Compressive Deformation Behavior of Closed-Cell Micro-Pore Magnesium Composite Foam

Abstract

1. Introduction

2. Experimental Details

2.1. Specimens Preparation

2.2. Compression Test

2.3. Microstructure Observation

2.4. Finite Element Modeling

3. Results and Discussion

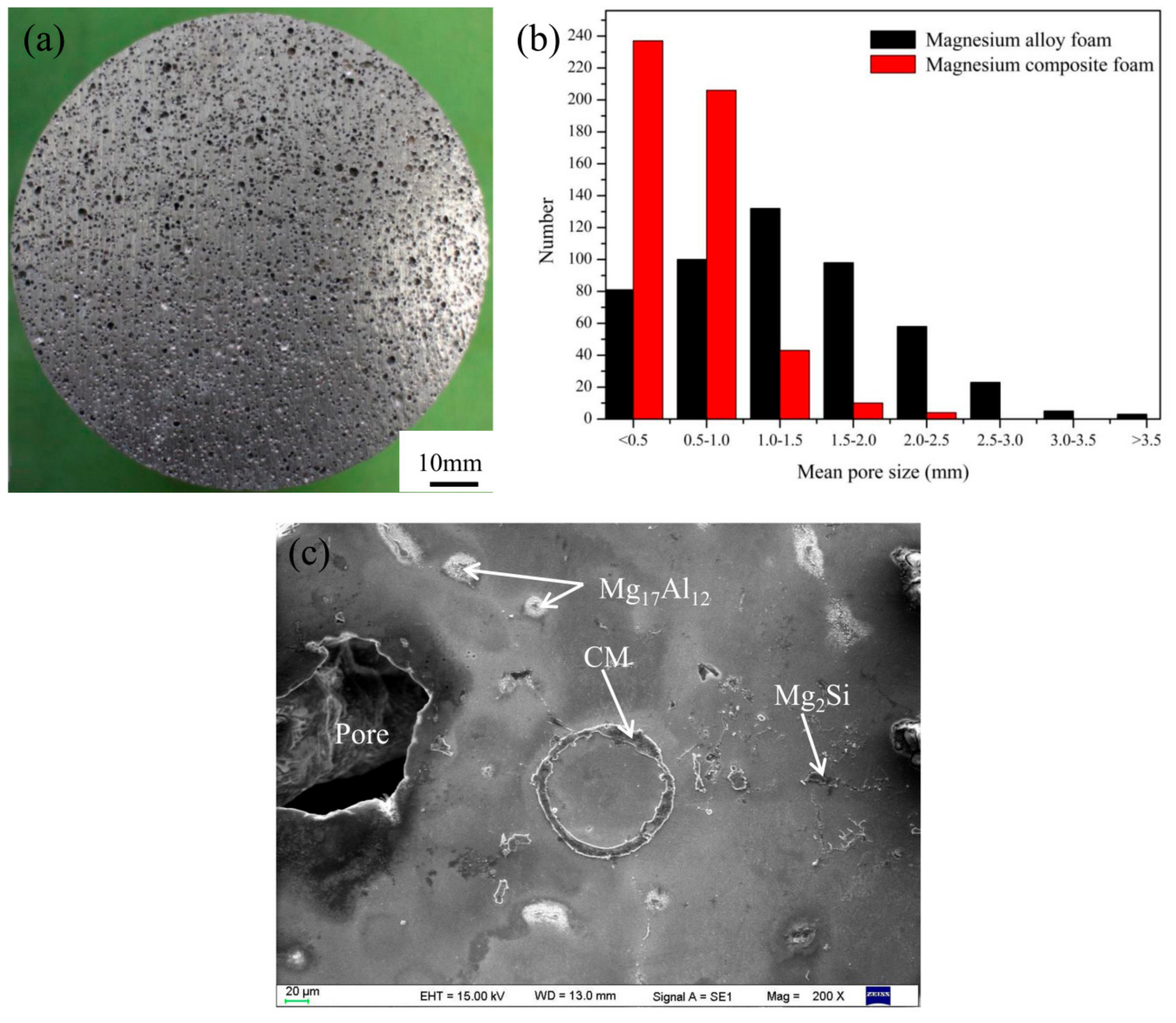

3.1. Morphology Observation

3.2. Compression Characteristics

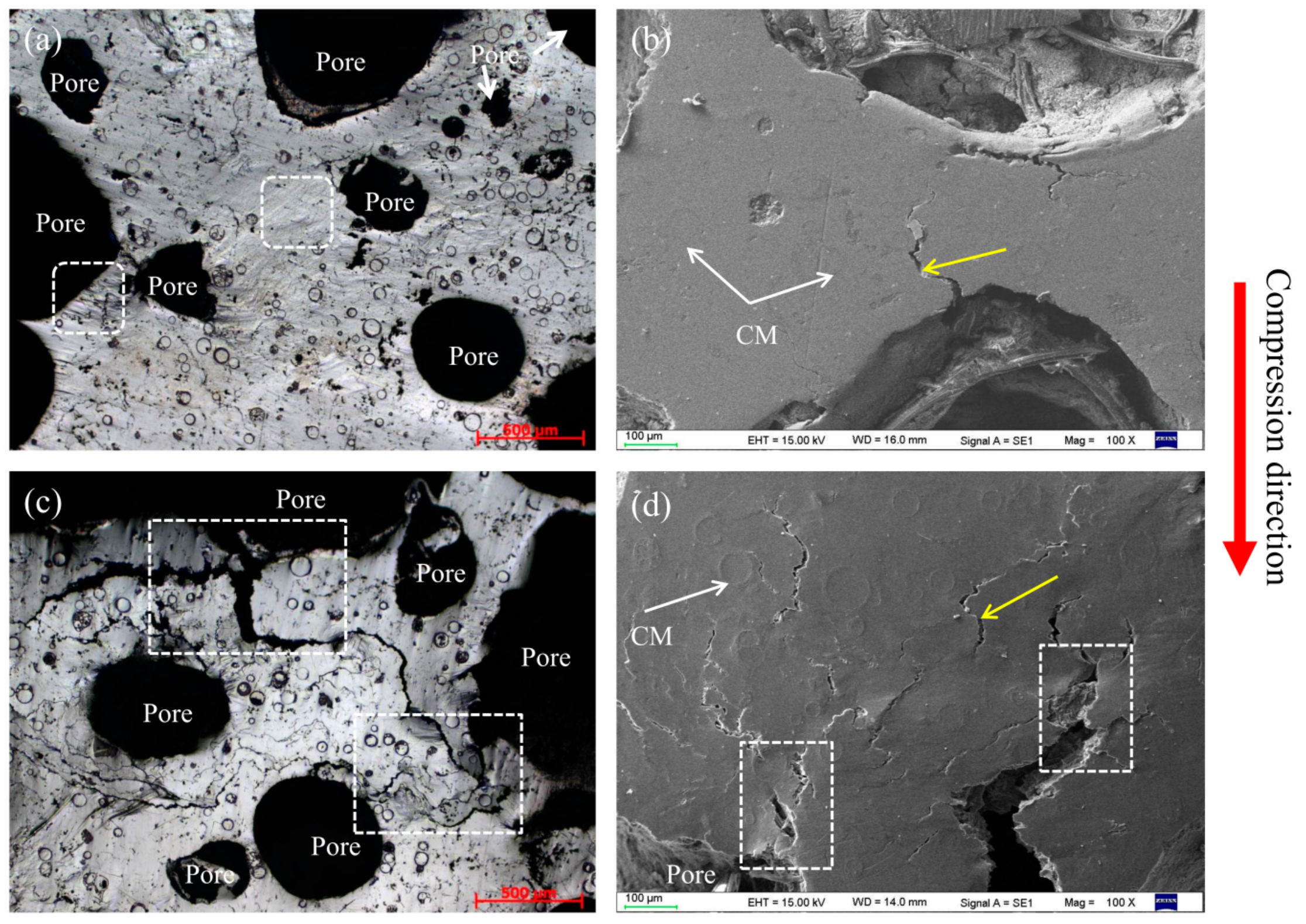

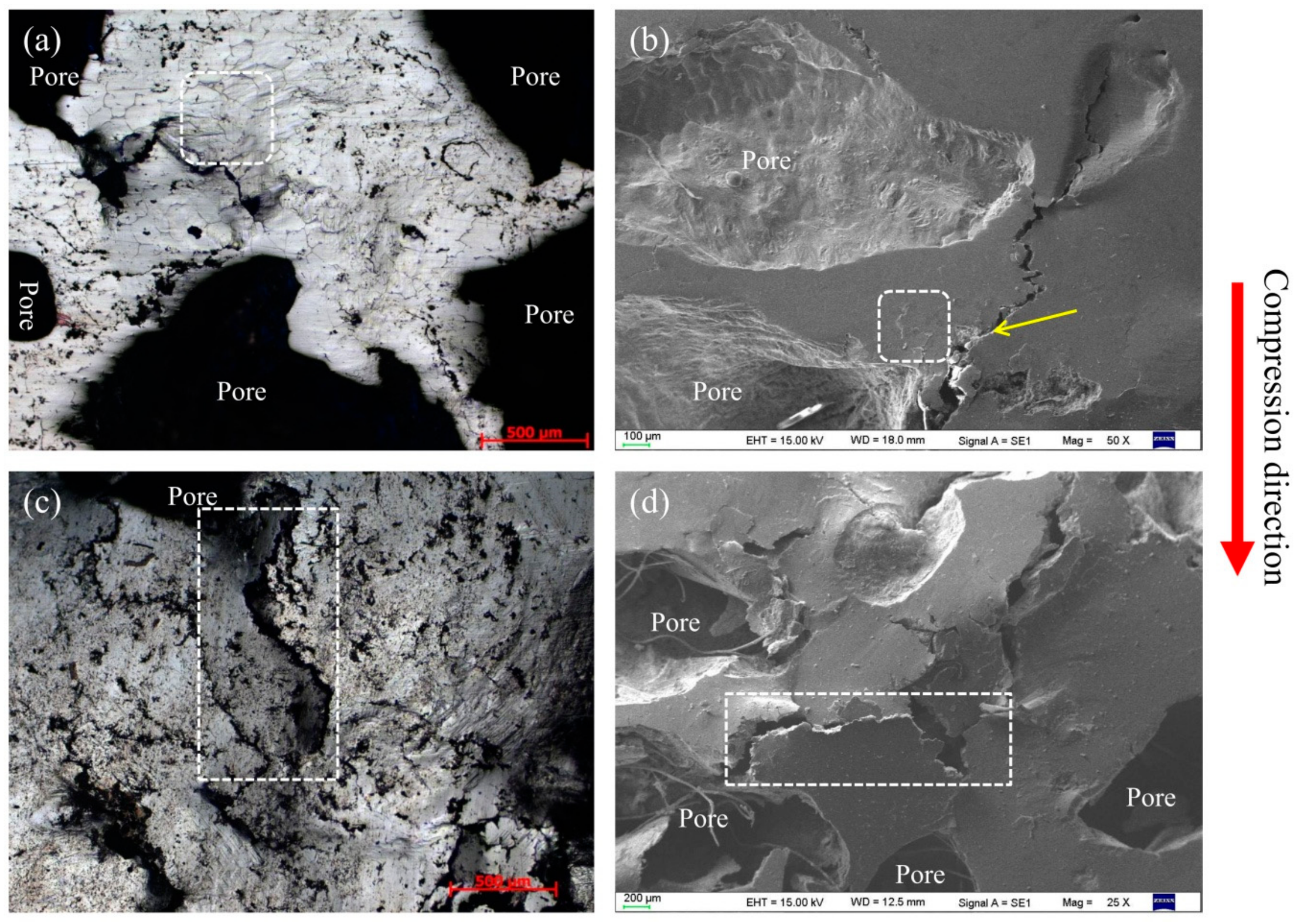

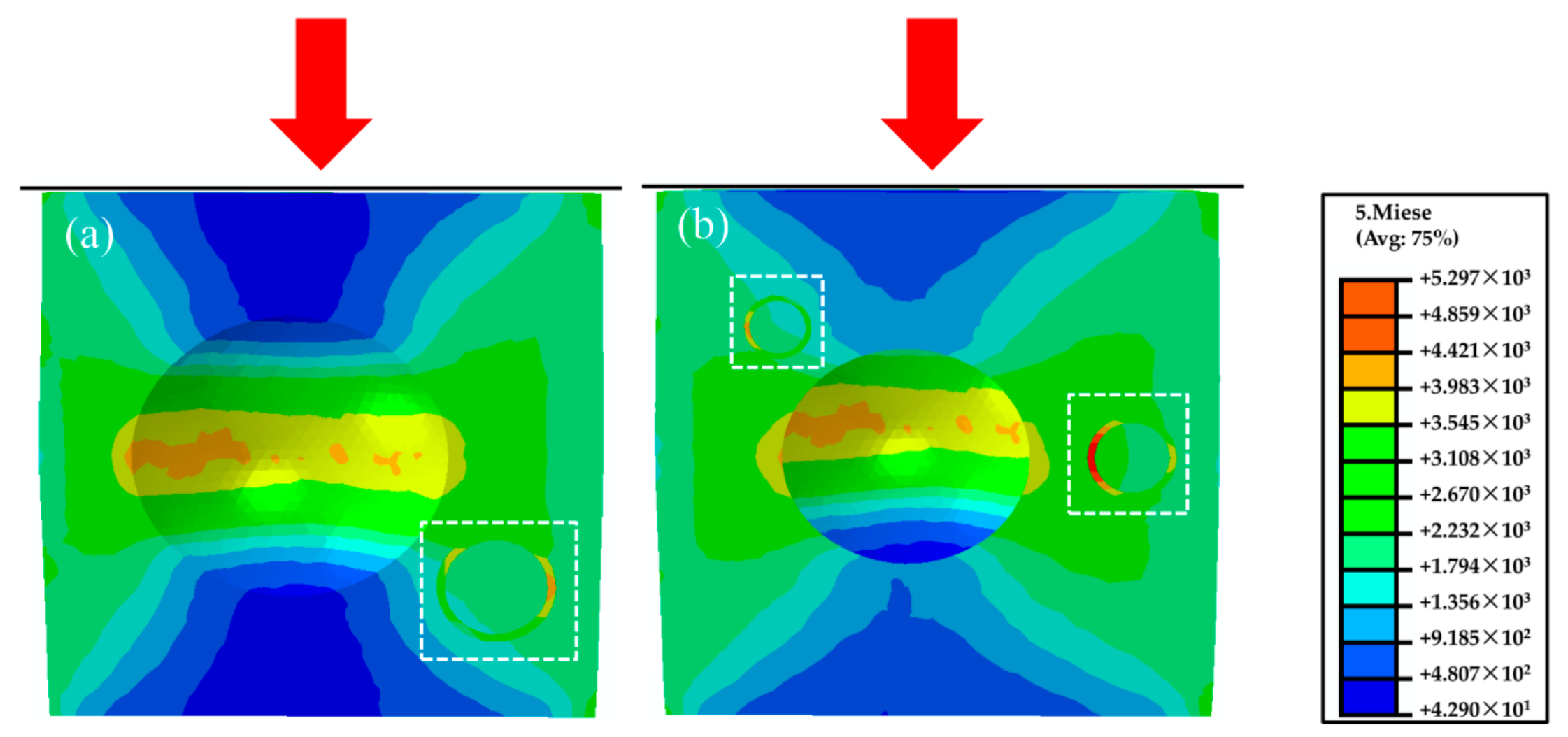

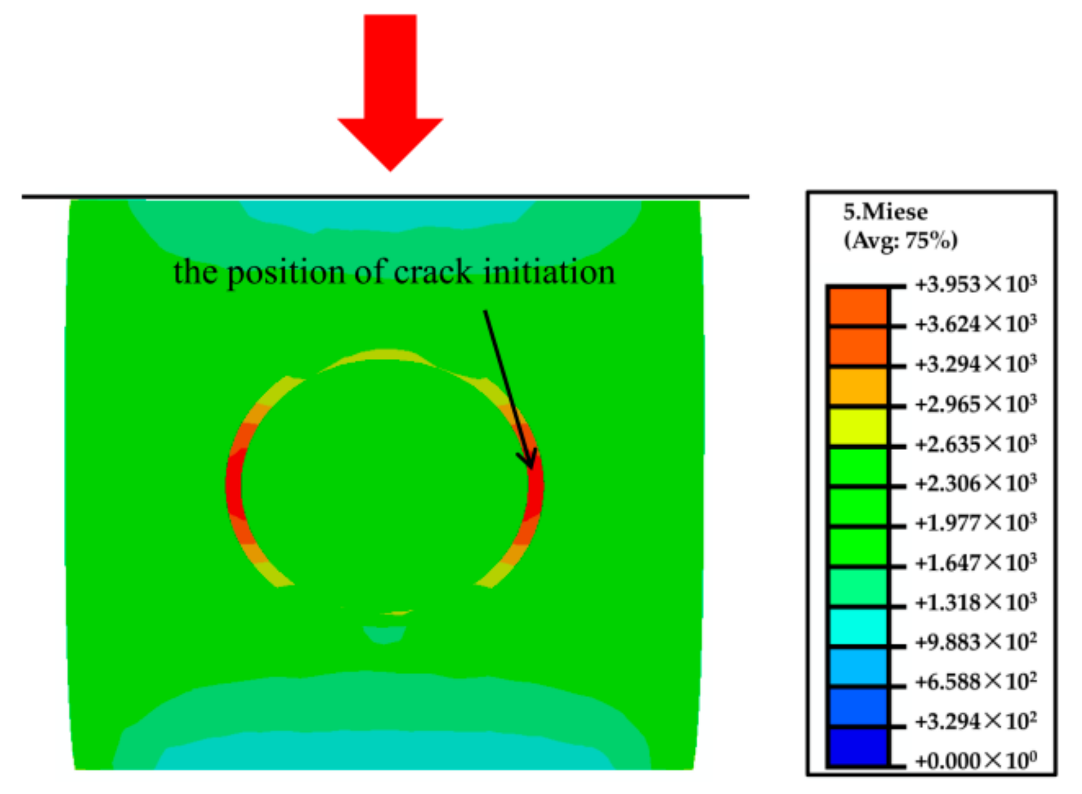

3.3. Effect of Pore and CMs on the Compressive Deformation Behavior

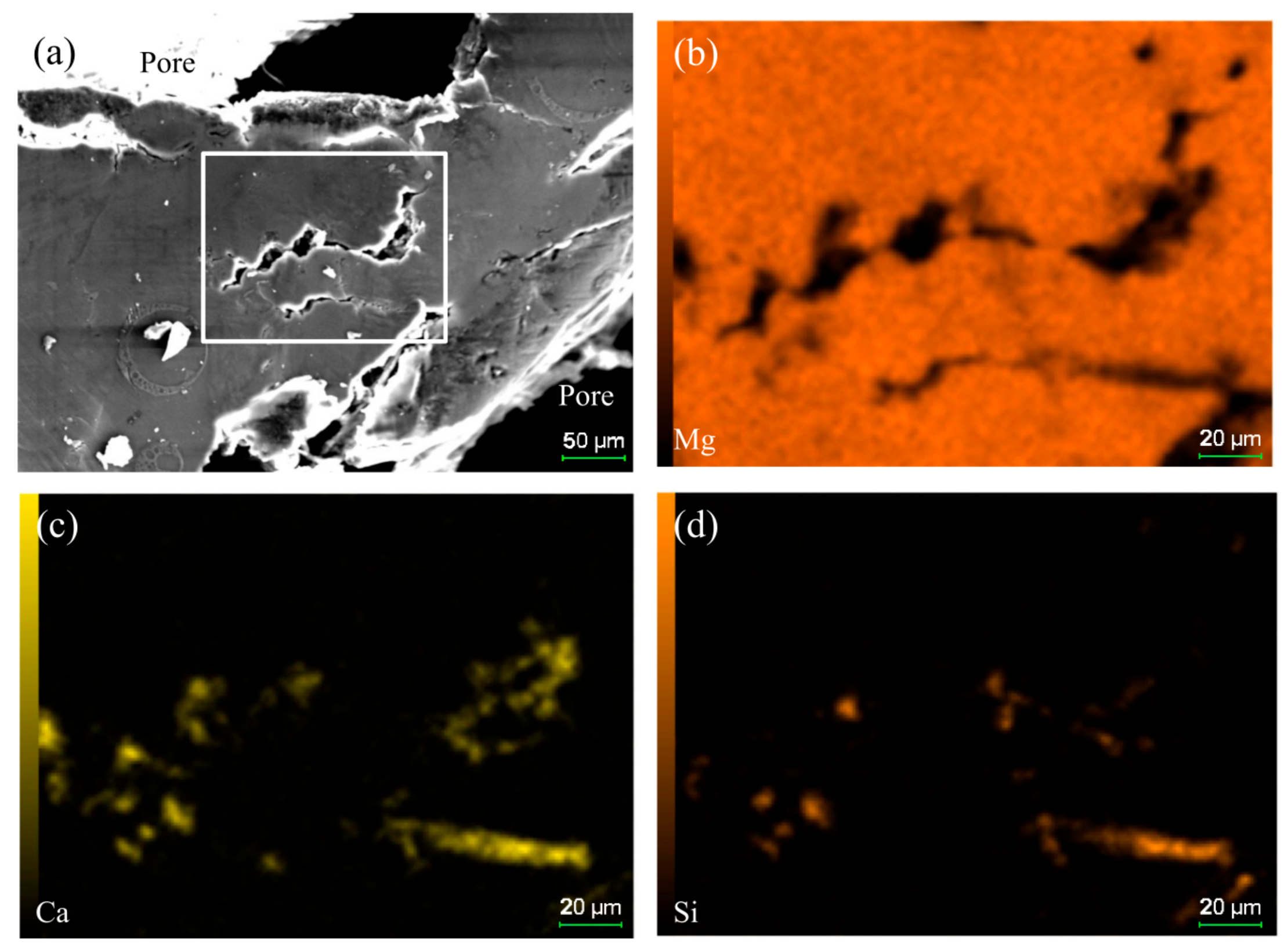

3.4. Effect of Mg2Si on the Compressive Deformation Behavior

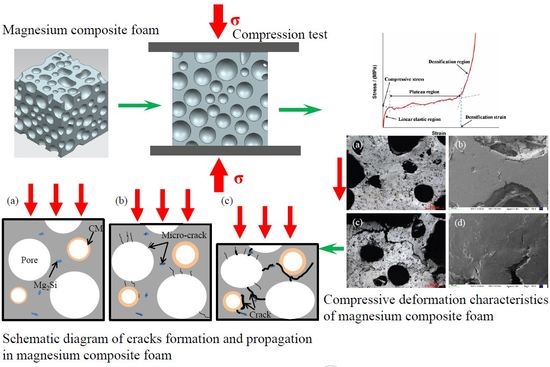

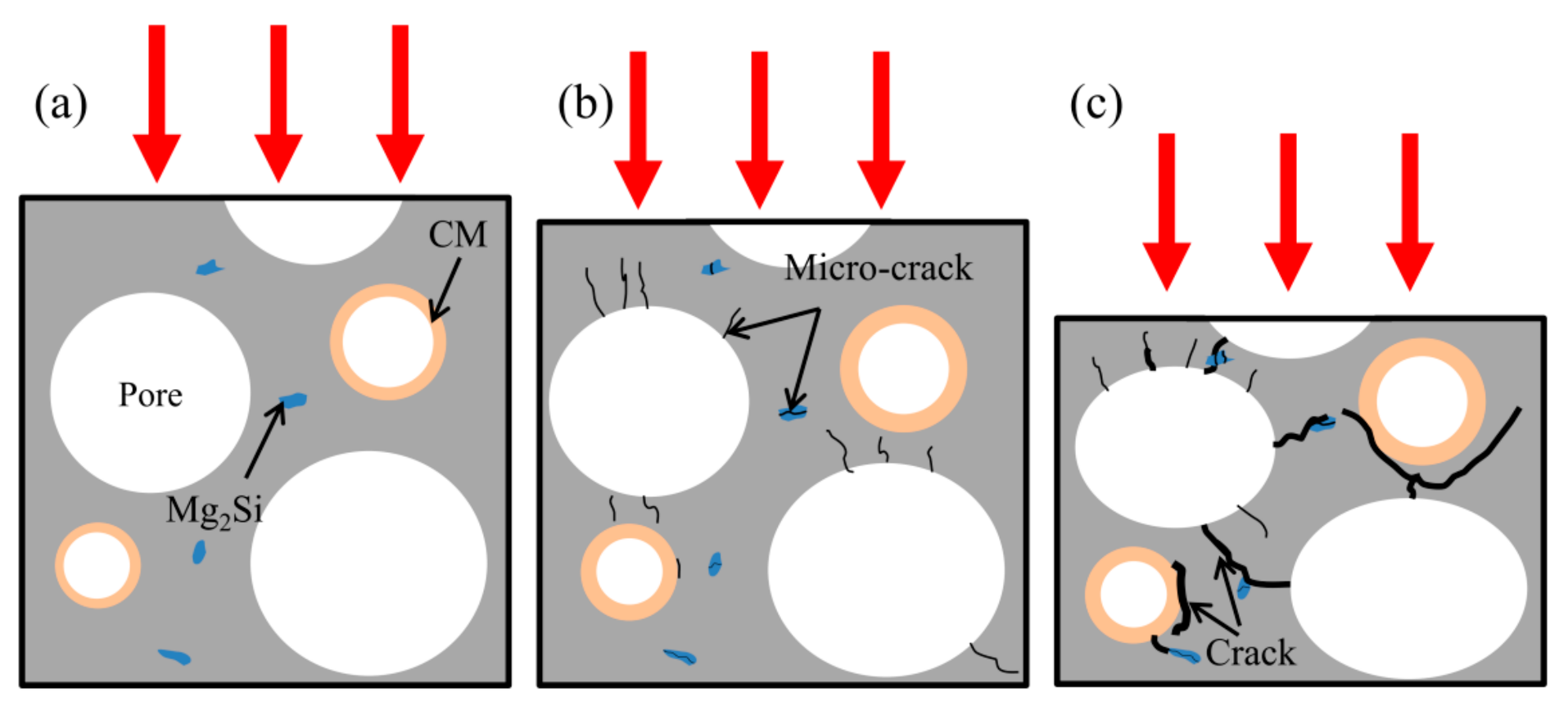

3.5. Failure Mechanism of Magnesium Composite Foam

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xia, X.C.; Chen, X.; Zhang, Z.; Chen, X.W.; Zhao, W.M.; Liao, B.; Hur, B.Y. Compressive properties of closed-cell aluminum foams with different contents of ceramic microspheres. Mater. Des. 2014, 56, 353–358. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Májlinger, K. Description of the compressive response of metal matrix syntactic foams. Mater. Des. 2013, 4, 1–9. [Google Scholar] [CrossRef]

- Altenaiji, M.; Guan, Z.W.; Cantwell, W.J.; Zhao, Y.; Schleyer, G.K. Characterization of aluminum matrix syntactic foams under drop weight impact. Mater. Des. 2014, 59, 296–302. [Google Scholar] [CrossRef]

- Májlinger, K.; Orbulov, I.N. Characteristic compressive properties of hybrid metal matrix syntactic foams. Mater. Sci. Eng. A. 2014, 606, 248–256. [Google Scholar] [CrossRef]

- Xia, X.C.; Zhang, Z.; Zhao, W.M.; Li, C.; Ding, J.; Liu, C.X.; Liu, Y.C. Acoustic properties of closed-cell aluminum foams with different macrostructures. J. Mater. Sci. Tech. 2017, 33, 1227–1234. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture, characterization and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Mondal, D.P.; Majumder, J.D.; Jha, N.; Badkul, A.; Das, S.; Patel, A. Titanium-cenosphere syntactic foam made through powder metallurgy route. Mater. Des. 2012, 34, 82–89. [Google Scholar] [CrossRef]

- Alizadeh, M.; Mirzaei-Aliabadi, M. Compressive properties and energy absorption behavior of Al-Al2O3 composite foam synthesized by spaceholder technique. Mater. Des. 2012, 35, 419–424. [Google Scholar] [CrossRef]

- Cox, J.; Luong, D.D.; Shunmugasamy, V.C.; Gupta, N.; Strbik, O.M.; Cho, K. Dynamic and thermal properties of aluminum alloy A356/silicon carbide hollow particle syntactic foams. Metals 2014, 4, 530–548. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Kim, J.K.; Guo, R.Q.; Robertson, D.P.; Gajdardziska-josifovska, M. Age-hardening characteristics of aluminum alloy-hollow fly ash composites. Metall. Mater. Trans. A 2002, 33, 1541–1547. [Google Scholar] [CrossRef]

- Balch, D.K.; O’Dwyer, J.G.; Davis, G.R.; Cady, C.M.; Gray, G.T.; Dunand, D.C. Plasticity and damage in aluminum syntactic foams deformed under dynamic and quasistatic conditions. Mater. Sci. Eng. A 2005, 391, 408–417. [Google Scholar] [CrossRef]

- Tao, X.F.; Zhang, L.P.; Zhao, Y.Y. Al matrix syntactic foam fabricated with bimodal ceramic microspheres. Mater. Des. 2009, 30, 2732–2736. [Google Scholar] [CrossRef]

- Xia, X.C.; Feng, J.L.; Ding, J.; Song, K.H.; Chen, X.W.; Zhao, W.M.; Liao, B.; Hur, B.Y. Fabrication and characterization of closed-cell magnesium-based composite foams. Mater. Des. 2015, 74, 36–43. [Google Scholar] [CrossRef]

- Wen, C.E.; Yamada, Y.; Shimojima, K.; Chino, Y.; Hosokawa, H.; Mabuchi, M. Compressibility of porous magnesium foam: dependency on porosity and pore size. Mater. Lett. 2004, 58, 357–360. [Google Scholar] [CrossRef]

- Park, S.H.; Um, Y.S.; Kum, C.H.; Hur, B.Y. Thermophysical properties of Al and Mg alloys for metal foam fabrication. Colloid. Surf. A 2005, 263, 280–283. [Google Scholar] [CrossRef]

- Xu, Z.G.; Fu, J.W.; Luo, T.J.; Yang, Y.S. Effects of cell size on quasi-static compressive properties of Mg alloy foams. Mater. Des. 2012, 34, 40–44. [Google Scholar] [CrossRef]

- Liu, J.A.; Yu, S.R.; Zhu, X.Y.; Wei, M.; Li, S.; Luo, Y.R.; Liu, Y.H. The compressive properties of closed-cell Zn-22Al foams. Mater. Lett. 2008, 62, 683–689. [Google Scholar] [CrossRef]

- Yang, D.H.; Hur, B.Y.; Yang, S.R. Study on fabrication and foaming mechanism of Mg foam using CaCO3 as blowing agent. J. Alloy Compd. 2008, 461, 221–227. [Google Scholar] [CrossRef]

- Lu, G.Q.; Hao, H.; Wang, F.Y.; Zhang, X.G. Preparation of closed-cell Mg foams using SiO2-coated CaCO3 as blowing agent in atmosphere. Trans. Nonferrous Met. Soc. China 2013, 23, 1832–1837. [Google Scholar] [CrossRef]

- Mcrae, J.D.; Naguib, H.E.; Atalla, N. Mechanical and acoustic performance of compression-molded open-cell polypropylene foams. J. Appl. Polym. Sci. 2010, 116, 1106–1115. [Google Scholar]

- Orbulov, I.N. Compressive properties of aluminium matrix syntactic foams. Mater. Sci. Eng. A 2012, 555, 52–56. [Google Scholar] [CrossRef]

- Birla, S.; Mondal, D.P.; Das, S.; Kashyap, D.K.; Ch, V.A.N. Effect of cenosphere content on the compressive deformation behaviour of aluminum-cenosphere hybrid foam. Mater. Sci. Eng. A 2017, 685, 213–226. [Google Scholar] [CrossRef]

- Myers, K.; Katona, B.; Cortes, P.; Orbulov, I.N. Quasi-static and high strain rate response of aluminum matrix syntactic foams under compression. Compos. Part A Appl. Sci. Manuf. 2015, 79, 82–91. [Google Scholar] [CrossRef]

- Maria, J.A.S.; Schultz, B.F.; Ferguson, J.B.; Gupta, N.; Rohatgi, P.K. Effect of hollow sphere size and size distribution on the quasi-static and high strain rate compressive properties of Al-A380-Al2O3 syntactic foams. J. Mater. Sci. 2013, 49, 1267–1278. [Google Scholar] [CrossRef]

- Daouda, A.; El-khair, M.T.A.; Abdel-Aziza, M.; Rohatgi, P. Fabrication, microstructure and compressive behavior of ZC63 Mg-microballoon foam composites. Compos. Sci. Technol. 2007, 67, 1842–1853. [Google Scholar] [CrossRef]

- Huang, Z.Q.; Yu, S.R.; Li, M.Q. Microstructures and compressive properties of AZ91D/fly-ash cenospheres composites. Trans. Nonferrous Met. Soc. China 2010, 20, 458–462. [Google Scholar] [CrossRef]

- Kainer, K.U. Magnesium Eigenschaften, Anwendungen, Potenziale; WILEY-VCH Verlag gmbH: Weinheim, Germany, 2003. [Google Scholar]

- Yu, M.; Zhu, P.; Ma, Y.Q. Experimental study and numerical prediction of tensile strength properties and failure modes of hollow spheres filled syntactic foams. Comp. Mater. Sci. 2012, 63, 232–243. [Google Scholar] [CrossRef]

- Xia, X.C.; Zhao, W.M.; Wei, Z.H.; Wei, Z.G. Effects of specimen aspect ratio on the compressive properties of Mg alloy foam. Mater. Des. 2012, 42, 32–36. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Z.; Jiang, Q.; Xia, X.C.; Qiu, C.R.; Ding, J.; Zhao, W.M. A novel bubble nucleation particle for magnesium composite foam. Mater. Lett. 2017, 193, 187–190. [Google Scholar] [CrossRef]

- Mondal, D.P.; Goel, M.D.; Das, S. Compressive deformation and energy absorption characteristics of closed cell aluminum-fly ash particle composite foam. Mater. Sci. Eng. 2009, 507, 102–109. [Google Scholar] [CrossRef]

- Mondal, D.P.; Goel, M.D.; Das, S. Effect of strain rate and relative density on compressive deformation behaviour of closed cell aluminum-fly ash composite foam. Mater. Des. 2009, 30, 1268–1274. [Google Scholar] [CrossRef]

- Goel, M.D.; Peroni, M.; Solomos, G.; Mondal, D.P.; Matsagar, V.A.; Gupta, A.K.; Larcher, M.; Marburg, S. Dynamic compression behavior of cenosphere aluminum alloy syntactic foam. Mater. Des. 2012, 42, 418–423. [Google Scholar] [CrossRef]

- Goel, M.D.; Matsagar, V.A.; Gupta, A.K.; Marburg, S. Strain rate sensitivity of closed cell aluminium fly ash foam. Trans. Nonferrous Met. Soc. China 2012, 23, 1080–1089. [Google Scholar] [CrossRef]

- Avalle, M.; Belingardi, G.; Montanini, R. Characterization of polymeric structural foams under compressive impact loading by means of energy-absorption diagram. Int. J. Impact Eng. 2001, 25, 455–472. [Google Scholar] [CrossRef]

- Bratt, P.W.; Cunnion, J.; Spivack, B.D. Mechanical testing of glass hollow microspheres. Adv. Mater. Charact. 1983, 15, 441–447. [Google Scholar]

- Carlisle, K.B.; Lewis, M.; Chawla, K.K.; Koopman, M.; Gladysz, G.M. Finite element modeling of the uniaxial compression behavior of carbon microballoons. Acta Mater. 2007, 55, 2301–2318. [Google Scholar] [CrossRef]

- Li, P.; Petrinic, N.; Siviour, C.R. Finite element modelling of the mechanism of deformation and failure in metallic thin-walled hollow spheres under dynamic compression. Mech. Mater. 2012, 54, 43–54. [Google Scholar] [CrossRef]

- Wang, H.F.; Kong, W.B.; Hu, P.X.; Hu, H. Effect of rare earth elements on microstructure and properties of as-cast AlMg5Si1 alloy. Foundry 2016, 65, 253–257. (In Chinese) [Google Scholar]

- Li, J.C.; Hao, X.M.; Wei, A.L.; Zhao, H.F. Effect of Mg on Microstructure and Mechanical Properties of Zn-based Alloy. Hot Work. Technol. 2008, 37, 38–39. (In Chinese) [Google Scholar]

- Emamy, M.; Jafari Nodooshan, H.R.; Malekan, A. The microstructure, hardness and tensile properties of Al-15%Mg2Si in situ composite with yttrium addition. Mater. Des. 2011, 32, 4559–4566. [Google Scholar] [CrossRef]

- Moussa, M.E.; Waly, M.A.; El-Sheikh, A.M. Effect of Ca addition on modification of primary Mg2Si, hardness and wear behavior in Mg2Si hypereutectic alloys. J. Magnes. Alloy 2014, 2, 230–238. [Google Scholar] [CrossRef]

- Li, C.F.; Wei, X.L.; Zheng, L.; Yu, W.B.; Huang, R.Q. Modifcation effect of calcium-magnesia phosphate fertilizer on microstructure and mechanical properties of Mg2Si/Mg-4Si composite. China Found. 2016, 13, 199–204. [Google Scholar]

- Rzychoń, T.; Janik, R. The Influence of Calcium on the Primary Mg2Si Phase in the Hypereutectic Mg-Si Alloys. Solid State Phenom. 2015, 229, 71–76. [Google Scholar] [CrossRef]

- Kim, J.J.; Kim, D.H.; Shin, K.S.; Kim, N.J. Modification of Mg2Si morphology in squeeze cast Mg-Al-Zn-Si alloys by Ca or P addition. Scr. Mater. 1999, 41, 333–340. [Google Scholar] [CrossRef]

| Al2O3 (wt %) | SiO2 (wt %) | Stacking Desity (g/cm3) | Size Range (μm) | Wall Thickness (μm) |

|---|---|---|---|---|

| ~10 | ~90 | 0.42 | 40–150 | 7.5 ± 0.8 |

| Al | Zn | Mn | Si | Fe | Cu | Ni | Mg |

|---|---|---|---|---|---|---|---|

| 2.7852 | 0.7925 | 0.5635 | 0.0032 | 0.0002 | 0.0003 | 0.0004 | Balance |

| Yield Strength (MPa) | Plateau Stress (MPa) | Densification Strain | Energy Absorption (MJ/m3) | Ideal Energy Absorption Efficiency | |

|---|---|---|---|---|---|

| Magnesium alloy foam | 21.18 | 27.93 | 0.50 | 16.89 | 0.75 |

| Magnesium composite foam | 25.75 | 30.60 | 0.57 | 18.47 | 0.77 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, N.; Liu, X.; Ding, J.; Xia, X.; Chen, X.; Zhao, W. Compressive Deformation Behavior of Closed-Cell Micro-Pore Magnesium Composite Foam. Materials 2018, 11, 731. https://doi.org/10.3390/ma11050731

Wang J, Wang N, Liu X, Ding J, Xia X, Chen X, Zhao W. Compressive Deformation Behavior of Closed-Cell Micro-Pore Magnesium Composite Foam. Materials. 2018; 11(5):731. https://doi.org/10.3390/ma11050731

Chicago/Turabian StyleWang, Jing, Nannan Wang, Xin Liu, Jian Ding, Xingchuan Xia, Xueguang Chen, and Weimin Zhao. 2018. "Compressive Deformation Behavior of Closed-Cell Micro-Pore Magnesium Composite Foam" Materials 11, no. 5: 731. https://doi.org/10.3390/ma11050731

APA StyleWang, J., Wang, N., Liu, X., Ding, J., Xia, X., Chen, X., & Zhao, W. (2018). Compressive Deformation Behavior of Closed-Cell Micro-Pore Magnesium Composite Foam. Materials, 11(5), 731. https://doi.org/10.3390/ma11050731