Design and Performance of Property Gradient Ternary Nitride Coating Based on Process Control

Abstract

:1. Introduction

2. Design Method and Experimental Procedures

2.1. Structure Design Method of the Gradient Coating

2.2. Design and Preparation of Gradient ZrTiN Coatings

2.3. Friction Test

2.4. Cutting Test

3. Results and Discussion

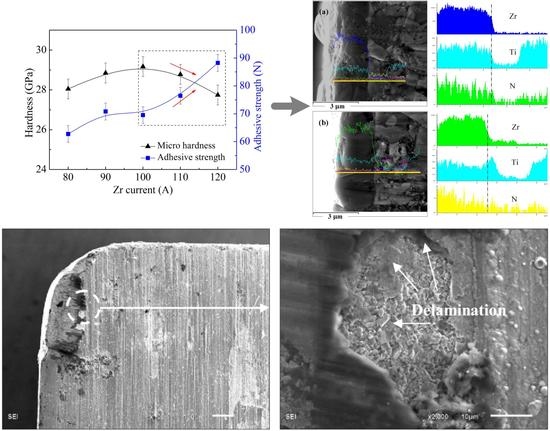

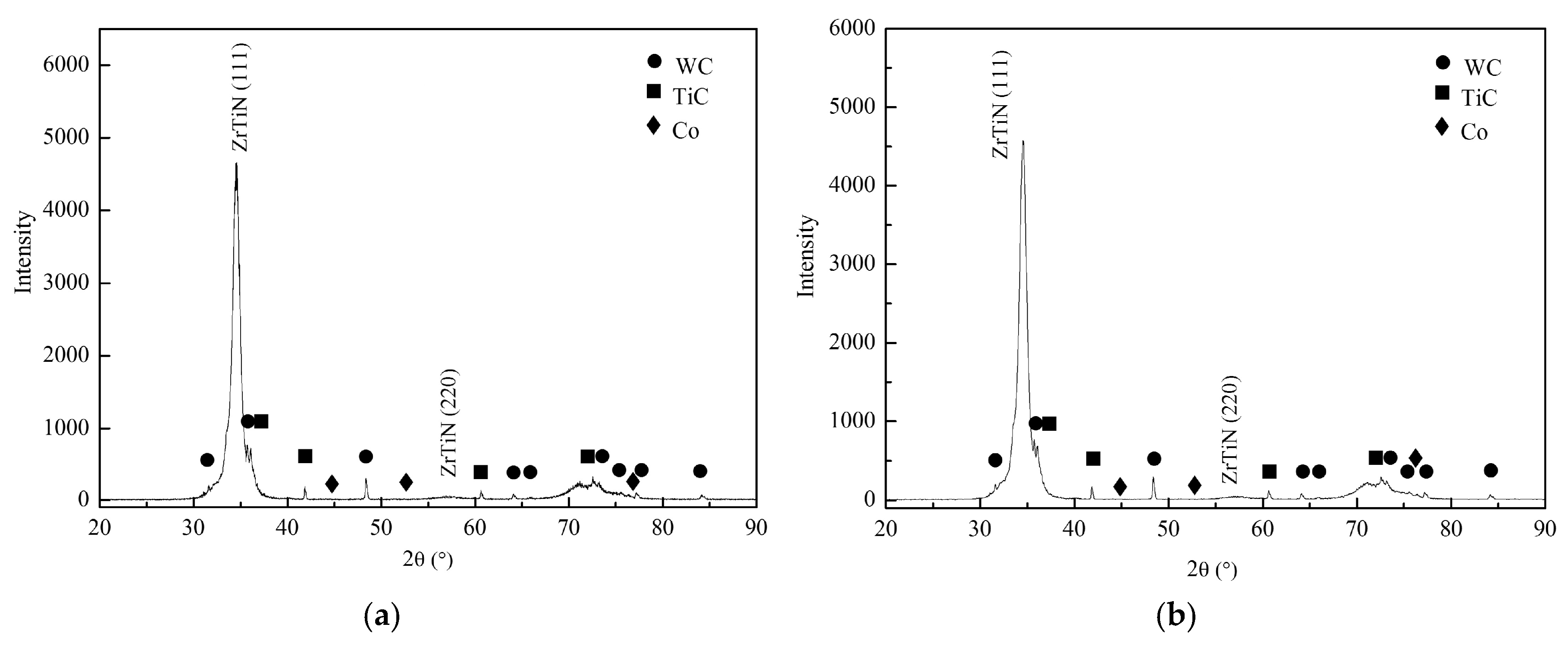

3.1. Structure and Property of the Coatings

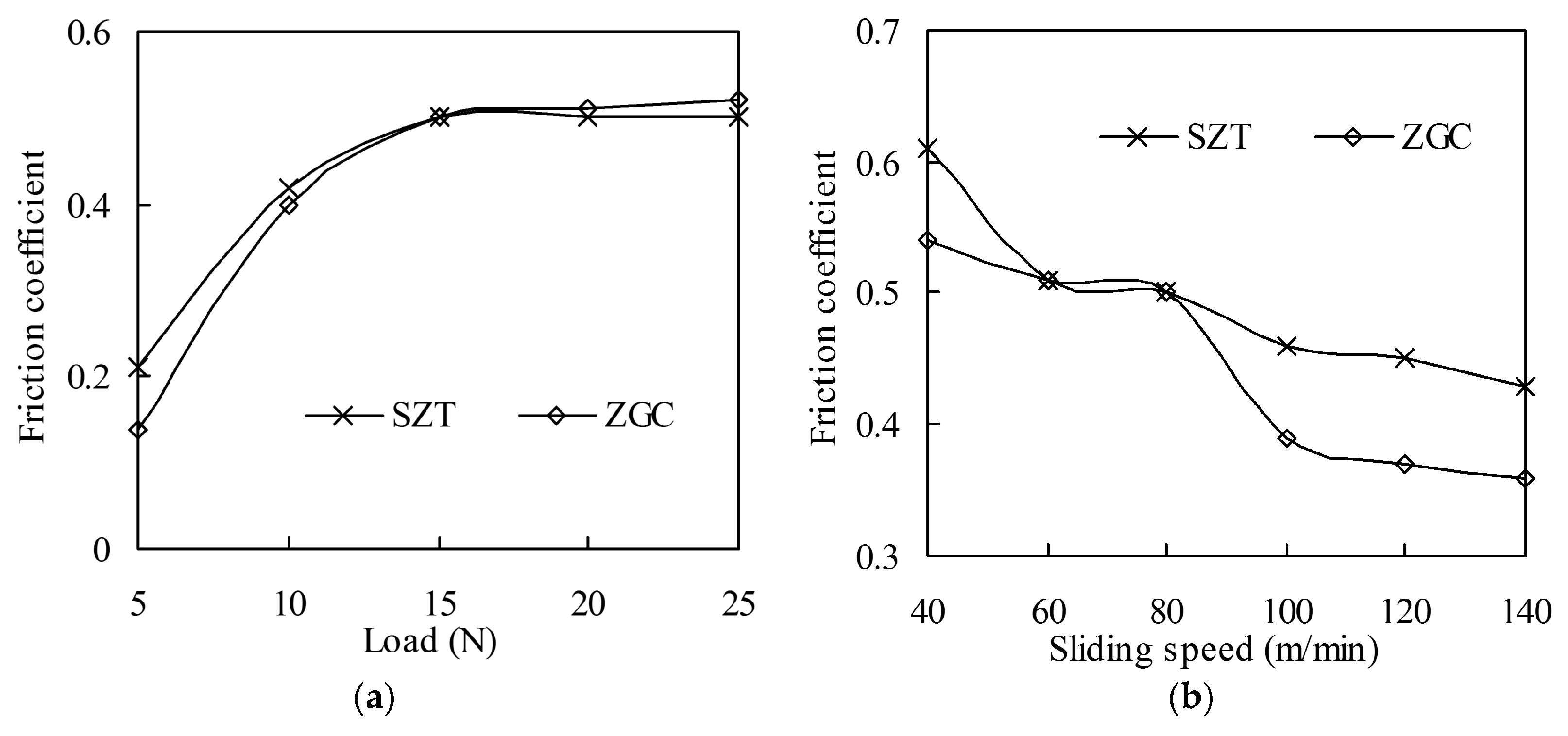

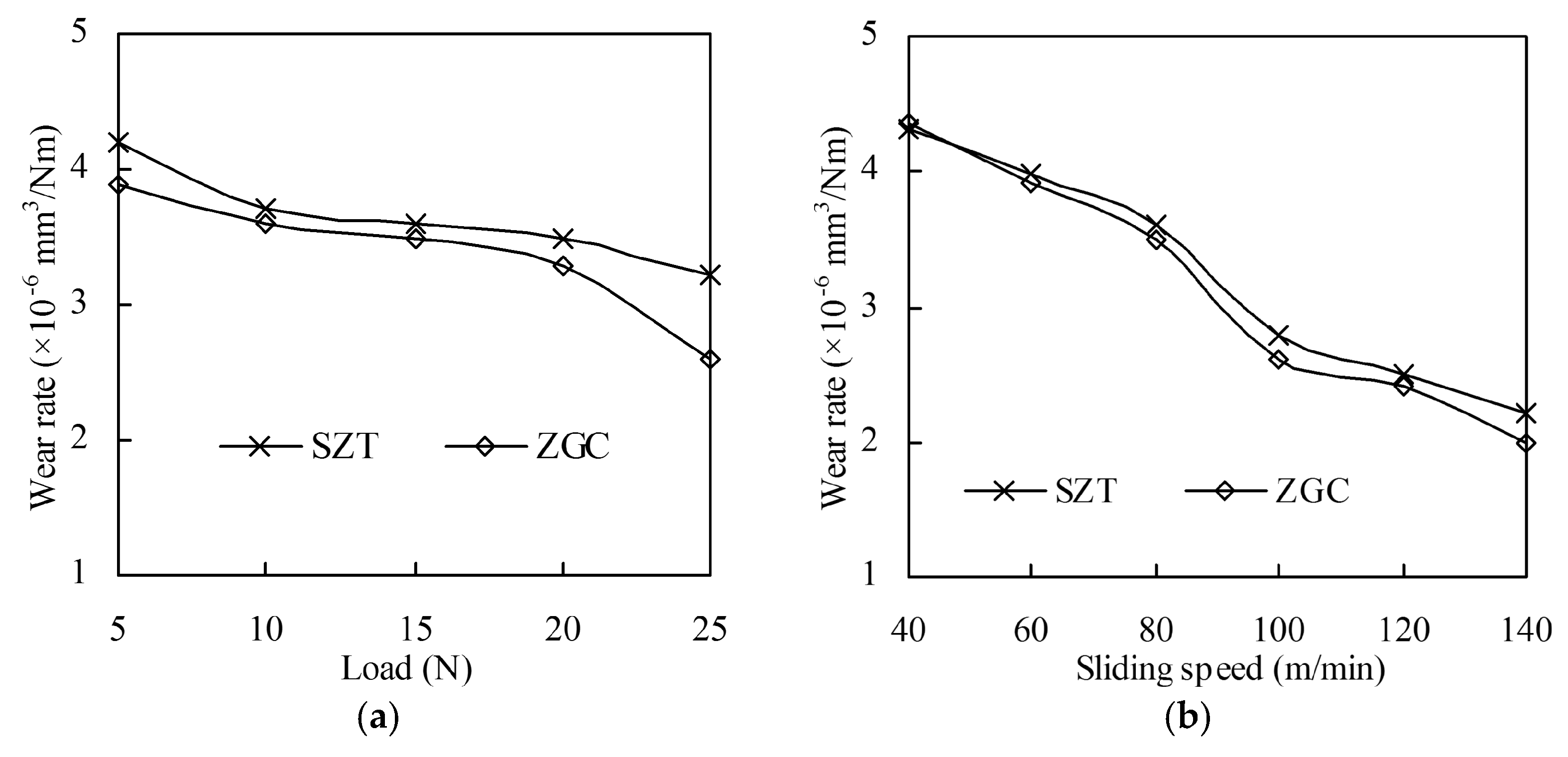

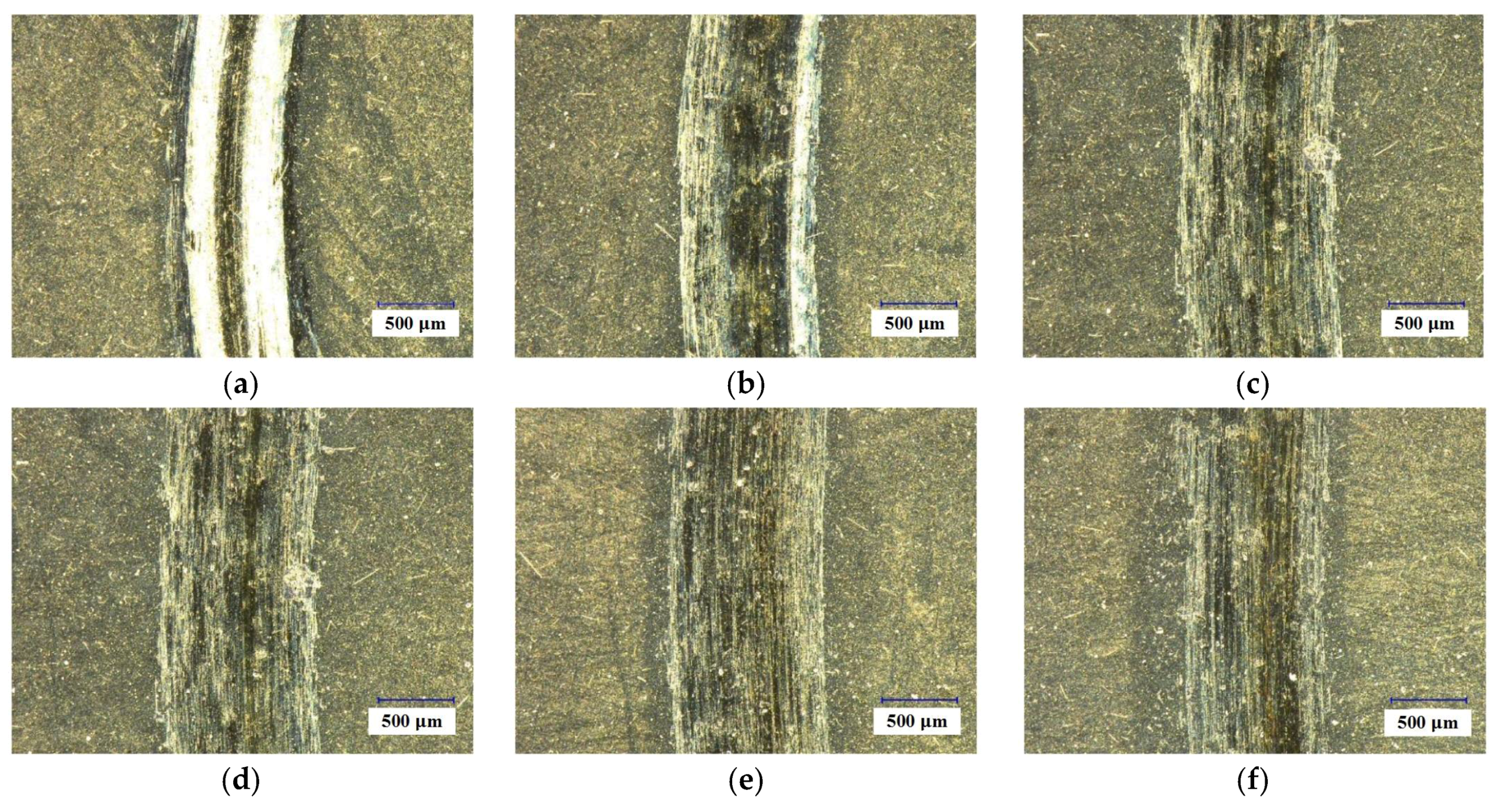

3.2. Friction and Wear Behavior of the Coatings

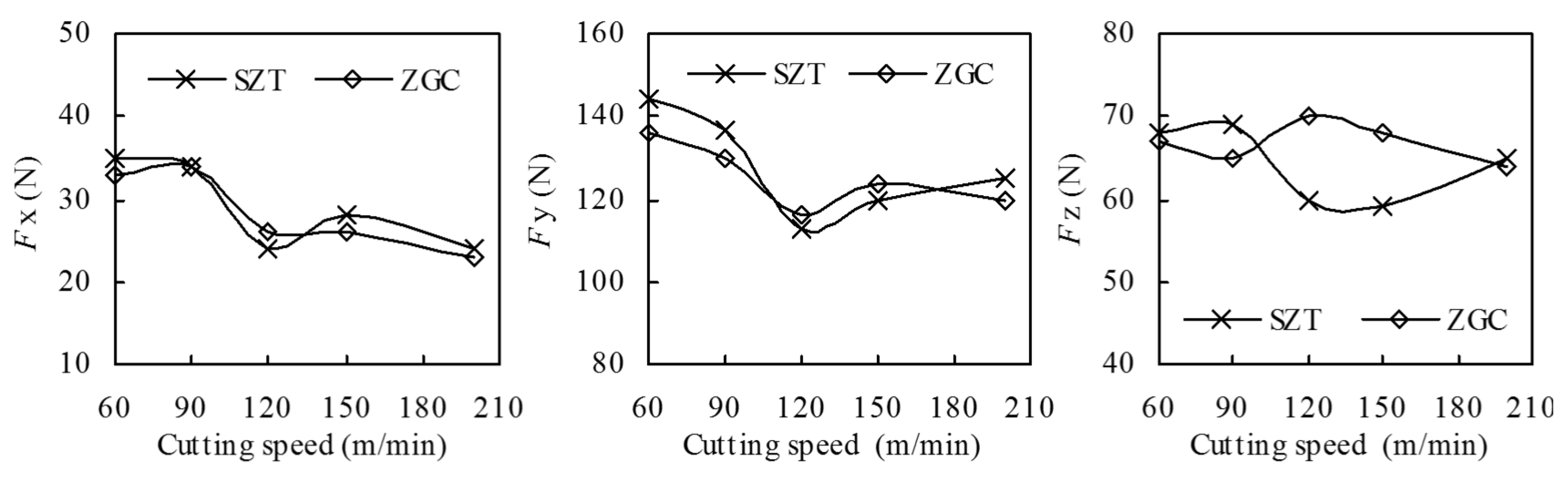

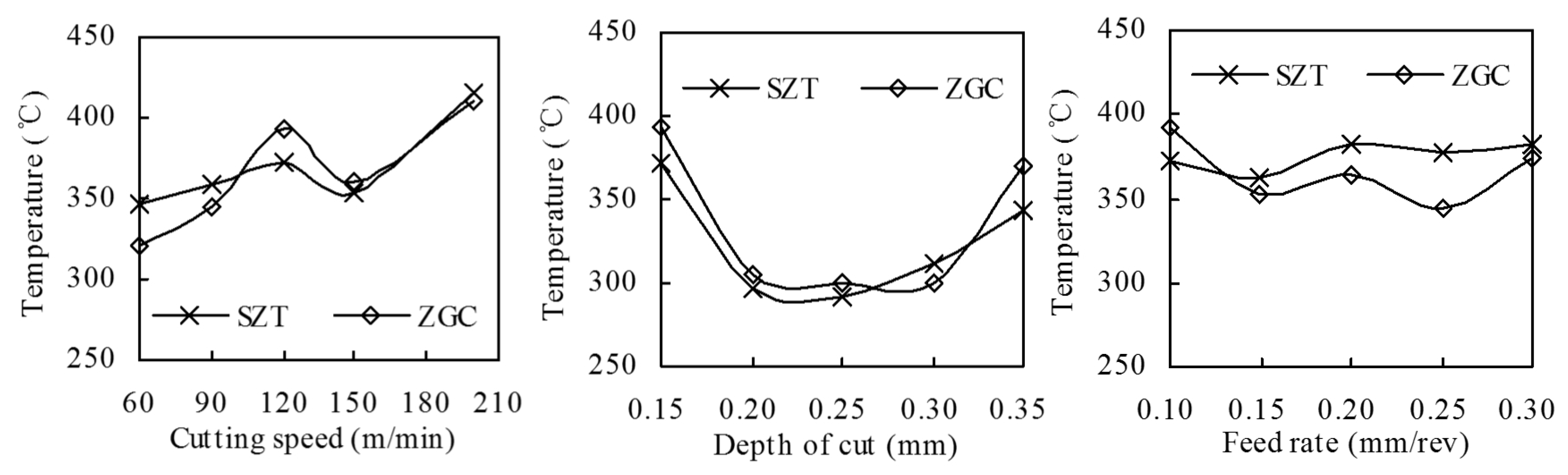

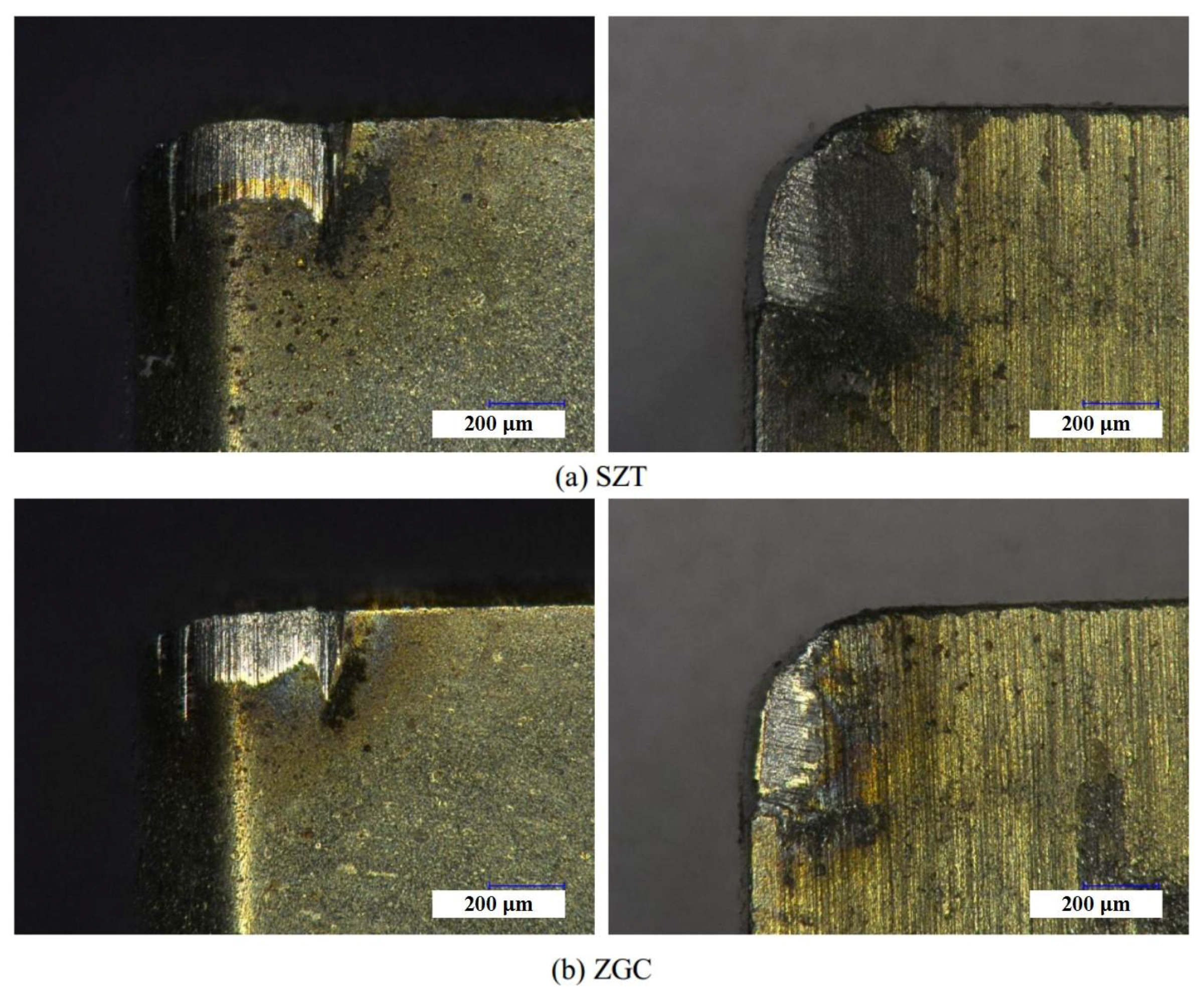

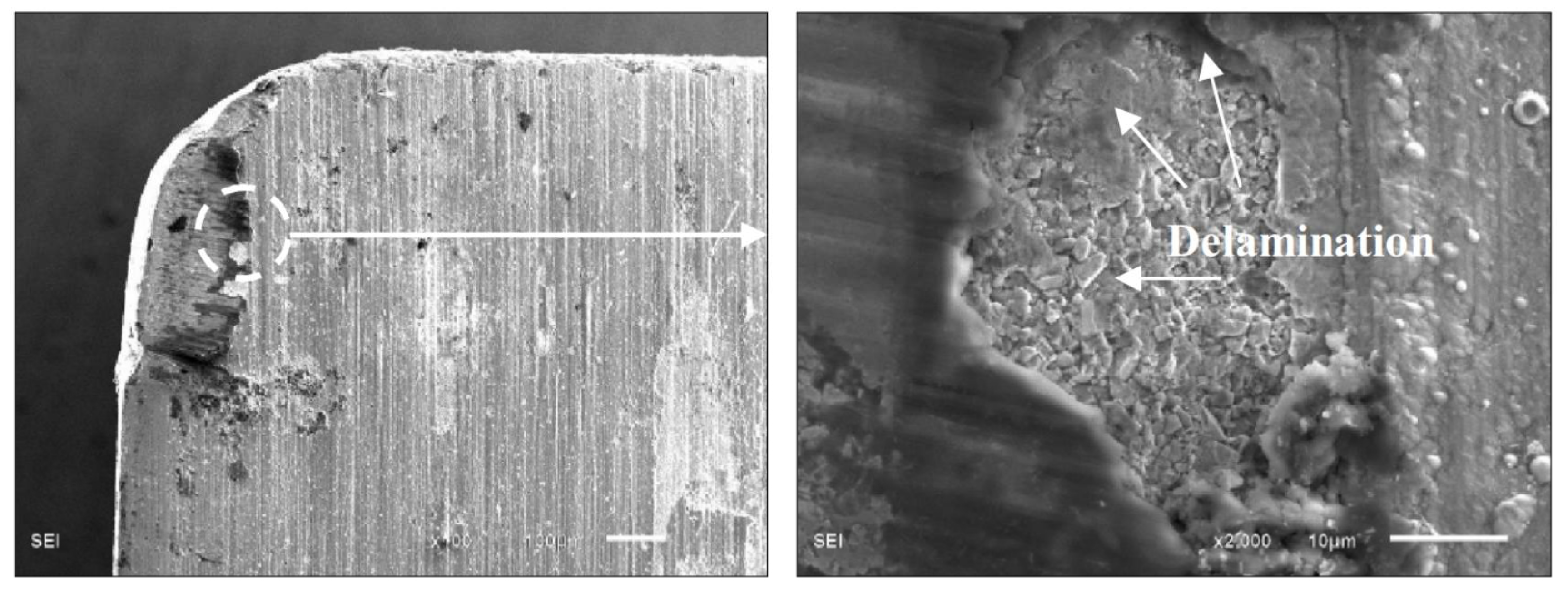

3.3. Cutting Performance of the Coatings

4. Conclusions

- (1)

- The property-component gradient which was designed and prepared by adjusting parameters during the deposition process could effectively improve the performances of the coatings.

- (2)

- The gradient coating ZGC had a better friction and wear performance with a lower wear rate and higher resistance to peeling off during sliding friction.

- (3)

- The gradient coating ZGC had a better wear and damage resistance in the cutting process, with lower machined surface roughness Ra.

- (4)

- A gradient structure in the coatings can effectively inhibit micro crack initiation and growth under alternating force and temperature load, with some slight delamination.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Okada, M.; Hosokawa, A.; Tanaka, R.; Ueda, T. Cutting performance of PVD-coated carbide and CBN tools in hard milling. Int. J. Mach. Tools Manuf. 2011, 51, 127–132. [Google Scholar] [CrossRef]

- Li, G.; Sui, X.; Jiang, C.; Gao, Y.; Wang, K.; Wang, Q.; Liu, D. Low adhesion effect of TaO functional composite coating on the titanium cutting performance of coated cemented carbide insert. Mater. Des. 2016, 110, 105–111. [Google Scholar] [CrossRef]

- Amirsaman, F.; Markus, B.; Javad, M. New smoothed particle hydrodynamics (SPH) formulation for modeling heat conduction with solidification and melting. Numer. Heat Transf. Part B Fundam. 2017, 71, 299–312. [Google Scholar]

- Amirsaman, F.; Thomas, W.C.; Javad, M. Numerical Study of Suspension Plasma Spraying. J. Therm. Spray Technol. 2017, 26, 12–36. [Google Scholar]

- Schulz, H.; Dörr, J.; Rass, I.J.; Schulze, M.; Leyendecker, T.; Erkens, G. Performance of oxide PVD-coatings in dry cutting operations. Surf. Coat. Technol. 2001, 146–147, 480–485. [Google Scholar] [CrossRef]

- Wang, G.; Xing, C.; Tao, F.; Ding, P.; Zhongjia, H. Enhancement in the corrosion resistance of WC coatings by adding a Fe-based alloy in simulated seawater. Surf. Coat. Technol. 2016, 305, 62–66. [Google Scholar] [CrossRef]

- Momeni, S.; Tillmann, W.; Pohl, M. Composite cavitation resistant PVD coatings based on NiTi thin films. Mater. Des. 2016, 110, 830–838. [Google Scholar] [CrossRef]

- Hong, X.; Tan, Y.; Wang, X.; Xu, T.; Gao, L. Microstructure and wear resistant performance of TiN/Zr-base amorphous-nanocrystalline composite coatings on titanium alloy by electrospark deposition. Surf. Coat. Technol. 2016, 305, 67–75. [Google Scholar] [CrossRef]

- Chen, L.; Wang, S.Q.; Zhou, S.Z.; Li, J.; Zhang, Y.Z. Microstructure and mechanical properties of Ti(C,N) and TiN/Ti(C,N) multilayer PVD coatings. Int. J. Refract. Met. Hard Mater. 2008, 26, 456–460. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Yamamoto, K.; Aguirre, M.H.; Cahill, D.G.; Veldhuis, S.C.; Biksa, A.; Dosbaeva, G.; Shuster, L.S. Multi-functional nano-multilayered AlTiN/Cu PVD coating for machining of Inconel 718 superalloy. Surf. Coat. Technol. 2010, 204, 2465–2471. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Yamamoto, K.; Kovalev, A.I.; Veldhuis, S.C.; Ning, L.; Shuster, L.S.; Elfizy, A. Wear behavior of adaptive nano-multilayered TiAlCrN/NbN coatings under dry high performance machining conditions. Surf. Coat. Technol. 2008, 202, 2015–2022. [Google Scholar] [CrossRef]

- Shaw, M.C. Metal Cutting Principles, 2nd ed.; Oxford University Press: New York, NY, USA, 2004. [Google Scholar]

- Freund, L.B.; Syresh, S. Thin Film Materials-Stress, Defect Formation and Surface Evolution; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Li, Y.Y.; Hsiao, Y.C.; Wu, C.C.; Wu, F.B. Phase transformation, thermal stability and indentation behavior of sputtering Ni-P-based interlayer enhanced CrN composite coatings. Surf. Coat. Technol. 2009, 204, 1002–1007. [Google Scholar] [CrossRef]

- Li, Y.; Huo, Y. Effectiveness of compositionally linearly graded interlayers for thermal stress reduction. Thin Solid Films 2009, 517, 2691–2696. [Google Scholar] [CrossRef]

- Klein, T.; Röhlsberger, R.; Crisan, O.; Schlage, K.; Burkel, E. Magnetic structure and interlayer exchange coupling in spring magnets--studied via nuclear resonant scattering. Thin Solid Films 2006, 515, 2531–2534. [Google Scholar] [CrossRef]

- Yan, P.; Deng, J.X.; Wu, Z.; Li, S.; Xing, Y.; Zhao, J. Friction and wear behavior of the PVD (Zr,Ti)N coated cemented carbide against 40Cr hardened steel. Int. J. Refract. Met. Hard Mater. 2012, 35, 213–220. [Google Scholar] [CrossRef]

- Yan, P.; Deng, J.X.; Rong, Y.M. Performance of PVD (Zr, Ti) N-coated cemented carbide inserts in cutting processes. Int. J. Adv. Manuf. Technol. 2014, 73, 1363–1371. [Google Scholar] [CrossRef]

- Chuang, C.C.; Liu, W.L.; Chen, W.J.; Huang, J.H. The role of Ti interlayer in carbon nanotube growth. Surf. Coat. Technol. 2008, 202, 2121–2125. [Google Scholar] [CrossRef]

- Polini, R.; Mantini, F.P.; Braic, M.; Amar, M.; Ahmed, W.; Taylor, H. Effects of Ti- and Zr-based interlayer coatings on the hot filament chemical vapour deposition of diamond on high speed steel. Thin Solid Films 2006, 494, 116–122. [Google Scholar] [CrossRef]

- Uglov, V.V.; Rusalski, D.P.; Zlotski, S.V.; Sevriuk, A.V.; Abadias, G.; Kislitsin, S.B.; Kadyrzhanov, K.K.; Gorlachev, I.D.; Dub, S.N. Stability of Ti–Zr–N coatings under Xe-ion irradiation. Surf. Coat. Technol. 2010, 204, 2095–2098. [Google Scholar] [CrossRef]

- Uglov, V.V.; Anishchik, V.M.; Zlotski, S.V.; Abadias, G.; Dub, S.N. Structural and mechanical stability upon annealing of arc-deposited Ti–Zr–N coatings. Surf. Coat. Technol. 2008, 202, 2394–2398. [Google Scholar] [CrossRef]

- Yan, P.; Deng, J.X.; Lian, Y.S.; Zhao, J.; Chen, Z.; Ai, X. Effect of depositing parameters on microstructures and properties of multi arc ion plating ZrTiN films. Surf. Eng. 2012, 28, 17–23. [Google Scholar] [CrossRef]

| Step. | Layer or Interface | Ti Current (A) | Zr Current (A) | N2 Flowrate (sccm) | Time (min) |

|---|---|---|---|---|---|

| 1 | Innermost transition | 60 | 0 | 0 | 2 |

| 2 | Intermediate transition | 60 | 90 | 0 | 2 |

| 3 | Outermost transition | 60 | 120 | 0 | 2 |

| 4 | - | 60 | 120 | 60 | 2 |

| 5 | Innermost coating | 60 | 120 | 120 | 25 |

| 6 | - | 64 | 116 | 120 | 2 |

| 7 | - | 67 | 113 | 120 | 2 |

| 8 | Intermediate coating | 70 | 110 | 120 | 25 |

| 9 | - | 74 | 106 | 120 | 2 |

| 10 | - | 77 | 103 | 120 | 2 |

| 11 | Outermost coating | 80 | 100 | 120 | 25 |

| Coating | Micro Hardness (GPa) | Adhesive Strength (N) | Thickness (μm) |

|---|---|---|---|

| SZT | 32.6 | 76.4 | 2.70 |

| ZGC | 31.7 | 83.2 | 2.67 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, P.; Chen, K.; Wang, Y.; Zhou, H.; Peng, Z.; Jiao, L.; Wang, X. Design and Performance of Property Gradient Ternary Nitride Coating Based on Process Control. Materials 2018, 11, 758. https://doi.org/10.3390/ma11050758

Yan P, Chen K, Wang Y, Zhou H, Peng Z, Jiao L, Wang X. Design and Performance of Property Gradient Ternary Nitride Coating Based on Process Control. Materials. 2018; 11(5):758. https://doi.org/10.3390/ma11050758

Chicago/Turabian StyleYan, Pei, Kaijie Chen, Yubin Wang, Han Zhou, Zeyu Peng, Li Jiao, and Xibin Wang. 2018. "Design and Performance of Property Gradient Ternary Nitride Coating Based on Process Control" Materials 11, no. 5: 758. https://doi.org/10.3390/ma11050758

APA StyleYan, P., Chen, K., Wang, Y., Zhou, H., Peng, Z., Jiao, L., & Wang, X. (2018). Design and Performance of Property Gradient Ternary Nitride Coating Based on Process Control. Materials, 11(5), 758. https://doi.org/10.3390/ma11050758