Effect of Rolling Temperature on Microstructure Evolution and Mechanical Properties of AISI316LN Austenitic Stainless Steel

Abstract

1. Introduction

2. Experimental Methods

3. Results

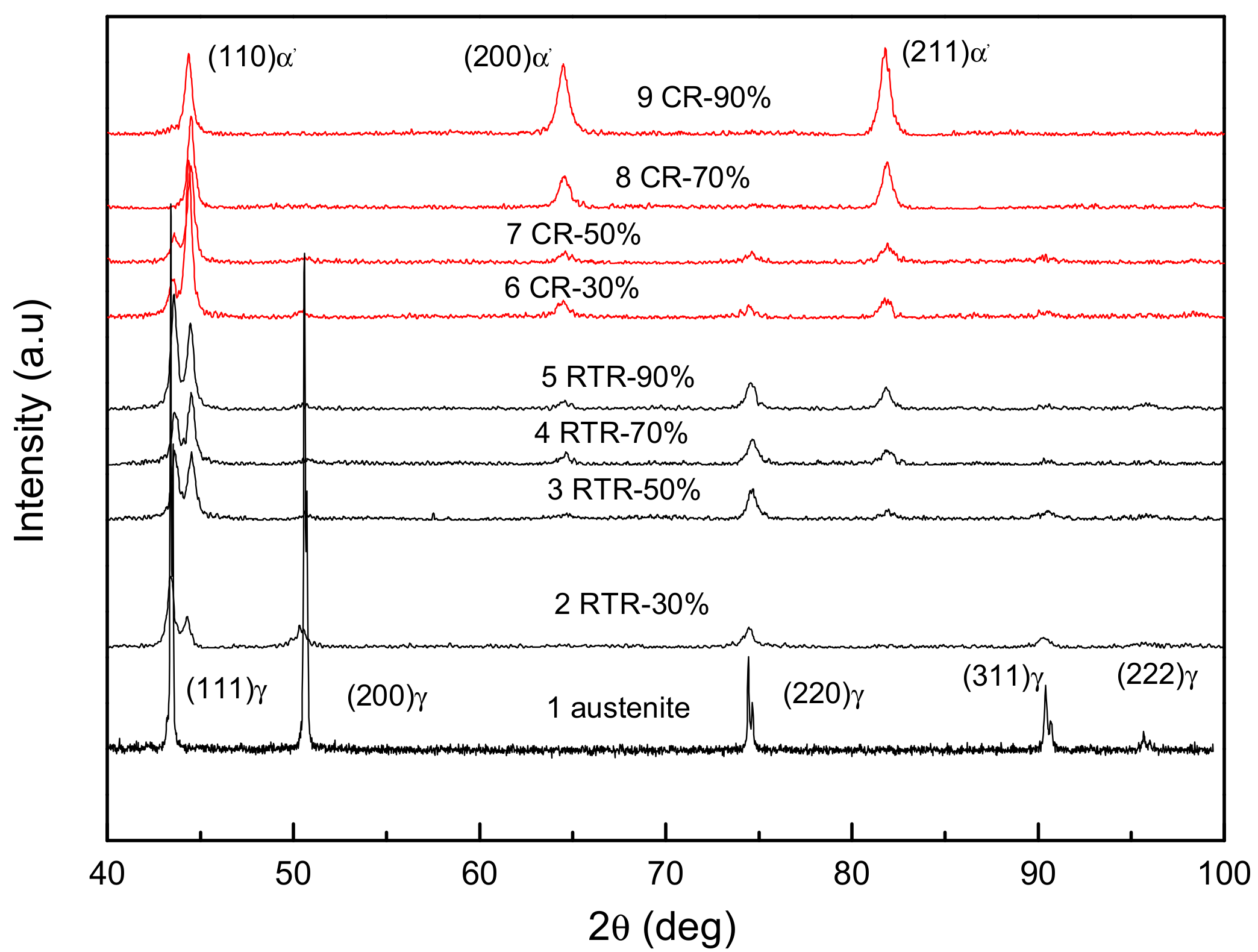

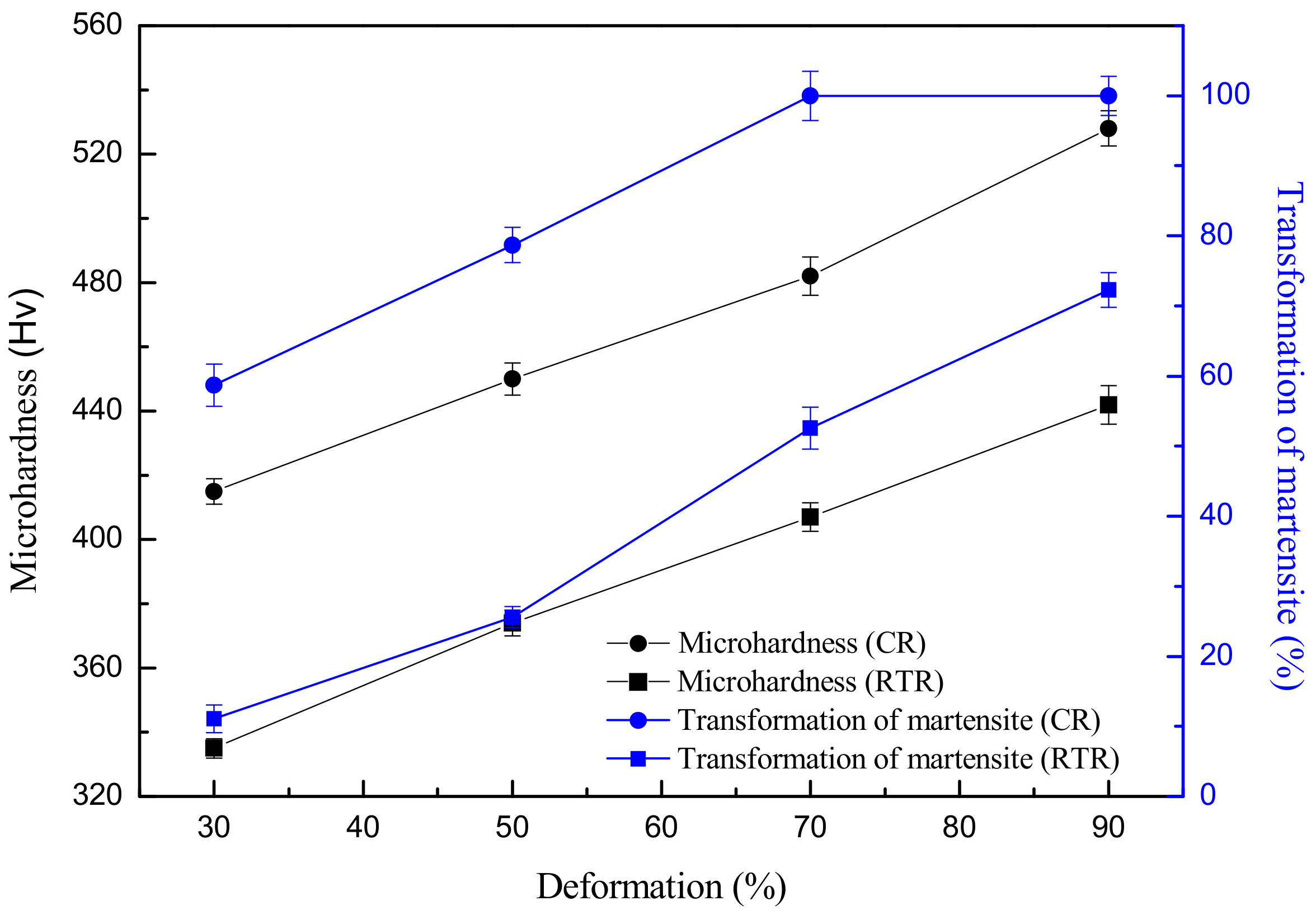

3.1. Martensite Transformation

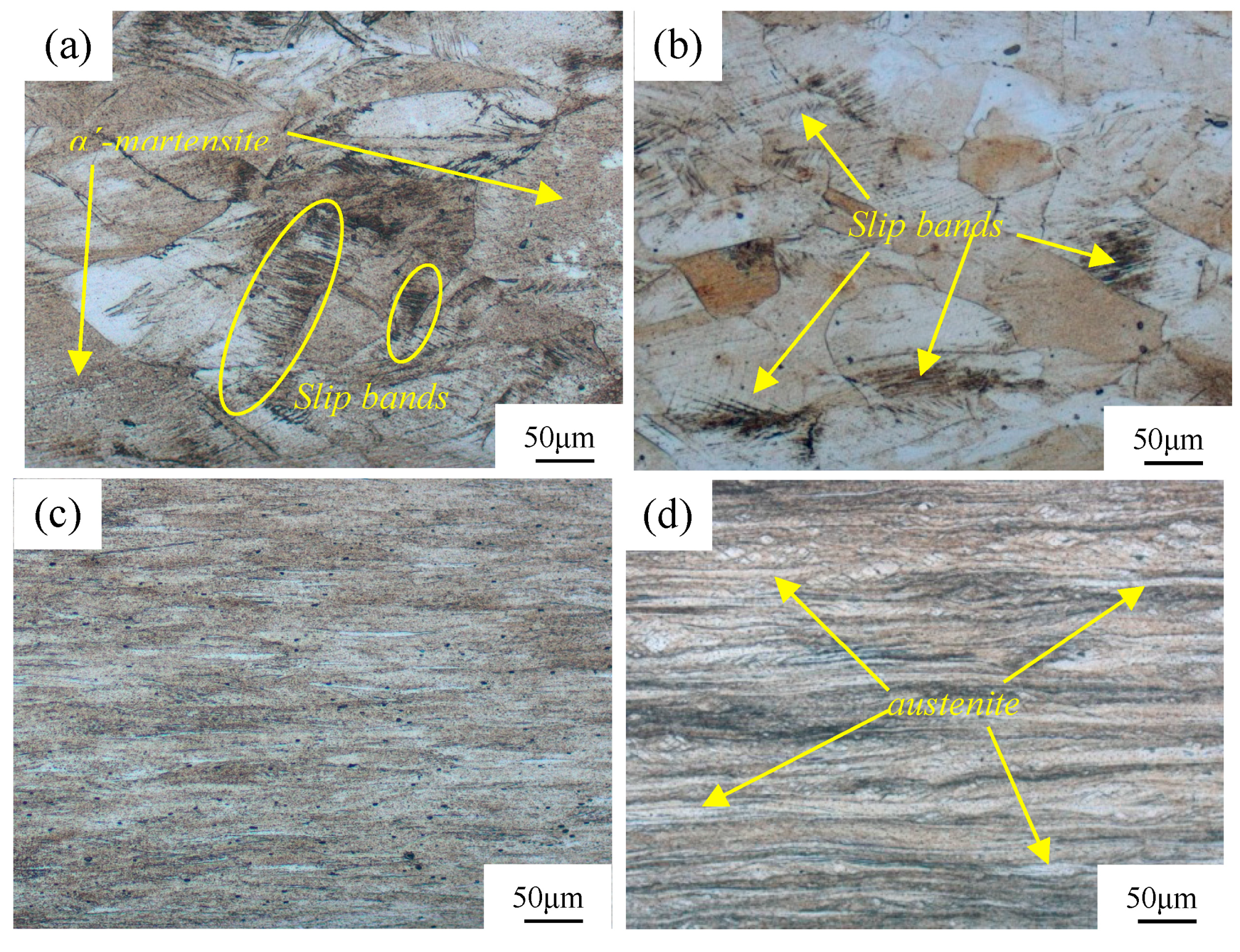

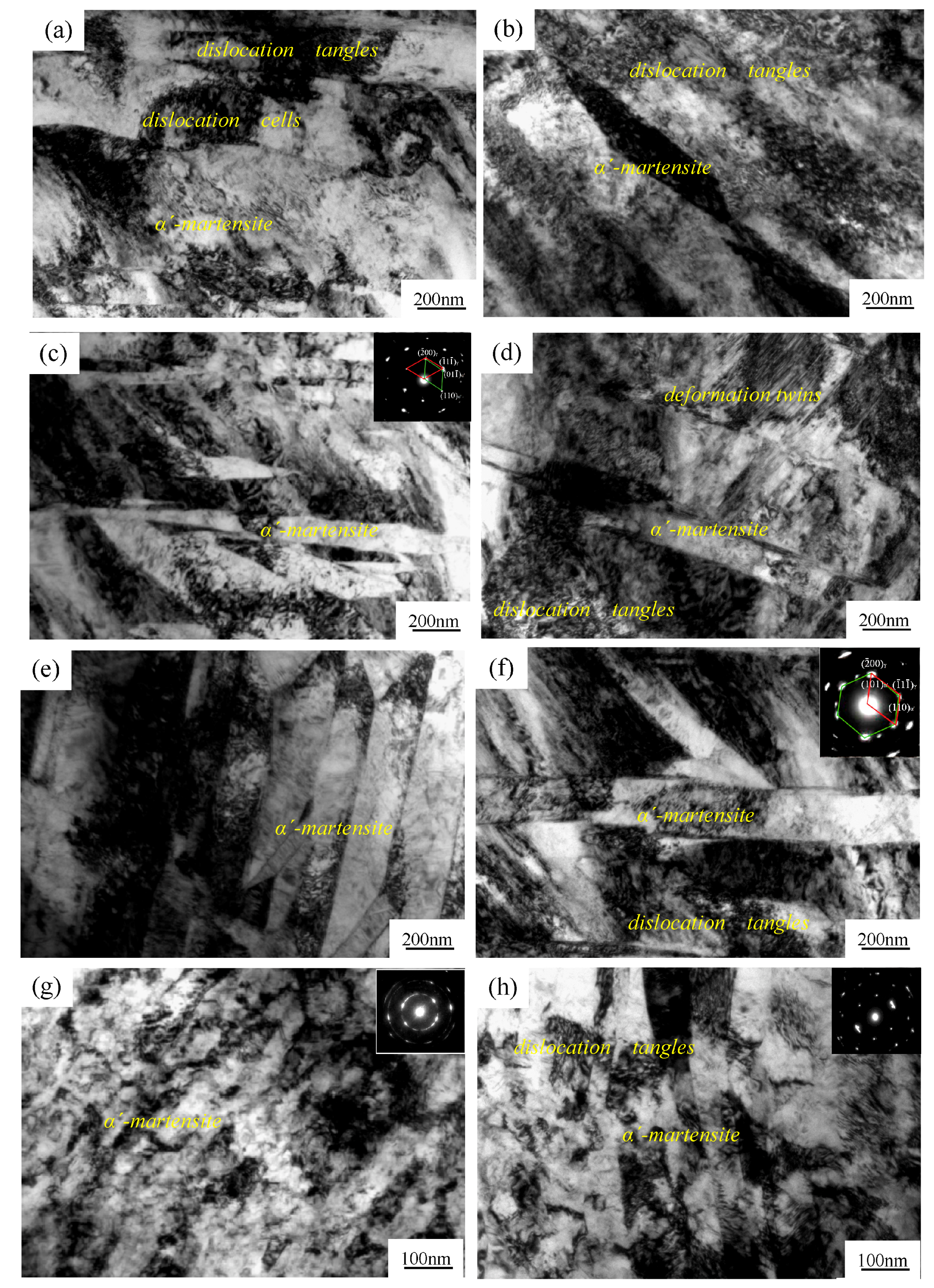

3.2. Microstructural Evolution

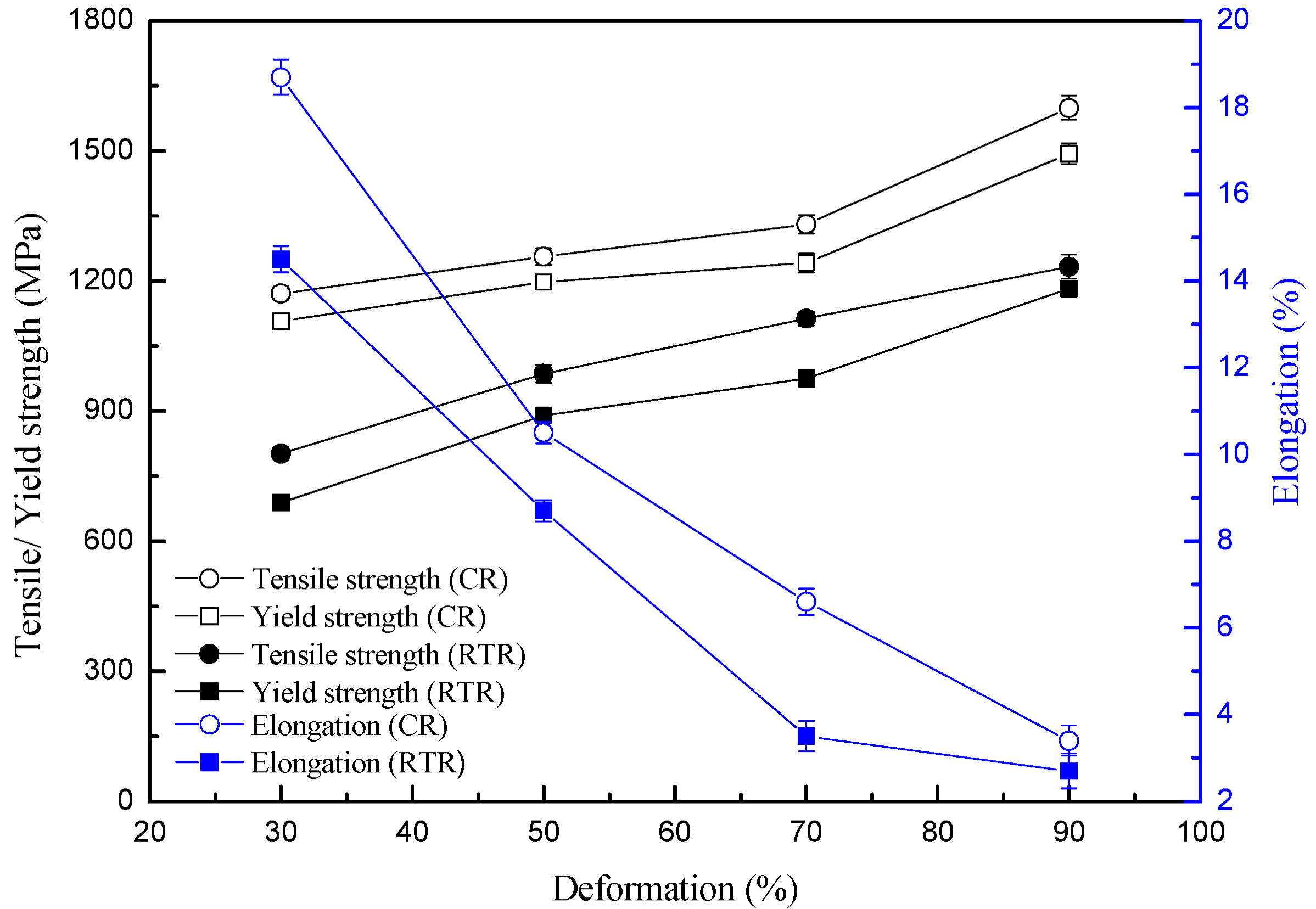

3.3. Mechanical Properties

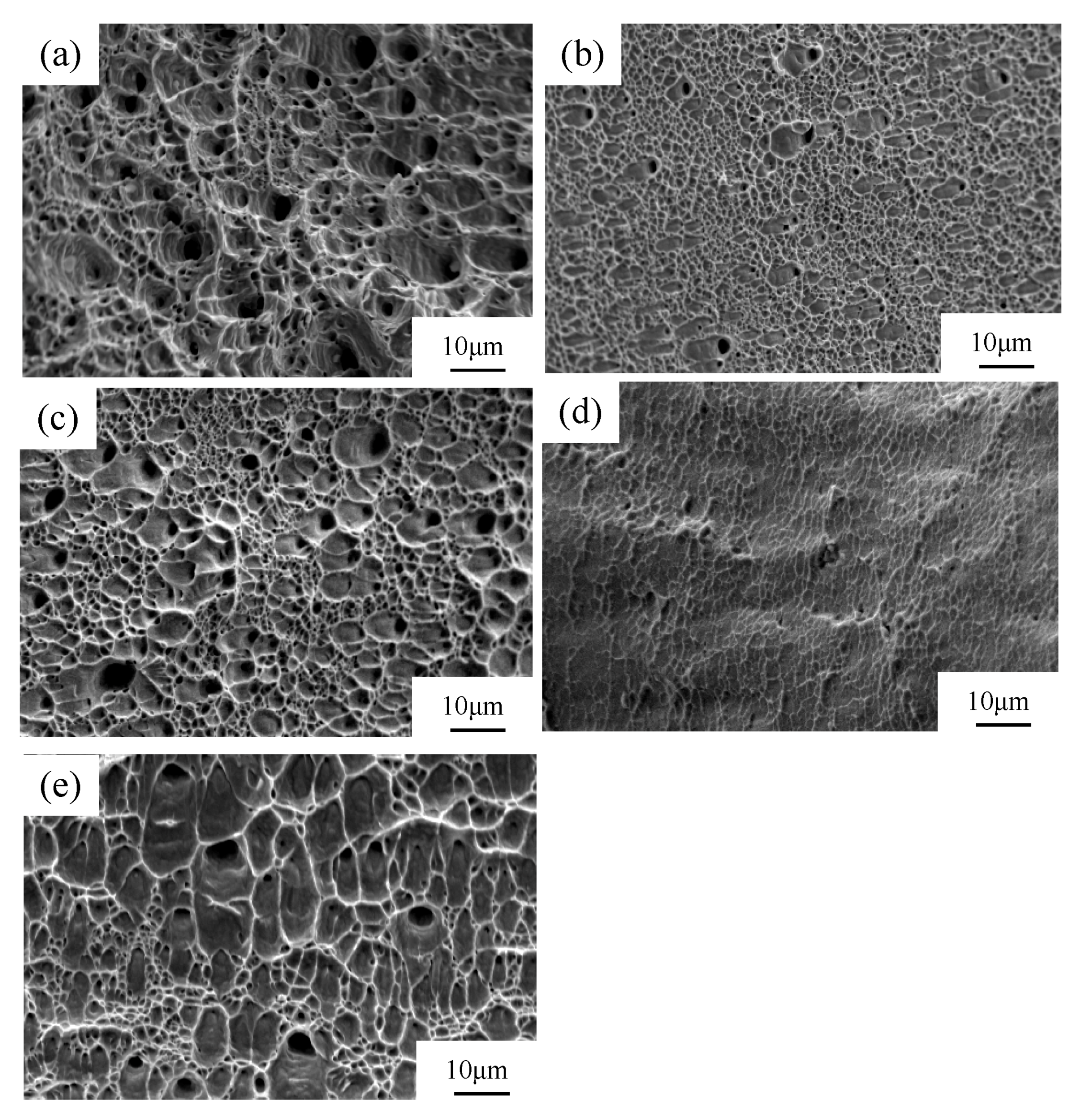

3.4. Fracture Morphology

4. Discussion

5. Conclusions

- Strain-induced martensite transformation occurred in AISI 316LN ASS during the CR and RTR process and the volume fraction of strain-induced martensite increased with the increase of strain. At the same strain, the amount of martensite by CR was obviously higher than that by RTR. The CR was more efficient than the RTR in promoting the martensite transformation and could obtain a 100% volume fraction of α′-martensite. During both rolling processes, the orientations between the transformed martensite and the parent austenite phase followed the Kurdjumov–Sachs relationship and no orientation change was observed due to the influence of deformation temperatures.

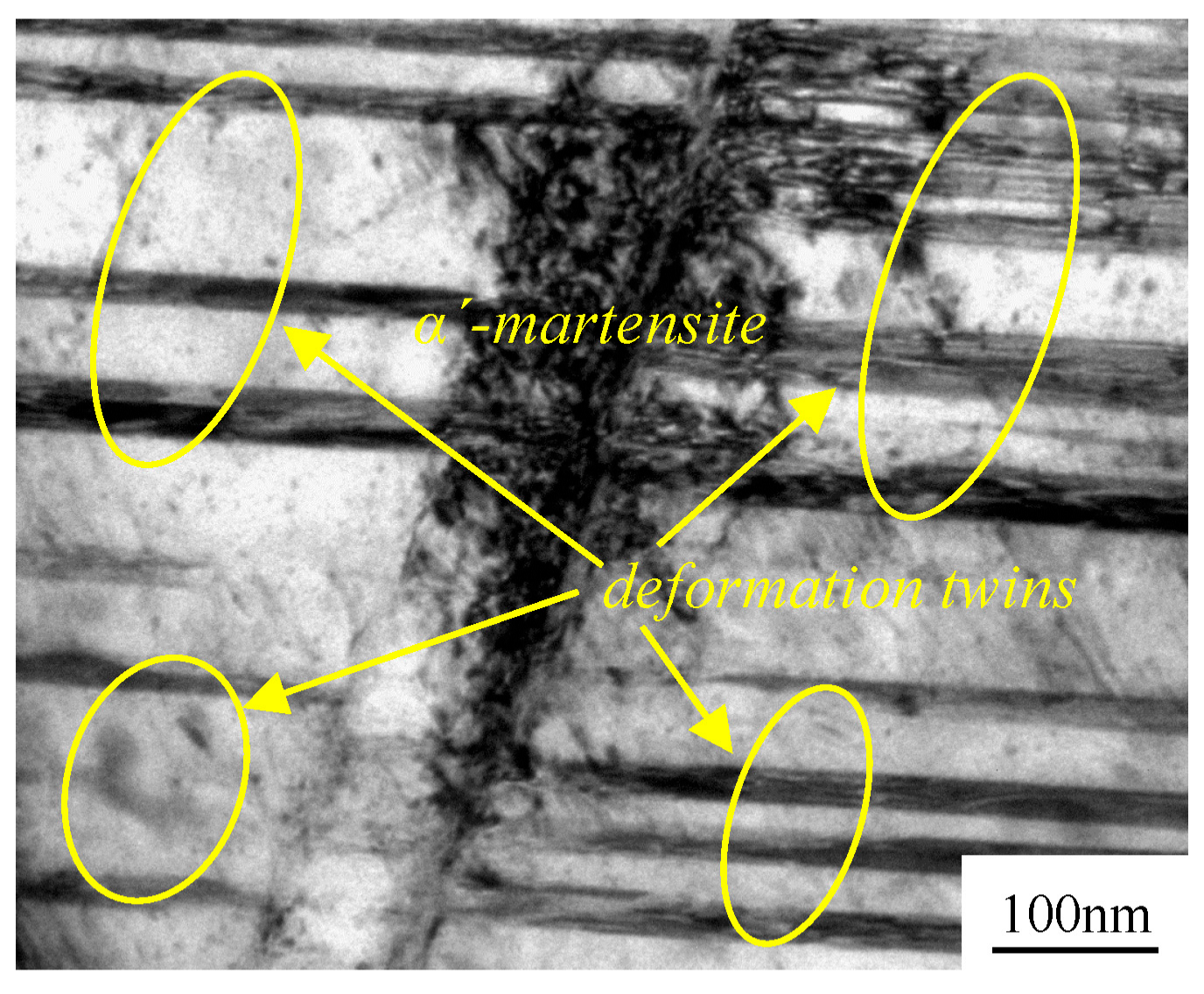

- The phase transition and deformation mechanism differed at the two rolling temperatures. Under the CR condition, the transformation mechanism was based on the deformation of martensite and the sequence of the transformation appeared to be γ-austenite → ε-martensite → α′-martensite. However, the main mechanism was austenite deformation during RTR and the transformation of martensite was γ-austenite → twin → α′-martensite.

- Both CR and RTR led to a remarkable increase in the strength and hardness of the 316LN stainless steel, but to drastic reductions of the elongation. The strength and hardness after CR were higher than those after RTR, but the elongation became lower. After CR or RTR, the tensile fracture morphology changed from a typical ductile rupture (before deformation) to a mixture of quasi-cleavage and ductile fracture (after deformation).

Author Contributions

Funding

Conflicts of Interest

References

- Roy, M.; Martinelli, L.; Ginestar, K.; Favergeon, J.; Moulin, G. Dissolution and oxidation behaviour of various austenitic steels and Ni rich alloys in lead-bismuth eutectic at 520 °C. J. Nucl. Mater. 2016, 468, 153–163. [Google Scholar] [CrossRef]

- Wang, S.L.; Sun, Y.H.; Yang, B.; Zhang, M.X. Grain size control method for the nozzles of AP1000 primary coolant pipes. Nucl. Eng. Des. 2017, 314, 121–130. [Google Scholar] [CrossRef]

- Xu, D.M.; Li, G.Q.; Wan, X.L.; Xiong, R.L.; Xu, G.; Wu, K.M.; Somani, M.C.; Misra, R.D.K. Deformation behavior of high yield strength-high ductility ultrafine-grained 316LN austenitic stainless steel. Mater. Sci. Eng. A 2017, 688, 407–415. [Google Scholar] [CrossRef]

- Eskandari, M.; Najafizadeh, A.; Kermanpur, A. Effect of strain-induced martensite on the formation of nanocrystalline 316L stainless steel after cold rolling and annealing. Mater. Sci. Eng. A 2009, 519, 46–50. [Google Scholar] [CrossRef]

- Hadji, M.; Badji, R. Microstructure and mechanical properties of austenitic stainless steels after cold rolling. J. Mater. Eng. Perform. 2002, 11, 145–151. [Google Scholar] [CrossRef]

- Xiong, Y.; He, T.T.; Wang, J.B.; Lu, Y.; Chen, L.F.; Ren, F.Z.; Liu, Y.L.; Volinsky, A.A. Cryorolling effect on microstructure and mechanical properties of Fe-25Cr-20Ni austenitic stainless steel. Mater. Des. 2015, 88, 398–405. [Google Scholar] [CrossRef]

- Morikawa, T.; Higashida, K. The role of deformation twinning in the formationof a fine-grained structure in cold-rolled 310 steels. J. Mater. Sci. 2006, 41, 2581–2585. [Google Scholar] [CrossRef]

- De Osilva, P.M.; de Abreu, H.F.G.; de Albuquerque, V.H.C.; Neto, P.D.; Tavares, J.M.R.S. Cold deformation effect on the microstructures and mechanical properties of AISI 301LN and 316L stainless steels. Mater. Des. 2011, 32, 605–614. [Google Scholar]

- Haušild, P.; Davydov, V.; Drahokoupil, J.; Landa, M.; Pilvin, P. Characterization of strain-induced martensitic transformation in a metastable austenitic stainless steel. Mater. Des. 2010, 31, 1821–1827. [Google Scholar] [CrossRef]

- Manjanna, J.; Kobayashi, S.; Kamada, Y.; Takahashi, S.; Kikuchi, H. Martensitic transformation in SUS 316LN austenitic stainless steel at RT. J. Mater. Sci. 2008, 43, 2659–2665. [Google Scholar] [CrossRef]

- Lebedev, A.A.; Kosarchuk, V.V. Influence of phase transformations on the mechanical properties of austenitic stainless steels. Int. J. Plast. 2000, 16, 749–767. [Google Scholar] [CrossRef]

- Powell, G.W.; Marshall, E.R.; Backofen, W.A. Strain hardening of austenitic stainless steel. ASM Trans 1958, 50, 478–497. [Google Scholar]

- Eskandari, M.; Hanzaki, A.Z.; Abedi, H.R. An investigation into the room temperature mechanical properties of nanocrystalline austenitic stainless steels. Mater. Des. 2013, 45, 674–681. [Google Scholar] [CrossRef]

- Xiong, Y.; Yue, Y.; Lu, Y.; He, T.T.; Fan, M.X.; Ren, F.Z.; Cao, W. Cryorolling impacts on microstructure and mechanical properties of AISI316 LN austenitic stainless steel. Mater. Sci. Eng. A 2018, 709, 270–276. [Google Scholar] [CrossRef]

- Sabooni, S.; Karimzadeh, F.; Enayati, M.H.; Ngan, A.H.W. The role of martensitic transformation on bimodal grain structure in ultrafine grained AISI304L stainless steel. Mater. Sci. Eng. A 2015, 636, 221–230. [Google Scholar] [CrossRef]

- Roy, B.; Kumar, R.; Das, J. Effect of cryorolling on the microstructure and tensile properties of bulk nano-austenitic stainless steel. Mater. Sci. Eng. A 2015, 63, 1241–1247. [Google Scholar] [CrossRef]

- Sabooni, S.; Karimzadeh, F.; Enayati, M.H. Thermalstability study of ultrafine grained 304L stainless steel produced by martensitic process. J. Mater. Eng. Perform. 2014, 23, 1665–1672. [Google Scholar] [CrossRef]

- Hedayati, A.; Najafizadeh, A.; Kermanpur, A.; Forouzan, F. The effect of cold rolling regime on microstructure and mechanical properties of AISI 304L stainless steel. J. Mater. Process. Technol. 2010, 210, 1017–1022. [Google Scholar] [CrossRef]

- Xu, J.L.; Huang, H.W.; Zhao, M.C.; Wang, Z.B.; Lu, K. Processes of deformation-induced martensite transformation and microstructure refinement of 316L stainless steel during surface mechanical rolling treatment. Chin. J. Mater. Res. 2016, 30, 15–22. [Google Scholar]

- Xu, D.M.; Li, G.Q.; Wan, X.L.; Misra, R.D.K.; Zhang, X.G.; Xu, G.; Wu, K.M. The effect of annealing on the microstructural evolution and mechanical properties in phase reversed 316LN austenitic stainless steel. Mater. Sci. Eng. A 2018, 720, 36–48. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Kinetics of strain-induced martensitic nucleation. Met. Trans. 1975, 6A, 791–795. [Google Scholar] [CrossRef]

- Sato, K.; Ichinose, M.; Hirotsu, Y.; Inoue, Y. Effects of deformation induced phase transformation and twinning on the mechanical properties of austenitic Fe-Mn-Al alloys. ISIJ Int. 1989, 29, 868–877. [Google Scholar] [CrossRef]

- Compilations Group of “Mechanical Property of Metal”, Mechanical Property of Metals; Mechanical Industry Press: Beijing, China, 1982; p. 230. (In Chinese)

- Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T. The morphology and crystallography of lath martensite in Fe-C alloys. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Sato, A.; Soma, K.; Mori, T. Hardening due to pre-existing ε-Martensite in an Fe-30Mn-1Si alloy single crystal. Acta Met. 1982, 30, 1901–1907. [Google Scholar] [CrossRef]

- Seetharaman, V.; Krishnan, R. Influence of the martensitic transformation on the deformation behaviour of an AISI 316 stainless steel at low temperatures. J. Mater. Sci. 1981, 16, 523–530. [Google Scholar] [CrossRef]

- Goodchild, D.; Roberts, W.T.; Wilson, D.V. Plastic deformation and phase transformation in textured austenitic stainless steel. Acta Met. 1970, 18, 1137–1145. [Google Scholar] [CrossRef]

- Byun, T.S.; Lee, E.H.; Hunn, J.D. Plastic deformation in 316LN stainlesssteel-characterization of deformation microstructures. J. Nucl. Mater. 2003, 321, 29–39. [Google Scholar] [CrossRef]

- Choi, J.Y.; Lee, J.; Lee, K.; Koh, J.Y.; Cho, J.H.; Han, H.N.; Park, K.T. Effects of the strain rate on the tensile properties of a TRIP-aided duplex stainless steel. Mater. Sci. Eng. A 2016, 666, 280–287. [Google Scholar] [CrossRef]

- Zou, D.Q.; Li, S.H.; He, J. Temperature and strain rate dependent deformation induced martensitic transformation and flow behavior of quenching and partitioning steels. Mater. Sci. Eng. A 2017, 680, 54–63. [Google Scholar] [CrossRef]

- Sinclair, C.W.; Hoagland, R.G. A molecular dynamics study of the fcc→bcc transformation at fault intersections. Acta Mater. 2008, 56, 4160–4171. [Google Scholar] [CrossRef]

- Talonen, J.; Hänninen, H. Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater. 2007, 55, 6108–6118. [Google Scholar] [CrossRef]

- Xu, Z.Y. Martensite Transformation and Martensite; China Science Press: Beijing, China, 1980; p. 1. (In Chinese) [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Y.; Yue, Y.; He, T.; Lu, Y.; Ren, F.; Cao, W. Effect of Rolling Temperature on Microstructure Evolution and Mechanical Properties of AISI316LN Austenitic Stainless Steel. Materials 2018, 11, 1557. https://doi.org/10.3390/ma11091557

Xiong Y, Yue Y, He T, Lu Y, Ren F, Cao W. Effect of Rolling Temperature on Microstructure Evolution and Mechanical Properties of AISI316LN Austenitic Stainless Steel. Materials. 2018; 11(9):1557. https://doi.org/10.3390/ma11091557

Chicago/Turabian StyleXiong, Yi, Yun Yue, Tiantian He, Yan Lu, Fengzhang Ren, and Wei Cao. 2018. "Effect of Rolling Temperature on Microstructure Evolution and Mechanical Properties of AISI316LN Austenitic Stainless Steel" Materials 11, no. 9: 1557. https://doi.org/10.3390/ma11091557

APA StyleXiong, Y., Yue, Y., He, T., Lu, Y., Ren, F., & Cao, W. (2018). Effect of Rolling Temperature on Microstructure Evolution and Mechanical Properties of AISI316LN Austenitic Stainless Steel. Materials, 11(9), 1557. https://doi.org/10.3390/ma11091557