The Mechanism of Ultrasonic Vibration on Grain Refining and Degassing in GTA Spot Welding of Copper Joints

Abstract

:1. Introduction

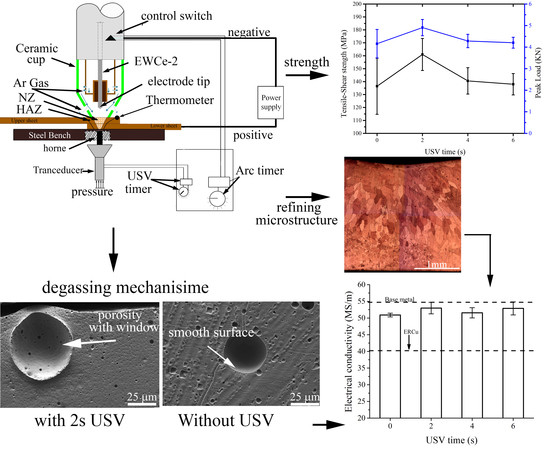

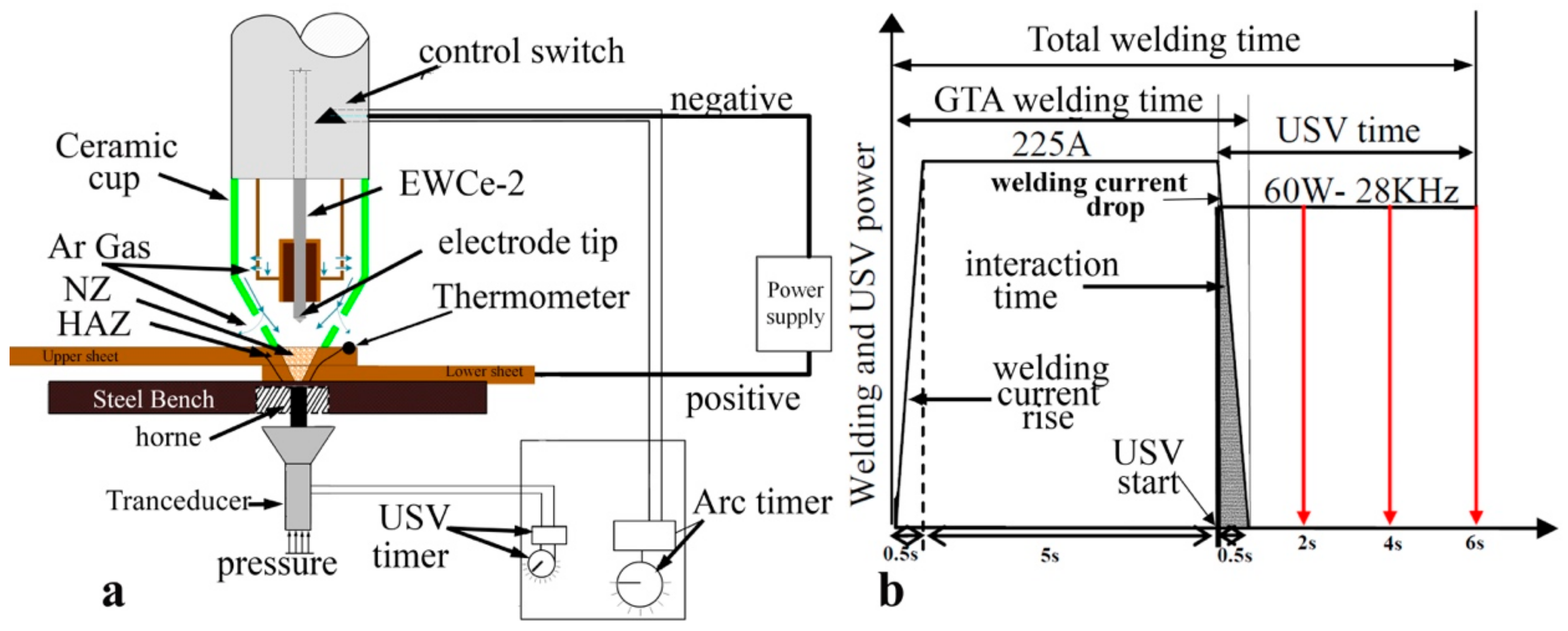

2. Materials and Methods

3. Results

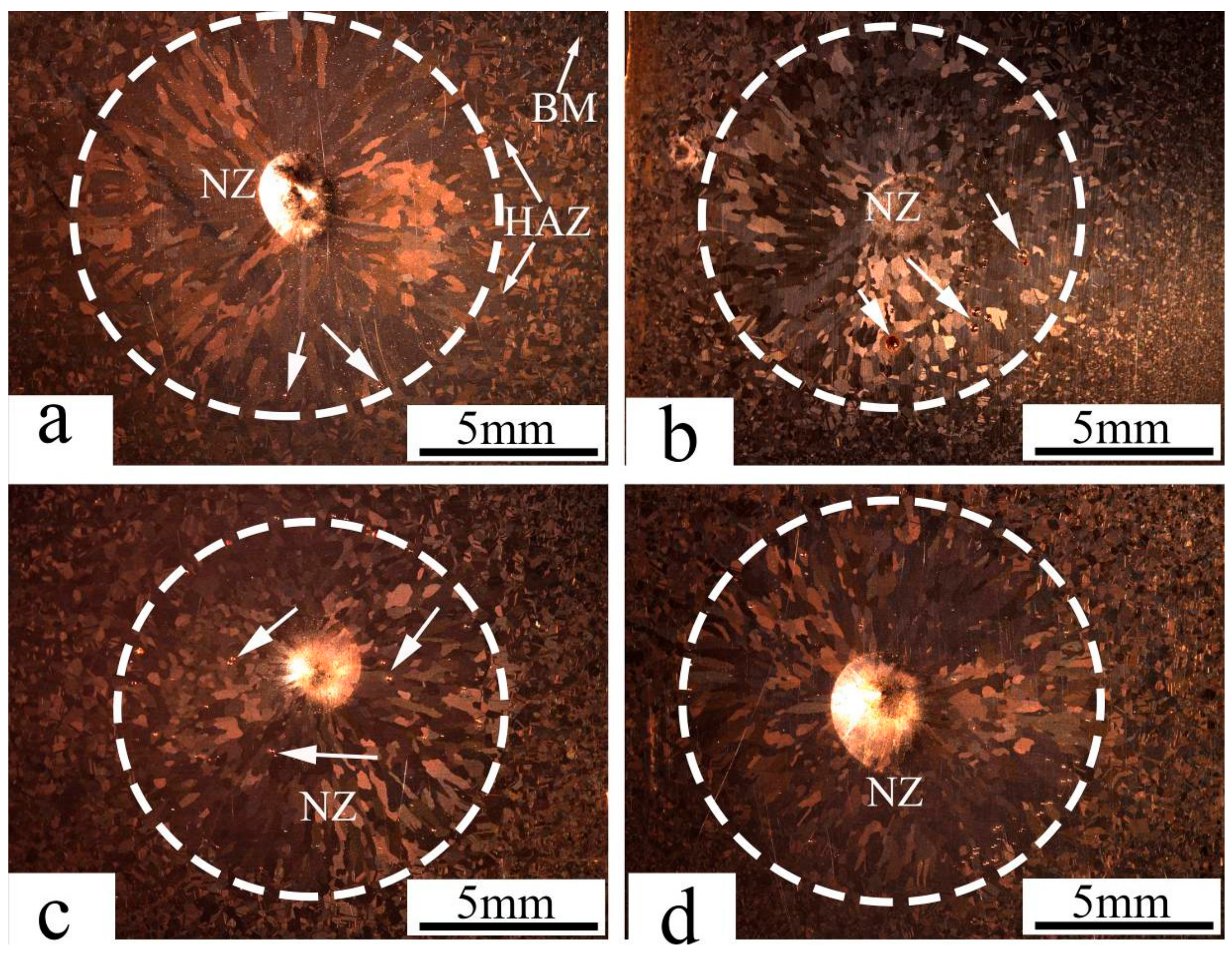

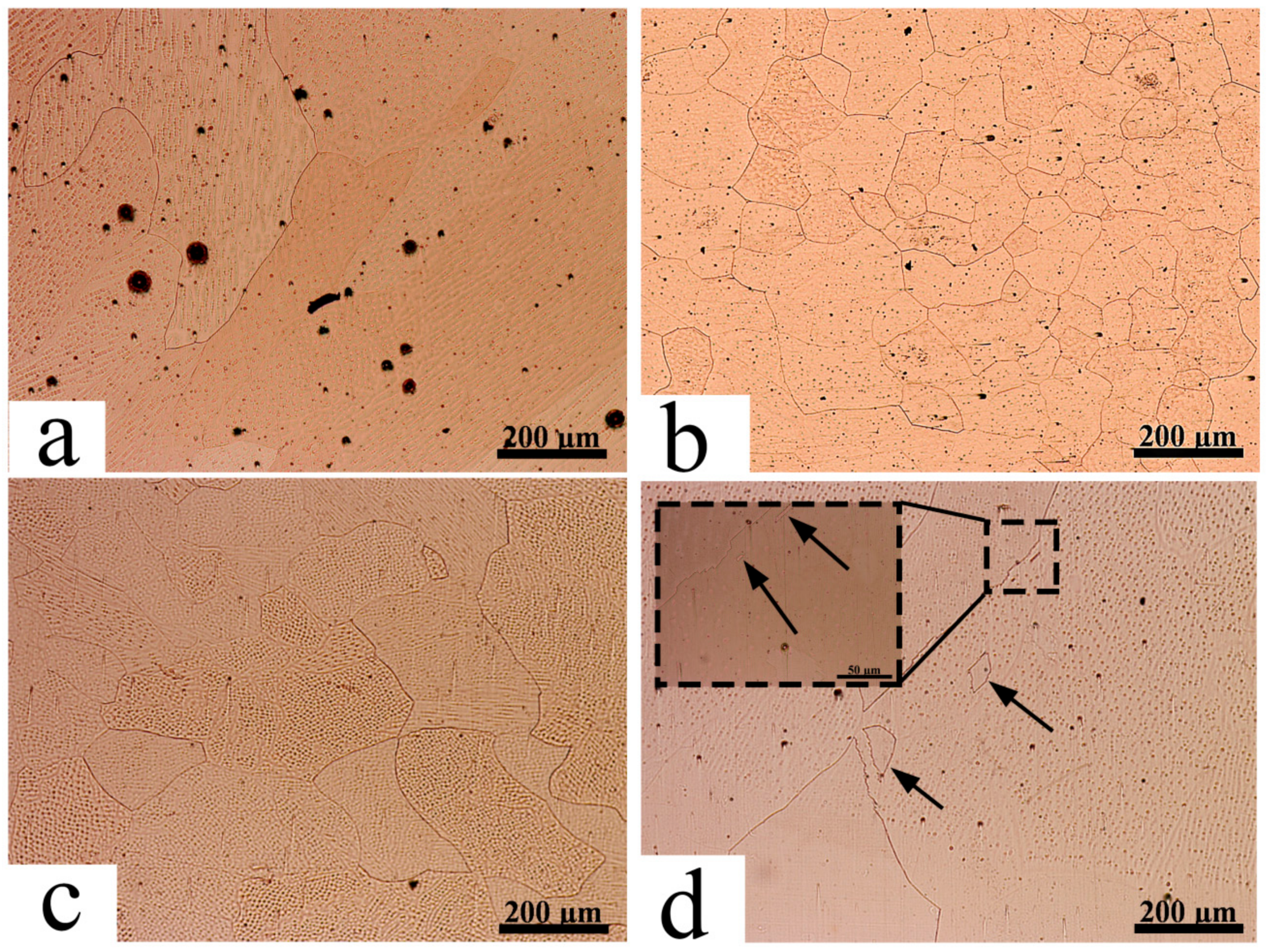

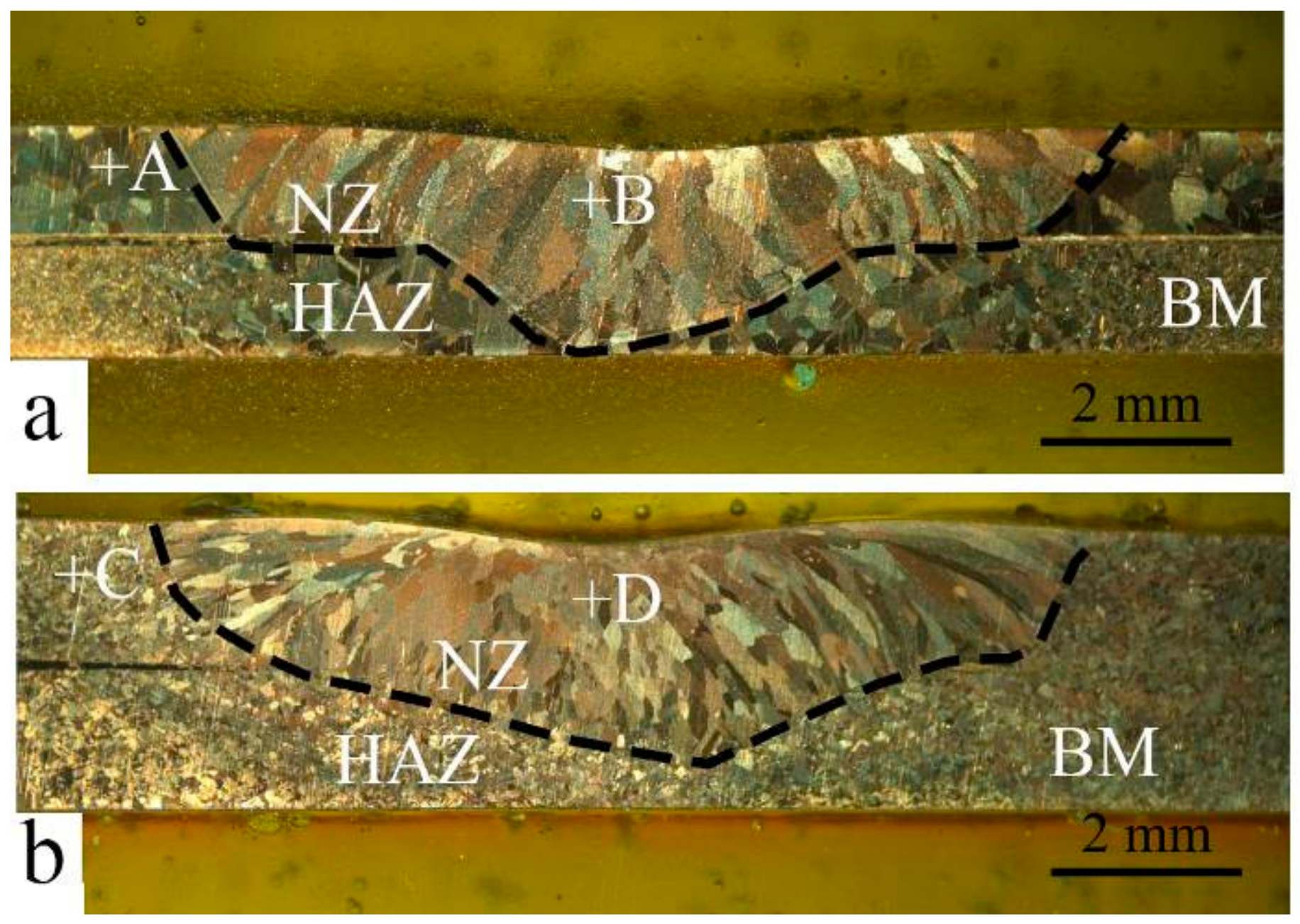

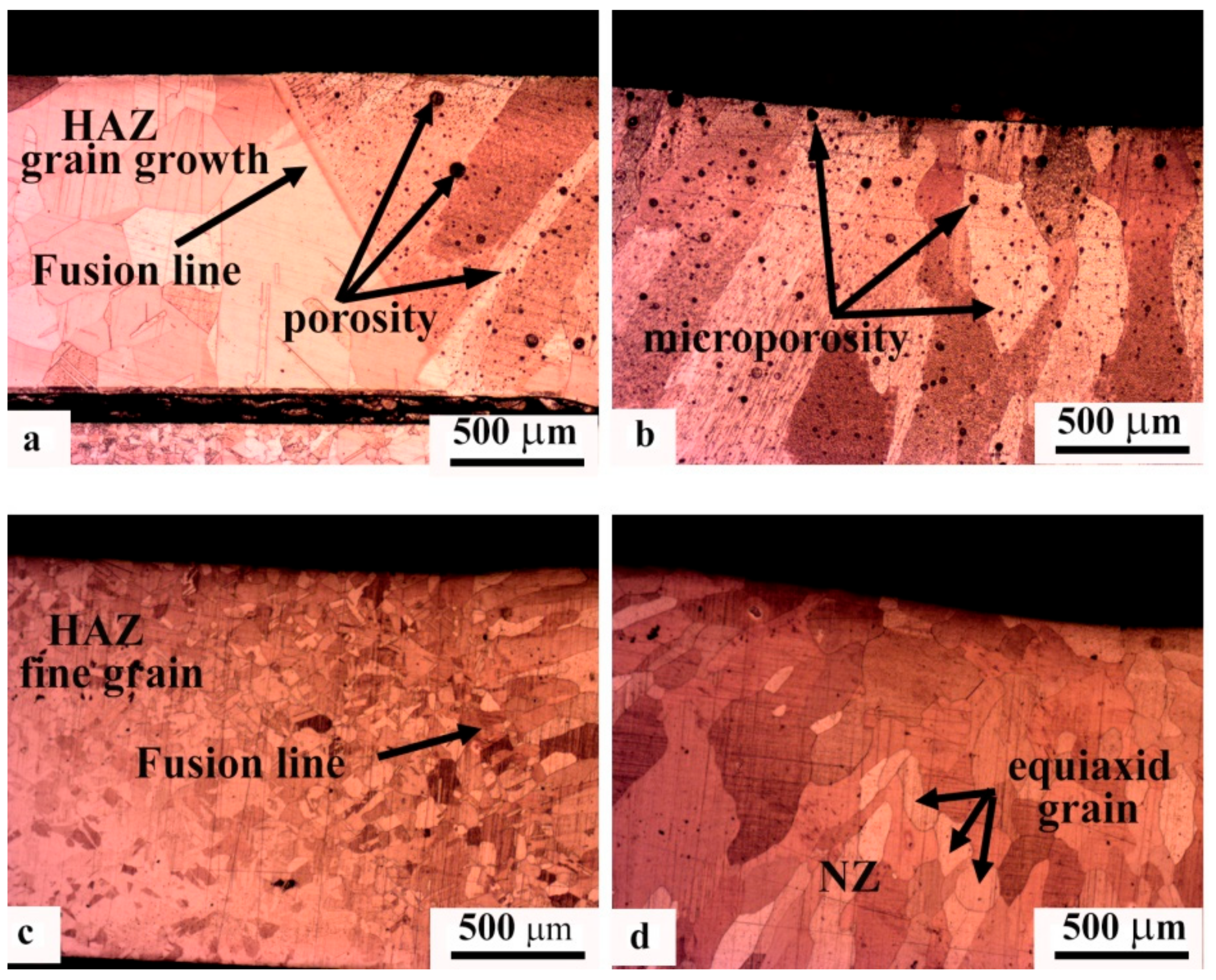

3.1. The Microstructure of GTA Spot-Welded Copper Joints

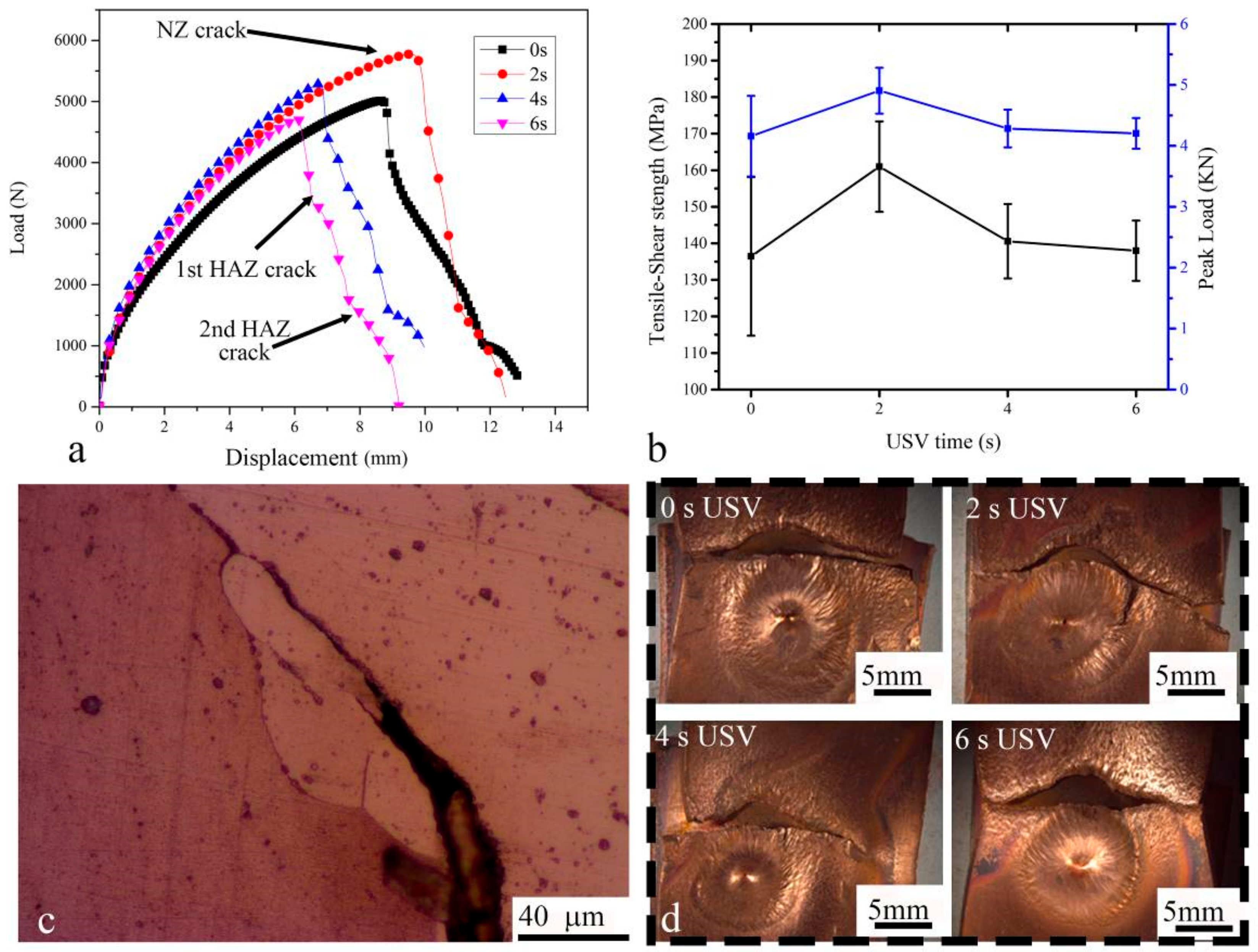

3.2. Strength of GTA Spot-Welded Copper Joints

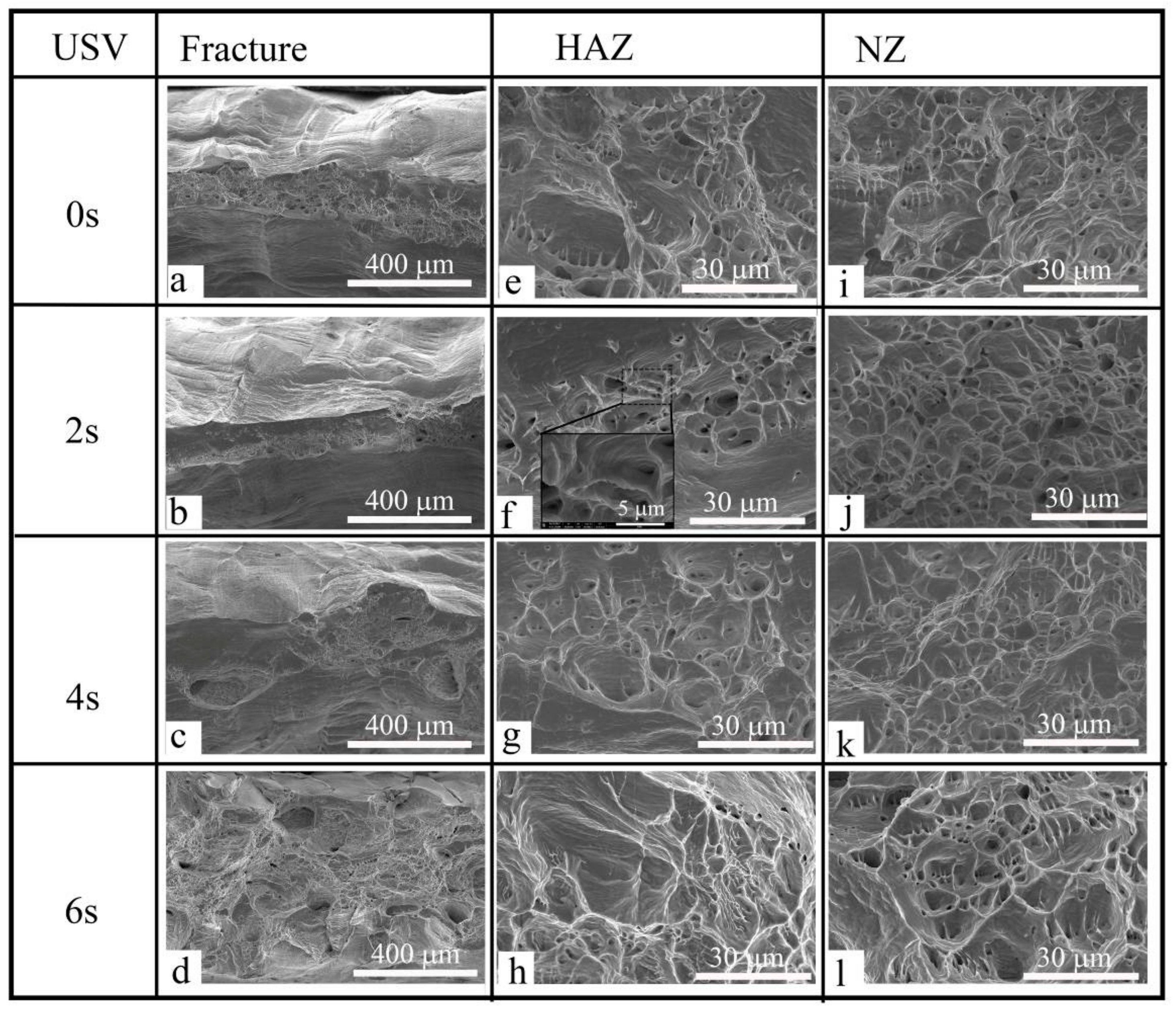

3.3. Fracture of GTA Spot-Welded Copper Joints

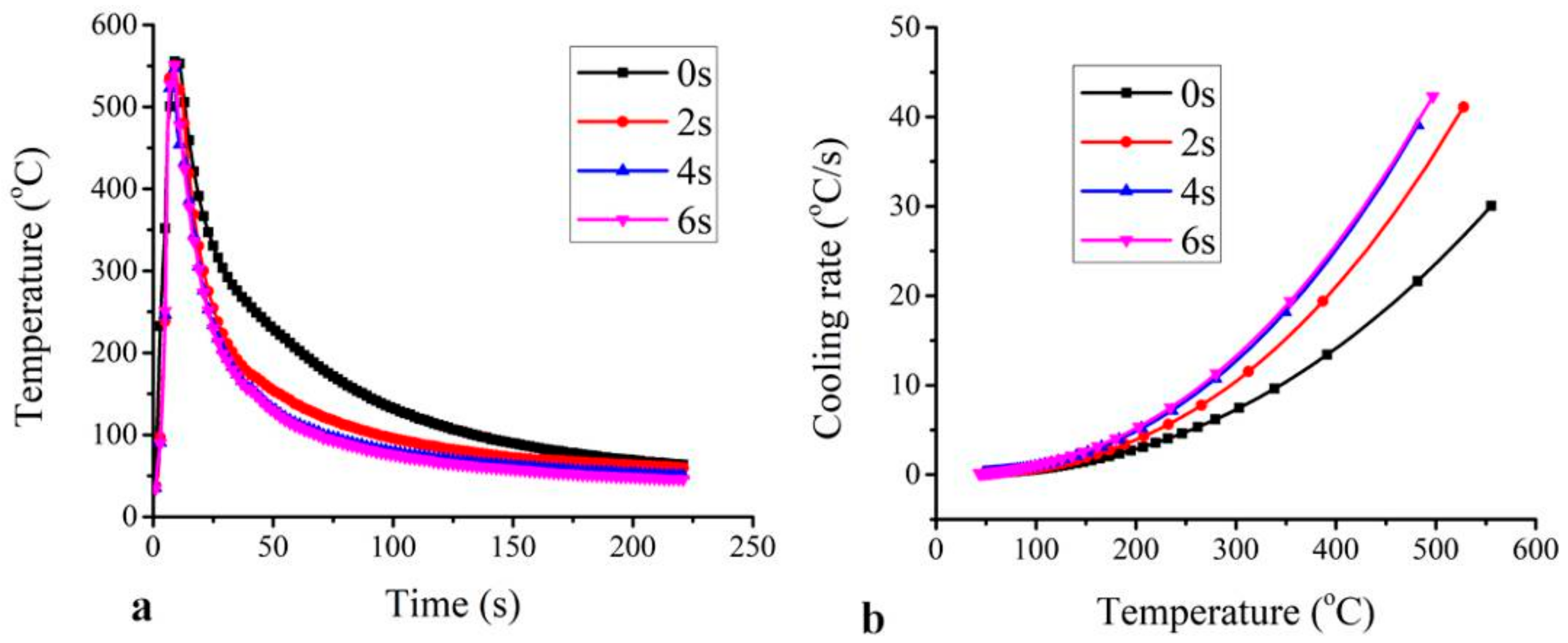

3.4. Cooling Curves of GTA Spot-Welded Copper Joints

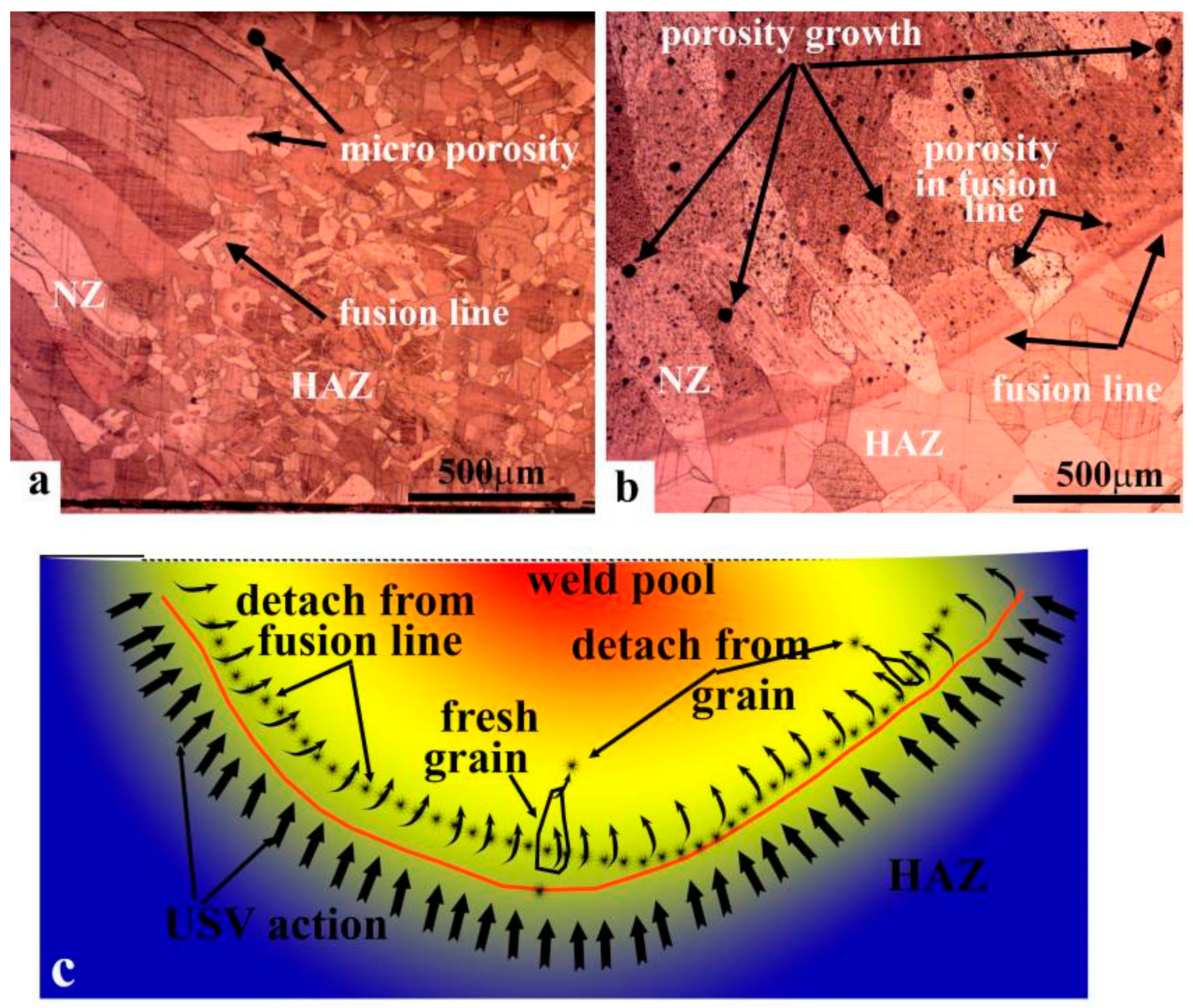

3.5. The Grain Refining Mechanism of GTA Spot-Welded Copper Joints

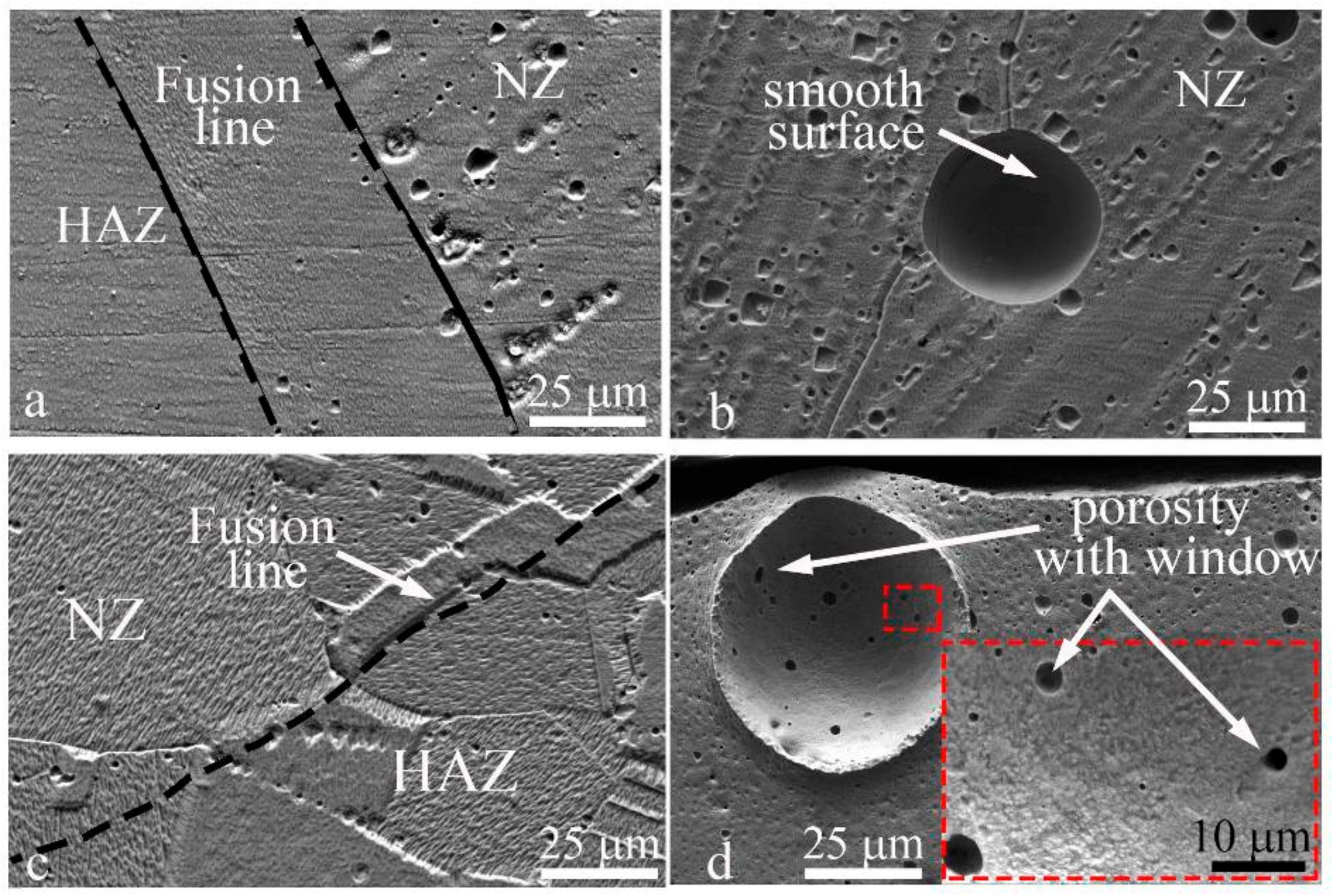

3.6. The Degassing Mechanism of GTA Spot-Welded Copper Joints

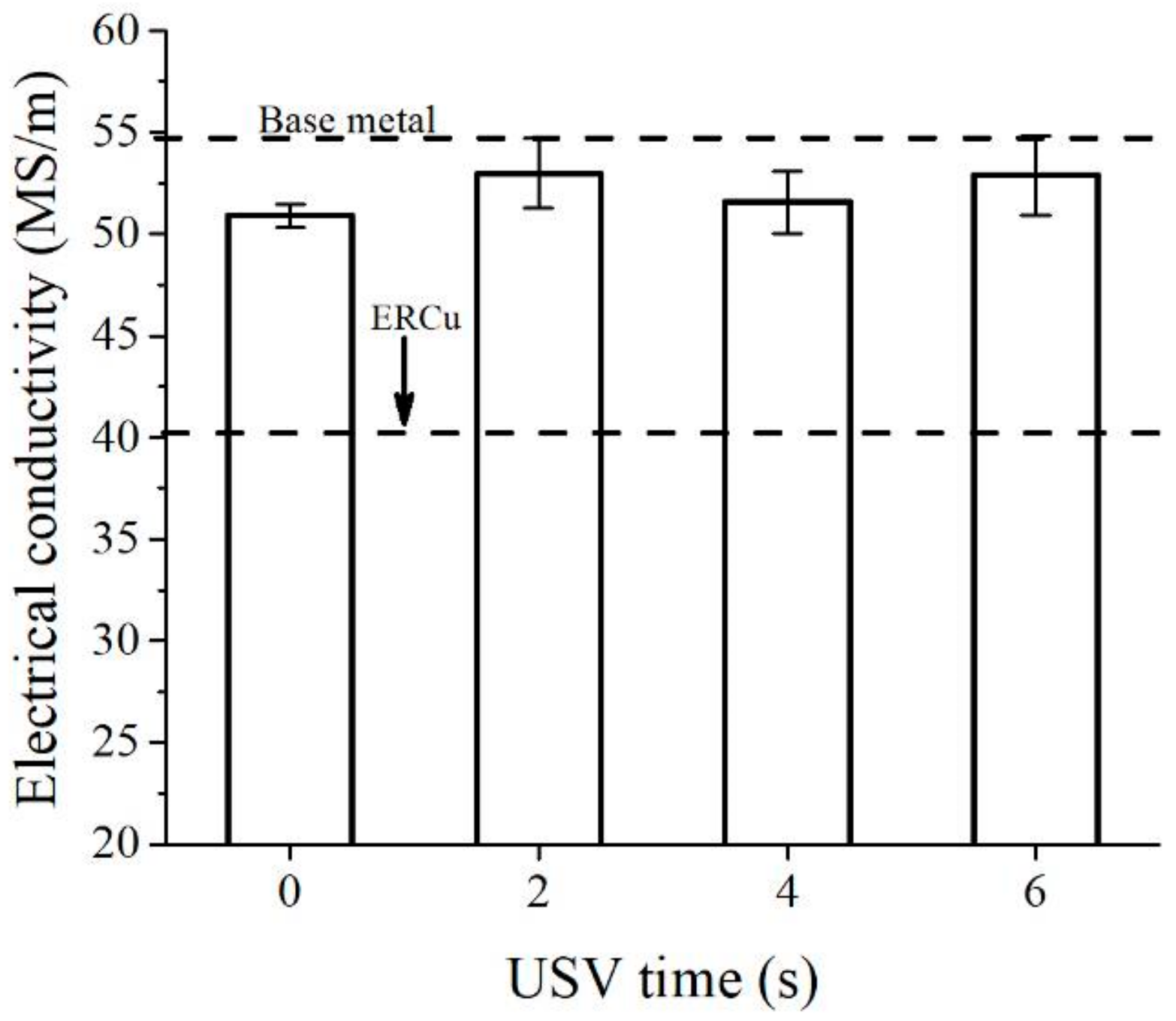

3.7. Electrical Conductivity of GTA Spot-Welded Copper Joints

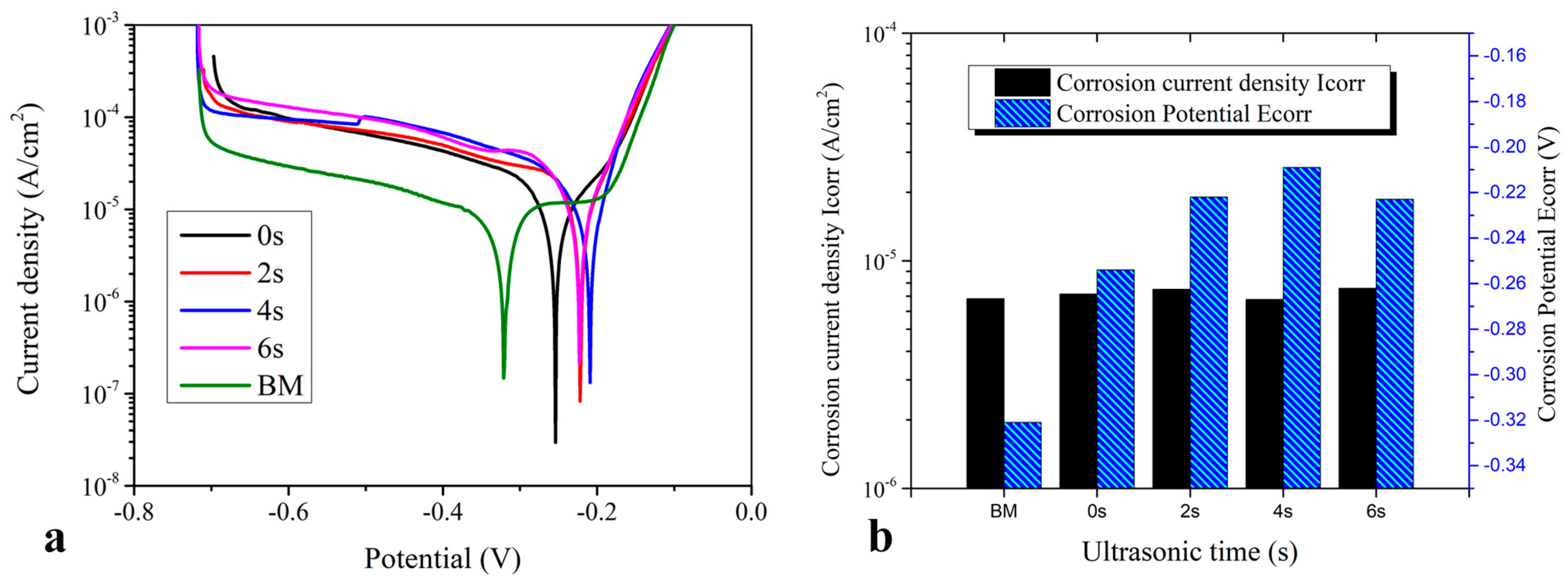

3.8. Corrosion Behavior of GTA Spot-Welded Copper Joints

4. Conclusions

- USV had no obvious effect on grain size at NZ. The vibration of NZ for 6 s reduced the grain size ~57%.

- The cooling rate of the welded metal increased for joints welded with the assistance of USV, which led to an increase of the heat dissipation rate from NZ to the surrounding space. Accordingly, it suppressed the grain growth at HAZ.

- The refining of grains at HAZ and NZ enhanced the tensile-shear strength of the copper arc spot-welded joints.

- The mechanism of grain refinement in GTA spot welding of copper assisted with USV was analyzed. It was concluded that USV dissolved the fusion line into small particles that detached to form the nucleation of the new grains at NZ.

- The mechanism of degassing of NZ was also analyzed. USV activated porosities to be joined and increased internal size and pressure, supporting the movement to be opened at the surface when the pressure of the bubble was 5 MPa.

- The peening action, degassing, and refining of grains reflected positively on the improvement of electrical conductivity and corrosion behavior of the GTA spot-welded copper joint.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Agapiou, J.S.; Perry, T.A. Resistance mash welding for joining of copper conductors for electric motors. J. Manuf. Process. 2013, 15, 549–557. [Google Scholar] [CrossRef]

- Zhao, D.; Ren, D.; Zhao, K.; Pan, S.; Guo, X. Effect of welding parameters on tensile strength of ultrasonic spot welded joints of aluminum to steel—By experimentation and artificial neural network. J. Manuf. Process. 2017, 30, 63–74. [Google Scholar] [CrossRef]

- Bergmann, J.P.; Petzoldt, F.; Schürer, R.; Schneider, S. Solid-state welding of aluminum to copper—case studies. Weld. World 2013, 57, 541–550. [Google Scholar] [CrossRef]

- Ning, J.; Zhang, L.-J.; Wang, A.; Bai, Q.-L.; Yang, J.-N.; Zhang, J.-X. Effects of double-pass welding and extrusion on properties of fiber laser welded 1.5-mm thick T2 copper joints. J. Mater. Process. Technol. 2016, 237, 75–87. [Google Scholar] [CrossRef]

- Dorsch, F.; Kaierle, S.; Ganser, A.; Liebl, S.; Schmitz, P.; Zaeh, M.F. Detection of transient reflections during laser beam welding of copper. Proc. SPIE 2016, 9741, 97410J. [Google Scholar]

- Zhang, L.-J.; Bai, Q.-L.; Ning, J.; Wang, A.; Yang, J.-N.; Yin, X.-Q.; Zhang, J.-X. A comparative study on the microstructure and properties of copper joint between MIG welding and laser-MIG hybrid welding. Mater. Des. 2016, 110, 35–50. [Google Scholar] [CrossRef]

- Gelbstein, Y.; Haim, Y.; Kalabukhov, S.; Kasiyan, V.; Hartmann, S.; Rothe, S.; Frage, N. Correlation between Thermal and Electrical Properties of Spark Plasma Sintered (SPS) Porous Copper; IntechOpen: Rijeka, Croatia, 2015. [Google Scholar]

- Shtrikman, M.M.; Pinskii, A.V.; Filatov, A.A.; Koshkin, V.V.; Mezentseva, E.A.; Guk, N.V. Methods for reducing weld porosity in argon-shielded arc welding of aluminium alloys. Weld. Int. 2011, 25, 457–462. [Google Scholar] [CrossRef]

- Eskin, G.I. Cavitation mechanism of ultrasonic melt degassing. Ultrason. Sonochem. 1995, 2, S137–S141. [Google Scholar] [CrossRef]

- Yuan, T.; Kou, S.; Luo, Z. Grain refining by ultrasonic stirring of the weld pool. Acta Mater. 2016, 106, 144–154. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; Wiley: Hoboken, NJ, USA, 2003. [Google Scholar]

- American Welding Society. Welding Handbook Materials and Applications—Part I, 8th ed.; AWS: Seattle, WA, USA, 1997; Volume 3. [Google Scholar]

- Da Cunha, T.V.; Bohorquez, C.E. Ultrasound in arc welding: A review. Ultrasonics 2015, 56, 201–209. [Google Scholar] [CrossRef] [PubMed]

- Zohoori-Shoar, V.; Eslami, A.; Karimzadeh, F.; Abbasi-Baharanchi, M. Resistance spot welding of ultrafine grained/nanostructured Al 6061 alloy produced by cryorolling process and evaluation of weldment properties. J. Manuf. Process. 2017, 26, 84–93. [Google Scholar] [CrossRef]

- Pouranvari, M.; Asgari, H.R.; Mosavizadch, S.M.; Marashi, P.H.; Goodarzi, M. Effect of weld nugget size on overload failure mode of resistance spot welds. Sci. Technol. Weld. Join. 2013, 12, 217–225. [Google Scholar] [CrossRef]

- Penner, P.; Liu, L.; Gerlich, A.; Zhou, Y. Dissimilar Resistance Spot Welding of Aluminum to Magnesium with Zn-Coated Steel Interlayers. Weld. J. 2014, 93, S225–S231. [Google Scholar]

- Dunn, B.D. Spacecraft Manufacturing—Failure Prevention and the Application of Material Analysis and Metallography. In Materials and Processes: For Spacecraft and High Reliability Applications; Springer International Publishing: Cham, Switzerland, 2016; pp. 115–245. [Google Scholar]

- Huin, T.; Dancette, S.; Fabrègue, D.; Dupuy, T. Investigation of the Failure of Advanced High Strength Steels Heterogeneous Spot Welds. Metals 2016, 6, 111. [Google Scholar] [CrossRef]

- Ghahremaninezhad, A.; Ravi-Chandar, K. Ductile failure in polycrystalline OFHC copper. Int. J. Solids Struct. 2011, 48, 3299–3311. [Google Scholar] [CrossRef]

- Fensin, S.J.; Escobedo-Diaz, J.P.; Brandl, C.; Cerreta, E.K.; Gray, G.T.; Germann, T.C.; Valone, S.M. Effect of loading direction on grain boundary failure under shock loading. Acta Mater. 2014, 64, 113–122. [Google Scholar] [CrossRef]

- Chen, Q.; Lin, S.; Yang, C.; Fan, C.; Ge, H. Grain fragmentation in ultrasonic-assisted TIG weld of pure aluminum. Ultrason. Sonochem. 2017, 39, 403–413. [Google Scholar] [CrossRef] [PubMed]

- Li, J.W.; Pu, Y. Application of ultrasonic treating to degassing of commercially pure copper melt: A preliminary investigation. Mater. Lett. 2015, 161, 60–63. [Google Scholar] [CrossRef]

- Littleton. Gas-Metal Reactions and Porosity in the Inert Gas Arc Welding of Copper; Aston University: Birmingham, UK, 1974. [Google Scholar]

- Kearns, W.H. (Ed.) Welding Handbook Metals and Their Weldability, 7th ed.; American Welding Society: Miami, FL, USA, 1997; Volume 4. [Google Scholar]

- Hao, K.; Gong, M.; Xie, Y.; Gao, M.; Zeng, X. Effects of alloying element on weld characterization of laser-arc hybrid welding of pure copper. Opt. Laser Technol. 2018, 102, 124–129. [Google Scholar] [CrossRef]

- Malaki, M.; Ding, H. A review of ultrasonic peening treatment. Mater. Des. 2015, 87, 1072–1086. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Ezzi, S.; Quan, G.; Elrayah, A. The Mechanism of Ultrasonic Vibration on Grain Refining and Degassing in GTA Spot Welding of Copper Joints. Materials 2018, 11, 737. https://doi.org/10.3390/ma11050737

Al-Ezzi S, Quan G, Elrayah A. The Mechanism of Ultrasonic Vibration on Grain Refining and Degassing in GTA Spot Welding of Copper Joints. Materials. 2018; 11(5):737. https://doi.org/10.3390/ma11050737

Chicago/Turabian StyleAl-Ezzi, Salih, Gaofeng Quan, and Adil Elrayah. 2018. "The Mechanism of Ultrasonic Vibration on Grain Refining and Degassing in GTA Spot Welding of Copper Joints" Materials 11, no. 5: 737. https://doi.org/10.3390/ma11050737

APA StyleAl-Ezzi, S., Quan, G., & Elrayah, A. (2018). The Mechanism of Ultrasonic Vibration on Grain Refining and Degassing in GTA Spot Welding of Copper Joints. Materials, 11(5), 737. https://doi.org/10.3390/ma11050737