A State-of-the-Art Review on Soil Reinforcement Technology Using Natural Plant Fiber Materials: Past Findings, Present Trends and Future Directions

Abstract

1. Introduction

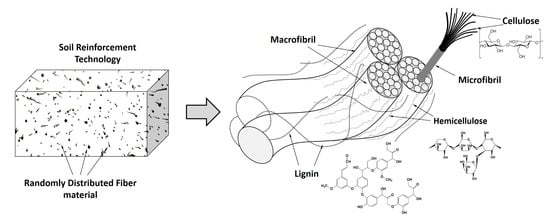

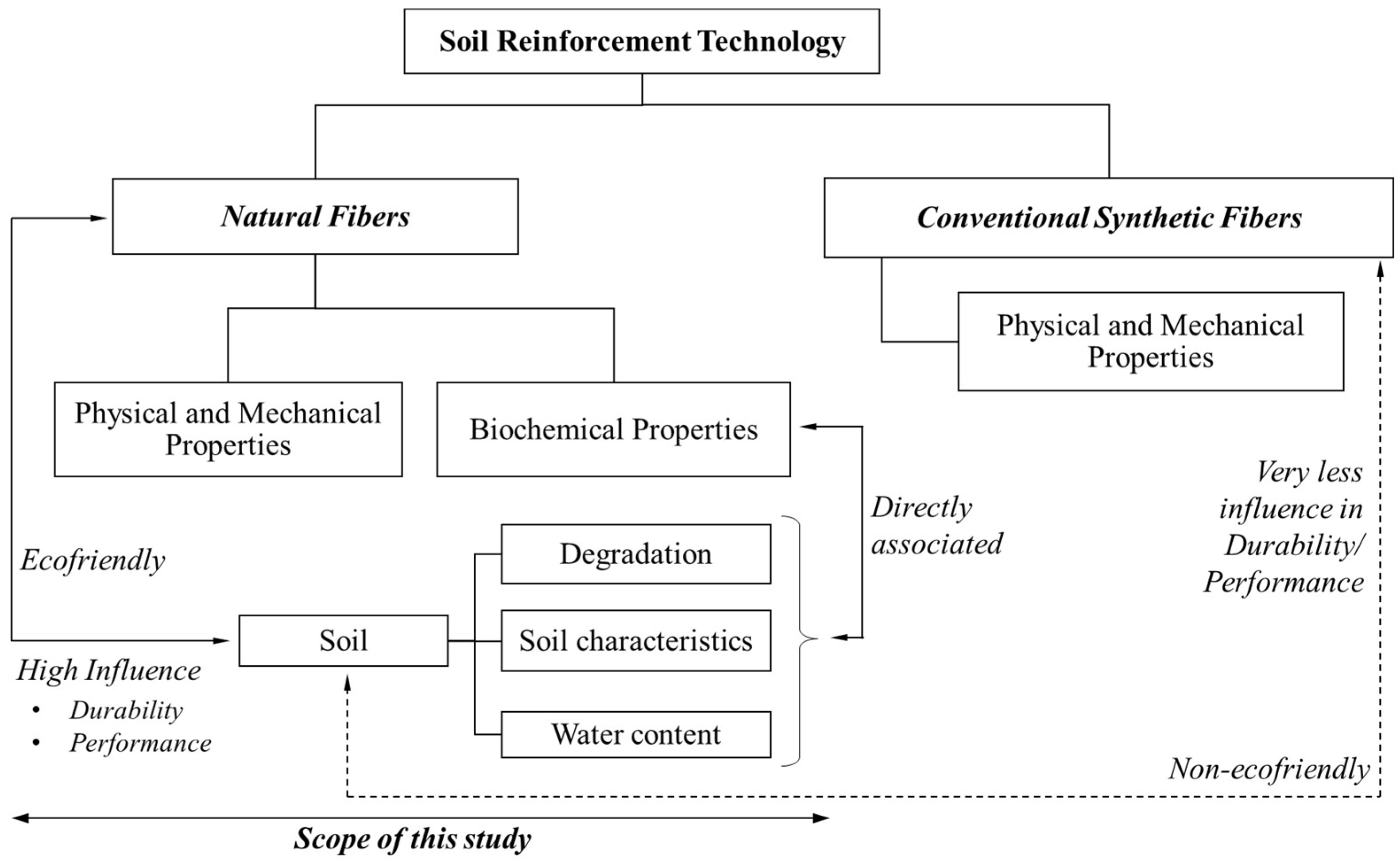

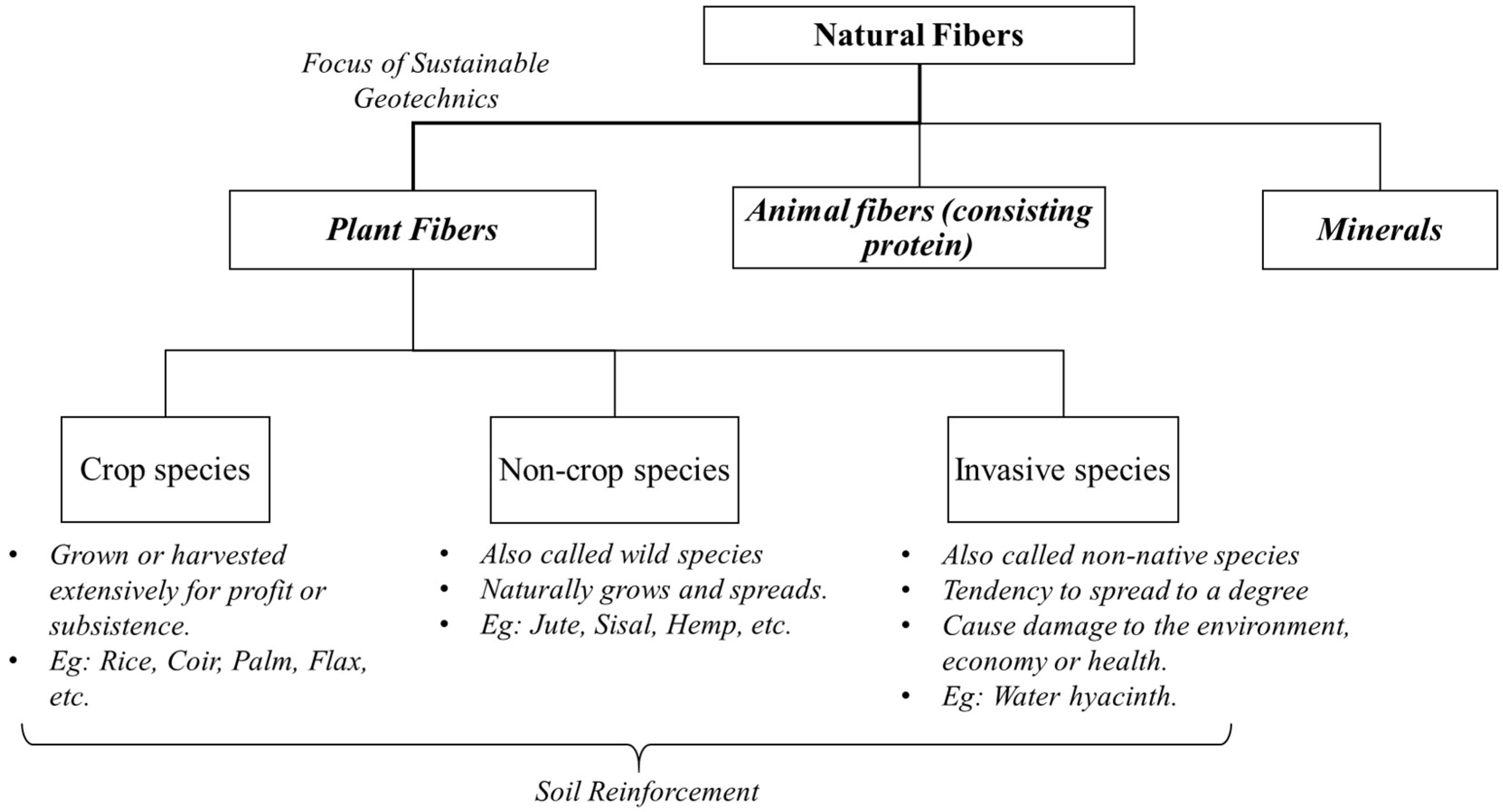

2. Natural Fiber Materials

2.1. Characterization of Natural Fibers

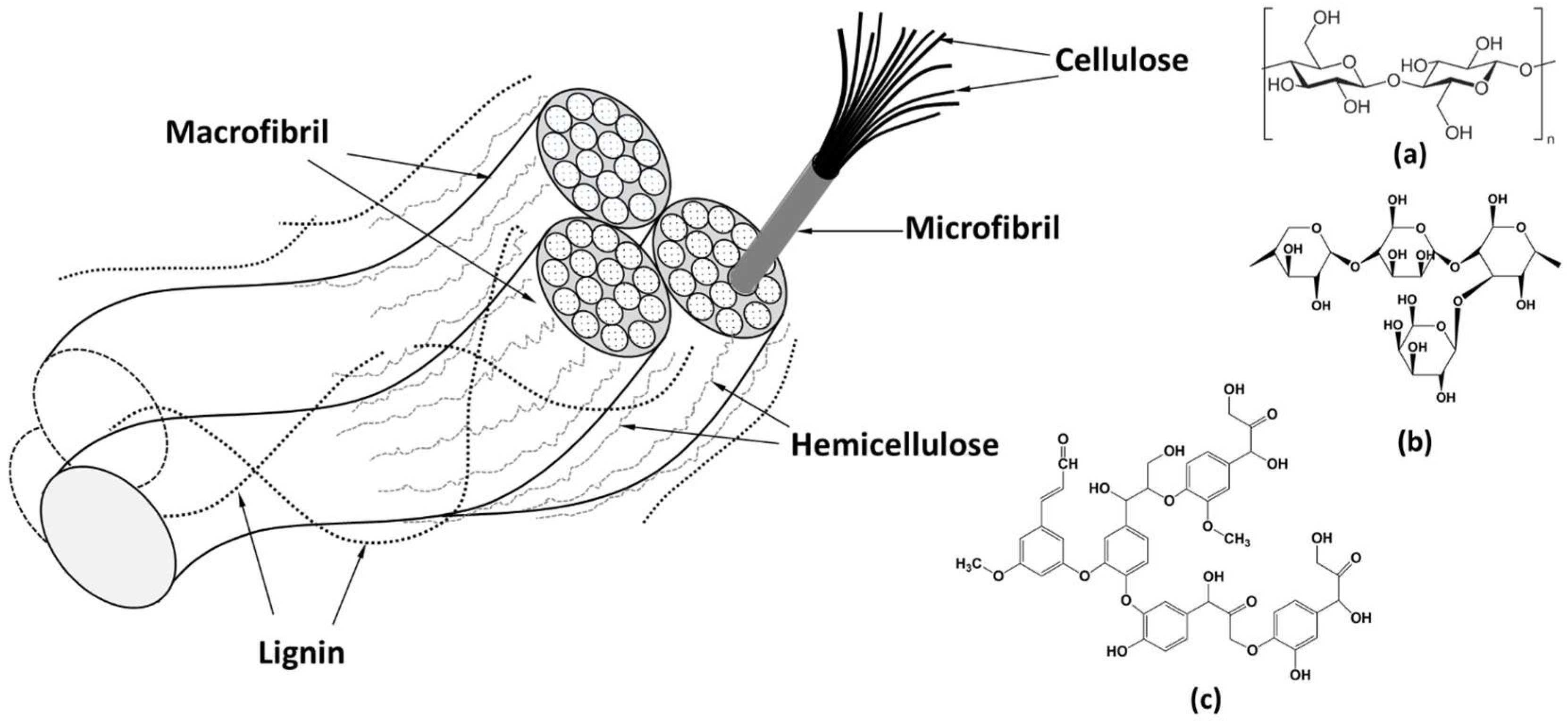

2.2. Biochemical Properties of Natural Fibers

2.3. Physical and Mechanical Properties of Natural Fibers

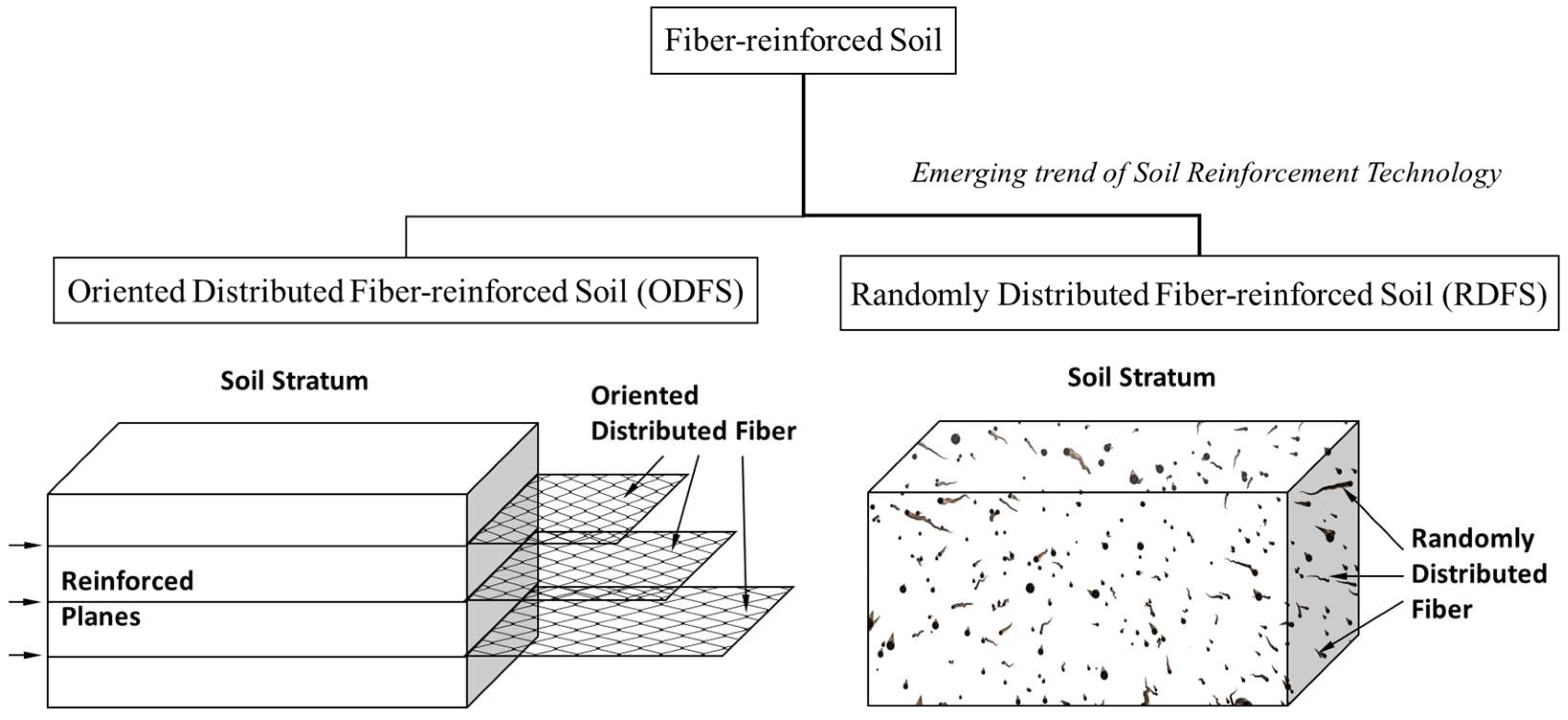

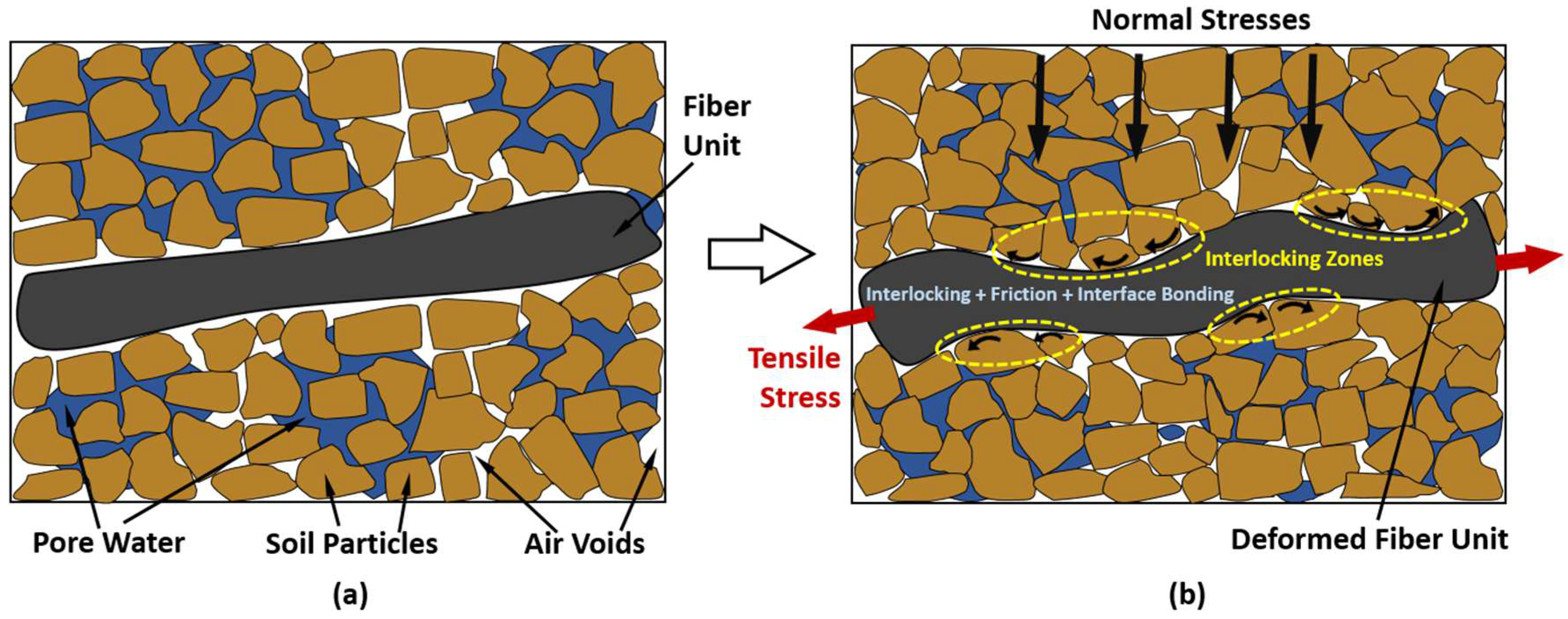

3. Behavior of Fiber-Reinforced Soil

4. Soil-Natural Fiber Reinforcing Applications

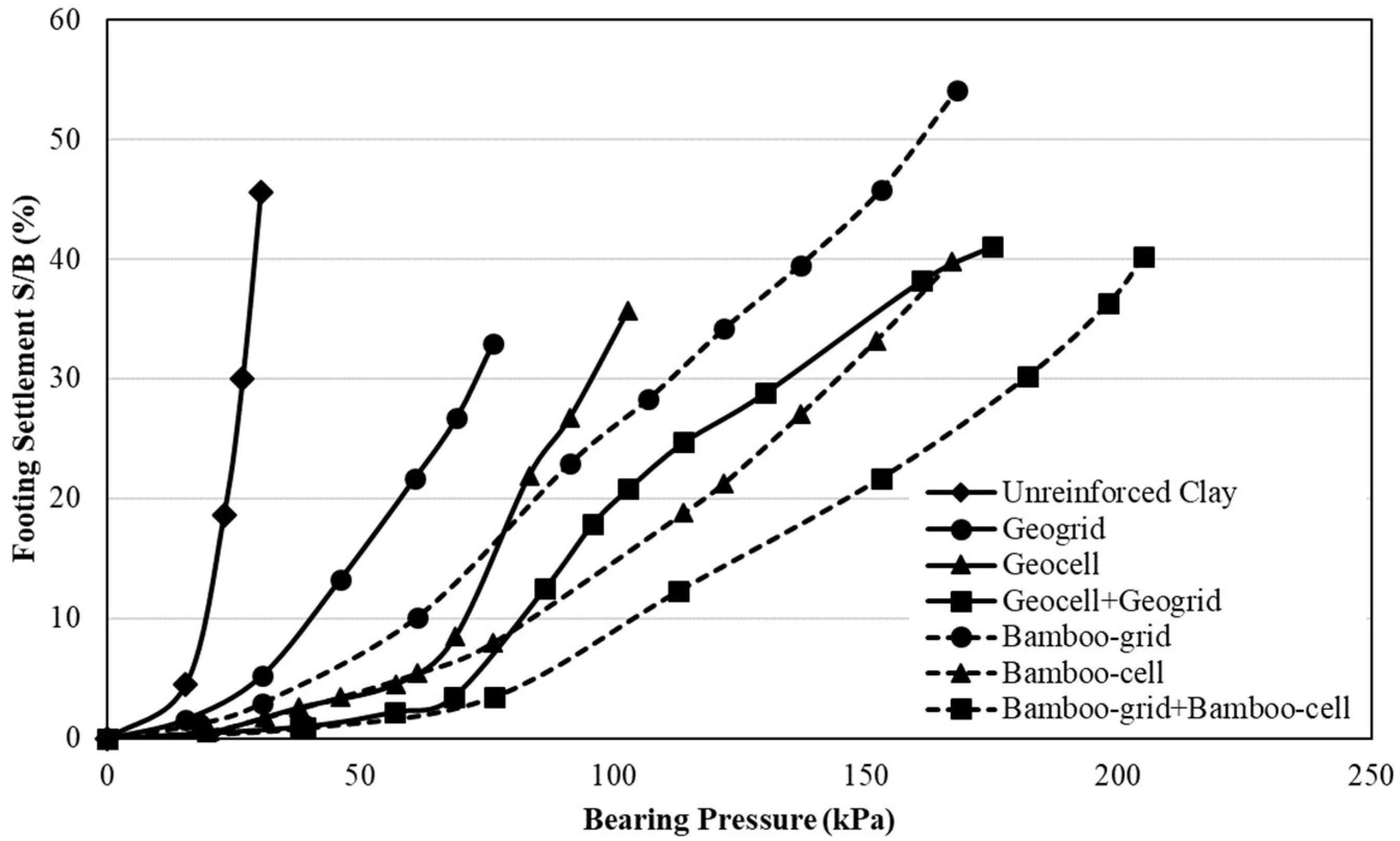

4.1. Bamboo Fiber

4.1.1. Bamboo ODFS Applications

4.1.2. Bamboo RDFS Applications

4.2. Jute Fiber

4.3. Coir Fiber

4.4. Palm Fiber

4.5. Sugar Cane Bagasse Fiber

4.6. Water Hyacinth Fiber

4.7. Rice Husk Fiber

4.8. Sisal Fiber

4.9. Other Fibers

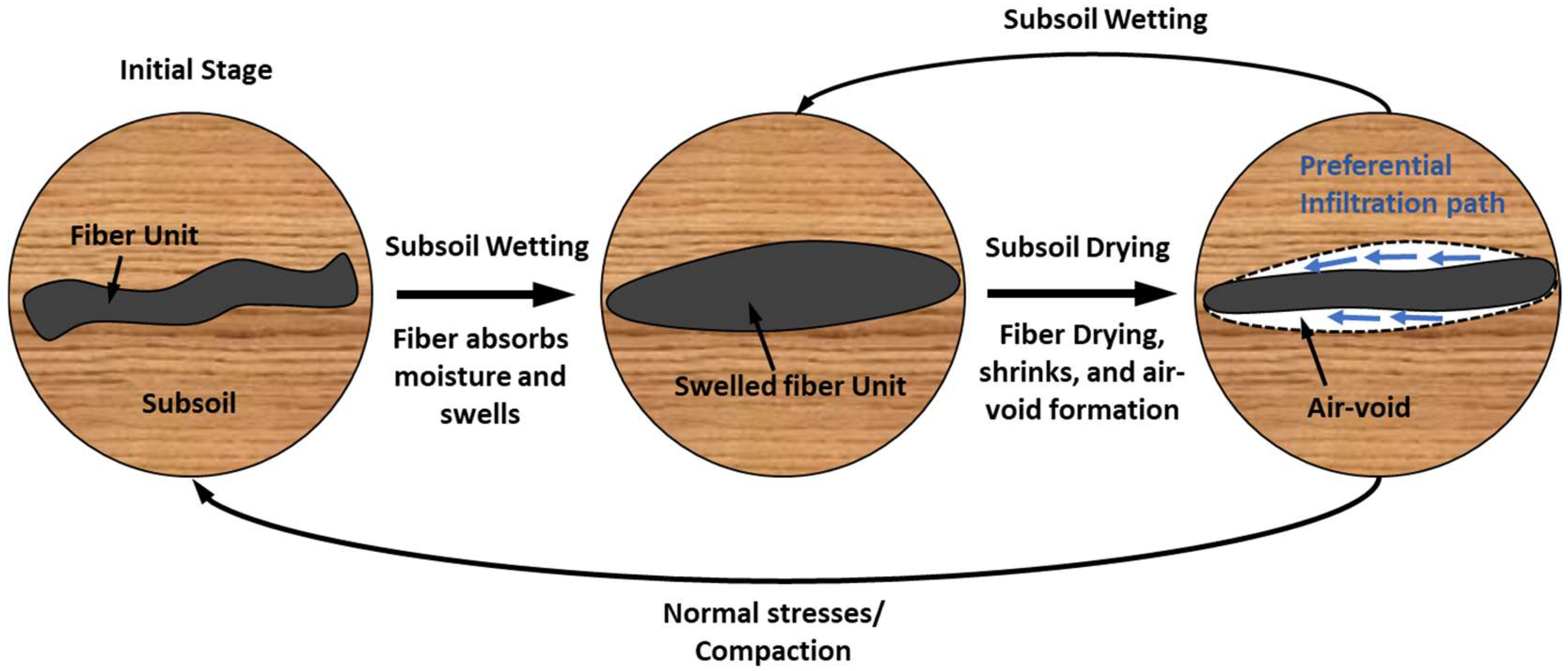

5. Effect of Water in Fiber-Reinforced Soil Behavior

6. Fiber Degradation and Recommended Treatments

7. Future Prospects

8. Concluding Remarks

Author Contributions

Conflicts of Interest

References

- Sato, A.; Kawasaki, S.; Hata, T.; Hayashi, T. Possibility for Solidification of Peaty Soil by Using Microbes. Int. J. GEOMATE 2016, 10, 2071–2076. [Google Scholar] [CrossRef]

- Bordoloi, S.; Garg, A.; Sekharan, S. A Review of Physio-Biochemical Properties of Natural Fibers and Their Application in Soil Reinforcement. Adv. Civ. Eng. Mater. 2017, 6, 323–359. [Google Scholar] [CrossRef]

- Celik, E.; Nalbantoglu, Z. Effects of ground granulated blastfurnace slag (GGBS) on the swelling properties of lime-stabilized sulfate-bearing soils. Eng. Geol. 2013, 163, 20–25. [Google Scholar] [CrossRef]

- Yadu, L.; Tripati, R.K. Effects of Granulated Blast Furnace Slag in the Engineering Behavior of Stabilized Soft Soil. Procedia Eng. 2013, 51, 125–131. [Google Scholar] [CrossRef]

- Ozdemir, M.A. Improvement in Bearing Capacity of a Soft Soil by Addition of Fly Ash. Procedia Eng. 2016, 143, 498–505. [Google Scholar] [CrossRef]

- Sharman, A.K.; Sivapullaiah, P.V. Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils Found. 2016, 56, 205–212. [Google Scholar] [CrossRef]

- Iorliam, A.Y.; Agbede, I.O.; Joel, M. Effect of bamboo leaf ash on cement stabilization of Makurdi shale for use as flexible pavement construction material. Am. J. Sci. Ind. Res. 2012, 3, 166–174. [Google Scholar] [CrossRef]

- Sakaray, H.; Togati, N.V.V.K.; Reddy, I.V.R. Investigation on Properties of Bamboo as Reinforcing Material in Concrete. Int. J. Eng. Res. Appl. 2012, 2, 077–083. [Google Scholar]

- Al-Swaidani, A.; Hammoud, I.; Mezia, A. Effect of adding natural pozzolana on geotechnical properties of lime-stabilized clayey soil. Rock Mech. Geotech. Eng. 2016, 8, 714–725. [Google Scholar] [CrossRef]

- Dilrukshi, R.A.N.; Watanabe, J.; Kawasaki, S. Strengthening of Sand Cemented with Calcium Phosphate Compounds Using Plant-Derived Urease. Int. J. GEOMATE 2016, 11, 2461–2467. [Google Scholar] [CrossRef]

- Achal, V.; Kawasaki, S. Biogrout: A Novel Binding Material for Soil Improvement and Concrete Repair. Front. Microbiol. 2016, 7, 314. [Google Scholar] [CrossRef] [PubMed]

- Fagone, M.; Loccarini, F.; Ranocchiai, G. Strength evaluation of jute fabric for the reinforcement of rammed earth structures. Compos. Part B 2017, 113, 1–13. [Google Scholar] [CrossRef]

- Vidal, H. The principle of reinforced earth. Highw. Res. Rec. 1969, 282, 1–16. [Google Scholar]

- Lekha, B.M.; Goutham, S.; Shankar, A.U.R. Evaluation of lateritic soil stabilized with Arecanut coir for low volume pavements. Transp. Geotech. 2015, 2, 20–29. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A Simple Review of Soil Reinforcement by Using Natural and Synthetic Fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

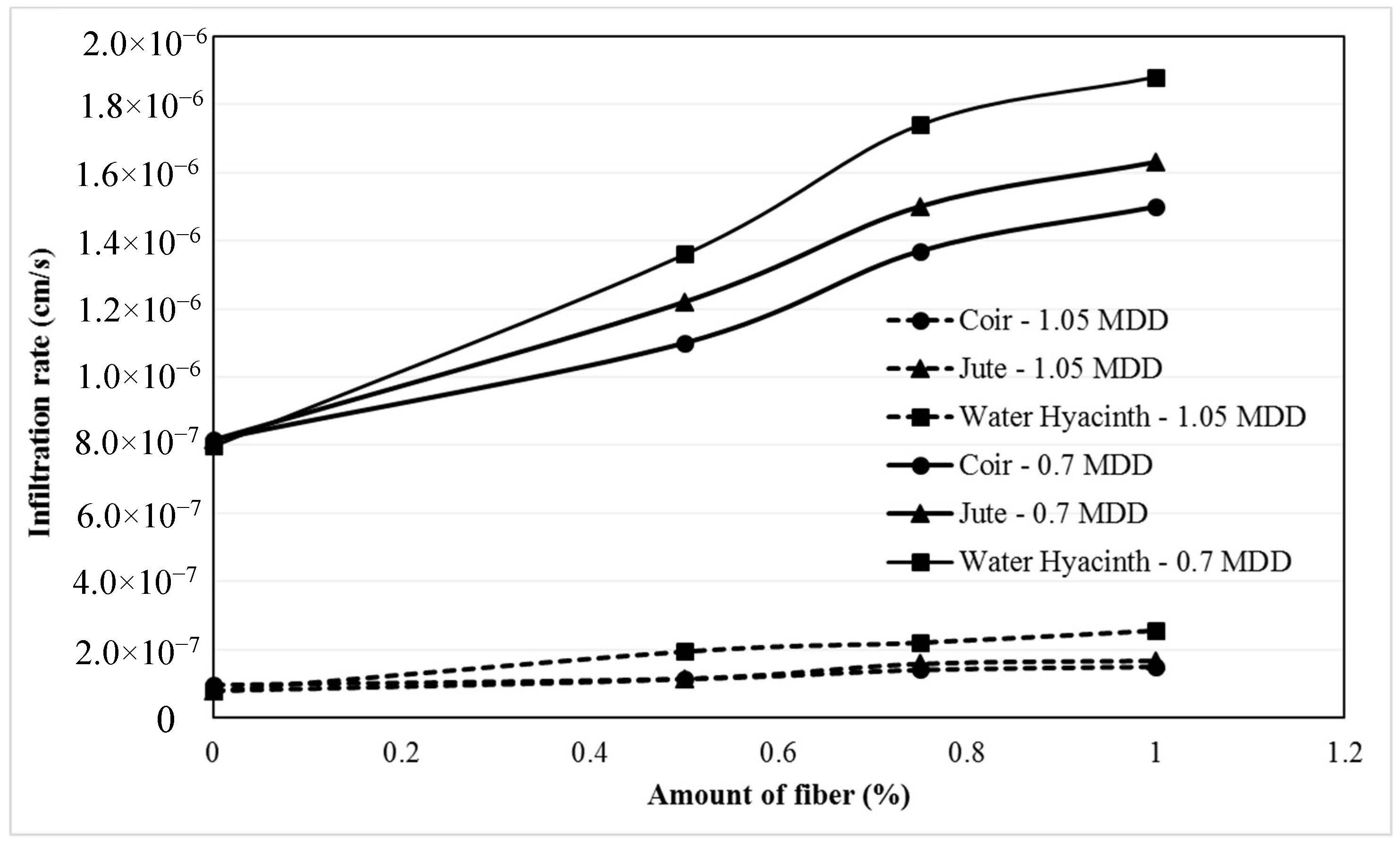

- Bordoloi, S.; Hussain, R.; Garg, A.; Sreedeep, S.; Zhou, W.H. Infiltration characteristics of natural fiber reinforced soil. Transp. Geotech. 2017, 12, 37–44. [Google Scholar] [CrossRef]

- Pujari, S.; Ramakrishna, A.; Padal, K.T.B. Comparison of ANN and Regression Analysis for Predicting the Water Absorption Behaviour of Jute and Banana Fiber Reinforced Epoxy composites. Mater. Today: Proc. 2017, 4, 1626–1633. [Google Scholar] [CrossRef]

- Gaw, B.; Zamora, S.; Albano, L.D.; Tao, M. Soil Reinforcement with Natural Fibers for Low-Income Housing Communities. Bachelor’s Thesis, Worcester Polytechinic Institute, Worcester, MA, USA, 2011. [Google Scholar]

- Ibrahim, M.M.; Dufresne, A.; El-Zawawy, W.K.; Agblevor, F.A. Banana fibers and microfibrils as lignocellulosic reinforcements in polymer composites. Carbohydr. Polym. 2010, 81, 811–819. [Google Scholar] [CrossRef]

- Sharma, V.; Vinayak, H.K.; Marwaha, B.M. Enhancing compressive strength of soil using natural fibers. Constr. Build. Mater. 2015, 93, 943–949. [Google Scholar] [CrossRef]

- Ghosha, S.K.; Bhattacharyyab, R.; Mondal, M.M. Potential Applications of Open Weave Jute Geotextile (Soil Saver) in Meeting Geotechnical Difficulties. Procedia Eng. 2017, 200, 200–205. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers-An overview. Int. Rev. J. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Zakikhani, P.; Zahari, R.; Sultan, M.T.H.; Majid, D.L. Extraction and preparation of bamboo fibre-reinforced composites. Mater. Des. 2014, 63, 820–828. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Maslinda, A.B.; Majid, M.S.A.; Ridzuan, M.J.M.; Afendi, M.; Gibson, A.G. Effect of water absorption on the mechanical properties of hybrid interwoven cellulosic-cellulosic fibre reinforced epoxy composites. Compos. Struct. 2017, 167, 227–237. [Google Scholar] [CrossRef]

- Bordoloi, S.; Garg, A.; Sreedeep, S. Potential of Uncultivated, Harmful and Abundant Weed as a Natural Geo-Reinforcement Material. Adv. Civ. Eng. Mater. 2016, 5, 276–288. [Google Scholar] [CrossRef]

- Li, X. Physical, Chemical, and Mechanical Properties of Bamboo and its Utilization Potential for Fiberboard Manufacturing, Master’s Thesis, Louisiana State University and Agriculture and Mechanical College, Baton Rouge, LA, USA, 2004. [Google Scholar]

- Okubo, K.; Fujii, T.; Yamamoto, Y. Development of bamboo-based polymer composites and their mechanical properties. Compos. Part A 2004, 35, 377–383. [Google Scholar] [CrossRef]

- Akil, H.M.; Cheng, L.W.; Ishak, Z.A.M.; Bakar, A.A.B.; Rahman, M.A.A. Water absorption study on pultruded jute fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2009, 69, 1942–1948. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Ismail, H.; Rozman, H.D.; Ahmad, M.N. The effect of acetylation on interfacial shear strength between plant fiber and various matrices. Eur. Polym. J. 2001, 37, 1037–1045. [Google Scholar] [CrossRef]

- Lekha, K.R. Field instrumentation and monitoring of soil erosion in coir geotextile stabilised slopes-A case study. Geotext. Geomembr. 2004, 22, 399–413. [Google Scholar] [CrossRef]

- Kaddami, H.; Dufresne, A.; Khelifi, B.; Bendahou, A.; Taourirte, M.; Raihane, M.; Issartel, N.; Sautereau, H.; Gerard, J.F.; Sami, N. Short palm tree fibers - Thermoset matrices composites. Compos. Part A 2006, 37, 1413–1422. [Google Scholar] [CrossRef]

- Yang, H.S.; Kim, H.J.; Park, H.J.; Lee, B.J.; Hwang, T.S. Effect of compatibilizing agents on rice-husk flour reinforced polypropylene composites. Compos. Struct. 2007, 77, 45–55. [Google Scholar] [CrossRef]

- Kim, H.J.; Seo, D.W. Effect of water absorption fatigue on mechanical properties of sisal textile-reinforced composites. Int. J. Fatigue 2006, 28, 1307–1314. [Google Scholar] [CrossRef]

- Preneron, A.L.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.P.J.; Virk, A.S.; Hall, W. A review of bast fibres and their composites. Part 1—Fibres as reinforcements. Compos. Part A 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- Lee, H.V.; Hamid, S.B.A.; Zain, S.K. Conversion of Lignocellulosic Biomass to Nanocellulose: Structure and Chemical Process. Sci. World J. 2014. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Chang, R.; Sheng, K.; Adl, M.; Qian, X. Impact Response of Bamboo-Plastic Composites with the Properties of Bamboo and Polyvinylchloride. Bionic Eng. 2008, 5, 28–33. [Google Scholar] [CrossRef]

- Javadian, A.A.; Wielopolski, M.B.; Smith, I.F.C.; Hebel, D.E. Bond-behavior study of newly developed bamboo-composite reinforcement in concrete. Constr. Build. Mater. 2016, 122, 110–117. [Google Scholar] [CrossRef]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J.; Hajek, P. Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Brahmakumar, M.; Pavithran, C.; Pillai, R.M. Coconut fibre reinforced polyethylene composites: Effect of natural waxy surface layer of the fibre on fibre/matrix interfacial bonding and strength of composites. Compos. Sci. Technol. 2005, 65, 563–569. [Google Scholar] [CrossRef]

- Leman, Z.; Sapuan, S.M.; Saifol, A.M.; Maleque, M.A.; Ahmad, M.M.H.M. Moisture absorption behavior of sugar palm fiber reinforced epoxy composites. Mater. Des. 2008, 29, 1666–1670. [Google Scholar] [CrossRef]

- El-Tayeb, N.S.M. A study on the potential of sugarcane fibers/polyester composite for tribological applications. Wear 2008, 265, 223–235. [Google Scholar] [CrossRef]

- Rassiah, K.; Ahmad, M.M.H.M. A Review on Mechanical Properties of Bamboo Fiber Reinforced Polymer Composite. Aust. J. Basic Appl. Sci. 2013, 7, 247–253. [Google Scholar]

- Dang, L.C.; Fatahi, B.; Khabbaz, H. Behaviour of Expansive Soils Stabilized with Hydrated Lime and Bagasse Fibers. Procedia Eng. 2016, 143, 658–665. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, Q.; Lei, Y.; Yao, F. Creep behavior of bagasse fiber reinforced polymer composites. Bioresour. Technol. 2010, 101, 3280–3286. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.; Parkash, E.V.; Kumar, E.V. Stabilization of Clayey Soil using Pine needles and Calcium Chloride. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 626–633. [Google Scholar] [CrossRef]

- Wang, Y.X.; Guo, P.P.; Ren, W.X.; Yuan, B.X.; Yuan, H.P.; Zhao, Y.L.; Shan, S.B.; Cao, P. Laboratory Investigation on Strength Characteristics of Expansive Soil Treated with Jute Fiber Reinforcement. Int. J. Geomech. 2017, 17. [Google Scholar] [CrossRef]

- Maher, M.H.; Gray, D.H. Static Response of Sands Reinforced with Randomly Distributed Fibers. J. Geotech. Eng. 1990, 116, 1661–1677. [Google Scholar] [CrossRef]

- Chauhan, M.S.; Mittal, S.; Mohanty, B. Performance evaluation of silty sand subgrade reinforced with fly ash and fibre. Geotext. Geomembr. 2008, 26, 429–435. [Google Scholar] [CrossRef]

- Ahmad, F.; Bateni, F.; Azmi, M. Performance evaluation of silty sand reinforced with fibers. Geotext. Geomembr. 2010, 28, 93–99. [Google Scholar] [CrossRef]

- Pollen, N. Temporal and spatial variability in root reinforcement of streambanks: Accounting for soil shear strength and moisture. Catena 2007, 69, 197–205. [Google Scholar] [CrossRef]

- Vannoppen, W.; Vanmaercke, M.; De Baets, S.; Poesen, J. A review of the mechanical effects of plant roots on concentrated flow erosion rates. Earth-Sci. Rev. 2015, 150, 666–678. [Google Scholar] [CrossRef]

- Gyssels, G.; Poesen, J.; Bochet, E.; Li, Y. Impact of plant roots on the resistance of soils to erosion by water: A review. Prog. Phys. Geogr. Earth Environ. 2005, 29, 189–217. [Google Scholar] [CrossRef]

- Xu, Q.; Harries, K.; Li, X.; Liu, Q.; Gottron, J. Mechanical properties of structural bamboo following immersion in water. Eng. Struct. 2014, 81, 230–239. [Google Scholar] [CrossRef]

- Yang, T.H.; Lee, C.H.; Lee, C.J.; Cheng, Y.W. Effects of different thermal modification media on physical and mechanical properties of moso bamboo. Constr. Build. Mater. 2016, 119, 251–259. [Google Scholar] [CrossRef]

- Ng, E.P.; Chow, J.H.; Mukti, R.R.; Muraza, O.; Ling, T.C.; Wong, K.L. Hydrothermal synthesis of zeolite from bamboo leaf biomass and its catalytic activity in cyanoethylation of methanol under autogenic pressure and air conditions. Mater. Chem. Phys. 2017, 201, 78–85. [Google Scholar] [CrossRef]

- Liu, H.; Huang, Y.; Yuan, L.; He, P.; Cai, Z.; Shen, Y.; Xu, Y.; Yu, Y.; Xiong, H. Isothermal crystallization kinetics of modified bamboo cellulose/PCL composites. Carbohydr. Polym. 2010, 79, 513–519. [Google Scholar] [CrossRef]

- Felisbertoa, M.H.F.; Miyakea, P.S.E.; Beraldob, A.L.; Clericia, M.T.P.S. Young bamboo culm: Potential food as source of fiber and starch. Food Res. Int. 2017, 101, 96–102. [Google Scholar] [CrossRef] [PubMed]

- Marak, A.A.; Russell, A.O. A comparative study of Bamboo reinforced concrete beams using different stirrup materials for rural construction. Int. J. Comput. Civ. Struct. Eng. 2011, 2, 407–423. [Google Scholar]

- Kabir, H.; Gafur, M.A.; Ahmed, F.; Begum, F.; Qadir, M.R. Investigation of Physical and Mechanical Properties of Bamboo Fiber and PVC Foam Sheet Composites. Univ. J. Mater. Sci. 2014, 2, 119–124. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Ismanti, S.; Yasufuku, N. Evaluation of bamboo material structure and its influence to mechanical behavior in sand soil mixture under static loading. Jpn. Geotech. Soc. Spec. Publ. 2017, 5, 161–166. [Google Scholar] [CrossRef]

- Hegde, A.; Sitharam, T.G. Use of Bamboo in Soft-Ground Engineering and Its Performance Comparison with Geosynthetics: Experimental Studies. Mater. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Waruwu, A.; Susanti, R.D. Behavior of Soil Peat with Reinforcement of Bamboo Grid. IOSR J. Eng. 2015, 5, 29–36. [Google Scholar]

- Bergado, D.T.; Bukkanasuta, A.; Balasubramaniam, A.S. Laboratory Pull-Out Tests Using Bamboo and Polymer Geogrids Including a Case Study. Geotext. Geomembr. 1987, 5, 153–189. [Google Scholar] [CrossRef]

- Hegde, A.; Sitharam, T.G. Experimental and Analytical Studies on Soft Clay Beds Reinforced with Bamboo Cells and Geocells. Int. J. Geosynth. Ground Eng. 2015, 1, 13. [Google Scholar] [CrossRef]

- Chacko, S.S.; Joseph, S. Experimental Investigation on Soil Reinforced with Bitumen coated Bamboo. Int. Res. J. Eng. Technol. 2016, 3, 66–68. [Google Scholar]

- Marto, A.; Othman, B.A. The Potential Use of Bamboo as Green Material for Soft Clay Reinforcement System. In Proceedings of the International Conference on Environmental Science and Engineering, Bali Island, Indonesia, 1–3 April 2011; pp. 129–133. [Google Scholar]

- Asaduzzaman, M.; Islam, M.I. Soil Improvement by Using Bamboo Reinforcement. Am. J. Eng. Res. 2014, 3, 362–368. [Google Scholar]

- Sai, L.K.; Heng, T.N. Bamboo-Geotextile Buoyant System for Hefty Construction over Deep Soft Subgrade. J. Built Environ. Technol. Eng. 2016, 1, 262–272. [Google Scholar]

- Toh, C.T.; Chee, S.K.; Lee, C.H.; Wee, S.H. Geotextile-Bamboo Fascine Mattress for Filling over Very Soft Soils in Malaysia. Geotext. Geomembr. 1994, 13, 357–369. [Google Scholar] [CrossRef]

- Yuan, M.; Ding, J.; Cao, Y. The Application of Bamboo Network Reinforcement Technology on Hydraulic Fill Soft-Soil Foundation Treatment. World J. Eng. Technol. 2014, 2, 68–72. [Google Scholar] [CrossRef]

- Kamali, B.; Hashim, R. Bamboo foundation mat for rubble mound breakwaters on mud deposits. Int. J. Phys. Sci. 2010, 5, 1406–1410. [Google Scholar]

- Nall, T.; Putra, A. Use of Bamboo Piles in Ground Improvement Design: Case Study. Int. J. Geotech. Geol. Eng. 2016, 3. [Google Scholar]

- Mustapha, A.M. Bamboo as Soil Reinforcement: A Laboratory Trial. Leonardo J. Sci. 2008, 13, 69–77. [Google Scholar]

- Ismanti, S.; Yasufuku, N. Effect of Bamboo Chips in Cemented Sand Soil on Permeability and Mechanical Properties in Triaxial Compression. Int. Sch. Sci. Res. Innov. 2016, 10, 917–923. [Google Scholar]

- Devi, D.; Jempen, B. Shear Strength Behaviour of Bamboo Fiber Reinforced Soil. Int. Res. J. Eng. Technol. 2016, 3, 433–437. [Google Scholar]

- Shigematsu, H.; Sakiura, Y.; Tanida, Y.; Tasaki, H. Geotechnical Properties of Bamboo-Chips Soil Mixture and Its Applicability as Pedestrian Pavement. J. Jpn. Soc. Civ. Eng. (JSCE) 2017, 73, 266–275. [Google Scholar] [CrossRef][Green Version]

- Maruf, M.F. Shear strength of Apus bamboo root reinforced soil. Ecol. Eng. 2012, 41, 84–86. [Google Scholar] [CrossRef]

- Sako, K.; Kitamura, R.; Kawaji, T.; Yotsuda, T. Erosion resistant Properties of Improved Soil using Bamboo Chips for Erosion Prevention of Alameda in Historic Places. Disaster Mitig. Urban Cult. Heritage Pap. 2013, 7, 1–6. [Google Scholar]

- Sato, K.; Fujikawa, T.; Koga, C. Improved Effect of the High Water Content Clay Using the Water Absorptivity of Bamboo. Geosynth. Eng. Pap. 2014, 29, 191–196. [Google Scholar] [CrossRef]

- Huang, H.; Jin, S.; Yamamoto, H. Study on strength characteristics of reinforced soil by cement and bamboo chips. J. Appl. Mech. Mater. 2011, 71–78, 1250–1254. [Google Scholar] [CrossRef]

- Tan, S.A.; Muhammad, N.; Karunaratne, G.P. Forming a Thin Sand Seam on a Clay Slurry with the Aid of a Jute Geotextile. Geotext. Geomembr. 1994, 13, 147–163. [Google Scholar] [CrossRef]

- Chattopadhyay, B.C.; Chakravarty, S. Application of jute geotextiles as facilitator in drainage. Geotext. Geomembr. 2009, 27, 156–161. [Google Scholar] [CrossRef]

- Ranganathan, S.R. Development and Potential of Jute Geotextiles. Geotext. Geomembr. 1994, 13, 421–433. [Google Scholar] [CrossRef]

- Saha, P.; Roy, D.; Manna, S.; Adhikari, B.; Sen, R.; Roy, S. Durability of transesterified jute geotextiles. Geotext. Geomembr. 2012, 35, 69–75. [Google Scholar] [CrossRef]

- Gosavi, M.; Patil, K.A.; Mittal, S.; Saran, S. Improvement of properties of black cotton soil subgrade through synthetic reinforcement. J. Inst. Eng. 2004, 84, 257–262. [Google Scholar]

- Bundela, A.K.; Lamoria, A.; Singh, B.; Tiwari, A.; Sharma, A.K.; Dhemla, P. Identification of Weaker Subgrade Soil in Rajasthan and Increment of CBR by Jute Fiber as Additive. Int. J. Eng. Technol. Manag. Appl. Sci. 2015, 3, 109–113. [Google Scholar]

- Kanchi, G.; Neeraja, V.; Babu, S.G. Effect of anisotropy of fibers on the stress-strain response of fiber-reinforced soil. Int. J. Geomech. 2015, 15. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Cermak, J. Strength anisotropy of fiber reinforced sand. Comput. Geotech. 2002, 29, 279–299. [Google Scholar] [CrossRef]

- Diambra, A.; Ibraim, E.; Wood, D.M.; Russell, A.R. Fibre reinforced sands: Experiments and modelling. Geotext. Geomembr. 2010, 28, 238–250. [Google Scholar] [CrossRef]

- Bera, A.K.; Chandra, S.N.; Ghosh, A.; Ghosh, A. Unconfined compressive strength of fly ash reinforced with jute geotextiles. Geotext. Geomembr. 2009, 27, 391–398. [Google Scholar] [CrossRef]

- Gullu, H.; Khudir, A. Effect of freeze-thaw cycles on unconfined compressive strength of fine-grained soil treated with jute fiber, steel fiber and lime. Cold Reg. Sci. Technol. 2014, 106–107, 55–65. [Google Scholar] [CrossRef]

- Anggraini, V. Potential of Coir Fibres as Soil Reinforcement. Pertanika J. Sch. Res. Rev. 2016, 2, 95–106. [Google Scholar]

- Yadav, J.S.; Tiwari, S.K. Behaviour of cement stabilized treated coir fibre-reinforced clay-pond ash mixtures. Build. Eng. 2016, 8, 131–140. [Google Scholar] [CrossRef]

- Marquesa, A.R.; Viannac, C.R.; Monteiroa, M.L.; Piresc, B.O.S.; Urashimad, D.C.; Pontesb, P.P. Utilizing coir geotextile with grass and legume on soil of Cerrado, Brazil: An alternative strategy in improving the input of nutrients in degraded pasture soil. Appl. Soil Ecol. 2016, 107, 290–297. [Google Scholar] [CrossRef]

- Dutta, R.K.; Khatri, V.N.; Gayathri, V. Effect of Addition of Treated Coir Fibres on the Compression Behaviour of Clay. Jordan J. Civ. Eng. 2012, 6, 476–488. [Google Scholar]

- Peter, L.; Jayasree, P.K.; Balan, K.; Raj, S.A. Laboratory Investigation in the Improvement of Subgrade Characteristics of Expansive Soil Stabilised with Coir Waste. Transp. Res. Procedia 2016, 17, 558–566. [Google Scholar] [CrossRef]

- Ravishankar, A.U.; Raghavan, K.S. Coir stabilized lateritic soil for pavements. In Proceedings of the Indian Geotechnical Conference, Ahmedabad, India, 17–19 December 2004; pp. 45–52. [Google Scholar]

- Anggraini, V.; Asadi, A.; Huat, B.B.K.; Nahazanan, H. Effects of coir fibers on tensile and compressive strength of lime treated soft soil. J. Int. Meas. Confed. 2015, 59, 372–381. [Google Scholar] [CrossRef]

- Jamellodin, Z.; Talib, Z.A.; Kolop, R.; Noor, N.M. The Effect of Oil Palm Fibre on Strength Behaviour of Soil. In Proceedings of the 3rd Southeast Asian Natural Resources and Environmental Management (SANREM) Conference, Kota Kinabalu, Sabah, Malaysia, 3–5 August 2010; pp. 68–72. [Google Scholar]

- Bilba, K.; Arsene, M.A. Silane treatment of bagasse fiber for reinforcement of cementitious composites. Compos. Part A 2008, 39, 1488–1495. [Google Scholar] [CrossRef]

- Hasan, H.; Dang, L.; Khabbaz, H.; Fatahi, B.; Terzaghi, S. Remediation of Expansive Soils Using Agricultural Waste Bagasse Ash. Procedia Eng. 2016, 143, 1368–1375. [Google Scholar] [CrossRef]

- Artidteang, S.; Tanchaisawat, T.; Bergado, D.T.; Chaiyaput, S. Natural Fibers in Reinforcement and Erosion Control Applications with Limited Life Geosynthetics, Ground Improvement Case Histories: Compaction. Grouting Geosynth. 2015, 717–740. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, B.; Quan, H.; Yamb, R.C.M.; Yuen, R.K.K.; Li, R.K.Y. Flame retardancy of rice husk-filled high-density polyethylene eco-composites. Compos. Sci. Technol. 2009, 69, 2675–2681. [Google Scholar] [CrossRef]

- Kumagai, S.; Sasaki, J. Carbon/silica composite fabricated from rice husk by means of binderless hot-pressing. Bioresour. Technol. 2009, 100, 3308–3315. [Google Scholar] [CrossRef] [PubMed]

- Hanifi, C.; Aram, A.; Fatih, C. Soil stabilization of clay with lignin, rice husk powder and ash. Geomech. Eng. 2015, 8, 67–79. [Google Scholar]

- Sapuan, S.M.; Leenie, A.; Harimi, M.; Beng, Y.K. Mechanical properties of woven banana fibre reinforced epoxy composites. Mater. Des. 2006, 27, 689–693. [Google Scholar] [CrossRef]

- Mattone, R. Sisal fibre reinforced soil with cement or cactus pulp in bahareque technique. Cem. Concr. Compos. 2005, 27, 611–616. [Google Scholar] [CrossRef]

- Prabakar, J.; Sridhar, R.S. Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Wu, Y.K.; Li, Y.B.; Niu, B. Investigation of Mechanical Properties of Randomly Distributed Sisal Fibre Reinforced Soil. Mater. Res. Innov. 2014, 18, 953–959. [Google Scholar] [CrossRef]

- Terzaghi, K. Theoretical Soil Mechanics; Wiley: New York, NY, USA, 1943. [Google Scholar]

- Fredlund, D.G.; Vanapalli, S.K. Shear Strength of Unsaturated Soils. In Methods of Soil Analysis; Soil Science Society of America: Madison, WI, USA, 2002. [Google Scholar]

- Jamei, M.; Villard, P.; Guiras, H. Shear failure criterion based on experimental and modeling results for fiber-reinforced clay. Int. J. Geomech. 2013, 13, 882–893. [Google Scholar] [CrossRef]

- Choudhurya, D.; Sahub, J.K.; Sharma, G.D. Moisture sorption isotherms, heat of sorption and properties of sorbed water of raw bamboo (Dendrocalamus longispathus) shoots. Ind. Crops Prod. 2011, 33, 211–216. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Das, S.; Rana, A.K. Dynamic mechanical and thermal analysis of vinylester-resin-matrix composites reinforced with untreated and alkali-treated jute fibers. Compos. Sci. Technol. 2002, 62, 911–917. [Google Scholar] [CrossRef]

- Sarkar, B.K.; Ray, D. Effect of the defect concentration on the impact fatigue endurance of untreated and alkali treated jute-vinylester composites under normal and liquid nitrogen atmosphere. Compos. Sci. Technol. 2004, 64, 2213–2219. [Google Scholar] [CrossRef]

- Deepaka, K.; Vattikutia, S.V.P.; Venkatesh, B. Experimental Investigation of Jute Fiber Reinforced Nano Clay Composite. Procedia Mater. Sci. 2015, 10, 238–242. [Google Scholar] [CrossRef]

- Brigida, A.I.S.; Calado, V.M.A.; Goncalves, L.R.B.; Coelho, M.A.Z. Effect of chemical treatments on properties of green coconut fiber. Carbohydr. Polym. 2010, 79, 832–838. [Google Scholar] [CrossRef]

- Shrivastava, R.; Telang, A.; Rana, R.S.; Purohit, R. Mechanical Properties of Coir/G Lass Fiber Epoxy Resin Hybrid Composite. J. Mater. Today Proc. Part A 2017, 4, 3477–3483. [Google Scholar] [CrossRef]

- Agrawal, R.; Saxena, N.S.; Sharma, K.B.; Thomas, S.; Sreekala, M.S. Activation Energy and Crystallization Kinetics of Untreated and Treated Oil Palm Fibre Reinforced Phenol Formaldehyde Composites. Mater. Sci. Eng. A 2000, 277, 77–82. [Google Scholar] [CrossRef]

- Hill, C.A.; Khalil, H.A.; Hale, M.D. A Study of the Potential of Acetylation to Improve the Properties of Plant Fibres. Ind. Crops Prod. 1998, 8, 53–63. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Parija, S.; Nayak, S.K.; Tripathy, S.S. Studies on Mechanical Performance of Biofibre/ Glass Reinforced Polyester Hybrid Composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

- Hegde, A. Geocell reinforced foundation beds-past findings, present trends and future prospects: A state-of-the-art review. Constr. Build. Mater. 2017, 154, 658–674. [Google Scholar] [CrossRef]

- De Jong, J.T.; Mortenensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated Soil Improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Van Paassen, L.A.; Ghose, R.; Van der Linden, T.J.M.; Van der Star, W.R.L.; Van Loosdrecht, M.C.M. Quantifying Biomediated Ground Improveent by Ureolysis: Large-Scale Biogrout Experiment. Geotech. Geoenviron. Eng. 2010, 136, 1721–1728. [Google Scholar] [CrossRef]

- Ivanov, V.; Stabnikov, V. Biotechnological Improvement of Construction Ground and Construction Materials. In Construction Biotechnology; Springer: Singapore, 2017; pp. 91–107. [Google Scholar]

- Cheng, L.; Shahin, M.A.; Ruwisch, R.C.; Addis, M.; Hartanto, T.; Elms, C. Soil Stabilisation by Microbial-Induced Calcite Precipitation (MICP): Investigation into Some Physical and Environmental Aspects. In Proceedings of the 7th International Congress on Environmental Geotechnics, Melbourne, Australia, 10–14 November 2014. [Google Scholar]

- Whiffin, V.S.; Van Paassen, L.A.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

| Fiber Material | Cost (USD/Ton) | Energy Content (GJ/Ton) | |

|---|---|---|---|

| Carbon Fiber | Conventional synthetic Fibers | 12,500 | 130 |

| Kevlar Fiber | 75,000 | 25 | |

| Glass Fiber | 1200–1800 | 30 | |

| Plant Fiber | Sustainable Alternation | 200–1000 | 4 |

| Source of Fiber | Species | Fiber Origin | Cellulose (%) | Hemicellulose (%) | Lignin (%) | References |

|---|---|---|---|---|---|---|

| Bamboo | (>1250 species) | Culm | 40–55 | 18–20.8 | 15–32.2 | [23,24,27,28] |

| Jute | Corchorus capsularis | Stem | 56–71 | 29–35 | 11–14 | [16,22,29] |

| Coir | Cocos nucifera | Fruit | 32–43 | 21 | 40–45 | [16,30,31] |

| Palm | Elaeis guineensis | Fruit | 32–35.8 | 24.1–28.1 | 26.5–28.9 | [32] |

| Sugarcane Bagasse | Saccharum officinarum | Stem | 32–44 | 25 | 19–24 | [22] |

| Water hyacinth | Eichhornia crassipes | Stem | 43.58–47.38 | 19.77–22.23 | 9.52–13.08 | [2,16,26] |

| Rice | Oryza sativa | Husk | 59.9 | 20.6 | [33] | |

| Sisal | Agave Sisiana | Leaf | 57–71 | 16 | 11–12 | [28,34] |

| Flax | Linum usitatissimum | Stem | 62–72 | 18.6–20.6 | 2–5 | [2,22] |

| Banana | Musa indica | Leaf | 60–65 | 25 | 5–10 | [22,35] |

| Hemp | Cannabis sativa | Stem | 67–78.3 | 5.5–16.1 | 2.9–3.7 | [36,37] |

| Kenaf | Hibiscus cannabinus | Stem | 70 | 3 | 19 | [35] |

| Pine | Pinus lambertiana | Straw | 67.29 | 11.57 | [20] | |

| Barely | Hordeum vulgare | Straw | 33–40 | 20–35 | 8–17 | [38] |

| Wheat | Triticum aestivum | Straw | 30 | 50 | 15 | [38] |

| Fiber | Density (kg/m3) | Young’s Modulus (GPa) | Ultimate Tensile Strength (MPa) | Elongation at Break (%) | Moisture Absorption (%) | References |

|---|---|---|---|---|---|---|

| Bamboo | 715–1225 | 33–40 | 400–1000 | - | 40–52.45 | [15,28,39,40,41] |

| Jute | 1300–1450 | 10–30 | 393–860 | 1.5–1.8 | 12 | [2,15,22,37] |

| Coir | 1390–1520 | 3–6 | 100–225 | 12–51.4 | 130–180 | [2,15,42] |

| Palm | 463 | 26–32 | 100–400 | 19 | 1–10 | [2,15,43] |

| Sugarcane Bagasse | 1250 | 15–19 | 66.29–290 | 1.1 | - | [22,44,45,46] |

| Water hyacinth | 800 | - | 295.5–329.5 | 13.6 | 32 | [2,16] |

| Rice Husk | - | - | - | - | - | - |

| Sisal | 700–1330 | 9–20 | 400–700 | 3.64–13 | 56–230 | [2] |

| Flax | 1500 | 27.6–80 | 345–1500 | 1.2–2.7 | 7 | [2,37] |

| Banana | 1350 | 27–32 | 711–779 | 2.5–3.7 | - | [22,45,47] |

| Hemp | 1140–1470 | 30–70 | 690–920 | 16 | 8–9 | [2,25,36,37] |

| Kenaf | 1040 | 136 | 1000 | - | 307 | [35] |

| Pine | 813 | - | 61.65 | 10.68 | - | [20,48] |

| Barley | 870 | - | - | - | 400 | [35] |

| Wheat | 868 | - | - | - | 280–350 | [35] |

| Fiber Material | Fiber Type | Density (kg/m3) | Young’s Modulus (GPa) | Ultimate Tensile Strength (MPa) | Reference |

|---|---|---|---|---|---|

| Carbon Fiber | Conventional synthetic Fibers | 1800 | 130 | 1710 | [22] |

| Kevlar Fiber | 1400 | 90 | 2710 | ||

| Glass Fiber | 2600 | 30 | 1350 | ||

| Plant Fiber | Natural Fiber | Up to 1500 | Up to 130 | Up to 1500 | Refer Table 3 |

| Fiber | Recommended Prior Treatments | Prime Targets | References |

|---|---|---|---|

| Bamboo | Heat treatment (in Oil at 150 °C for 4 h) | Enhance thermal stability, weather resistance | [40,57,69] |

| Coating of bitumen or water-based paints | Prevention of water ingress, prevention of microbial degradation | ||

| Application of two-component epoxy resin (Enamel, ExaPhen) | Enhancement of composite bonding | ||

| Hot press | Densifying, strengthening | ||

| Jute | 4 h of alkali treatment in 5% NaOH and reinforcement using vinylester resin matrix at 30 °C | Increase surface roughness of fiber | [12,17,88,119,120,121] |

| Reinforcement with polyester resin and Nano-clay | Increase strength, decrease water absorption | ||

| Coatings of bitumen or antimicrobial benzothiazole chemicals | Prevention of water ingress, prevention of microbial degradation | ||

| Coir | Treatment with H2O2 | Increase thermal stability, removal of waxes and fatty acids | [100,103,122,123] |

| Treatment with phenol and bitumen | Enhancement of durability | ||

| Treatment using NaOCl/NaOH for the exposition of cellulose and hemicellulose | Reduction of water absorption | ||

| Treatment using CCl4 | Prevention of microbial degradation | ||

| Palm | Coating with acrylic butadiene styrene (ABS) thermoplastic to protect from biodegradation and to increase the friction with soil particles | Prevention of biodegradation, increase surface friction | [52] |

| Sisal | Acetylation by acetic anhydride | Modification of fiber cell wall as hydrophobic, increase rigidity and roughness of fiber | [2] |

| Permanganate treatment | Reduce hydrophilic tendency | ||

| Flax, hemp | Ultrasonic impact can be applicable | Increase durability | [2] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gowthaman, S.; Nakashima, K.; Kawasaki, S. A State-of-the-Art Review on Soil Reinforcement Technology Using Natural Plant Fiber Materials: Past Findings, Present Trends and Future Directions. Materials 2018, 11, 553. https://doi.org/10.3390/ma11040553

Gowthaman S, Nakashima K, Kawasaki S. A State-of-the-Art Review on Soil Reinforcement Technology Using Natural Plant Fiber Materials: Past Findings, Present Trends and Future Directions. Materials. 2018; 11(4):553. https://doi.org/10.3390/ma11040553

Chicago/Turabian StyleGowthaman, Sivakumar, Kazunori Nakashima, and Satoru Kawasaki. 2018. "A State-of-the-Art Review on Soil Reinforcement Technology Using Natural Plant Fiber Materials: Past Findings, Present Trends and Future Directions" Materials 11, no. 4: 553. https://doi.org/10.3390/ma11040553

APA StyleGowthaman, S., Nakashima, K., & Kawasaki, S. (2018). A State-of-the-Art Review on Soil Reinforcement Technology Using Natural Plant Fiber Materials: Past Findings, Present Trends and Future Directions. Materials, 11(4), 553. https://doi.org/10.3390/ma11040553