Effects of Loading Frequency and Specimen Geometry on High Cycle and Very High Cycle Fatigue Life of a High Strength Titanium Alloy

Abstract

1. Introduction

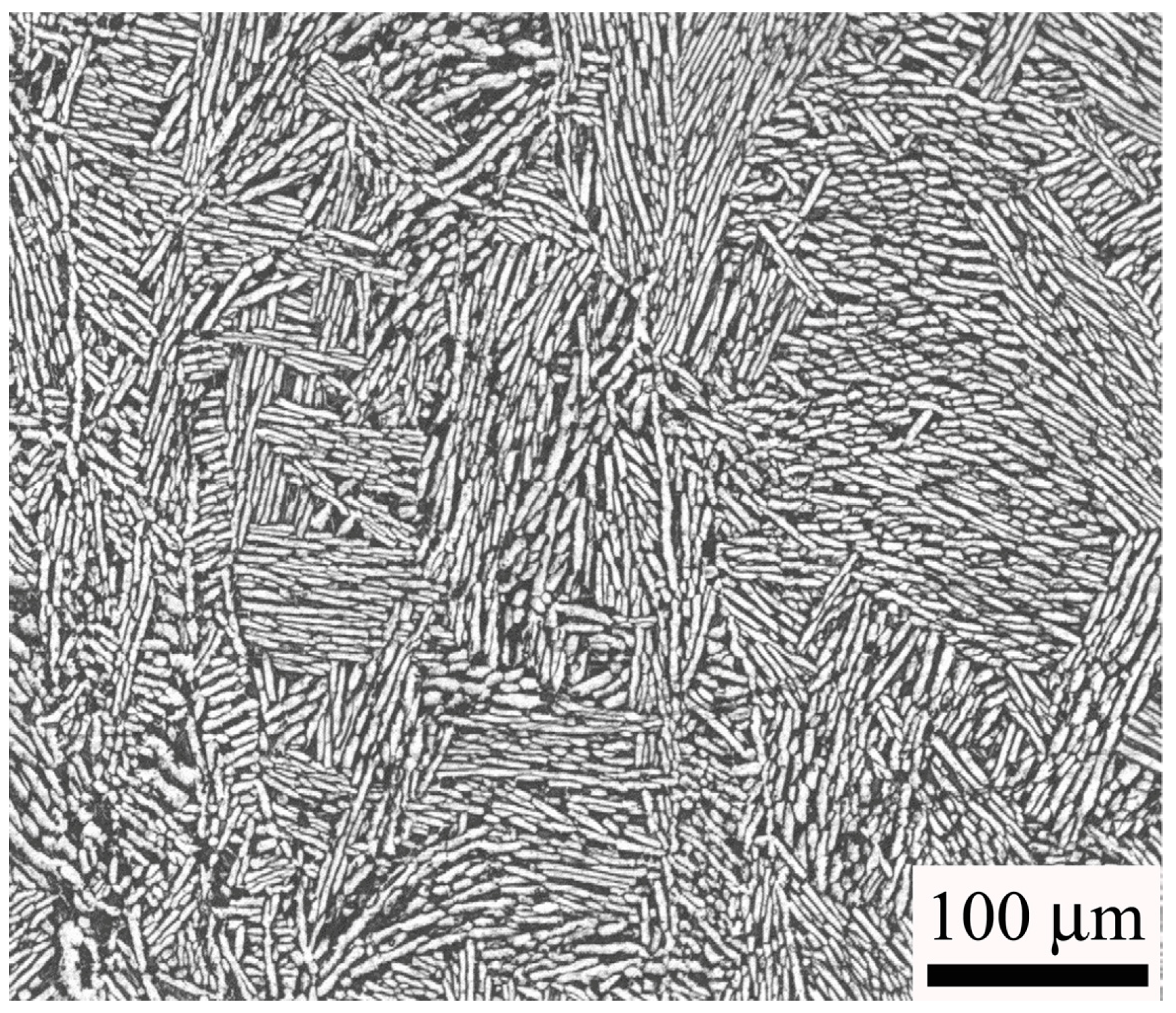

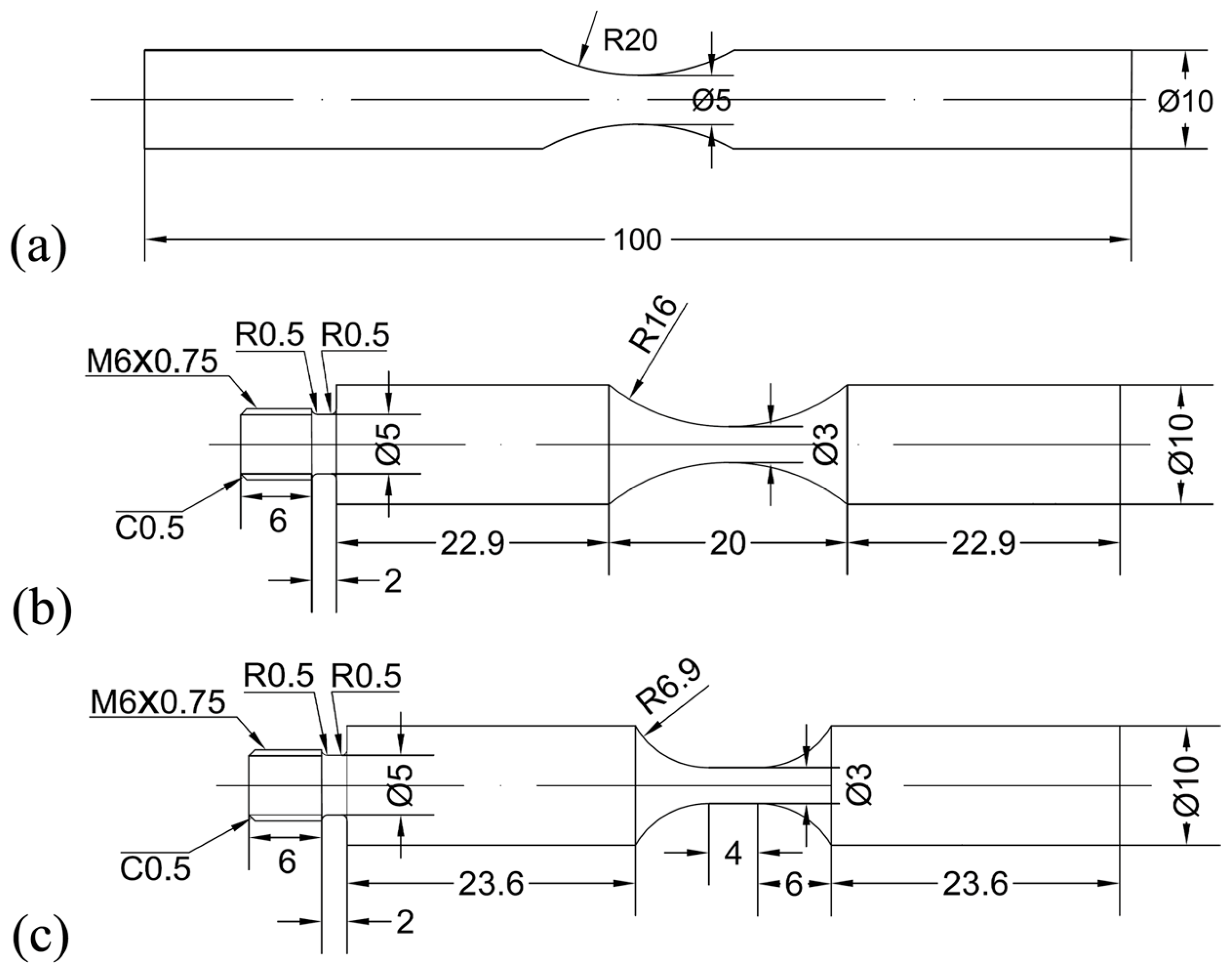

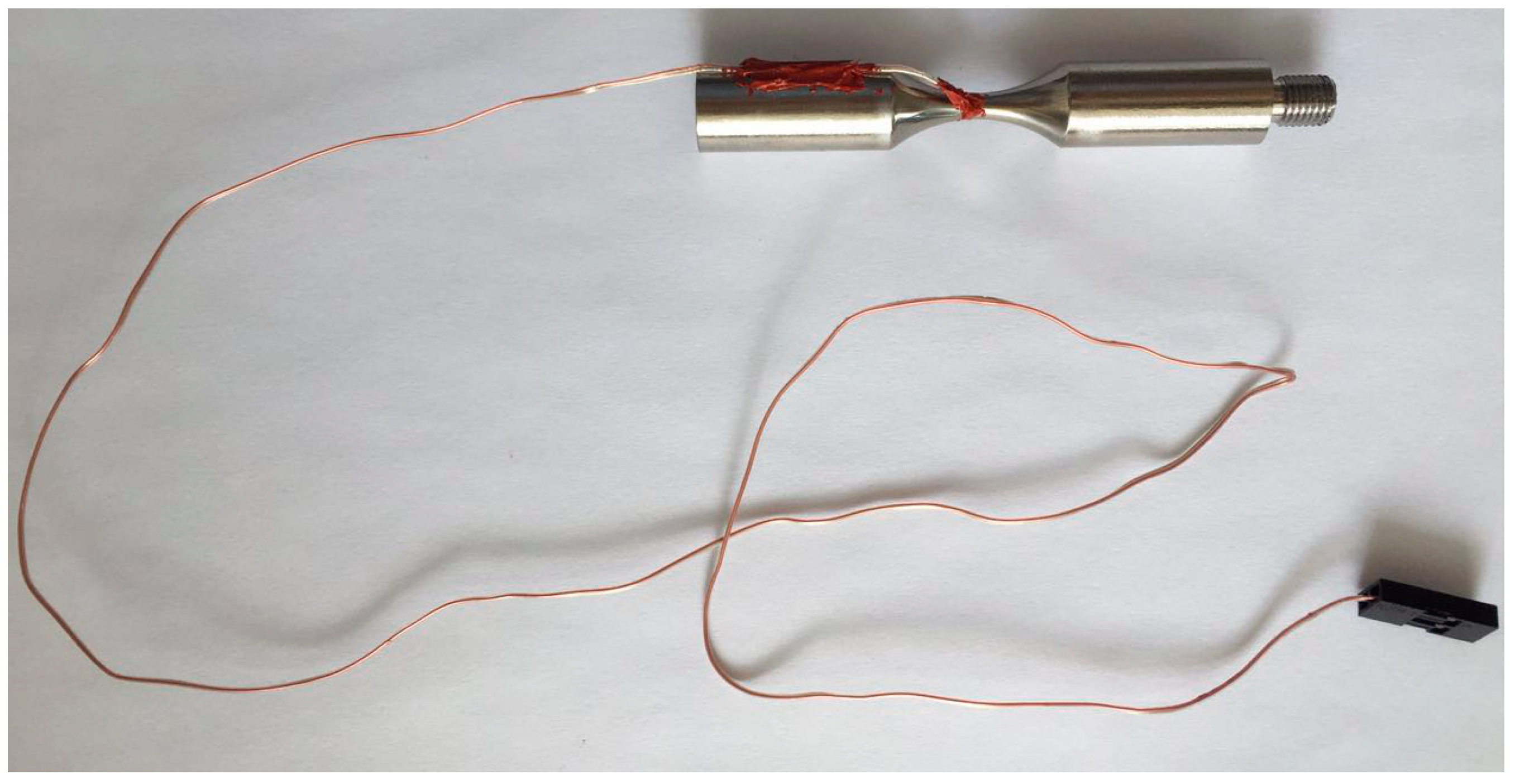

2. Materials and Methods

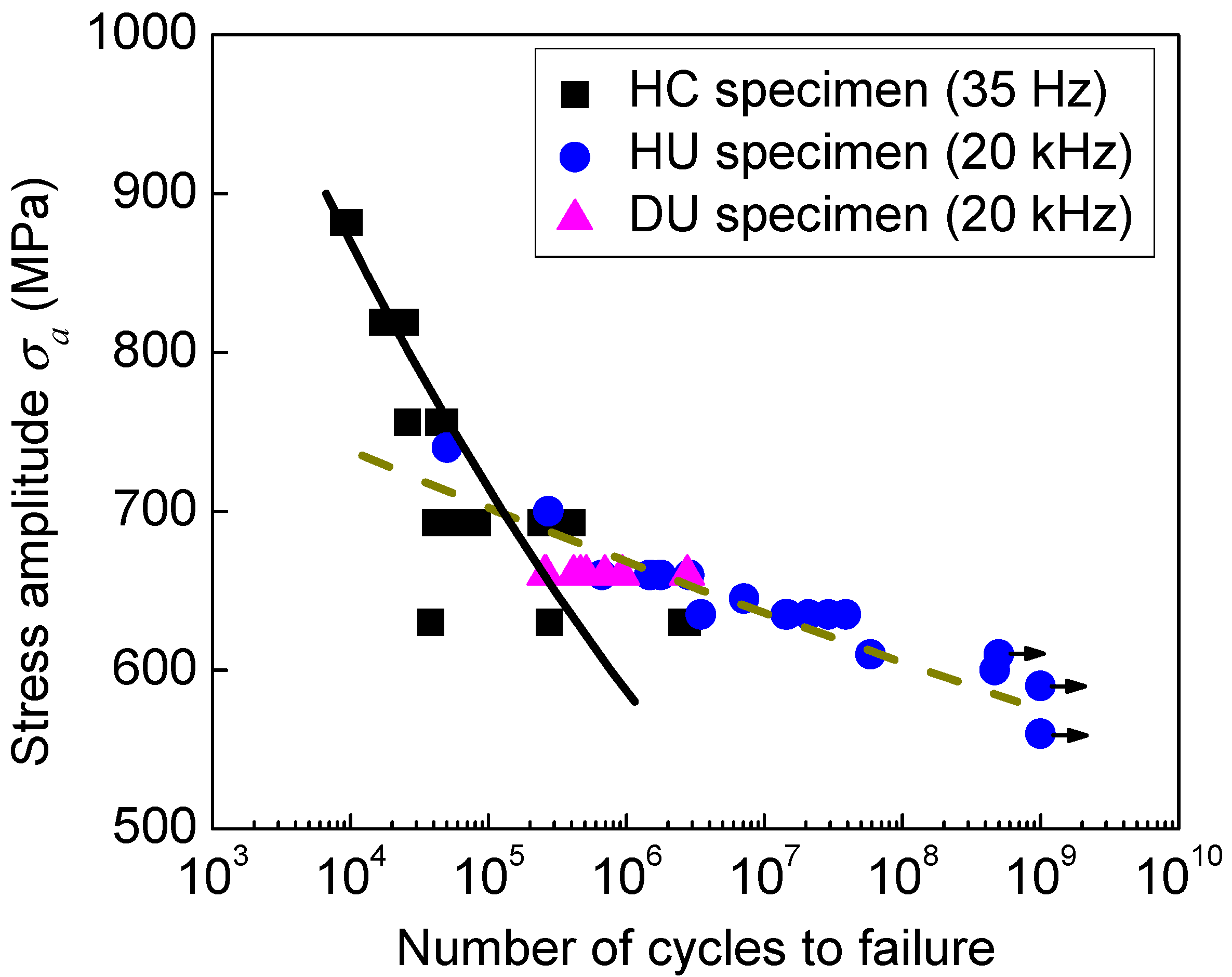

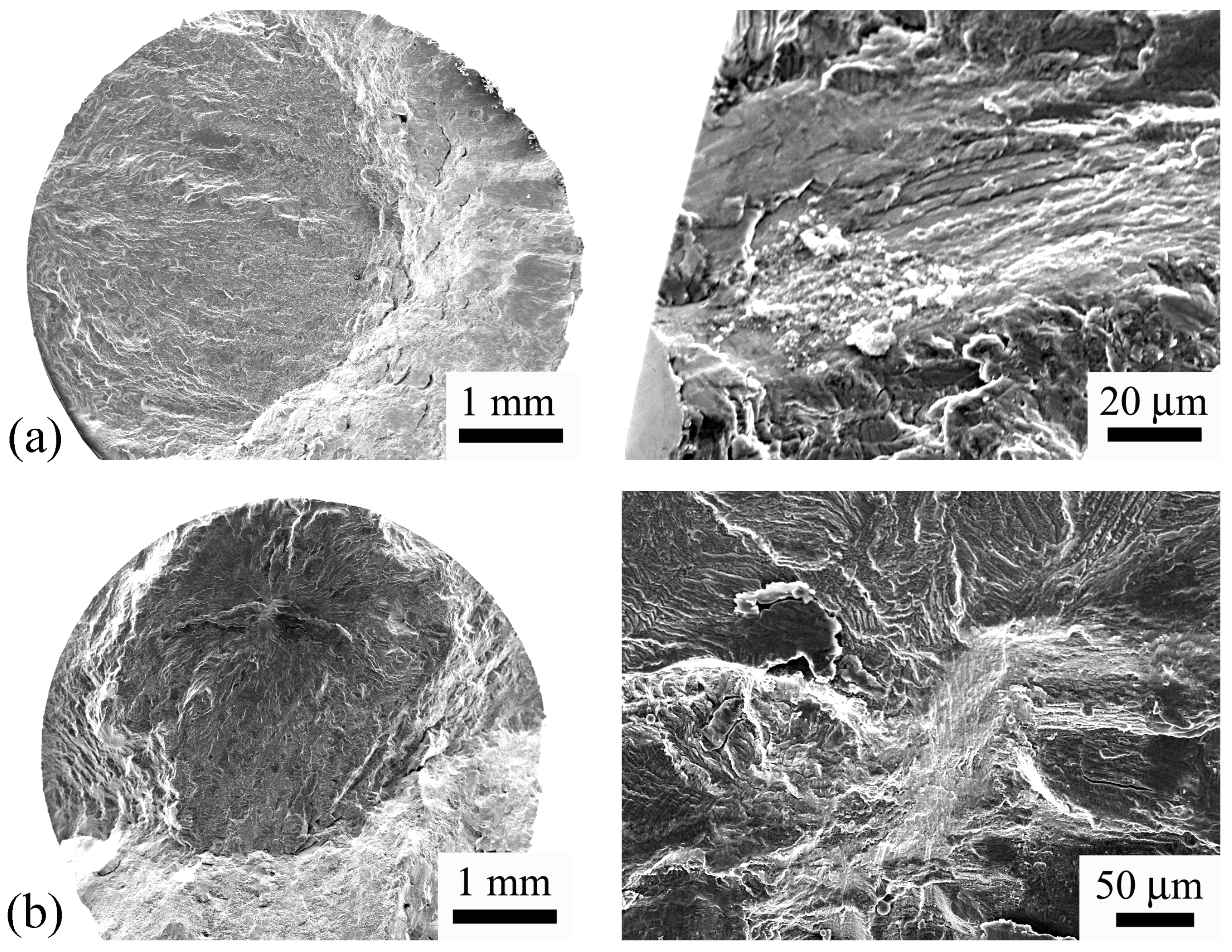

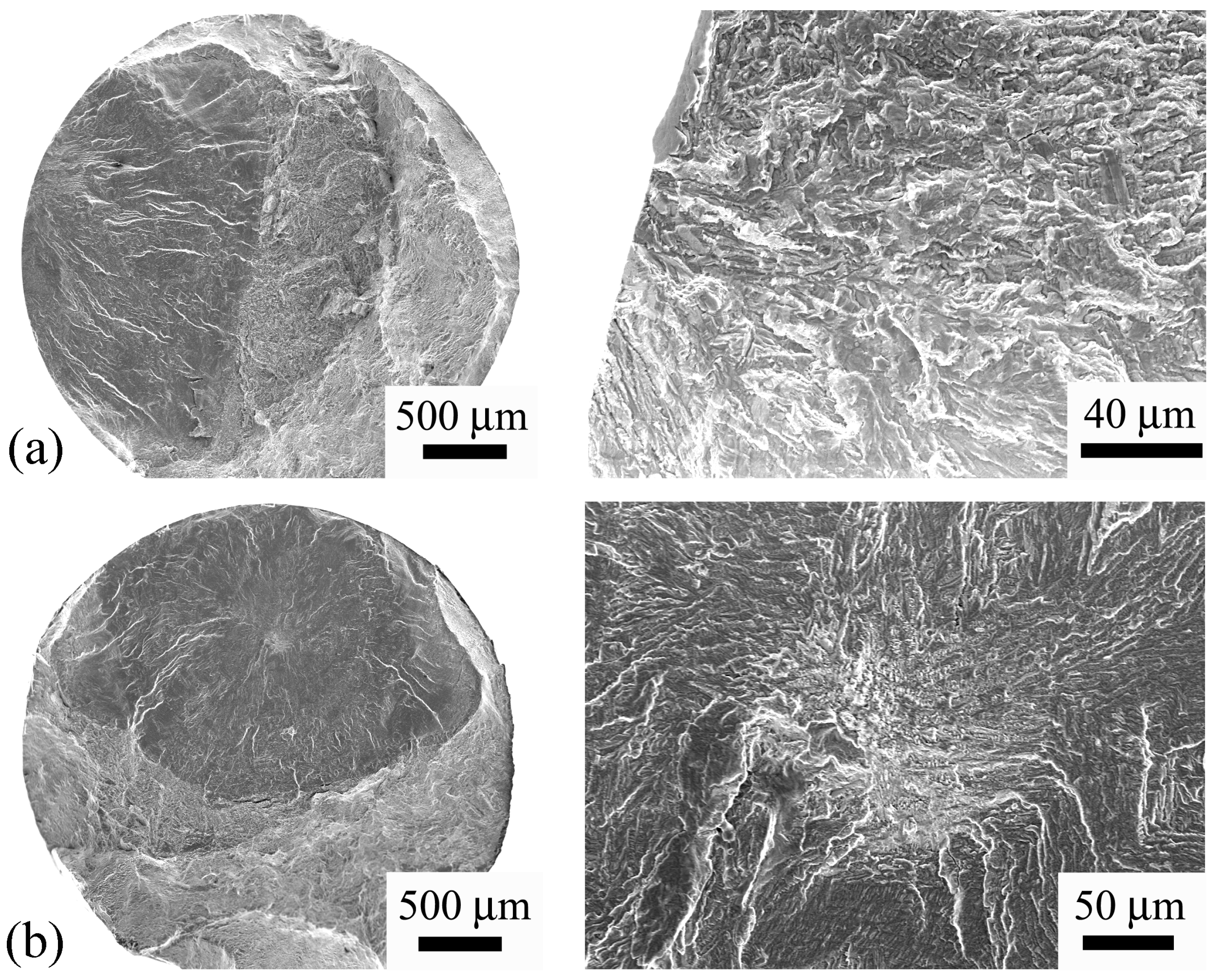

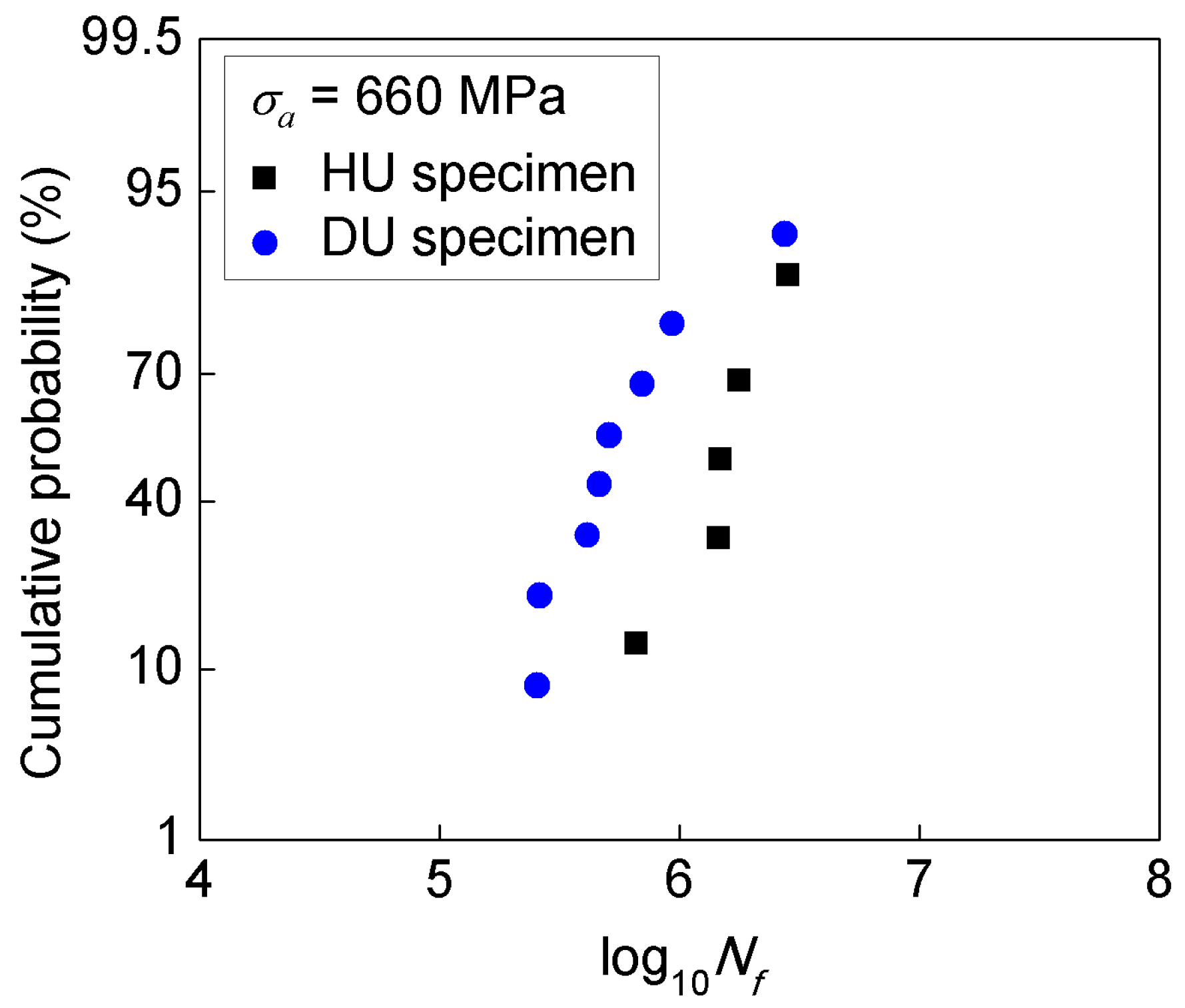

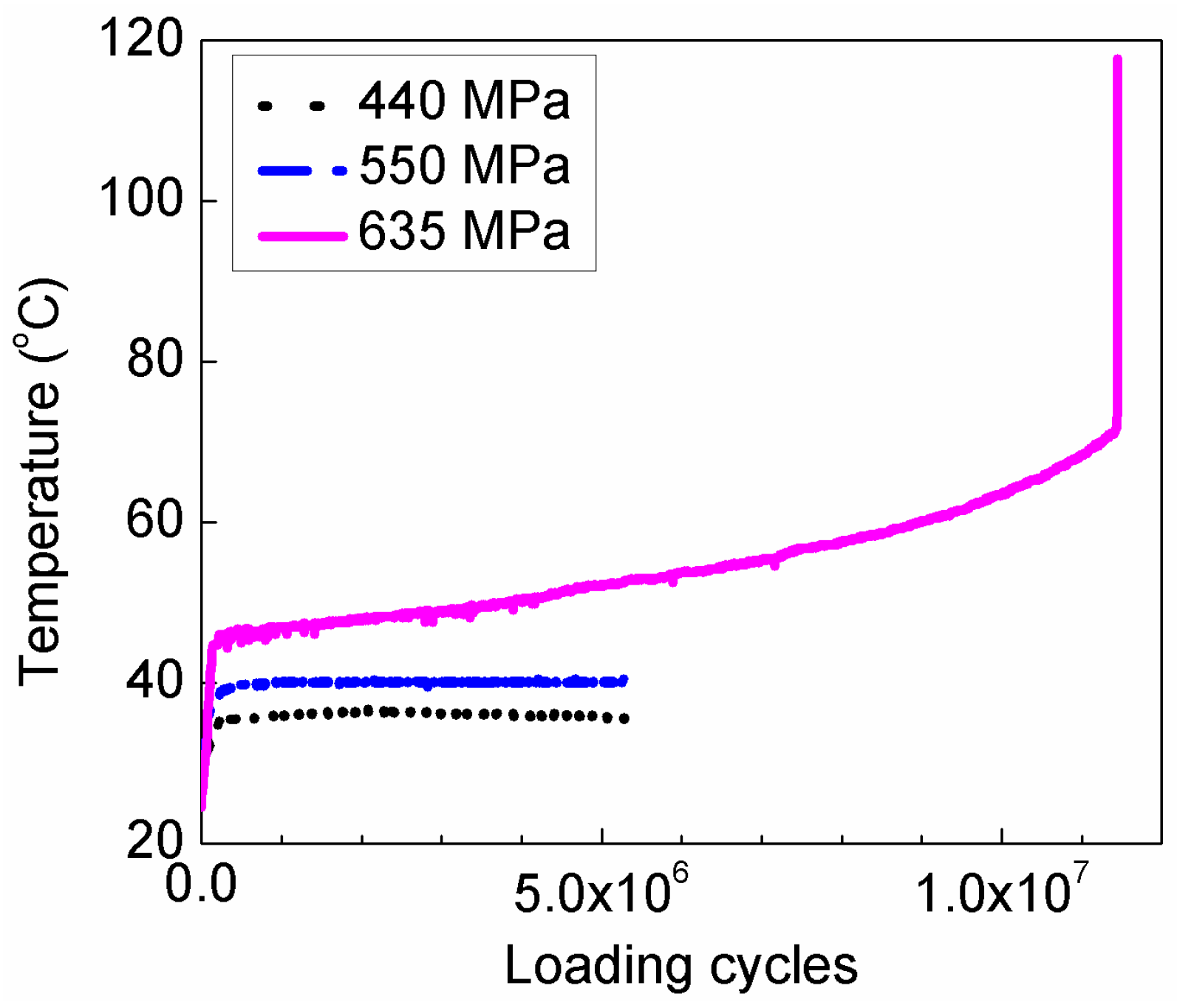

3. Results and Discussion

3.1. Experimental Results and Analysis

3.2. Effect of Specimen Geometry

3.3. Ultrasonic Frequency Effect on Fatigue Life

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Chai, G.; Zhou, N.; Ciurea, S.; Andersson, M.; Peng, R.L. Local plasticity exhaustion in a very high cycle fatigue regime. Scr. Mater. 2012, 66, 769–772. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Liu, H.Q.; Wang, C.; Wang, Q.Y. Fatigue life dispersion and thermal dissipation investigations for titanium alloy TC17 in very high cycle regime. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1285–1293. [Google Scholar] [CrossRef]

- Sander, M.; Müller, T.; Lebahn, J. Influence of mean stress and variable amplitude loading on the fatigue behaviour of a high strength steel in VHCF regime. Int. J. Fatigue 2014, 62, 10–20. [Google Scholar] [CrossRef]

- Ogawa, T.; Stanzl-Tschegg, S.E.; Schönbauer, B.M. A fracture mechanics approach to interior fatigue crack growth in the very high cycle regime. Eng. Fract. Mech. 2014, 115, 241–254. [Google Scholar] [CrossRef]

- Sun, C.; Liu, X.; Hong, Y. A two-parameter model to predict fatigue life of high-strength steels in a very high cycle fatigue regime. Acta Mech. Sin. 2015, 31, 383–391. [Google Scholar] [CrossRef]

- Liu, H.; He, C.; Huang, Z.; Wang, Q. Very high cycle fatigue failure mechanism of TC17 alloy. Acta Metall. Sin. 2017, 53, 1047–1054. [Google Scholar]

- Tofique, M.W.; Bergström, J.; Svensson, K. Very high cycle fatigue of cold rolled stainless steels, crack initiation and formation of the fine granular area. Int. J. Fatigue 2017, 100, 238–250. [Google Scholar] [CrossRef]

- Morrissey, R.J.; Nicholas, T. Fatigue strength of Ti–6Al–4V at very long lives. Int. J. Fatigue 2005, 27, 1608–1612. [Google Scholar] [CrossRef]

- Takeuchi, E.; Furuya, Y.; Nagashima, N.; Matsuoka, S. The effect of frequency on the giga-cycle fatigue properties of a Ti-6Al-4V alloy. Fatigue Fract. Eng. Mater. Struct. 2008, 31, 599–605. [Google Scholar] [CrossRef]

- Guennec, B.; Ueno, A.; Sakai, T.; Takanashi, M.; Itabashi, Y. Effect of the loading frequency on fatigue properties of JIS S15C low carbon steel and some discussions based on micro-plasticity behavior. Int. J. Fatigue 2014, 66, 29–38. [Google Scholar] [CrossRef]

- Morrissey, R.J.; McDowell, D.L. Frequency and stress ratio effects in high cycle fatigue of Ti-6Al-4V. Int. J. Fatigue 1999, 21, 679–685. [Google Scholar] [CrossRef]

- Furuya, Y.; ABE, T.; Matsuoka, S. 1010-cycle fatigue properties of 1800 MPa-class JIS-SUP7 spring steel. Eng. Mater. Struct. 2003, 26, 641–645. [Google Scholar] [CrossRef]

- Beretta, S.; Ghidini, A.; Lombardo, F. Fracture mechanics and scale effects in the fatigue of railway axles. Eng. Fract. Mech. 2005, 72, 195–208. [Google Scholar] [CrossRef]

- Shirani, M.; Härkegård, G. Fatigue life distribution and size effect in ductile cast iron for wind turbine components. Eng. Fail. Anal. 2011, 18, 12–24. [Google Scholar] [CrossRef]

- Furuya, Y. Notable size effects on very high cycle fatigue properties of high-strength steel. Mater. Sci. Eng. A 2011, 528, 5234–5240. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, X.; Liu, X.; Hong, Y. Effects of specimen size on fatigue life of metallic materials in high-cycle and very-high-cycle fatigue regimes. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 770–779. [Google Scholar] [CrossRef]

- Wang, R.; Li, D.; Hu, D.; Meng, F.; Liu, H.; Ma, Q. A combined critical distance and highly-stressed-volume model to evaluate the statistical size effect of the stress concentrator on low cycle fatigue of TA19 plate. Int. J. Fatigue 2017, 95, 8–17. [Google Scholar] [CrossRef]

- Ji, Z.; Shen, C.; Wei, F.; Li, H. Dependence of macro- and micro-properties on α plates in Ti-6Al-2Zr-1Mo-1V alloy with tri-modal microstructure. Metals 2018, 8, 299. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Șerban, N. Effects of solution treating on microstructural and mechanical properties of a heavily deformed new biocompatible Ti–Nb–Zr–Fe alloy. Metals 2018, 8, 297. [Google Scholar] [CrossRef]

- Su, H.; Liu, X.; Sun, C.; Hong, Y. Nanograin layer formation at crack initiation region for very-high-cycle fatigue of a Ti–6Al–4V alloy. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 979–993. [Google Scholar] [CrossRef]

- National Standard of the People’s Republic of China. Metallic Materials—Fatigue Testing—Statistical Planning and Analysis of Data; GB/T 24176-2009/ISO 12107; Standards Press of China: Beijing, China, 2003.

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Elsevier Science Ltd.: Oxford, UK, 2002. [Google Scholar]

- Härkegård, G.; Halleraker, G. Assessment of methods for prediction of notch and size effects at the fatigue limit based on test data by Böhm and Magin. Int. J. Fatigue 2010, 32, 1701–1709. [Google Scholar] [CrossRef]

- Lv, W.; Chen, L.J.; Che, X.; Liu, Z. Influence of temperature and rolling direction on fatigue behavior of TC1 titanium alloy plate. J. Shenyang Univ. Technol. 2012, 34, 504–508. [Google Scholar]

- Nonaka, I.; Setowaki, S.; Ichikawa, Y. Effect of load frequency on high cycle fatigue strength of bullet. Int. J. Fatigue 2014, 60, 43–47. [Google Scholar] [CrossRef]

- Ran, C.; Chen, P.W.; Li, L.; Zhang, W.F. Experimental research on dynamic mechanical behavior of TC18 titanium alloy under medium and high strain rates. Acta Armamentarii 2017, 9, 1723–1728. [Google Scholar]

| HC Specimen | HU Specimen | DU Specimen | |||

|---|---|---|---|---|---|

| σa (MPa) | Nf | σa (MPa) | Nf | σa (MPa) | Nf |

| 882 | 8.98 × 103 | 740 | 4.99 × 104 | 660 | 2.75 × 106 |

| 882 | 9.40 × 103 | 700 | 2.72 × 105 | 660 | 9.34 × 105 |

| 882 | 9.82 × 103 | 660 | 2.84 × 106 | 660 | 4.64 × 105 |

| 819 | 1.79 × 104 | 660 | 1.78 × 106 | 660 | 4.13 × 105 |

| 819 | 2.48 × 104 | 660 | 1.48 × 106 | 660 | 2.61 × 105 |

| 819 | 1.82 × 104 | 660 | 1.46 × 106 | 660 | 6.99 × 105 |

| 819 | 1.70 × 104 | 660 | 6.64 × 105 | 660 | 2.55 × 105 |

| 756 | 4.34 × 104 | 645 | 7.10 × 106 | 660 | 5.10 × 105 |

| 756 | 4.36 × 104 | 635 | 3.88 × 107 | - | - |

| 756 | 2.58 × 104 | 635 | 2.91 × 107 | - | - |

| 756 | 4.83 × 104 | 635 | 4.09 × 107 | - | - |

| 693 | 2.39 × 105 | 635 | 1.46 × 107 | - | - |

| 693 | 6.45 × 104 | 635 | 1.42 × 107 | - | - |

| 693 | 3.27 × 105 | 635 | 3.46 × 106 | - | - |

| 693 | 7.97 × 104 | 610 | 5.85 × 107 | - | - |

| 693 | 4.04 × 105 | 600 | 4.65 × 108 | - | - |

| 693 | 4.16 × 104 | 610 * | 5.0 × 108 | - | - |

| 693 | 4.90 × 104 | 590 * | 1.0 × 109 | - | - |

| 693 | 8.29 × 104 | 560 * | 1.0 × 109 | - | - |

| 630 | 2.74 × 105 | - | - | - | - |

| 630 | 2.77 × 106 | - | - | - | - |

| 630 | 2.52 × 106 | - | - | - | - |

| 630 | 3.82 × 104 | - | - | - | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Song, Q.; Feng, S.; Sun, C. Effects of Loading Frequency and Specimen Geometry on High Cycle and Very High Cycle Fatigue Life of a High Strength Titanium Alloy. Materials 2018, 11, 1628. https://doi.org/10.3390/ma11091628

Li Y, Song Q, Feng S, Sun C. Effects of Loading Frequency and Specimen Geometry on High Cycle and Very High Cycle Fatigue Life of a High Strength Titanium Alloy. Materials. 2018; 11(9):1628. https://doi.org/10.3390/ma11091628

Chicago/Turabian StyleLi, Yanqing, Qingyuan Song, Shichao Feng, and Chengqi Sun. 2018. "Effects of Loading Frequency and Specimen Geometry on High Cycle and Very High Cycle Fatigue Life of a High Strength Titanium Alloy" Materials 11, no. 9: 1628. https://doi.org/10.3390/ma11091628

APA StyleLi, Y., Song, Q., Feng, S., & Sun, C. (2018). Effects of Loading Frequency and Specimen Geometry on High Cycle and Very High Cycle Fatigue Life of a High Strength Titanium Alloy. Materials, 11(9), 1628. https://doi.org/10.3390/ma11091628