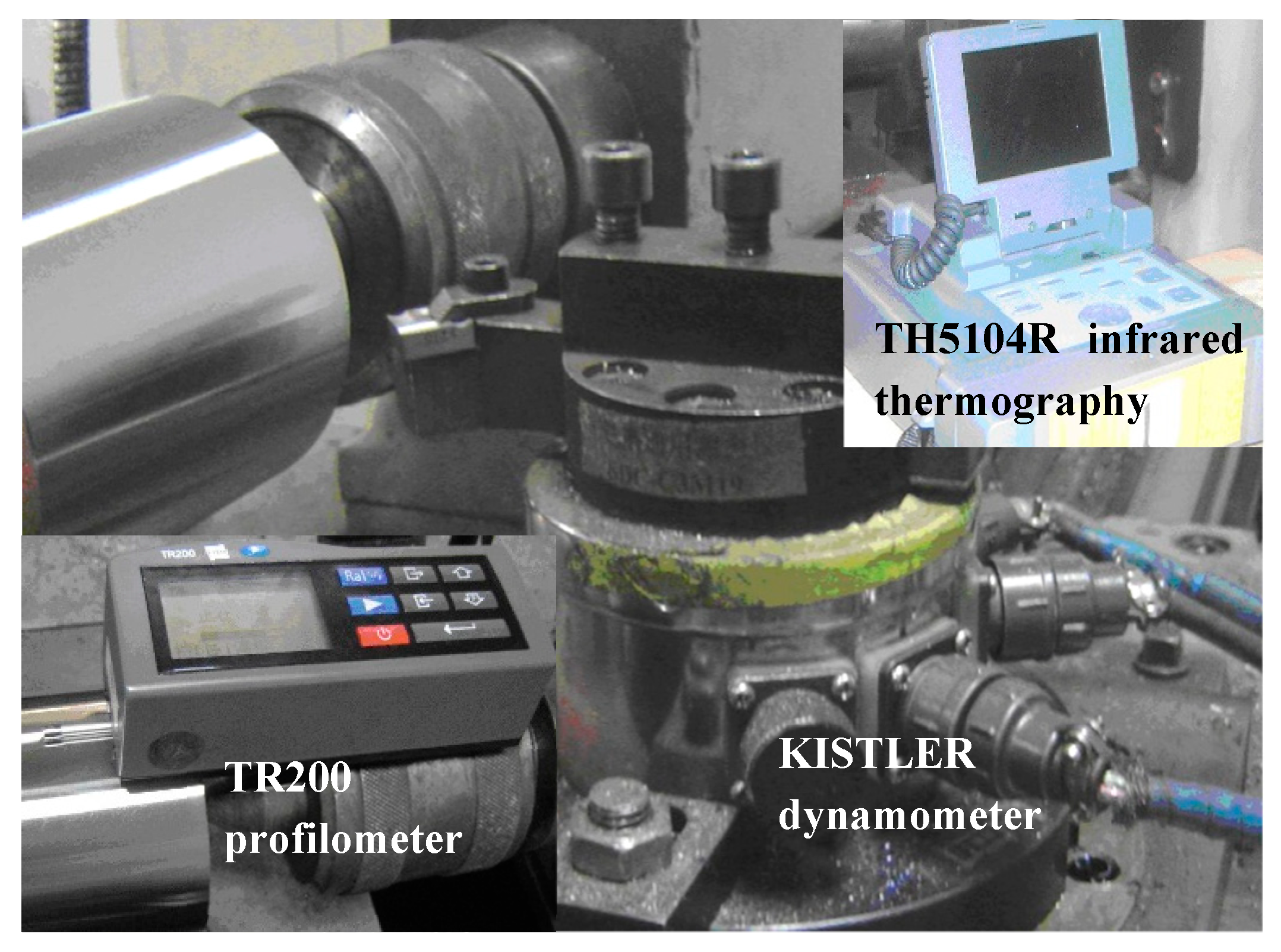

2.3. Cutting Tests

3. Results and Discussion

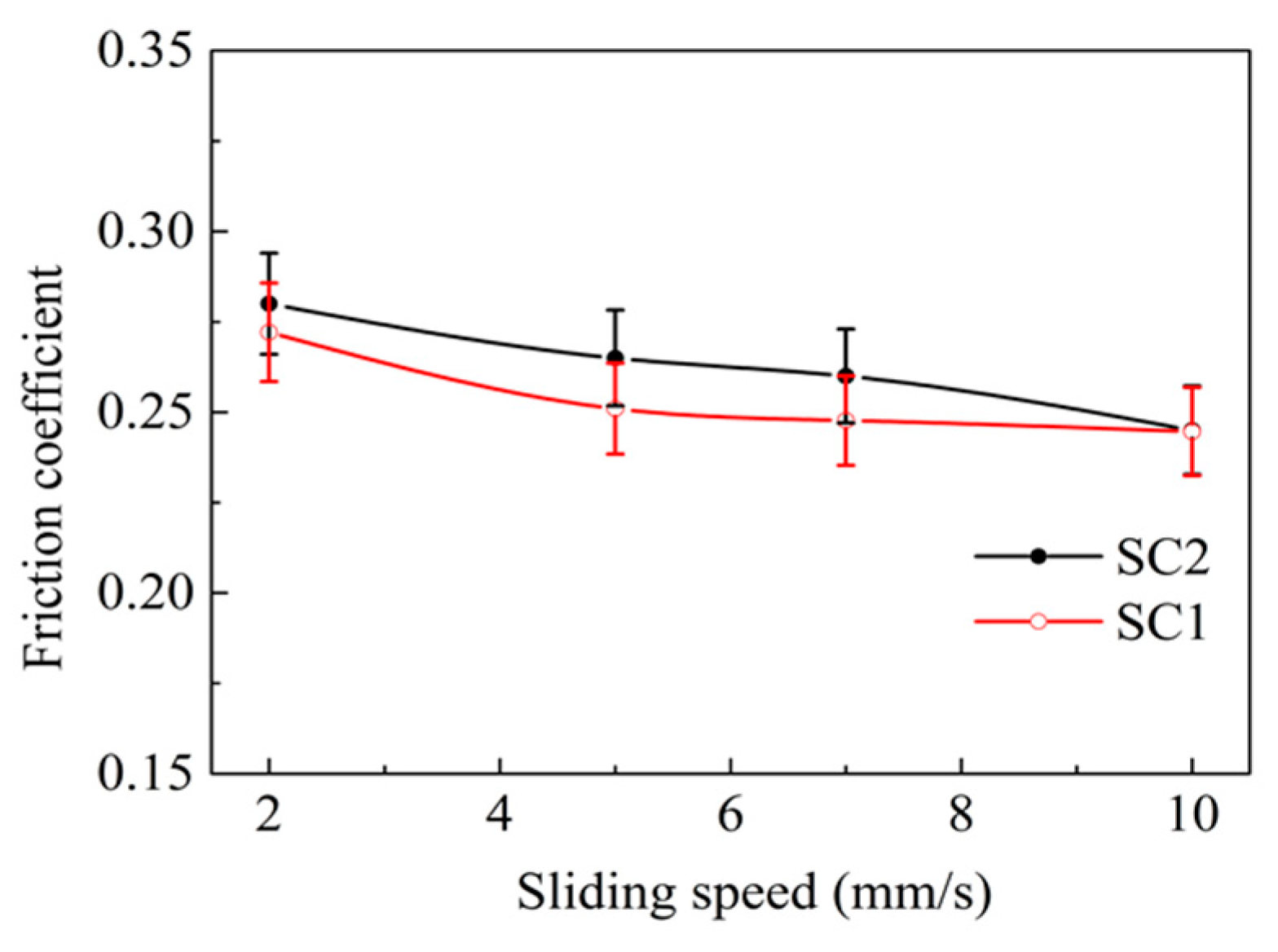

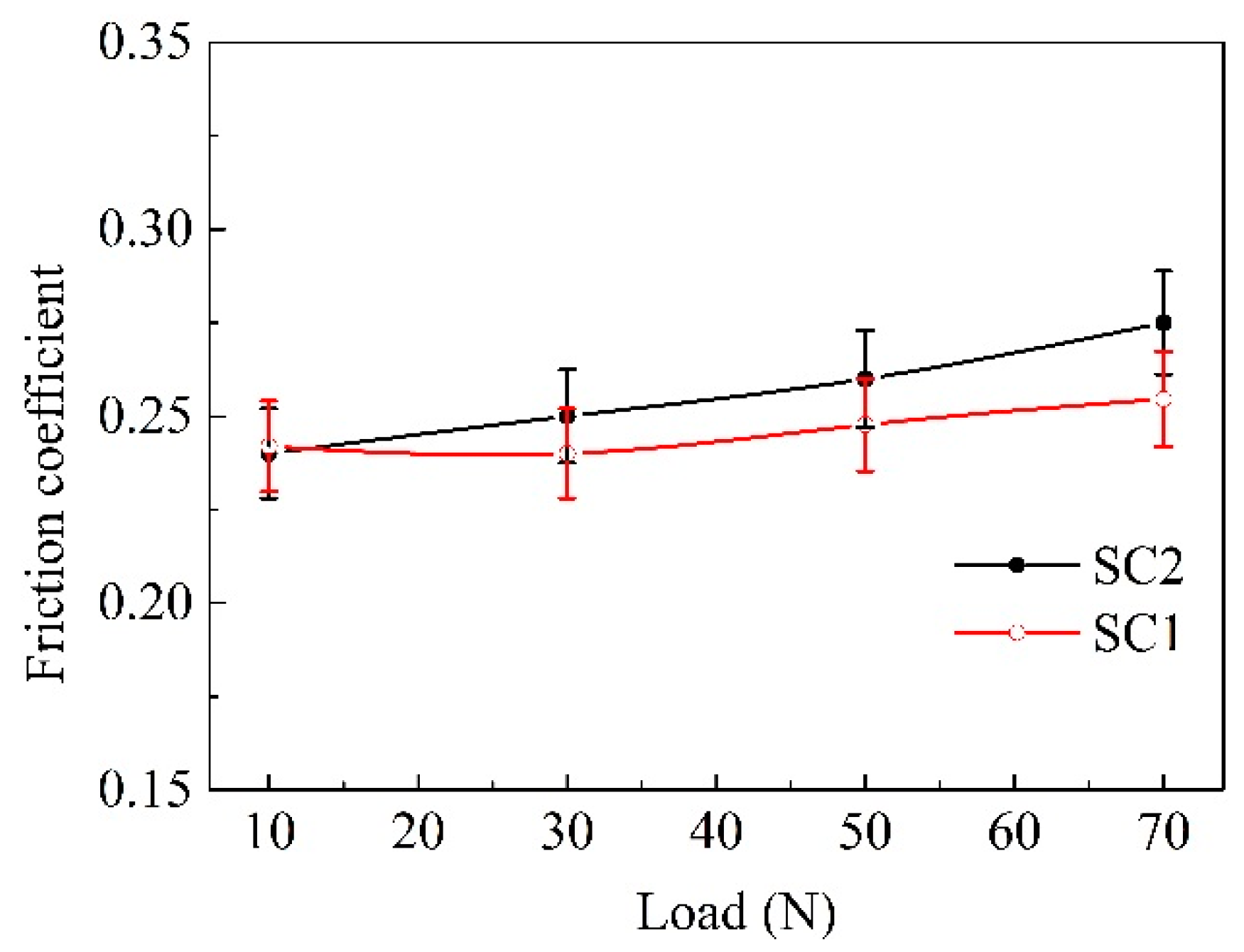

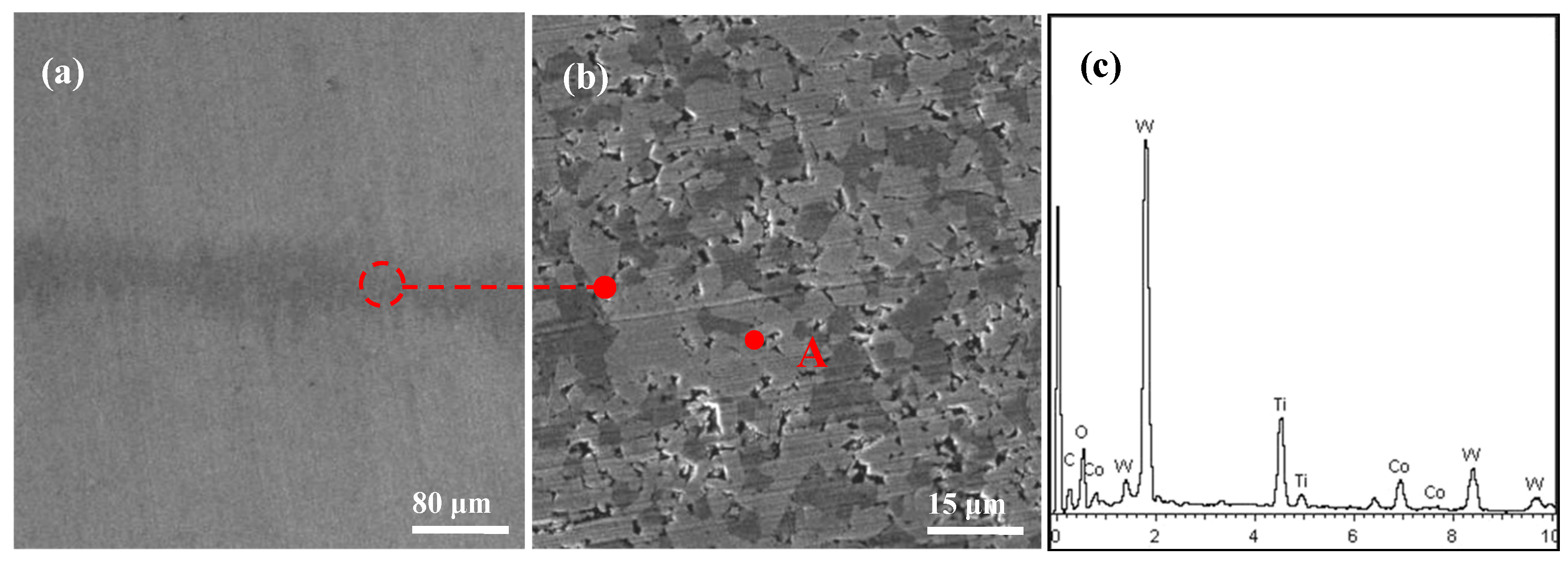

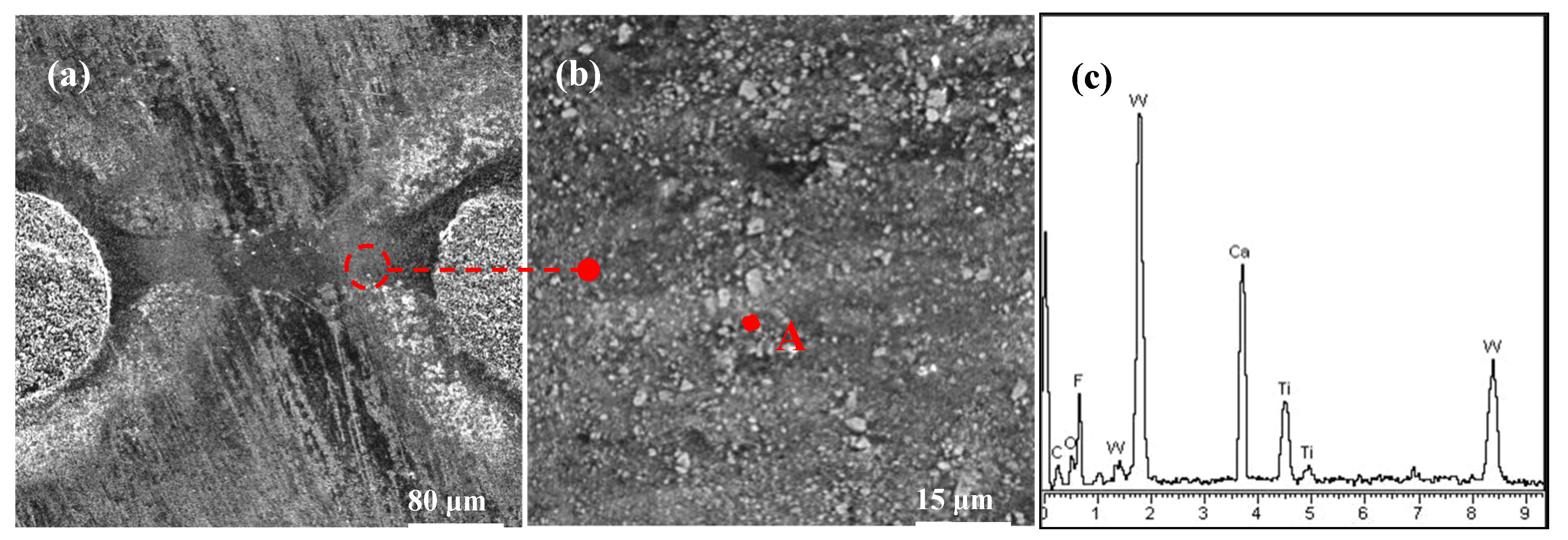

3.1. Friction Test and Surface Wear

3.2. Cutting Performance

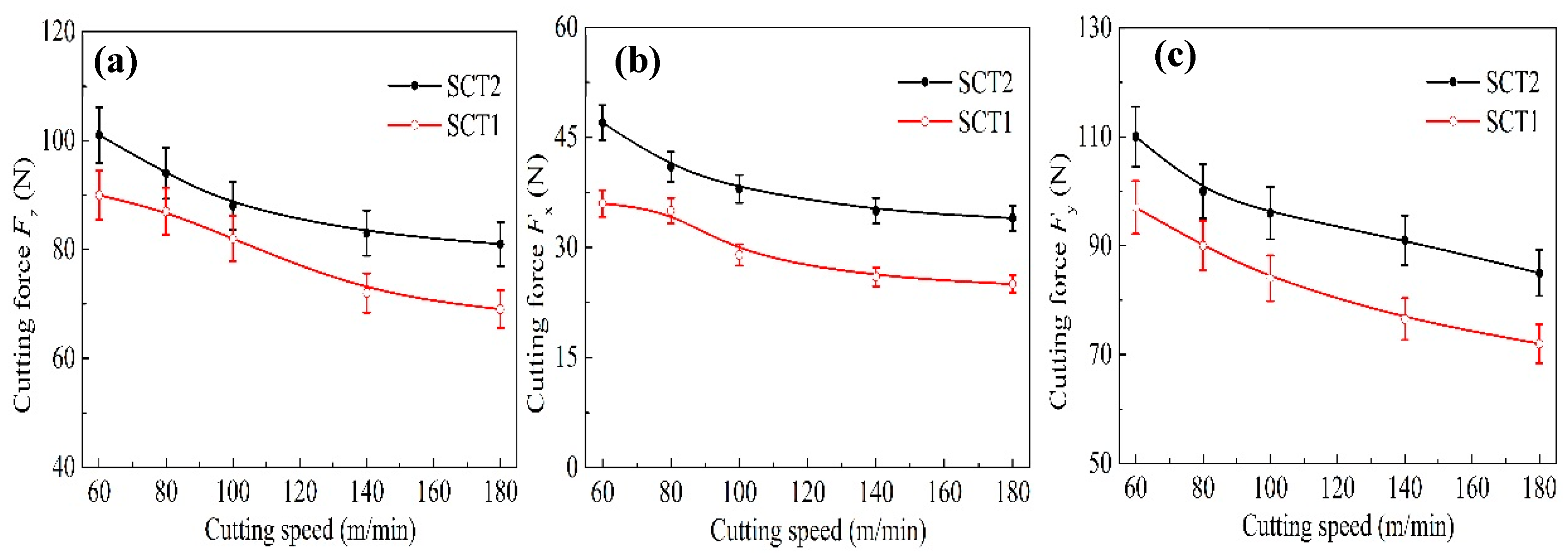

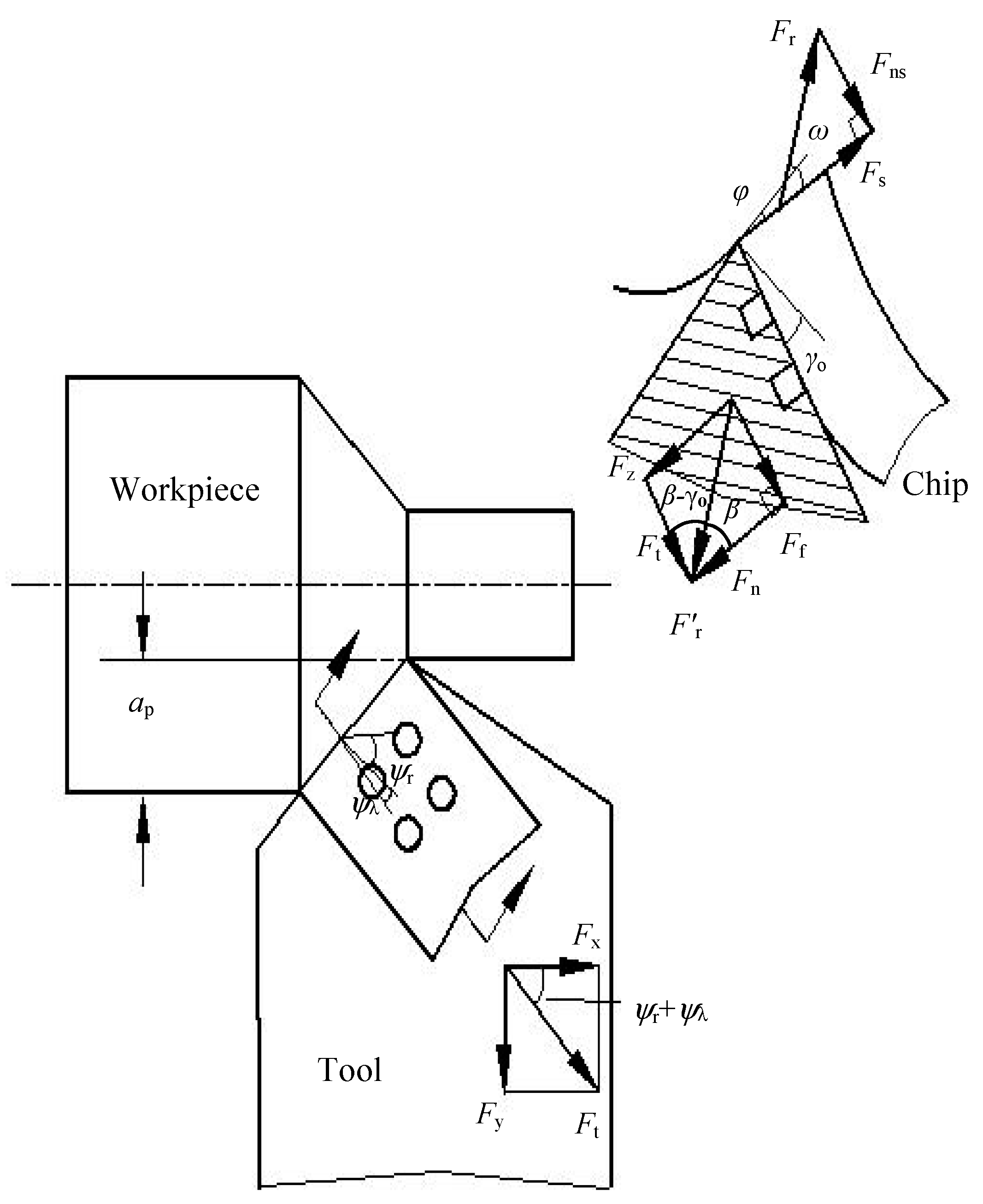

3.2.1. Cutting Forces

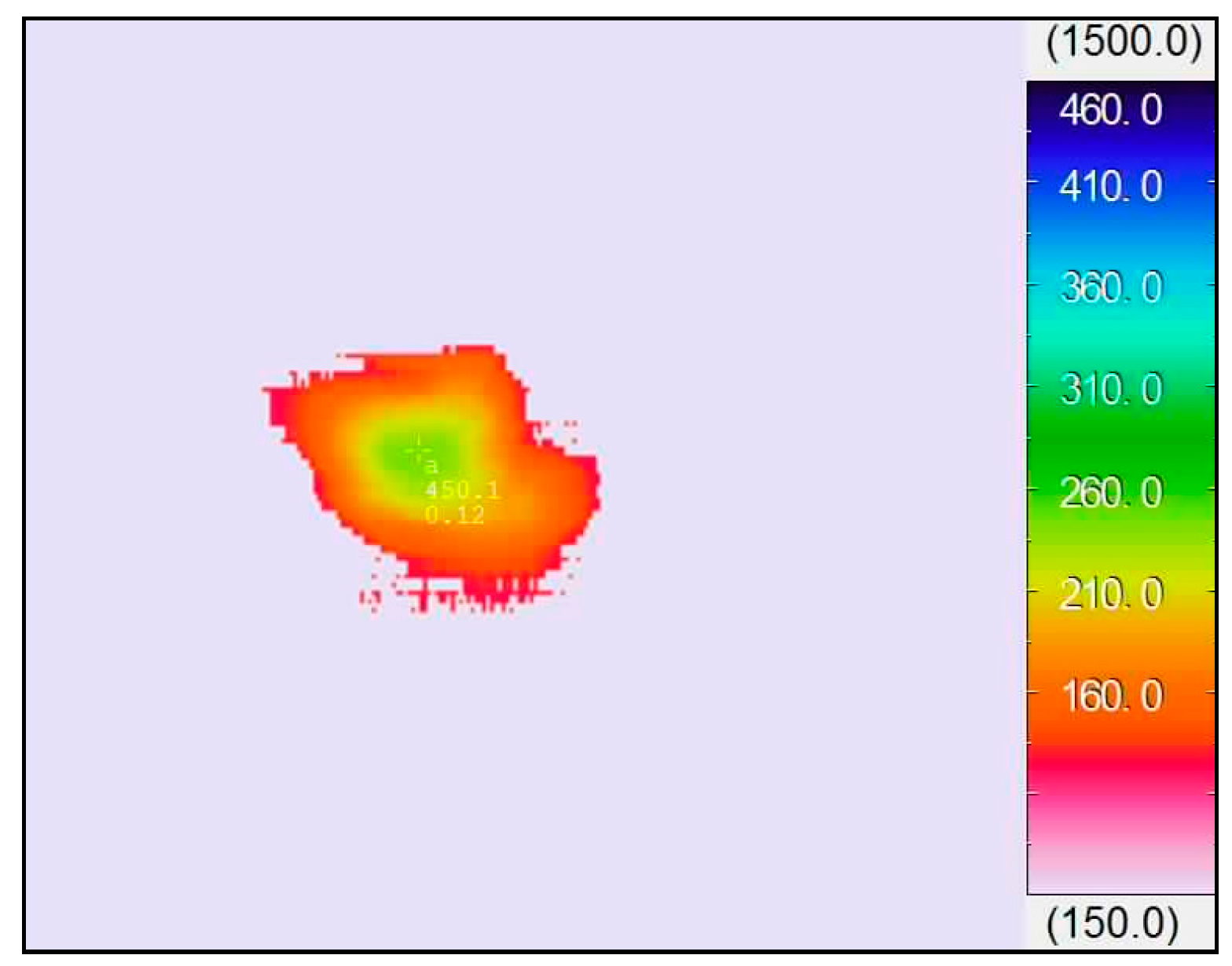

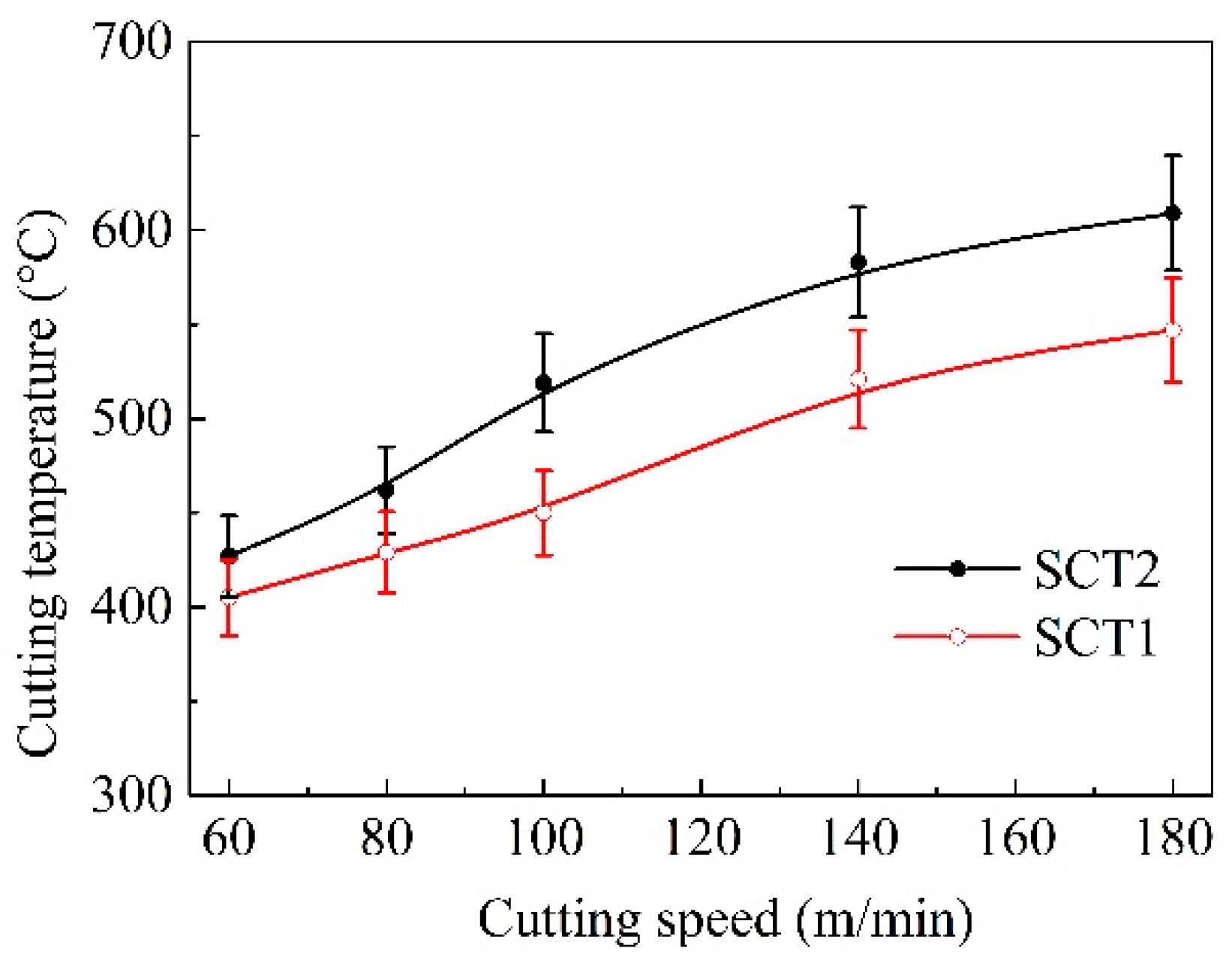

3.2.2. Cutting Temperature

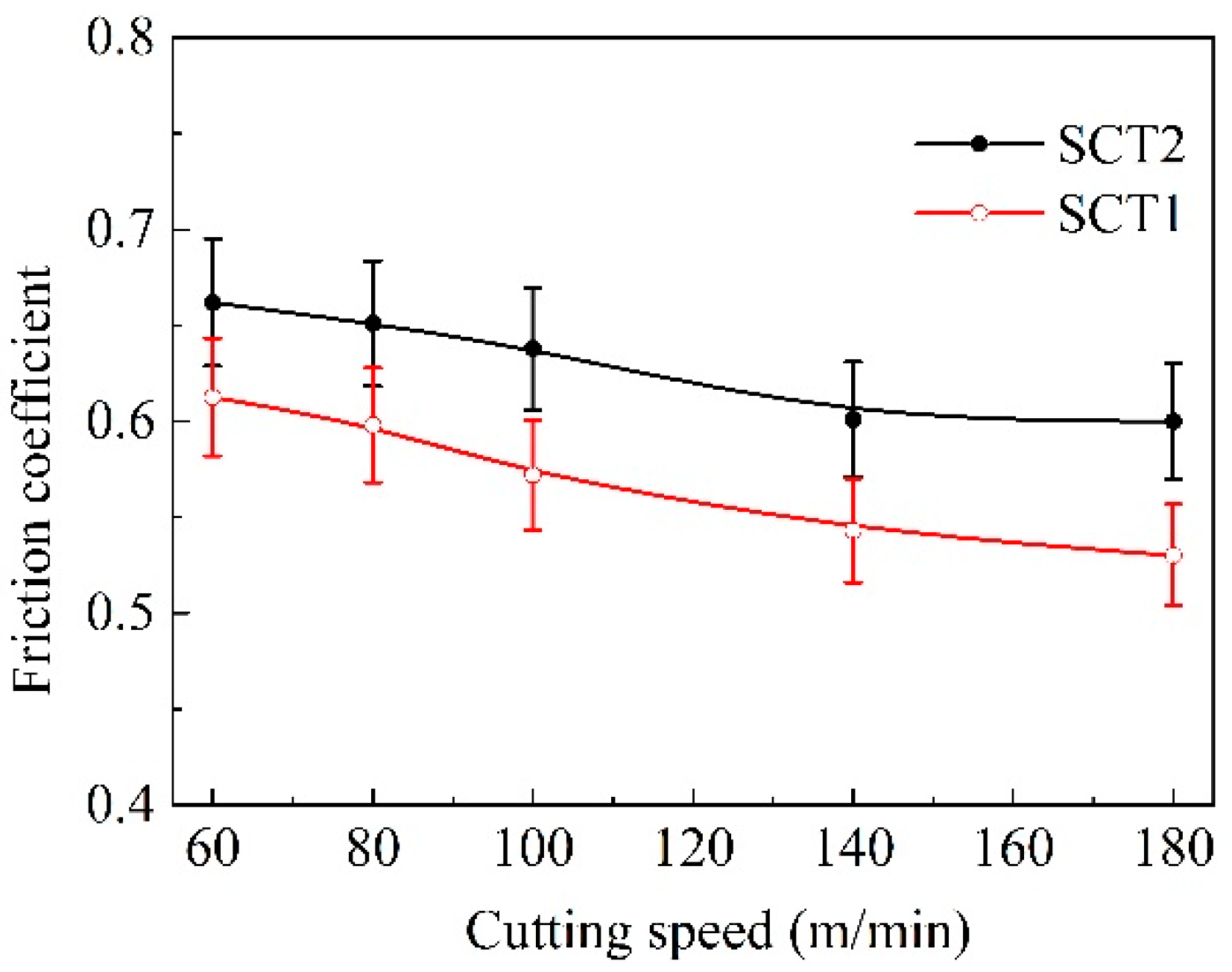

3.2.3. Average Friction Coefficient on the Rake Face

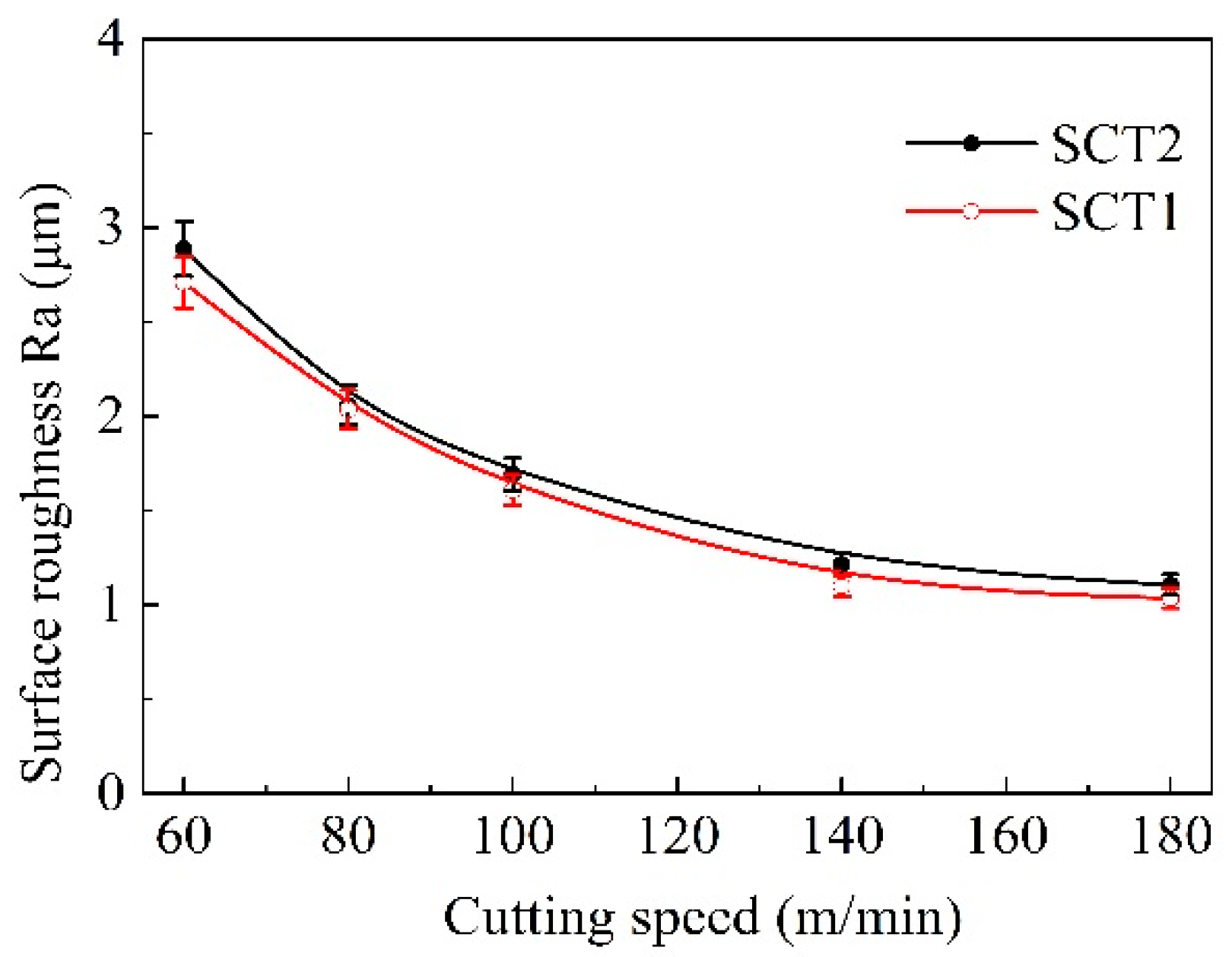

3.2.4. Surface Roughness of Machined Workpiece

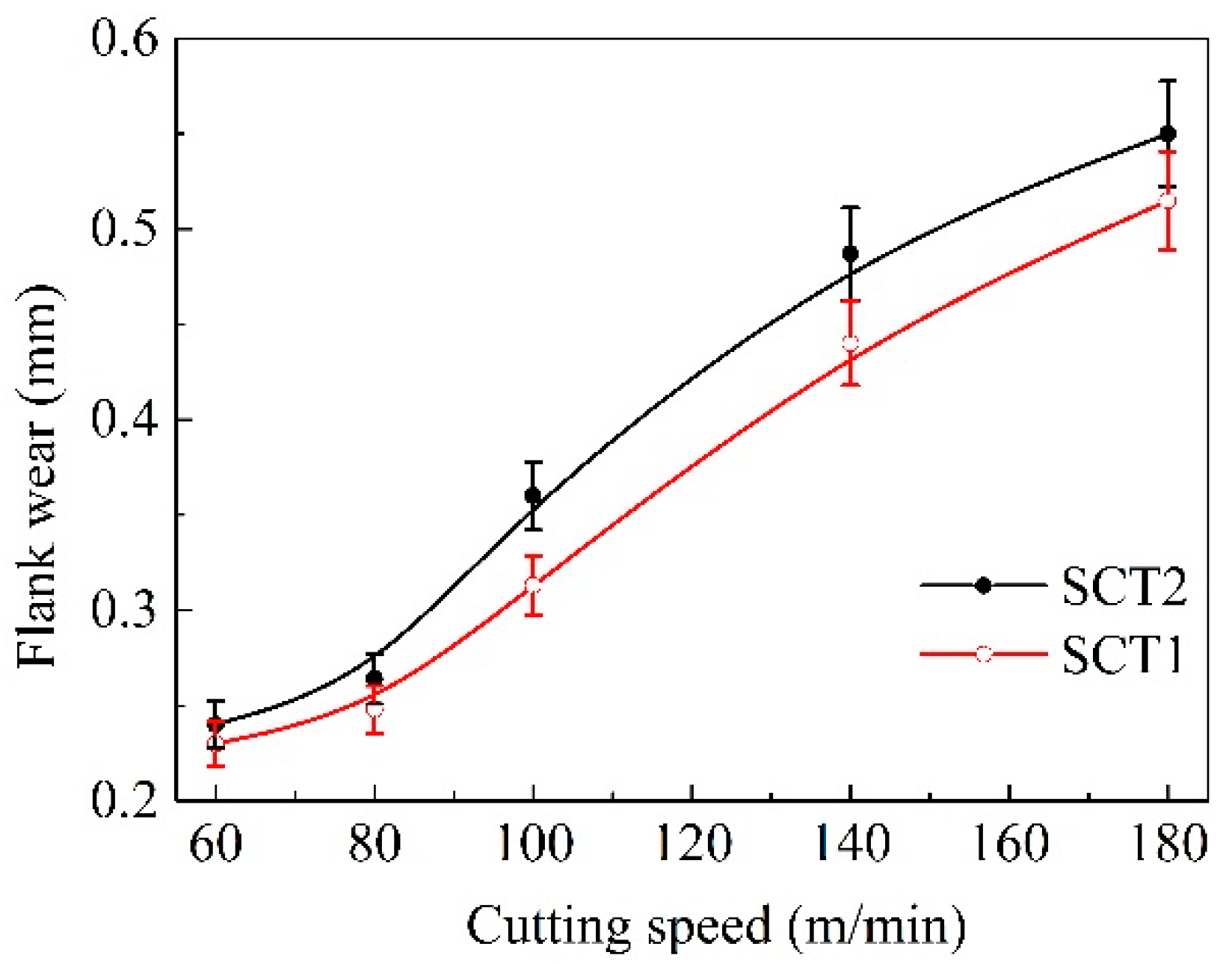

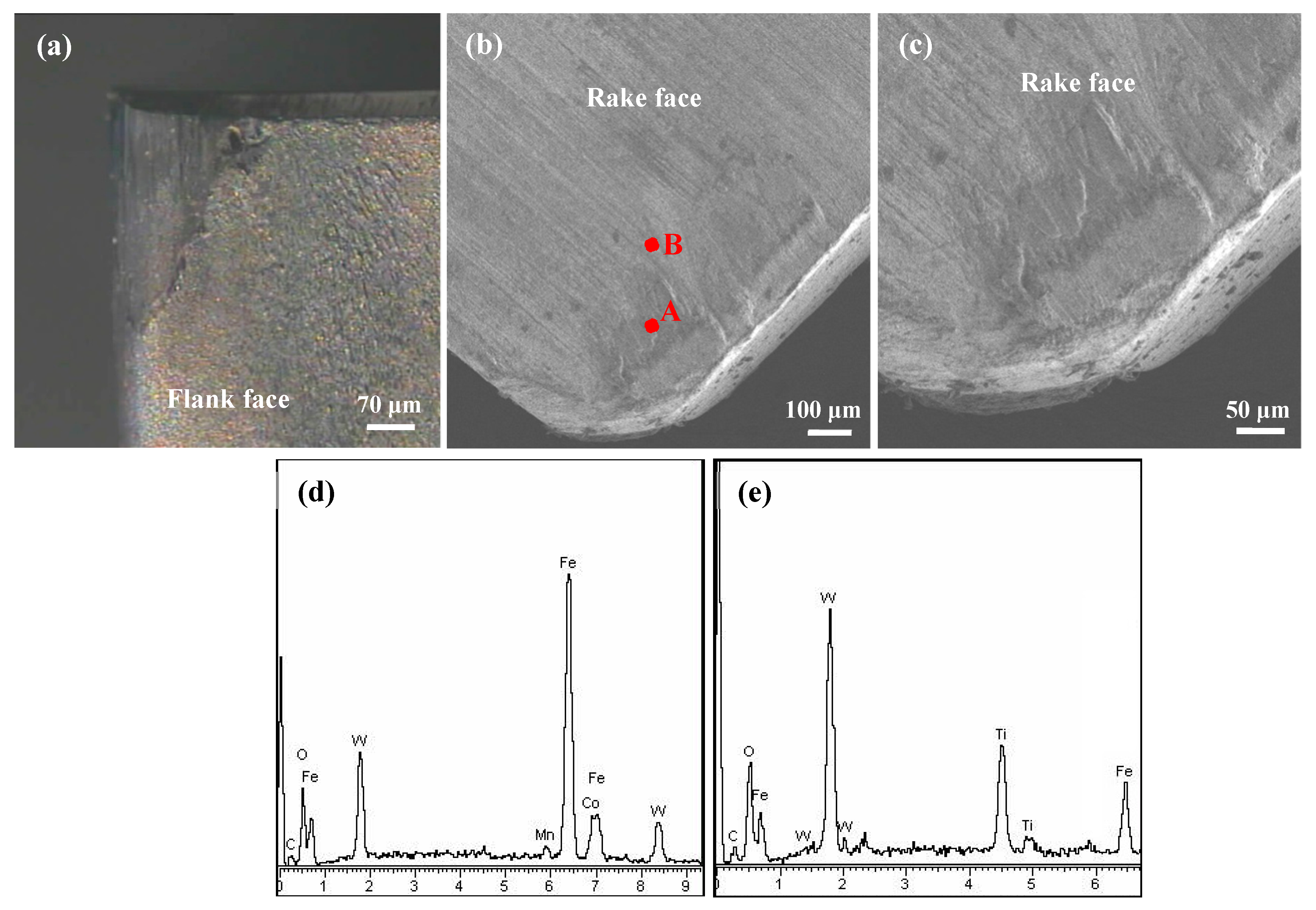

3.2.5. Wear Properties

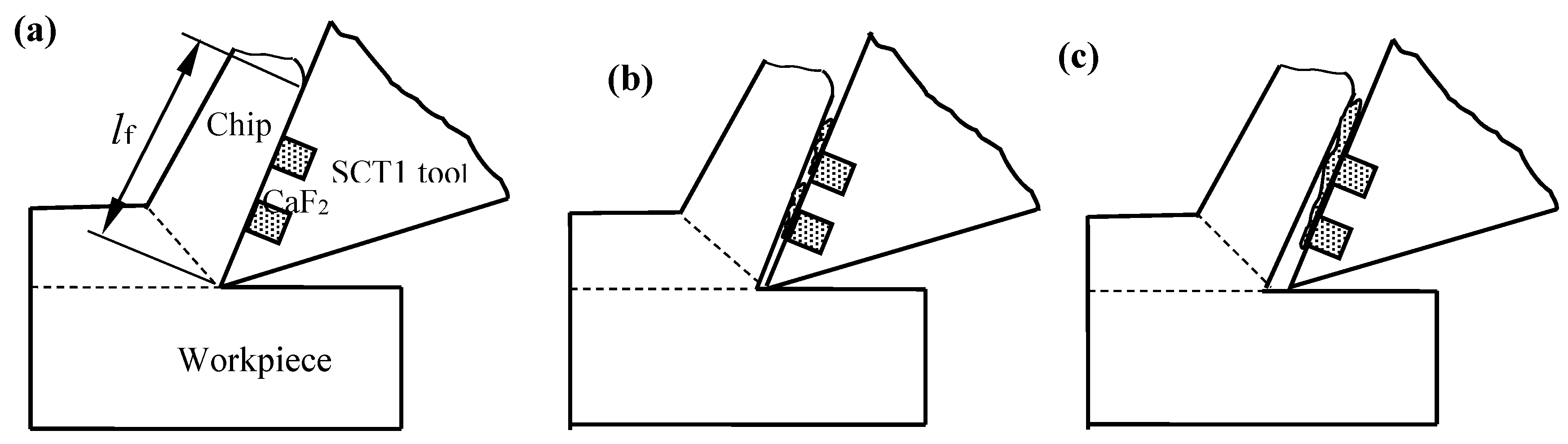

4. Discussion

4.1. Cutting Forces

4.2. Cutting Temperature

4.3. Average Friction Coefficient at The Sliding Interface

5. Conclusions

- There was no significant change in the friction coefficient of the conventional microhole-textured carbide filled with CaF2 (SC1) and an conventional one (SC2) in sliding tests with WC ball.

- Compared with the untextured carbide tool (SCT2), the microhole-textured carbide tool filled with CaF2 (SCT1) was effective in promoting machining performance. The tool rake face revealed adhesion and abrasive wear, and flank face indicated severe abrasive wear.

- Service temperature was found to affect the tribological performance of the textured carbide, which was probably due to the sensitivity of CaF2 solid lubricant to the cutting temperature. At machining speeds higher than 100 m/min, corresponding to temperature of 450 °C, the textured carbide improved the tribological performance compared to the untextured carbide; while at machining speeds lower than 100 m/min, the tribological properties of the textured carbide were only slightly improved in comparison with the smooth one, and it lost the lubrication effect at room temperature.

- The reasons of performance improvement for the textured tool were as follows: Owing to high cutting heat and friction, CaF2 powders may be drawn out of the microhole textures, adhere to the tool surface and create an uneven CaF2 layer on the rake face, which is propitious to reducing cutting forces, cutting temperature, friction coefficient and tool wear. On the other hand, the microhole textures at the tool face could lower the tool-chip contact length and entrap workpiece debris, which is beneficial to increasing machining performance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ai, X. High Speed Machining Technology; National Defense Industry Press: Beijing, China, 2004. [Google Scholar]

- Liu, X.L. Guide for Selection of CNC Cutting Tools; China Machine Press: Beijing, China, 2014. [Google Scholar]

- Özbek, N.A.; Çiçek, A.; Gülesin, M.; Özbek, O. Investigation of the effects of cryogenic treatment applied at different holding times to cemented carbide inserts on tool wear. Int. J. Mach. Tools Manuf. 2014, 86, 34–43. [Google Scholar] [CrossRef]

- Akıncıoğlu, S.; Gökkaya, H.; Uygur, İ. The effects of cryogenic-treated carbide tools on tool wear and surface roughness of turning of Hastelloy C22 based on taguchi method. Int. J. Adv. Manuf. Technol. 2016, 82, 303–314. [Google Scholar] [CrossRef]

- Serdyuk, Y.D.; Semizhon, O.A.; Prokopiv, N.M.; Petasyuk, G.A.; Kharchenko, O.V.; Omel’Chuk, T.V. The influence of thermal compression treatment parameters on quality characteristics and wear mechanisms of T5K10 carbide inserts in rough turning. J. Superhard Mater. 2011, 33, 120–128. [Google Scholar] [CrossRef]

- Haubner, R.; Lessiak, M.; Pitonak, R.; Köpf, A.; Weissenbacher, R. Evolution of conventional hard coatings for its use on cutting tools. Int. J. Refract. Met. Hard Mater. 2016, 62, 210–218. [Google Scholar] [CrossRef]

- Xiao, B.J.; Chen, Y.; Dai, W.; Kwork, K.Y.; Zhang, T.F.; Wang, Q.M.; Wang, C.; Kim, K.H. Microstructure, mechanical properties and cutting performance of AlTiN coatings prepared via arc ion plating using the arc splitting technique. Surf. Coat. Technol. 2017, 311, 98–103. [Google Scholar] [CrossRef]

- Zheng, G.; Li, L.; Li, Z.; Gao, J.; Niu, Z. Wear mechanisms of coated tools in high-speed hard turning of high strength steel. Int. J. Adv. Manuf. Technol. 2018, 94, 4553–4563. [Google Scholar] [CrossRef]

- Lorenzo-Martin, C.; Ajayi, O.; Erdemir, A.; Wei, R. Tribological performance of quaternary CrSiCN coatings under dry and lubricated conditions. Wear 2017, 376, 1682–1690. [Google Scholar] [CrossRef]

- Chowdhury, M.S.I.; Chowdhury, S.; Yamamoto, K.; Beake, B.D.; Bose, B.; Elfizy, A.; Cavelli, D.; Dosbaeva, G.; Aramesh, M.; Fox-Rabinovich, G.S.; et al. Wear behaviour of coated carbide tools during machining of Ti6Al4V aerospace alloy associated with strong built up edge formation. Surf. Coat. Technol. 2017, 313, 319–327. [Google Scholar] [CrossRef]

- Tazehkandi, A.H. Cutting forces and surface roughness in wet machining of Inconel alloy 738 with coated carbide tool. Proc. Inst. Mech. E Part B J. Eng. Manuf. 2016, 230, 215–226. [Google Scholar] [CrossRef]

- Armarego, E.J.A.; Verezub, S.; Samaranayake, P. The effect of coatings on the cutting process, friction, forces and predictive cutting models in machining operations. Proc. Inst. Mech. E Part B J. Eng. Manuf. 2017, 216, 347–356. [Google Scholar] [CrossRef]

- Yan, P.; Chen, K.; Wang, Y.; Zhou, H.; Peng, Z.; Jiao, L.; Wang, X.B. Design and performance of property gradient ternary nitride coating based on process control. Materials 2018, 11, 758. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, V.; Pandey, R.K.; Agarwal, V.K. Experimental investigations for tribo-dynamic behaviors of conventional and textured races ball bearings using fresh and MoS2 blended greases. Tribol. Int. 2016, 113, 149–168. [Google Scholar] [CrossRef]

- Hua, X.; Sun, J.; Zhang, P.; Ge, H.; Fu, Y.; Ji, J.; Yin, B. Research on discriminating partition laser surface micro-texturing technology of engine cylinder. Tribol. Int. 2016, 98, 190–196. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Wu, Z.; Liu, L.; Huang, P.; Jiao, A. Analysis of tool-chip interface characteristics of self-lubricating tools with nanotextures and WS2/Zr coatings in dry cutting. Int. J. Adv. Manuf. Technol. 2018, 97, 1637–1647. [Google Scholar] [CrossRef]

- Song, W.; Deng, J.; Zhang, H.; Yan, P.; Zhao, J.; Ai, X. Performance of a cemented carbide self-lubricating tool embedded with MoS2 solid lubricants in dry machining. J. Manuf. Process. 2011, 13, 8–15. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, C.; Wang, X. The wear behavior of textured steel sliding against polymers. Materials 2017, 10, 330. [Google Scholar] [CrossRef] [PubMed]

- Lin, N.; Qiang, L.; Zou, J.; Guo, J.; Li, D.; Yuan, S.; Ma, Y.; Wang, Z.; Wang, Z.; Tang, B. Surface texturing-plasma nitriding duplex treatment for improving tribological performance of AISI 316 stainless steel. Materials 2016, 9, 875. [Google Scholar] [CrossRef] [PubMed]

- Basnyat, P.; Luster, B.; Muratore, C.; Voevodin, A.A.; Haasch, R.; Zakeri, R.; Kohli, P.; Aouadi, S.M. Surface texturing for adaptive solid lubrication. Surf. Coat. Technol. 2008, 203, 73–79. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Griepentrog, M.; Spaltmann, D.; Krüger, J. Femtosecond laser texturing of surfaces for tribological applications. Materials 2018, 11, 801. [Google Scholar] [CrossRef] [PubMed]

- Segu, D.Z.; Si, G.C.; Choi, J.H.; Kim, S.S. The effect of multi-scale laser textured surface on lubrication regime. Appl. Surf. Sci. 2013, 270, 58–63. [Google Scholar] [CrossRef]

- Lei, S.; Devarajan, S.; Chang, Z. A study of micropool lubricated cutting tool in machining of mild steel. J. Mater. Process Technol. 2009, 209, 1612–1620. [Google Scholar] [CrossRef]

- Li, J.; Xiong, D.; Dai, J.; Huang, Z.; Tyagi, R. Effect of surface laser texture on friction properties of nickel-based composite. Tribol. Int. 2010, 43, 1193–1199. [Google Scholar] [CrossRef]

- Kawasegi, N.; Sugimori, H.; Morimoto, H.; Morita, N.; Hori, I. Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis. Eng. 2009, 33, 248–254. [Google Scholar] [CrossRef]

- Deng, J.; Wu, Z.; Lian, Y.; Qi, T.; Cheng, J. Performance of carbide tools with textured rake face filled with solid lubricants in dry cutting processes. Int. J. Refract. Met. Hard Mater. 2012, 30, 164–172. [Google Scholar] [CrossRef]

- Meng, R.; Deng, J.; Liu, Y.; Duan, R.; Zhang, G. Improving tribological performance of cemented carbides by combining laser surface texturing and W-S-C solid lubricant coating. Int. J. Refract. Met. Hard Mater. 2018, 72, 163–171. [Google Scholar] [CrossRef]

- Lian, Y.; Mu, C.; Wang, L.; Yao, B.; Deng, J.; Lei, S. Numerical simulation and experimental investigation on friction and wear behaviour of micro-textured cemented carbide in dry sliding against TC4 titanium alloy balls. Int. J. Refract. Met. Hard Mater. 2018, 73, 121–131. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Meng, R.; Lei, S.; Yu, X. Influence of laser substrate pretreatment on anti- adhesive wear properties of WC/Co-based TiAlN coatings against AISI 316 stainless steel. Int. J. Refract. Met. Hard Mater. 2016, 57, 101–114. [Google Scholar] [CrossRef]

- Song, W.; Wang, Z.; Deng, J.; Zhou, K.; Wang, S.; Guo, Z. Cutting temperature analysis and experiment of Ti-MoS2/Zr-coated cemented carbide tool. Int. J. Adv. Manuf. Technol. 2017, 93, 799–809. [Google Scholar] [CrossRef]

- Renevier, N.M.; Oosterling, H.; König, U.; Dautzenberg, H.; Kim, B.J.; Geppert, L. Performance and limitations of MoS2/Ti composite coated inserts. Surf. Coat. Technol. 2003, 172, 13–23. [Google Scholar] [CrossRef]

- Kao, W.H. Tribological properties and high speed drilling application of MoS2-Cr coatings. Wear 2005, 258, 812–825. [Google Scholar] [CrossRef]

- Renevier, N.M.; Hamphire, J.; Fox, V.C. Advantages of using self-lubricating, hard, wear-resistant MoS2-based coatings. Surf. Coat. Technol. 2001, 142, 67–77. [Google Scholar] [CrossRef]

- Shi, M.S. Solid Lubricating Materials; China Chemical Industry Press: Beijing, China, 2000. [Google Scholar]

- Deng, J.; Cao, T.; Yang, X. Self-lubrication of sintered ceramic tools with CaF2 additions in dry cutting. Int. J. Mach. Tools Manuf. 2006, 46, 957–963. [Google Scholar] [CrossRef]

- Deng, J.; Cao, T.; Ding, Z. Tribological behaviors of hot-pressed Al2O3/TiC ceramic composites with the additions of CaF2 solid lubricants. J. Eur. Ceram. Soc. 2006, 26, 1317–1323. [Google Scholar] [CrossRef]

- Song, W.; Deng, J.; Wu, Z.; Zhang, H.; Yan, P.; Zhao, J.; Xing, A. Cutting performance of cemented-carbides-based self-lubricated tool embedded with different solid lubricants. Int. J. Adv. Manuf. Technol. 2011, 52, 477–485. [Google Scholar] [CrossRef]

- Chen, R.Y. Metal-Cutting Principles; China Machine Press: Beijing, China, 2005. [Google Scholar]

- Wen, S.Z. Principles of Tribology; Tinghua University Press: Beijing, China, 2012. [Google Scholar]

- Usui, E. Mechanical Metal Processing; China Machine Press: Beijing, China, 1982. [Google Scholar]

- Nakayama, K. Theory of Metal Cutting; China Machine Press: Beijing, China, 1985. [Google Scholar]

| Composition (wt. %) | Density (g/cm3) | Hardness (GPa) | Flexural Strength (MPa) | Young’s Modulus (GPa) | Thermal Expansion Coefficient (10−6/K) | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| WC + 15%TiC + 6%Co | 11.5 | 15.5 | 1130.0 | 510 | 6.51 | 0.25 |

| Element Content | Before EDM (wt. %) | After EDM (wt. %) |

|---|---|---|

| C | 11.41 | 20.97 |

| O | 0 | 10.6 |

| Ti | 5.57 | 5.31 |

| Co | 8.18 | 5.84 |

| Cu | 0 | 0.37 |

| W | 74.84 | 56.91 |

| Total | 100% | 100% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, W.; Wang, S.; Lu, Y.; Xia, Z. Tribological Performance of Microhole-Textured Carbide Tool Filled with CaF2. Materials 2018, 11, 1643. https://doi.org/10.3390/ma11091643

Song W, Wang S, Lu Y, Xia Z. Tribological Performance of Microhole-Textured Carbide Tool Filled with CaF2. Materials. 2018; 11(9):1643. https://doi.org/10.3390/ma11091643

Chicago/Turabian StyleSong, Wenlong, Shoujun Wang, Yang Lu, and Zixiang Xia. 2018. "Tribological Performance of Microhole-Textured Carbide Tool Filled with CaF2" Materials 11, no. 9: 1643. https://doi.org/10.3390/ma11091643

APA StyleSong, W., Wang, S., Lu, Y., & Xia, Z. (2018). Tribological Performance of Microhole-Textured Carbide Tool Filled with CaF2. Materials, 11(9), 1643. https://doi.org/10.3390/ma11091643