Unexpected Event Prediction in Wire Electrical Discharge Machining Using Deep Learning Techniques

Abstract

1. Introduction

2. Materials and Methods

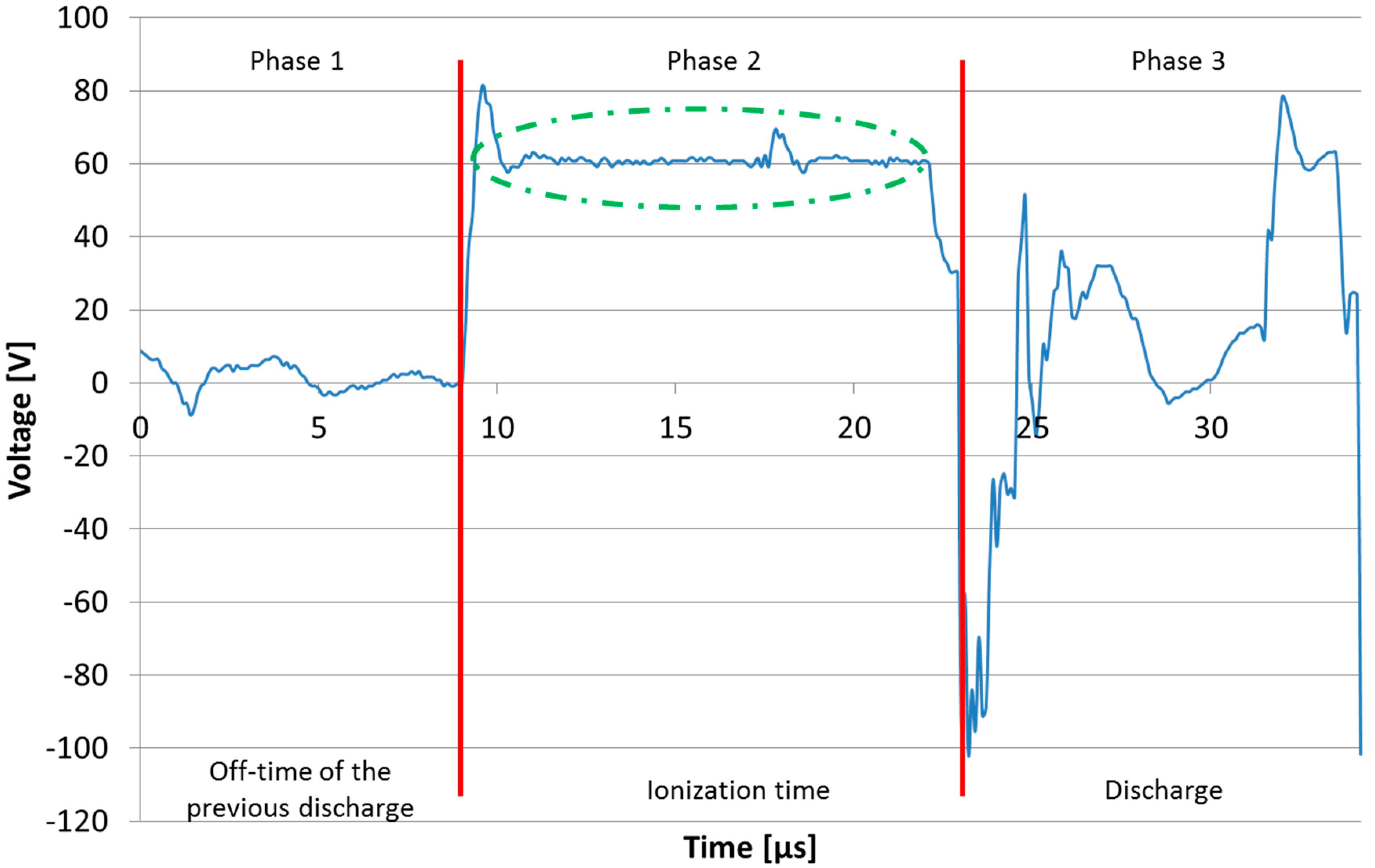

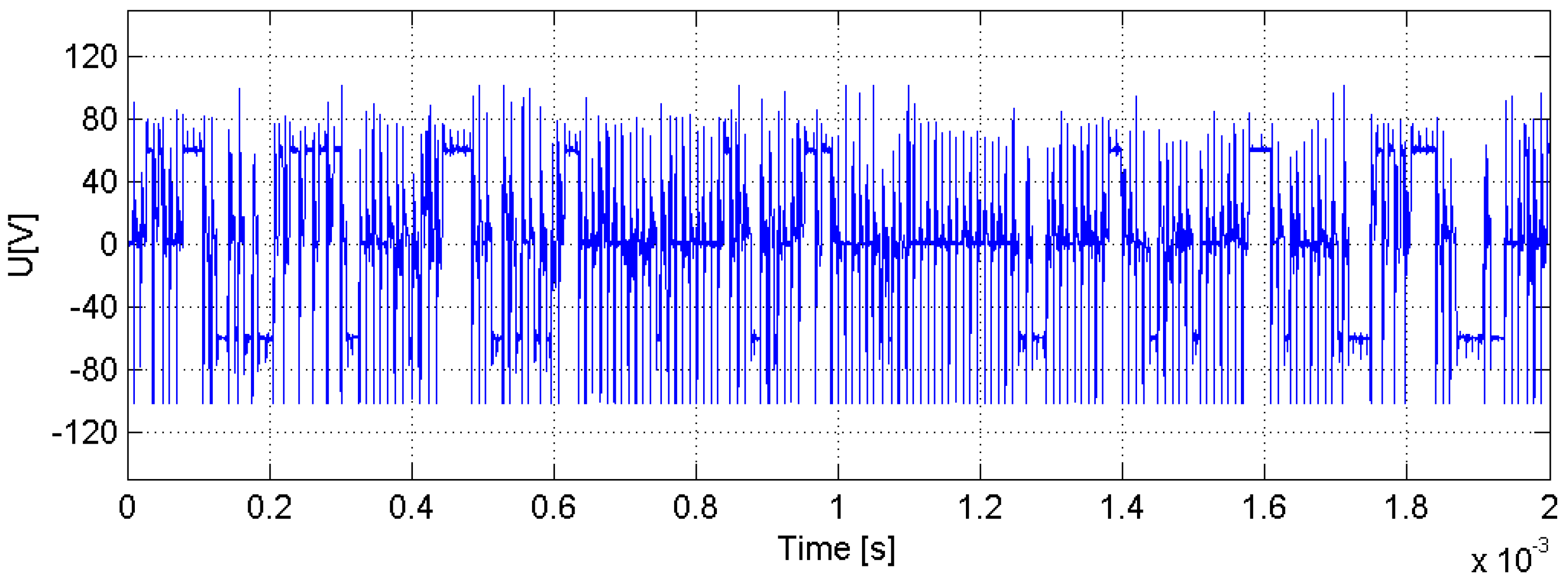

2.1. Instrumentation and Measured Variables

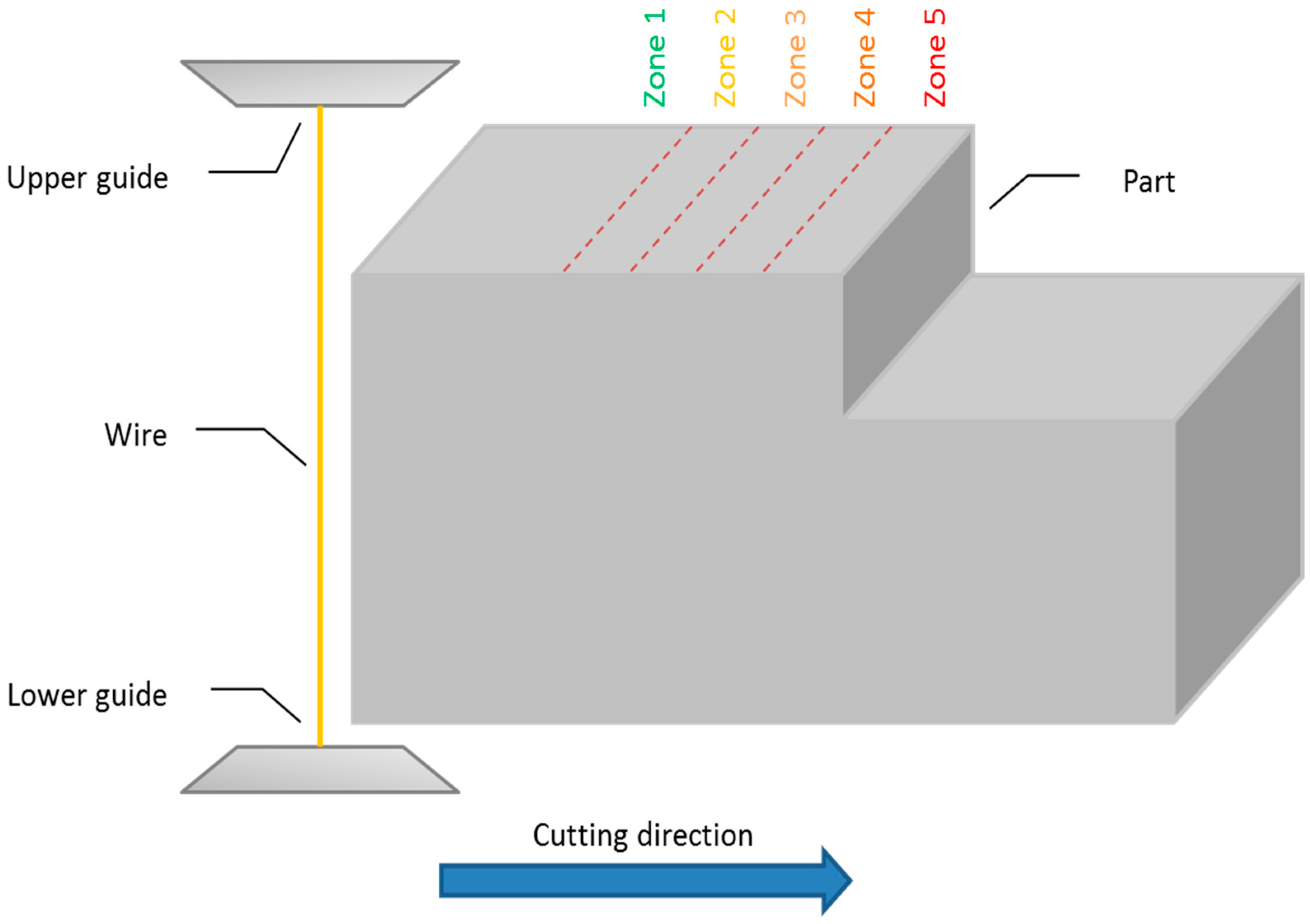

2.2. Experimental Methodology: WEDM Tests

2.3. Deep Learning Architectures Tested

- CNN: the first layer was a convolutional layer with 50 filters of 10 × 1 dimension (10 × 1 × 50). The signals were of one dimension and, therefore, a 1D convolutional layer was used. The following layer was a stacked convolutional layer composed of 100 layers of 10 × 1 dimensions. After these two layers, a max pooling layer was used to down sample the input by two. Moreover, a dropout of 0.2 was also used to avoid overfitting. A further two convolutional layers of 150 filters with a smaller dimension (5 × 1) were then used. In this case a max-pooling layer was also used to down sample by two and dropout. The fully connected layer of 150 neurons with ReLu and dropout was used. Finally, a softmax activation function was used in the last layer. In all convolutional layers, a ReLu is used.

- GRU: in the case of the model with GRUs, the model had three layers of 50, 50, and 25 units with dropout of 0.2 intercalated between the layers to avoid overfitting. Finally, the last layer was fully connected with a softmax activation function.

- Bidirectional GRU: the model with bidirectional GRU layers was quite similar to the GRU model but with fewer units in each layer. Thus, the model was composed of three bidirectional GRU (BiGru) of 10, 50, and 25, with 0.2 dropout intercalated and softmax activation function in the last fully connected layer, as in the GRU model.

- Convolutional layer + GRU: the last model had a convolutional first layer to extract features from the signals, followed by two layers of GRU units. Hence, the first convolutional layer had 100 filters of 10 × 1 dimension followed by a max pooling of 2 for down sampling with a dropout and ReLu. Two GRU layers of 150 and 50 with dropout were then stacked. Finally, as in the case of both the GRU and BiGRU models, a fully connected layer with softmax activation function was used.

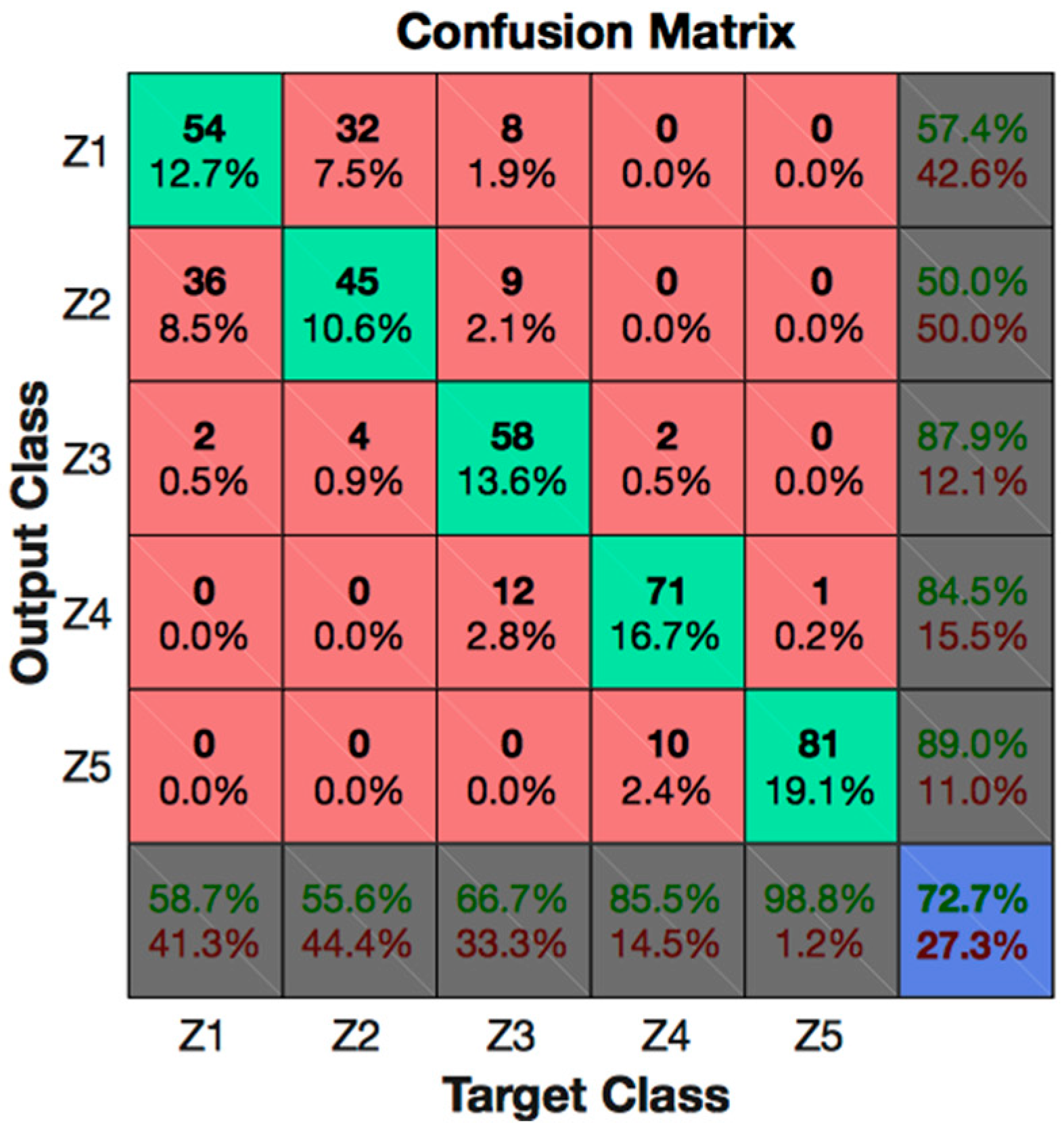

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Steinhardt, E. Future Aero Engine: Impact on Design and Production Technology. In Proceedings of the International Conference on Turbomachinery Manufacturing, Aachen, Germany, 20–21 February 2013. [Google Scholar]

- Ho, K.H.; Newman, S.T.; Rahimifard, S.; Allen, R.D. State of the art in wire electrical discharge machining (WEDM). Int. J. Mach. Tools Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Klocke, F.; Welling, D.; Klink, A.; Veselovac, D.; Nöthe, T.; Perez, R. Evaluation of Advanced Wire-EDM Capabilities for the Manufacture of Fir Tree Slots in Inconel 718. Proced. CIRP 2014, 14, 430–435. [Google Scholar] [CrossRef]

- Klocke, F.; Welling, D.; Klinka, A.; Perez, R. Quality Assessment through in-process Monitoring of Wire-EDM for Fir Tree Slot Production. Proced. CIRP 2014, 24, 97–102. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet Classification with Deep Convolutional Neural Networks. In Proceedings of the International Conference on Neural Information Processing Systems, Lake Tahoe, NV, USA, 3–6 December 2012; Volume 25, pp. 1106–1114. [Google Scholar]

- Ciresan, D.C.; Schmidhuber, J. Multi-Column Deep Neural Networks for Offline Handwritten Chinese Character Classification. arXiv, 2013; arXiv:1309.0261. [Google Scholar]

- Sutskever, I.; Vinyals, O.; Quoc, V.L. Sequence to sequence learning with neural networks. In Proceedings of the 27th International Conference on Neural Information Processing Systems, Montreal, QC, Canada, 8–13 December 2014; pp. 3104–3112. [Google Scholar]

- Vinyals, O.; Toshev, A.; Bengio, S.; Erhan, D. Show and tell: A Neural Image Caption Generator. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Boston, MA, USA, 7–12 June 2015; pp. 3156–3164. [Google Scholar]

- Ciresan, D.C.; Giusti, A.; Gambardella, L.M.; Schmidhuber, J. Mitosis detection in breast cancer histology images with deep neural networks. In Proceedings of the International Conference on Medical Image Computing and Computer-Assisted Intervention, Nagoya, Japan, 22–26 September 2013; pp. 411–418. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016; Available online: http://www.deeplearningbook.org (accessed on 27 June 2018).

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning Internal Representations by Error Propagation; Technical Report, DTIC Document; MIT Press: Cambridge, MA, USA, 1985. [Google Scholar]

- Elman, J. Finding Structure in Time. Cogn. Sci. 1990, 14, 179–211. [Google Scholar] [CrossRef]

- Bengio, Y.; Simard, P.; Frasconi, P. Learning long-term dependencies with gradient descent is difficult. IEEE Trans. Neural Netw. 1994, 5, 157–166. [Google Scholar] [CrossRef] [PubMed]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

- Chung, J.; Gulcehre, C.; Cho, K.H.; Bengio, Y. Empirical Evaluation of Gated Recurrent Neural Networks on Sequence Modeling. In Proceedings of the NIPS Deep Learning Workshop, Montreal, QC, Canada, 11 December 2014. [Google Scholar]

- Cho, K.; Merrienboer, B.; Bahdanau, D.; Bengio, Y. On the properties of neural machine translation: Encoder-decoder approaches. arXiv, 2014; arXiv:1409.1259. [Google Scholar]

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Fukushima, K. Neocognitron: A Self-organizing Neural Network Model for a Mechanism of Patter Recognition Unaffected by Shift Position. Biol. Cybern. 1980, 36, 193–202. [Google Scholar] [CrossRef] [PubMed]

- LeCun, Y. Generalization and Network Design Strategies; Connectionism in Perspective; Elsevier: Zurich, Switzerland, 1989. [Google Scholar]

- Yin, J.; Zhao, W. Fault diagnosis network design for vehicle on-board equipments of high speed railway: A deep learning approach. Eng. Appl. Artif. Intell. 2016, 56, 250–259. [Google Scholar] [CrossRef]

- Dou, D.; Zhou, S. Comparison of four direct classification methods for intelligent fault diagnosis of rotating machinery. Appl. Soft Comput. 2016, 46, 459–468. [Google Scholar] [CrossRef]

- Samanta, S.; Chakraborty, S. Parametric optimization of some non-traditional machining processes using artificial bee colony algorithm. Eng. Appl. Artif. Intell. 2011, 24, 946–957. [Google Scholar] [CrossRef]

- Rao, R.V.; Kalyankar, V.D. Parameter optimization of modern machining processes using teaching–learning-based optimization algorithm. Eng. Appl. Artif. Intell. 2013, 26, 524–531. [Google Scholar]

- Rao, R.V.; Rai, D.P.; Balic, J. A multi-objective algorithm for optimization of modern machining processes. Eng. Appl. Artif. Intell. 2017, 61, 103–125. [Google Scholar] [CrossRef]

- Arriandiaga, A.; Portillo, E.; Sánchez, J.A.; Cabanes, I.; Zubizarreta, A. Downsizing training data with weighted FCM for predicting the evolution of specific grinding energy with RNNs. Appl. Soft Comput. 2017, 61, 211–221. [Google Scholar] [CrossRef]

- Wang, P.; Gao, R.X.; Yan, R. A deep learning-based approach to material removal rate prediction in polishing. CIRP Ann. 2017, 66, 429–432. [Google Scholar] [CrossRef]

- Günther, J.; Pilarski, P.M.; Helfrich, G.; Shen, H.; Diepold, K. Intelligent laser welding through representation, prediction, and control learning: An architecture with deep neural networks and reinforcement learning. Mechatronics 2016, 34, 1–11. [Google Scholar] [CrossRef]

- Mukherjee, R.; Chakraborty, S.; Samanta, S. Selection of wire electrical discharge machining process parameters using non-traditional optimization algorithms. Appl. Soft Comput. 2012, 12, 2506–2516. [Google Scholar] [CrossRef]

- Portillo, E.; Marcos, M.; Cabanes, I.; Zubizarreta, A. Recurrent ANN for monitoring degraded behaviors in a range of workpiece thicknesses. Eng. Appl. Artif. Intell. 2009, 22, 1270–1283. [Google Scholar] [CrossRef]

- Conde, A.; Arriandiaga, A.; Sanchez, J.A.; Portillo, E.; Plaza, S.; Cabanes, I. High-accuracy wire electrical discharge machining using artificial neural networks and optimization techniques. Robot. Comput. Integr. Manuf. 2018, 49, 24–38. [Google Scholar] [CrossRef]

- Caggiano, A.; Teti, R.; Perez, R.; Xirouchakis, E.D.M. Wire Monitoring for Zero-Defect Manufacturing based on Advanced Sensor Signal Processing. Proced. CIRP 2015, 33, 315–320. [Google Scholar] [CrossRef]

- Caggiano, A.; Perez, R.; Segreto, T.; Teti, R.; Xirouchakis, P. Advanced Sensor Signal Feature Extraction and Pattern Recognition for Wire EDM Process Monitoring. Proced. CIRP 2016, 42, 34–39. [Google Scholar] [CrossRef]

- Almacinha, J.A.; Mendes-Lopes, A.; Rosa, P.; Duarte-Marafona, J. How Hydrogen Dielectric Strength Forces the Work Voltage in the Electric Discharge Machining. Micromachines 2018, 9, 240. [Google Scholar] [CrossRef]

- Cabanes, I.; Portillo, E.; Marcos, M.; Sánchez, J.A. An industrial application for on-line detection of instability and wire breakage in wire EDM. J. Mater. Process. Technol. 2008, 195, 101–109. [Google Scholar] [CrossRef]

- Liao, Y.S.; Chuang, T.J.; Yu, Y.P. On-line Workpiece Height Estimation and its Application in Servo Feed Control of WEDM Process. Procedia CIRP, 6 (2013) 226-231.Kingma, D.P.; Ba, J.L. Adam: A method for stochastic optimization. arXiv, 2015; arXiv:1412.6980. [Google Scholar]

- Jozefowicz, R.; Zaremba, W.; Sutskever, I. An Empirical Exploration of Recurrent Network Architectures. In Proceedings of the International Conference on Machine Learning, Lille, France, 7–9 July 2015. [Google Scholar]

| WEDM Parameters | Settings |

|---|---|

| Height [mm] | 100 |

| Off-time [µs] | 9.0 |

| On-time [µs] | 1.2 |

| Current intensity [A] | 5.0 |

| Open-circuit voltage [V] | 60.0 |

| Initial dielectric pressure [bar] | 17.0 |

| Wire tension [kg] | 1.2 |

| Denotation | Zones | Sequences |

|---|---|---|

| Z_all | 1, 2, 3, 4, 5 | 2835 (5 × 567) |

| Z_135 | 1, 3, 5 | 2088 (688 + 677 + 723) |

| Z_15 | 1, 5 | 1411 (688 + 723) |

| Model | Precision | Recall | F1 Score |

|---|---|---|---|

| CNN | 0.5806 | 0.5765 | 0.5785 |

| GRU | 0.6969 | 0.5788 | 0.6324 |

| BiGRU | 0.6968 | 0.6706 | 0.6835 |

| CGRU | 0.7260 | 0.7106 | 0.7182 |

| Model | Precision | Recall | F1 Score |

| Precision | Recall | F1 Score | |

|---|---|---|---|

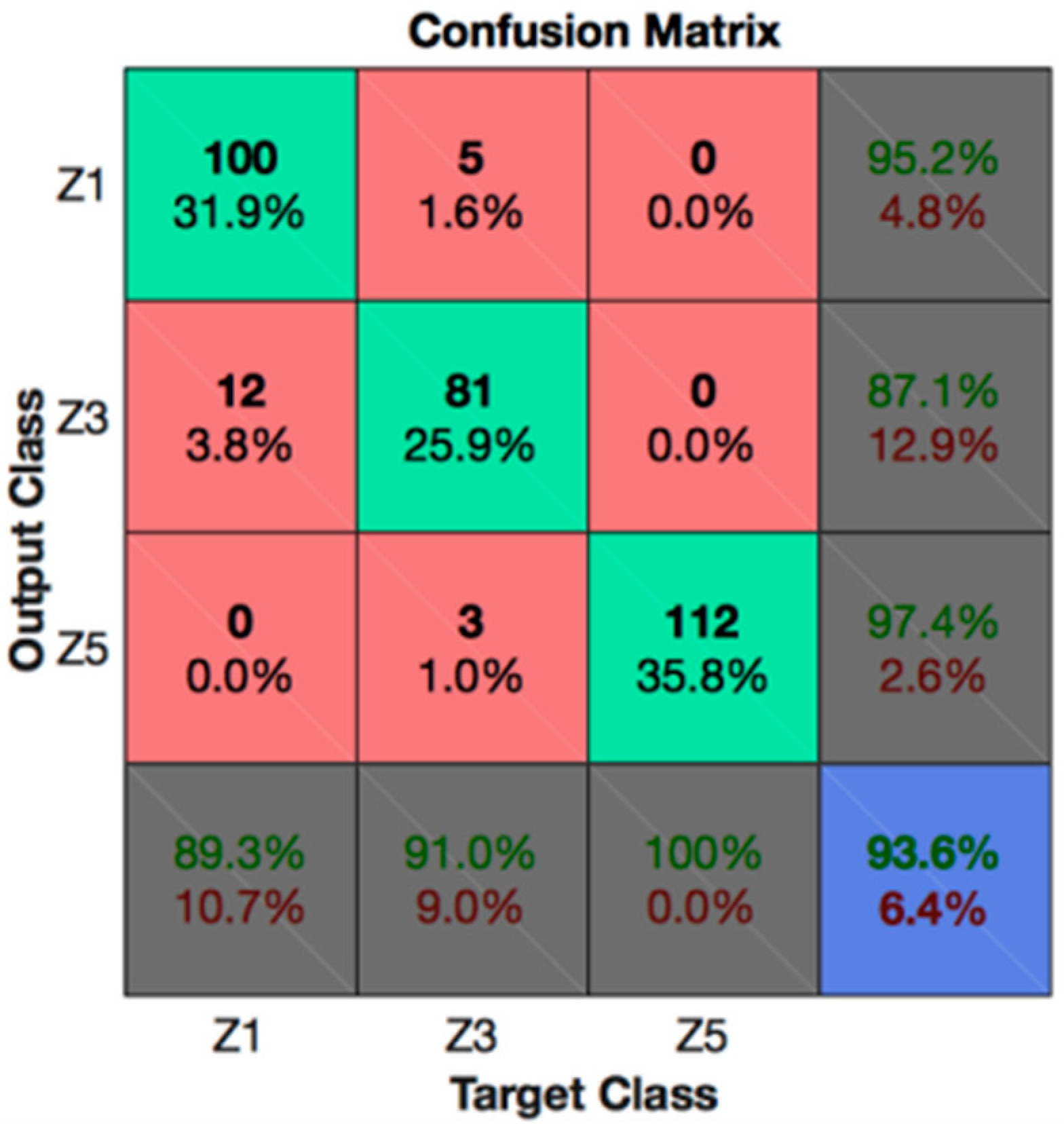

| Z_135 | 0.9361 | 0.9361 | 0.9361 |

| Z_15 | 1 | 1 | 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanchez, J.A.; Conde, A.; Arriandiaga, A.; Wang, J.; Plaza, S. Unexpected Event Prediction in Wire Electrical Discharge Machining Using Deep Learning Techniques. Materials 2018, 11, 1100. https://doi.org/10.3390/ma11071100

Sanchez JA, Conde A, Arriandiaga A, Wang J, Plaza S. Unexpected Event Prediction in Wire Electrical Discharge Machining Using Deep Learning Techniques. Materials. 2018; 11(7):1100. https://doi.org/10.3390/ma11071100

Chicago/Turabian StyleSanchez, Jose A., Aintzane Conde, Ander Arriandiaga, Jun Wang, and Soraya Plaza. 2018. "Unexpected Event Prediction in Wire Electrical Discharge Machining Using Deep Learning Techniques" Materials 11, no. 7: 1100. https://doi.org/10.3390/ma11071100

APA StyleSanchez, J. A., Conde, A., Arriandiaga, A., Wang, J., & Plaza, S. (2018). Unexpected Event Prediction in Wire Electrical Discharge Machining Using Deep Learning Techniques. Materials, 11(7), 1100. https://doi.org/10.3390/ma11071100