Electrodeposition of p-Type Sb2Te3 Films and Micro-Pillar Arrays in a Multi-Channel Glass Template

Abstract

1. Introduction

2. Materials and Methods

3. Results

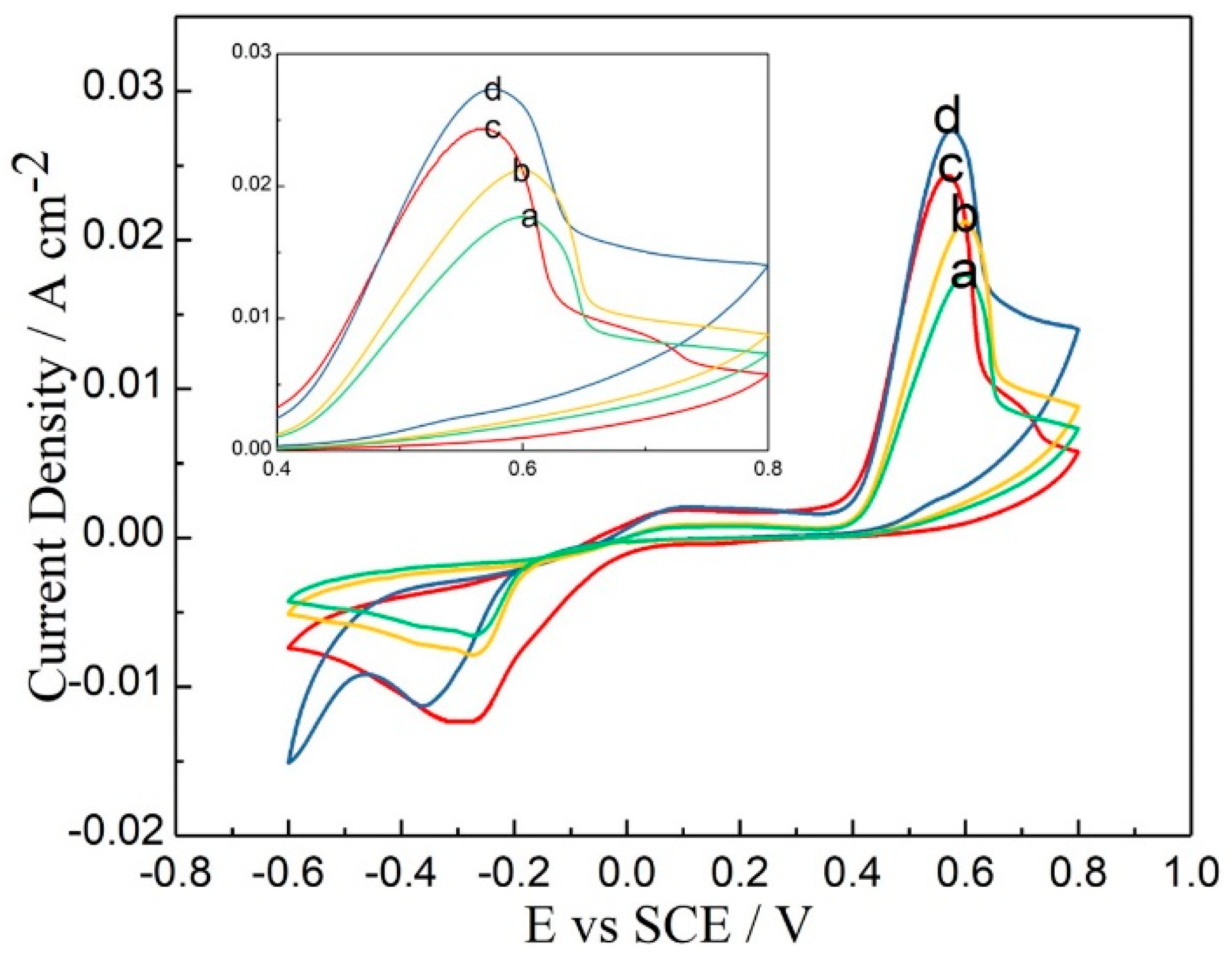

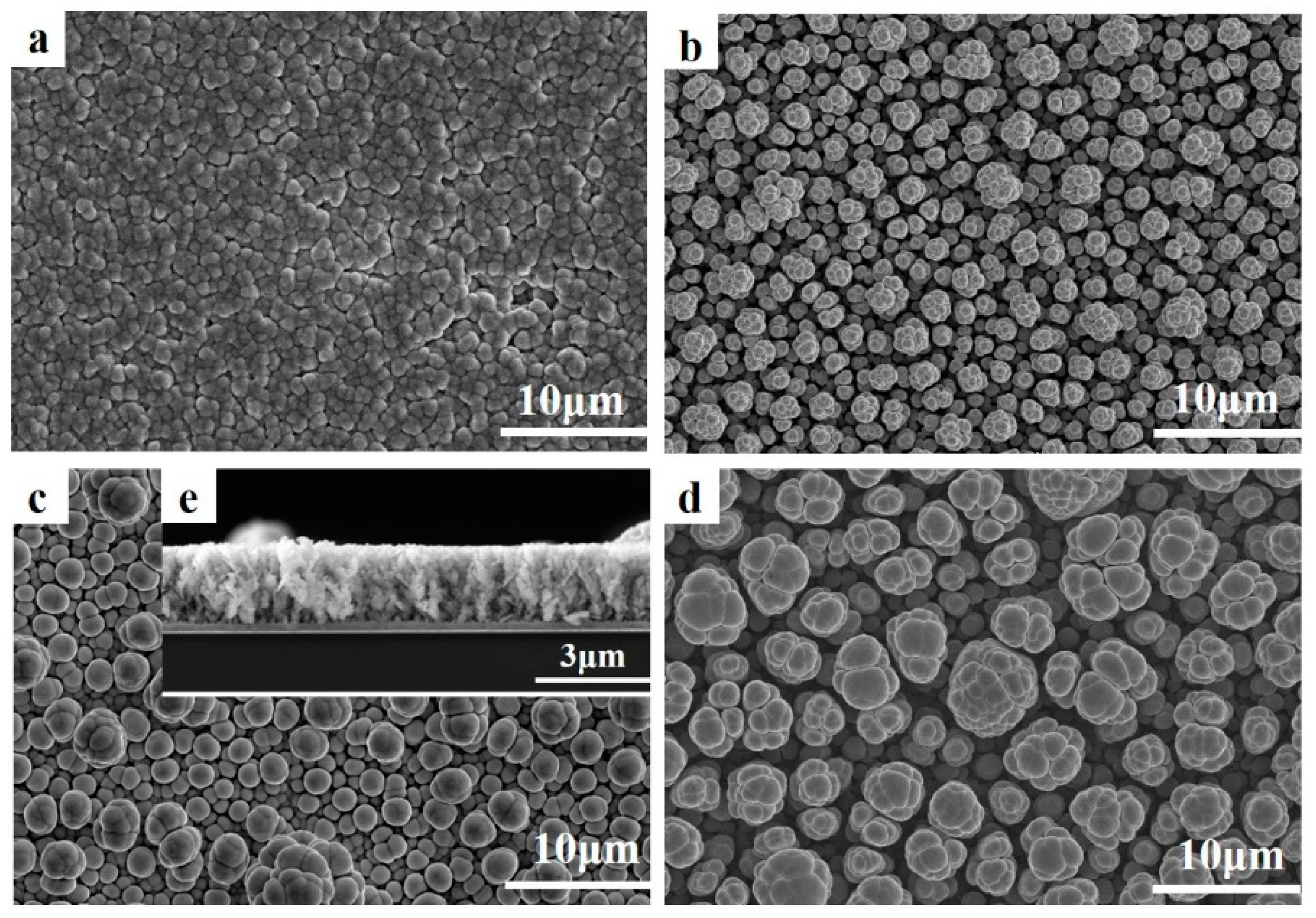

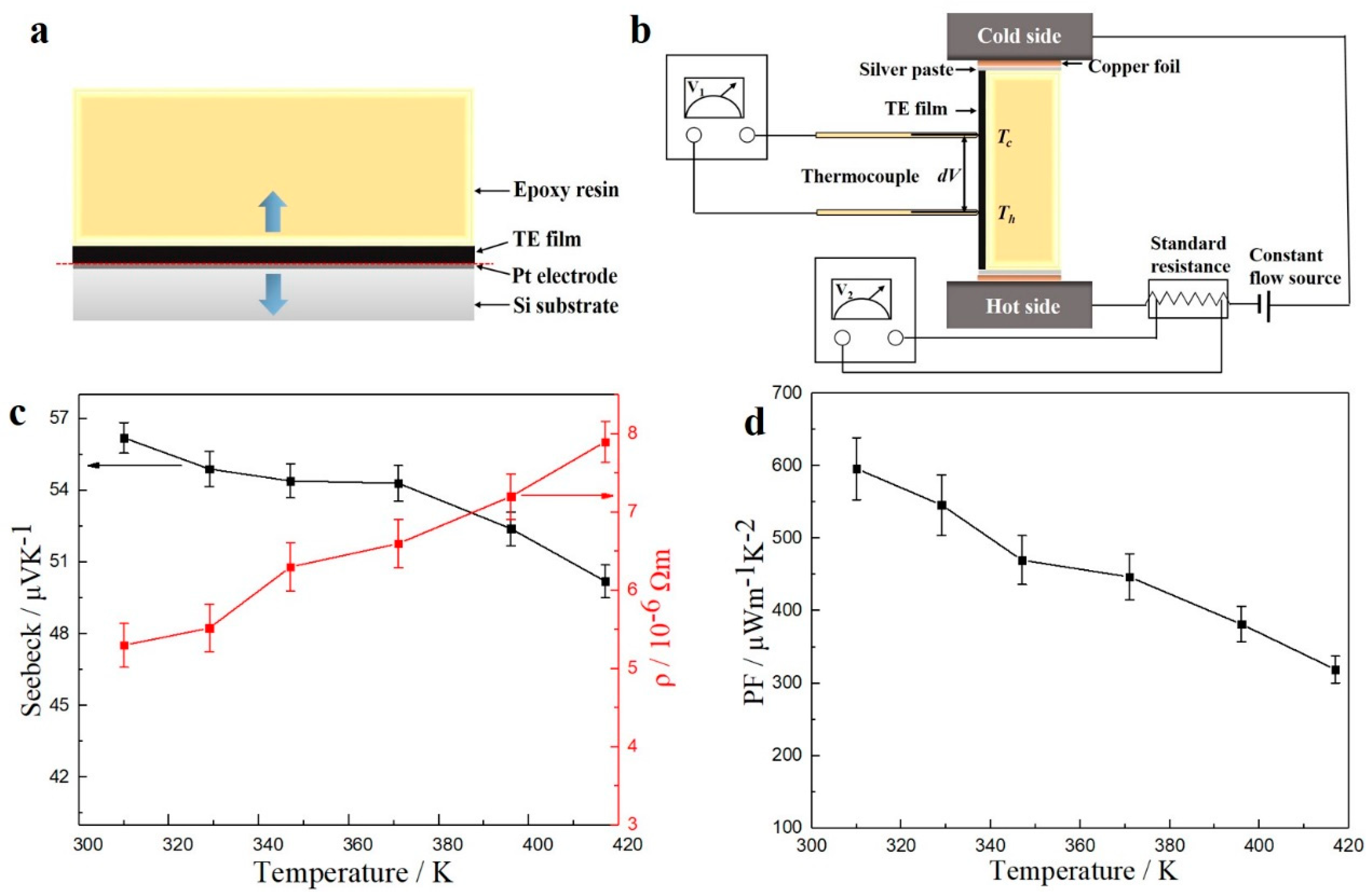

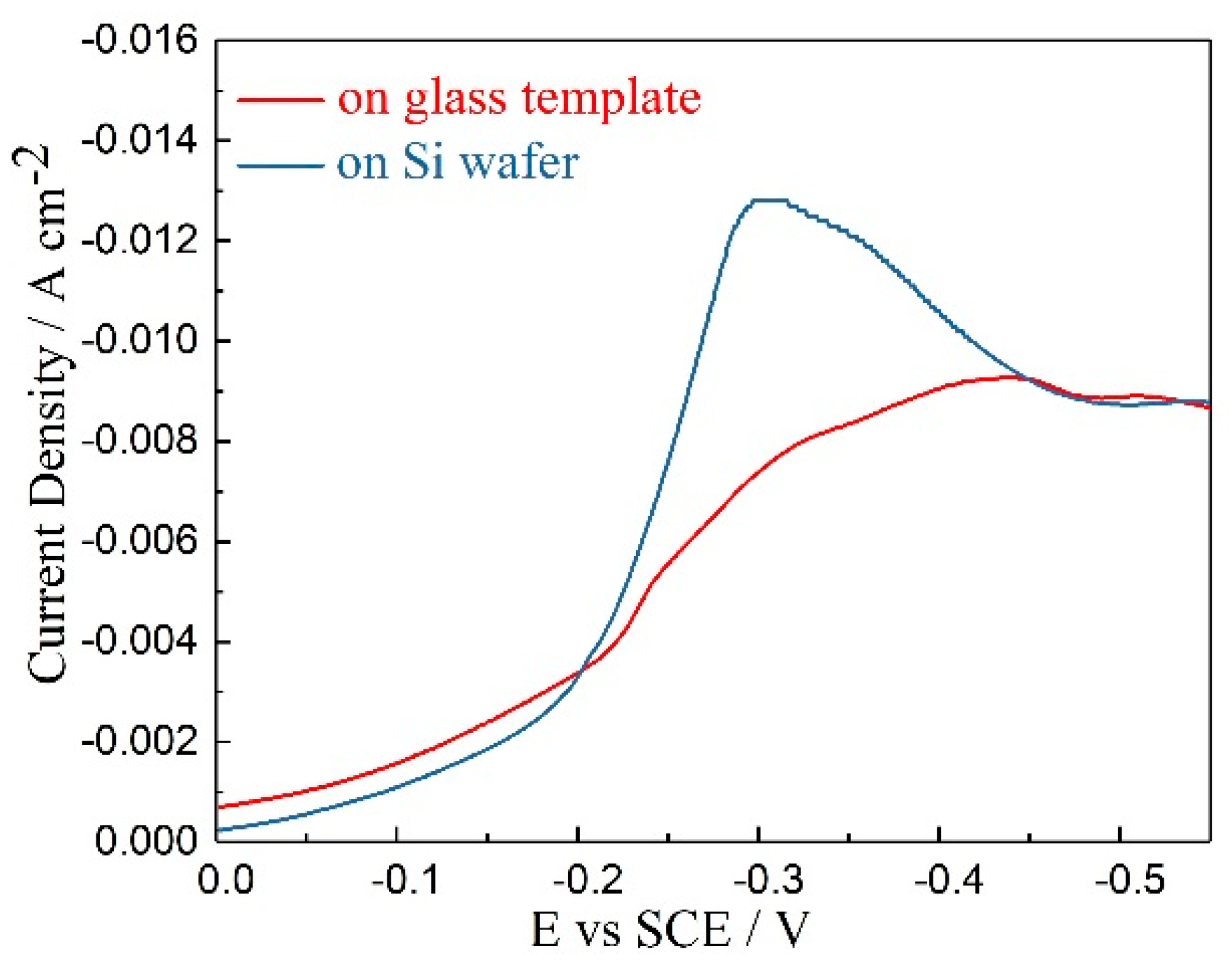

3.1. Electrodeposition on Si Wafer-Based Pt Electrode

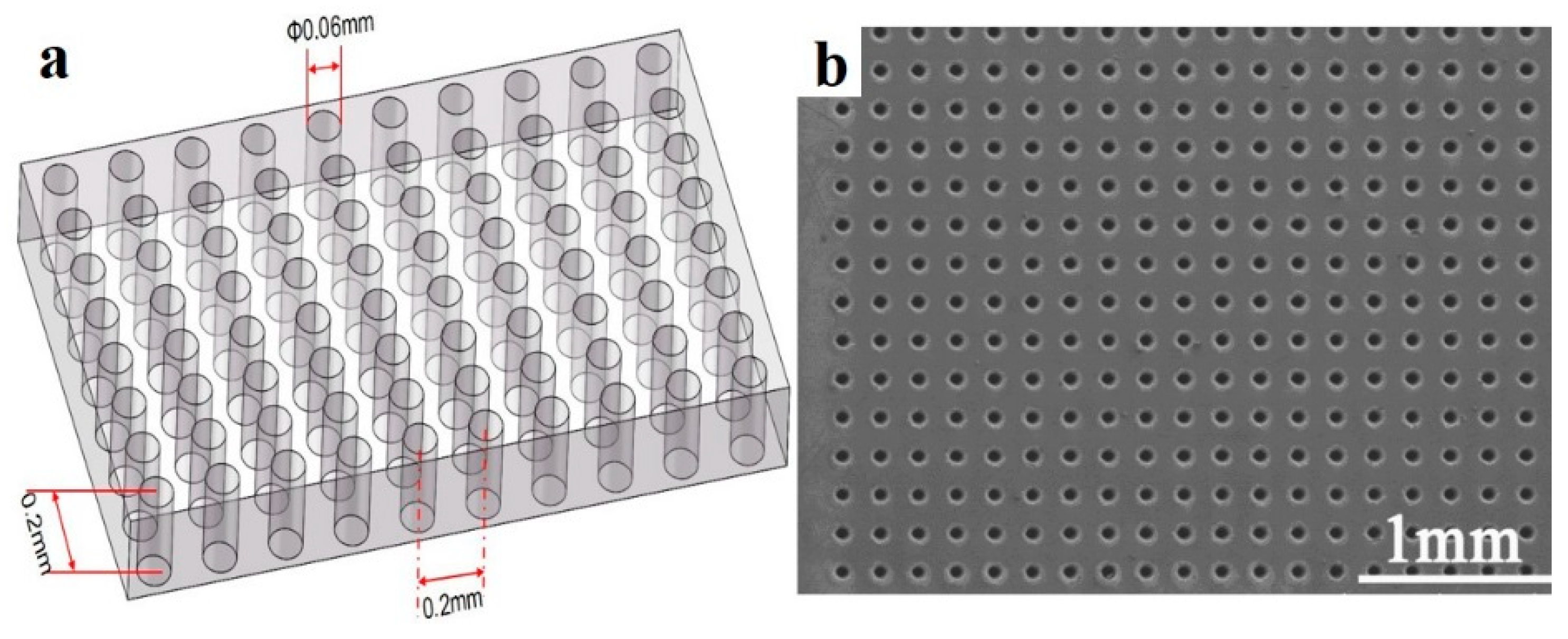

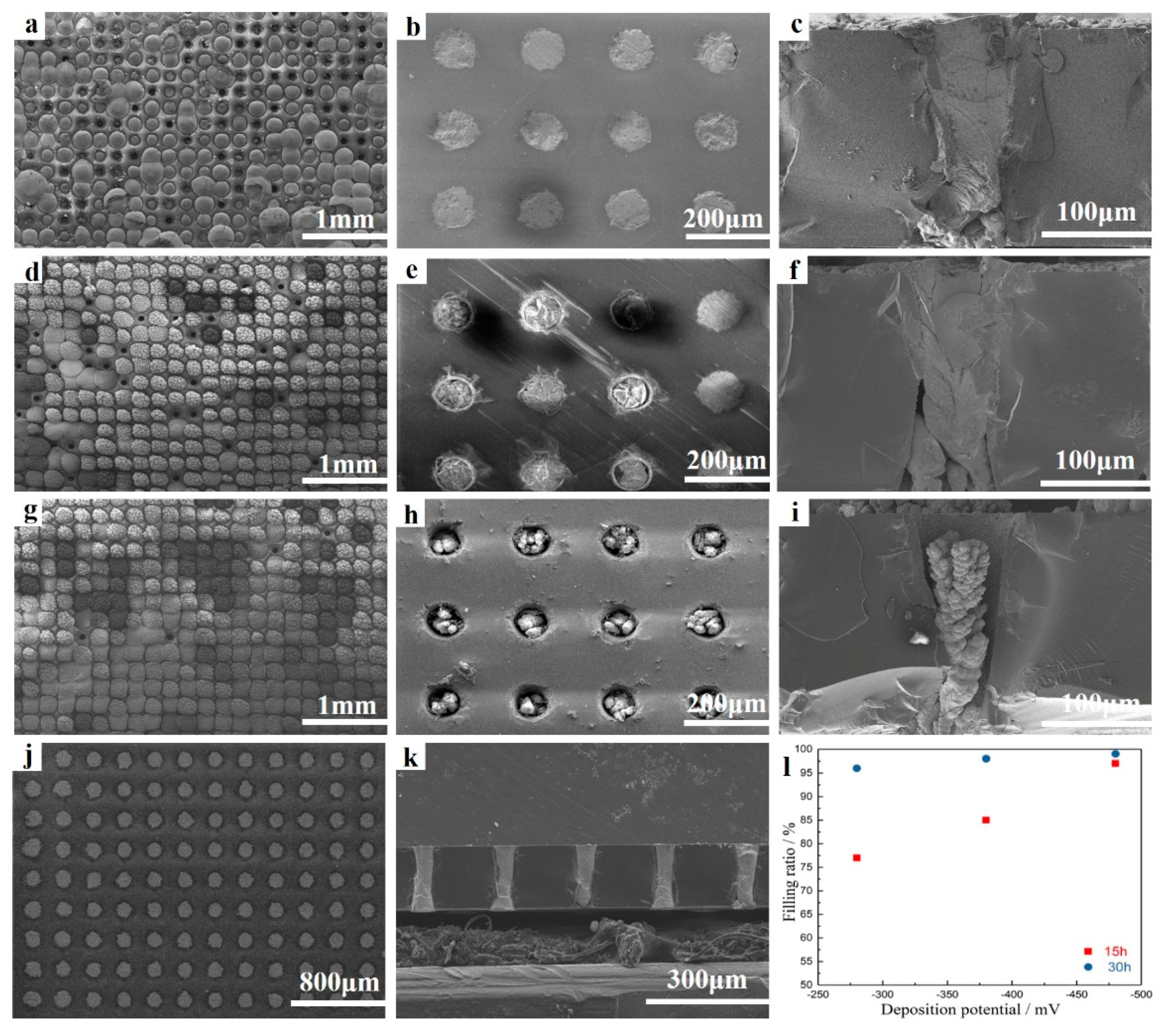

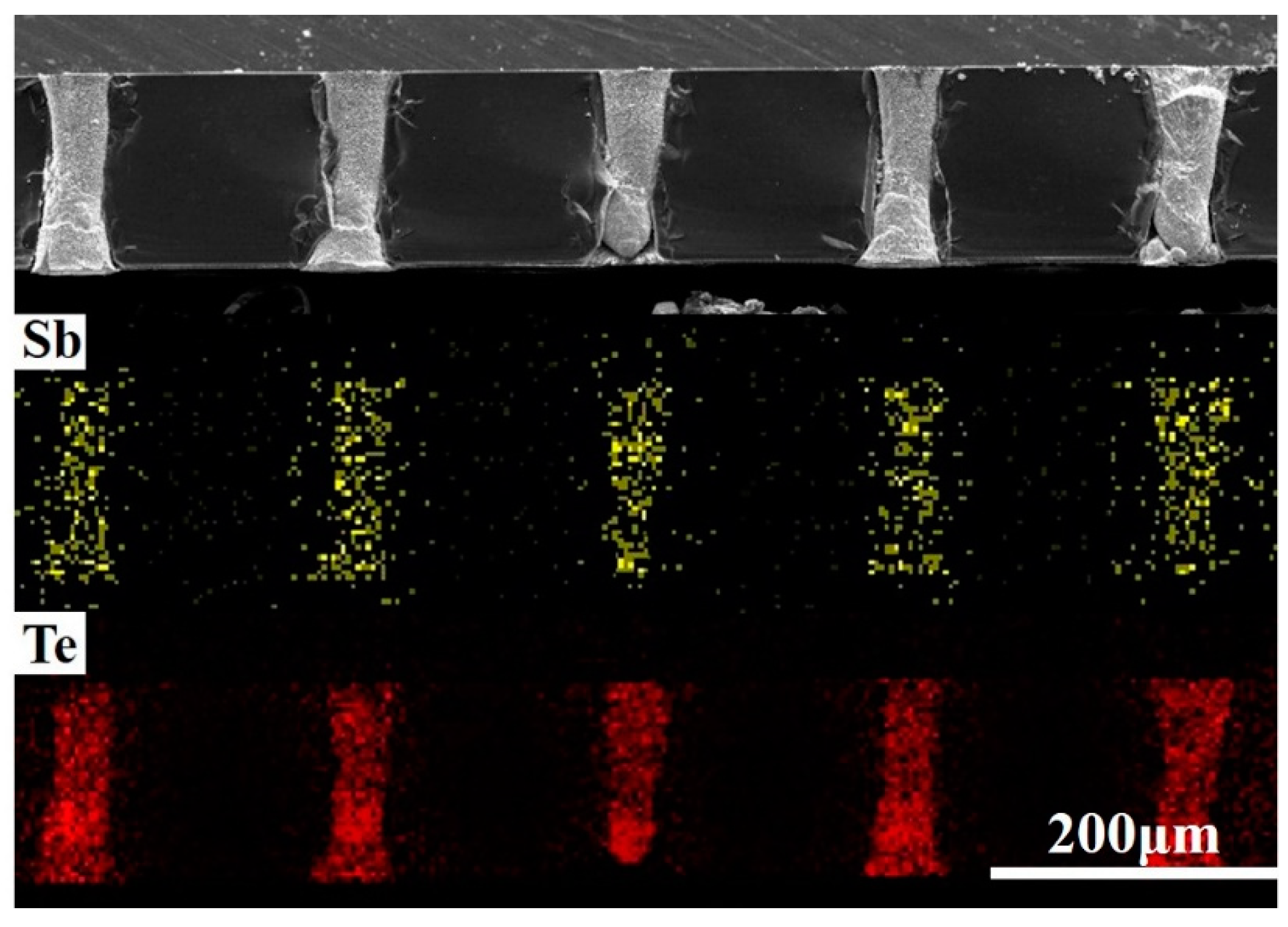

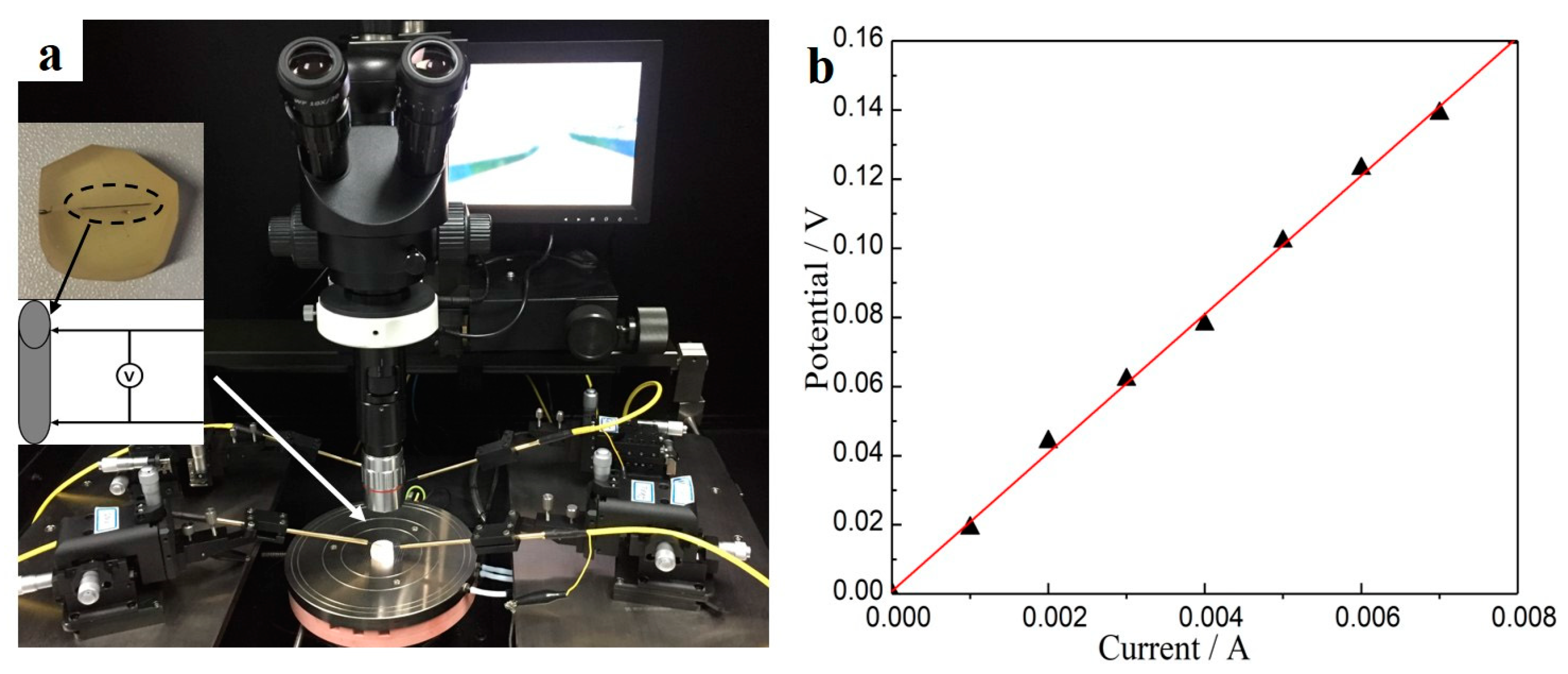

3.2. Electrodeposition onto Multi-Channel Glass Templates

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nour, A.; Hassan, N.; Refaat, H.M.; Soliman, H.M.A.; El-Dissouky, A. Effect of reducing agent strength on the growth and thermoelectric performance of nanocrystalline bismuth telluride. Mater. Res. Express 2018, 5, 035033. [Google Scholar] [CrossRef]

- Adam, A.M.; Petkov, P. Structural and optical properties of nano-powder-based (Sb1−xBix)2Te3 thin films. Mater. Res. Express 2017, 4, 085029. [Google Scholar] [CrossRef]

- Shen, S.; Zhu, W.; Deng, Y.; Zhao, H.; Peng, Y.; Wang, C. Enhancing thermoelectric properties of Sb2Te3 flexible thin film through microstructure control and crystal preferential orientation engineering. Appl. Surf. Sci. 2017, 414, 197–204. [Google Scholar] [CrossRef]

- Martin-Gonzalez, M.S.; Prieto, A.L.; Gronsky, R.; Sands, T.; Stacy, A.M. Insights into the electrodeposition of Bi2Te3. J. Electrochem. Soc. 2002, 149, C546–C554. [Google Scholar] [CrossRef]

- Rowe, D.M. CRC Handbook of Thermoelectrics; CRC: Washington, DC, USA, 1995. [Google Scholar]

- Li, J.; Pan, Y.; Wu, C.; Sun, F.; Wei, T. Processing of advanced thermoelectric materials. Sci. China Technol. Sci. 2017, 60, 1347–1364. [Google Scholar] [CrossRef]

- Sajid, M.; Hassan, I.; Rahman, A. An overview of cooling of thermoelectric devices. Renew. Sustain. Energy. Rev. 2017, 78, 15–22. [Google Scholar] [CrossRef]

- Zhao, D.; Tan, G. A review of thermoelectric cooling: Materials, modeling and applications. Appl. Therm. Eng. 2014, 66, 15–24. [Google Scholar] [CrossRef]

- Liu, D.W.; Li, J.F. Electrocrystallization process during deposition of Bi-Te films. J. Electrochem. Soc. 2008, 155, D493–D498. [Google Scholar] [CrossRef]

- Wu, Y.; Lin, Z.; Tian, Z.; Han, C.; Liu, J.; Zhang, H.; Zhang, Z.; Wang, Z.; Dai, L.; Cao, Y.; et al. Fabrication of Microstructured thermoelectric Bi2Te3 thin films by seed layer assisted electrodeposition. Mater. Sci. Semicond. Process. 2016, 46, 17–22. [Google Scholar] [CrossRef]

- Wu, M.; Binnemans, K.; Fransaer, J. Electrodeposition of antimony from chloride-free ethylene glycol solutions and fabrication of thermoelectric Bi2Te3/(Bi1−xSbx)2Te3 multilayers using pulsed potential electrodeposition. Electrochim. Acta 2014, 147, 451–459. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Shen, Z.; Yang, M.; Liu, X.; Wang, W. Preparation of Bi2Te3/Nano-SiC Composite Thermoelectric Films by Electrodeposition. J. Electron. Mater. 2015, 44, 2166–2171. [Google Scholar] [CrossRef]

- Tu, F.; Xie, J.; Cao, G.; Zhao, X. Self-Assembly of Bi2Te3-Nanoplate/Graphene-Nanosheet Hybrid by One-Pot Route and Its Improved Li-Storage Properties. Materials 2012, 5, 1275–1284. [Google Scholar] [CrossRef]

- Goldsmid, H.J. Bismuth Telluride and Its Alloys as Materials for Thermoelectric Generation. Materials 2014, 7, 2577–2592. [Google Scholar] [CrossRef] [PubMed]

- Jood, P.; Ohta, M. Hierarchical Architecturing for Layered Thermoelectric Sulfides and Chalcogenides. Materials 2015, 8, 1124–1149. [Google Scholar] [CrossRef] [PubMed]

- Merrill, D.R.; Moore, D.B.; Bauers, S.R.; Falmbigl, M.; Johnson, D.C. Misfit Layer Compounds and Ferecrystals: Model Systems for Thermoelectric Nanocomposites. Materials 2015, 8, 2000–2029. [Google Scholar] [CrossRef] [PubMed]

- Hao, F.; Qiu, P.F.; Song, Q.F.; Chen, H.Y.; Lu, P.; Ren, D.D.; Shi, X.; Chen, L.D. Roles of Cu in the Enhanced Thermoelectric Properties in Bi0.5Sb1.5Te3. Materials 2017, 10, 251. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Sipe, D.M.; Yong, X.; Qiao, L. A MEMS Thermal Biosensor for Metabolic Monitoring Applications. J. Microelectromech. Syst. 2008, 17, 318–327. [Google Scholar]

- Bar-Cohen, A.; Wang, P. On-chip Hot Spot Remediation with Miniaturized Thermoelectric Coolers. Microgravity Sci. Technol. 2009, 21, 351–359. [Google Scholar] [CrossRef]

- Snyder, G.J.; Lim, J.R.; Huang, C.K.; Fleurial, J.P. Thermoelectric microdevice fabricated by a MEMS-like electrochemical process. Nat. Mater. 2003, 2, 528–531. [Google Scholar] [CrossRef] [PubMed]

- Huang, I.Y.; Lin, J.C.; She, K.D.; Li, M.C.; Chen, J.H.; Kuo, J.S. Development of low-cost micro-thermoelectric coolers utilizing MEMS technology. Sens. Actuators A Phys. 2008, 148, 176–185. [Google Scholar] [CrossRef]

- Cao, Y.; Zeng, Z.G.; Liu, Y.L.; Zhang, X.P.; Shen, C.; Wang, X.H.; Gan, Z.X.; Wu, H.; Hu, Z.Y. Electrodeposition and Thermoelectric Characterization of (00L)-Oriented Bi2Te3 Thin Films on Silicon with Seed Layer. J. Electrochem. Soc. 2013, 160, D565–D569. [Google Scholar] [CrossRef]

- Nanda, M.M. Joining Techniques of Bi2te3 Elements in Thermoelectric Cooling Devices. J. Electrochem. Soc. 1963, 110, C54. [Google Scholar]

- Patil, P.B.; Mali, S.S.; Kondalkar, V.V.; Mane, R.M.; Patil, P.S.; Hong, C.K.; Bhosale, P.N. Morphologically controlled electrodeposition of fern shaped Bi2Te3 thin films for photoelectrochemical performance. J. Electroanal. Chem. 2015, 758, 178–190. [Google Scholar] [CrossRef]

- Datta, A.; Sangle, A.; Hardingham, N.; Cooper, C.; Kraan, M.; Ritchie, D.; Narayan, V.; Kar-Narayan, S. Structure and Thermoelectric Properties of Bi2-xSbxTe3 Nanowires Grown in Flexible Nanoporous Polycarbonate Templates. Materials 2017, 10, 553. [Google Scholar] [CrossRef] [PubMed]

- Gierczak, M.; Prazmowska-Czajka, J.; Dziedzic, A. Thermoelectric Mixed Thick-/Thin Film Microgenerators Based on Constantan/Silver. Materials 2018, 11, 115. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.L.; Chen, Y.Y.; Lin, S.J.; Ho, J.C.; Lee, P.C.; Chen, C.D.; Harutyunyan, S.R. Fabrication and Characterization of Electrodeposited Bismuth Telluride Films and Nanowires. J. Phys. Chem. C 2010, 114, 3385–3389. [Google Scholar] [CrossRef]

- Heo, P.; Hagiwara, K.; Ichino, R.; Okido, M. Electrodeposition and thermoelectric characterization of Bi2Te3. J. Electrochem. Soc. 2006, 153, C213–C217. [Google Scholar] [CrossRef]

- Leimkuhler, G.; Kerkamm, I.; Reineke-Koch, R. Electrodeposition of antimony telluride. J. Electrochem. Soc. 2002, 149, C474–C478. [Google Scholar] [CrossRef]

- Trung, N.H.; Sakamoto, K.; Toan, N.V.; Ono, T. Synthesis and Evaluation of Thick Films of Electrochemically Deposited Bi2Te3 and Sb2Te3 Thermoelectric Materials. Materials 2017, 10, 154. [Google Scholar] [CrossRef] [PubMed]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Kuleshova, J.; Koukharenko, E.; Li, X.H.; Frety, N.; Nandhakumar, I.S.; Tudor, J.; Beeby, S.P.; White, N.M. Optimization of the Electrodeposition Process of High-Performance Bismuth Antimony Telluride Compounds for Thermoelectric Applications. Langmuir 2010, 26, 16980–16985. [Google Scholar] [CrossRef] [PubMed]

- Snyder, G.J. Application of the compatibility factor to the design of segmented and cascaded thermoelectric generators. Appl. Phys. Lett. 2004, 84, 2436–2438. [Google Scholar] [CrossRef]

- Miyazaki, Y.; Kajitani, T. Preparation of Bi2Te3 films by electrodeposition. J. Cryst. Growth 2001, 229, 542–546. [Google Scholar] [CrossRef]

- Mun, H.; Lee, K.H.; Kim, S.J.; Kim, J.Y.; Lee, J.H.; Lim, J.H.; Park, H.J.; Roh, J.W.; Kim, S.W. Fe-Doping Effect on Thermoelectric Properties of p-Type Bi0.48Sb1.52Te3. Materials 2015, 8, 959–965. [Google Scholar] [CrossRef] [PubMed]

- Schumacher, C.; Reinsberg, K.G.; Akinsinde, L.; Zastrow, S.; Heiderich, S.; Toellner, W.; Rampelberg, G.; Detavernier, C.; Broekaert, J.A.C.; Nielsch, K.; et al. Optimization of Electrodeposited p-Doped Sb2Te3 Thermoelectric Films by Millisecond Potentiostatic Pulses. Adv. Energy Mater. 2012, 2, 345–352. [Google Scholar] [CrossRef]

- Li, X.H.; Koukharenko, E.; Nandhakumar, I.S.; Tudor, J.; Beeby, S.P.; White, N.M. High density p-type Bi0.5Sb1.5Te3 nanowires by electrochemical templating through ion-track lithography. Phys. Chem. Chem. Phys. 2009, 11, 3584–3590. [Google Scholar] [CrossRef] [PubMed]

- Li, F.H.; Wang, W. Electrodeposition of BixSb2-xTey thermoelectric thin films from nitric acid and hydrochloric acid systems. Appl. Surf. Sci. 2009, 255, 4225–4231. [Google Scholar] [CrossRef]

- Li, J.-F.; Tanaka, S.; Umeki, T.; Sugimoto, S.; Esashi, M.; Watanabe, R. Microfabrication of thermoelectric materials by silicon molding process. Sens. Actuators A Phys. 2003, 108, 97–102. [Google Scholar] [CrossRef]

- Lim, J.R.; Whitacre, J.F.; Fleurial, J.P.; Huang, C.K.; Ryan, M.A.; Myung, N.V. Fabrication method for thermoelectric nanodevices. Adv. Mater. 2005, 17, 1488–1492. [Google Scholar] [CrossRef]

- Liu, D.-W.; Xu, Y.; Li, J.-F. Electrodeposition of Bi2Te3 films and micro-pillar arrays on p-Si(100) wafers. Phys. Status Solidi A 2010, 207, 354–359. [Google Scholar] [CrossRef]

- Martin, J.; Manzano, C.V.; Caballero-Calero, O.; Martin-Gonzalez, M. High-aspect-ratio and highly ordered 15-nm porous alumina templates. ACS Appl. Mater. Interfaces 2013, 5, 72–79. [Google Scholar] [CrossRef] [PubMed]

- Chu, S.Z.; Wada, K.; Inoue, S.; Segawa, H. Direct Growth of Highly Ordered Crystalline Zirconia Nanowire Arrays with High Aspect Ratios on Glass by a Tailored Anodization. J. Electrochem. Soc. 2011, 158, C148–C157. [Google Scholar] [CrossRef]

- Kim, M.Y.; Oh, T.S. Thermoelectric Power Generation Characteristics of a Thin-Film Device Consisting of Electrodeposited n-Bi2Te3 and p-Sb2Te3 Thin-Film Legs. J. Electron. Mater. 2013, 42, 2752–2757. [Google Scholar] [CrossRef]

- Del Frari, D.; Diliberto, S.; Stein, N.; Boulanger, C.; Lecuire, J.-M. Comparative study of the electrochemical preparation of Bi2Te3, Sb2Te3, and (BixSb1−x)2Te3 films. Thin Solid Films 2005, 483, 44–49. [Google Scholar] [CrossRef]

- Zhu, Y.-B.; Wang, W. Microstructure and thermoelectric properties of p-type Bi–Sb–Te–Se thin films prepared by electrodeposition method. Thin Solid Films 2012, 520, 2474–2478. [Google Scholar] [CrossRef]

- Kim, M.-Y.; Oh, T.-S. Electrodeposition and Thermoelectric Characteristics of Bi2Te3 and Sb2Te3 Films for Thermopile Sensor Applications. J. Electron. Mater. 2009, 38, 1176–1181. [Google Scholar] [CrossRef]

- Kim, M.-Y.; Oh, T.-S. Processing and Thermoelectric Performance Characterization of Thin-Film Devices Consisting of Electrodeposited Bismuth Telluride and Antimony Telluride Thin-Film Legs. J. Electron. Mater. 2011, 40, 759–764. [Google Scholar] [CrossRef]

- Danaher, W.J.; Lyons, L.E. The Kinetics of the Electrodeposition of Cadmium Telluride. Aust. J. Chem. 1984, 37, 689–701. [Google Scholar] [CrossRef]

- Michel, S.; Stein, N.; Schneider, M.; Boulanger, C.; Lecuire, J.-M. Optimization of chemical and electrochemical parameters for the preparation of n-type Bi2Te2.7Se0.3 thin films by electrodeposition. J. Appl. Electrochem. 2003, 33, 23–27. [Google Scholar] [CrossRef]

- Kroger, F.A. Cathodic Deposition and Characterization of Metallic or Semiconducting Binary Alloys or Compounds. J. Electrochem. Soc. 1978, 125, 2028–2034. [Google Scholar] [CrossRef]

- Zou, Z.G.; Cai, K.F.; Chen, S.; Qin, Z. Pulsed electrodeposition and characterization of Bi2Te3−ySey films. Mater. Res. Bull. 2012, 47, 3292–3295. [Google Scholar] [CrossRef]

- Pinisetty, D.; Gupta, M.; Karki, A.B.; Young, D.P.; Devireddy, R.V. Fabrication and characterization of electrodeposited antimony telluride crystalline nanowires and nanotubes. J. Mater. Chem. 2011, 21, 4098–4107. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, N.; Guo, S.; Li, F.; Liu, D.; Li, B. Electrodeposition of p-Type Sb2Te3 Films and Micro-Pillar Arrays in a Multi-Channel Glass Template. Materials 2018, 11, 1194. https://doi.org/10.3390/ma11071194

Su N, Guo S, Li F, Liu D, Li B. Electrodeposition of p-Type Sb2Te3 Films and Micro-Pillar Arrays in a Multi-Channel Glass Template. Materials. 2018; 11(7):1194. https://doi.org/10.3390/ma11071194

Chicago/Turabian StyleSu, Ning, Shuai Guo, Fu Li, Dawei Liu, and Bo Li. 2018. "Electrodeposition of p-Type Sb2Te3 Films and Micro-Pillar Arrays in a Multi-Channel Glass Template" Materials 11, no. 7: 1194. https://doi.org/10.3390/ma11071194

APA StyleSu, N., Guo, S., Li, F., Liu, D., & Li, B. (2018). Electrodeposition of p-Type Sb2Te3 Films and Micro-Pillar Arrays in a Multi-Channel Glass Template. Materials, 11(7), 1194. https://doi.org/10.3390/ma11071194