Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives

Abstract

1. Introduction

- Design concepts are generated from scratch or using 3D scanners, computed tomography (CT) scans, or magnetic resonance imaging (MRI) in the case of medical implants.

- A 3D computer aided design (CAD) model is prepared.

- The CAD model is analyzed and optimized with the aid of computer optimization techniques such as finite element analysis (FEA).

- The CAD model is commonly transformed into a Standard Triangulation or Tessellation Language (STL) file and imported into an AM setup. Nevertheless, the STL format lacks many features such as color or materials in the parts. For these reasons a new format was implemented by ASTM ISO, the Additive Manufacturing File Format (AMF) [4]. Besides AMF, more than 30 other alternatives to the STL file exist, three important examples of which are OBJ, PLY, and 3MF [5]. This last one (3MF) is supported among others by Microsoft, Autodesk, Dessault Systemes, 3D Systems, Materialise, Ultimaker, Mcor, PTC, FIT, GE, EOS, HP, Siemens PLM, nTopology, SLM solutions, Stratasys, and Shapeways [6]. Only time will tell which file format becomes the standard file in the future.

- The geometric shape in the STL or other format files is sliced into thin layers and the movement of the depositing or fusing unit (“printing head”), and substrate (“printing platform”), as well as other parameters are programmed by specialized software that prepares the G-code, which is a numerical control programming language.

- The AM machine builds the tridimensional object layer by layer with the specified parameters.

- The built part is removed from the building platform and the removal of support structures used to build complex geometries is conducted. The excess unbound building material needs to be removed in a cleaning step depending on the type of AM technique used.

- After the object is removed and cleaned, it might require further post-processing such as polishing, coating, or thermal treatment to obtain a functional part.

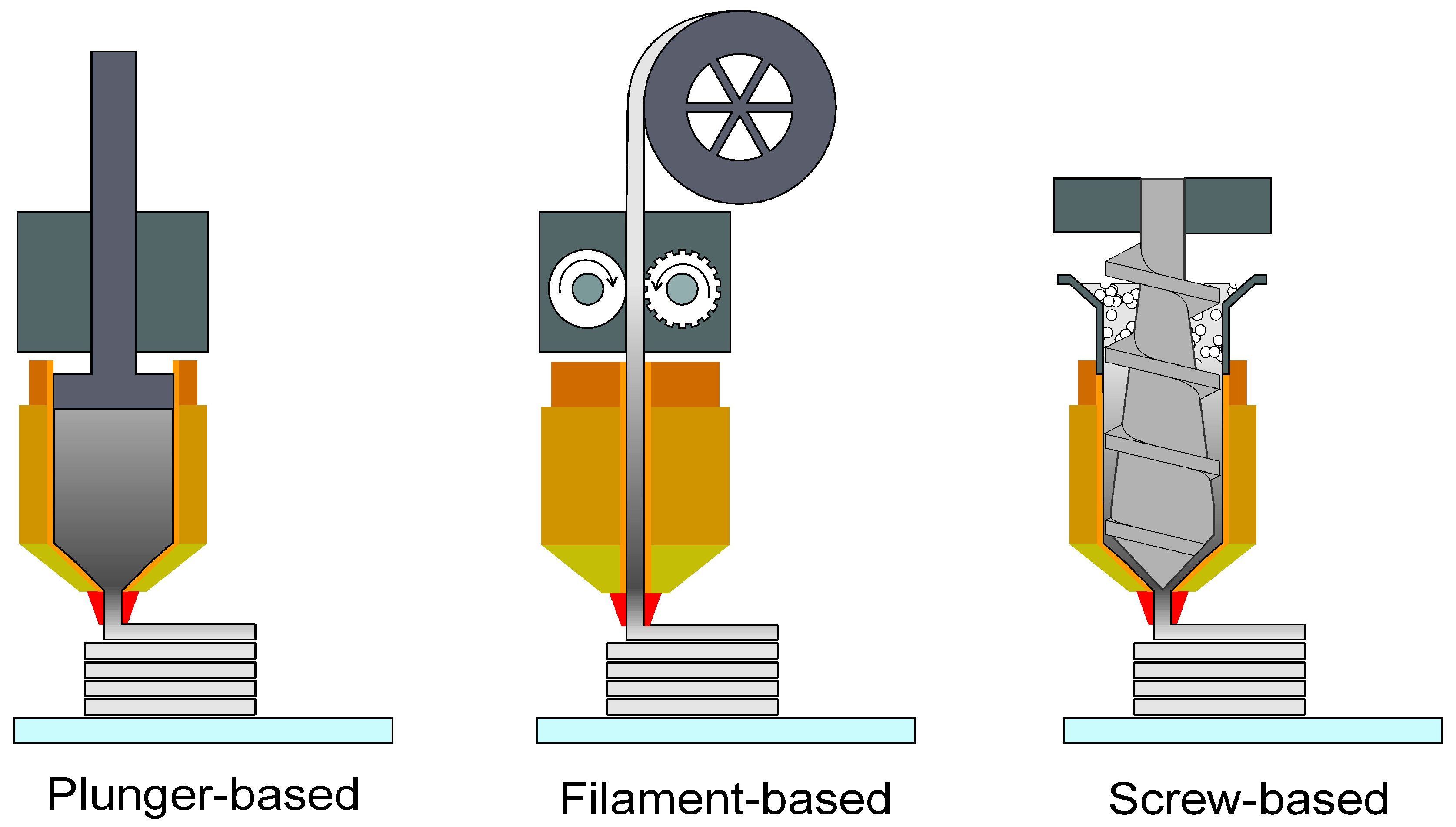

2. Material Extrusion Additive Manufacturing (MEAM)

2.1. Types of Material Extrusion Additive Manufacturing

2.1.1. Material Extrusion with Plungers

2.1.2. Material Extrusion with Filaments

2.1.3. Material Extrusion with Screws

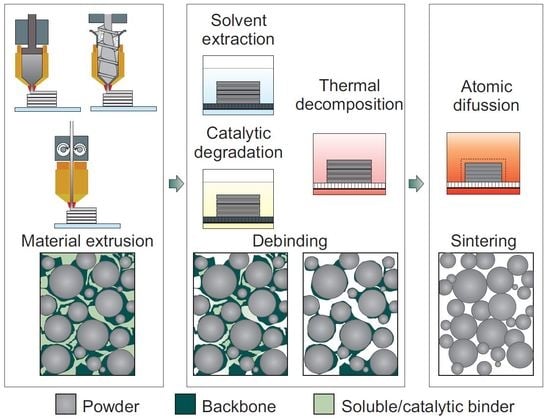

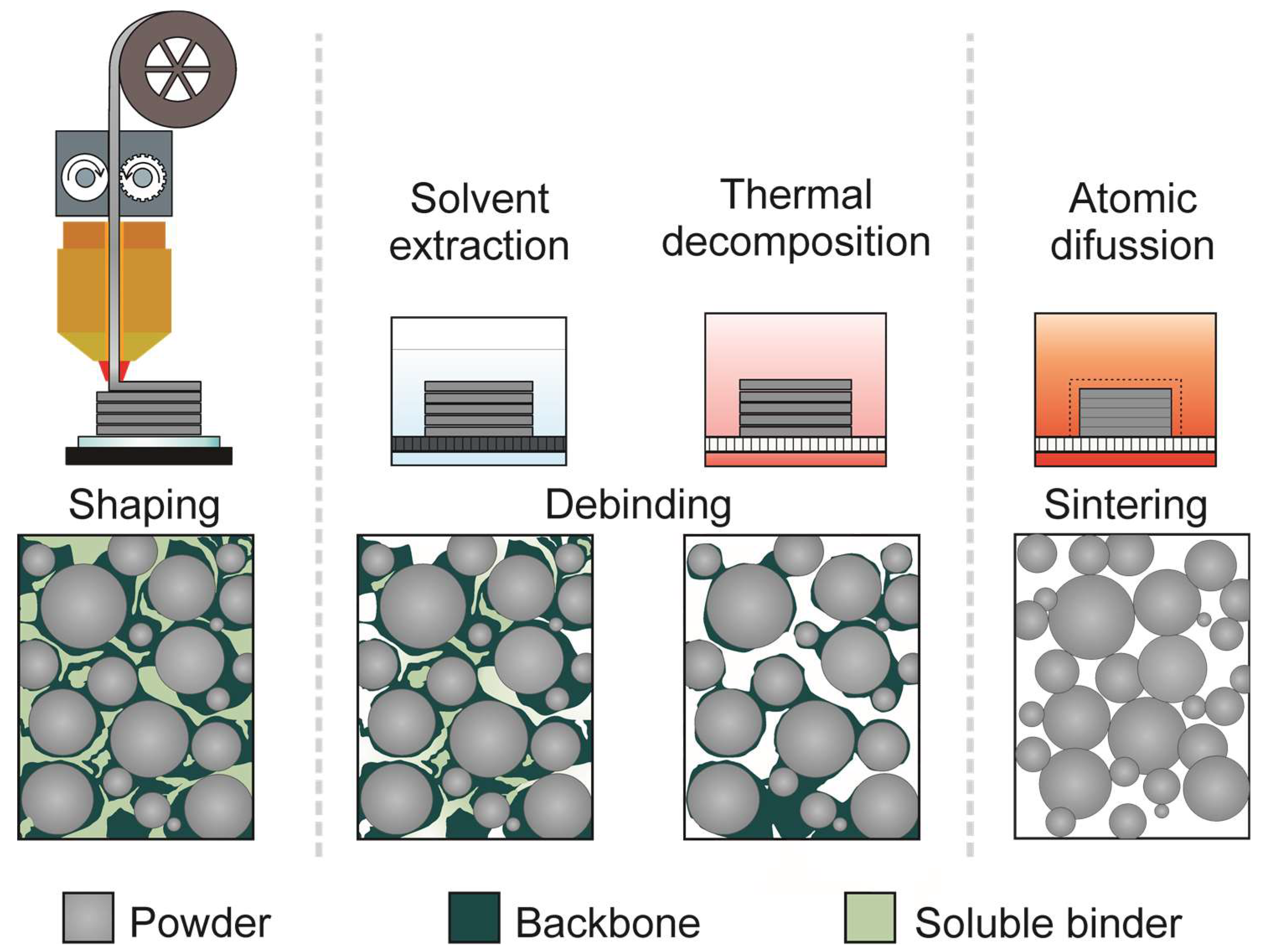

3. Material Extrusion Additive Manufacturing of Highly-Filled Polymers

3.1. PIM and MEAM-HP Feedstocks

3.1.1. Binder Systems

- The main binder component is the component present in the largest amount and it is removed first during the debinding step. The main binder component represents between 50 and 90 vol % of the total binder system

- The backbone is the component used to hold together the shape of the part while the main binder component is removed during the first debinding stage. The backbone is thermally decomposed prior to sintering. The backbone represents 0 to 50 vol% of the total binder system.

- Additives like dispersant agents, compatibilizers, and stabilizers help to disperse the filler particles in the polymeric binder, preventing agglomeration and phase separation. Additives represent between 0 to 10 vol % of the binder system.

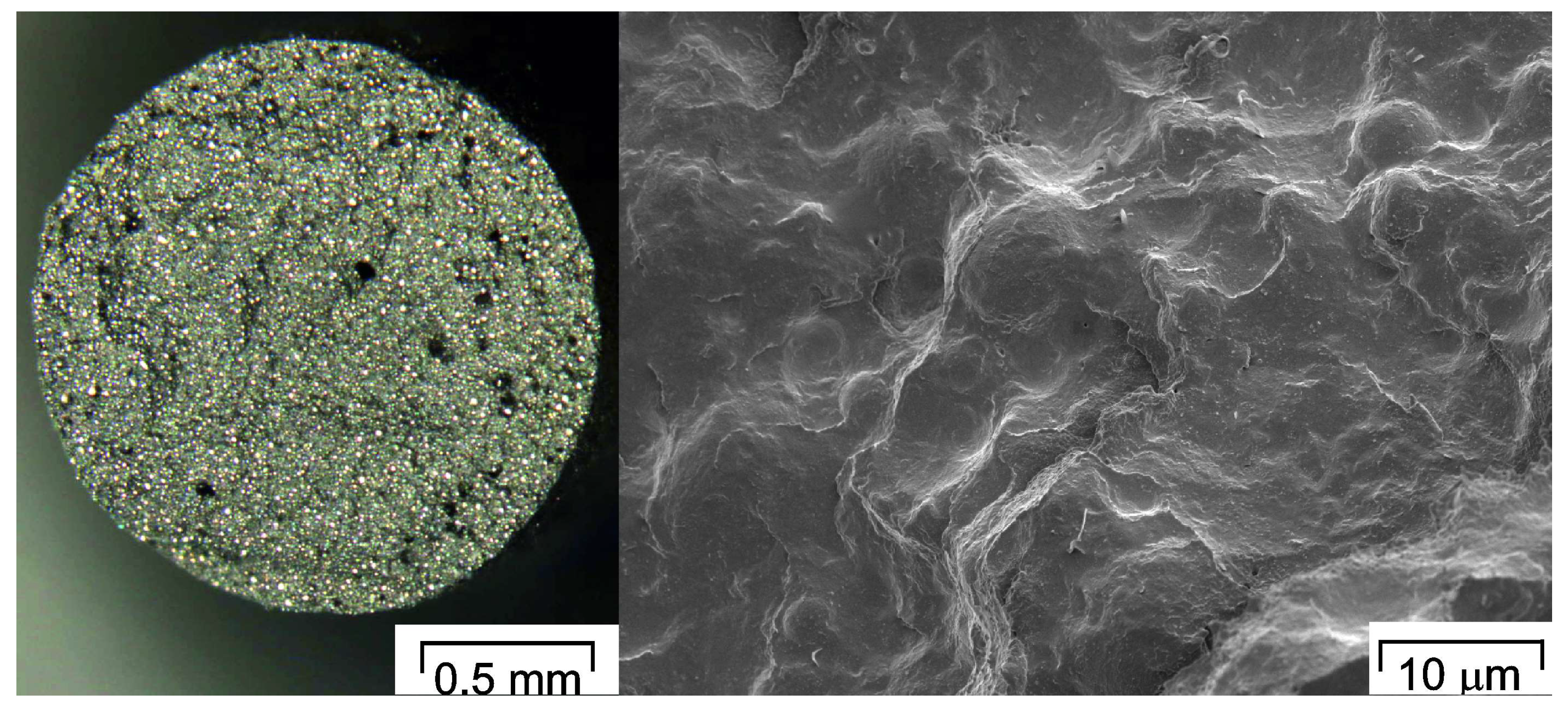

3.1.2. Powder Fillers

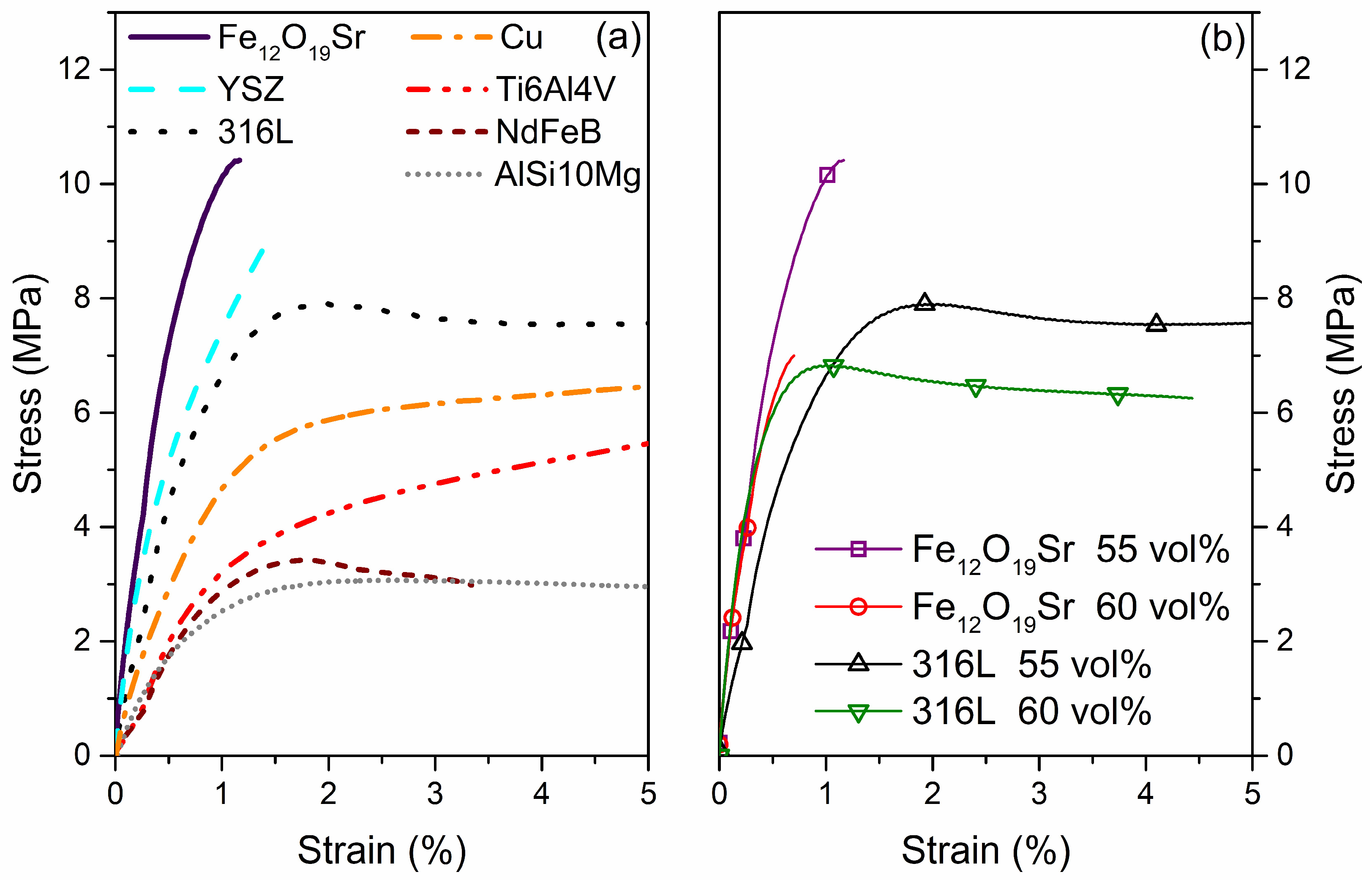

3.2. Effect of Processing on Properties of Feedstocks and Filaments

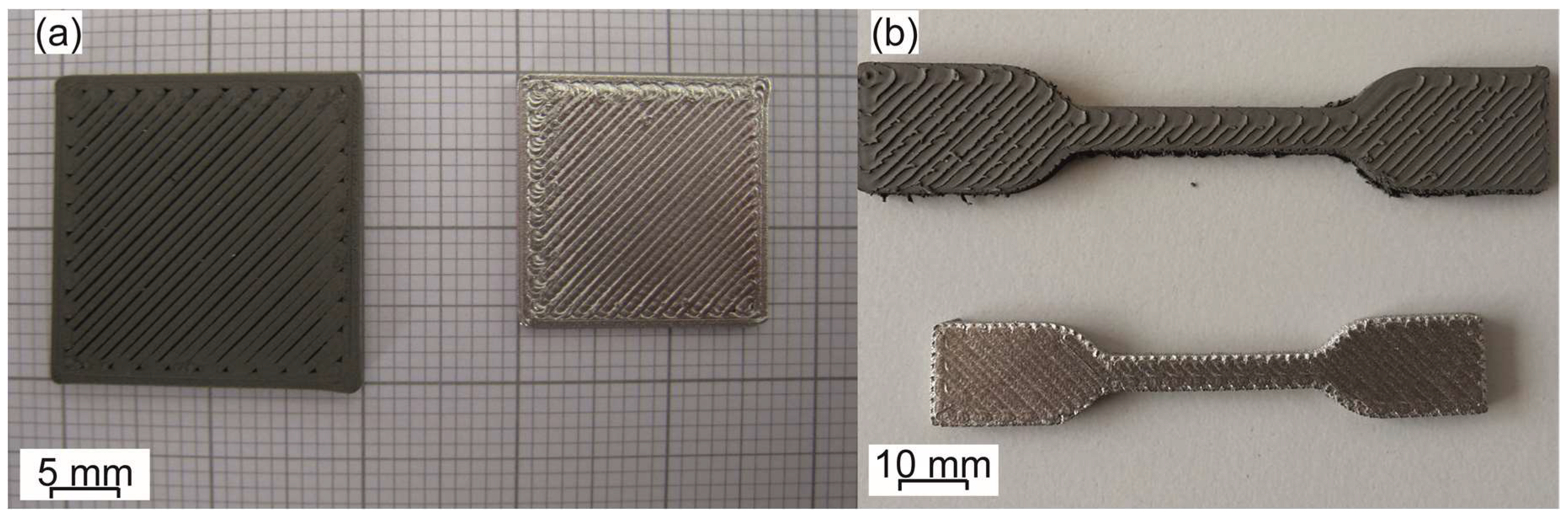

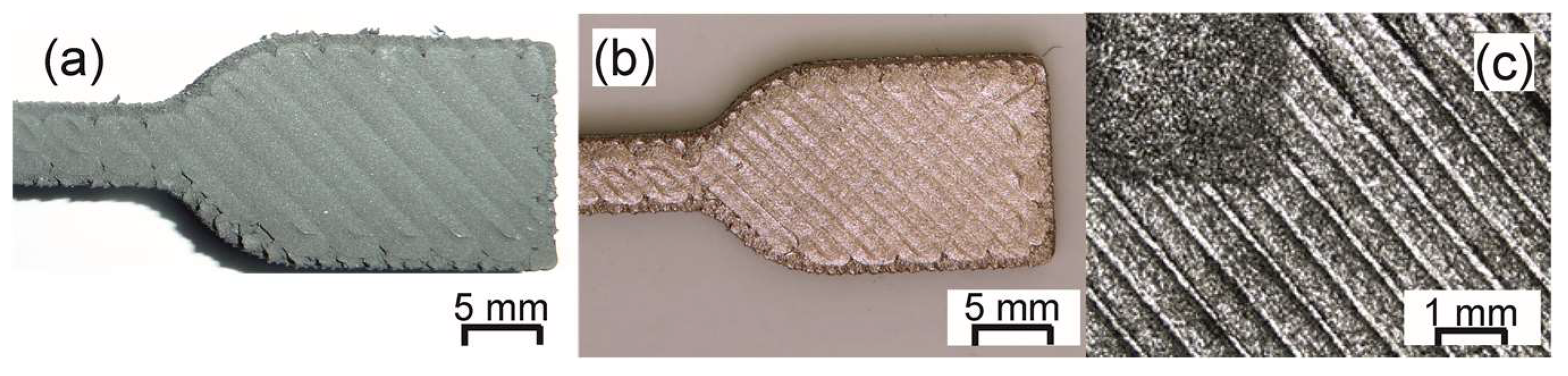

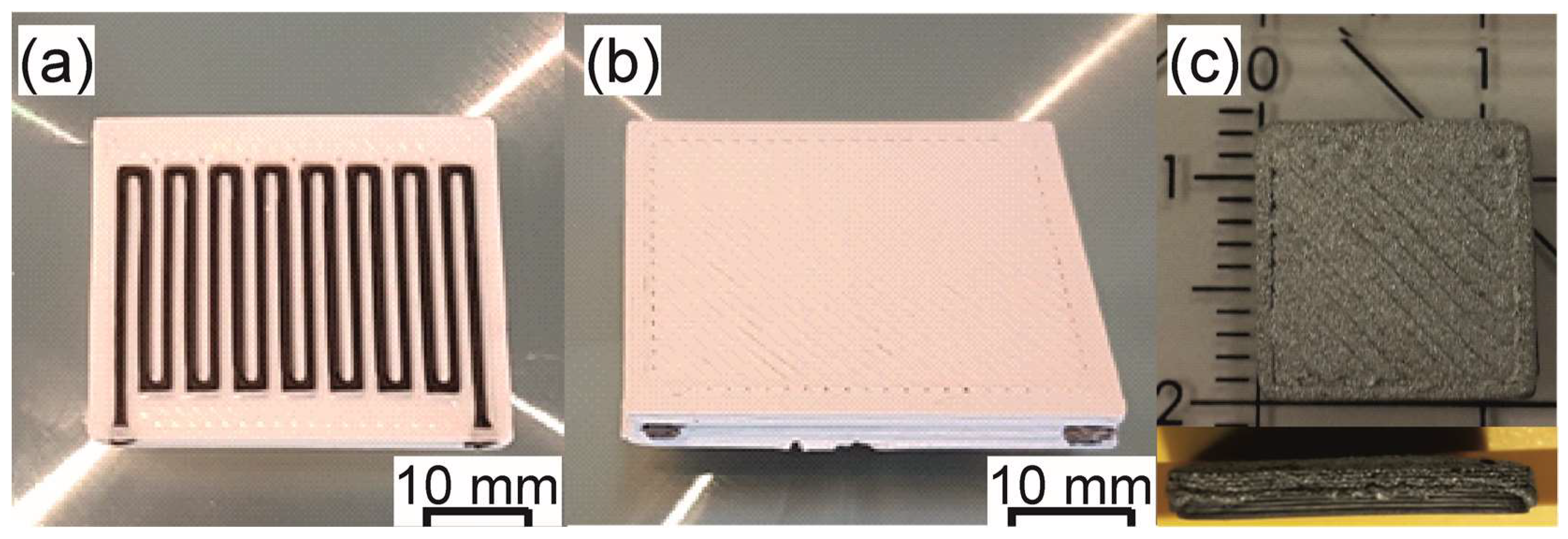

4. Building of Parts

Effect of Processing on Properties of Built Parts

5. Post-Shaping Operations

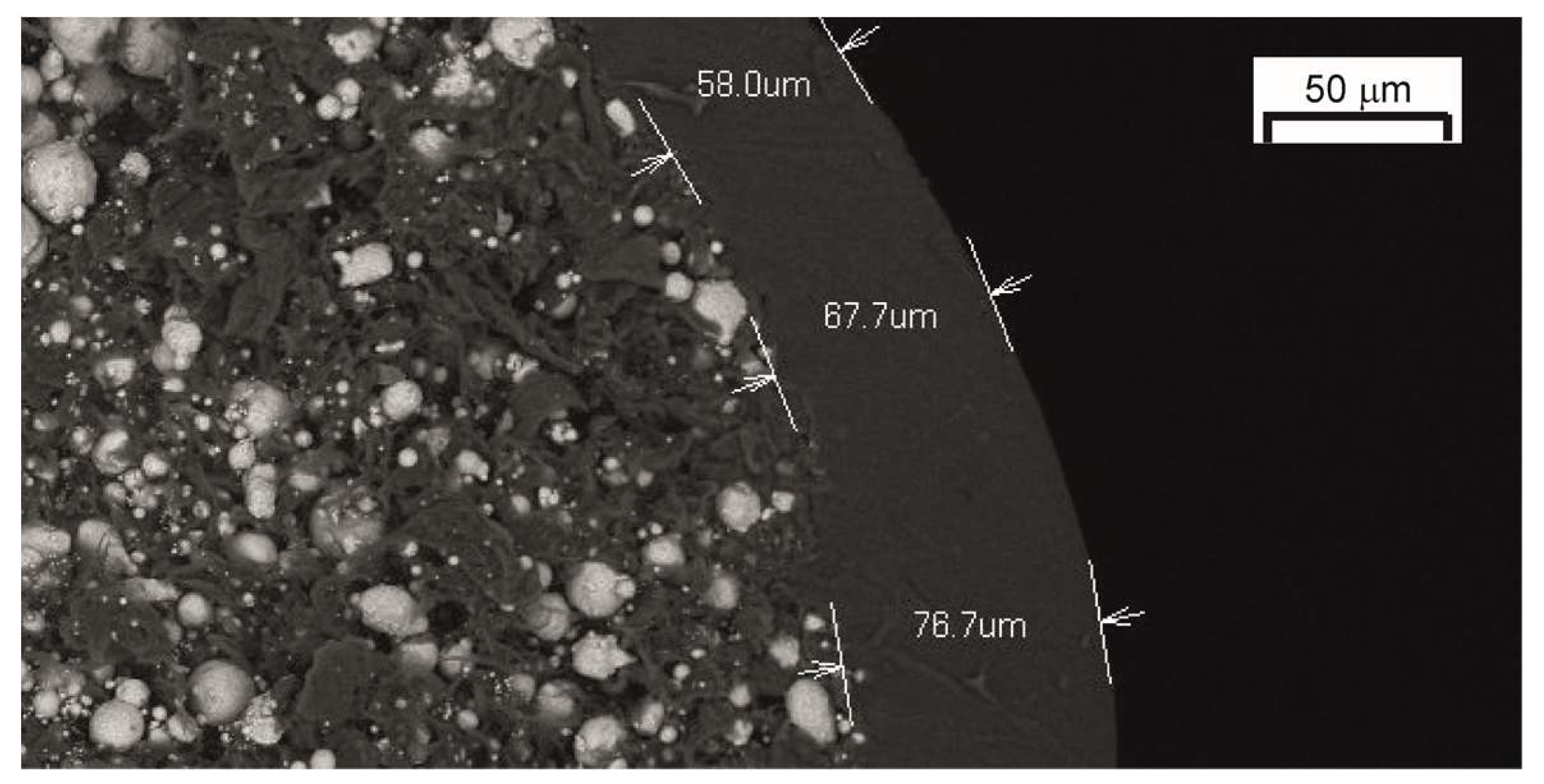

5.1. Surface Treatment

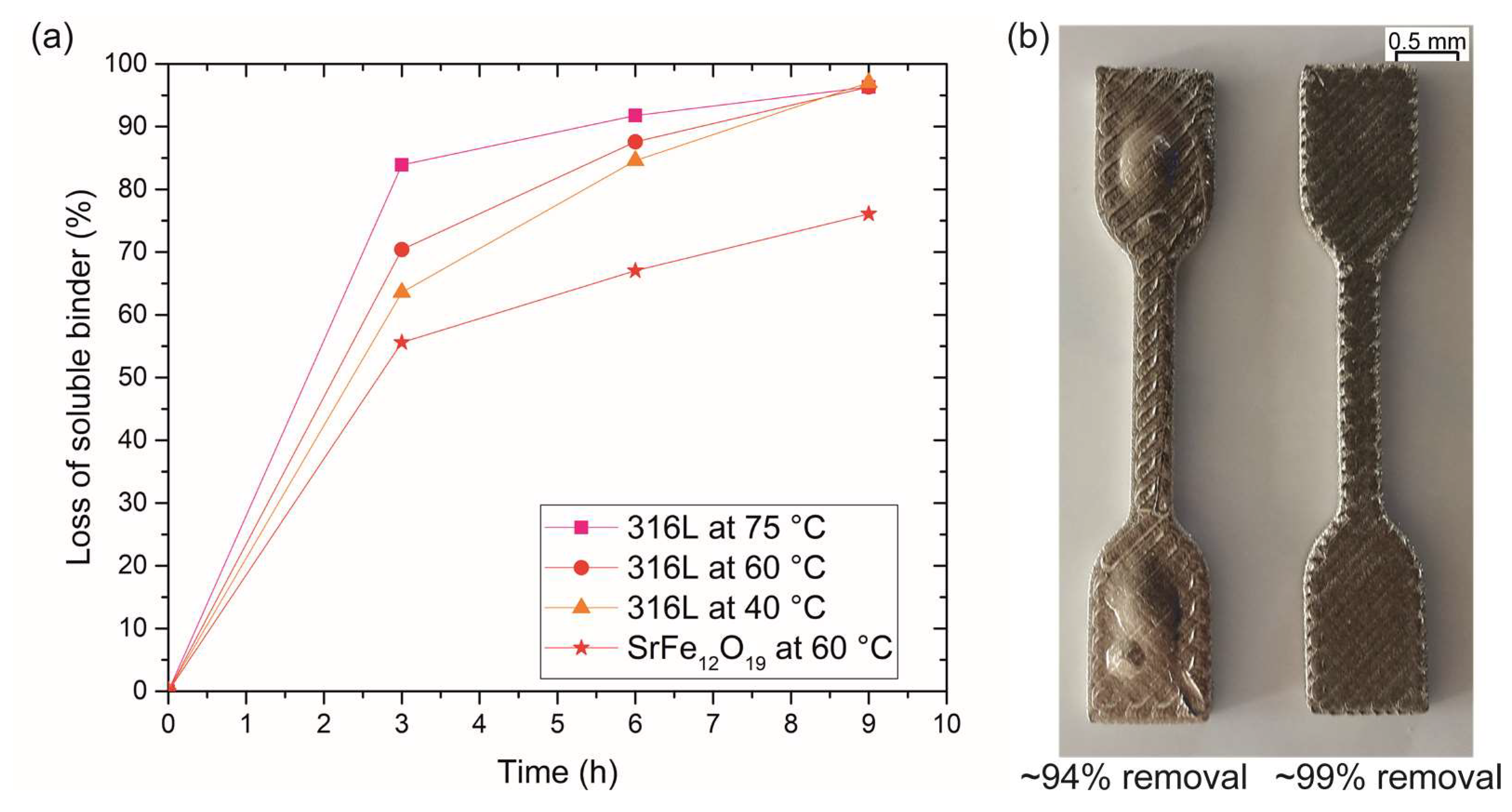

5.2. Debinding

5.3. Sintering

5.4. Co-Sintering

5.5. Post-Sintering Operations

6. Comparison to Other Manufacturing Techniques

7. Summary and Future Direction

- The development of improved simulation tools that can predict the properties of built parts by knowing the material properties, processing parameters, and building strategies. This could allow the optimization of the printing process before it is actually done.

- The development of simulations tools for the debinding and sintering processes.

- The development of automatic monitoring systems that supervise the building process that stop and adjust the processing parameters to reduce the amount of unwanted defects on the printed part.

- The development of mechanisms to smooth the surface of the deposited strands as they are being deposited to reduce the surface roughness of the printed parts and to increase the mechanical properties of printed parts.

- The development of new binder systems for filaments and pellets, which are faster to remove and can use other solvents, such as water.

- The development of new feedstock materials with different filler particles that can be co-sintered for the fabrication of new multi-material components with new functionalities.

- The development of simulation tools that could speed up the development of new highly-filled polymers to be used in MEAM. Such simulation tools should take into account the compatibility and interaction of the different polymeric components, as well as the chemical and physical characteristics of powders.

- The improvement of the reliability of screw-based MEAM machines to replace the filaments by pellets, since filaments are hard to make and limit the amount of powder that can be added to the feedstock.

- The improvement of the properties of the interface of multi-material components so as to promote good adhesion between the different materials and obtain multi-material components with a long service life.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies. 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015. [Google Scholar]

- Bourell, D.L. Perspectives on Additive Manufacturing. Annu. Rev. Mater. Res. 2016, 46, 1–18. [Google Scholar] [CrossRef]

- F42 Committee. Specification for Additive Manufacturing File Format (AMF) Version 1.2; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Chakravorty, D. STL File Format for 3D Printing—Simply Explained: Are there any alternatives to the STL File Format? Available online: https://all3dp.com/what-is-stl-file-format-extension-3d-printing/#pointnine (accessed on 8 May 2018).

- 3MF Consortium. Enabling the Full Potential of 3D Printing. Available online: https://3mf.io/ (accessed on 8 May 2018).

- Hegab, H.A. Design for additive manufacturing of composite materials and potential alloys: A review. Manuf. Rev. 2016, 3, 11. [Google Scholar] [CrossRef]

- Giannatsis, J.; Dedoussis, V. Additive fabrication technologies applied to medicine and health care: A review. Int. J. Adv. Manuf. Technol. 2009, 40, 116–127. [Google Scholar] [CrossRef]

- Goffard, R.; Sforza, T.; Clarinval, A.; Dormal, T.; Boilet, L.; Hocquet, S.; Cambier, F. Additive manufacturing of biocompatible ceramics. Adv. Prod. Eng. Manag. 2013, 8, 96–106. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Lopez, H.; Martinez, E.; Machado, B.I.; Hernandez, D.H.; Martinez, L.; Lopez, M.I.; Wicker, R.B.; et al. Next-generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2010, 368, 1999–2032. [Google Scholar] [CrossRef] [PubMed]

- EN ISO/ASTM. Additive Manufacturing—General Principles—Terminology; (52900:2017-02); International Organization for Standardization (ISO): Geneve, Switzerland, 2017. [Google Scholar]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2013, 57, 133–164. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed]

- Majewski, C.E.; Oduye, D.; Thomas, H.R.; Hopkinson, N. Effect of infra-red power level on the sintering behaviour in the high speed sintering process. Rapid Prototyp. J. 2008, 14, 155–160. [Google Scholar] [CrossRef]

- Ellis, A.; Noble, C.J.; Hopkinson, N. High Speed Sintering: Assessing the influence of print density on microstructure and mechanical properties of nylon parts. Addit. Manuf. 2014, 1–4, 48–51. [Google Scholar] [CrossRef]

- Kumar, S.; Kruth, J.-P. Composites by rapid prototyping technology. Mater. Des. 2010, 31, 850–856. [Google Scholar] [CrossRef]

- Zein, I.; Hutmacher, D.W.; Tan, K.C.; Teoh, S.H. Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials 2002, 23, 1169–1185. [Google Scholar] [CrossRef]

- Malinauskas, M.; Rekstyt, S.; Lukosevicius, L.; Butkus, S.; Balciunas, E.; Peciukaityt, M.; Baltriukien, D.; Bukelskien, V.; Butkevicius, A.; Kucevicius, P.; et al. 3D Microporous Scaffolds Manufactured via Combination of Fused Filament Fabrication and Direct Laser Writing Ablation. Micromachines 2014, 5, 839–858. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Caffrey, T.; Wohlers, T.; Campbell, I. (Eds.) Wohlers Report 2016. 3D Printing and Additive Manufacturing State of the Industry: Annual Worldwide Progress Report; Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2016. [Google Scholar]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Design 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Mireles, J.; Espalin, D.; Roberson, D.; Zinniel, B.; Medina, F.; Wicker, R. Fused Deposition Modeling of Metals. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; pp. 836–845. [Google Scholar]

- Valkenaers, H.; Vogeler, F.; Ferraris, E.; Voet, A.; Kruth, J.P. A Novel Approach to Additive Manufacturing: Screw Extrusion 3D-Printing. In Proceedings of the 10th International Conference on Multi-Material Micro Manufacture, San Sebastian, Spain, 8–10 October 2013; Azcarate, S., Dimov, S., Eds.; Research Publishing: San Sebastian, Spain, 2013; pp. 235–238. [Google Scholar]

- Wohlers, T. Desktop Metal: A Rising Star of Metal AM Targets Speed, Cost and High-Volume Production. Metal AM [Online]. 2017, pp. 89–92. Available online: http://www.metal-am.com/wp-content/uploads/sites/4/2017/06/MAGAZINE-Metal-AM-Summer-2017-PDF-sp.pdf (accessed on 11 July 2017).

- Campbell, I.; Wohlers, T. Markforged: Taking a Different Approach to Metal Additive Manufacturing. Metal AM [Online]. 2017, pp. 113–115. Available online: http://www.metal-am.com/wp-content/uploads/sites/4/2017/06/MAGAZINE-Metal-AM-Summer-2017-PDF-sp.pdf (accessed on 11 July 2017).

- Schuh, C.A.; Myerberg, J.S.; Fulop, R.; Chiang, Y.-M.; Hart, A.J.; Schroers, J.; Vereminski, M.D.; Mykulowycz, N.; Shim, J.J.; Fontana, R.R.; et al. Methods and Systems for Additive Manufacturing. International Patent PCT/US2016/067378, 16 December 2016. [Google Scholar]

- Martínez-Vázquez, F.J.; Pajares, A.; Miranda, P. A simple graphite-based support material for robocasting of ceramic parts. J. Eur. Ceram. Soc. 2018, 38, 2247–2250. [Google Scholar] [CrossRef]

- Cesarano, J. A Review of Robocasting Technology. MRS Proc. 1998, 542, 125. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Stringari, G.; Emri, I. Powder Injection Molding of Metal and Ceramic Parts. In Some Critical Issues for Injection Molding; Wang, J., Ed.; InTech: Rijeka, Croatia, 2012; pp. 65–86. [Google Scholar]

- Markforged Inc. Complete Metal Solution. Available online: https://markforged.com/metal-x/ (accessed on 7 June 2017).

- Desktop Metal Inc. Prototype and Mass Produce with the Same Alloys. Available online: https://www.desktopmetal.com/products/materials/ (accessed on 29 March 2018).

- Crump, S. Apparatus and Method for Creating Three-Dimensional Objects. US Patent 07/429,012, 30 October 1989. [Google Scholar]

- Arburg GmbH & Co. KG. Freeformer System: No Mold Required for a Fully Functional Part. Available online: https://www.arburg.com/us/us/products-and-services/additive-manufacturing/freeformer-system/ (accessed on 19 July 2017).

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. Handb. Res. Mass Cust. Personal. 2009, 2, 568–580. [Google Scholar] [CrossRef]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Sapkota, J.; Schuschnigg, S.; Holzer, C. Effect of the printing bed temperature on the adhesion of parts produced by fused filament fabrication. Plast. Rubber Compos. 2018, 47, 17–24. [Google Scholar] [CrossRef]

- Agarwala, M.K.; Jamalabad, V.R.; Langrana, N.A.; Safari, A.; Whalen, P.J.; Danforth, S.C. Structural quality of parts processed by fused deposition. Rapid Prototyp. J. 1996, 2, 4–19. [Google Scholar] [CrossRef]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Lichal, C.; Cajner, H.; Berger, G.; Schuschnigg, S.; Cardon, L.; Holzer, C. Optimisation of the Adhesion of Polypropylene-Based Materials during Extrusion-Based Additive Manufacturing. Polymers 2018, 10, 490. [Google Scholar] [CrossRef]

- Elkins, K.; Nordby, H.; Janak, C.; Gray, R.W.; Bøhn, H.H.; Baird, D.G. Soft Elastomers for Fused Deposition Modeling. In Proceedings of the 8th Solid Freeform Fabrication Symposium, Austin, TX, USA, 11–13 August 1997; pp. 441–448. [Google Scholar]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2016. [Google Scholar] [CrossRef]

- McNulty, T.F.; Mohammadi, F.; Bandyopadhyay, A.; Shanefield, D.J.; Danforth, S.C.; Safari, A. Development of a binder formulation for fused deposition of ceramics. Rapid Prototyp. J. 1998, 4, 144–150. [Google Scholar] [CrossRef]

- Bellini, A.; Shor, L.; Guceri, S.I. New developments in fused deposition modeling of ceramics. Rapid Prototyp. J. 2005, 11, 214–220. [Google Scholar] [CrossRef]

- Bellini, A. Fused Deposition of Ceramics: A Comprehensive Experimental, Analytical and Computational Study of Material Behavior, Fabrication Process and Equipment Design. Ph.D. Thesis, Drexen University, Philadelpia, PA, USA, 2002. [Google Scholar]

- Cruz, N.; Santos, L.; Vasco, J.; Barreiros, F.M. Binder System for Fused Deposition of Metals. In Proceedings of the Euro PM2013, Congress & Exhibition, Gothenburg, Sweden, 15–18 September 2013; EPMA: Athens, Greece, 2013; pp. 79–84. [Google Scholar]

- Drescher, P.; Lieberwirth, C.; Seitz, H. Process and Installation for Manufacturing the Additive of Amorphous Crystalline and/or Semi-Crystalline Metal Components—Selective Amorphous Metal Extrusion (SAME). DE Patent 201410018080, 6 December 2014. [Google Scholar]

- AIM3D GmbH. Edelstahl. Available online: http://www.aim3d.de/materialien/edelstaehle/ (accessed on 7 July 2017).

- Pollen AM Inc. Meet PAM: Pellet Additive Manufacturing. Available online: https://www.pollen.am (accessed on 22 August 2017).

- Koslow, T. Pollen Introduces Pam: Their New Professional-Grade Multi-Material 3D Printer. Available online: https://3dprint.com/140595/pollen-pam-multi-material/ (accessed on 22 August 2017).

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big Area Additive Manufacturing of High Performance Bonded NdFeB Magnets. Sci. Rep. 2016, 6, 36212. [Google Scholar] [CrossRef] [PubMed]

- Cincinnati Inc. BAAM: Fact Sheet. Available online: http://wwwassets.e-ci.com/PDF/Products/baam-fact-sheet.pdf (accessed on 7 June 2017).

- Gonzalez-Gutierrez, J.; Duretek, I.; Kukla, C.; Poljšak, A.; Bek, M.; Emri, I.; Holzer, C. Models to Predict the Viscosity of Metal Injection Molding Feedstock Materials as Function of Their Formulation. Metals 2016, 6, 129. [Google Scholar] [CrossRef]

- German, R.M. (Ed.) Powder Metallurgy Science, 2nd ed.; Metal Powder Industries Federation: Princeton, NJ, USA, 1994. [Google Scholar]

- German, R.M. Metal powder injection molding (MIM): Key trends and markets. In Handbook of Metal Injection Molding; Heaney, D.F., Ed.; Woodhead Publishing: Cambridge, UK; Philadelphia, PA, USA, 2012; pp. 1–25. [Google Scholar]

- Wu, G.; Langrana, N.A.; Rangarajan, S.; McCuiston, R.; Sadanji, R.; Danforth, S.C.; Safari, A. Fabrication of Metal Components using FDMet: Fused Deposition of Metals. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 1999; pp. 775–782. [Google Scholar]

- Wu, G.; Langrana, N.A.; Sadanji, R.; Danforth, S.C. Solid freeform fabrication of metal components using fused deposition of metals. Mater. Des. 2002, 23, 97–105. [Google Scholar] [CrossRef]

- Agarwala, M.K.; van Weeren, R.; Bandyopadhyay, A.; Whalen, P.J.; Safari, A.; Danforth, S.C. Fused Deposition of Ceramics and Metals: An Overview. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 1996. [Google Scholar]

- Agarwala, M.K.; van Weeren, R.; Bandyopadhyay, A.; Safari, A.; Danforth, S.C.; Priedeman, W.R. Filament Feed Materials for Fused Deposition Processing of Ceramics and Metals. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 1996. [Google Scholar]

- Gonzalez-Gutierrez, J.; Godec, D.; Kukla, C.; Schlauf, T.; Burkhardt, C.; Holzer, C. Shaping, Debinding and Sintering of Steel Components via Fused Filament Fabrication. In CIM 2017 Computer Integrated Manufacturing and High Speed Machining, Proceedings of the 16th International Scientific Conference on Production Engineering, Zadar, Croatia, 8–10 June 2017; Abele, E., Udijak, T., Ciglar, D., Eds.; Croatian Association of Production Engineering: Zagreb, Croatia, 2017; pp. 99–104. [Google Scholar]

- Shahzad, K.; Deckers, J.; Kruth, J.-P.; Vleugels, J. Additive manufacturing of alumina parts by indirect selective laser sintering and post processing. J. Mater. Process. Technol. 2013, 213, 1484–1494. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Zhang, Z.; Kruth, J.-P.; Vleugels, J. Additive manufacturing of zirconia parts by indirect selective laser sintering. J. Eur. Ceram. Soc. 2014, 34, 81–89. [Google Scholar] [CrossRef]

- Bai, Y.; Williams, C.B. An exploration of binder jetting of copper. Rapid Prototyp. J. 2015, 21, 177–185. [Google Scholar] [CrossRef]

- Nandwana, P.; Elliott, A.M.; Siddel, D.; Merriman, A.; Peter, W.H.; Babu, S.S. Powder bed binder jet 3D printing of Inconel 718: Densification, microstructural evolution and challenges☆. Curr. Opin. Solid State Mater. Sci. 2017, 21, 207–218. [Google Scholar] [CrossRef]

- Gonzalez, J.A.; Mireles, J.; Lin, Y.; Wicker, R.B. Characterization of ceramic components fabricated using binder jetting additive manufacturing technology. Ceram. Int. 2016, 42, 10559–10564. [Google Scholar] [CrossRef]

- Homa, J.; Schwentenwein, M. A Novel Additive Manufacturing Technology for High-Performance Ceramics. In Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials; John Wiley & Sons, Inc: New York, NY, USA, 2014; pp. 33–40. [Google Scholar]

- Schwentenwein, M.; Homa, J. Additive Manufacturing of Dense Alumina Ceramics. Int. J. Appl. Ceram. Technol. 2015, 12, 1–7. [Google Scholar] [CrossRef]

- Scheithauer, U.; Schwarzer, E.; Richter, H.-J.; Moritz, T. Thermoplastic 3D Printing-An Additive Manufacturing Method for Producing Dense Ceramics. Int. J. Appl. Ceram. Technol. 2015, 12, 26–31. [Google Scholar] [CrossRef]

- Scheithauer, U.; Poetschke, J.; Weingarten, S.; Schwarzer, E.; Vornberger, A.; Moritz, T.; Michaelis, A. Droplet-based additive manufacturing of hard metal components by thermoplastic 3D Printing (T3DP). J. Ceram. Sci. Technol. 2017, 8, 155–158. [Google Scholar]

- Schwarzer, E.; Götz, M.; Markova, D.; Stafford, D.; Scheithauer, U.; Moritz, T. Lithography-based ceramic manufacturing (LCM)—Viscosity and cleaning as two quality influencing steps in the process chain of printing green parts. J. Eur. Ceram. Soc. 2017. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Godec, D.; Guran, R.; Spoerk, M.; Kukla, C.; Holzer, C. 3D printing conditions determination for feedstock used in fused filament fabrication (FFF) of 17-4PH stainless steel parts. Metalurgija 2018, 57, 117–120. [Google Scholar]

- Kukla, C.; Gonzalez-Gutierrez, J.; Cano, S.; Burkhardt, C.; Hampel, S.; Moritz, T.; Holzer, C. Fused Filament Fabrication for the production of metal and/or ceramic parts and feedstocks therefore. In Proceedings of the 19th Plansee Seminar, Reutte, Austria, 29 May–2 June 2017; Plansee Group Service GmbH: Reutte, Austria, 2017. [Google Scholar]

- German, R.M. Markets applications, and financial aspects of global metal powder injection moulding (MIM) technologies. Met. Powder Rep. 2012, 67, 18–26. [Google Scholar] [CrossRef]

- Bloemacher, M.; Weinand, D. CatamoldTM-A new direction for powder injection molding. J. Mater. Process. Technol. 1997, 63, 918–922. [Google Scholar] [CrossRef]

- Farrow, G.; Conciatori, A.B. Polyacetal Binders for Injection Moulding of Ceramics. DE3477767 D1, 24 May 1989. [Google Scholar]

- Liu, L.; Ni, X.L.; Yin, H.Q.; Qu, X.H. Mouldability of various zirconia micro gears in micro powder injection moulding. J. Eur. Ceram. Soc. 2015, 35, 171–177. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Oblak, P.; Megen, Z.M.; Emri, I. Viscosity and creep compliance of polyoxymethylene copolymers of various average molecular weights. Polimery 2015, 61, 620–627. [Google Scholar] [CrossRef]

- Wiech, R.E. Manufacture of Parts from Particulate Material. U.S. Patent 497,698, 12 April 1976. [Google Scholar]

- Kong, X.; Barriere, T.; Gelin, J.C. Determination of critical and optimal powder loadings for 316 L fine stainless steel feedstocks for micro-powder injection molding. J. Mater. Process. Technol. 2012, 212, 2173–2182. [Google Scholar] [CrossRef]

- Thomas-Vielma, P.; Cervera, A.; Levenfeld, B.; Várez, A. Production of alumina parts by powder injection molding with a binder system based on high density polyethylene. J. Eur. Ceram. Soc. 2008, 28, 763–771. [Google Scholar] [CrossRef]

- Sotomayor, M.E.; Ospina, L.M.; Levenfeld, B.; Várez, A. Characterization of 430 L porous supports obtained by powder extrusion moulding for their application in solid oxide fuel cells. Mater. Charact. 2013, 86, 108–115. [Google Scholar] [CrossRef]

- Aggarwal, G.; Smid, I.; Park, S.J.; German, R.M. Development of niobium powder injection molding. Part II: Debinding and sintering. Int. J. Refract. Met. Hard Mater. 2007, 25, 226–236. [Google Scholar] [CrossRef]

- Park, S.-J.; Wu, Y.; Heaney, D.F.; Zou, X.; Gai, G.; German, R.M. Rheological and Thermal Debinding Behaviors in Titanium Powder Injection Molding. Met. Mat. Trans. A 2009, 40, 215–222. [Google Scholar] [CrossRef]

- Martin, R.; Vick, M.; Kelly, M.; Souza, J.P.d.; Enneti, R.K.; Atre, S.V. Powder injection molding of a mullite–zirconia composite. J. Mater. Res. Technol. 2013, 2, 263–268. [Google Scholar] [CrossRef]

- Ma, J.; Qin, M.; Zhang, L.; Tian, L.; Li, R.; Chen, P.; Qu, X. Effect of ball milling on the rheology and particle characteristics of Fe–50%Ni powder injection molding feedstock. J. Alloy. Compd. 2014, 590, 41–45. [Google Scholar] [CrossRef]

- Heng, S.Y.; Raza, M.R.; Muhamad, N.; Sulong, A.B.; Fayyaz, A. Micro-powder injection molding (μPIM) of tungsten carbide. Int. J. Refract. Met. Hard Mater. 2014, 45, 189–195. [Google Scholar] [CrossRef]

- Chuankrerkkul, N.; Davies, H.A.; Messer, P.F. Application of PEG/PMMA Binder for Powder Injection Moulding of Hardmetals. MSF 2007, 561–565, 953–956. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, R.; Qu, X. X-ray tomographic analysis of powder-binder separation in SiC green body. J. Eur. Ceram. Soc. 2013, 33, 2935–2941. [Google Scholar] [CrossRef]

- Chakartnarodom, P.; Chuankrerkkul, N. Statistical Analysis of Binder Behavior during Debinding Step in Powder Injection Molding (PIM). AMR 2014, 970, 172–176. [Google Scholar] [CrossRef]

- Krauss, V.A.; Oliveira, A.; Klein, A.N.; Al-Qureshi, H.A.; Fredel, M.C. A model for PEG removal from alumina injection moulded parts by solvent debinding. J. Mater. Process. Technol. 2007, 182, 268–273. [Google Scholar] [CrossRef]

- Yang, W.-W.; Yang, K.-Y.; Hon, M.-H. Effects of PEG molecular weights on rheological behavior of alumina injection molding feedstocks. Mater. Chem. Phys. 2003, 78, 416–424. [Google Scholar] [CrossRef]

- Yang, W.-W.; Yang, K.-Y.; Wang, M.-C.; Hon, M.-H. Solvent debinding mechanism for alumina injection molded compacts with water-soluble binders. Ceram. Int. 2003, 29, 745–756. [Google Scholar] [CrossRef]

- Hauf, G. Verfahren zur Herstellung von Formkörpern aus Keramischen und/Oder Metallischen Pulvern und Dabei Verwendetes Bindersystem. DE Patent 103 47747.0, 14 Octomber 2003. [Google Scholar]

- Wohlfromm, H.; Assmann, J.; ter Maat, J.; Mehdizadeh, A. Thermoplastic Masses Containing Binding Agents for the Production of Metallic Molds. International Patent PCT/EP2007/056857, 5 July 2007. [Google Scholar]

- Sterzel, H.-J.; ter Maat, J.; Ebenhoech, J.; Meyer, M. Thermoplastic Materials for the Production of Ceramic Moldings. U.S. Patent 823,607, 17 January 1992. [Google Scholar]

- LaSalle, J.C.; Behi, M.; Glandz, G.A.; Burlew, J.V. Aqueous Nonferrous Feedstock Material for Injection Molding. U.S. Patent 09/768,411, 24 January 2001. [Google Scholar]

- Yang, X.; Petcavich, R.J. Powder and Binder Systems for Use in Metal and Ceramic Powder Injection Molding. U.S. Patent 6008281, 13 January 1999. [Google Scholar]

- Danforth, S.C.; Agarwala, M.K.; Bandyopadhyay, A.; Langrana, N.; Jamalabad, V.R.; Safari, A.; van Weeren, R. Solid Freeform Fabrication Methods. U.S. Patent 5900207, 4 May 1999. [Google Scholar]

- Daute, P.; Jaeckel, M.; Waldmann, J. Sinterable Feedstock for Use in 3d Printing Devices. International Patent PCT/EP2014/064646, 8 July 2014. [Google Scholar]

- Heikkila, K.E. Surface Modified Particulate and Sintered Extruded Products. WIPO Patent WO/2015/006697, 15 January 2015. [Google Scholar]

- Pekin, S.; Zangvil, A.; Ellingson, W. Binder Formulation in EVA-wax system for Fused Deposition of Ceramics. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 1998. [Google Scholar]

- Iyer, S.; McIntosh, J.; Bandyopadhyay, A.; Langrana, N.; Safari, A.; Danforth, S.C.; Clancy, R.B.; Gasdaska, C.; Whalen, P.J. Microstructural Characterization and Mechanical Properties of Si3N4 Formed by Fused Deposition of Ceramics. Int. J. Appl. Ceram. Technol. 2008, 5, 127–137. [Google Scholar] [CrossRef]

- Riecker, S.; Clouse, J.; Studnitzky, T.; Andersen, O.; Kieback, B. Fused Deposition Modeling-Opportunities for cheap metal AM. In Proceedings of the World PM2016 Congress & Exhibition, Hamburg, Germany, 9–13 October 2016. [Google Scholar]

- Giberti, H.; Strano, M.; Annoni, M.; Yuan, Y.; Menon, L.; Xu, X. An innovative machine for Fused Deposition Modeling of metals and advanced ceramics. MATEC Web Conf. 2016, 43, 3003. [Google Scholar] [CrossRef]

- McNulty, T.F.; Shanefield, D.J.; Danforth, S.C.; Safari, A. Dispersion of Lead Zirconate Titanate for Fused Deposition of Ceramics. J. Am. Ceram. Soc. 1999, 82, 1757–1760. [Google Scholar] [CrossRef]

- Pistor, C.M. Thermal Properties of Green Parts for Fused Deposition of Ceramics (FDC). Adv. Eng. Mater. 2001, 3, 418–423. [Google Scholar] [CrossRef]

- Pekin, S.; Bukowski, J.; Zangvil, A. A Study on Weight Loss Rate Controlled Binder Removal From Parts Produced by FDC. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 1998. [Google Scholar]

- Kukla, C.; Duretek, I.; Schuschnigg, S.; Gonzalez-Gutierrez, J.; Holzer, C. Properties for PIM Feedstocks Used in Fused Filament Fabrication. In Proceedings of the World PM2016 Congress & Exhibition, Hamburg, Germany, 9–13 October 2016. [Google Scholar]

- Kukla, C.; Gonzalez-Gutierrez, J.; Duretek, I.; Schuschnigg, S.; Holzer, C. Effect of Particle Size on the Properties of Highly-Filled Polymers for Fused Filament Fabrication. In Proceedings of the 32nd PPS International Conference, Lyon, France, 25–29 July 2016; pp. 274–277. [Google Scholar]

- Kukla, C.; Gonzalez-Gutierrez, J.; Cano, S.; Hampel, S.; Burkhardt, C.; Moritz, T.; Holzer, C. Fused Filament Fabrication (FFF) of PIM Feedstocks. In Proceedings of VI Congreso Nacional de Pulvimetalurgia y I Congreso Iberoamericano de Pulvimetalurgia; Ciudad Real, Spain, 7–9 June 2017.

- Kukla, C.; Gonzalez-Gutierrez, J.; Burkhardt, C.; Weber, O.; Holzer, C. The Production of Magnets by FFF-Fused Filament Fabrication. In Proceedings of the Euro PM2017 Congress & Exhibition, Milan, Italy, 1–5 October 2017; EPMA: Shrewsbury, UK, 2017; pp. 1–6. [Google Scholar]

- Abel, J.; Scheithauer, U.; Hampel, S.; Cano, S.; Müller-Köhn, A.; Günther, A.; Kukla, C.; Moritz, T. Fused Filament Fabrication (FFF) of metal-ceramic components. J. Vis. Exp. under revision.

- Kukla, C.; Cano, S.; Kaylani, D.; Schuschnigg, S.; Holzer, C.; Gonzalez-Gutierrez, J. Debinding behaviour of feedstock for material extrusion additive manufacturing of zirconia. Powder Metall. 2017. submitted. [Google Scholar]

- Nestle, N.; Hermant, M.; Schimdt, K. Mixture for Use in a Fused Filament Fabrication Process. International Patent PCT/EP2015/066728, 22 July 2015. [Google Scholar]

- Ren, L.; Zhou, X.; Song, Z.; Zhao, C.; Liu, Q.; Xue, J.; Li, X. Process Parameter Optimization of Extrusion-Based 3D Metal Printing Utilizing PW–LDPE–SA Binder System. Materials 2017, 10, 305. [Google Scholar] [CrossRef] [PubMed]

- Agarwala, M.K.; van Weeren, R.; Vaidyanathan, R.; Bandyopadhyay, A.; Carrasquillo, G.; Jamalabad, V.R.; Langrana, N.; Safari, A.; Garofalini, S.H.; Danforth, S.C.; et al. Structural Ceramics by Fused Deposition of Ceramics. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 1995. [Google Scholar]

- Bandyopadhyay, A.; Das, K.; Marusich, J.; Onagoruwa, S. Application of fused deposition in controlled microstructure metal-ceramic composites. Rapid Prototyp. J. 2006, 12, 121–128. [Google Scholar] [CrossRef]

- Onagoruwa, S.; Bose, S.; Bandyopadhyay, A. Fused Deposition of Ceramics (FDC) and Composites. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2001. [Google Scholar]

- Bhat, V.V.; Geetha, K.; Das, R.N.; Gurumoorthy, B.; Umarji, A.M. Characterization of Polyolefin-Aluminacompounded mix for FDC processing. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2000. [Google Scholar]

- Stanimirovic, Z.; Stanimirovic, I. Ceramic Injection Molding. In Some Critical Issues for Injection Molding; Wang, J., Ed.; InTech: Rijeka, Croatia, 2012; pp. 131–148. [Google Scholar]

- Venkataraman, N.; Rangarajan, S.; Matthewson, M.J.; Safari, A.; Danforth, S.C.; Yardimci, A.; Guceri, S.I. Mechanical and Rheological Properties of Feedstock Material for Fused Deposition of Ceramics and Metals (FDC and FDMet) and their Relationship to Process Performance. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 1999. [Google Scholar]

- Gonzalez-Gutierrez, J.; Duretek, I.; Holzer, C.; Arbeiter, F.; Kukla, C. Filler Content and Properties of Highly Filled Filaments for Fused Filament Fabrication of Magnets. In Proceedings of the ANTEC 2017, Anaheim, CA, USA, 8–10 May 2017; Society of Plastics Engineers, Ed.; Society of Plastics Engineers: Bethel, CT, USA, 2017; pp. 1–4. [Google Scholar]

- Burkhardt, C.; Freigassner, P.; Weber, O.; Imgrund, P.; Hampel, S. Fused Filament Fabrication (FFF) of 316L Green Parts for the MIM process. In Proceedings of the World PM2016 Congress & Exhibition, Hamburg, Germany, 9–13 October 2016; EPMA: Shrewsbury, UK, 2016; pp. 1–7. [Google Scholar]

- EVO-Tech GmbH. FMP: Filament Metal Printing. Available online: http://evo-tech.eu/de/Filament-Metal-Printing (accessed on 22 August 2017).

- Hausnerova, B.; Kitano, T.; Kuritka, I.; Prindis, J.; Marcanikova, L. The Role of Powder Particle Size Distribution in the Processability of Powder Injection Molding Compounds. Int. J. Polym. Anal. Charact. 2011, 16, 141–151. [Google Scholar] [CrossRef]

- Brostow, W.; Buchman, A.; Buchman, E.; Olea-Mejia, O. Microhybrids of metal powder incorporated in polymeric matrices: Friction, mechanical behavior, and microstructure. Polym. Eng. Sci. 2008, 48, 1977–1981. [Google Scholar] [CrossRef]

- Uhm, Y.R.; Kim, J.; Son, K.J.; Kim, C.S. Effect of particle size, dispersion, and particle–matrix adhesion on W reinforced polymer composites. Res. Chem. Intermed. 2014, 40, 2145–2153. [Google Scholar] [CrossRef]

- Venkataraman, N.; Rangarajan, S.; Matthewson, M.J.; Harper, B.; Safari, A.; Danforth, S.C.; Wu, G.; Langrana, N.; Guceri, S.I.; Yardimci, A. Feedstock material property-process relationships in fused deposition of ceramics (FDC). Rapid Prototyp. J. 2000, 6, 244–253. [Google Scholar] [CrossRef]

- Beer, F.P.; Johnston, E.R.; DeWolf, J.T. Mechanics of Materials, 2nd ed.; McGraw-Hill: London, UK, 1992. [Google Scholar]

- Barnes, H.A.; Hutton, J.F.; Walters, K. An Introduction to Rheology; Elsevier Science Pub. Co.: Amsterdam, The Netherlands; New York, NY, USA, 1989. [Google Scholar]

- Rangarajan, S.; Qi, G.; Venkataraman, N.; Safari, A.; Danforth, S.C. Powder Processing, Rheology, and Mechanical Properties of Feedstock for Fused Deposition of Si3N4 Ceramics. J. Am. Ceram. Soc. 2000, 83, 1663–1669. [Google Scholar] [CrossRef]

- Grida, I.; Evans, J.R. Extrusion freeforming of ceramics through fine nozzles. J. Eur. Ceram. Soc. 2003, 23, 629–635. [Google Scholar] [CrossRef]

- Griffin, E.A.; McMillin, S. Selective Laser Sintering and Fused Deposition Modeling Processes for Functional Ceramic Parts. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 1995. [Google Scholar]

- Edirisinghe, M.J.; Evans, J.R.G. Compounding Ceramic Powders Prior to Injection Moulding. Br. Ceram. Proc. 1986, 38, 67–81. [Google Scholar]

- Clancy, R.; Jamalabad, V.R.; Whalen, P.; Bhargava, P.; Dai, C.; Rangarajan, S.; Wu, S.; Danforth, S.C.; Langrana, N.; Safari, A. Fused Deposition of Ceramics: Progress Torwards a Robust and Controlled Process for Commercialization. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 11–13 August 1997. [Google Scholar]

- Spoerk, M.; Arbeiter, F.; Cajner, H.; Sapkota, J.; Holzer, C. Parametric optimization of intra- and inter-layer strengths in parts produced by extrusion-based additive manufacturing of poly(lactic acid). J. Appl. Polym. Sci. 2017, 134, 45401. [Google Scholar] [CrossRef]

- Allahverdi, M.; Danforth, S.C.; Jafari, M.A.; Safari, A. Processing of advanced electroceramic components by fused deposition technique. J. Eur. Ceram. Soc. 2001, 21, 1485–1490. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Mao, R.-C. Development of a Precision Surface Polishing System for Parts Fabricated by Fused Deposition Modeling. Mater. Manuf. Process. 2015, 31, 1113–1118. [Google Scholar] [CrossRef]

- Garg, A.; Bhattacharya, A.; Batish, A. On Surface Finish and Dimensional Accuracy of FDM Parts after Cold Vapor Treatment. Mater. Manuf. Process. 2015, 31, 522–529. [Google Scholar] [CrossRef]

- Takagishi, K.; Umezu, S. Development of the Improving Process for the 3D Printed Structure. Sci. Rep. 2017, 7, 39852. [Google Scholar] [CrossRef] [PubMed]

- Enneti, R.K.; Park, S.J.; German, R.M.; Atre, S.V. Review: Thermal Debinding Process in Particulate Materials Processing. Mater. Manuf. Process. 2012, 27, 103–118. [Google Scholar] [CrossRef]

- Banerjee, S.; Joens, C.J. Debinding and sintering of metal injection molding (MIM) components. In Handbook of Metal Injection Molding; Heaney, D.F., Ed.; Woodhead Publishing: Cambridge, UK; Philadelphia, PA, USA, 2012; pp. 133–180. [Google Scholar]

- Lous, G.M.; Cornejo, I.A.; McNulty, T.F.; Safari, A.; Danforth, S.C. Fabrication of curved ceramic/polymer composite transducer for ultrasonic imaging applications by fused deposition of ceramics. In Proceedings of the Eleventh IEEE International Symposium on Applications of Ferroelectrics, Montreux, Switzerland, 24–27 August 1998; pp. 239–242. [Google Scholar]

- Krug, S.; Evans, J.; ter Maat, J. Differential sintering in ceramic injection moulding: Particle orientation effects. J. Eur. Ceram. Soc. 2002, 22, 173–181. [Google Scholar] [CrossRef]

- Huang, M.-S.; Hsu, H.-C. Influence of injection moulding and sintering parameters on properties of 316L MIM compact. Powder Met. 2013, 54, 299–307. [Google Scholar] [CrossRef]

- Scheithauer, U.; Slawik, T.; Schwarzer, E.; Richter, H.-J.; Moritz, T.; Michaelis, A. Additive manufacturing of metallic and ceramic multimaterial components using thermoplastic 3D printing (T3DP). J. Ceram. Sci. Technol. 2015, 6, 125–131. [Google Scholar]

- Jafari, M.A.; Han, W.; Mohammadi, F.; Safari, A.; Danforth, S.C.; Langrana, N. A novel system for fused deposition of advanced multiple ceramics. Rapid Prototyp. J. 2000, 6, 161–175. [Google Scholar] [CrossRef]

- Scheithauer, U.; Johne, R.; Weingarten, S.; Schwarzer, E.; Abel, J.; Müller-Köhn, A.; Günther, A.; Moritz, T. CerAMfacturing: Development of ceramic and multi material components by additive manufacturing methods for personalized medical products. J. 3D Print. Med. 2018, 2, 15–25. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Panda, R.K.; Janas, V.F.; Danforth, S.C.; Safari, A. Processing of Piezocomposites via Solid Freeform Fabrication (SFF) Techniques. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 Augus 1996. [Google Scholar]

- Lous, G.M.; Cornejo, I.A.; McNulty, T.F.; Safari, A.; Danforth, S.C. Fabrication of Piezoelectric CeramicPolymer Composite Transducers Using Fused Deposition of Ceramics. J. Am. Ceram. Soc. 2000, 83, 124–128. [Google Scholar] [CrossRef]

- Atisivan, R.; Bose, S.; Bandyopadhyay, A. Porous Mullite Preforms via Fused Deposition. J. Am. Ceram. Soc. 2001, 84, 221–223. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, C.-J. Three-dimensional Printing for Catalytic Applications: Current Status and Perspectives. Adv. Funct. Mater. 2017, 27, 1701134. [Google Scholar] [CrossRef]

| AM Process Category | Technologies | Description | Typical Materials | Strengths/Weaknesses |

|---|---|---|---|---|

| Material extrusion | Fused filament fabrication (FFF) Fused deposition modeling (FDMTM) Robocasting | Process in which material is selectively extruded through a nozzle or orifice. | Pellets or filaments of thermoplastic polymers, composites, and highly-filled polymers with metals or ceramics. Highly-filled inks containing a ceramic or metallic powder. | Inexpensive equipment. Great variety of materials. Easy to use.Small to large building spaces. Multi-material parts are possible. / Rougher surface, limited by nozzle radius. Accuracy and speed can be low. Anisotropy of properties. Support structures are needed. |

| Vat photo-polymerization | Stereolithographic apparatus (SLATM) Digital light processing (DLPTM) Scan, spin, and selectively photocure (3SPTM) Continuous liquid interface production (CLIPTM) | Process which uses photopolymerization. Liquid photopolymer is selectively cured by light (ultraviolet)-activated polymerization. | UV-curable photopolymer resins (with various fillers). | High level of complexity and accuracy. Smooth surface finish. Accommodates large build areas. / Photo-resins only. Liquid monomers can be harmful. Material creeping can occur after curing. Lengthy post-processing needed. Support structures might be needed.Expensive equipment. |

| Material jetting | Polyjet TM Smooth curvatures printing (SCPTM) Multi-jet modeling (MJMTM) | Process in which droplets of build material are selectively deposited. | Photopolymers, thermoplastic polymers, waxes, composites. | High level of accuracy. Allows for full color parts. Multi-material parts are possible. / Support structures are required. Limited number of materials. |

| Binder jetting | 3D printing (3DPTM) ExOne VoxelJet | Process in which a liquid adhesive/bonding agent is selectively deposited to join powder materials. | Powdered plastics, metals, ceramics, glass, and sand. | Allows for full color parts. High productivity. Wide range of materials available. / Properties are dependent on the binder used. Post-processing is needed. Powders can be harmful. |

| Sheet lamination | Laminated object manufacture (LOM) Selective deposition lamination (SDL) Ultrasonic additive manufacturing (UAM) | Process in which sheets of material are bonded to form an object. | Paper, plastic sheets, metal foils/tapes | High volumetric build rates. Relatively low cost (non-metals). Allows for combination of metal foils, including embedding components. / Finishing depends on material used. Post-processing is required. Limited materials. Properties are dependent on the adhesive used. |

| Powder bed fusion | Selective laser sintering (SLSTM) Direct metal laser sintering (SLMTM) Electron beam melting (EBMTM) Selective heat sintering (SHSTM) Multi-jet fusion (MJFTM) HP Jet fusionTM High speed sintering | Process in which thermal energy selectively fuses regions of a powder bed. | Plastics, metals, ceramics powders, and sand. | High level of complexity. Powder acts as support material. Wide range of materials available. / Equipment is more expensive. Special powders are required that are more expensive and can be harmful. Powders can age/oxidase fast. Post-processing is generally needed. |

| Directed energy deposition | Laser metal depositionLaser engineered net shaping (LENSTM) Direct metal deposition (DMDTM) | Process in which focused thermal energy is used to fuse materials by melting as the material is being deposited. | Metal wire and powders, and powder ceramics | Not limited by direction or axis. Effective for adding features and repairs. Multiple materials can be deposited in a single part. Highest single-point deposition rate. / Powders can be harmful. Finishes depend on material. Post-processing is needed. Limited materials. |

| Main Component (50–90 vol %) | Backbone (10–50 vol %) | Additives (1–10 vol %) | Ref. |

|---|---|---|---|

| Carnauba wax | Polypropylene (PP) | Stearic acid | [81] |

| Paraffin wax | Ethylvinylacetate (EVA) | Stearic acid | [78] |

| Paraffin wax | High density polyethylene (HDPE) | Stearic acid | [78,81,82,83] |

| Paraffin wax | Polyethylene (PE), PP | Stearic acid | [84,85,86] |

| Paraffin wax | HDPE, PP, Polystyrene (PS) | Stearic acid | [87] |

| Paraffin wax | PE | Stearic acid, oleic acid | [88] |

| Polyethylene glycol (PEG) | Polymethyl methacrylate (PMMA) | Stearic acid | [89,90,91] |

| PEG | Polyvinylbutyral (PVB) | Stearic Acid | [92] |

| PEG | Polyethylene wax | Stearic acid | [93,94] |

| PEG | Polyimide diisocyanate | 2, 6-di-tert-butyl-4-hydroxytoluene | [95] |

| Polyoxymethylene (POM) | Low density polyethylene (LDPE) | Stearic acid | [77] |

| POM | Polyolefins | Poly-1,3-dioxepane or poly-1,3-dioxolane or mixtures thereof | [96] |

| POM | PE | Butanediol formal | [97] |

| Agar (gel forming polysaccharide) | Glucose | Deionized water, calcium borate, methyl-p-hydroxybenzoate and propyl-p-hydroxybenzoate as biocides | [98] |

| PEG or polypropylene glycol or polyvinyl alcohol | PS and/or PE | Methylene chloride | [80] |

| Partially hydrolyzed cold water soluble polyvinyl alcohol | PE or PP | Glycerin, INT-33PA, steric acid, water | [99] |

| Main Component (50–90 vol %) | Backbone (0–50 vol %) | Additives (0–10 vol %) | Ref. |

|---|---|---|---|

| Elastomer and wax | Polymer | Plasticizer, tackifier, oleyl alcohol | [60,61,100] |

| Amorphous polyolefin | Amorphous polyolefin | Tackifier, wax, plasticizer, surfactant | [45,107,108] |

| Microcrystalline wax | Ethylene Vinyl Acetate (EVA) | None | [103,109] |

| Thermoplastic elastomer (TPE) | Grafted polyolefin | Unspecified compatibilizer | [62,73,74,110,111,112,113,114,115] |

| 4 hydroxybenzoic acid-behenylester solid, and 4 hydroxybenzoic acid-ethyhexylester | Co-polyamide (PA) 6/12 | None | [101] |

| HDPE | None | Isopropyl tri(dioctyl)pyrophosphato titanate, tri(dioctyl)phosphato zirconate or mixtures thereof | [102] |

| POM | Polyolefin, and other polymer (polyether, polyurethane, polyepoxide, polyamide, etc) | None | [116] |

| PA | None | Undisclosed | [105] |

| Undisclosed | Undisclosed | Stearic acid | [58,59] |

| LDPE wax | LDPE | None | [117] |

| Polypropylene | Elastomer | Wax, tackifier, plasticizer | [118,119,120] |

| Main Component (50–100 vol %) | Backbone (0–50 vol %) | Additives (0–10 vol %) | Ref. |

|---|---|---|---|

| PE wax, paraffin wax, PEG | PP | None | [48] |

| PEG | None | None | [106] |

| Paraffin wax | LDPE | SA | [117] |

| Metal or Ceramic | Type | Powder Content in Feedstock (vol %) | Ref. |

|---|---|---|---|

| Ceramic | Silicon nitrate (Si3N4) | 55 and 60 | [60,61,104] |

| Ceramic | Fused silica (SiO2) | 56, 60, and 65 | [60,61,119] |

| Ceramic | Lead zirconium titanate | 50 and 52.6 | [60,61,123] |

| Ceramic | Zirconia | 85 | [106] |

| Ceramic | Yttria stabilized zirconia | 47 | [114] |

| Ceramic | Strontium ferrite (SrFe12O19) | 53, 55, and 60 | [112,124] |

| Ceramic | Alumina | 50 | [121] |

| Ceramic | Mullite + Alumina + MgO | 47.93 + 6.85 + 0.69 = 55.47 | [120] |

| Ceramic | Fused silica + MgO | 53 + 3 = 56 | [120] |

| Ceramic | Titanium dioxide + MgO | 51 + 4 = 55 | [120] |

| Metal | Stainless steel (17-4PH) | 55 and 60 | [58,59,61,62,73] |

| Metal | Stainless steel (316L) | 50 and 55 | [62,74,105,110,111,112,125] |

| Metal | Stainless steel (AISI 630) | 79 | [106] |

| Metal | Tungsten carbide-cobalt | 50 | [60,61] |

| Metal | Carbonyl iron | 65 | [48] |

| Metal | Titanium (Ti6Al4V) | 55 | [90] |

| Metal | Rare earth magnet (NdFeB) | 55 | [113] |

| Company | Powders | Ref. |

|---|---|---|

| Markforged Inc. | Stainless steels 316L and 17-4PH. | [35] |

| Desktop Metal Inc. | 4140 (chrome moly), copper, Kovar F-15, Inconel 625, 316L (austenitic), 17-4 PH, and tool steel H13 | [36] |

| AIM3D GmbH | Stainless steels 17-4PH, 316L, 410L, 430 and 440C, tool steel M2, and low-alloy steel 4340 | [50] |

| EVO-tech GmbH | Stainless steel 316L | [126] |

| Compounding Method | Ultimate Tensile Strength—UTS (MPa) | Elongation at UTS (%) | Secant Modulus (MPa) |

|---|---|---|---|

| Twin screw extruder | 13.7 | 3.07 | 1250 |

| Roller mixer | 10.6 | 1.28 | 1860 |

| MEAM Model | Fillers in Feedstocks | Building Parameters Given | Refs. |

|---|---|---|---|

| Stratasys FDMTM 1650 (Filament-based) | Mullite, fused silica, and titanium dioxide | Ext. Temp: 235–237 °C Envelope Temp: 48 °C Material flow rate: 130% | [120] |

| Hage3D-72L (Filament-based) | Stainless steel 316L at 55 vol % | Nozzle diameter: 0.5 mm Ext. Temp: 240 °C Deposition speed: 50 mm/s | [125] |

| Hage3D-72L (Filament-based) | Yttria stabilized zirconia at 47 vol % Modified stainless steel 17-4PH powder at 47 vol % | Ext. Temp: 220–240 °C Bed Temp: 20 °C Print speed: 10 mm/s Layer thickness: 0.25 mm | [114] |

| Wanhao Duplicator i3 v2 (Filament-based) | Stainless steel 316L and 17-4PH at 55 vol % | Printing surface: glass or PP Nozzle diameter: 0.6 mm Ext. Temp: 210–260 °C Bed Temp: 60 °C Flow rate: 100–200% Deposition speed: 40–80 mm/s Layer thickness: 0.15–0.20 mm | [62,73] |

| Ultimaker 2 (Filament-based) | Stainless steel 316L | Nozzle diameter: 0.8 mm Feed speeds: 0.5–7 mm/s Deposition speed: 14 mm/s Ext. Temp: 235–240 °C Built rate: 0.62–5 mm3/s | [105] |

| Stratasys 3D Modeler (Filament based) | Si3N4 (Honewell’s GS44 grade) | Nozzle diameter: 0.25 mm Ext. Temp: 185 °C Envelope Temp: 37 °C Layer thickness: 0.254 mm | [104] |

| Mini-Extruder Deposition (MED) (Screw-based) | Piezoelectric ceramic ECG9/PZT [107] | Top liquefier temp.: 145–160 °C Lower liquefier temp.: 135–145 °C Nozzle diameter: 0.3 and 0.6 mm Pellet size: 1–5 mm | [46] |

| Fused Deposition of Metals (FDMe)(Screw-based) | Carbonyl iron at 57 to 59 vol % | Top liquefier temp.: 155–159 °C Lower liquefier temp.: 180–18 7 °C Nozzle diameter: 2 mm | [48] |

| Material | Linear Shrinkage (%) | Percentage Density from Theoretical (%) | Ref. |

|---|---|---|---|

| Fused silica | 1–4 | 70 | [60] |

| Mullite | 10–12 | N/A | [120] |

| Fused silica | 8–12 | N/A | [120] |

| 316L stainless steel | 19.2 ± 0.02 | 95 | [125] |

| Piezoelectric ceramics | 16–20 | N/A | [145] |

| Silicon nitride | 12–20 | 95–98 | [41] |

| NdFeB | 16–19 | 94–96 | [113] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. https://doi.org/10.3390/ma11050840

Gonzalez-Gutierrez J, Cano S, Schuschnigg S, Kukla C, Sapkota J, Holzer C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials. 2018; 11(5):840. https://doi.org/10.3390/ma11050840

Chicago/Turabian StyleGonzalez-Gutierrez, Joamin, Santiago Cano, Stephan Schuschnigg, Christian Kukla, Janak Sapkota, and Clemens Holzer. 2018. "Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives" Materials 11, no. 5: 840. https://doi.org/10.3390/ma11050840

APA StyleGonzalez-Gutierrez, J., Cano, S., Schuschnigg, S., Kukla, C., Sapkota, J., & Holzer, C. (2018). Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials, 11(5), 840. https://doi.org/10.3390/ma11050840