Microstructure and Mechanical Properties of Al2O3/Er3Al5O12 Binary Eutectic Ceramic Prepared by Bridgman Method

Abstract

1. Introduction

2. Experimental

2.1. Preparation of the Sintered Al2O3/EAG Ceramic

2.2. Preparation of the Solidified Al2O3/EAG Ceramic via Bridgman Method

2.3. Characterization

3. Results and Discussion

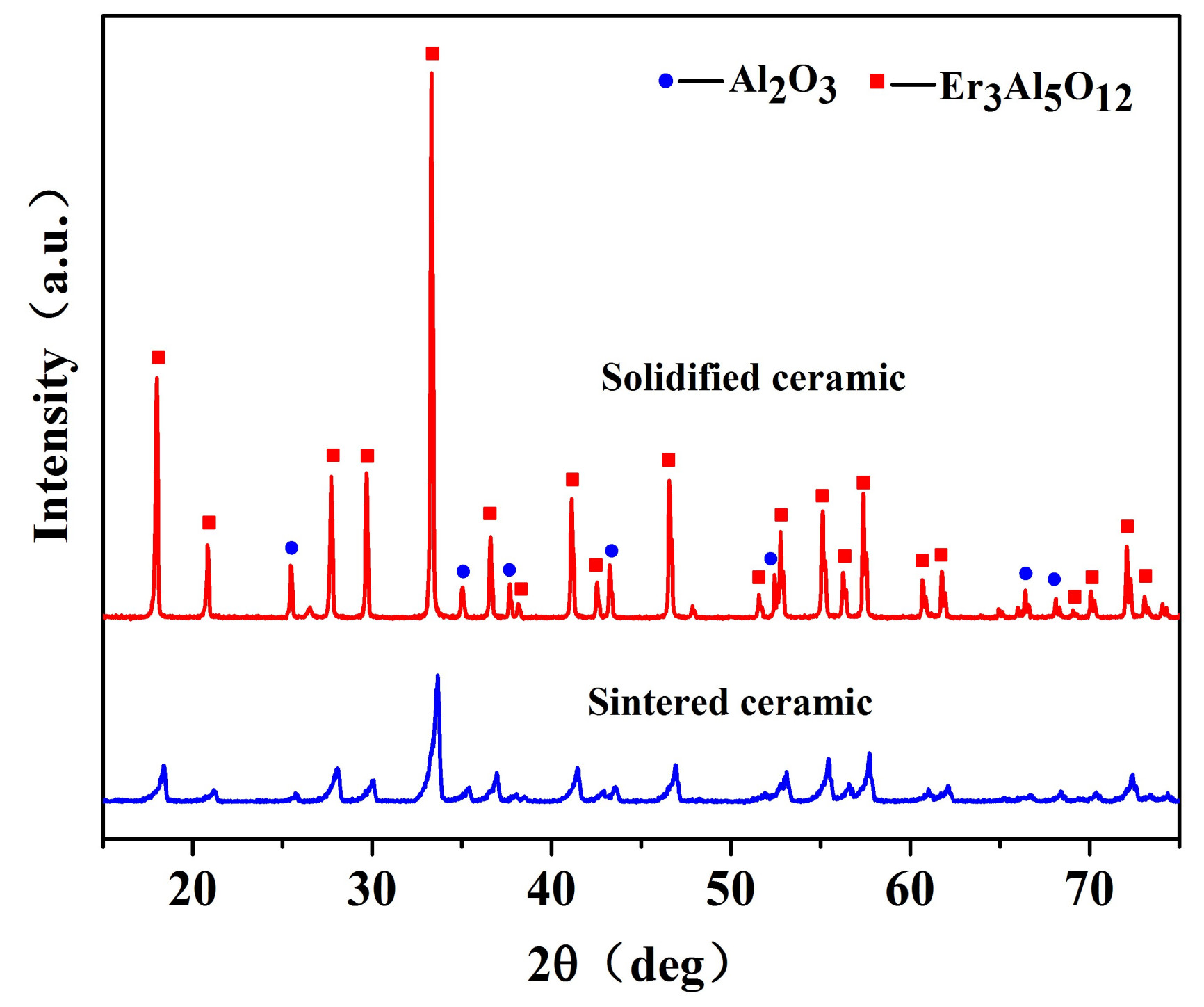

3.1. Phase Analysis

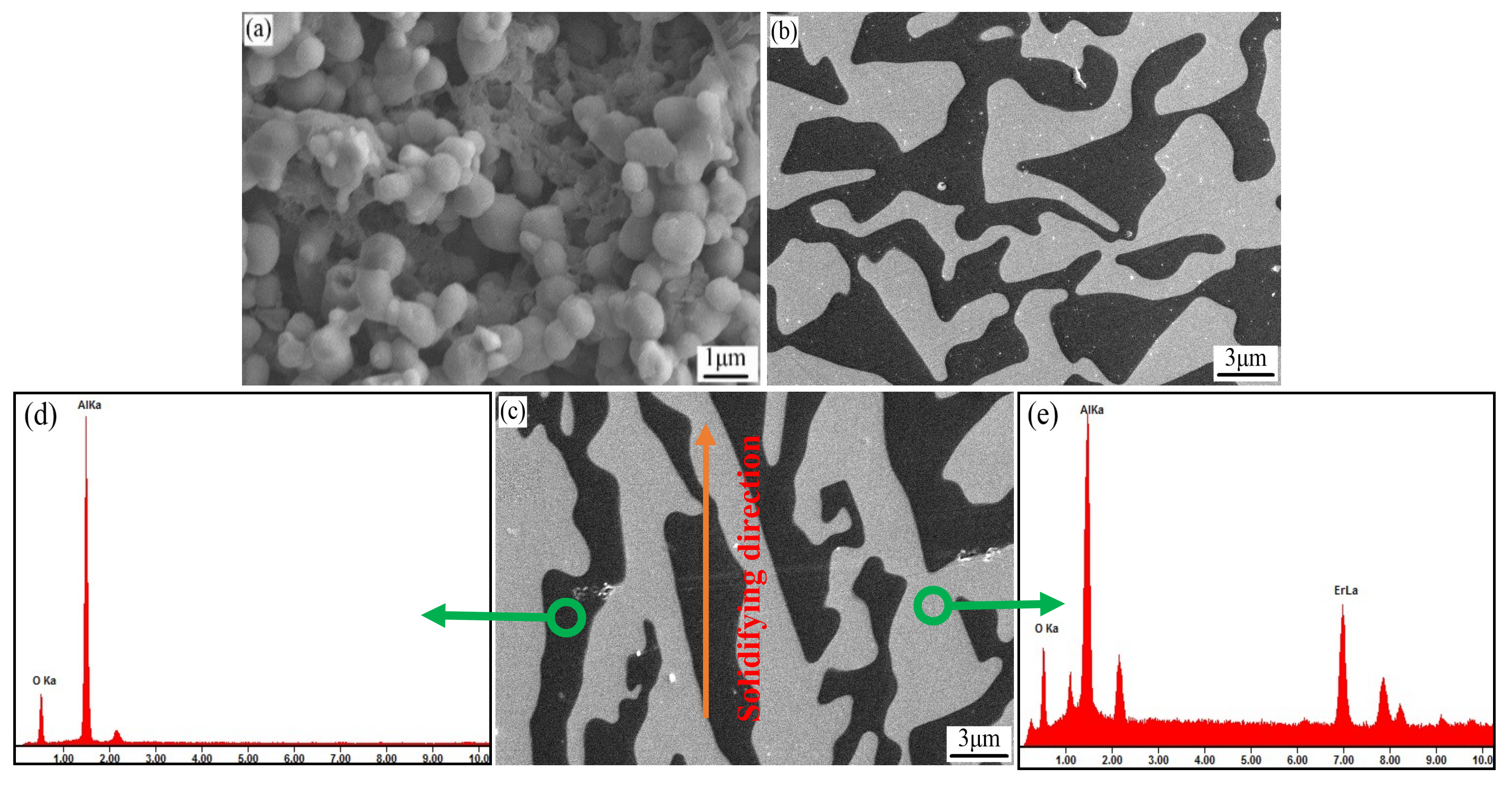

3.2. Microstructure

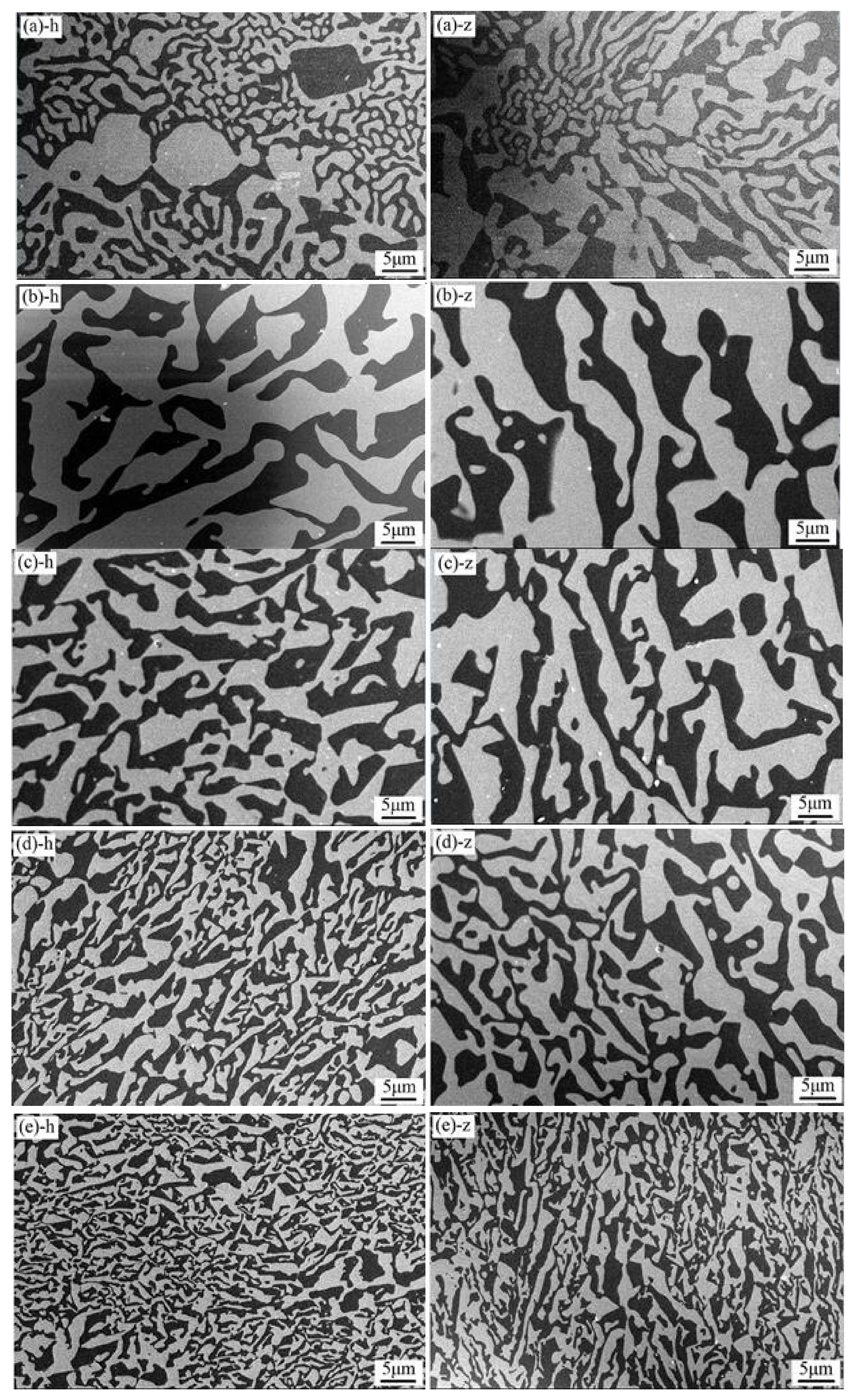

3.3. Effects of Growth Rate on the Microstructure of the Solidified Ceramic

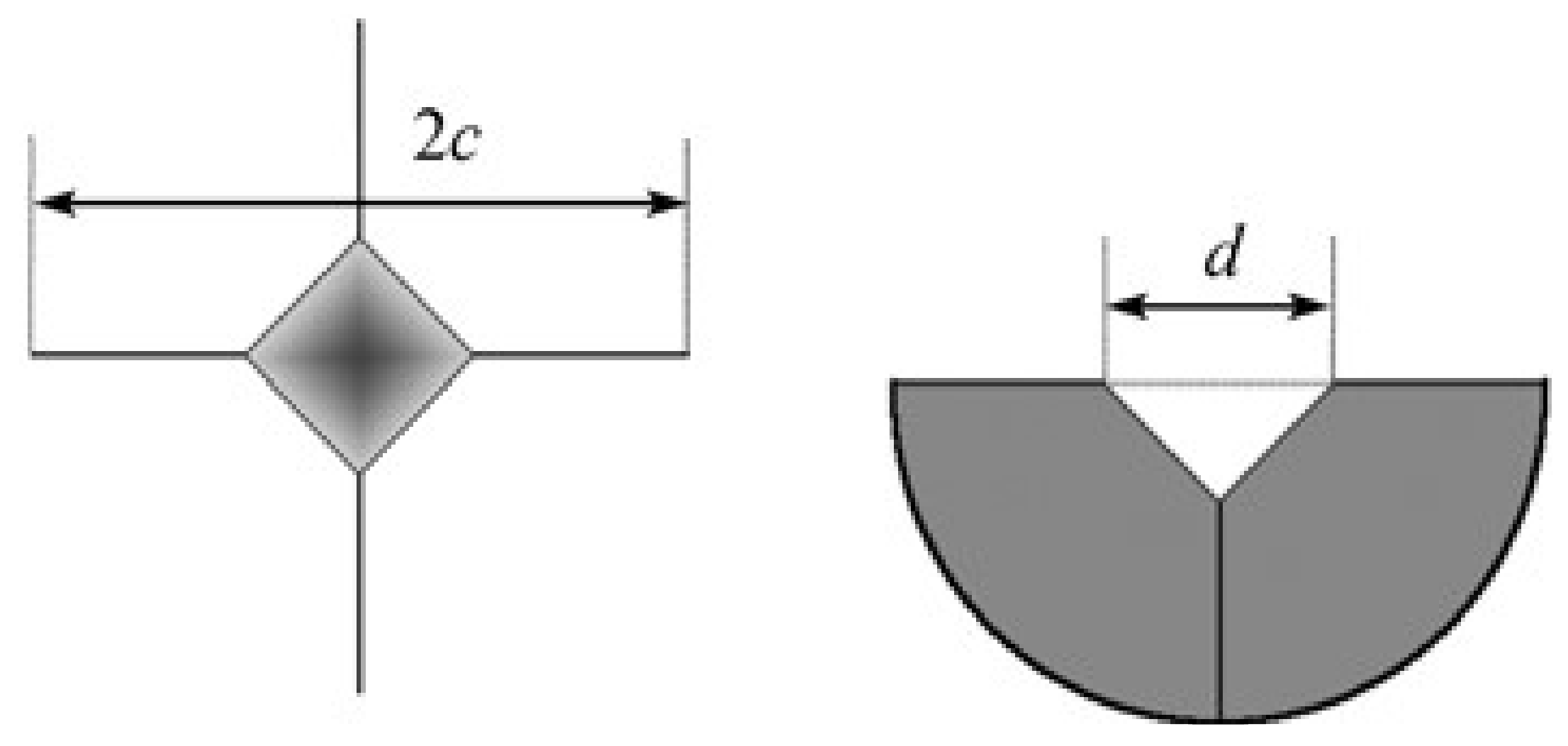

3.4. Hardness and Fracture Toughness of the Solidified Al2O3/EAG Ceramic

4. Conclusions

- (1)

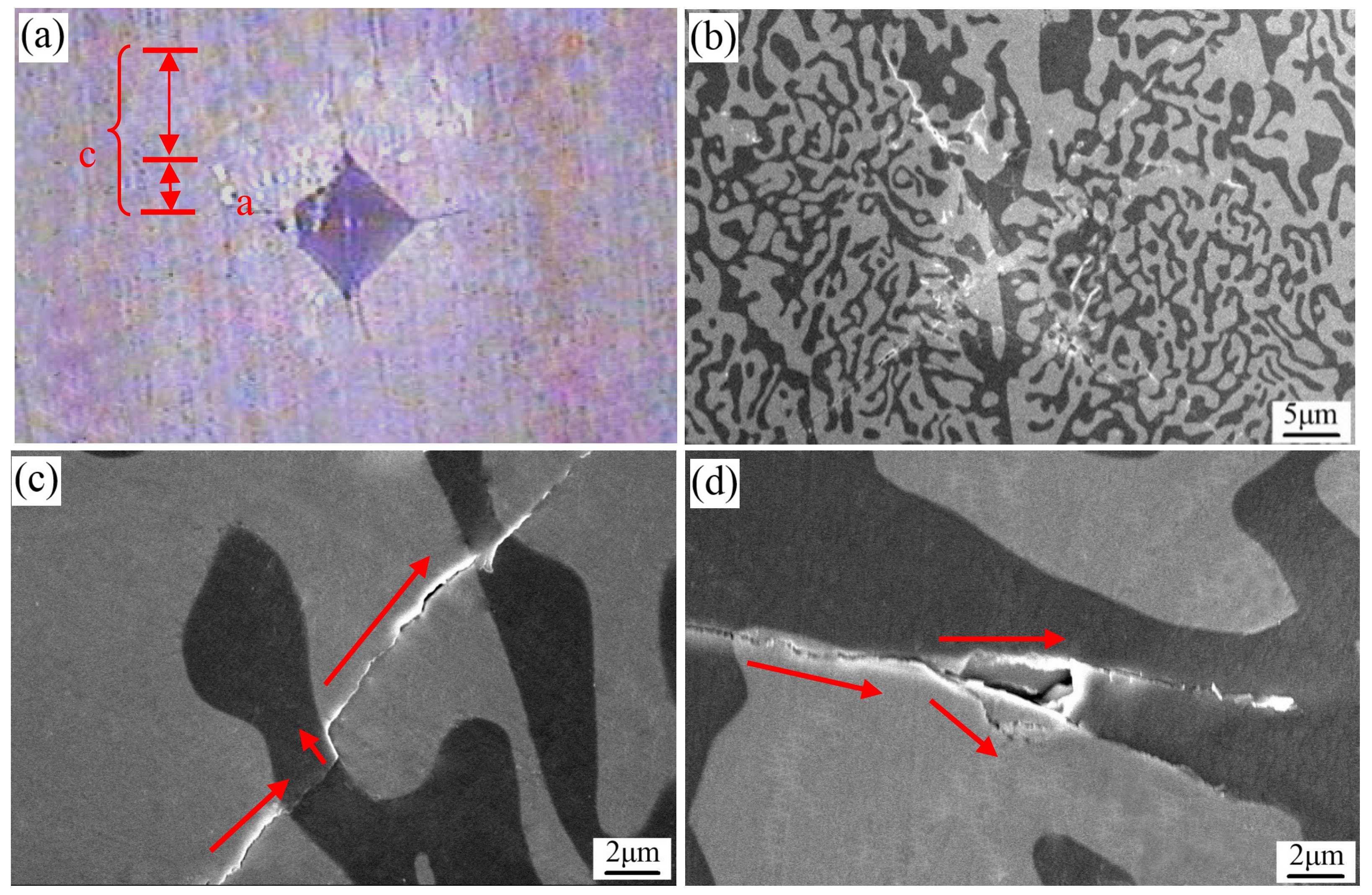

- The sintered ceramic was composed of polycrystalline grains, which contain pores and grain boundaries. While there were no pores and grain boundaries in the directionally solidified Al2O3/EAG eutectic ceramic, where Al2O3 phase was embedded in the EAG matrix phase, and the two phases were intertwined with each other to form a typical binary eutectic “hieroglyphic” structure. The cross section microstructure of the solidified ceramic always exhibited an irregular eutectic growth, while the longitudinal section microstructure presented a directional growth.

- (2)

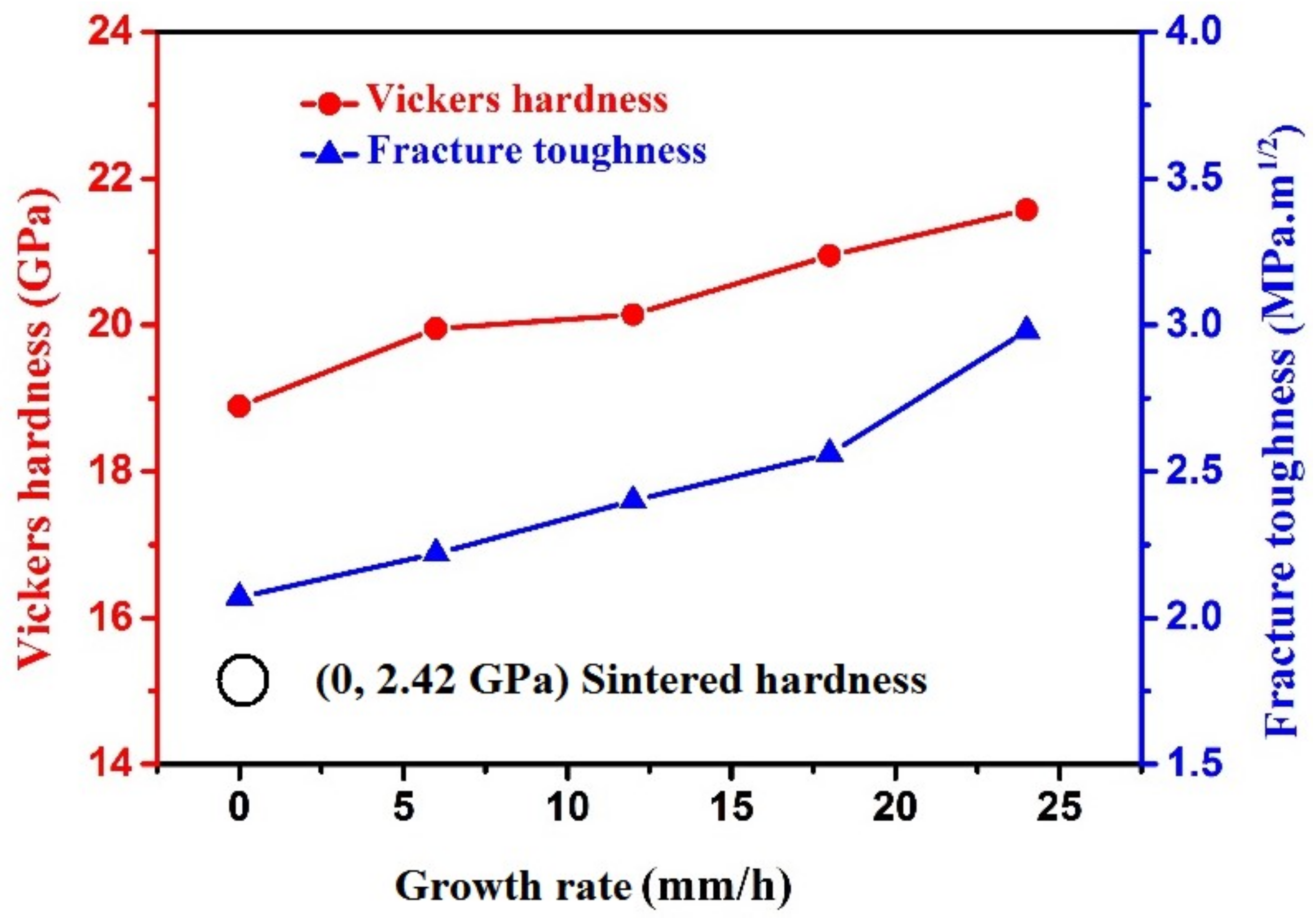

- The maximum hardness and fracture toughness of the directionally solidified ceramic could reach 21.57 GPa and 2.98 MPa·m1/2 at the growth rate of 24 mm/h, respectively. The former is 8.9 times that of the sintered ceramic. The main reason could be attributed to the absence of grain boundaries and pores in the microstructure of the sintered ceramic, playing a crucial role in degradation of the mechanical properties of ceramic materials. And the crack deflection and the branching are the main toughening mechanisms of the solidified ceramic.

- (3)

- The mechanical properties of the solidified ceramic gradually increased with the increase of growth rate. This could be attributed mainly to the refinement of microstructures. With the increase of growth rate, the phase size and spacing of the solidified Al2O3/EAG ceramic both decreased, and the growth rate and phase spacing satisfied the λ2v ≈ 60 (constant) formula of Jackson-Hunt theory. The finer the microstructure, the more significant the toughening effects of the crack deflection and the branching.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Feng, Q.; Picard, Y.N.; Liu, H.; Yalisove, S.M.; Mourou, G.; Pollock, T.M. Femtosecond laser micromachining of a single-crystal superalloy. Scr. Mater. 2005, 53, 511–516. [Google Scholar] [CrossRef]

- Liu, G.; Huang, Z.; Liu, X.; Jiang, D. Removal Behaviors of Different SiC Ceramics during Polishing. J. Mater. Sci. Technol. 2010, 26, 125–130. [Google Scholar] [CrossRef]

- Yao, D.J.; Li, H.J.; Wu, H.; Fu, Q.G.; Qiang, X.F. Ablation resistance of ZrC/SiC gradient coating for SiC-coated carbon/carbon composites prepared by supersonic plasma spraying. J. Eur. Ceram. Soc. 2016, 36, 3739–3746. [Google Scholar] [CrossRef]

- Hu, M.H.; Li, K.Z.; Li, H.J.; Wang, B.; Ma, H.L. Double layer ZrSi–ZrC–SiC/SiC oxidation protective coating for carbon/carbon composites. Surf. Eng. 2014, 31, 335–341. [Google Scholar] [CrossRef]

- Kim, J.D.; Lee, S.J.; Suh, J. Characteristics of laser assisted machining for silicon nitride ceramic according to machining parameters. J. Mech. Sci. Technol. 2011, 25, 995. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Sayir, A.; Farmer, S.C. The effect of the microstructure on mechanical properties of directionally solidified Al2O3/ZrO2(Y2O3) eutectic. Acta Mater. 2000, 48, 4691–4697. [Google Scholar] [CrossRef]

- Farmer, S.C.; Dickerson, P.O.; Yun, H.M. High Temperature Mechanical Properties of Al2O3/ZrO2(Y2O3)Fibers. MRS Online Proc. Libr. 1994, 365. [Google Scholar] [CrossRef]

- Martinez Fernandez, J.; Sayir, A.; Farmer, S.C. High temperature creep deformation of directionally solidified Al2O3/Er3Al5O12. Acta Mater. 2003, 51, 1705–1720. [Google Scholar] [CrossRef]

- Waku, Y. A New Ceramic Eutectic Composite with High Strength at High Temperatures. Key Eng. Mater. 1998, 161, 155–160. [Google Scholar] [CrossRef]

- Londaitzbéhère, L.; Lartigue-Korinek, S.; Mazerolles, L. Microstructure, interfaces and creep behaviour of Al2O3–Sm2O3(ZrO2) eutectic ceramic composites. J. Mater. Sci. 2017, 52, 1–14. [Google Scholar] [CrossRef]

- Liu, Z.; Song, K.; Gao, B.; Tian, T.; Yang, H.; Lin, X.; Huang, W. Microstructure and Mechanical Properties of Al2O3/ZrO2 Directionally Solidified Eutectic Ceramic Prepared by Laser 3D Printing. J. Mater. Sci. Technol. 2016, 32, 320–325. [Google Scholar] [CrossRef]

- Nakagawa, N.; Ohtsubo, H.; Waku, Y.; Yugami, H. Thermal emission properties of Al2O3/Er3Al5O12 eutectic ceramics. J. Eur. Ceram. Soc. 2005, 25, 1285–1291. [Google Scholar] [CrossRef]

- Hu, H.Q. Metal Solidification Principle; Machinery Industry Press: Beijing, China, 2000. [Google Scholar]

- Tyschenko, J.S.; Lakiza, S.M.; Lopato, L.M. Phase Diagram of the Al2O3–HfO2–Er2O3 System. J. Am. Ceram. Soc. 2012, 95, 4015–4020. [Google Scholar] [CrossRef]

- Deng, Y.F.; Zhang, J.; Haijun, S.U.; Song, K.; Liu, L.; Hengzhi, F.U. Microstructure and Fracture Toughness of Al2O3/Er3Al5O12 Eutectic Ceramic Prepared by Laser Zone Remelting. J. Inorg. Mater. 2011, 26, 841–846. [Google Scholar] [CrossRef]

- Su, H.J.; Zhang, J.; Ren, Q.; Deng, Y.F.; Liu, L.; Fu, H.Z.; Soh, A.K. Laser zone remelting of Al2O3/Er3Al5O12 bulk oxide in situ composite thermal emission ceramics: Influence of rapid solidification. Mater. Res. Bull. 2013, 48, 544–550. [Google Scholar] [CrossRef]

- Waku, Y.; Nakagawa, N.; Ohtsubo, H.; Mitani, A.; Shimizu, K. Fracture and deformation behaviour of melt growth composites at very high temperatures. J. Mater. Sci. 2001, 36, 1585–1594. [Google Scholar] [CrossRef]

- Mesa, M.C.; Oliete, P.B.; Pastor, J.Y.; Martín, A.; Llorca, J. Mechanical properties up to 1900 K of Al2O3/Er3Al5O12/ZrO2 eutectic ceramics grown by the laser floating zone method. J. Eur. Ceram. Soc. 2014, 34, 2081–2087. [Google Scholar] [CrossRef]

- Lee, J.H.; Yoshikawa, A.; Kaiden, H.; Lebbou, K.; Fukuda, T.; Yoon, D.H.; Waku, Y. Microstructure of Y2O3 doped Al2O3/ZrO2 eutectic fibers grown by the micro-pulling-down method. J. Cryst. Growth 2001, 231, 179–185. [Google Scholar] [CrossRef]

- Mesa, M.C.; Oliete, P.B.; Orera, V.M.; Pastor, J.Y.; Martín, A.; Llorca, J. Microstructure and mechanical properties of Al2O3/Er3Al5O12 eutectic rods grown by the laser-heated floating zone method. J. Eur. Ceram. Soc. 2011, 31, 1241–1250. [Google Scholar] [CrossRef]

- Zhai, S.; Liu, J.; Wang, J. Microstructure of the Directionally Solidified Ternary Eutectic Ceramic Al2O3/MgAl2O4/ZrO2. Ceram. Int. 2016, 42, 8079–8084. [Google Scholar] [CrossRef]

- Mizutani, Y.; Yasuda, H.; Ohnaka, I.; Maeda, N.; Waku, Y. Coupled growth of unidirectionally solidified Al2O3-YAG eutectic ceramics. J. Cryst. Growth 2002, 244, 384–392. [Google Scholar] [CrossRef]

- Ludwig, A.; Leibbrandt, S. Generalised ‘Jackson–Hunt’ model for eutectic solidification at low and large Peclet numbers and any binary eutectic phase diagram. Mater. Sci. Eng. A 2004, 375, 540–546. [Google Scholar] [CrossRef]

- Su, H.; Zhang, J.; Deng, Y.; Liu, L.; Fu, H. A modified preparation technique and characterization of directionally solidified Al2O3/Y3Al5O12 eutectic in situ composites. Scr. Mater. 2009, 60, 362–365. [Google Scholar] [CrossRef]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B. A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Özerdem, E.; Ayas, E. Fabrication and microstructural stability of spark plasma sintered Al2O3/Er3Al5O12 eutectic. Ceram. Int. 2015, 41, 12869–12877. [Google Scholar] [CrossRef]

- Khasanov, O.; Osipov, V.; Dvilis, E.; Kachaev, A.; Khasanov, A.; Shitov, V. Nanoscaled grain boundaries and pores, microstructure and mechanical properties of translucent Yb:[LuxY(1−x)O3] ceramics. J. Alloys Compd. 2011, 509, S338–S342. [Google Scholar] [CrossRef]

- Calderon-Moreno, J.M.; Yoshimura, M. Microstructure and mechanical properties of quasi-eutectic Al2O3–Y3Al5O12–ZrO2 ternary composites rapidly solidified from melt. Mater. Sci. Eng. A 2004, 375, 1246–1249. [Google Scholar] [CrossRef]

- Su, H.; Zhang, J.; Yu, J.; Liu, L.; Fu, H. Rapid solidification and fracture behavior of ternary metastable eutectic Al2O3/YAG/YSZ in situ composite ceramic. Mater. Sci. Eng. A 2011, 528, 1967–1973. [Google Scholar] [CrossRef]

| v (μm/s) | λ (μm) | λ2v |

|---|---|---|

| 1.67 | 6.09 | 61.94 |

| 3.33 | 4.28 | 61.00 |

| 5.00 | 4.28 | 59.51 |

| 6.67 | 3.00 | 60.03 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, C.; Wang, S.; Liu, J.; Zhai, S. Microstructure and Mechanical Properties of Al2O3/Er3Al5O12 Binary Eutectic Ceramic Prepared by Bridgman Method. Materials 2018, 11, 534. https://doi.org/10.3390/ma11040534

Song C, Wang S, Liu J, Zhai S. Microstructure and Mechanical Properties of Al2O3/Er3Al5O12 Binary Eutectic Ceramic Prepared by Bridgman Method. Materials. 2018; 11(4):534. https://doi.org/10.3390/ma11040534

Chicago/Turabian StyleSong, Caiyu, Shunheng Wang, Juncheng Liu, and Shuoyan Zhai. 2018. "Microstructure and Mechanical Properties of Al2O3/Er3Al5O12 Binary Eutectic Ceramic Prepared by Bridgman Method" Materials 11, no. 4: 534. https://doi.org/10.3390/ma11040534

APA StyleSong, C., Wang, S., Liu, J., & Zhai, S. (2018). Microstructure and Mechanical Properties of Al2O3/Er3Al5O12 Binary Eutectic Ceramic Prepared by Bridgman Method. Materials, 11(4), 534. https://doi.org/10.3390/ma11040534