Optimization and Characterization of Preceramic Inks for Direct Ink Writing of Ceramic Matrix Composite Structures

Abstract

:1. Introduction

2. Materials and Methods

2.1. List of Reagents

- Preceramic polymer: poly(methyl-silsesquioxane) Silres MK (Wacker Chemie AG, Nünchritz, Germany);

- Solvent: isopropanol;

- Inert filler: SiC powder Starceram S Grade UF 10 (H.C. Starck Ceramics GmbH, Selb, Germany, d50 = 0.7 µm);

- Dispersant: BYK 180 (BYK-Chemie GmbH, Wesel, Germany);

- Reinforcement: chopped, uncoated carbon fibers MF100 (Ferrari Carbon Srl, Milano, Italy) with a length of 100 µm and a thickness of 7.5 µm;

- Rheology modifier: hydrophobic fumed silica Aerosil R106 (Evonik, Essen, Germany; specific surface area = 220–280 m2/g);

- Crosslinking catalyst: Geniosil GF91 (Wacker Chemie AG, Nünchritz, Germany).

2.2. Preparation of Ink A

- MK dissolution into isopropanol in a 70:30 weight ratio at room temperature via ball milling for ~8 h (higher volumes of the solution were prepared in advance and stored at room temperature in a sealed container);

- Addition of SiC powder and dispersant and mechanical stirring at low speed (<200 rpm) to avoid air entrapment. The SiC powder was added to reduce the formation of cracks upon pyrolysis generated during the polymer-to-ceramic conversion of the preceramic polymer [31]. As the preceramic polymer converts to SiOC in inert atmosphere with a ceramic yield of ~85 wt %, the SiC addition was calculated as a 50:50 weight ratio on the SiOC amount. The dispersant was employed to assure a good dispersion of the powder in the ink.

- Dispersion of carbon fibers (~17 vol % of the ceramized CMC) via mechanical stirring at low speed for ~30 min;

- Addition of fumed silica under mechanical stirring at low speed;

- Addition of GF91 (0.5 wt % ratio on MK) under mechanical stirring at low speed for 10 min to catalyze the crosslinking of the preceramic polymer.

2.3. Preparation of Ink B

- MK dissolution into isopropanol;

- Addition of SiC powder and dispersant; the SiC content was slightly decreased (45:55 weight ratio for the SiOC amount);

- Dispersion of carbon fibers (~21 vol % of the ceramized CMC);

- Controlled evaporation of the solvent achieved by stirring the ink on a hot plate at 100 °C (Ink B) until a thick gel was achieved;

- Addition of GF91.

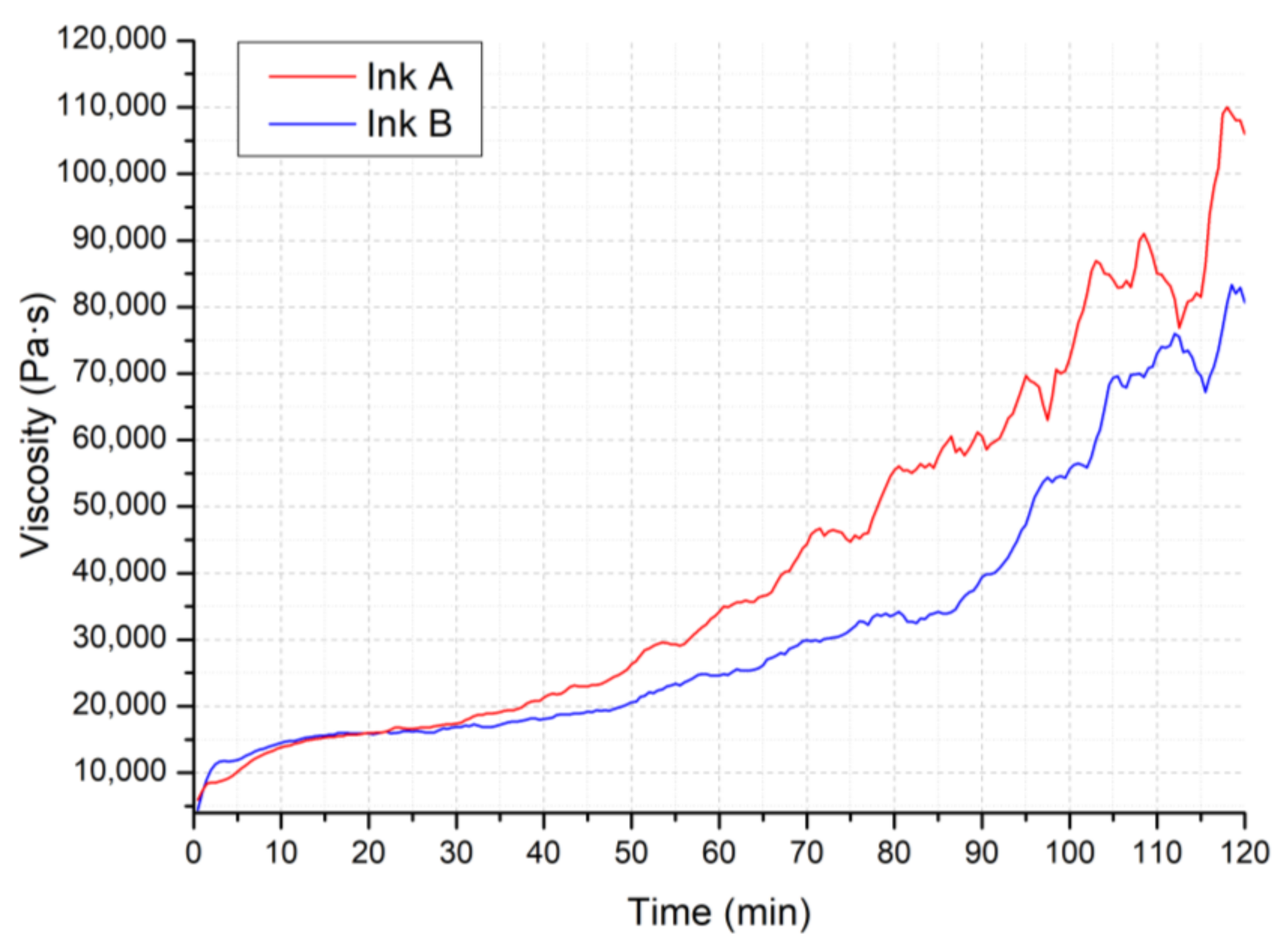

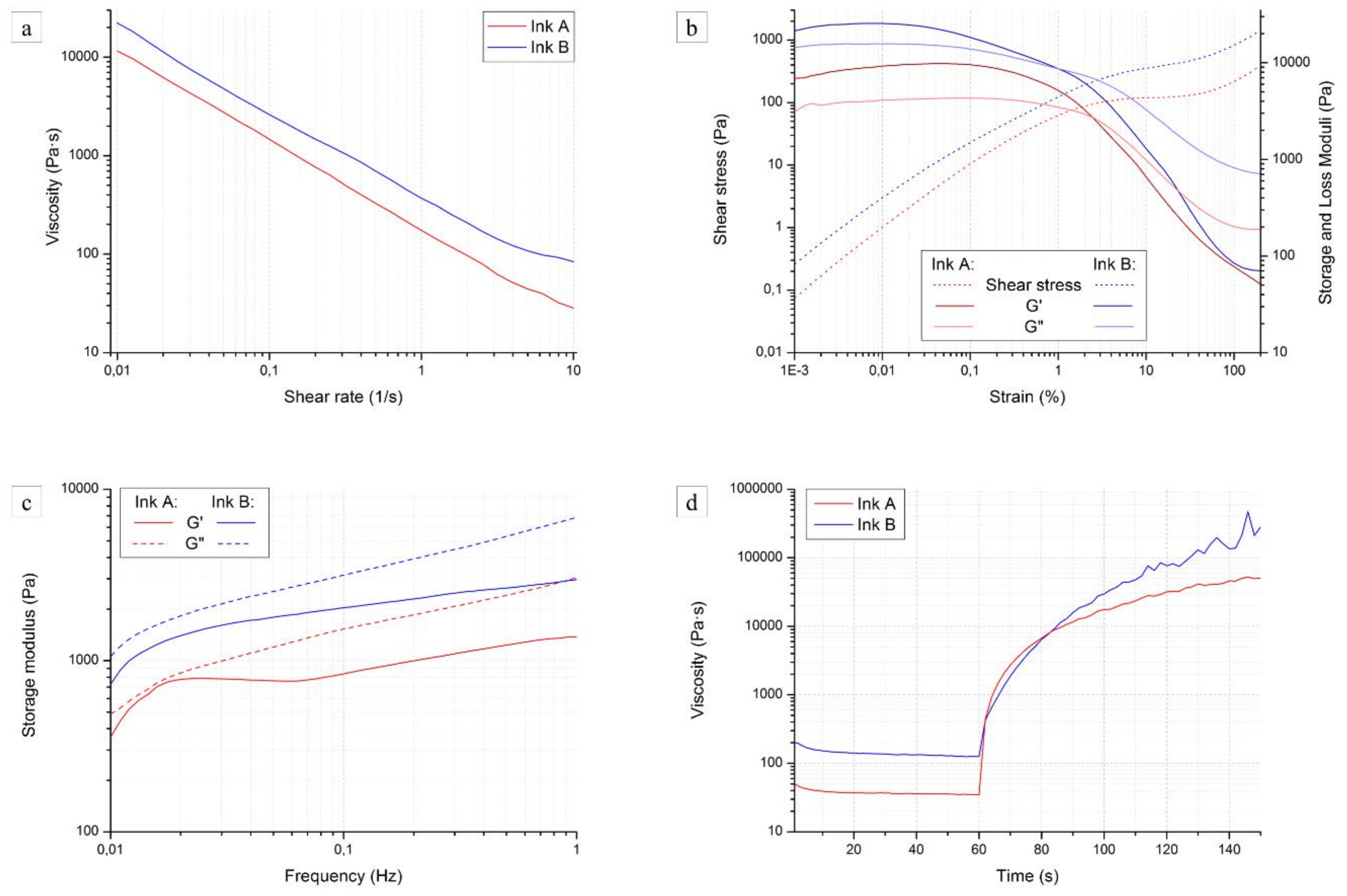

2.4. Rheological Properties

- Working time: constant shear rate of 0.01 1/s over 2 h;

- Steady rate sweep: shear rate increasing from 0.01 to 10 1/s;

- Dynamic strain sweep: strain varying from 0.001 to 100% with a frequency of 1 Hz;

- Dynamic frequency sweep: frequency varying from 0.1 to 100 Hz with a strain of 5%;

- Viscosity recovery, in two steps: first, a shear rate of 10 1/s for 60 s was applied, followed by the application of a controlled shear stress of 15 Pa for 120 s in order to measure the recovery of viscosity. The shear rate needed to be high enough to overcome the initial yield stress of the ink; in the second stage, the shear stress needed to be lower than the yield stress to allow for recovery. Values were chosen according to the results of the first two tests.

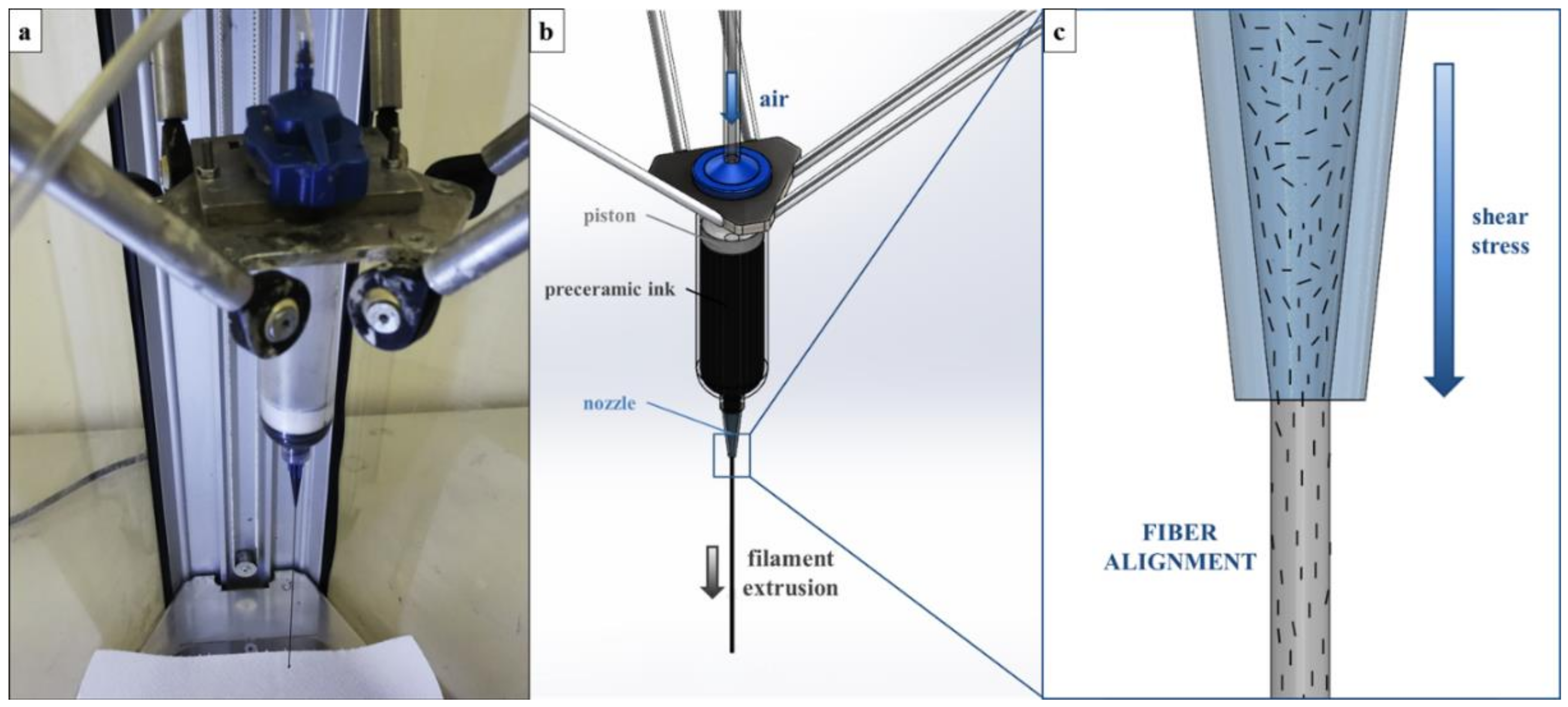

2.5. Extrusion and Pyrolysis of Single Filaments

2.6. Physical Characterization of the Filaments

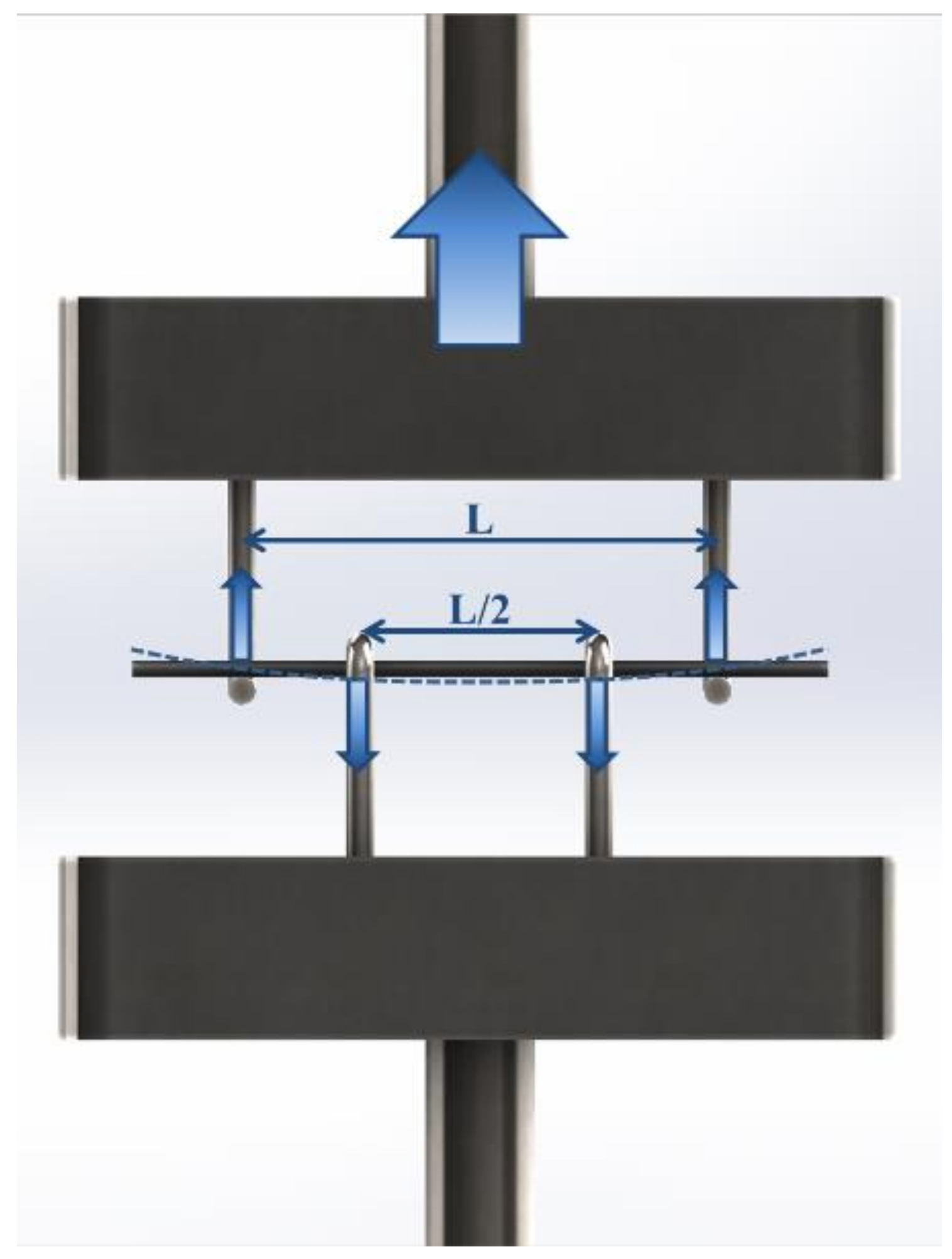

2.7. Four-Point Bending Test

3. Results and Discussion

3.1. Rheological Properties of the Inks

- At low to intermediate strain, both G′ and G′′ showed a plateau, with G′ > G′′; the shear stress increased at a constant rate;

- At high strainer, G′ and G′′ decreased rapidly and intersected; at the same time, the slope of the shear stress decreased;

- After that, all values stabilized again.

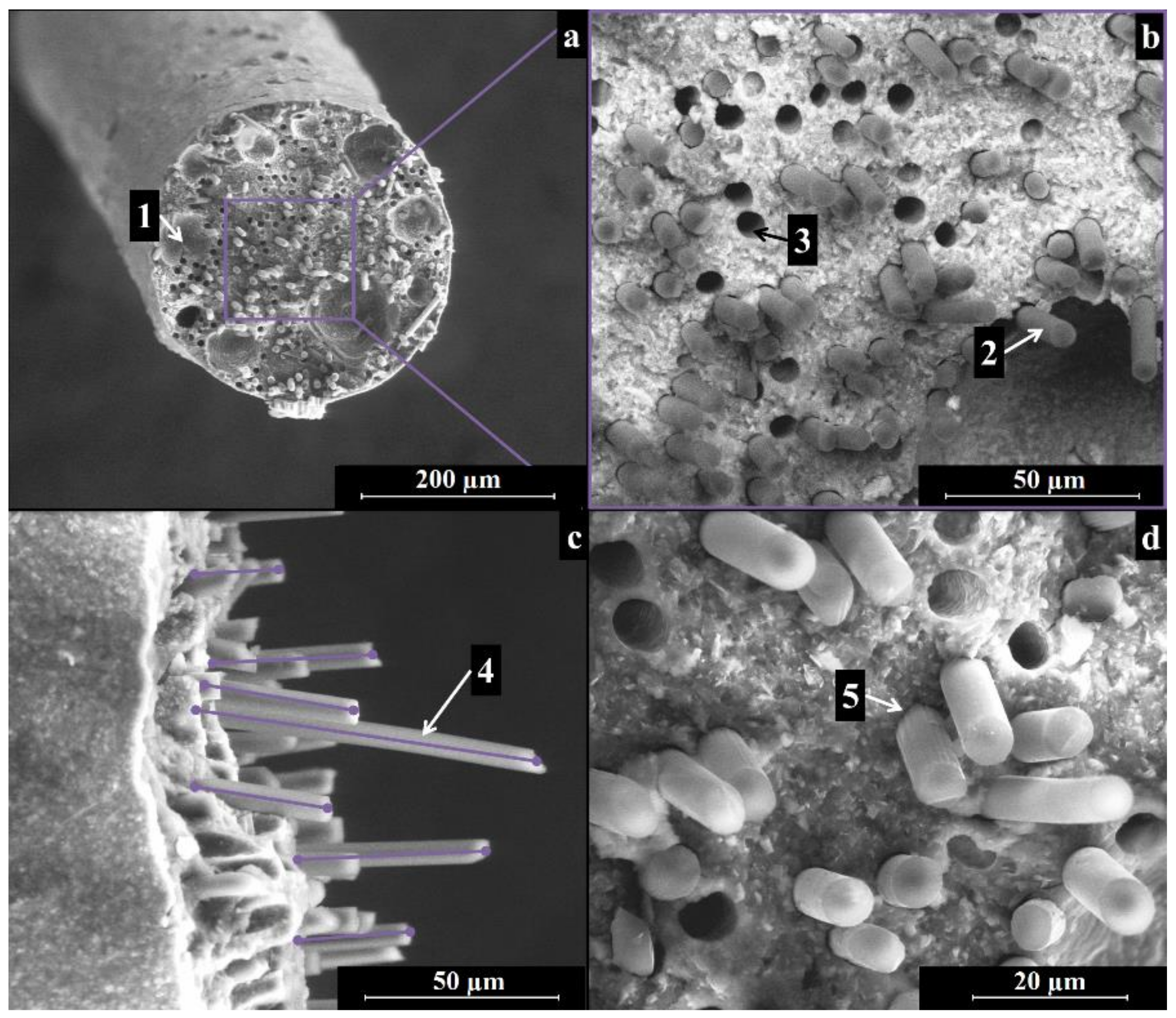

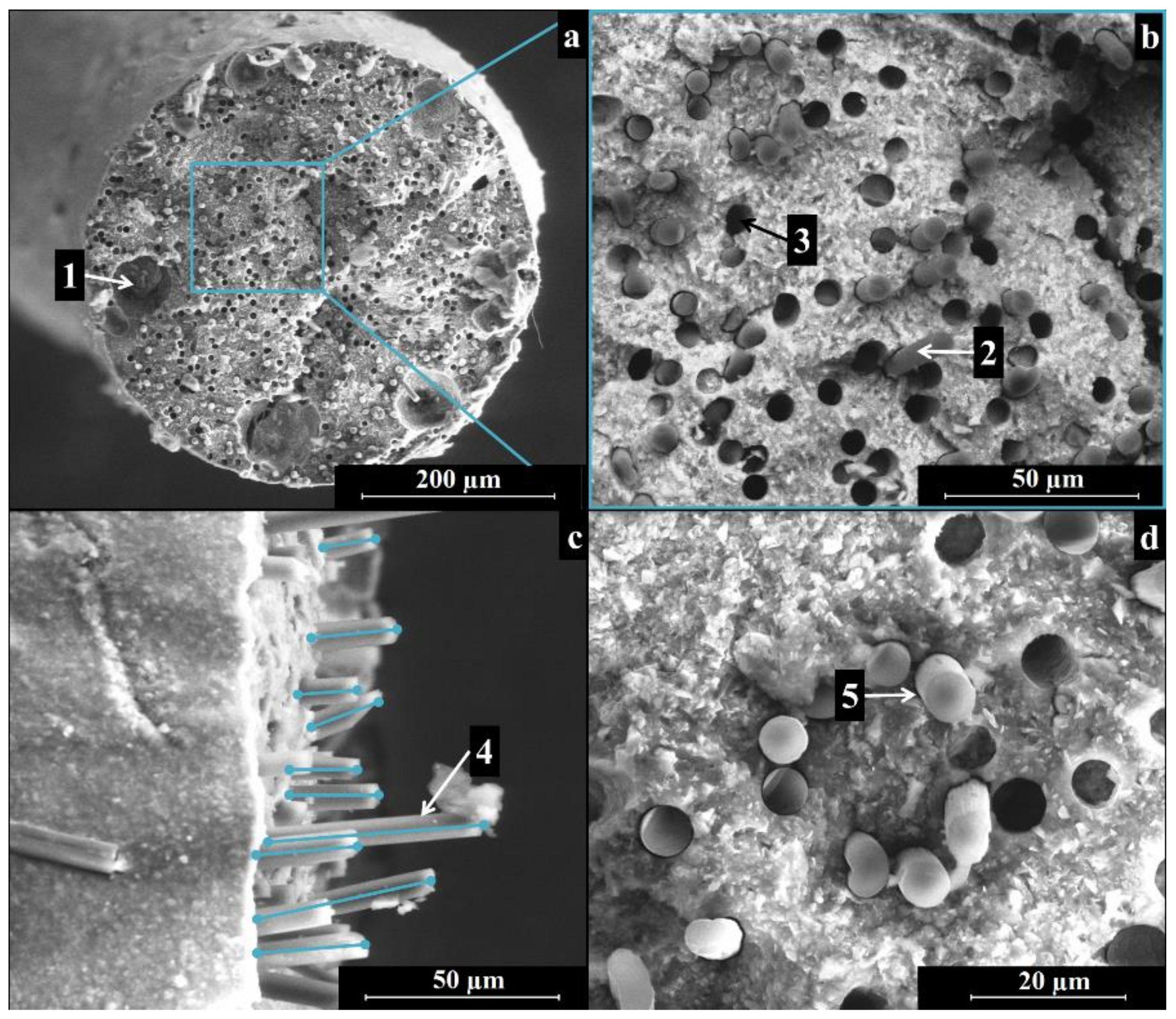

3.2. Filaments Characterization

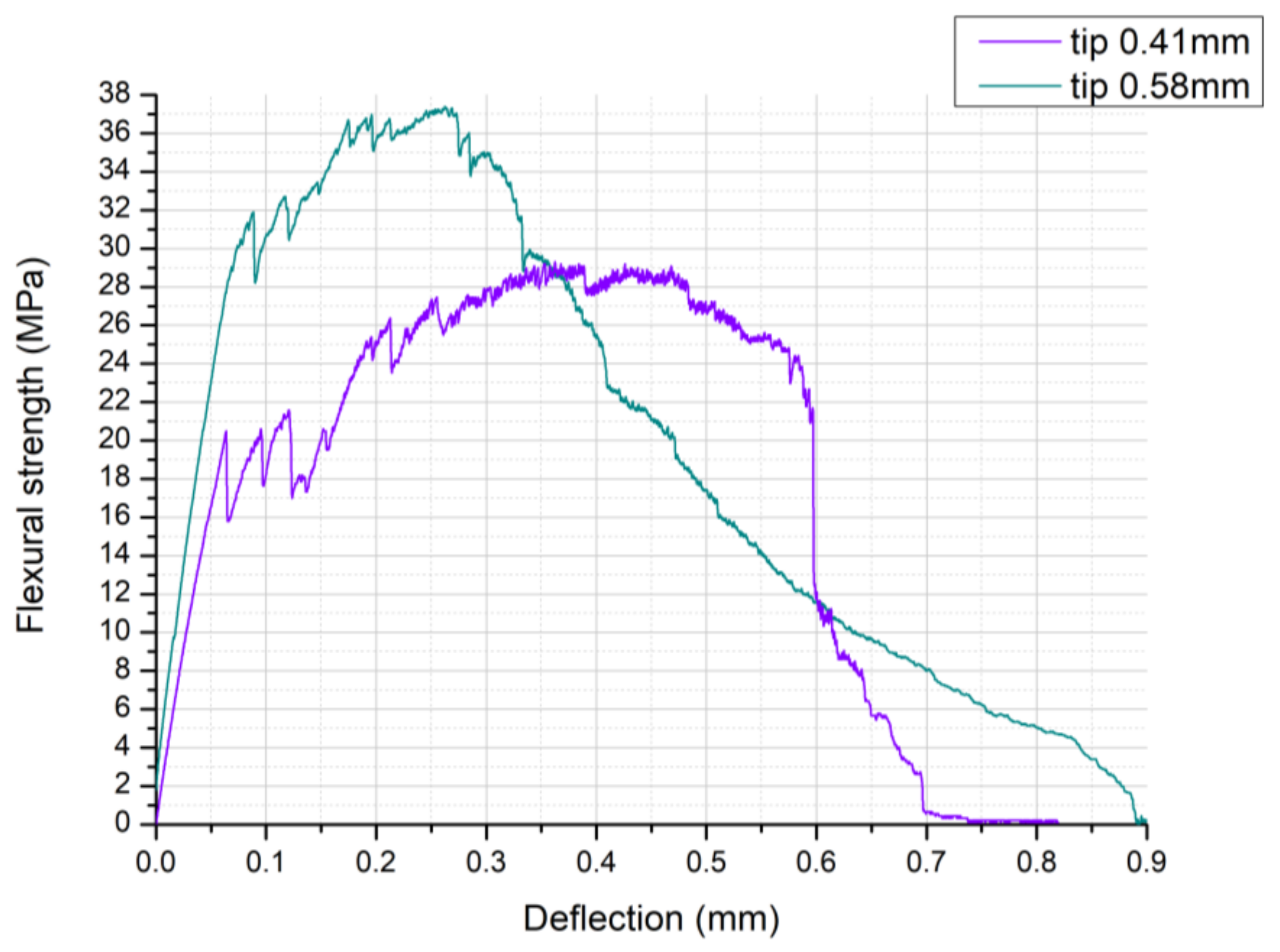

3.3. Four-Point Bending Test

4. Conclusions

- It forms a unique SiOC glassy matrix, which can only be synthesized through a molecular route;

- It allows tailoring of the ink rheology thanks to its intrinsic pseudo-plasticity.

- A dense, crack-free matrix in which the carbon fibers (and the SiC powder) appear homogeneously distributed;

- Affective alignment of the fibers along the filament extrusion direction;

- Fiber pull-out at the fracture surface;

- Moreover, the addition of the carbon fibers provided multiple benefits: for example, they increased the toughness of the filaments, which could deflect consistently before breaking, and they caused graceful, non-catastrophic failure after the maximum stress was reached.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| AM | additive manufacturing |

| c | distance from the neutral axis (mm) |

| CMC | ceramic matrix composite |

| γ | strain (%) |

| γ′ | shear rate (1/s) |

| d | diameter of the tested filament (mm) |

| DIW | direct ink writing |

| EBC | environmental barrier coating |

| F | maximum load (N) |

| FS | fumed silica |

| G′ | storage modulus (Pa) |

| G′′ | loss modulus (Pa) |

| η | viscosity (Pa·s) |

| I | moment of inertia (mm4) |

| l | loading span (mm) |

| L | support span (mm) |

| LAOS | large amplitude oscillatory shear |

| LPI | liquid polymer infiltration |

| M | applied moment (N·mm) |

| MK | poly(methyl-silsequioxane) Silres MK (Wacker Chemie AG, Nünchritz, DE) |

| PDC | polymer-derived ceramics |

| PIP | polymer infiltration and pyrolysis |

| SEM | scanning electron microscopy |

| flexural strength (MPa) | |

| t | time (min) |

| τ | shear stress (Pa) |

| τy | yield stress (Pa) |

References

- Colombo, P.; Mera, G.; Riedel, R.; Sorarù, G.D. Polymer-Derived Ceramics: 40 Years of Research and Innovation in Advanced Ceramics. J. Am. Ceram. Soc. 2010, 93, 1805–1837. [Google Scholar] [CrossRef]

- Narisawa, M.; Watase, S.; Matsukawa, K.; Dohmaru, T.; Okamura, K. White Si-O-C(-H) particles with photoluminescence synthesized by decarbonization reaction on polymer precursor in a hydrogen atmosphere. Bull. Chem. Soc. Jpn. 2012, 85, 724–726. [Google Scholar] [CrossRef]

- Kim, K.J.; Eom, J.-H.; Kim, Y.-W.; Seo, W.-S. Electrical conductivity of dense, bulk silicon-oxycarbide ceramics. J. Eur. Ceram. Soc. 2015, 35, 1355–1360. [Google Scholar] [CrossRef]

- Toma, L.; Kleebe, H.J.; Müller, M.M.; Janssen, E.; Riedel, R.; Melz, T.; Hanselka, H. Correlation between intrinsic microstructure and piezoresistivity in a SiOC polymer-derived ceramic. J. Am. Ceram. Soc. 2012, 95, 1056–1061. [Google Scholar] [CrossRef]

- Sorarù, G.D.; Modena, S.; Guadagnino, E.; Colombo, P.; Egan, J.; Pantano, C. Chemical Durability of Silicon Oxycarbide Glasses. J. Am. Ceram. Soc. 2002, 85, 1529–1536. [Google Scholar] [CrossRef]

- Perale, G.; Giordano, C.; Daniele, F.; Masi, M.; Colombo, P.; Gottardo, L.; Maccagnan, S. A novel process for the manufacture of ceramic microelectrodes for biomedical applications. Int. J. Appl. Ceram. Technol. 2008, 5, 37–43. [Google Scholar] [CrossRef]

- Zhuo, R.; Colombo, P.; Pantano, C.; Vogler, E.A. Silicon oxycarbide glasses for blood-contact applications. Acta Biomater. 2005, 1, 583–589. [Google Scholar] [CrossRef] [PubMed]

- Mott, M.; Evans, J.R.G. Solid freeforming of silicon carbide by ink-jet printing using a polymeric precursor. J. Am. Chem. Soc. 2001, 84, 307–313. [Google Scholar] [CrossRef]

- Friedel, T.; Travitzky, N.; Niebling, F.; Scheffler, M.; Greil, P. Fabrication of polymer derived ceramic parts by selective laser curing. J. Eur. Ceram. Soc. 2005, 25, 193–197. [Google Scholar] [CrossRef]

- Zocca, A.; Gomes, C.M.; Staude, A.; Bernardo, E.; Günster, J.; Colombo, P. SiOC ceramics with ordered porosity by 3D-printing of a preceramic polymer. J. Mater. Res. 2013, 28, 2243–2252. [Google Scholar] [CrossRef]

- Zocca, A.; Elsayed, H.; Bernardo, E.; Gomes, C.M.; Lopez-Heredia, M.A.; Knabe, C.; Colombo, P.; Gunster, J. 3D-printed silicate porous bioceramics using a non-sacrificial preceramic polymer binder. Biofabrication 2015, 7, 25008. [Google Scholar] [CrossRef] [PubMed]

- Pierin, G.; Grotta, C.; Colombo, P.; Mattevi, C. Direct Ink Writing of micrometric SiOC ceramic structures using a preceramic polymer. J. Eur. Ceram. Soc. 2015, 36, 1589–1594. [Google Scholar] [CrossRef]

- Zocca, A.; Franchin, G.; Elsayed, H.; Gioffredi, E.; Bernardo, E.; Colombo, P. Direct Ink Writing of a Preceramic Polymer and Fillers to Produce Hardystonite (Ca2ZnSi2O7) Bioceramic Scaffolds. J. Am. Ceram. Soc. 2016, 99, 1960–1967. [Google Scholar] [CrossRef]

- Zanchetta, E.; Cattaldo, M.; Franchin, G.; Schwentenwein, M.; Homa, J.; Brusatin, G.; Colombo, P. Stereolithography of SiOC Ceramic Microcomponents. Adv. Mater. 2016, 28, 370–376. [Google Scholar] [CrossRef] [PubMed]

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. Additive manufacturing of polymer-derived ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, J.; Colombo, P. Digital light processing of ceramic components from polysiloxanes. J. Eur. Ceram. Soc. 2018, 38, 57–66. [Google Scholar] [CrossRef]

- Colombo, P.; Schmidt, J.; Franchin, G.; Zocca, A.; Günster, J. Additive manufacturing techniques for fabricating complex ceramic components from preceramic polymers. Am. Ceram. Soc. Bull. 2017, 96, 16–23. [Google Scholar]

- Krenkel, W. Ceramic Matrix Composites—Fiber Reinforced Ceramics and their Applications; WILEY-VCH Verlag: Weinheim, Germany, 2008; ISBN 978-3-527-31361-7. [Google Scholar]

- Krenkel, W.; Langhof, N. Ceramic Matrix Composites for High Performance Friction Applications. In Proceedings of the IV Advanced Ceramics and Applications Conference; Springer: Berlin, Germany, 2017; pp. 13–28. [Google Scholar]

- Brembo SGL Ceramic Carbon Group Carbon Ceramic Technology. Available online: http://www.carbonceramicbrakes.com/en/technology/Pages/Technology.aspx (accessed on 28 February 2018).

- Thomas, D.J. 3-D printing of polymer-derived CMCs for next-generation turbine blade manufacture. Am. Ceram. Soc. Bull. 2017, 96, 28–30. [Google Scholar]

- Azarnoush, S.; Laubscher, F.; Zoli, L.; Raj, R. Additive Manufacturing of SiCN Ceramic Matrix for SiC Fiber Composites by Flash Pyrolysis of Nanoscale Polymer Films. J. Am. Ceram. Soc. 2016, 99, 1855–1858. [Google Scholar] [CrossRef]

- Singh, M.; Halbig, M.C.; Grady, J.E. Additive manufacturing of light weight ceramic matrix composites for gas turbine engine applications. In Ceramic Engineering and Science Proceedings 36 (6); Wiley: Hoboken, NJ, USA, 2016; pp. 145–150. [Google Scholar]

- Christ, S.; Schnabel, M.; Vorndran, E.; Groll, J.; Gbureck, U. Fiber reinforcement during 3D printing. Mater. Lett. 2015, 139, 165–168. [Google Scholar] [CrossRef]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef] [PubMed]

- Kokkinis, D.; Schaffner, M.; Studart, A.R. Multimaterial magnetically assisted 3D printing of composite materials. Nat. Commun. 2015, 6, 8643. [Google Scholar] [CrossRef] [PubMed]

- Erb, R.M.; Libanori, R.; Rothfuchs, N.; Studart, A.R. Composites Reinforced in Three Dimensions by Using Low Magnetic Fields. Science 2012, 335, 199–204. [Google Scholar] [CrossRef] [PubMed]

- Calvert, P.; Lin, T.L.; Martin, H. Extrusion freeform fabrication of chopped-fibre reinforced composites. High Perform. Polym. 1997, 9, 449–456. [Google Scholar] [CrossRef]

- Compton, B.G.; Lewis, J.A. 3D-printing of lightweight cellular composites. Adv. Mater. 2014, 26, 5930–5935. [Google Scholar] [CrossRef] [PubMed]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber-polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Franchin, G.; Wahl, L.; Colombo, P. Direct ink writing of ceramic matrix composite structures. J. Am. Ceram. Soc. 2017. [Google Scholar] [CrossRef]

- Westwood, M.E.; Webster, J.D.; Day, R.J.; Hayes, F.H.; Taylor, R. Review Oxidation protection for carbon fibre composites. J. Mater. Sci. 1996, 31, 1389–1397. [Google Scholar] [CrossRef]

- Mitchell, M.R.; Link, R.E.; Quinn, G.D.; Sparenberg, B.T.; Koshy, P.; Ives, L.K.; Jahanmir, S.; Arola, D.D. Flexural Strength of Ceramic and Glass Rods. J. Test. Eval. 2009, 37, 101649. [Google Scholar] [CrossRef]

- Takahashi, T.; Kachta, J.; Mümstedt, H. Melt rheology and structure of silicone resins. Rheol. Acta 2001, 40, 490–498. [Google Scholar] [CrossRef]

- Harrison, G.; Franks, G. Suspensions and polymers–common links in rheology. Aust. Rheol. 1999, 11, 197–218. [Google Scholar] [CrossRef]

- Hyun, K.; Wilhelm, M.; Klein, C.O.; Cho, K.S.; Nam, J.G.; Ahn, K.H.; Lee, S.J.; Ewoldt, R.H.; McKinley, G.H. A Review of Nonlinear Oscillatory Shear Tests: Analysis and Application of Large Amplitude Oscillatory Shear (LAOS). Prog. Polym. Sci. 2011, 36, 1697–1753. [Google Scholar] [CrossRef]

- Goodyer, S. Measuring Polymers Using a Rotational Rheometer in Oscillatory Mode Product Manager for Rheology; Telford Polymer Association: Telford, UK, 2013; pp. 1–35. [Google Scholar]

| Ink | Isopropyl Alcohol (g) | MK (g) | SiC (g) | Carbon Fibers (g) | Fumed Silica (g) | Crosslinker GF91 (mL) | Dispersant BYK430 (mL) |

|---|---|---|---|---|---|---|---|

| Ink A | 9 | 21 | 17.85 | 5.35 | 2.68 | 0.1 | 1.15 |

| Ink B | 9 (before evaporation) | 21 | 14.88 | 5.95 | / | 0.1 | 0.75 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franchin, G.; Maden, H.S.; Wahl, L.; Baliello, A.; Pasetto, M.; Colombo, P. Optimization and Characterization of Preceramic Inks for Direct Ink Writing of Ceramic Matrix Composite Structures. Materials 2018, 11, 515. https://doi.org/10.3390/ma11040515

Franchin G, Maden HS, Wahl L, Baliello A, Pasetto M, Colombo P. Optimization and Characterization of Preceramic Inks for Direct Ink Writing of Ceramic Matrix Composite Structures. Materials. 2018; 11(4):515. https://doi.org/10.3390/ma11040515

Chicago/Turabian StyleFranchin, Giorgia, Halide Selin Maden, Larissa Wahl, Andrea Baliello, Marco Pasetto, and Paolo Colombo. 2018. "Optimization and Characterization of Preceramic Inks for Direct Ink Writing of Ceramic Matrix Composite Structures" Materials 11, no. 4: 515. https://doi.org/10.3390/ma11040515

APA StyleFranchin, G., Maden, H. S., Wahl, L., Baliello, A., Pasetto, M., & Colombo, P. (2018). Optimization and Characterization of Preceramic Inks for Direct Ink Writing of Ceramic Matrix Composite Structures. Materials, 11(4), 515. https://doi.org/10.3390/ma11040515