Effect of Shear Stress on Isothermal Crystallization Behavior of CaO-Al2O3-SiO2-Na2O-CaF2 Slags

Abstract

:1. Introduction

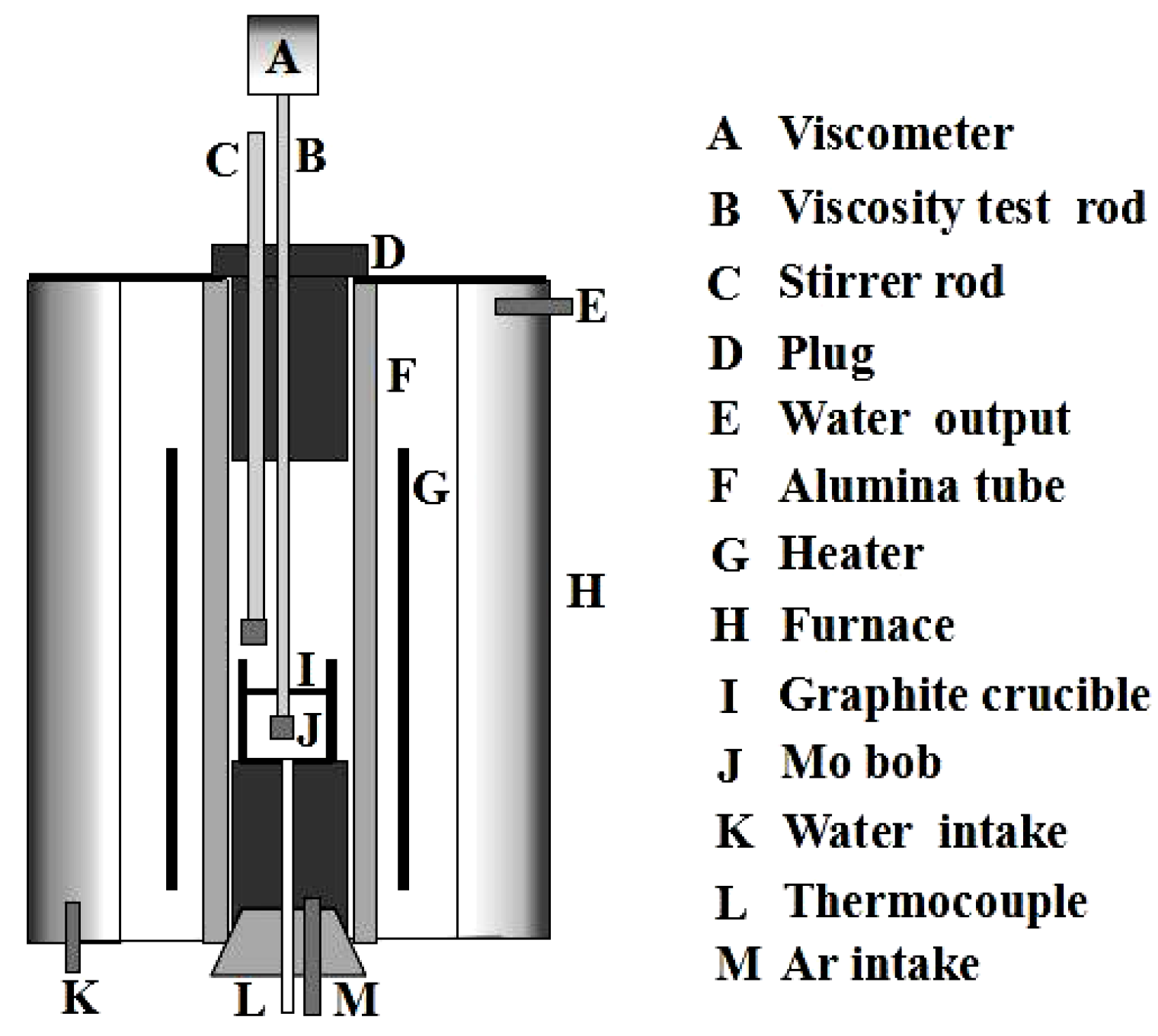

2. Experimental Section

2.1. Material Preparation

2.2. Experimental Methods

3. Results and Discussion

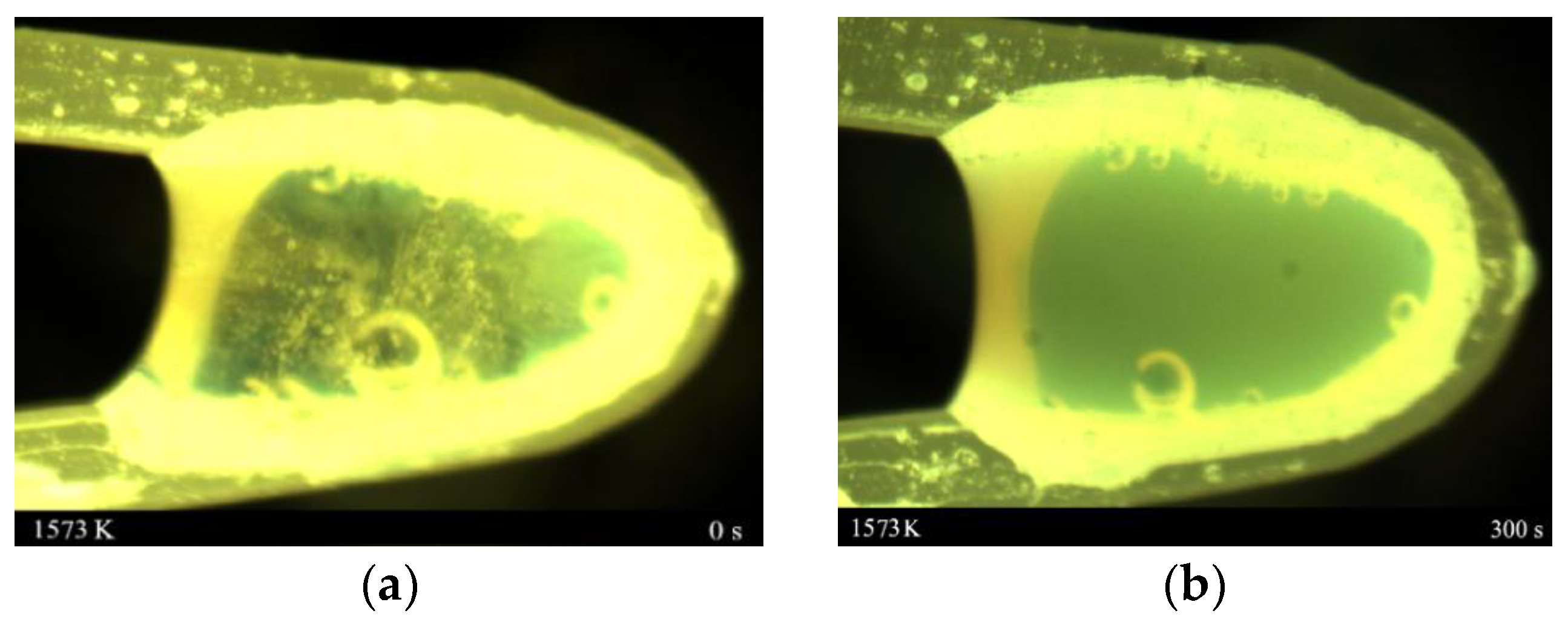

3.1. State of Slags at 1300 °C

3.2. Quantitative Effect of Shear Stress on the Crystallization Property of Mold Fluxes

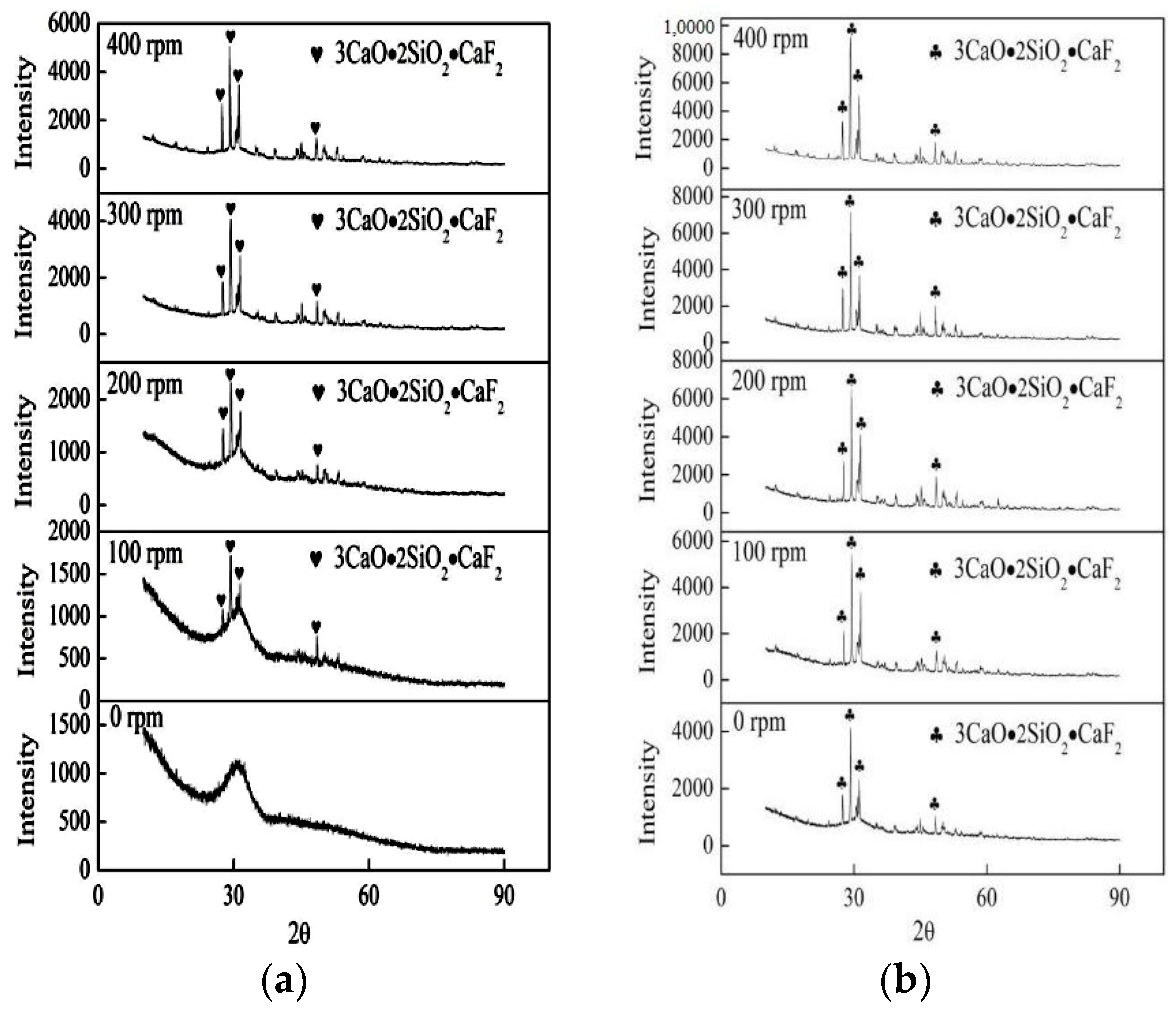

3.3. Effect of Shear Stress on Crystalline Phase of Mold Fluxes

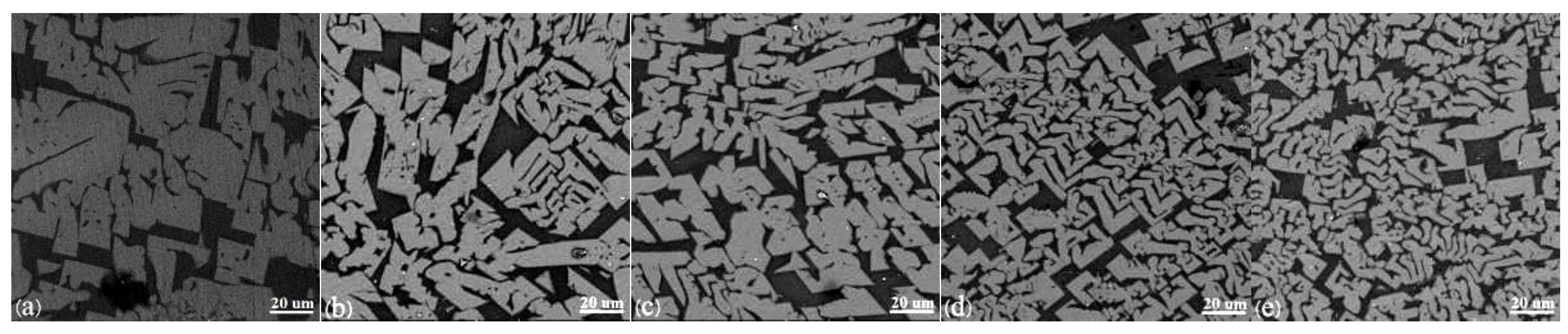

3.4. Effect of Shear Stress on Micromorphology of Mold Fluxes

3.5. Effect of Shear Stress on Crystallization Kinetics of Mold Fluxes

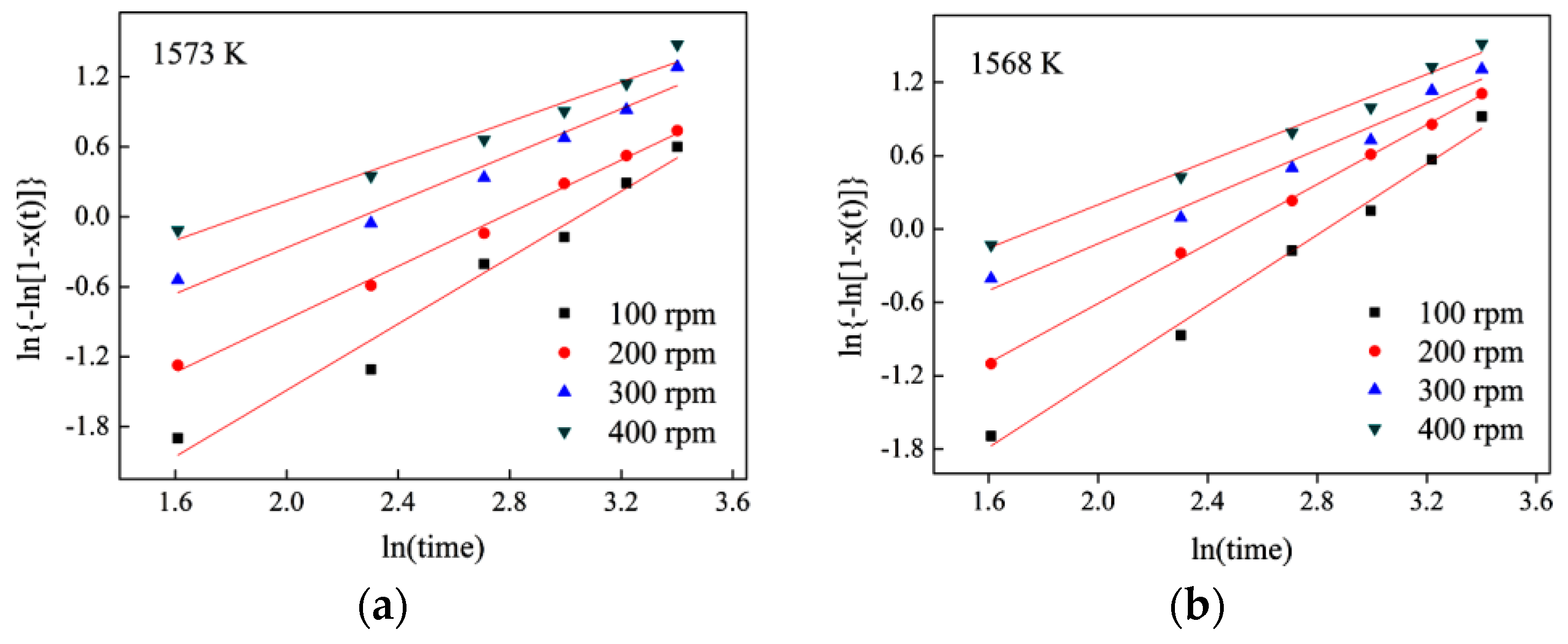

3.5.1. Effect of Shear Stress on the Crystallization Mechanisms of Mold Fluxes

3.5.2. Effect of Shear Stress on the Crystallization Activation Energy of Mold Fluxes

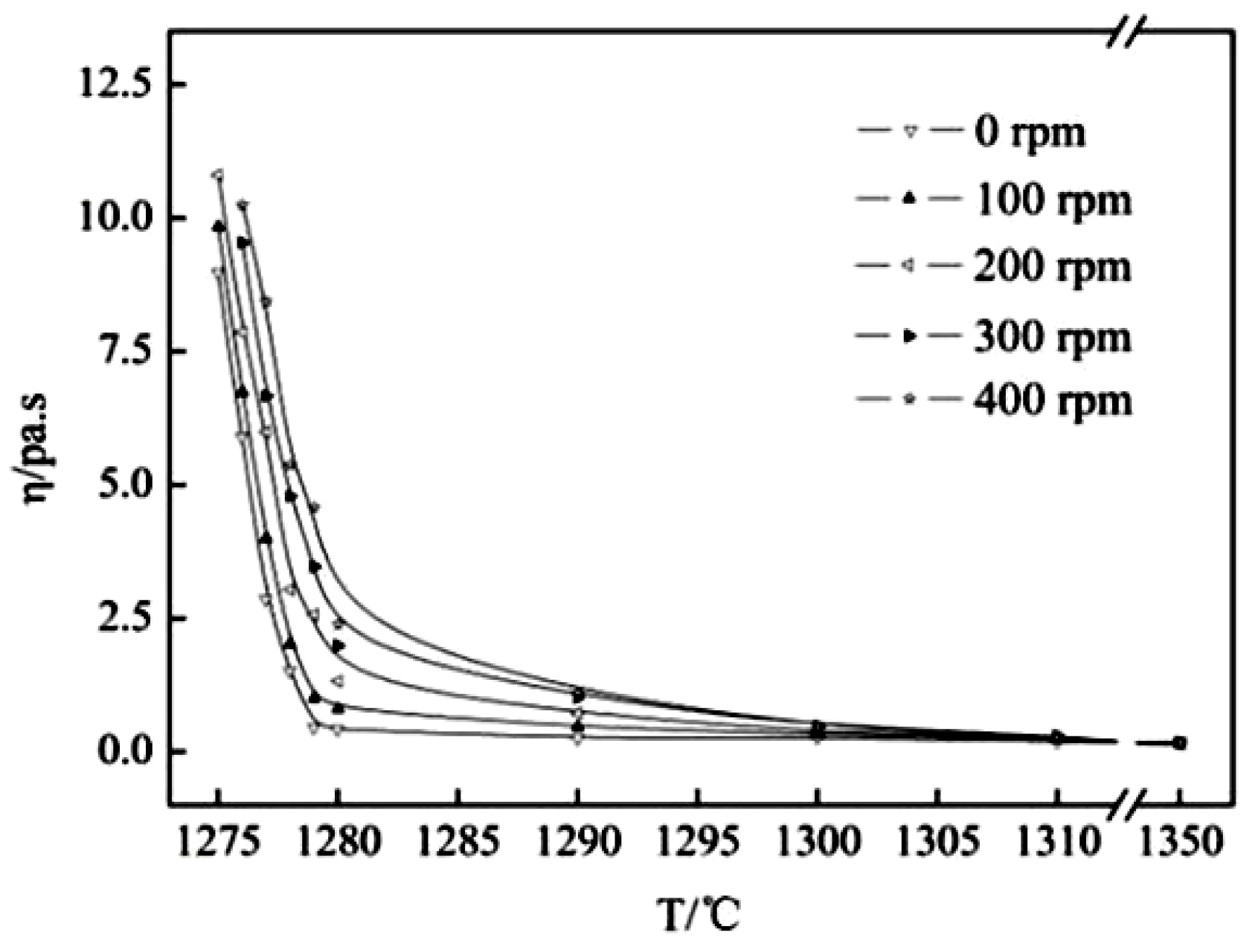

3.6. Effect of Shear Stress on the Lubricating Property of Mold Fluxes

4. Conclusions

- The crystallization performance of mold fluxes is promoted by the shear stress, and the quantified crystalline fraction of slag films with different rotating speeds at 1573 K is obtained;

- The shear stress affects the microscopic morphology of crystals, leading to smaller grain size. However, it has no effect on the crystalline phase of the mold fluxes;

- The crystallization activation energy reduces under the shear stress through improving the crystallization kinetics of crystals precipitated by the molten slags;

- The effect of shear stress on the viscosity–temperature curve of the mold fluxes is small. The break temperature and face activation energy slightly increase with the increasing rotational speed, which does not influence the lubrication property in the continuous casting process.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mills, K.C. Structure and properties of slags used in the continuous casting of steel: Part 1 conventional mould powders. ISIJ Int. 2016, 56, 1–13. [Google Scholar] [CrossRef]

- Mills, K.C.; Fox, A.B. The role of mould fluxes in continuous casting-so simple yet so complex. ISIJ Int. 2003, 43, 1479–1486. [Google Scholar] [CrossRef]

- Wang, W.L.; Yan, X.; Zhou, L.J.; Xie, S.L.; Huang, D.Y. Influences of basicity and Li2O on the properties of fluorine-free mold flux for the casting of medium carbon steels. Metall. Mater. Trans. B 2016, 47, 963–973. [Google Scholar] [CrossRef]

- Long, X.; Wang, Q.; He, S.P.; Pistorius, C.P. Structure evolution of slag films of ultrahigh-basicity mold flux during solidification. Metall. Mater. Trans. B 2017, 48, 1938–1942. [Google Scholar] [CrossRef]

- Long, X.; He, S.P.; Xu, J.F.; Huo, X.L.; Wang, Q. Properties of High Basicity Mold Fluxes for Peritectic Steel Slab Casting. J. Iron Steel Res. Int. 2012, 19, 39–45. [Google Scholar] [CrossRef]

- He, Y.M.; Wang, Q.; Hu, B.; Zhu, L.L.; Chen, W.M.; He, S.P. Application of high-basicity mould fluxes for continuous casting of large steel slabs. Ironmak. Steelmak. 2016, 43, 588–593. [Google Scholar] [CrossRef]

- Mills, K.C. Structure and properties of slags used in the continuous casting of steel: Part 2 specialist mould powders. ISIJ Int. 2016, 56, 14–23. [Google Scholar] [CrossRef]

- Shin, S.H.; Cho, J.W.; Kim, S.H. Structural investigations of CaO-CaF2-SiO2-Si3N4 based glasses by Raman spectroscopy and XPS considering its application to continuous casting of steels. Mater. Des. 2015, 76, 1–8. [Google Scholar] [CrossRef]

- Shin, S.H.; Cho, J.W.; Kim, S.H. Shear thinning behavior of calcium silicate-based mold fluxes at 1623 K. JACS 2015, 97, 3263–3269. [Google Scholar] [CrossRef]

- Shin, S.H.; Cho, J.W.; Kim, S.H. Controlling the shear thinning property of calcium silicate melts by addition of Si3N4. J. Non-Cryst. Solids 2015, 423, 45–49. [Google Scholar] [CrossRef]

- Shin, S.H.; Yoon, D.W.; Cho, J.W.; Kim, S.H. Controlling shear thinning property of lime silica based mold flux system with borate additive at 1623 K. J. Non-Cryst. Solids 2015, 425, 83–90. [Google Scholar] [CrossRef]

- Suzuki, M.; Mizukami, H.; Kitagawa, T.; Kawakami, K.; Uchida, S.; Komatsu, Y. Development of a new mold oscillation mode for high-speed continuous casting of steel slabs. ISIJ Int. 1991, 31, 254–261. [Google Scholar] [CrossRef]

- Xu, Y.; Yuan, Z.P.; Zhu, L.G.; Han, Y.H.; Wang, X.J. Shear-thinning behavior of the CaO-SiO2-CaF2-Si3N4 system mold flux and its practical application. Int. J. Miner. Metall. Mater. 2017, 24, 1096–1103. [Google Scholar] [CrossRef]

- Saito, N.; Kusada, K.; Sukenaga, S.; Ohta, Y.; Nakashima, K. Effect of agitation on crystallization behavior of CaO-SiO2-R2O (R=Li, Na or K) system characterized by electrical capacitance measurement. ISIJ Int. 2012, 52, 2123–2129. [Google Scholar] [CrossRef]

- Harada, Y.; Kusada, K.; Sukenaga, S.; Yamamura, H.; Ueshima, Y.; Mizoguchi, T.; Saito, N.; Nakashima, K. Effects of agitation and morphology of primary crystalline phase on crystallization behavior of CaO-SiO2-CaF2 supercooled melts. ISIJ Int. 2014, 54, 2071–2076. [Google Scholar] [CrossRef]

- Harada, Y.; Sakaguchi, S.; Mizoguchi, T.; Saito, N.; Nakashima, K. Shear rate and crystalline phase effects on the super-cooling degree and crystallization behavior of CaO-SiO2-CaF2-RO (R=Mg, or Sr) flux systems. ISIJ Int. 2017, 57, 1313–1318. [Google Scholar] [CrossRef]

- Li, J.L.; Shu, Q.F.; Chou, K.C. Effect of agitation on crystallization behavior of CaO-Al2O3-SiO2-Na2O-CaF2 mold fluxes with varying basicity. Metall. Mater. Trans. B 2015, 46, 1555–1563. [Google Scholar] [CrossRef]

- Watanabe, K.; Tsutsumi, K.; Suzuki, M.; Fujita, H.; Hatori, S.; Suzuki, T.; Omoto, T. Development of new mold flux for continuous casting based on non-newtonian fluid properties. ISIJ Int. 2014, 54, 865–871. [Google Scholar] [CrossRef]

- Wen, G.H.; Sridhar, S.; Tang, P.; Qi, X.; Liu, Y.Q. Development of fluoride-free mold powders for peritectic steel slab casting. ISIJ Int. 2007, 47, 1117–1125. [Google Scholar] [CrossRef]

- Yang, C.L.; Wen, G.H.; Tang, P. Non-isothermal crystallization kinetics of mold fluxes containing Li2O for high aluminum steel casting. Steel Res. Int. 2016, 87, 880–889. [Google Scholar] [CrossRef]

- Gao, J.X.; Wen, G.H.; Sun, Q.H.; Tang, P.; Liu, Q. The influence of Na2O on the solidification and crystallization behavior of CaO-SiO2-Al2O3-based mold flux. Metall. Mater. Trans. B 2015, 46, 1850–1859. [Google Scholar] [CrossRef]

- Sridhar, S.; Mills, K.C.; Afrange, O.D.C.; Lörz, H.P.; Carli, R. Break temperatures of mould fluxes and their relevance to continuous casting. Ironmak. Steelmak. 2000, 27, 238–242. [Google Scholar] [CrossRef]

- Seo, M.D.; Shi, C.B.; Baek, J.Y.; Cho, J.K.; Kim, S.H. Kinetics of isothermal melt crystallization in CaO-SiO2-CaF2-based mold fluxes. Metall. Mater. Trans. B 2015, 46, 2374–2383. [Google Scholar] [CrossRef]

- Torrens-Serra, J.; Venkataraman, S.; Stoica, M.; Kuehn, U.; Roth, S.; Eckert, J. Non-isothermal kinetic analysis of the crystallization of metallic glasses using the master curve method. Materials 2011, 4, 2231–2243. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.T.; Wen, G.H.; Liao, J.L.; Sridhar, S. Observations of crystallization in mold slags with varying Al2O3/SiO2 Ratio. Steel Res. Int. 2010, 81, 516–528. [Google Scholar] [CrossRef]

- Flemings, M.C. Behavior of metal alloys in the semisolid state. Metall. Trans. A 1991, 22, 957–981. [Google Scholar] [CrossRef]

- Morozova, A.; Borodin, E.; Bratov, V.; Zherebtsov, S.; Belyakov, A.; Kaibyshev, R. Grain refinement kinetics in a low alloyed Cu–Cr–Zr alloy subjected to large strain deformation. Materials 2017, 10, 1934. [Google Scholar] [CrossRef] [PubMed]

- Ye, C.; Ran, G.; Zhou, W.; Shen, Q.; Feng, Q.J.; Lin, J.X. Recrystallization-induced surface cracks of carbon ions irradiated 6H-SiC after annealing. Materials 2017, 10, 1231. [Google Scholar] [CrossRef] [PubMed]

- Papageorgiou, G.Z.; Achilias, D.S.; Bikiaris, D.N.; Karayannidis, D.P. Crystallization kinetics and nucleation activity of filler in polypropylene/surface-treated SiO2 nanocomposites. Thermochim. Acta 2005, 427, 117–128. [Google Scholar] [CrossRef]

- Zhou, L.J.; Wang, W.L.; Ma, F.J.; Li, J.; Wei, J. A kinetic study of the effect of basicity on the mold fluxes crystallization. Metall. Mater. Trans. B 2012, 43, 354–362. [Google Scholar] [CrossRef]

- Shi, C.B.; Seo, M.D.; Wang, H.; Cho, J.W.; Kim, S.H. Crystallization kinetics and mechanism of CaO-Al2O3-based mold flux for casting high-aluminum TRIP Steels. Metall. Mater. Trans. B 2015, 46, 345–356. [Google Scholar] [CrossRef]

- Wang, Z.; Shu, Q.F.; Chou, K.C. Crystallization kinetics and structure of mold fluxes with SiO2 being substituted by TiO2 for casting of titanium-stabilized Stainless Steel. Mater. Trans. B 2013, 44, 606–613. [Google Scholar] [CrossRef]

- Li, J.; Wang, W.L.; Wei, J.; Huang, D.Y.; Matsuura, H. A kinetic study of the effect of Na2O on the crystallization behavior of mold fluxes for casting medium carbon steel. ISIJ Int. 2012, 52, 2220. [Google Scholar] [CrossRef]

- Bykov, Y.V.; Egorov, S.V.; Eremeev, A.G.; Kholoptsev, V.V.; Plotnikov, I.V.; Rybakov, K.I.; Sorokin, A.A. On the mechanism of microwave flash sintering of ceramics. Materials 2016, 9, 684. [Google Scholar] [CrossRef] [PubMed]

- Ilyushechkin, A.Y.; Hla, S.S.; Roberts, D.G.; Kinaev, N.N. The effect of solids and phase compositions on viscosity behaviour and TCV of slags from Australian bituminous coals. J. Non-Cryst. Solids 2011, 357, 893–902. [Google Scholar] [CrossRef]

- Dyre, J.C.; Olsen, N.B.; Christensen, T. Local elastic expansion model for viscous-flow activation energies of glass-forming molecular liquids. Phys. Rev. B 1996, 53, 2171–2174. [Google Scholar] [CrossRef]

- Mayr, S.G. Activation energy of shear transformation zones: A key for understanding rheology of glasses and liquids. Phys. Rev. Lett. 2006, 97, 195501–195504. [Google Scholar] [CrossRef] [PubMed]

- Dienes, G.J. Activation energy for viscous flow and short-range order. J. Appl. Phys. 1953, 24, 779–782. [Google Scholar] [CrossRef]

- Mills, K.C.; Fox, A.B.; Li, Z.; Thackray, R.P. Performance and properties of mould fluxes. Ironmak. Steelmak. 2005, 32, 26–34. [Google Scholar] [CrossRef]

| Chemical Compositions | Contents(Weight Percent) |

|---|---|

| CaO | 37.7 |

| SiO2 | 34.3 |

| Al2O3 | 5 |

| CaF2 | 15 |

| Na2O | 8 |

| Rotating Speed/rpm | Crystalline Fraction/% | Increment |

|---|---|---|

| 0 | 2.7 | - |

| 100 | 10.3 | 7.6 |

| 200 | 25.1 | 14.8 |

| 300 | 42.8 | 17.7 |

| 400 | 47.6 | 4.8 |

| Temperature/K | Rotating Speed/rpm | n | lnk |

|---|---|---|---|

| 1573 | 100 | 1.43 | −4.33 |

| 200 | 1.13 | −3.16 | |

| 300 | 0.99 | −2.25 | |

| 400 | 0.85 | −1.56 | |

| 1568 | 100 | 1.45 | −4.11 |

| 200 | 1.22 | −3.05 | |

| 300 | 1.01 | −2.04 | |

| 400 | 0.89 | −1.54 |

| Crystals Growth Mode | Crystallization Mode | |

|---|---|---|

| Diffusion Controlled | Interface Reaction Controlled | |

| Constant nucleation rate | ||

| Three-Dimensional growth | 2.5 | 4 |

| Two-Dimensional growth | 2 | 3 |

| One-Dimensional growth | 1.5 | 2 |

| Instantaneous nucleation | ||

| Three-Dimensional growth | 1.5 | 3 |

| Two-Dimensional growth | 1 | 2 |

| One-Dimensional growth | 0.5 | 1 |

| Surface nucleation | 0.5 | 1 |

| Rotating Speed/rpm | Crystallization Activation Energy/kJ·mol−1 | Decrement |

|---|---|---|

| 100 | −13.109 | - |

| 200 | −72.103 | −58.993 |

| 300 | −137.650 | −65.547 |

| 400 | −154.205 | −16.554 |

| Rotational Speed/rpm | Break Temperature/°C | Viscous-Flow Activation Energy/kJ·mol−1 |

|---|---|---|

| 0 | 1277 | 121.602 |

| 100 | 1277 | 121.797 |

| 200 | 1280 | 126.978 |

| 300 | 1281 | 128.771 |

| 400 | 1281 | 130.449 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, S.; Wen, G.; Ding, Z.; Tang, P.; Liu, Q. Effect of Shear Stress on Isothermal Crystallization Behavior of CaO-Al2O3-SiO2-Na2O-CaF2 Slags. Materials 2018, 11, 1085. https://doi.org/10.3390/ma11071085

Gu S, Wen G, Ding Z, Tang P, Liu Q. Effect of Shear Stress on Isothermal Crystallization Behavior of CaO-Al2O3-SiO2-Na2O-CaF2 Slags. Materials. 2018; 11(7):1085. https://doi.org/10.3390/ma11071085

Chicago/Turabian StyleGu, Shaopeng, Guanghua Wen, Zequan Ding, Ping Tang, and Qiang Liu. 2018. "Effect of Shear Stress on Isothermal Crystallization Behavior of CaO-Al2O3-SiO2-Na2O-CaF2 Slags" Materials 11, no. 7: 1085. https://doi.org/10.3390/ma11071085

APA StyleGu, S., Wen, G., Ding, Z., Tang, P., & Liu, Q. (2018). Effect of Shear Stress on Isothermal Crystallization Behavior of CaO-Al2O3-SiO2-Na2O-CaF2 Slags. Materials, 11(7), 1085. https://doi.org/10.3390/ma11071085