Microstructures and Compressive Properties of Al Matrix Composites Reinforced with Bimodal Hybrid In-Situ Nano-/Micro-Sized TiC Particles

Abstract

:1. Introduction

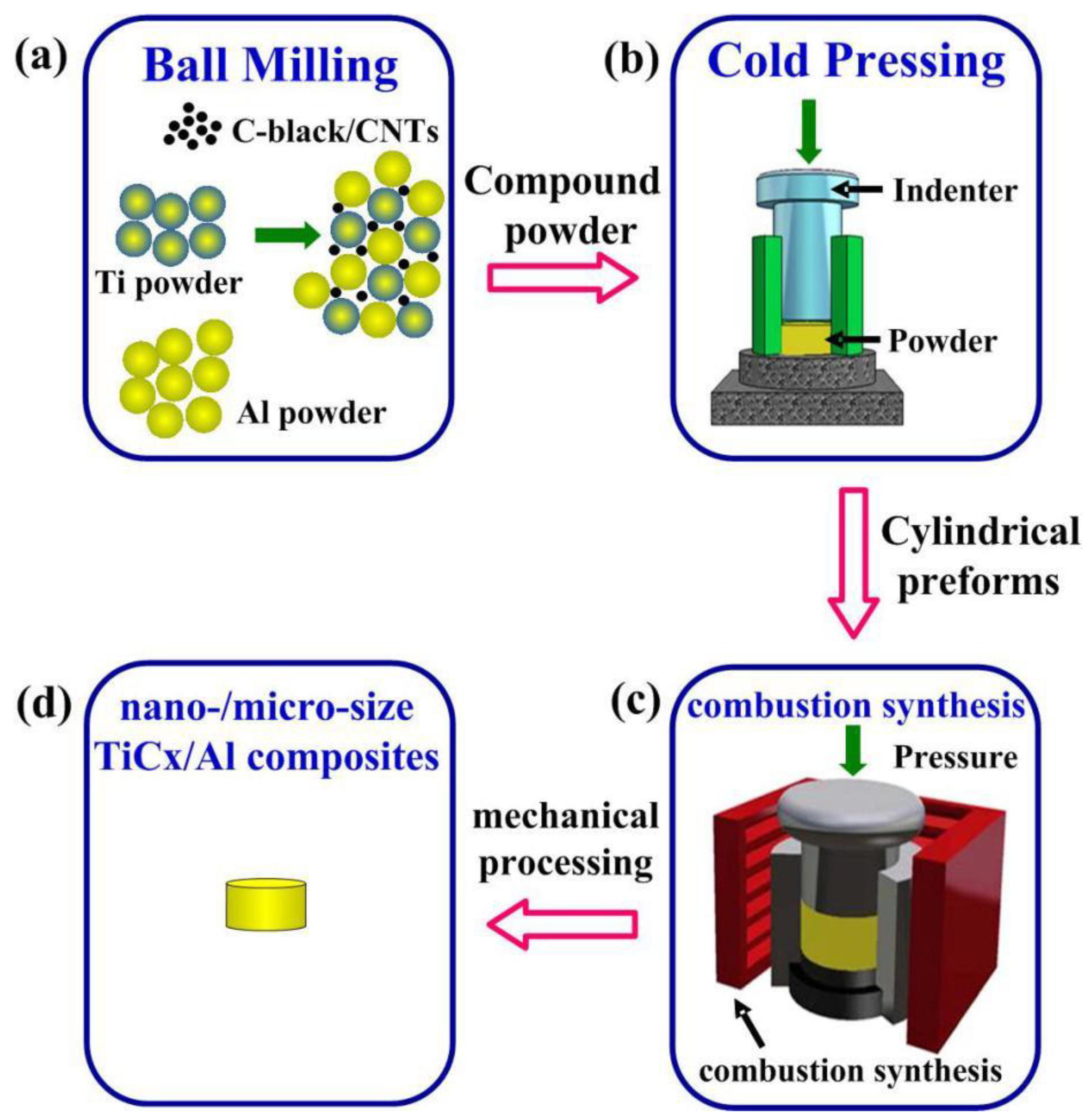

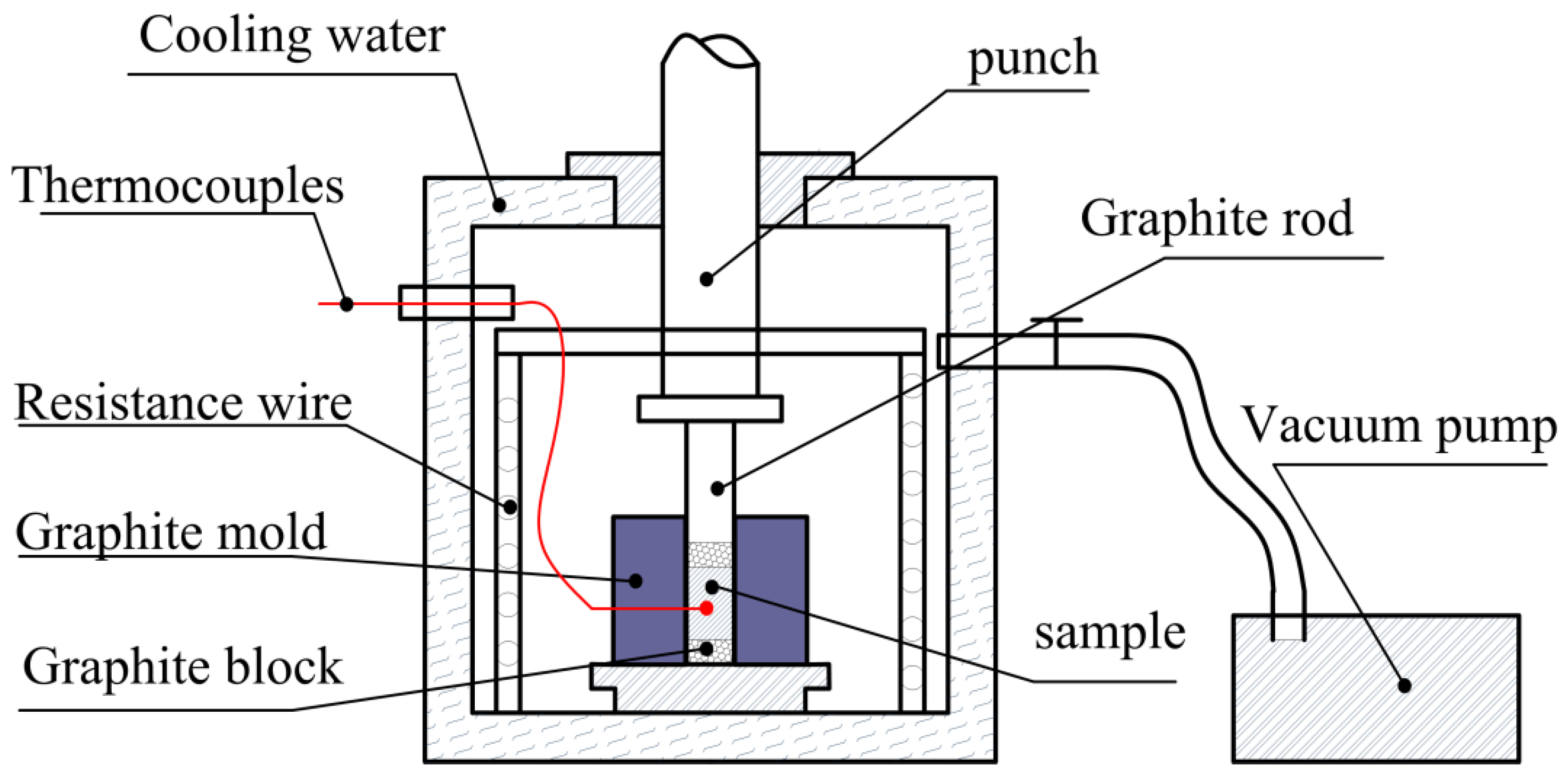

2. Materials and Methods

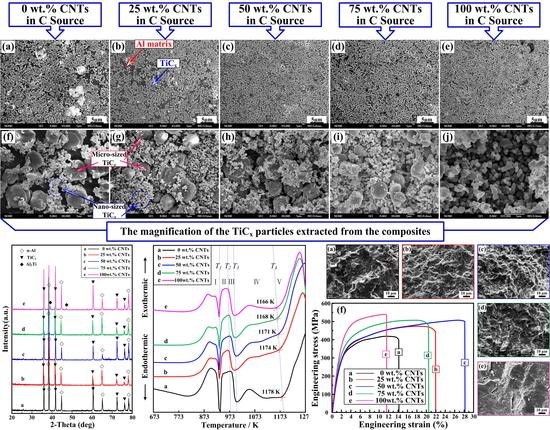

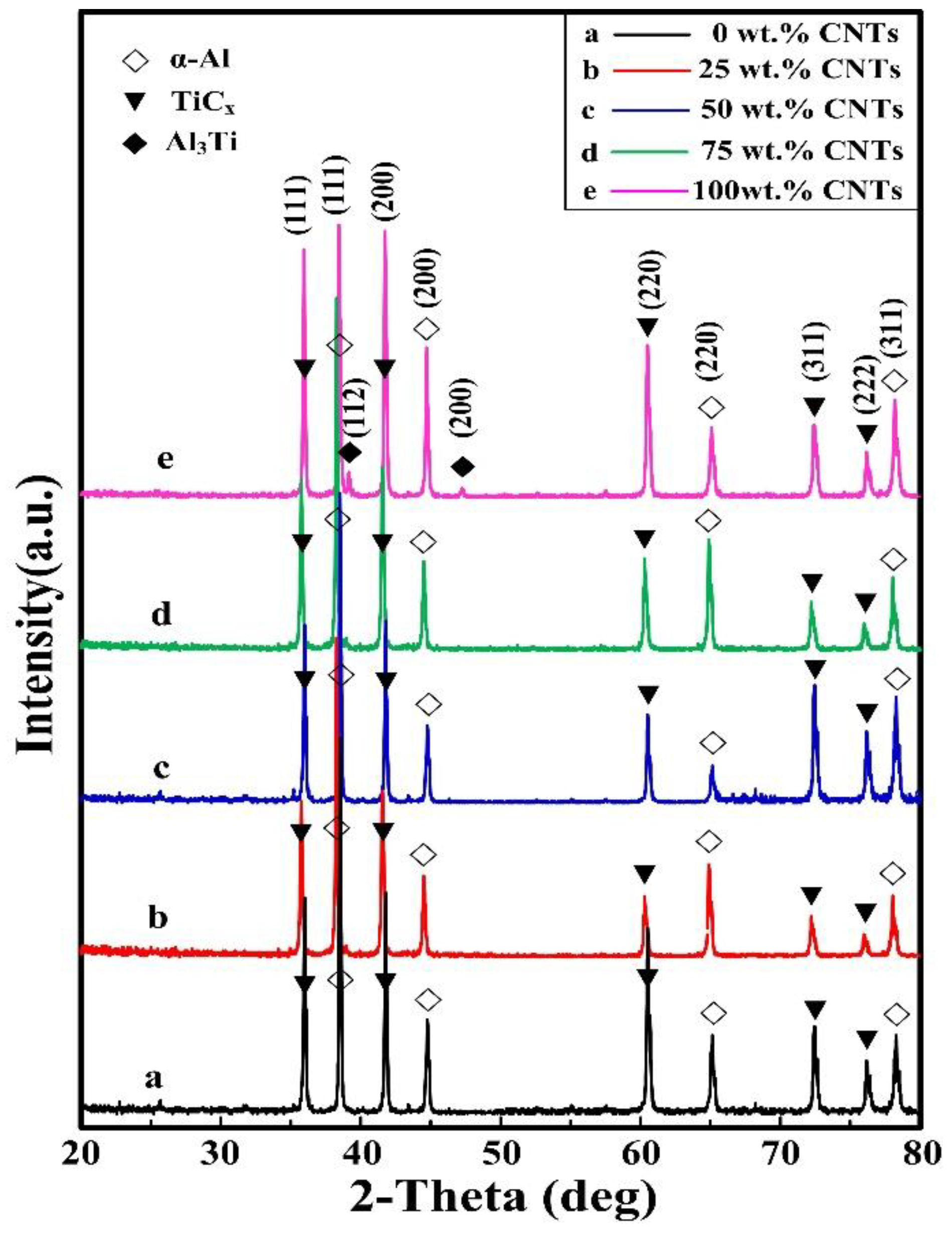

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zhao, Q.; Liang, Y.H.; Zhang, Z.H.; Li, X.J.; Ren, L.Q. Study on the Impact Resistance of Bionic Layered Composite of TiC-TiB2/Al from Al-Ti-B4C System. Materials 2016, 9, 708. [Google Scholar] [CrossRef] [PubMed]

- Hekner, B.; Myalski, J.; Pawlik, T.; Sopicka-Lizer, M. Effect of carbon in fabrication Al-SiC nanocomposites for tribological application. Materials 2017, 10, 679. [Google Scholar] [CrossRef] [PubMed]

- Shu, S.L.; Yang, H.Y.; Tong, C.Z.; Qiu, F. Fabrication of TiCx-TiB2/Al composites for application as a Heat Sink. Materials 2016, 9, 642. [Google Scholar] [CrossRef] [PubMed]

- Przestacki, D. Conventional and laser assisted machining of composite A359/20SiCp. Procedia CIRP 2014, 14, 229–233. [Google Scholar] [CrossRef]

- Zhang, L.J.; Yang, D.L.; Qiu, F.; Wang, J.G.; Jiang, Q.C. Effects of reinforcement surface modification on the microstructures and tensile properties of SiCp/Al2014 composites. Mater. Sci. Eng. A 2015, 624, 102–109. [Google Scholar] [CrossRef]

- Yang, D.L.; Qiu, F.; Lei, Z.K.; Zhao, Q.L.; Jiang, Q.C. The interfacial structure and mechanical properties of Ti5Si3-coated SiCP/Al2014 composites fabricated by powder metallurgy with hot pressing. Mater. Sci. Eng. A 2015, 661, 217–221. [Google Scholar] [CrossRef]

- Guo, R.F.; Shen, P.; Sun, C.; Wang, Y.; Shaga, A.; Jiang, Q.C. Processing and mechanical properties of lamellar-structured Al–7Si–5Cu/TiC composites. Mater. Des. 2016, 106, 446–453. [Google Scholar] [CrossRef]

- Kennedy, A.R.; Karantzalis, A.E.; Wyatt, S.M. The microstructure and mechanical properties of TiCx and TiB2-reinforced cast metal matrix composites. J. Mater. Sci. 1999, 34, 933–940. [Google Scholar] [CrossRef]

- Przestacki, D.; Szymanski, P.; Wojciechowski, S. Formation of surface layer in metal matrix composite A359/20SiCP during laser assisted turning. Compos. Part. A 2016, 91, 370–379. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Löber, L.; Wang, P.; Attara, H.; Schimansky, F.P.; Pyczak, F.; Eckert, J. Processing of Al–12Si–TNM composites by selective laser melting and evaluation of compressive and wear properties. J. Mater. Res. 2016, 31, 55–65. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Shakur Shahabi, H.; Attara, H.; Srivastava, V.C.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J.; Scudino, S. Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Attara, H.; Haghighi, S.E.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. Int. J. Mach. Tools Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Hong, S.H.; Chung, K.H. Effects of vacuum hot pressing parameters on the tensile properties and microstructures of SiC-2124 Al composites. Mater. Sci. Eng. A 1995, 194, 165–170. [Google Scholar] [CrossRef]

- Li, G.R.; Zhao, Y.T.; Wang, H.M.; Chen, G.; Dai, Q.X.; Cheng, X.N. Fabrication and properties of in situ (Al3Zr + Al2O3)p/A356 composites cast by permanent mould and squeeze casting. J. Alloys Compd. 2009, 471, 530–535. [Google Scholar] [CrossRef]

- Zhu, H.; Min, J.; Ai, Y.L.; Chu, D.; Wang, H.; Wang, H.Z. The reaction mechanism and mechanical properties of the composites fabricated in an Al-ZrO2-C system. Mater. Sci. Eng. A 2010, 527, 6178–6183. [Google Scholar] [CrossRef]

- Shu, S.L.; Lu, J.B.; Qiu, F.; Xuan, Q.Q.; Jiang, Q.C. Effects of alloy elements (Mg, Zn, Sn) on the microstructures and compression properties of high-volume-fraction TiCx/Al composites. Scripta Mater. 2010, 63, 1209–1211. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Ouyang, L.C.; Wang, H.Y.; Zha, M.; Shu, S.L.; Zhao, Q.L.; Jiang, Q.C. A Novel Approach of Using Ground CNTs as the Carbon source to fabricate uniformly distributed nano-sized TiCx/2009Al composites. Materials 2015, 8, 8839–8849. [Google Scholar] [CrossRef] [PubMed]

- Rahimian, M.; Ehsani, N.; Parvin, N.; Baharvandi, H.R. The effect of particle size, sintering temperature and sintering time on the properties of Al-Al2O3 composites made by powder metallurgy. J. Mater. Process. Technol. 2009, 209, 5387–5393. [Google Scholar] [CrossRef]

- Zhou, Y.; Yu, Z.Y.; Zhao, N.Q.; Shi, C.S.; Liu, E.Z.; Du, X.W.; He, C.N. Microstructure and properties of in situ generated MgAl2O4 spinel whisker reinforced aluminum matrix composites. Mater. Des. 2013, 46, 724–730. [Google Scholar] [CrossRef]

- Chen, L.Y.; Xu, J.Q.; Choi, H.S.; Pozuelo, M.; Ma, X.L.; Bhowmick, S.; Yang, J.M.; Mathaudhu, S.; Li, X.C. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539–543. [Google Scholar] [CrossRef] [PubMed]

- Bahrami, M.; Helmi, N.; Dehghani, K.; Besharati-Givi, M.K. Exploring the effects of SiC reinforcement incorporation on mechanical properties of friction stir welded 7075 aluminum alloy: Fatigue life, impact energy, tensile strength. Mater. Sci. Eng. A 2014, 595, 173–178. [Google Scholar] [CrossRef]

- Tjong, S.C. Novel Nanoparticle-Reinforced Metal Matrix Composites with Enhanced Mechanical Properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Akbari, M.K.; Baharvandi, H.R.; Shirvanimoghaddam, K. Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites. Mater. Des. 2015, 66, 150–161. [Google Scholar] [CrossRef]

- Shen, M.J.; Wang, X.J.; Zhang, M.F.; Zheng, M.Y.; Wu, K. Significantly improved strength and ductility in bimodal-size grained microstructural magnesium matrix composites reinforced by bimodal sized SiCp over traditional magnesium matrix composites. Compos. Sci. Technol. 2015, 118, 85–93. [Google Scholar] [CrossRef]

- Zhang, L.J.; Qiu, F.; Wang, J.G.; Wang, H.Y.; Jiang, Q.C. Microstructures and mechanical properties of the Al2014 composites reinforced with bimodal sized SiC particles. Mater. Sci. Eng. A 2015, 637, 70–74. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Liu, J.Y.; Wang, H.Y.; Wang, J.G.; Zhu, L.; Jiang, Q.C. Microstructure and tensile properties of in situ synthesized nano-sized TiCx/2009Al composites. Mater. Des. 2015, 79, 68–72. [Google Scholar] [CrossRef]

- Jin, S.B.; Shen, P.; Zhou, D.S.; Jiang, Q.C. Self-propagating high-temperature synthesis of nano-TiCx particles with different shapes by using carbon nano-tube as C source. Nanoscale Res. Lett. 2011, 6, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Qiu, F.; Shu, S.L.; Zhao, Q.L.; Jiang, Q.C. Effects of different carbon sources on the compressive properties of in situ high-volumefraction TiCx/2009Al composites. Powder Metall. 2016, 59, 370–375. [Google Scholar] [CrossRef]

- Choi, Y.; Rhee, S.W. Effect of carbon sources on the combustion synthesis of TiC. J. Mater. Sci. 1995, 30, 4637–4644. [Google Scholar] [CrossRef]

- Charlier, J.C. Defects in carbon nanotubes. Acc. Chem. Res. 2002, 35, 1063–1069. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.B.; Shen, P.; Zou, B.L.; Jiang, Q.C. Morphology evolution of TiCx grains during SHS in an Al−Ti−C system. Cryst. Growth Des. 2009, 9, 646–649. [Google Scholar] [CrossRef]

- Song, M.S.; Huang, B.; Huo, Y.Q.; Zhang, S.G.; Zhang, M.X.; Hu, Q.D.; Li, J.G. Growth of TiC octahedron obtained by self-propagating reaction. J. Cryst. Growth 2009, 311, 378–382. [Google Scholar] [CrossRef]

- Tian, W.S.; Zhao, Q.L.; Zhang, Q.Q.; Qiu, F.; Jiang, Q.C. Enhanced strength and ductility at room and elevated temperatures of Al-Cu alloy matrix composites reinforced with bimodal-sized TiCp compared with monomodal–sized TiCp. Mater. Sci. Eng. A 2018, 724, 368–375. [Google Scholar] [CrossRef]

| Samples | Composition of Mixed Raw Material Powders |

|---|---|

| 30 vol. % TiC/Al (0 wt. % CNTs) | 70 wt. % Al + 24 wt. % Ti + (6.0 wt. % C black + 0.0 wt. % CNTs) |

| 30 vol. % TiC/Al (25 wt. % CNTs) | 70 wt. % Al + 24 wt. % Ti + (4.5 wt. % C black + 1.5 wt. % CNTs) |

| 30 vol. % TiC/Al (50 wt. % CNTs) | 70 wt. % Al + 24 wt. % Ti + (3.0 wt. % C black + 3.0 wt. % CNTs) |

| 30 vol. % TiC/Al (75 wt. % CNTs) | 70 wt. % Al + 24 wt. % Ti + (1.5 wt. % C black + 4.5 wt. % CNTs) |

| 30 vol. % TiC/Al (100 wt. % CNTs) | 70 wt. % Al + 24 wt. % Ti + (0.0 wt. % C black + 6.0 wt. % CNTs) |

| C/CNTs Ratios | Micro-Size of TiC (μm) | Nano-Size of TiC (nm) | Volume Ratios (%) |

|---|---|---|---|

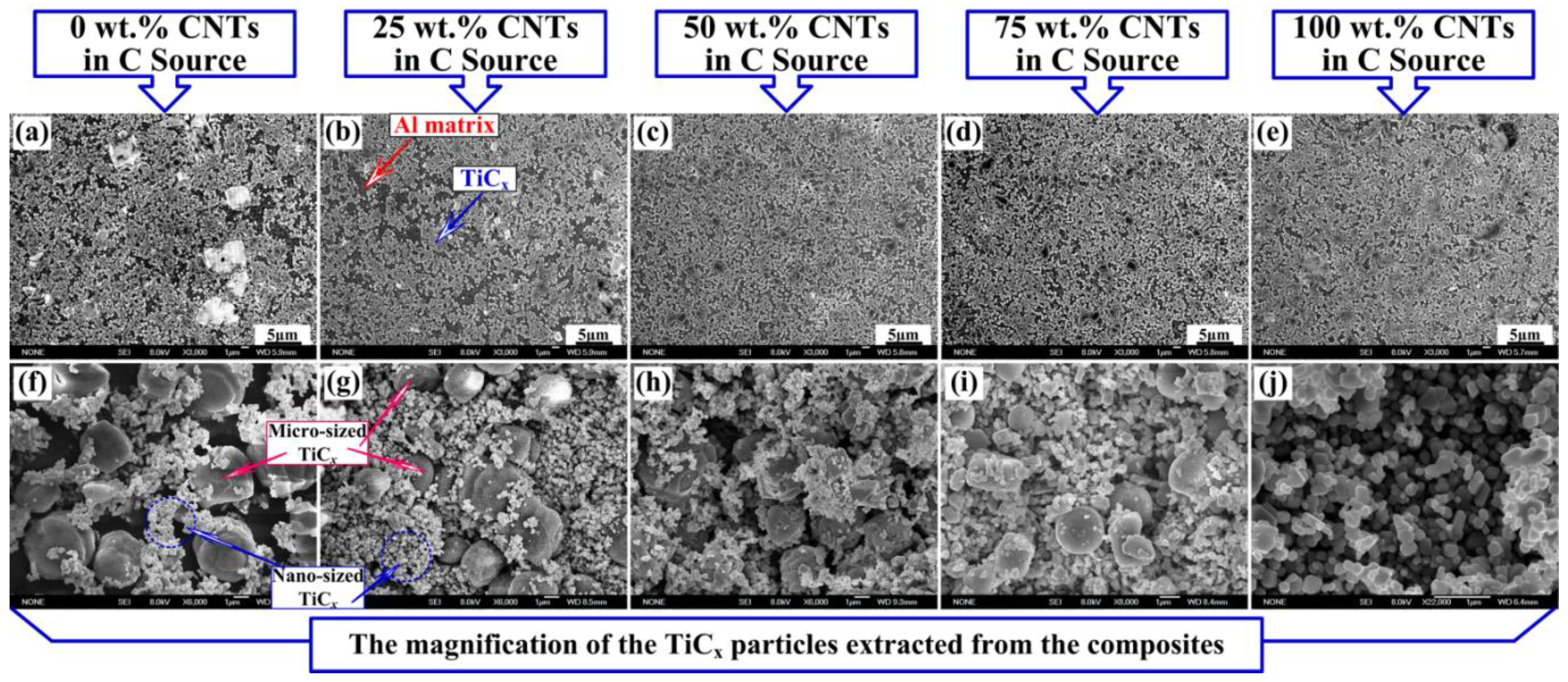

| C | 3.44 | 265.31 | 59.19 |

| 3:1 | 2.43 | 250.08 | 44.72 |

| 1:1 | 1.94 | 240.86 | 37.14 |

| 1:3 | 1.25 | 233.04 | 5.362 |

| CNTs | --- | 175.25 | 0.0 |

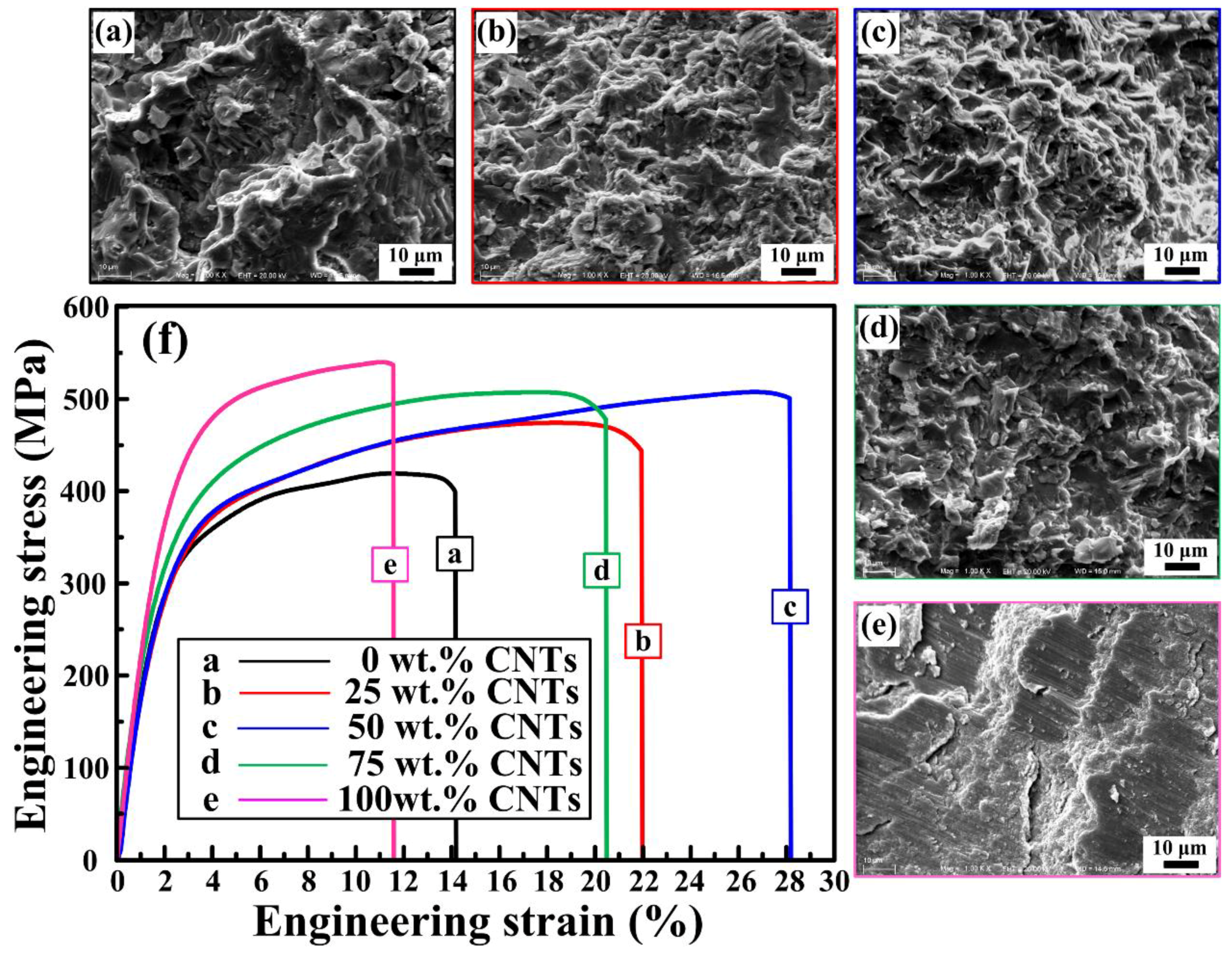

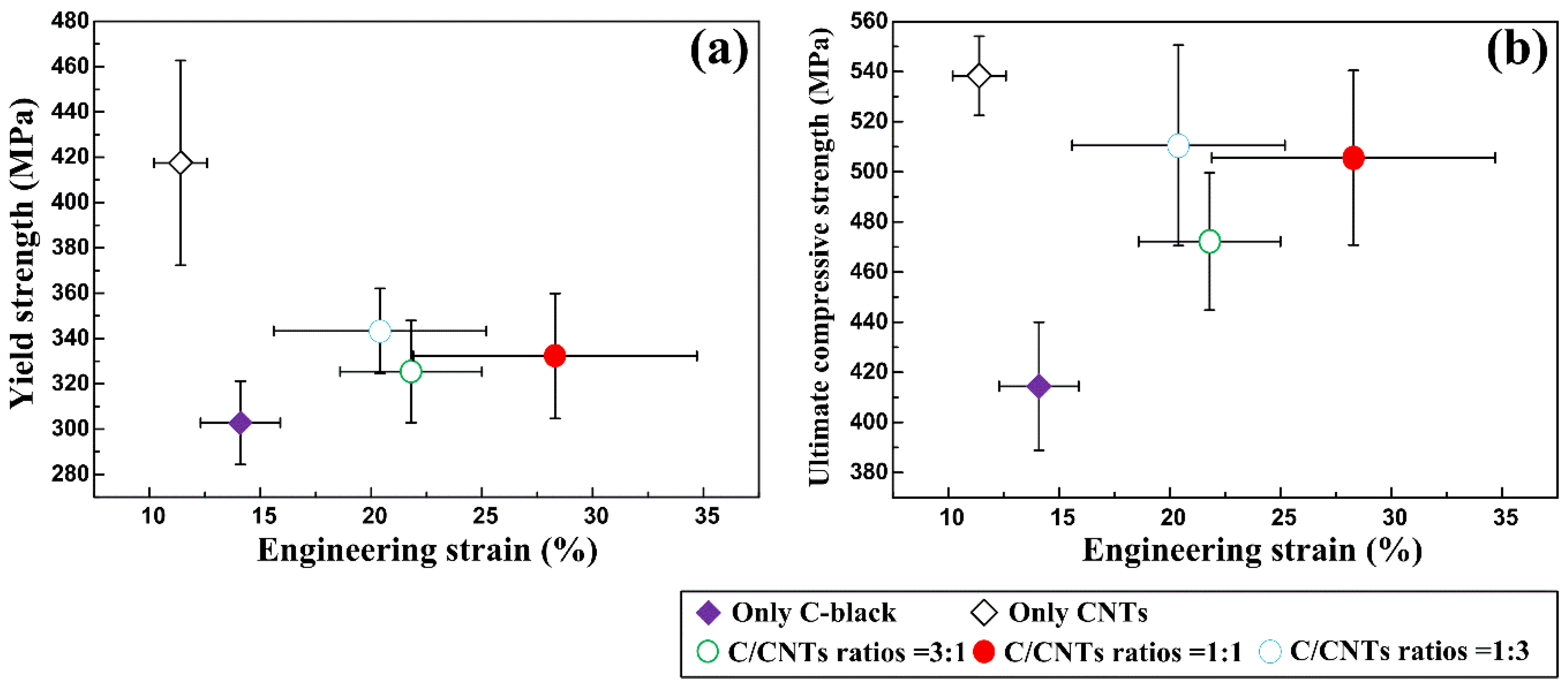

| C/CNTs Ratios | σ0.2 (MPa) | σUCS (MPa) | εf (%) |

|---|---|---|---|

| C | 302.8 ± 18.4 | 414.4 ± 25.6 | 14.1 ± 1.8 |

| 3:1 | 325.4 ± 22.5 | 472.2 ± 27.4 | 21.8 ± 3.2 |

| 1:1 | 332.3 ± 27.6 | 505.6 ± 34.8 | 28.3 ± 6.4 |

| 1:3 | 343.2 ± 18.8 | 510.5 ± 40.0 | 20.4 ± 4.8 |

| CNTs | 417.5 ± 45.2 | 538.3 ± 15.8 | 11.4 ± 1.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, F.; Tong, H.-T.; Gao, Y.-Y.; Zou, Q.; Dong, B.-X.; Li, Q.; Chu, J.-G.; Chang, F.; Shu, S.-L.; Jiang, Q.-C. Microstructures and Compressive Properties of Al Matrix Composites Reinforced with Bimodal Hybrid In-Situ Nano-/Micro-Sized TiC Particles. Materials 2018, 11, 1284. https://doi.org/10.3390/ma11081284

Qiu F, Tong H-T, Gao Y-Y, Zou Q, Dong B-X, Li Q, Chu J-G, Chang F, Shu S-L, Jiang Q-C. Microstructures and Compressive Properties of Al Matrix Composites Reinforced with Bimodal Hybrid In-Situ Nano-/Micro-Sized TiC Particles. Materials. 2018; 11(8):1284. https://doi.org/10.3390/ma11081284

Chicago/Turabian StyleQiu, Feng, Hao-Tian Tong, Yu-Yang Gao, Qian Zou, Bai-Xin Dong, Qiang Li, Jian-Ge Chu, Fang Chang, Shi-Li Shu, and Qi-Chuan Jiang. 2018. "Microstructures and Compressive Properties of Al Matrix Composites Reinforced with Bimodal Hybrid In-Situ Nano-/Micro-Sized TiC Particles" Materials 11, no. 8: 1284. https://doi.org/10.3390/ma11081284

APA StyleQiu, F., Tong, H.-T., Gao, Y.-Y., Zou, Q., Dong, B.-X., Li, Q., Chu, J.-G., Chang, F., Shu, S.-L., & Jiang, Q.-C. (2018). Microstructures and Compressive Properties of Al Matrix Composites Reinforced with Bimodal Hybrid In-Situ Nano-/Micro-Sized TiC Particles. Materials, 11(8), 1284. https://doi.org/10.3390/ma11081284