Transmission Attenuation Power Ratio Analysis of Flexible Electromagnetic Absorber Sheets Combined with a Metal Layer

Abstract

1. Introduction

2. Materials and Methods

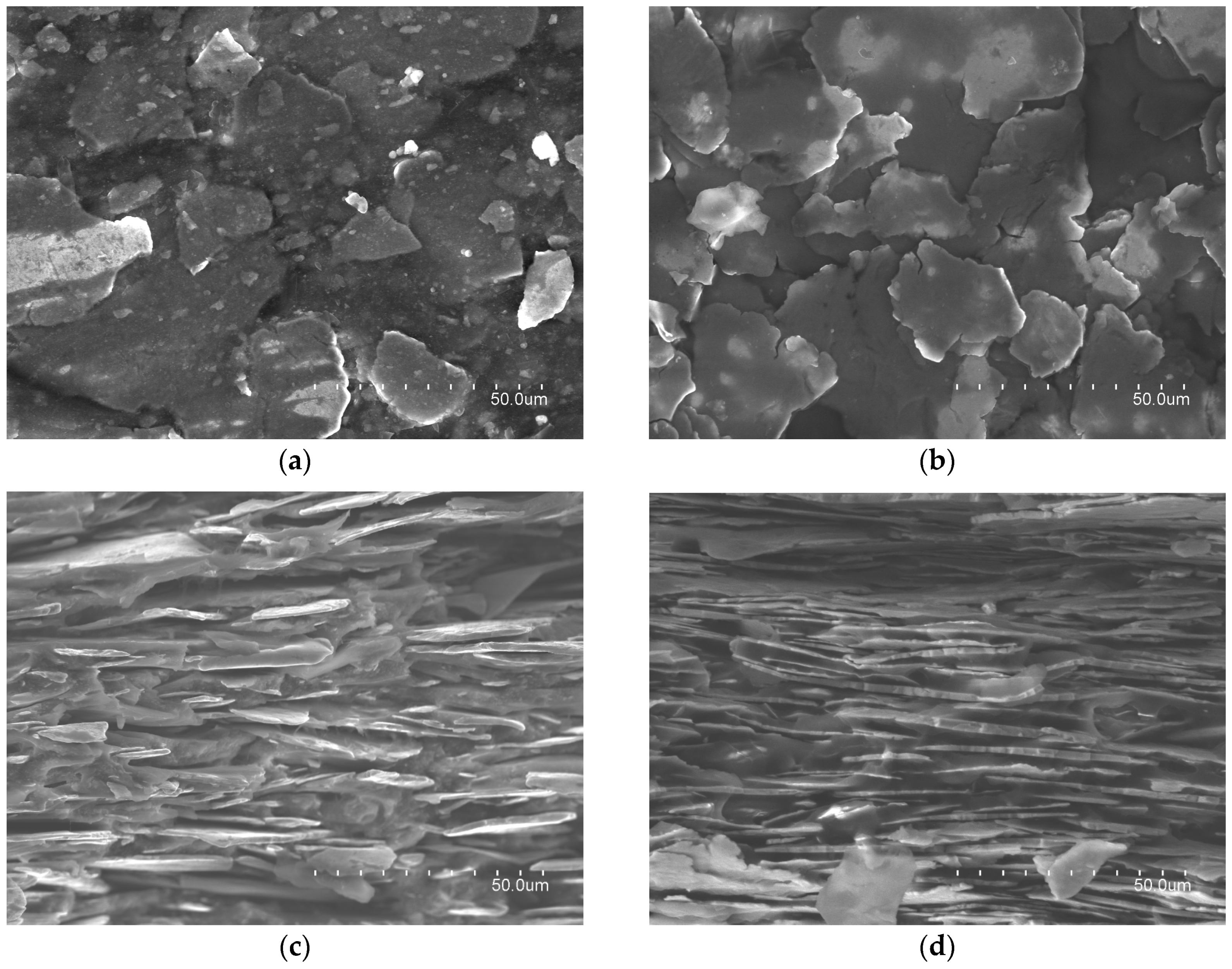

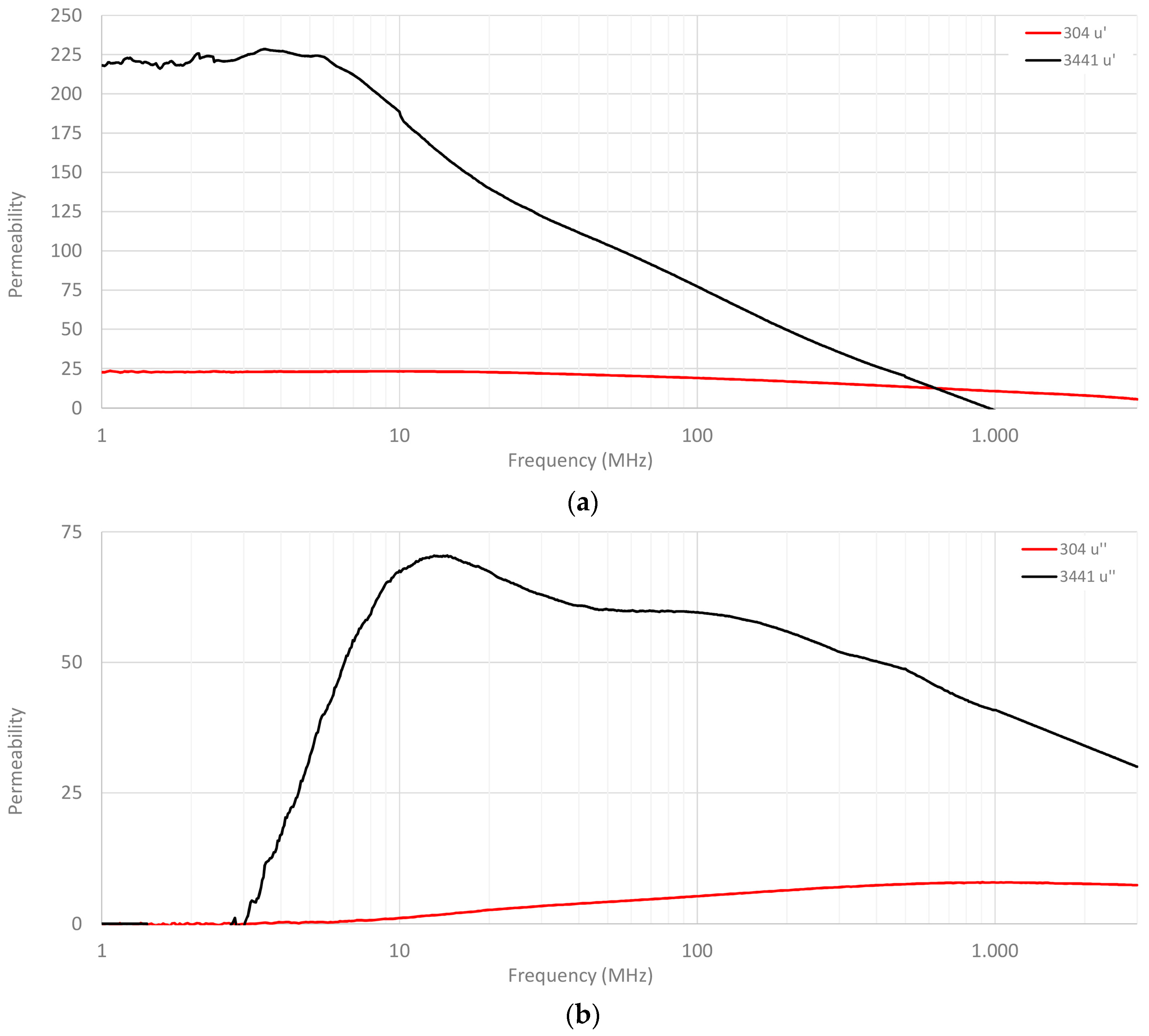

2.1. FAS Characterization

2.2. Metal Layer Characteristics

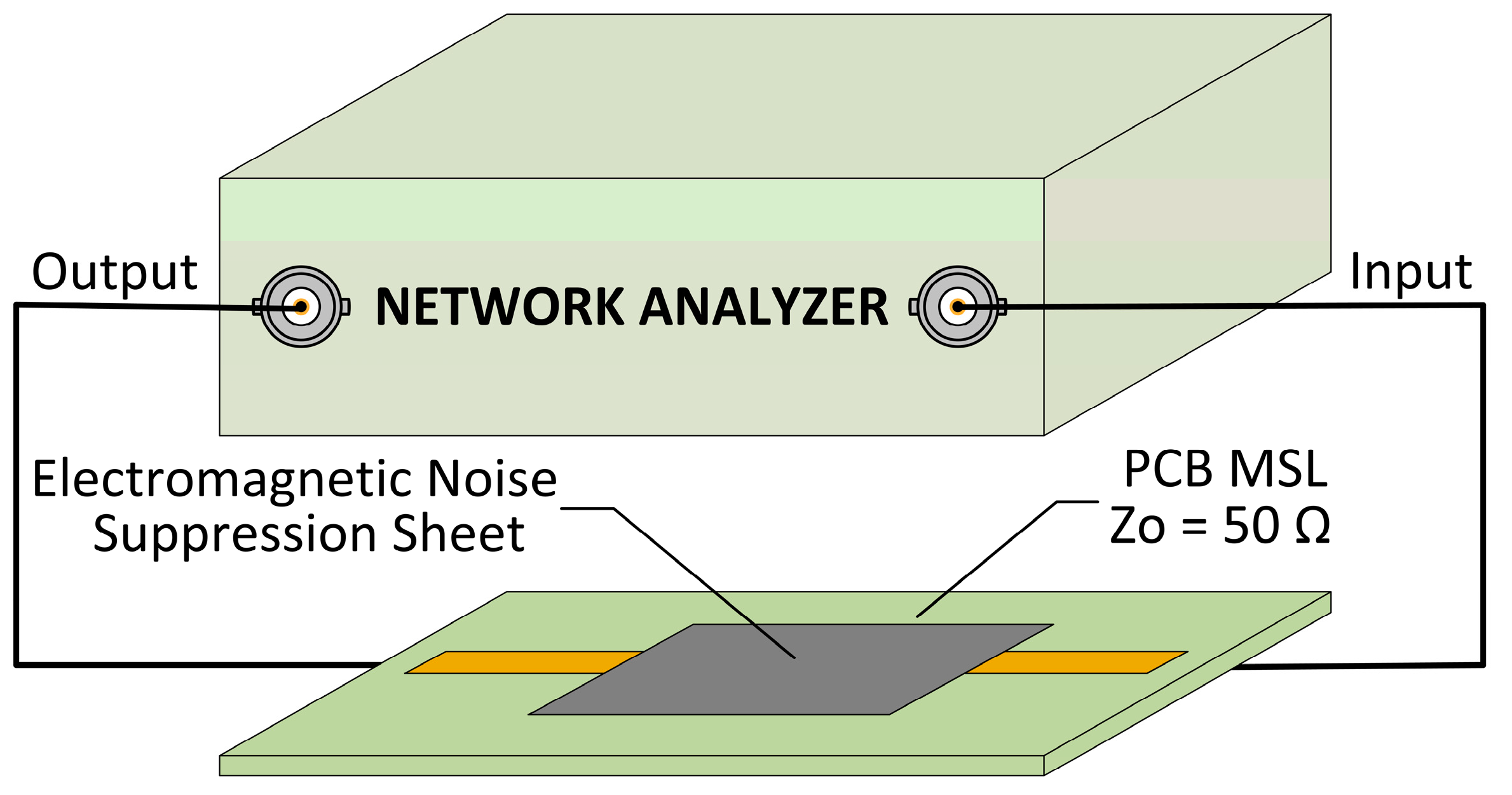

2.3. Transmission Attenuation Power Ratio Measurement

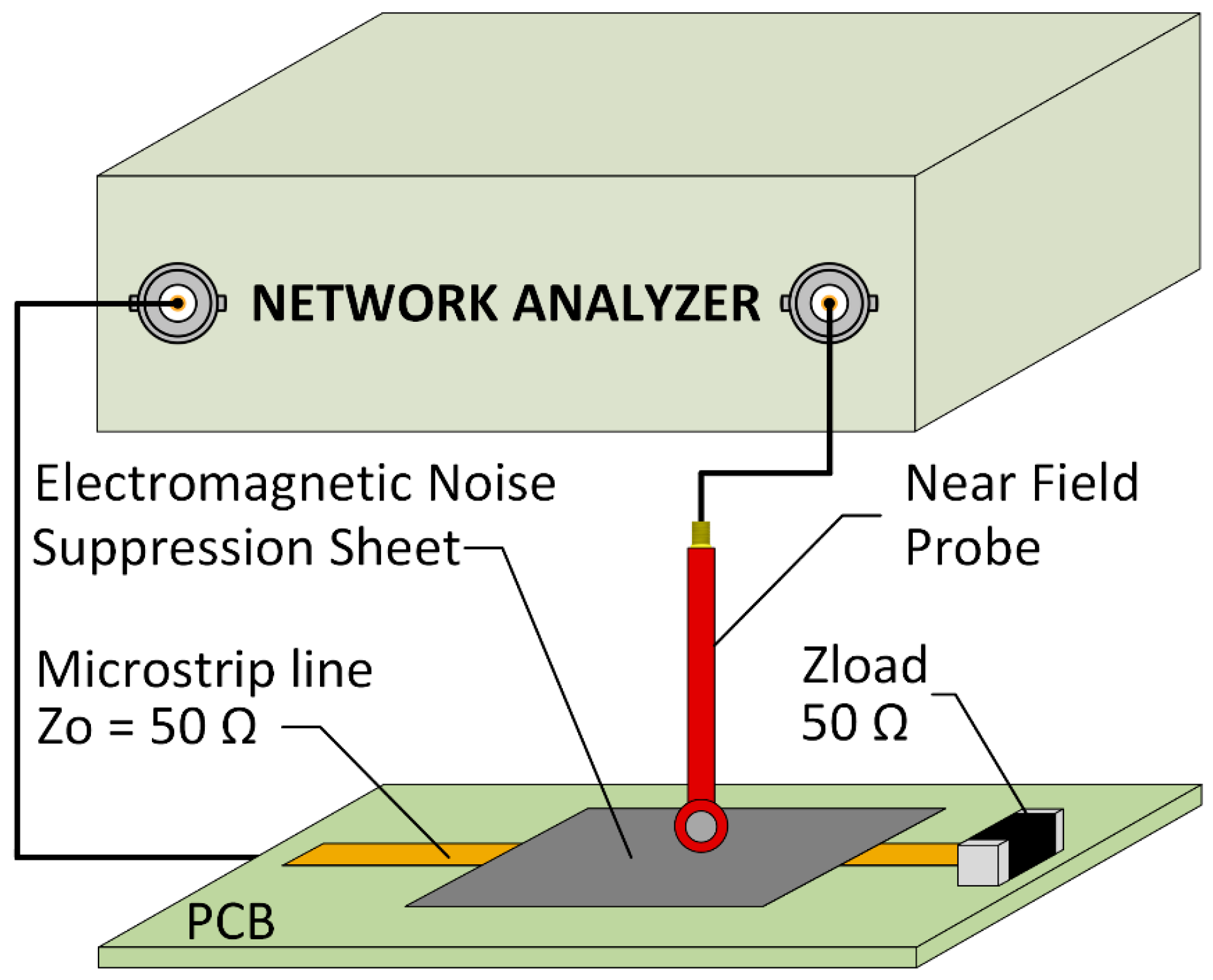

2.4. Re-Radiation Measurement Setup

3. Results and Discussion

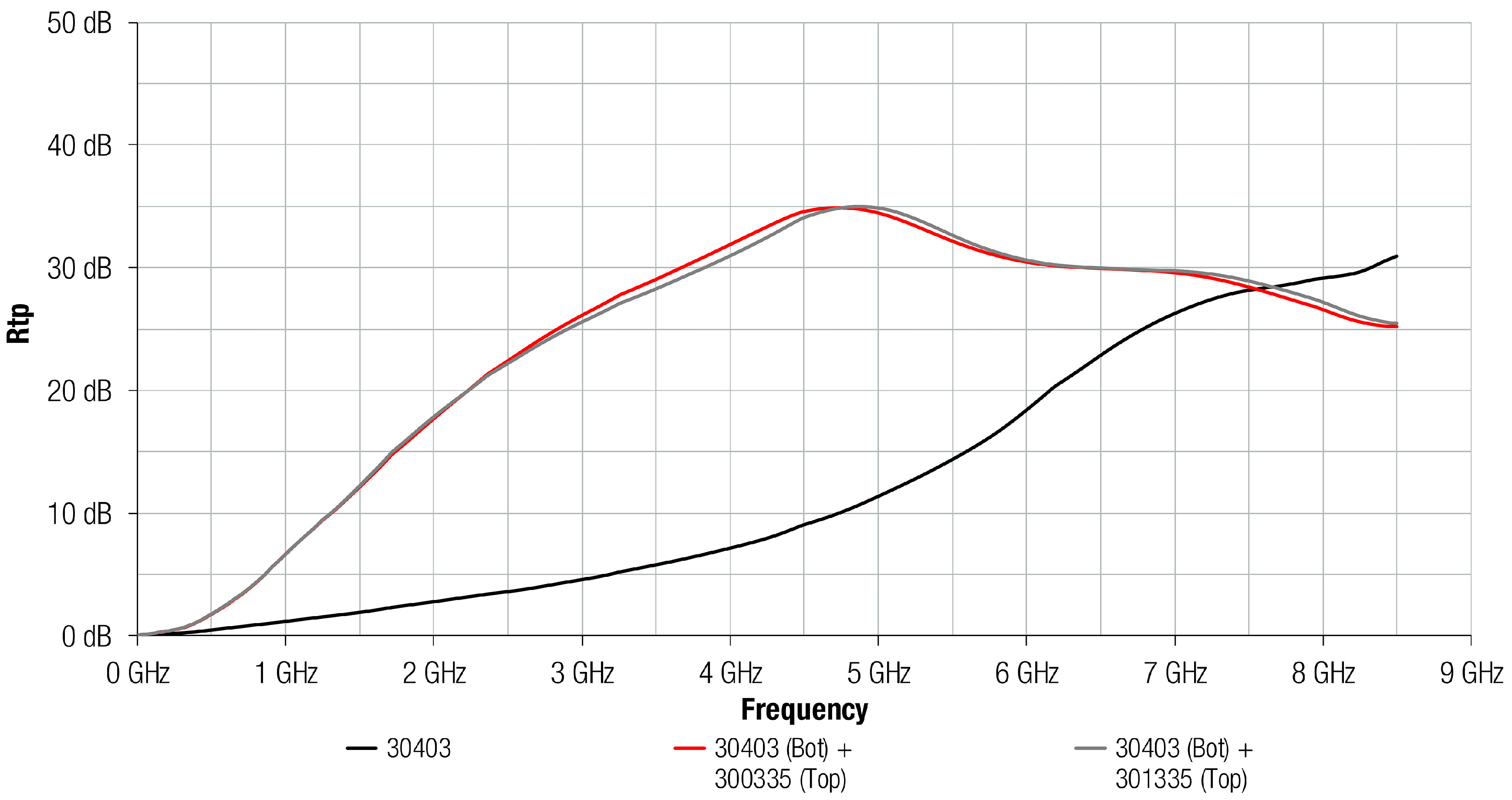

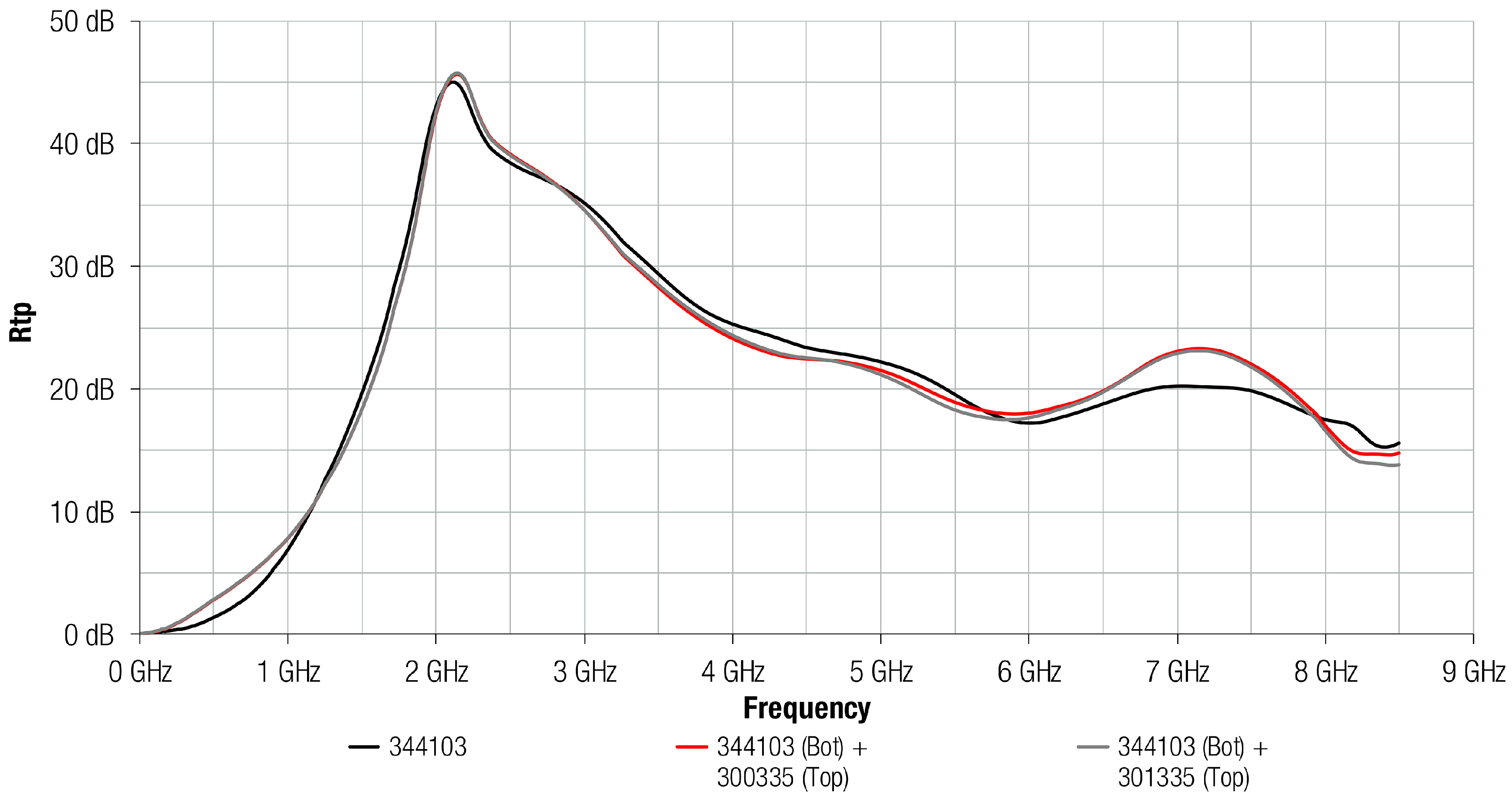

3.1. Depending on the Material Composition and Kind of Metal Layer

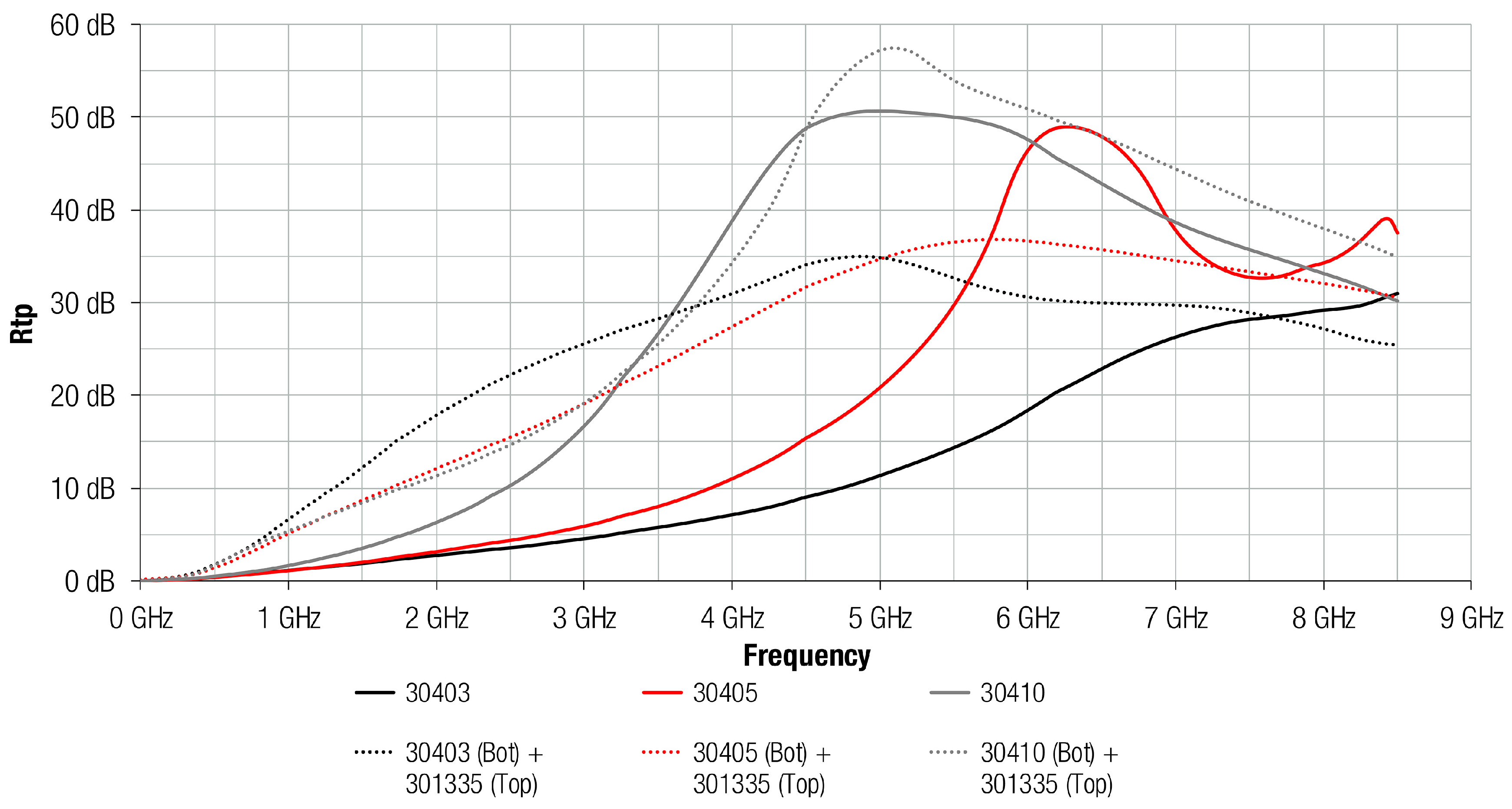

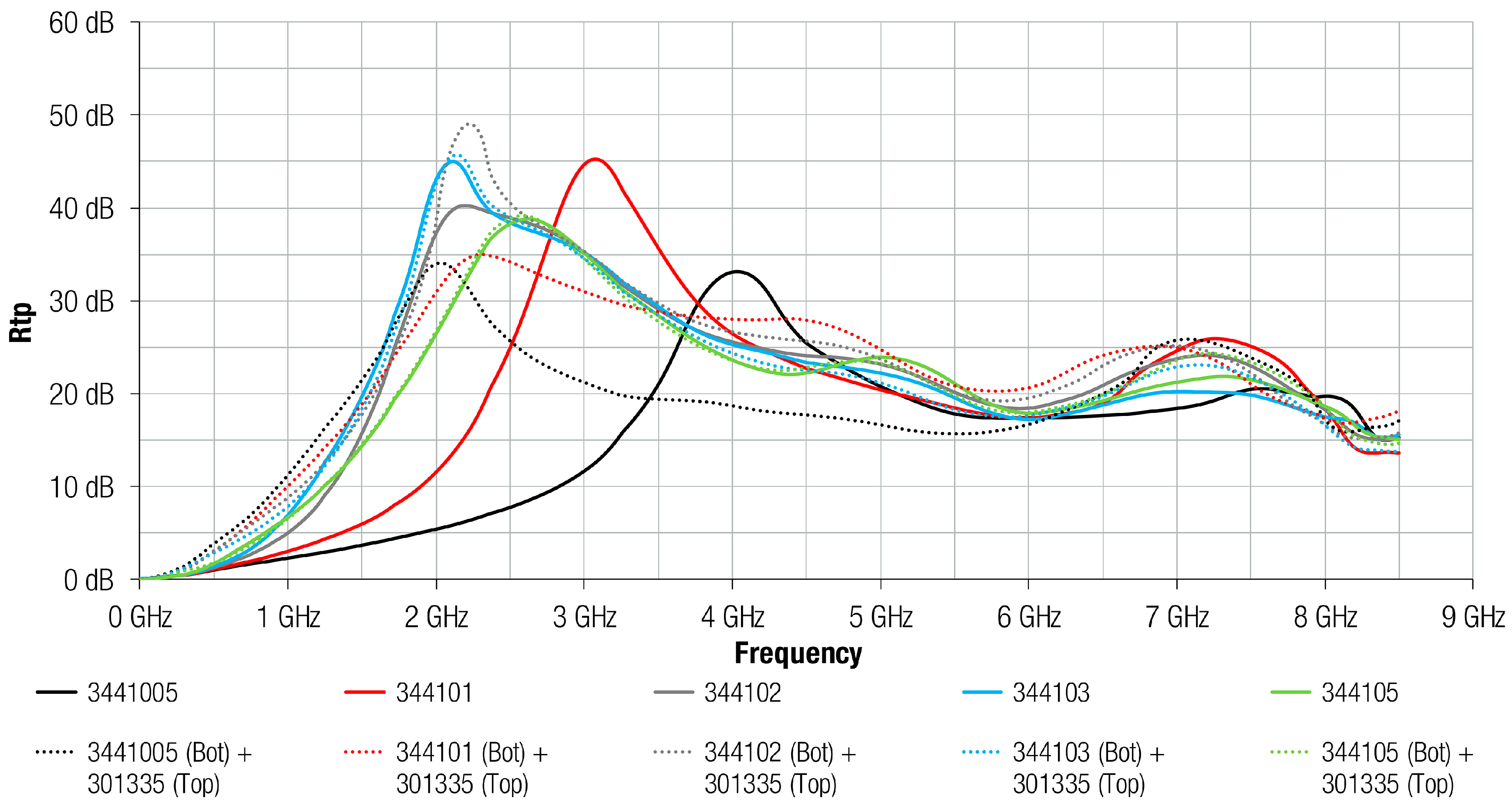

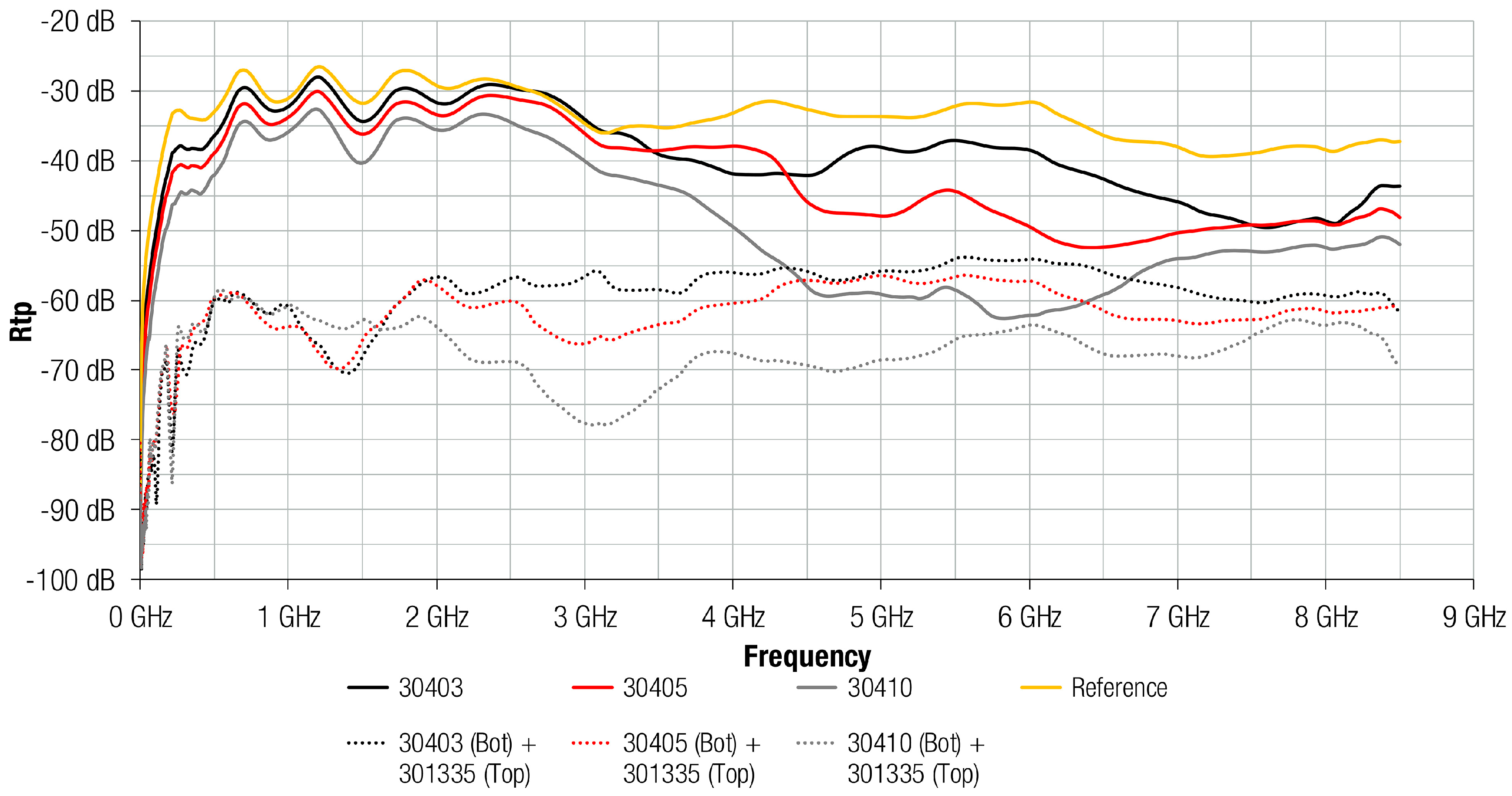

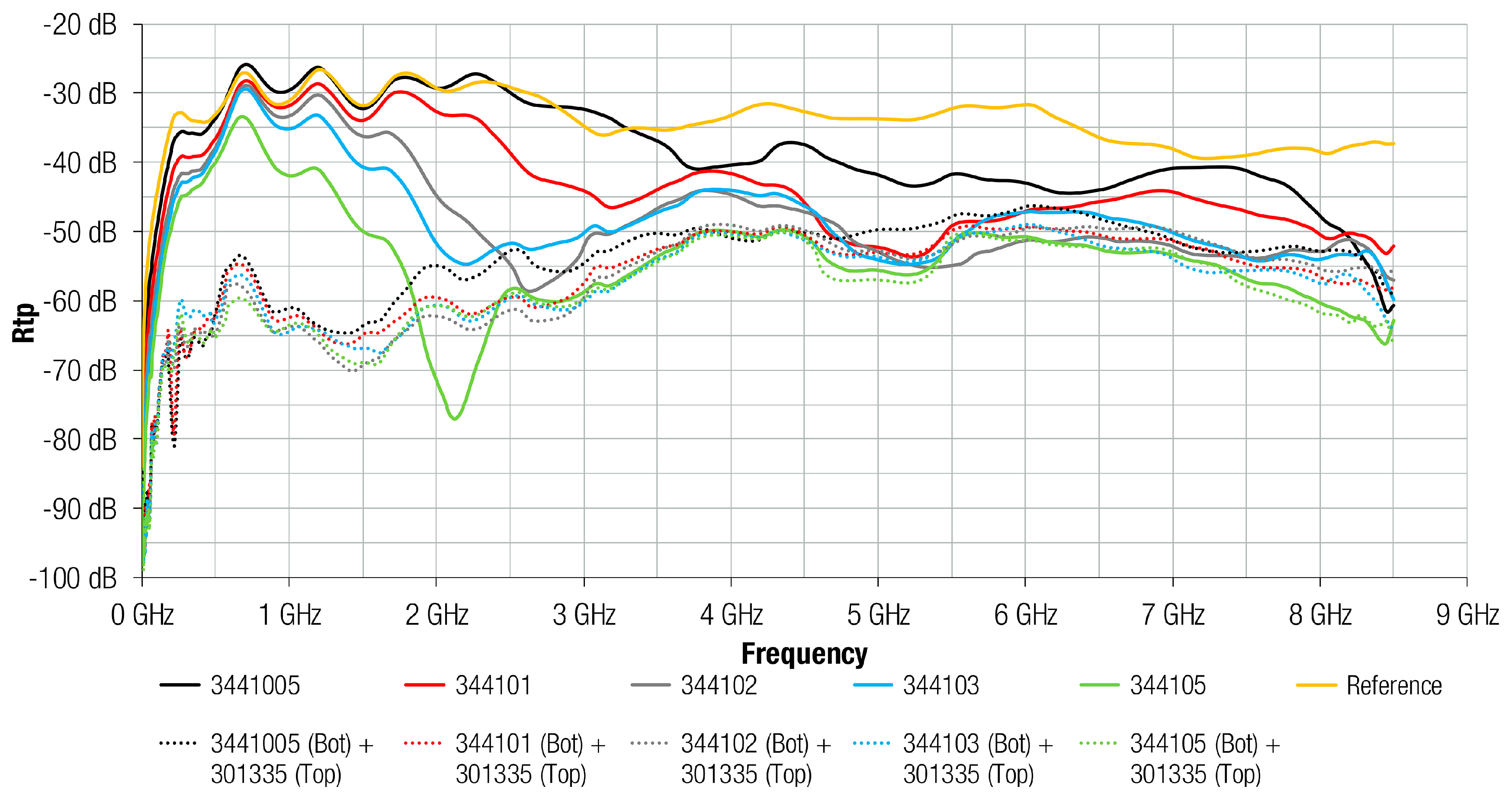

3.2. Depending on the Material Composition and the Absorber Sheet Thickness

3.3. Re-Radiation Analysis

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Piersanti, S.; de Paulis, F.; Orlandi, A.; Connor, S.; Liu, Q.; Archambeault, B.; Dixon, P.; Khorrami, M.; Drewniak, J.L. Near-Field Shielding Performances of EMI Noise Suppression Absorbers. IEEE Trans. Electromagn. Compat. 2017, 59, 654–661. [Google Scholar] [CrossRef]

- Paul, C.R. Introduction to Electromagnetic Compatibility, 2nd ed.; Wiley Interscience: Hoboken, NJ, USA, 2006; ISBN 978-047-175-500-5. [Google Scholar]

- Matsushita, N.; Nakamura, T.; Abe, M. Spin-sprayed Ni–Zn–Co ferrite films with high μr″>100 in extremely wide frequency range 100 MHz–1 GHz. J. Appl. Phys. 2003, 93, 7133–7135. [Google Scholar] [CrossRef]

- Idris, F.M.; Hashim, M.; Abbas, Z.; Ismail, I.; Nazlan, R.; Ibrahim, I.R. Recent developments of smart electromagnetic absorbers based polymer-composites at gigahertz frequencies. J. Magn. Magn. Mater. 2016, 405, 197–208. [Google Scholar] [CrossRef]

- Nisanci, M.H.; De Paulis, F.; Di Febo, D.; Orlandi, A. Synthesis of composite materials with conductive aligned cylindrical inclusions. In Proceedings of the Progress in Electromagnetics Research Symposium (PIERS), Kuala Lumpur, Malaysia, 27–30 March 2012; pp. 646–649. [Google Scholar]

- Lal, K.; Singh, V. Broad-Band EMI Suppression Absorber. In Proceedings of the Antenna Test & Measurement Society (ATMS India—2017), Hyderabad, India, 6–8 February 2017. [Google Scholar]

- Koledintseva, M.Y.; Drewniak, J.L.; DuBroff, R.E.; Rozanov, K.N.; Archambeault, B. Modeling of shielding composite materials and structures for microwave frequencies. Prog. Electromagn. Res. B 2009, 15, 197–215. [Google Scholar] [CrossRef]

- Nisanci, M.H.; de Paulis, F.; Di Febo, D.; Orlandi, A. Sensitivity analysis of electromagnetic transmission, reflection and absorption coefficients for biphasic composite structures. In Proceedings of the 2014 International Symposium on Electromagnetic Compatibility (EMC Europe), Gothenburg, Sweden, 1–4 September 2014; pp. 438–443. [Google Scholar]

- De Paulis, F.; Nisanci, M.H.; Koledintseva, M.Y.; Drewniak, J.L.; Orlandi, A. Derivation of homogeneous permittivity of composite materials with aligned cylindrical inclusions for causal electromagnetic simulations. Prog. Electromagn. Res. B 2012, 37, 205–235. [Google Scholar] [CrossRef]

- Nisanci, M.H.; De Paulis, F.; Orlandi, A. Synthesis of composite materials with conductive and/or lossy spherical inclusions. In Proceedings of the 2013 International Symposium on Electromagnetic Compatibility (EMC Europe), Brugge, Belgium, 2–6 September 2013; pp. 593–598. [Google Scholar]

- Shimada, Y.; Yamaguchi, M.; Ohnuma, S.; Itoh, T.; Li, W.D.; Ikeda, S.; Kim, K.H.; Nagura, H. Granular thin films with high RF permeability. IEEE Trans. Magn. 2003, 39, 3052–3056. [Google Scholar] [CrossRef]

- Rizza, C.; Ciattoni, A.; De Paulis, F.; Palange, E.; Orlandi, A.; Columbo, L.; Prati, F. Reconfigurable photoinduced metamaterials in the microwave regime. J. Phys. D Appl. Phys. 2015, 48, 135103. [Google Scholar] [CrossRef]

- De Paulis, F.; Nisanci, M.H.; Orlandi, A.; Koledintseva, M.Y.; Drewniak, J.L. Design of homogeneous and composite materials from shielding effectiveness specifications. IEEE Trans. Electromagn. Compat. 2014, 56, 343–351. [Google Scholar] [CrossRef]

- Ryu, G.B.; Kim, S.S. Numerical analysis on power loss mechanism of Fe55Al18O27 thin films for conduction noise through microstrip line. J. Appl. Phys. 2009, 105, 07A5081–07A5083. [Google Scholar] [CrossRef]

- Yoshida, S.; Ono, H.; Ando, S.; Tsuda, F.; Ito, T.; Shimada, Y.; Masumoto, T. High-frequency noise suppression in downsized circuits using magnetic granular films. IEEE Trans. Magn. 2001, 37, 2401–2403. [Google Scholar] [CrossRef]

- Hayt, W.H.; Buck, J.A. Engineering Electromagnetics; McGraw-Hill: New York, NY, USA, 2001; ISBN 978-007-338-066-7. [Google Scholar]

- Ott, H.W. Electromagnetic Compatibility Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 978-04-7050-850-3. [Google Scholar]

- Kondo, K.; Chiba, T.; Ono, H.; Yoshida, S.; Shimada, Y.; Matsushita, N.; Abe, M. Conducted noise suppression effect up to 3 GHz by NiZn ferrite film plated at 90 °C directly onto printed circuit board. J. Appl. Phys. 2003, 93, 7130–7132. [Google Scholar] [CrossRef]

- Kim, S.T.; Cho, H.S.; Kim, S.S. Conducted noise attenuation by iron particles-rubber composites attached on microstrip line. In Proceedings of the IEEE International Magnetics Conference (INTERMAG), Nagoya, Japan, 4–8 April 2005; pp. 1101–1102. [Google Scholar]

- Kim, S.; Park, Y.; Kim, S. The influence of magnetic and dielectric loss on the noise absorption of iron particles-rubber composites attached to a microstrip line. Met. Mater. Int. 2008, 14, 233–237. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S. Conduction noise absorption by ITO thin films attached to microstrip line utilizing Ohmic loss. J. Appl. Phys. 2010, 108, 0249041–0249046. [Google Scholar] [CrossRef]

- Kim, S. Conduction noise absorption by Sn-O thin films on microstrip lines. Korean J. Met. Mater. 2011, 49, 329–333. [Google Scholar] [CrossRef]

- Lovat, G.; Burghignoli, P.; Celozzi, S. Shielding Properties of a Wire-Medium Screen. IEEE Trans. Electromagn. Compat. 2008, 50, 80–88. [Google Scholar] [CrossRef]

- Silveirinha, M.; Fernandes, C. Effective Permittivity of Metallic Crystals: A Periodic Green’s Function Formulation. Electromagnetics 2003, 23, 647–663. [Google Scholar] [CrossRef]

- Diaz, R.E.; Merrill, W.M.; Alexopoulos, N.G. Analytic framework for the modeling of effective media. J. Appl. Phys. 1998, 84, 6815–6826. [Google Scholar] [CrossRef]

- Koledintseva, M.; Rawa, P.C.; Dubroff, R.; Drewniak, J.; Rozanov, K.; Archambeault, B. Engineering of composite media for shields at microwave frequencies. In Proceedings of the 2005 International Symposium on IEEE Electromagnetic Compatibility, Chicago, IL, USA, 8–12 August 2005; pp. 169–174. [Google Scholar]

- Goldman, A. Modern Ferrite Technology, 2nd ed.; Springer Science & Business Media: Pittsburgh, PA, USA, 2006; ISBN 978-0-387-28151-3. [Google Scholar]

- Suarez, A.; Victoria, J.; Alcarria, A.; Torres, J.; Martinez, P.A.; Martos, J.; Soret, J.; Garcia-Olcina, R.; Muetsch, S. Characterization of Different Cable Ferrite Materials to Reduce the Electromagnetic Noise in the 2–150 kHz Frequency Range. Materials 2018, 11, 174. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Rahman, N.; Obol, M.; Afsar, M. Precise characterization and design of composite absorbers for wideband microwave applications. In Proceedings of the European Microwave Conference, Paris, France, 28–30 September 2010; pp. 160–163. [Google Scholar]

- Brander, T.; Gerfer, A.; Rall, B.; Zenkner, H. Trilogy of Magnetics: Design Guide for EMI Filter Design, SMP & RF Circuits, 4th ed.; Swiridoff Verlag: Künzelsau, Germany, 2010; ISBN 978-3-89929-157-5. [Google Scholar]

- Nisanci, M.H.; De Paulis, F.; Koledintseva, M.Y.; Drewniak, J.L.; Orlandi, A. From Maxwell Garnett to Debye Model for Electromagnetic Simulation of Composite Dielectrics-Part II: Random Cylindrical Inclusions. IEEE Trans. Electromagn. Compat. 2012, 54, 280–289. [Google Scholar] [CrossRef]

- De Paulis, F.; Nisanci, M.; Koledintseva, M.Y.; Drewniak, J.L.; Orlandi, A. From Maxwell Garnett to Debye Model for Electromagnetic Simulation of Composite Dielectrics Part I: Random Spherical Inclusions. IEEE Trans. Electromagn. Compat. 2011, 53, 933–942. [Google Scholar] [CrossRef]

- Nicolson, A.M.; Ross, G.F. Measurement of the Intrinsic Properties of Materials by Time-Domain Techniques. IEEE Trans. Instrum. Meas. 1970, 19, 377–382. [Google Scholar] [CrossRef]

- Barry, W. A Broad-band, automated, stripline technique for the simultaneous measurement of complex permittivity and permeability. IEEE Trans. Microw. Theory Tech. 1986, 34, 80–84. [Google Scholar] [CrossRef]

- Yoshida, S.; Kondo, K.; Ono, H. High-frequency noise suppression using ferrite-plated film. NEC Tech. J. 2006, 1, 77–81. [Google Scholar]

- International Electrotechnical Commission. IEC 62333-2: 2006 (E), Noise Suppression Sheet for Digital Devices and Equipment Part 2: Measuring Methods; IEC: Geneva, Switzerland, 2006; ISBN 978-288-912-593-7. [Google Scholar]

- Suarez, A.; Victoria, J.; Alcarria, A.; Torres, J. Characterization of electromagnetic noise suppression sheet for aerospace applications. In Proceedings of the ESA Workshop on Aerospace EMC, Valencia, Spain, 23–25 May 2016; pp. 1–6. [Google Scholar]

- Tsuda, F.; Ono, H.; Shinohara, S.; Sato, R. Effect of installing magnetic-polymer-composite sheeting on transmission line to suppress conducted-electromagnetic noise. In Proceedings of the 2005 International Symposium on IEEE Electromagnetic Compatibility, Washington, DC, USA, 21–25 August 2000; pp. 867–870. [Google Scholar]

- Ono, H.; Ito, T.; Yoshida, S.; Takase, Y.; Hashimoto, O.; Shimada, Y. Noble magnetic films for effective electromagnetic noise absorption in the gigahertz frequency range. IEEE Trans. Magn. 2004, 40, 2853–2857. [Google Scholar] [CrossRef]

| Parameters | 3441 | 304 |

|---|---|---|

| Thickness (mm) | 0.3 | 0.3 |

| Size (mm) | 50 × 100 | 50 × 100 |

| Surface resistivity (Ω/sq) | 1 × 106 | 1 × 109 |

| Density (g/cm3) | 3.9 | 3.5 |

| Relaxation frequ. (GHz) | 0.163 | 2.185 |

| Initial permeability | 200 | 25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Victoria, J.; Suarez, A.; Torres, J.; Martinez, P.A.; Alcarria, A.; Martos, J.; Garcia-Olcina, R.; Soret, J.; Muetsch, S.; Gerfer, A. Transmission Attenuation Power Ratio Analysis of Flexible Electromagnetic Absorber Sheets Combined with a Metal Layer. Materials 2018, 11, 1612. https://doi.org/10.3390/ma11091612

Victoria J, Suarez A, Torres J, Martinez PA, Alcarria A, Martos J, Garcia-Olcina R, Soret J, Muetsch S, Gerfer A. Transmission Attenuation Power Ratio Analysis of Flexible Electromagnetic Absorber Sheets Combined with a Metal Layer. Materials. 2018; 11(9):1612. https://doi.org/10.3390/ma11091612

Chicago/Turabian StyleVictoria, Jorge, Adrian Suarez, Jose Torres, Pedro A. Martinez, Antonio Alcarria, Julio Martos, Raimundo Garcia-Olcina, Jesus Soret, Steffen Muetsch, and Alexander Gerfer. 2018. "Transmission Attenuation Power Ratio Analysis of Flexible Electromagnetic Absorber Sheets Combined with a Metal Layer" Materials 11, no. 9: 1612. https://doi.org/10.3390/ma11091612

APA StyleVictoria, J., Suarez, A., Torres, J., Martinez, P. A., Alcarria, A., Martos, J., Garcia-Olcina, R., Soret, J., Muetsch, S., & Gerfer, A. (2018). Transmission Attenuation Power Ratio Analysis of Flexible Electromagnetic Absorber Sheets Combined with a Metal Layer. Materials, 11(9), 1612. https://doi.org/10.3390/ma11091612