Investigation of the Microstructure and Mechanical Properties of Copper-Graphite Composites Reinforced with Single-Crystal α-Al2O3 Fibres by Hot Isostatic Pressing

Abstract

:1. Introduction

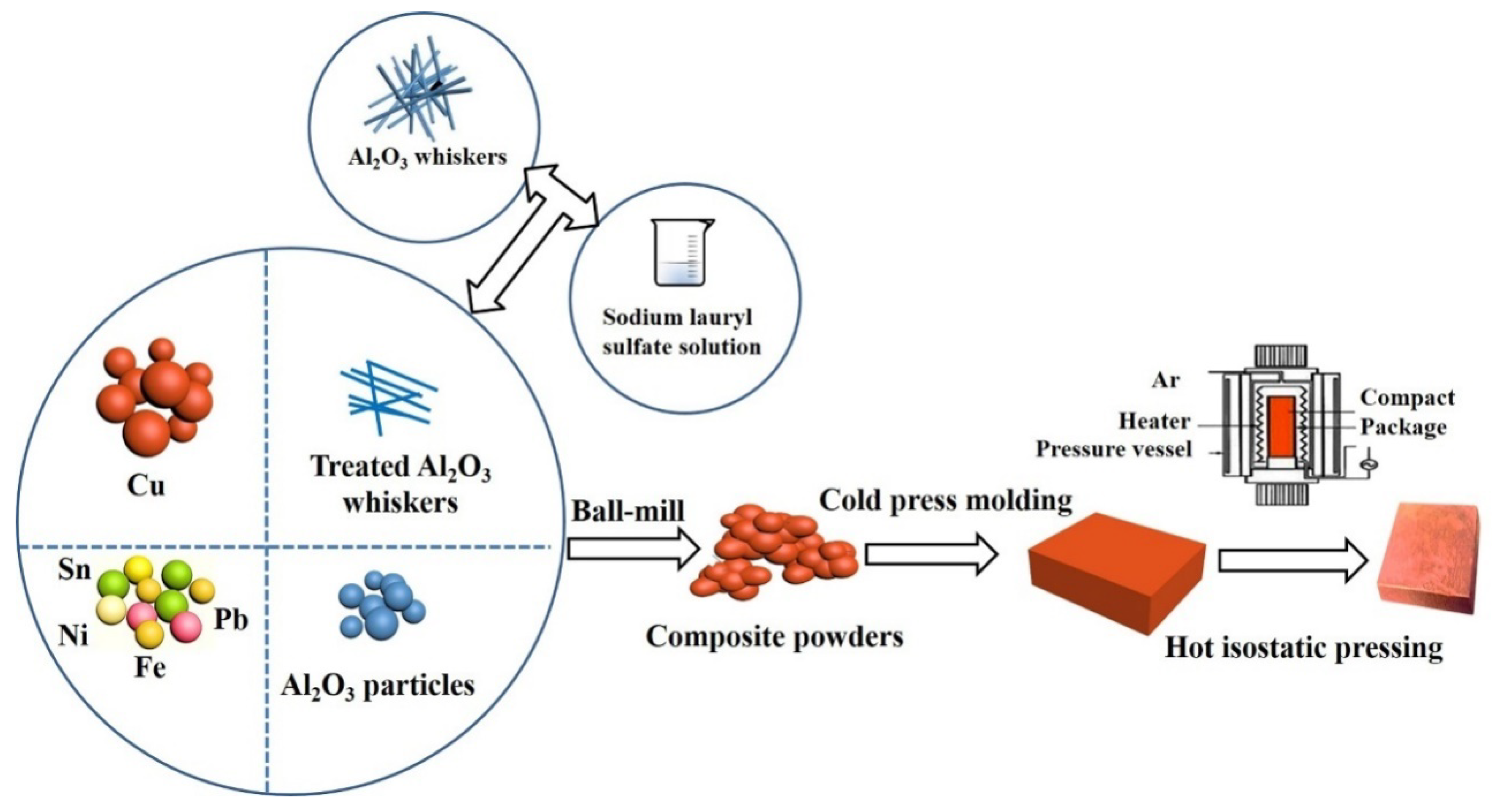

2. Materials and Methods

3. Results and Discussion

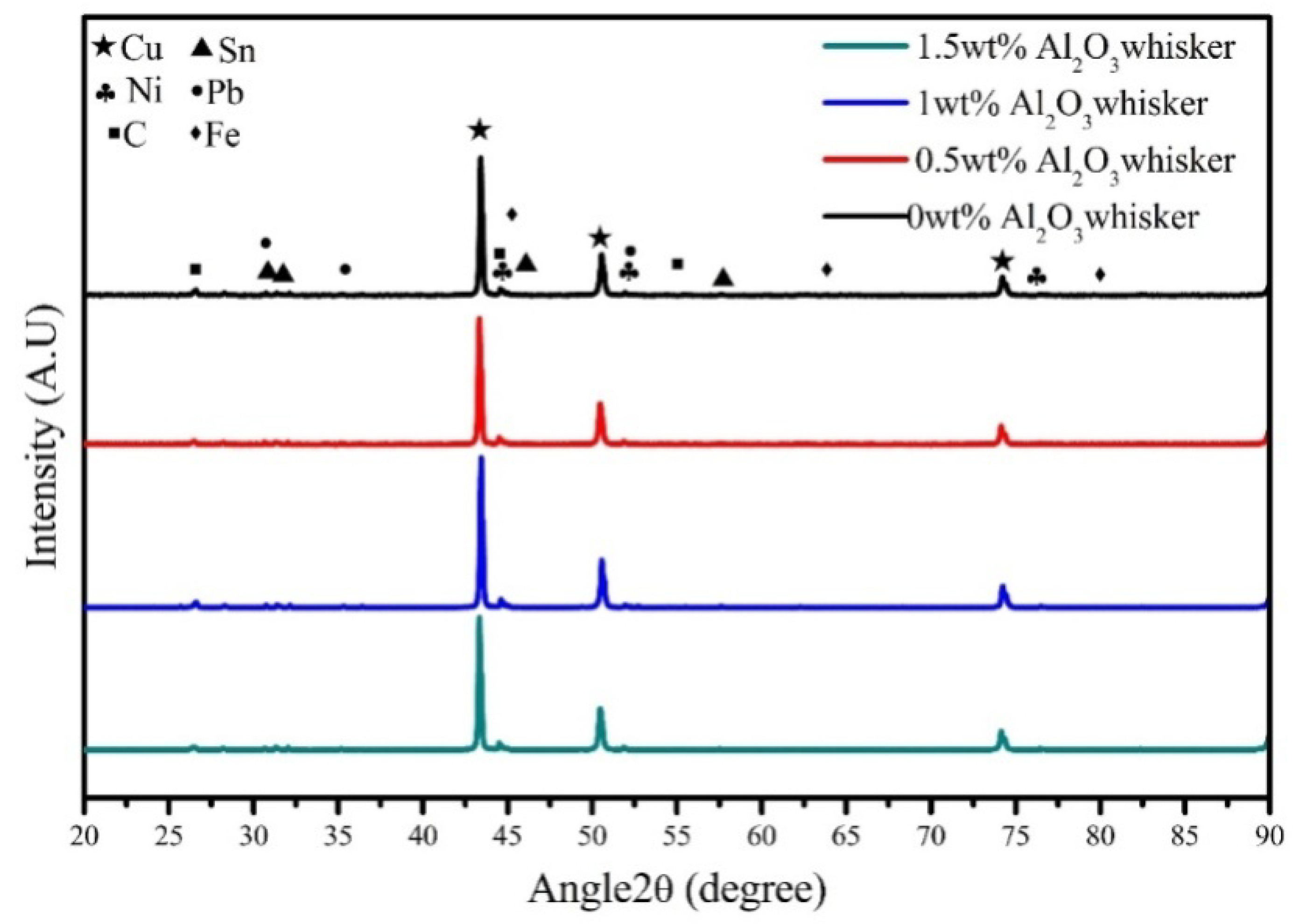

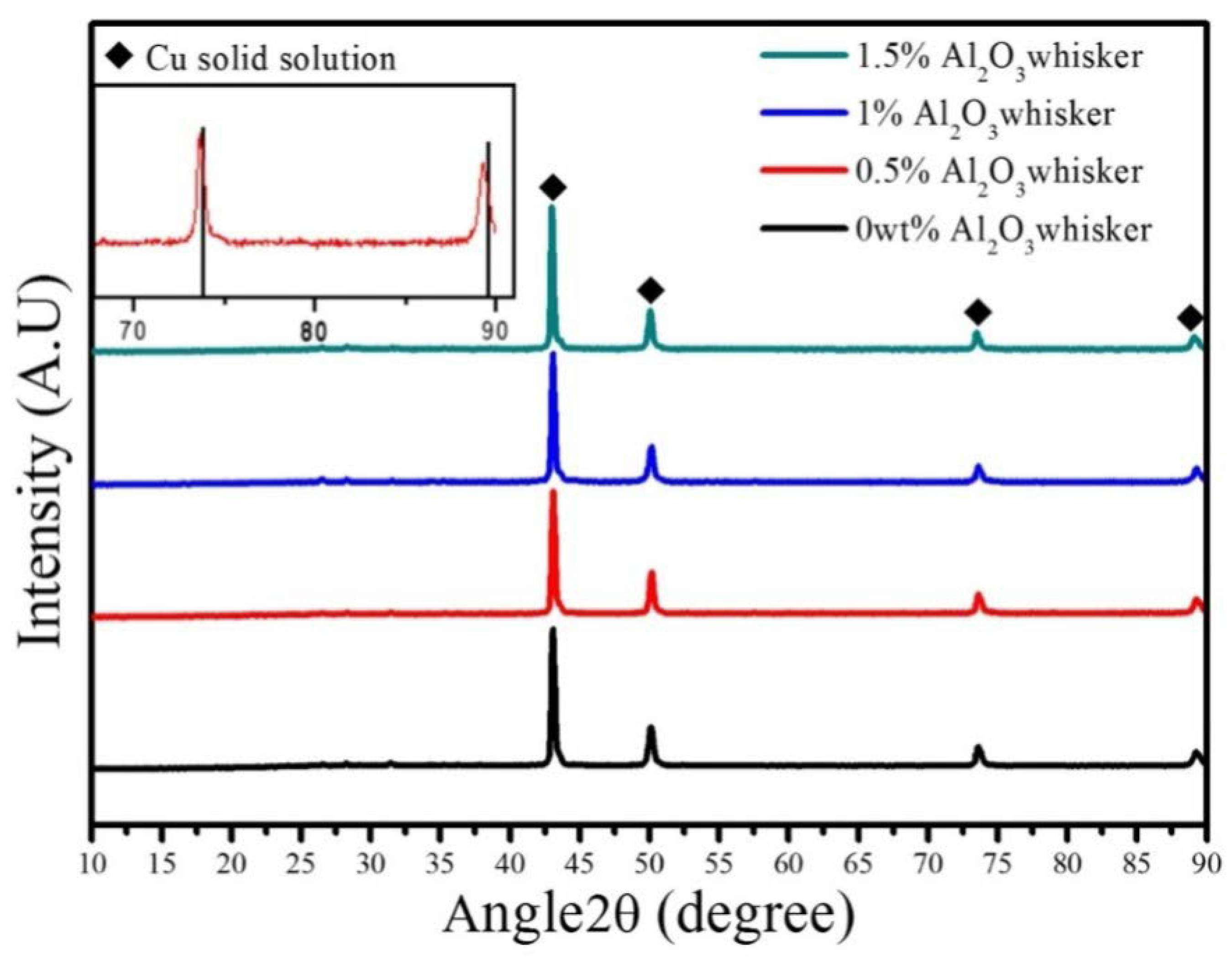

3.1. Results of the Composites PowderAnalysis

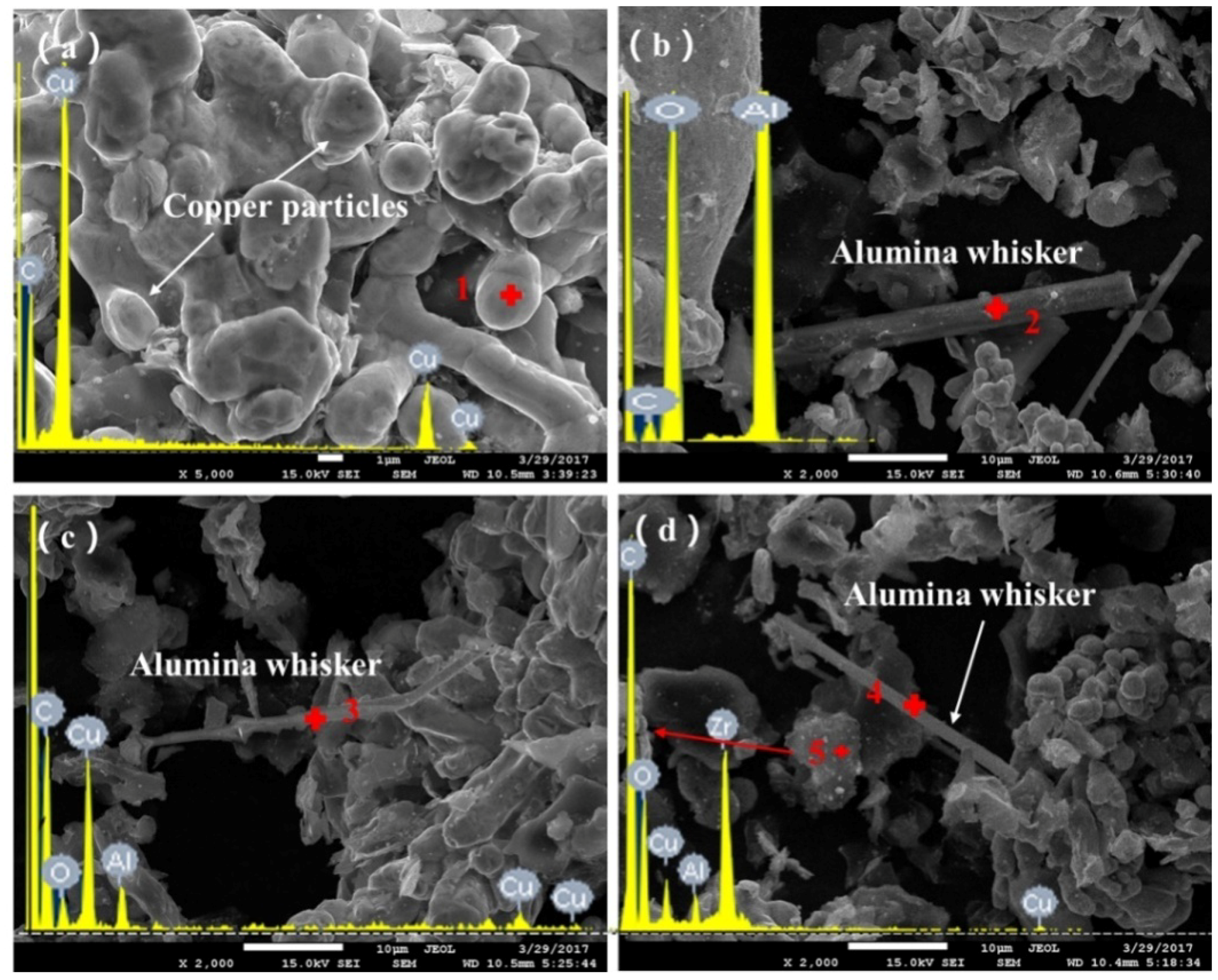

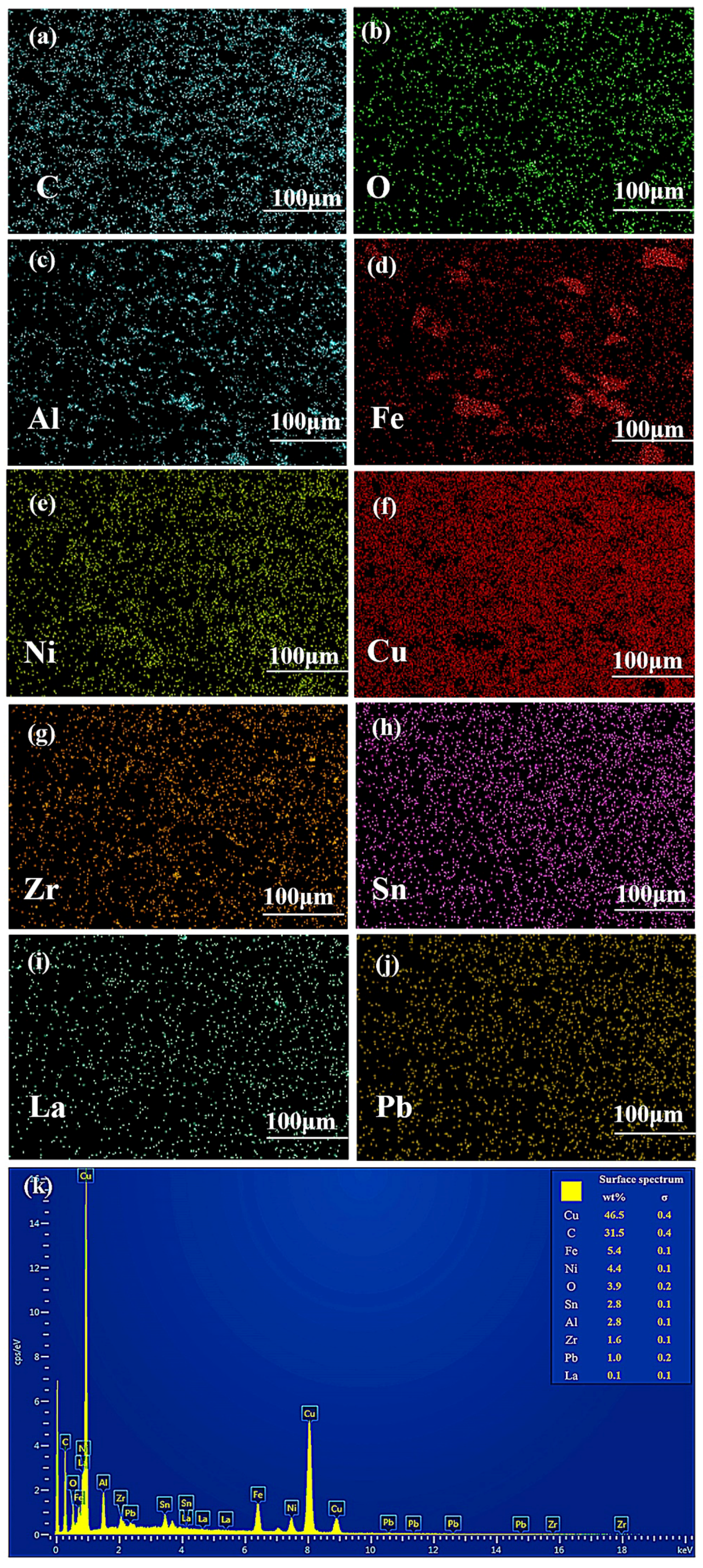

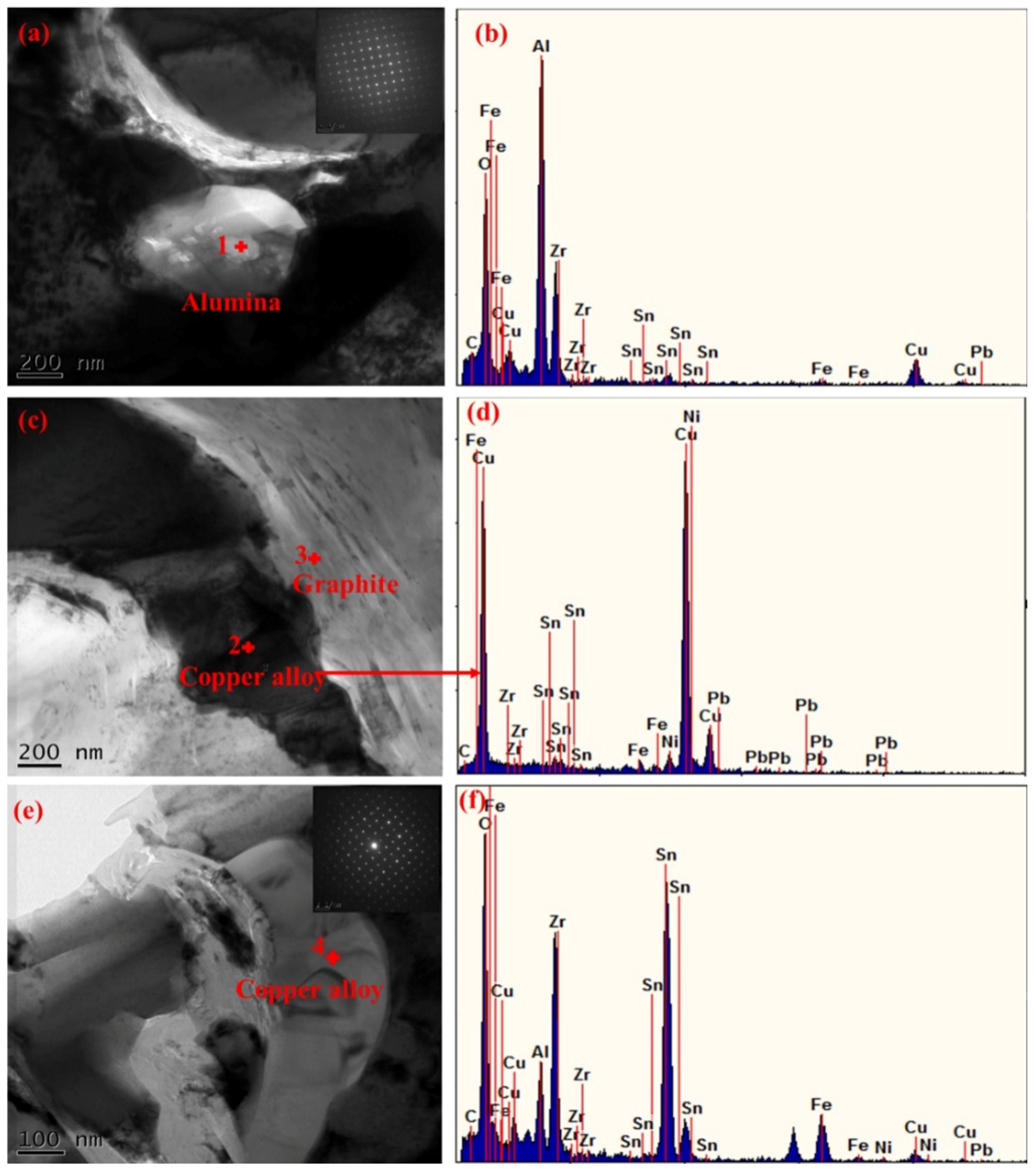

3.2. Microscopic Morphology Analysis of the Composites

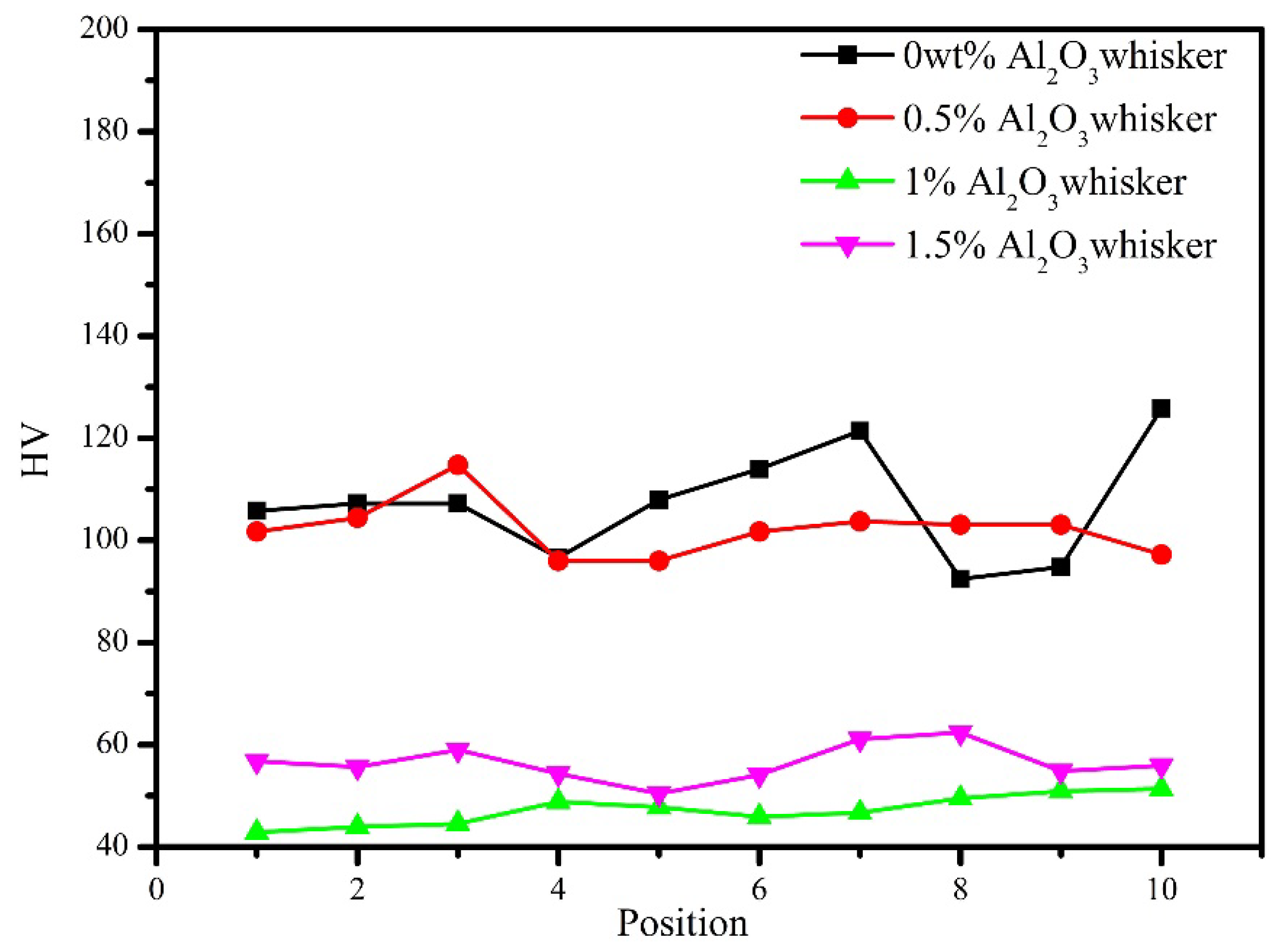

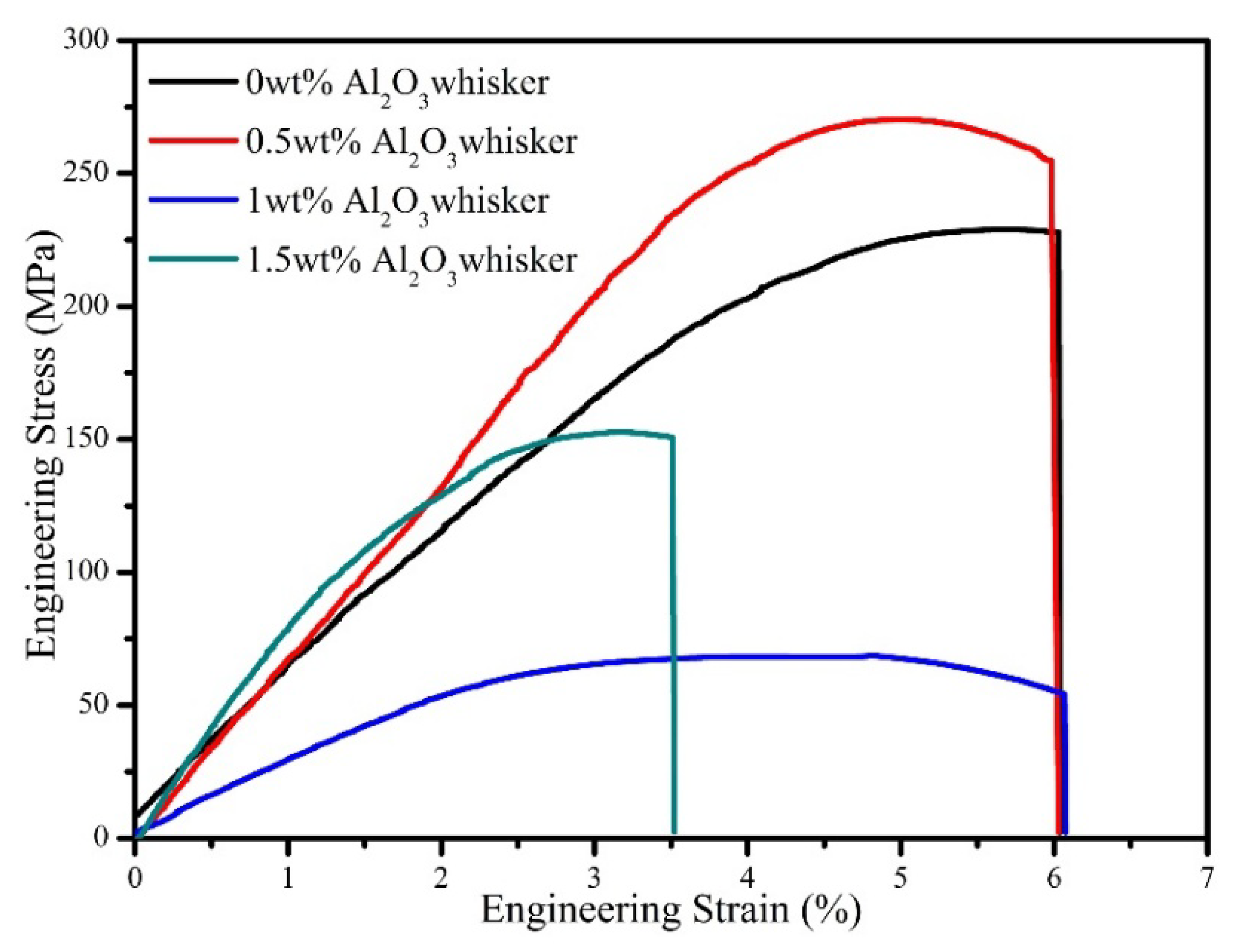

3.3. Mechanical Properties of the Composites

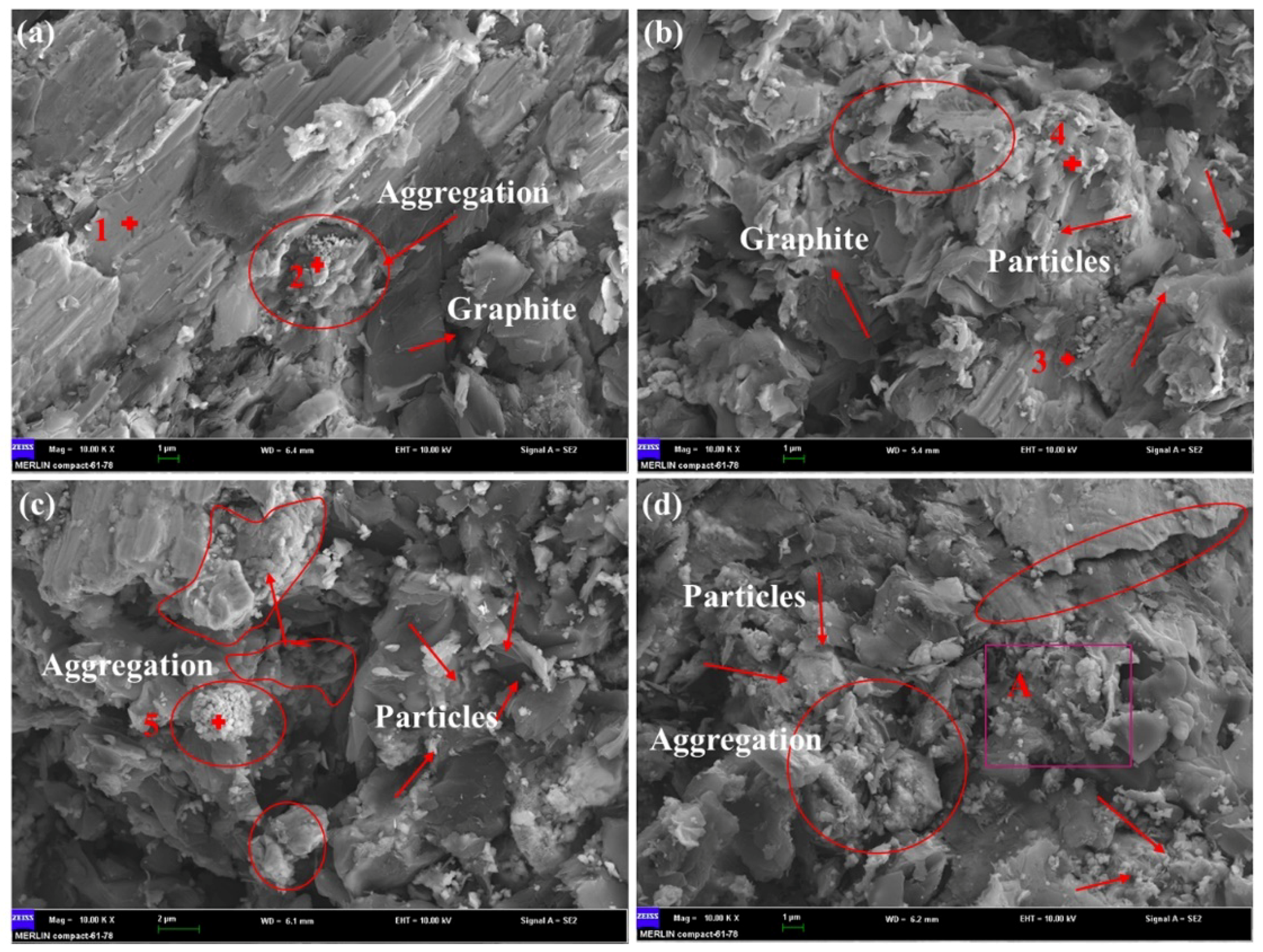

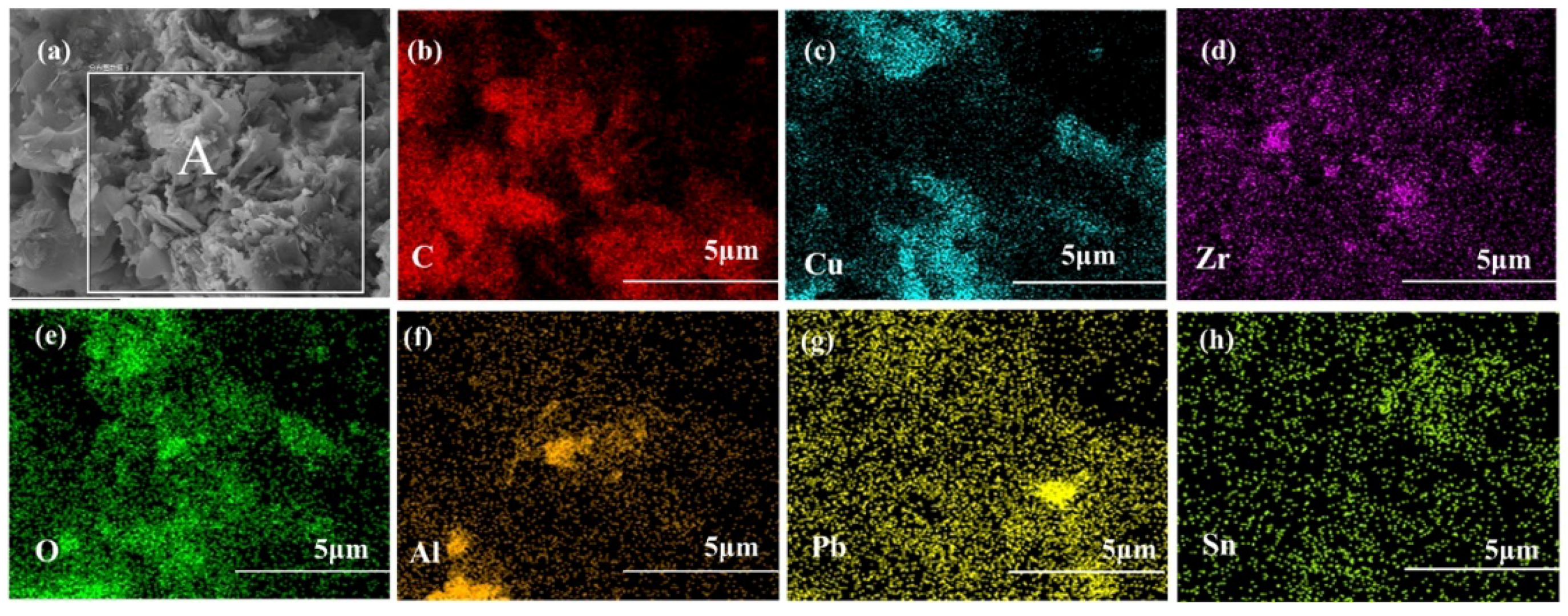

3.4. The Compression Fracture Analysis of the Composites

4. Conclusions

- (1)

- In this study, Al2O3-enriched copper matrix composites were successfully prepared by mechanical alloying and hot isostatic pressing. When the content of Al2O3 whiskers was in the range of 0–1.5 wt %, the hardness of the composites decreased with the increase of the Al2O3 whisker content, while the compressive strength of the composites first increased and then decreased with the increase of the Al2O3whisker content.

- (2)

- The main strengthening mechanism in the composites was fine grain strengthening and solid solution strengthening, and Orowan mechanism and dislocation strengthening were also present. It can be seen from the XRD results that the process of dynamic recovery and recrystallization occurred during the sintering process, and the presence of La and other alloying elements played the role of refining grain, and the composites also showed a fine grain strengthening effect. Combining the results of EPMA and TEM, it was known that the composites showed a solid solution phenomenon in the sintering process, therefore, a solution strengthening effect was present. Additionally, Al2O3 particles and other reinforcements embedded in the copper matrix could show the strengthening effect of dislocation and Orowan mechanism.

- (3)

- The fracture type of the composites was brittle fracture. From results of SEM and EPMA, it can be seen that holes, clusters of the reinforcements, and weak interface bonding were present in the composite, naturally causing stress concentration at the positions of these defects. When the sample was loaded, these positions often become an area of micro-crack source, and with further loadings, cracks continued to expand, resulting in fracture.

Author Contributions

Funding

Conflicts of Interest

References

- Simoncini, A.; Tagliaferri, V.; Ucciardello, N. High thermal conductivity of copper matrix composite coatings with highly-aligned graphite nanoplatelets. Materials 2017, 10, 1226. [Google Scholar] [CrossRef] [PubMed]

- Strojny-Nędza, A.; Pietrzak, K.; Węglewski, W. The influence of Al2O3 powder morphology on the properties of Cu-Al2O3 composites designed for functionally graded materials (FGM). J. Mater. Perform. 2016, 25, 1–12. [Google Scholar] [CrossRef]

- Ritasalo, R.; Liua, X.W.; Söderberg, O.; Keski-Honkola, A.; Pitkänen, V.; Hannula, S.-P. The microstructural effects on the mechanical and thermal properties of pulsed electric current sintered Cu-Al2O3 composites. Procedia Eng. 2011, 10, 124–129. [Google Scholar] [CrossRef]

- Jiang, X.S.; Liu, W.X.; Li, J.R.; Shao, Z.Y.; Zhu, D.G. Microstructures and mechanical properties of Cu/Ti3SiC2/C/MWCNTs composites prepared by vacuum hot-pressing sintering. J. Alloy. Compd. 2015, 618, 700–706. [Google Scholar] [CrossRef]

- Li, M.; He, H. Study on electrochemical performance of multi-wall carbon nanotubes coated by iron oxide nanoparticles as advanced electrode materials for super capacitors. Vacuum 2017, 143, 371–379. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically alloyed nanocomposites. Prog. Mater. Sci. 2013, 58, 383–502. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Gao, Y.M.; Wei, S.Z.; Hu, Y.J. Characterization of Al2O3 in high-strength Mo alloy sheets by high-resolution transmission electron microscopy. Microsc. Microanal. 2016, 22, 122–130. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.G.; Yang, X.H.; Xu, S.C.; Shi, Y.G.; Yang, J.F. Fabrication of highly dense Al2O3 ceramics. Scr. Mater. 2013, 68, 393–395. [Google Scholar] [CrossRef]

- Shabana, Y.M.; Karihaloo, B.L.; Zhu, H.X.; Kulasegaram, S. Influence of processing defects on the measured properties of Cu-Al2O3composites: A forensic investigation. Compos. Part A Appl. Sci. Manuf. 2013, 46, 140–146. [Google Scholar] [CrossRef]

- Asano, K.; Yoneda, H. High temperature properties of AZ91D magnesium alloy composite reinforced with short alumina fiber and Mg2Si particle. Mater. Trans. 2008, 49, 1688–1693. [Google Scholar] [CrossRef]

- El-Azim, A.N.A.; Kassem, M.A.; El-Baradie, Z.M.; Waly, M. Structure and properties of short alumina fibre reinforced AlSi18CuNi produced by stir casting. Mater. Lett. 2002, 56, 963–969. [Google Scholar] [CrossRef]

- Valcárcel, V.; Souto, A.; Guitián, F. Development of single-crystal α-Al2O3 fibers by vapor-liquid-solid deposition (VLS) from aluminum and powdered silica. Adv. Mater. 1998, 10, 138–140. [Google Scholar] [CrossRef]

- Víctor, V.; Antonio, P.; Marek, C.; Francisco, G. Novel ribbon-shaped α-Al2O3 fibers. Adv. Mater. 1998, 10, 1370–1373. [Google Scholar]

- Chandrasekhar, S.B.; Sarma, S.S.; Ramakrishna, M.; Babu, P.S.; Rao, T.N.; Kashyap, B.P. Microstructure and properties of hot extruded Cu–1 wt % Al2O3nano-composites synthesized by various techniques. Mater. Sci. Eng. A 2014, 591, 46–53. [Google Scholar] [CrossRef]

- Ferkel, H.; Hellmig, R.J. Effect of nanopowderdeagglomeration on the densities of nanocrystalline ceramic green bodies and their sintering behaviour. Nanostruct. Mater. 1999, 11, 617–622. [Google Scholar] [CrossRef]

- Zhou, D.S.; Zhang, D.L.; Kong, C.; Munroe, P. Factors controlling the tensile properties of ultrafine structured Cu-5 vol % Al2O3nanocomposite prepared by high energy mechanical milling and powder compact extrusion. Mater. Sci. Eng. A 2013, 584, 67–72. [Google Scholar] [CrossRef]

- Tian, B.H.; Liu, P.; Song, K.X.; Li, Y.; Liu, Y.; Ren, F.Z.; Su, J.H. Microstructure and properties at elevated temperature of a nano-Al2O3particles dispersion-strengthened copper base composite. Mater. Sci. Eng. A 2006, 435, 705–710. [Google Scholar] [CrossRef]

- Afshar, A.; Simchi, A. Flow stress dependence on the grain size in alumina dispersion-strengthened copper with a bimodal grain size distribution. Mater. Sci. Eng. A 2009, 518, 41–46. [Google Scholar] [CrossRef]

- Dalirbod, A.; Sorkhe, Y.A.; Aghajani, H. Mechanical properties and fracture study of alumina dispersion hardened copper-based nano-composite at elevated temperatures. Adv. Mater. Res. 2014, 829, 583–588. [Google Scholar] [CrossRef]

- Fathy, A.; El-Kady, O. Thermal expansion and thermal conductivity characteristics of Cu-Al2O3 nanocomposites. Mater. Des. 2013, 46, 355–359. [Google Scholar] [CrossRef]

- Fathy, A.; Shehata, F.; Abdelhameed, M.; Elmahdy, M. Compressive and wear resistance of nanometric alumina reinforced copper matrix composites. Mater. Des. 2012, 36, 100–107. [Google Scholar] [CrossRef]

- Brocchi, E.D.A.; Motta, M.S.; Moura, F.J.; Solórzano-Naranjo, I.G. Reduction reactions applied for synthesizing different nano-structured materials. Mater. Chem. Phys. 2013, 140, 273–283. [Google Scholar] [CrossRef]

- Jena, P.K.; Brocchi, E.A.; Solórzano, I.G.; Motta, M.S. Identification of a third phase in Cu–Al2O3 nanocomposites prepared by chemical routes. Mater. Sci. Eng. A 2004, 371, 72–78. [Google Scholar] [CrossRef]

- Zúberová, Z. Synthesis of copper alloys with extended solid solubility and nano-Al2O3dispersion by mechanical alloying and equal channel angular pressing. Philos. Mag. 2010, 90, 1465–1483. [Google Scholar] [CrossRef]

- Mehr, V.Y.; Rezaeian, A.; Toroghinejad, M.R. Application of accumulative roll bonding and anodizing process to produce Al-Cu-Al2O3 composite. Mater. Des. 2015, 70, 53–59. [Google Scholar] [CrossRef]

- Jena, P.K.; Brocchi, E.A.; Motta, M.S. In-situ formation of Cu-Al2O3nano-scale composites by chemical routes and studies on their microstructures. Mater. Sci. Eng. A 2001, 313, 180–186. [Google Scholar] [CrossRef]

- Ramos, M.I.; Suguihiro, N.M.; Brocchi, E.A.; Navarro, R.; Solorzano, I.G. Microstructure investigation of Cu-Ni base Al2O3 nanocomposites: From nanoparticles synthesis to consolidation. Metall. Mater. Trans. A 2017, 48, 2643–2653. [Google Scholar] [CrossRef]

- Moustafa, E. Effect of Multi-Pass Friction Stir Processing on Mechanical Properties for AA2024/Al2O3 Nanocomposites. Materials 2017, 10, 1053. [Google Scholar] [CrossRef] [PubMed]

- Rajkovic, V.M.; Božić, D.; Popovic, M.; Jovanovic, M. The influence of powder particle size on properties of Cu-Al2O3 composites. Sci. Sinter. 2009, 41, 185–192. [Google Scholar] [CrossRef]

- Wagih, A.; Fathy, A. Experimental investigation and FE simulation of spherical indentation on nano-alumina reinforced copper-matrix composite produced by three different techniques. Adv. Powder Technol. 2017, 28, 1954–1965. [Google Scholar] [CrossRef]

- Zhang, X.H.; Li, X.X.; Chen, H.; Guo, S.D. Investigation on microstructure and properties of Cu-Al2O3 composites fabricated by a novel in-situ reactive synthesis. Mater. Des. 2016, 92, 58–63. [Google Scholar] [CrossRef]

- Zhang, Z.; Tremblay, R.; Dube, D. Microstructure and mechanical properties of ZA104 (0.3–0.6 Ca) die-casting magnesium alloys. Mater. Sci. Eng. A 2004, 385, 286–291. [Google Scholar] [CrossRef]

- Mula, S.; Sahani, P.; Pratihar, S.K.; Mal, S.; Koch, C.C. Mechanical properties and electrical conductivity of Cu-Cr and Cu-Cr-4%SiC nanocomposites for thermo-electric applications. Mater. Sci. Eng. A 2011, 528, 4348–4356. [Google Scholar] [CrossRef]

- Sahlot, P.; Jha, K.; Dey, G.K.; Arora, A. Quantitative wear analysis of H13 steel tool during friction stir welding of Cu-0.8%Cr-0.1%Zr alloy. Wear 2017, 378–379, 82–89. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, Z.; Xiao, Z.; Zhao, Z.; Yang, Z. Microstructure evolution and properties of Cu-Cr alloy during continuous extrusion process. J. Alloy. Compd. 2017, 703, 454–460. [Google Scholar] [CrossRef]

- Peng, L.J.; Xie, H.F.; Huang, G.J.; Xu, G.L.; Yin, X.Q.; Feng, X.; Mi, X.J.; Yang, Z. The phase transformation and strengthening of a Cu-0.71 wt. % Cr alloy. J. Alloy. Compd. 2017, 708, 1096–1102. [Google Scholar] [CrossRef]

- Zhou, J.M.; Zhu, D.G.; Tang, L.T.; Jiang, X.S.; Chen, S.; Peng, X.; Hu, C.F. Microstructure and properties of powder metallurgy Cu-1%Cr-0.65%Zr alloy prepared by hot pressing. Vacuum 2016, 131, 156–163. [Google Scholar] [CrossRef]

- Poblano-Salas, C.A. The effect of cobalt additions on the mechanical and electrical properties of Cu-Cr-Zr melt-spun ribbons. Mater. Sci. Eng. A 2008, 491, 309–314. [Google Scholar] [CrossRef]

- Liu, J.B.; Zhang, K.; Han, J.T.; Li, X.G.; Li, Y.J.; Ma, M.L.; Yuan, J.W.; Li, M. Homogenization heat treatment of Mg-7.0 wt %Y-1.0 wt %Nd-0.5 wt %Zr alloy. Rare Met. 2015, 1–6. [CrossRef]

- Shehata, F.; Fathy, A.; Abdelhameed, M.; Moustafa, S.F. Preparation and properties of Al2O3nanoparticle reinforced copper matrix composites by in situ processing. Mater. Des. 2009, 30, 2756–2762. [Google Scholar] [CrossRef]

- Ďurišinová, K.; Ďurišin, J.; Orolínová, M.; Ďurišin, M.; Szabó, J. Effect of mechanical milling on nanocrystalline grain stability and properties of Cu-Al2O3 composite prepared by thermo-chemical technique and hot extrusion. J. Alloy. Compd. 2015, 618, 204–209. [Google Scholar] [CrossRef]

- Choi, H.; Bor, A.; Sakuragi, S.; Lee, J.; Lim, H.T. The grinding behavior of ground copper powder for Cu/CNT nanocomposite fabrication by using the dry grinding process with a high-speed planetary ball mill. J. Korean. Phys. Soc. 2016, 68, 147–153. [Google Scholar] [CrossRef]

- Salvo, C.; Aguilar, C.; Cardoso-Gil, R.; Medina, A.; Bejar, L.; Mangalaraja, R.V. Study on the microstructural evolution of Ti-Nb based alloy obtained by high-energy ball milling. J. Alloy. Compd. 2017, 720, 254–263. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Gupta, M. Microstructure and mechanical characteristics of AZ31B/Al2O3 nanocomposite with addition of Ca. J. Compos. Mater. 2009, 43, 5–17. [Google Scholar] [CrossRef]

- Dash, K.; Panda, S.; Ray, B.C. Process and progress of sintering behavior of Cu-Al2O3 composites. Emerg. Mater. Res. 2015, 2, 32–38. [Google Scholar] [CrossRef]

- Száraz, Z.; Trojanová, Z.; Cabbibo, M.; Evangelista, E. Strengthening in a WE54 magnesium alloy containing SiC particles. Mater. Sci. Eng. A 2007, 462, 225–229. [Google Scholar] [CrossRef]

- Kim, W.J.; Lee, T.J.; Han, S.H. Multi-layer graphene/copper composites: Preparation using high-ratio differential speed rolling, microstructure and mechanical properties. Carbon 2014, 69, 55–65. [Google Scholar] [CrossRef]

- Asano, K.; Yoneda, H. Effects of particle-dispersion on the strength of an alumina fiber-reinforced aluminum alloy matrix composite. Mater. Trans. 2005, 44, 1172–1180. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Development of high strength magnesium copper based hybrid composites with enhanced tensile properties. Mater. Sci. Technol. 2003, 19, 253–259. [Google Scholar] [CrossRef]

- Salahi, E.; Rajabi, A. Fabrication and characterisation of copper–alumina nanocomposites prepared by high-energy fast milling. Mater. Sci. Technol. 2016, 32, 1212–1217. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, C.; Cui, S.; Li, Z. Characteristics of nano-alumina particles dispersion strengthened copper fabricated by reaction synthesis. Rare Met. Mater. Eng. 2016, 45, 893–896. [Google Scholar] [CrossRef]

- Carreño-Morelli, E.; Urreta, S.E.; Schaller, R. Mechanical spectroscopy of thermal stress relaxation in aluminium alloys reinforced with short alumina fiberes. Phys. Status Solidi. 1998, 167, 61–69. [Google Scholar] [CrossRef]

| Original Materials | Graphite | Alumina Whisker | Al2O3 | Ni | Fe | Sn | Pb | ZrO2 | La | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| Density (g/cm3) | 2.2 | 3.99 | 3.9 | 8.91 | 7.86 | 7.28 | 11.34 | 5.85 | 6.7 | 8.9 |

| Mesh number | 200 | Diameter, μm: 0.1–4 Length, μm: 5–30 | 200 | 250 | 250 | 250 | 250 | 200 | - | 250 |

| Elements | C | O | Al | Fe | Ni | Cu | Sn |

|---|---|---|---|---|---|---|---|

| Point 1 | 0 | 0 | 0 | 2.32 | 4.62 | 87.56 | 5.5 |

| Point 2 | 0 | 45.26 | 46.20 | 0 | 0 | 8.54 | 0 |

| Point 3 | 0 | 35.33 | 32.12 | 0 | 1.56 | 28.71 | 2.28 |

| Point 4 | 84.39 | 0 | 0 | 0 | 0 | 15.61 | 0 |

| Point 5 | 53.07 | 10.96 | 9.50 | 3.57 | 2.11 | 18.98 | 1.82 |

| Point 6 | 0 | 5.64 | 8.35 | 1.18 | 4.30 | 75.25 | 5.27 |

| Samples | Alumina Whiskers Content (wt %) | (111) Crystal Plane | (200) Crystal Plane | (220) Crystal Plane |

|---|---|---|---|---|

| Composite powders | 0 | 576.5 | 351.5 | 357.5 |

| 0.5 | 584 | 393 | 358.5 | |

| 1 | 625.5 | 407 | 420.5 | |

| 1.5 | 611.5 | 385.5 | 435.5 | |

| Composites | 0 | 316 | 217.5 | 238 |

| 0.5 | 324 | 264 | 256.5 | |

| 1 | 339.5 | 223 | 239.5 | |

| 1.5 | 357 | 249.5 | 242.5 |

| Elements | C | O | Al | Fe | Ni | Cu | Zr | Sn | Pb |

|---|---|---|---|---|---|---|---|---|---|

| Point 1 | 67.29 | 0 | 1.10 | 0.84 | 1.57 | 28.73 | 0.90 | 0.57 | 0 |

| Point 2 | 32.93 | 6.94 | 2.63 | 5.91 | 3.66 | 37.71 | 8.16 | 2.06 | 0 |

| Point 3 | 61.99 | 5.00 | 2.12 | 0.92 | 1.36 | 25.02 | 0 | 1.28 | 2.30 |

| Point 4 | 27.29 | 9.79 | 0.54 | 1.16 | 2.83 | 43.91 | 11.90 | 2.58 | 0 |

| Point 5 | 34.23 | 19.10 | 9.30 | 0 | 0 | 7.22 | 30.15 | 0 | 0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Jiang, X.; Qiao, C.; Shao, Z.; Zhu, D.; Zhu, M.; Valcarcel, V. Investigation of the Microstructure and Mechanical Properties of Copper-Graphite Composites Reinforced with Single-Crystal α-Al2O3 Fibres by Hot Isostatic Pressing. Materials 2018, 11, 982. https://doi.org/10.3390/ma11060982

Zhang G, Jiang X, Qiao C, Shao Z, Zhu D, Zhu M, Valcarcel V. Investigation of the Microstructure and Mechanical Properties of Copper-Graphite Composites Reinforced with Single-Crystal α-Al2O3 Fibres by Hot Isostatic Pressing. Materials. 2018; 11(6):982. https://doi.org/10.3390/ma11060982

Chicago/Turabian StyleZhang, Guihang, Xiaosong Jiang, ChangJun Qiao, Zhenyi Shao, Degui Zhu, Minhao Zhu, and Victor Valcarcel. 2018. "Investigation of the Microstructure and Mechanical Properties of Copper-Graphite Composites Reinforced with Single-Crystal α-Al2O3 Fibres by Hot Isostatic Pressing" Materials 11, no. 6: 982. https://doi.org/10.3390/ma11060982

APA StyleZhang, G., Jiang, X., Qiao, C., Shao, Z., Zhu, D., Zhu, M., & Valcarcel, V. (2018). Investigation of the Microstructure and Mechanical Properties of Copper-Graphite Composites Reinforced with Single-Crystal α-Al2O3 Fibres by Hot Isostatic Pressing. Materials, 11(6), 982. https://doi.org/10.3390/ma11060982