Mechanical and Thermal Properties of Dental Composites Cured with CAD/CAM Assisted Solid-State Laser

Abstract

1. Introduction

2. Materials and Methods

2.1. Dental Composites

2.2. Light Curing Units

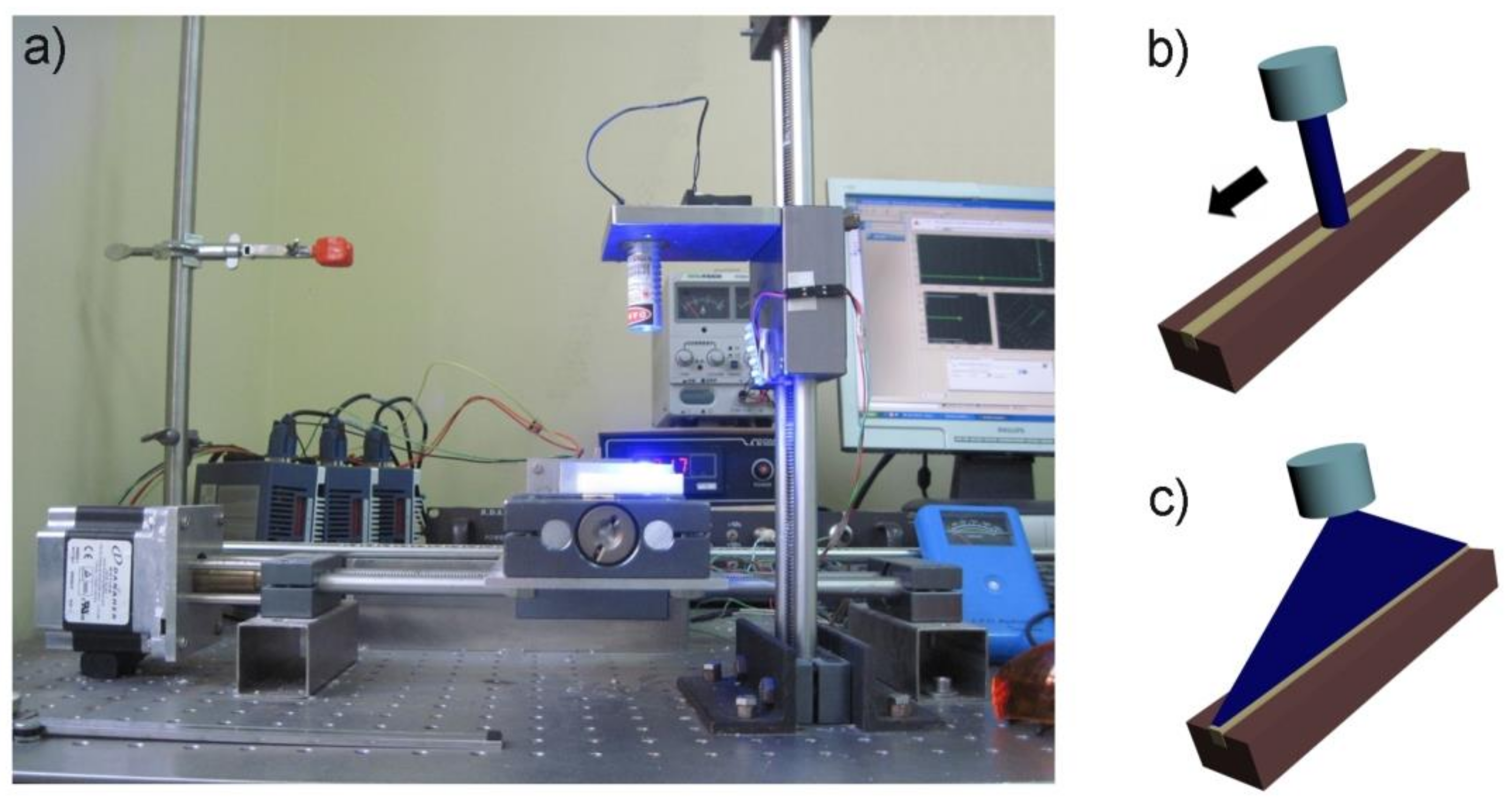

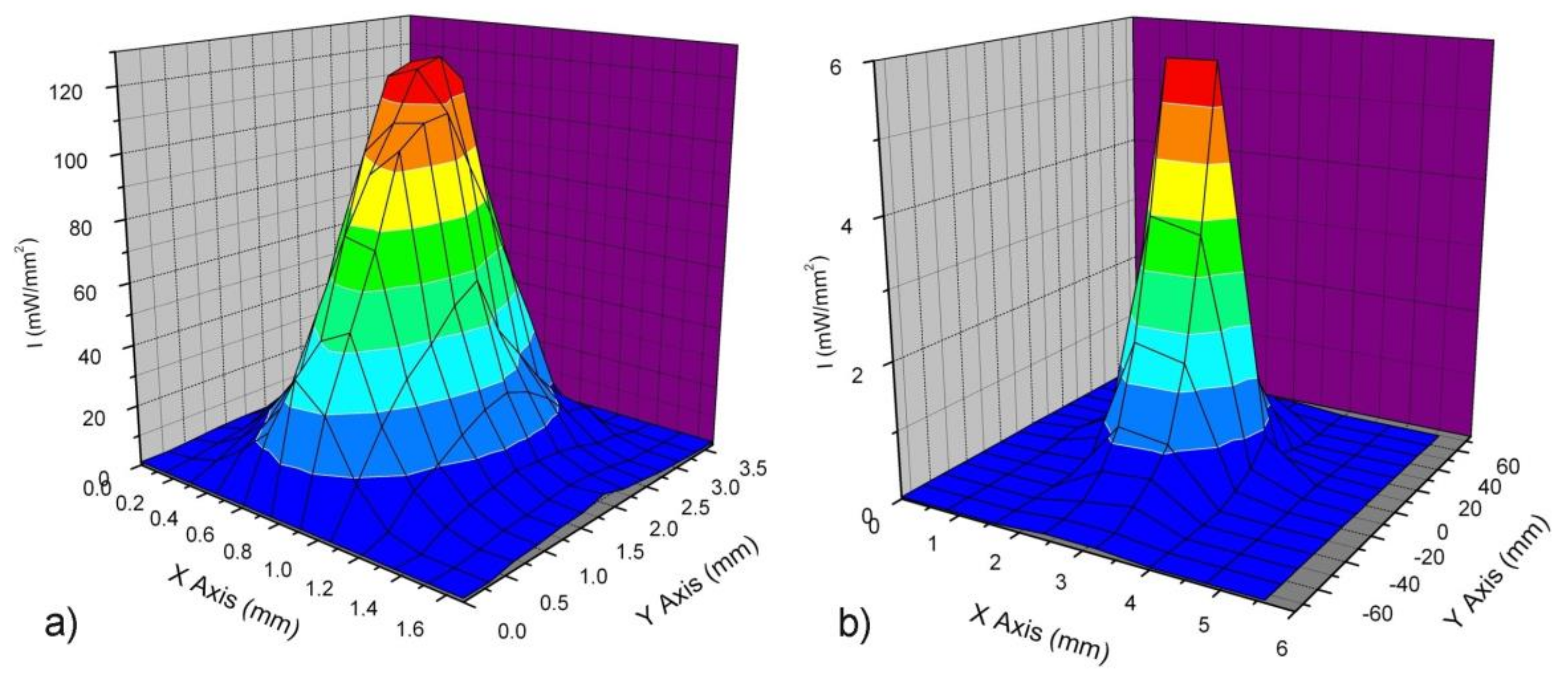

2.3. Optical Measurements

2.4. Specimen Preparation

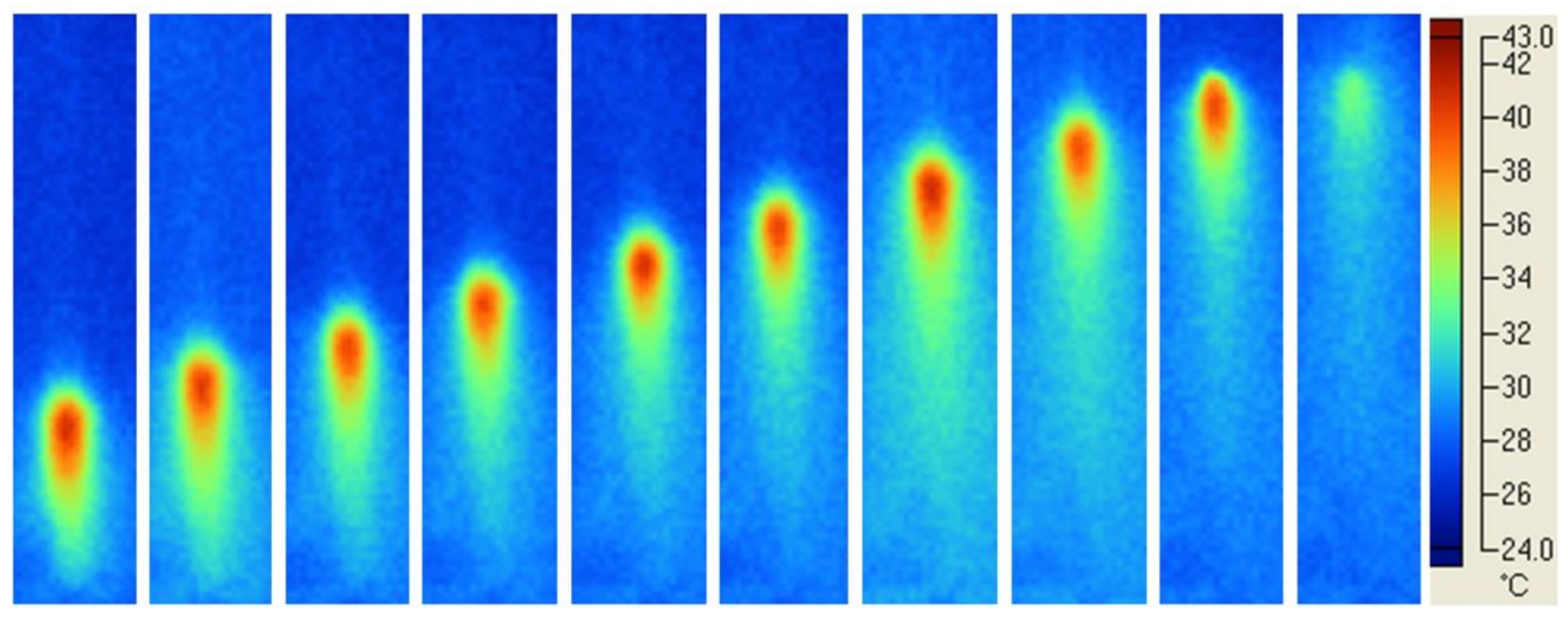

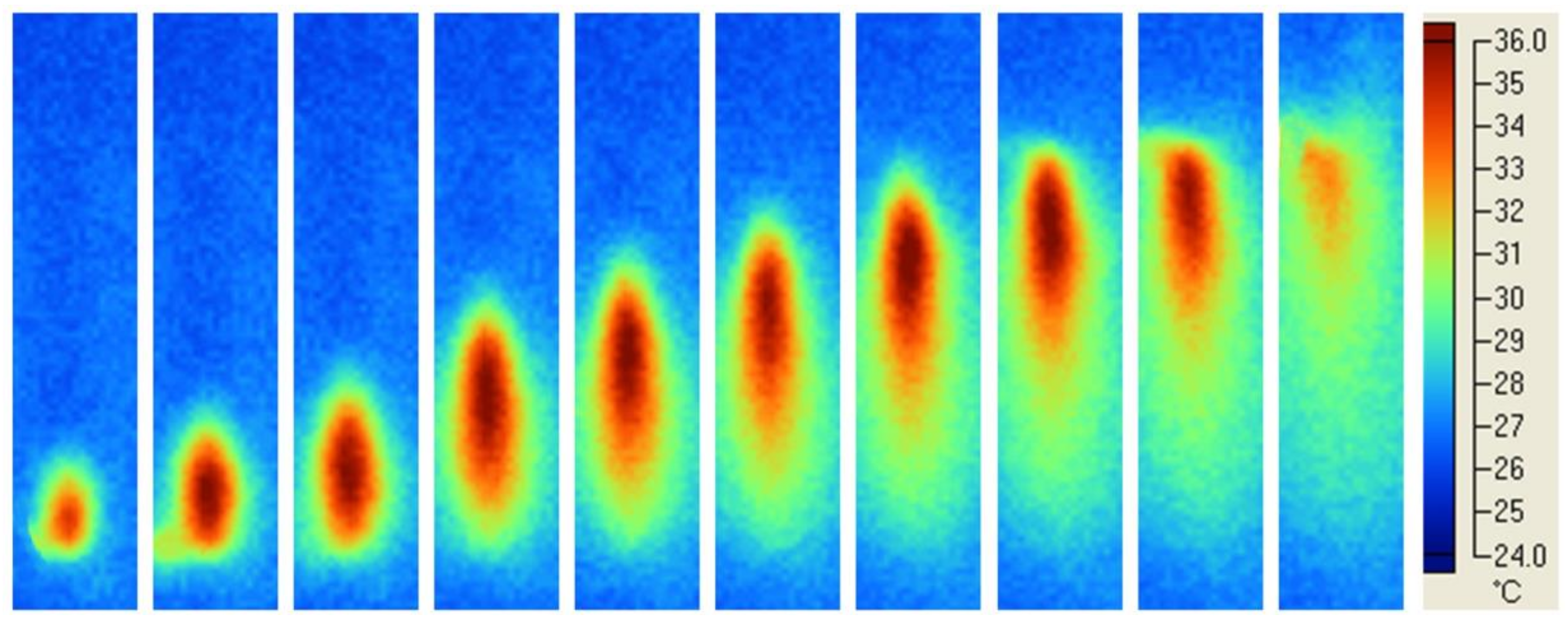

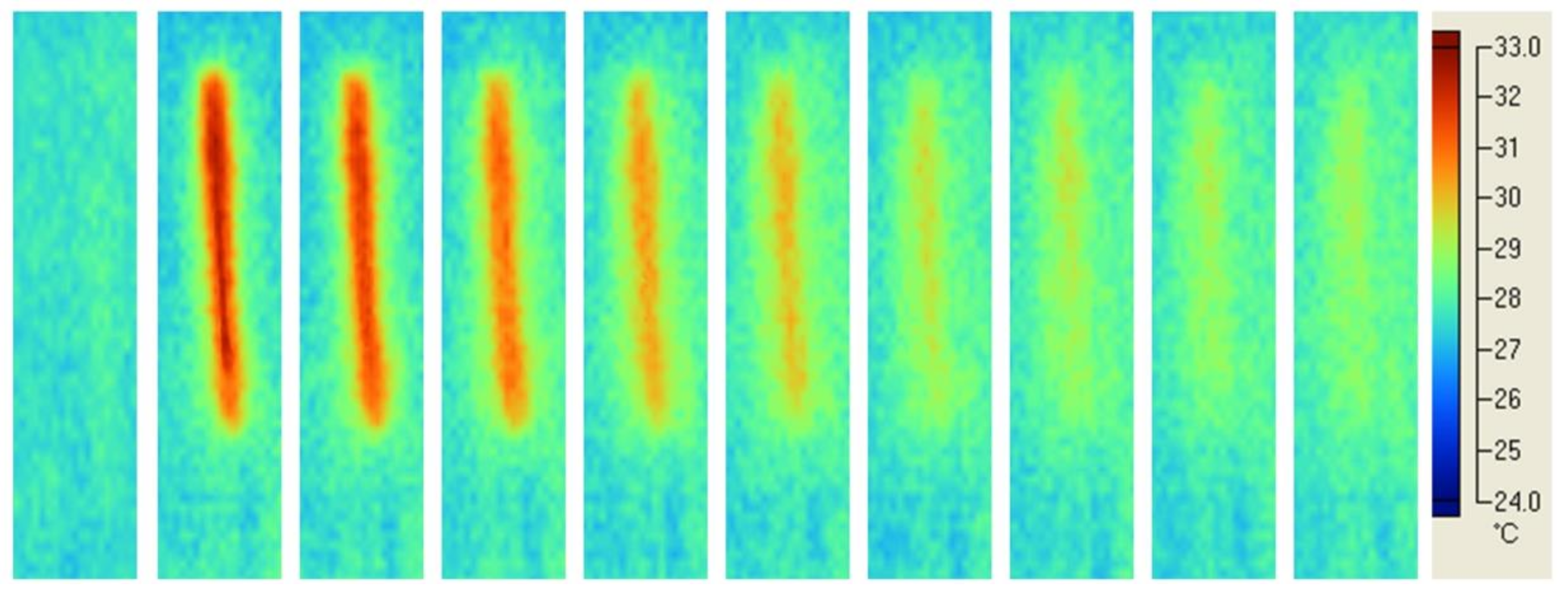

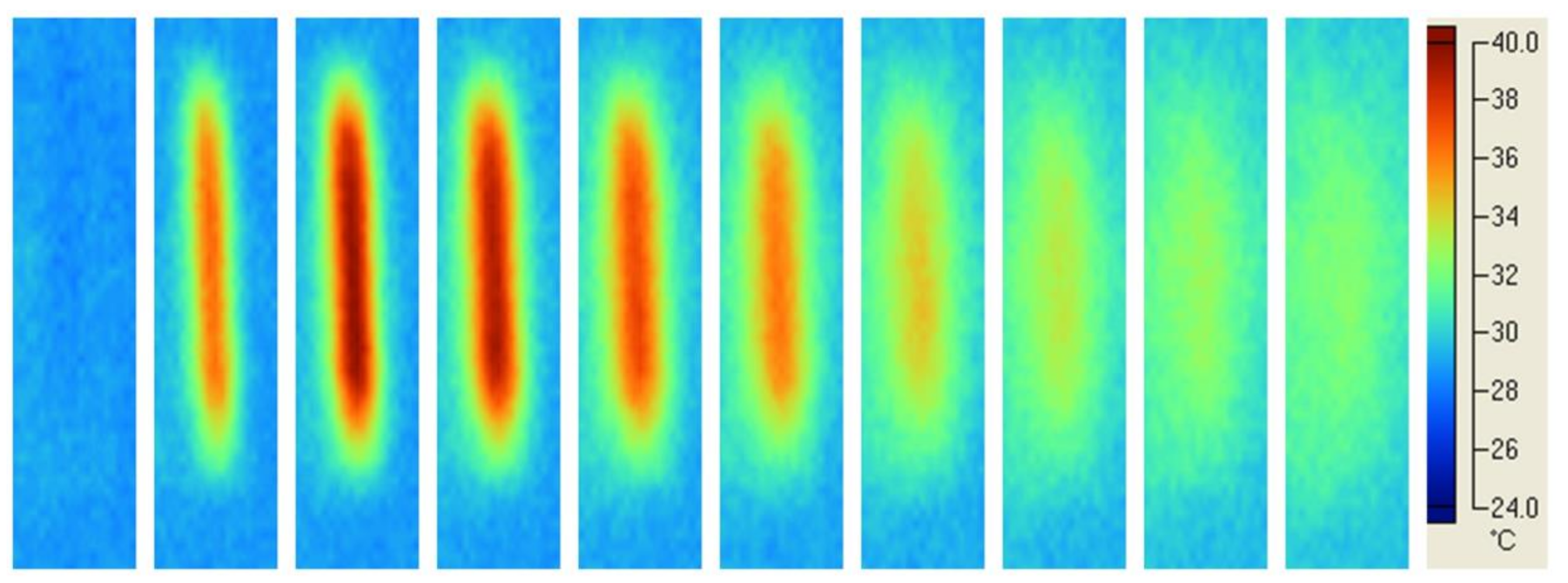

2.5. Temperature Measurements

2.6. Mechanical Tests

3. Results

3.1. Characteristics of LCUs

3.2. Temperature Measurements

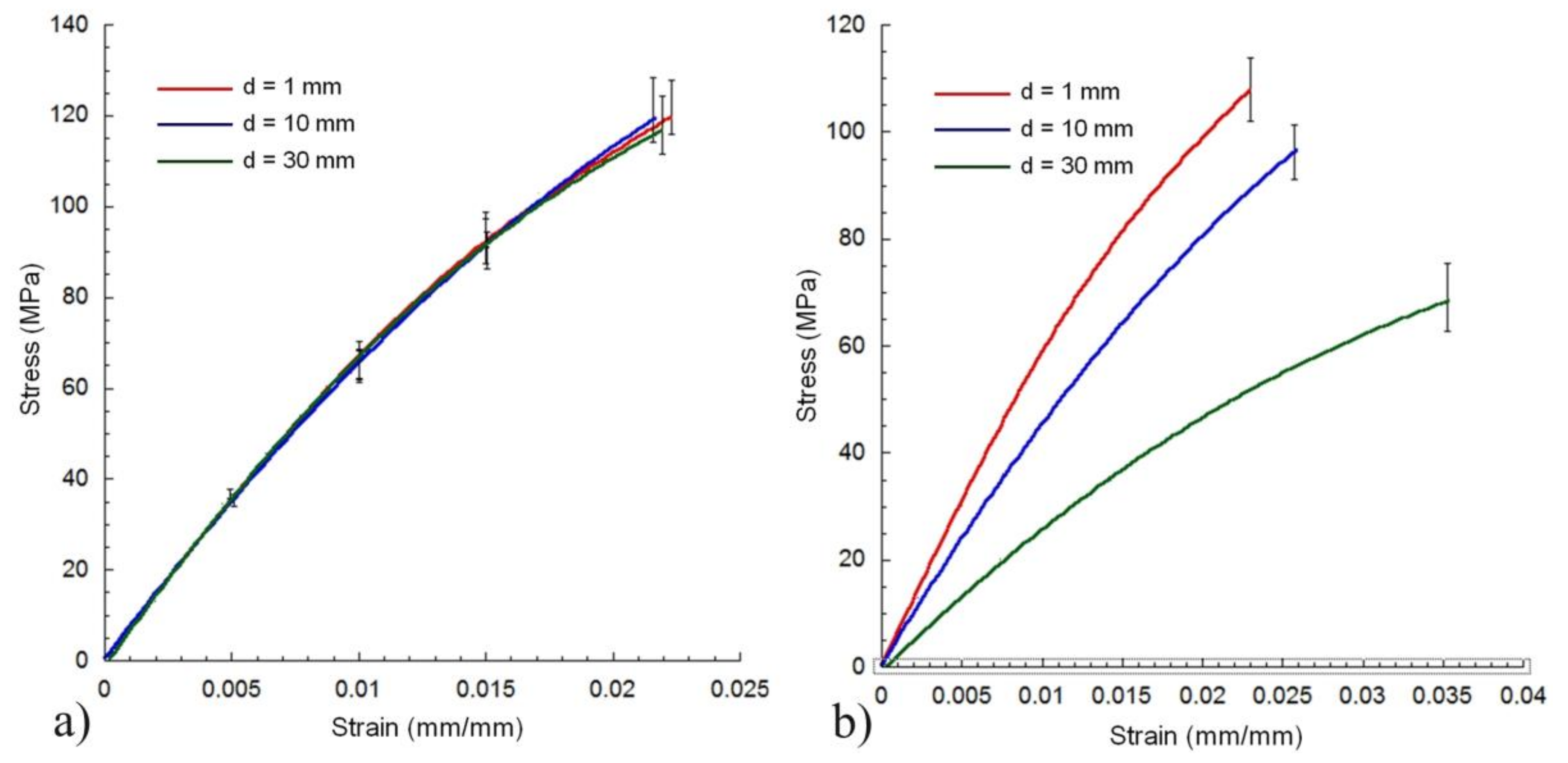

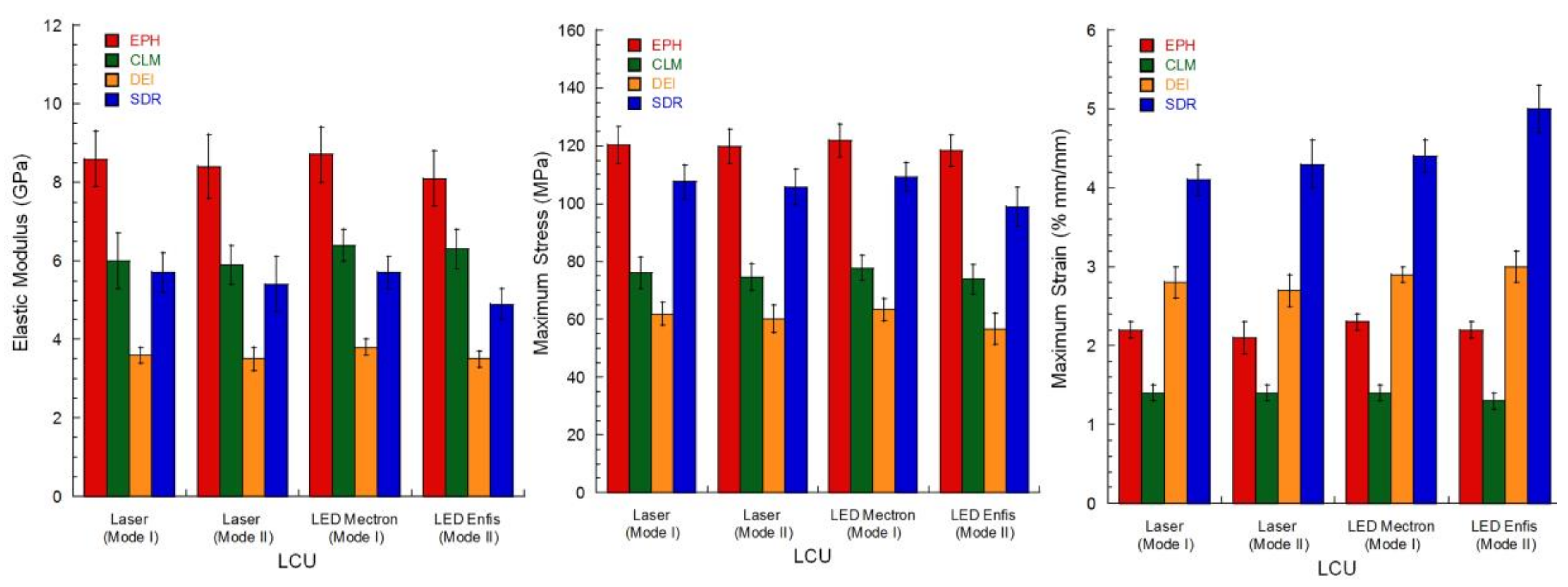

3.3. Mechanical Tests

4. Discussion

5. Conclusions

- Diode laser would be suitable for curing dental composites. Similarly to argon laser, diode laser photopolymerisation does not suffer from the tip-to-tooth distance. This feature is important for the polymerisation of composites deeply positioned into the tooth cavity.

- By providing similar light energy dose, a significant difference in temperature rise was found for laser emitting intensity, that was higher than LED (Mode I).

- By providing similar light energy dose, no significant difference in temperature rise was observed when the two light sources provided similar intensity (Mode II).

- After 7 days since curing, bending properties of composites cured with laser and LED were similar.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mustata, F.; Tudorachi, N.; Bicu, I. Thermosetting resins obtained via sequential photo and thermal crosslinking of epoxy resins. Curing kinetics, thermal properties and morphology. Compos. Part B Eng. 2013, 55, 470–478. [Google Scholar] [CrossRef]

- Ferracane, J.L. Resin composite—State of the art. Dent. Mater. 2011, 27, 29–38. [Google Scholar] [CrossRef] [PubMed]

- Rueggeberg, F.A. State-of-the-art: Dental photocuring—A review. Dent. Mater. 2011, 27, 39–52. [Google Scholar] [CrossRef] [PubMed]

- Ferracane, J.L.; Pfeifer, C.S.; Hilton, T.J. Microstructural features of current resin composite materials. Curr. Oral Health Rep. 2014, 1, 205–212. [Google Scholar] [CrossRef]

- Habib, E.; Wang, R.; Wang, Y.; Zhu, M.; Zhu, X. Inorganic fillers for dental resin composites: Present and future. ACS Biomater. Sci. Eng. 2015, 2, 1–11. [Google Scholar] [CrossRef]

- Thorat, S.; Patra, N.; Ruffilli, R.; Diaspro, A.; Salerno, M. Preparation and characterization of a BisGMA-resin dental restorative composites with glass, silica and Titania fillers. Dent. Mater. J. 2012, 31, 635–644. [Google Scholar] [CrossRef] [PubMed]

- Thorat, S.; Diaspro, A.; Salerno, M. Effect of alumina reinforcing fillers in BisGMA-based resin composites for dental applications. Adv. Mater. Lett. 2013, 4, 15–21. [Google Scholar] [CrossRef]

- Lovell, L.G.; Stansbury, J.W.; Syrpes, D.C.; Bowman, C.N. Effects of composition and reactivity on the reaction kinetics of dimethacrylate/dimethacrylate copolymerizations. Macromolecules 1999, 32, 3913–3921. [Google Scholar] [CrossRef]

- Truffier-Boutry, D.; Gallez, X.A.; Demoustier-Champagne, S.; Devaux, J.; Mestdagh, M.; Champagne, B.; Leloup, G. Identification of free radicals trapped 6 in solid methacrylated resins. J. Polym. Sci. Polm. Chem. 2003, 41, 1691–1699. [Google Scholar] [CrossRef]

- Bindu, M.G.; Satapathy, B.K.; Jaggi, H.S.; Ray, A.R. Size-scale effects of silica on bis-GMA/TEGDMA based nanohybrid dental restorative composites. Compos. Part B Eng. 2013, 53, 92–102. [Google Scholar] [CrossRef]

- Ferracane, J.L.; Greener, E.H. The effect of resin formulation on the degree of conversion and mechanical properties of dental restorative resins. J. Biomed. Mater. Res. 2004, 20, 121–131. [Google Scholar] [CrossRef] [PubMed]

- Rameshbabu, A.P.; Mohanty, S.; Bankoti, K.; Ghosh, P.; Dhara, S. Effect of alumina, silk and ceria short fibers in reinforcement of Bis-GMA/TEGDMA dental resin. Compos. Part B Eng. 2015, 70, 238–246. [Google Scholar] [CrossRef]

- De Santis, R.; Gloria, A.; Ambrosio, L.; Nicolais, L. Recent patents on light curing of dental materials. Recent Pat. Biomed. Eng. 2009, 2, 97–109. [Google Scholar] [CrossRef]

- De Santis, R.; Gloria, A.; Sano, H.; Amendola, E.; Prisco, D.; Mangani, F.; Rengo, S.; Ambrosio, L.; Nicolais, L. Effect of light curing and dark reaction phases on the thermomechanical properties of a Bis-GMA based dental restorative material. J. Appl. Biomater. Biomech. 2009, 7, 132–140. [Google Scholar] [PubMed]

- Kelsey, W.P.; Blankenau, R.J.; Powell, G.L.; Barkmeier, W.W.; Cavel, W.T.; Whisenant, B.K. Enhancement of physical properties of resin restorative materials by laser polymerization. Laser Surg. Med. 1989, 9, 623–627. [Google Scholar] [CrossRef]

- Pradhan, R.; Melikechi, N.; Eichmiller, F. Effect of Source Bandwidth, Focusing and Fluence on the Depth of Cure in Polymer Dental Composites. In Proceedings of the APS Meeting Abstracts of the American Physical Society Annual March Meeting, Minneapolis, MN, USA, 20–24 March 2000. [Google Scholar]

- Fleming, M.G.; Maillet, W.A. Photopolymerization of composite resin using the argon laser. J. Can. Dent. Assoc. 1999, 65, 447–452. [Google Scholar] [PubMed]

- Kwon, Y.H.; Jang, C.M.; Shin, D.H.; Seol, H.J.; Kim, H.I. The applicability of DPSS laser for light curing of composite resins. Laser Med. Sci. 2008, 23, 407–414. [Google Scholar] [CrossRef] [PubMed]

- Powell, G.L.; Blankenau, R.J. Laser curing of dental materials. Dent. Clin. N. Am. 2000, 44, 923–930. [Google Scholar] [PubMed]

- Lloret, P.R.; Turbino, M.L.; Kawano, Y.; Aguilera, F.S.; Osorio, R.; Toledano, M. Flexural properties, microleakage, and degree of conversion of a resin polymerized with conventional light and argon laser. Quintessence Int. 2008, 39, 581–586. [Google Scholar]

- Kameyama, A.; Hatayama, H.; Kato, J.; Haruyama, A.; Teraoka, H.; Takase, Y.; Yoshinari, M.; Tsunoda, M. Light-curing of dental resins with GaN violet laser diode: The effect of photoinitiator on mechanical strength. Laser Med. Sci. 2011, 26, 279–283. [Google Scholar] [CrossRef] [PubMed]

- Rastelli, A.N.; Andrade, M.F.; Bagnato, V.S. Polymerization of Composite Resin Using Different Light-curing Units by Direct and Indirect Techniques. J. Oral Laser Appl. 2008, 8, 175–182. [Google Scholar]

- Pradhan, R.D.; Melikechi, N.; Eichmiller, F. The effect of irradiation wavelength bandwidth and spot size on the scraping depth and temperature rise in composite exposed to an argon laser or a conventional quartz–tungsten–halogen source. Dent. Mater. 2002, 18, 221–226. [Google Scholar] [CrossRef]

- Rode, K.M.; de Freitas, P.M.; Lloret, P.R.; Powell, L.G.; Turbino, M.L. Micro-hardness evaluation of a micro-hybrid composite resin light cured with halogen light, light-emitting diode and argon ion laser. Laser Med. Sci. 2009, 24, 87–92. [Google Scholar] [CrossRef] [PubMed]

- Bouillaguet, S.; Caillot, G.; Forchelet, J.; Cattani-Lorente, M.; Wataha, J.C.; Krejci, I. Thermal risks from LED-and high-intensity QTH-curing units during polymerization of dental resins. J. Biomed. Mater. Res. B Appl. Biomater. 2005, 72, 260–267. [Google Scholar] [CrossRef] [PubMed]

- De Santis, R.; Gloria, A.; Prisco, D.; Amendola, E.; Puppulin, L.; Pezzotti, G.; Rengo, S.; Ambrosio, L.; Nicolais, L. Fast curing of restorative materials through the soft light energy release. Dent. Mater. 2010, 26, 891–900. [Google Scholar] [CrossRef] [PubMed]

- Simeone, M.; De Santis, R.; Ametrano, G.; Prisco, D.; Borrelli, M.; Paduano, S.; Riccitiello, F.; Spagnuolo, G. Temperature Profiles Along the Root with Gutta-percha Warmed through Different Heat Sources. Open Dent. J. 2014, 8, 229–235. [Google Scholar] [PubMed]

- Meniga, A.; Tarle, Z.; Ristic, M.; Sutalo, J.; Pichler, G. Pulsed blue laser curing of hybrid composite resins. Biomaterials 1997, 18, 1349–1354. [Google Scholar] [CrossRef]

- Pal, R. New models for effective Young’s modulus of particulate composites. Compos. Part B Eng. 2005, 36, 513–523. [Google Scholar] [CrossRef]

- Mollica, F.; De Santis, R.; Ambrosio, L.; Nicolais, L.; Prisco, D.; Rengo, S. Mechanical and leakage behaviour of the dentin-adhesive interface. J. Mater. Sci. Mater. Med. 2004, 15, 485–492. [Google Scholar] [CrossRef] [PubMed]

- Chadda, H.; Satapathy, B.K.; Patnaik, A.; Ray, A.R. Mechanistic interpretations of fracture toughness and correlations to wear behavior of hydroxyapatite and silica/hydroxyapatite filled bis-GMA/TEGDMA micro/hybrid dental restorative composites. Compos. Part B Eng. 2017, 130, 132–146. [Google Scholar] [CrossRef]

- Fischer, N.G.; Wong, J.; Baruth, A.; Cerutis, D.R. Effect of Clinically Relevant CAD/CAM Zirconia Polishing on Gingival Fibroblast Proliferation and Focal Adhesions. Materials 2017, 10, 1358. [Google Scholar] [CrossRef] [PubMed]

- De Santis, R.; D’Amora, U.; Russo, T.; Ronca, A.; Gloria, A.; Ambrosio, L. 3D fibre deposition and stereolithography techniques for the design of multifunctional nanocomposite magnetic scaffolds. J. Mater. Sci. Mater. Med. 2015, 26, 250. [Google Scholar] [CrossRef] [PubMed]

- Martorelli, M.; Maietta, S.; Gloria, A.; De Santis, R.; Pei, E.; Lanzotti, A. Design and analysis of 3D customized models of a human mandible. Procedia CIRP 2016, 49, 199–202. [Google Scholar] [CrossRef]

- Almohaimeed, M.; El Halim, S.A. Influence of Polishing Procedures on Properties of Nano-Composite Resins. Life Sci. J. 2014, 11, 120–124. [Google Scholar]

- Chapple, P.B. Beam waist and M 2 measurement using a finite slit. Opt. Eng. 1994, 33, 2461–2467. [Google Scholar] [CrossRef]

- Riza, N.A.; Mughal, M.J. Optical power independent optical beam profiler. Opt. Eng. 2004, 43, 793–798. [Google Scholar] [CrossRef]

- Sheikh, M.; Riza, N.A. Demonstration of pinhole laser beam profiling using a digital micromirror device. IEEE Photonic Technol. Lett. 2009, 21, 666–668. [Google Scholar] [CrossRef]

- Rockwell, D.A. A review of phase-conjugate solid-state lasers. IEEE J. Quantum Electron. 1988, 24, 1124–1140. [Google Scholar] [CrossRef]

- Soto, J.; Rendón, M.; Martín, M. Experimental demonstration of tomographic slit technique for measurement of arbitrary intensity profiles of light beams. Appl. Opt. 1997, 36, 7450–7454. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Zhou, H.; Chen, Q.; Yang, H.L. Beam profile and frequency distribution characterization of broadband terahertz wave. J. Shenzhen Univ. Sci. Eng. 2010, 27, 167–172. [Google Scholar]

- Janisch, C.; Wang, Y.; Ma, D.; Mehta, N.; Elías, A.L.; Perea-López, N.; Terrones, M.; Crespi, V.; Liu, Z. Extraordinary second harmonic generation in tungsten disulfide monolayers. Sci. Rep. 2014, 4, 5530. [Google Scholar] [CrossRef] [PubMed]

- Davis, C.C. Lasers and Electro-Optics: Fundamentals and Engineering; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Gan, Z.; Tang, Q. Visual Sensing and Its Applications: Integration of Laser Sensors to Industrial Robots; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Nomoto, R.; Asada, M.; McCabe, J.F.; Hirano, S. Light exposure required for optimum conversion of light activated resin systems. Dent. Mater. 2006, 22, 1135–1142. [Google Scholar] [CrossRef] [PubMed]

- Musanje, L.; Darvell, B. Polymerization of resin composite restorative materials: Exposure reciprocity. Dent. Mater. 2003, 19, 531–541. [Google Scholar] [CrossRef]

- Chung, C.-M.; Kim, J.-G.; Kim, M.-S.; Kim, K.-M.; Kim, K.-N. Development of a new photocurable composite resin with reduced curing shrinkage. Dent. Mater. 2002, 18, 174–178. [Google Scholar] [CrossRef]

- Calheiros, F.C.; Braga, R.R.; Kawano, Y.; Ballester, R.Y. Relationship between contraction stress and degree of conversion in restorative composites. Dent. Mater. 2004, 20, 939–946. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, A.; Ario, S. Resin-based composite and LCU-related factors affecting the degree of cure. A literature review: Part 2. Light curing units & related factors. Acta Med. Marisiensis 2015, 61, 255–260. [Google Scholar]

- Aldossary, M.; Roebuck, E.M.; Santini, A. Bulk fill resin composite materials cured with single-peak versus dual-peak LED LCUs. Acta Med. Marisiensis 2016, 62, 5–14. [Google Scholar] [CrossRef][Green Version]

- Lindberg, A.; Peutzfeldt, A.; van Dijken, J.W. Effect of power density of curing unit, exposure duration, and light guide distance on composite depth of cure. Clin. Oral Investig. 2005, 9, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Halvorson, R.H.; Erickson, R.L.; Davidson, C.L. Energy dependent polymerization of resin-based composite. Dent. Mater. 2002, 18, 463–469. [Google Scholar] [CrossRef]

- Watts, D.C.; Al Hindi, A. Intrinsic ‘soft-start’ polymerisation shrinkage-kinetics in an acrylate-based resin-composite. Dent. Mater. 1999, 15, 39–45. [Google Scholar] [CrossRef]

- Fusco, R.; d’Apuzzo, F.; De Santis, R.; Prisco, D.; Perillo, L. SLER® (Soft Light Energy Release)—A Novel Curing Technology for Orthodontic Bracket Bonding. Dentistry 2013, 3, 166. [Google Scholar]

| Composite | Code | Type | Manufacturer | Organic Matrix | Inorganic Phase |

|---|---|---|---|---|---|

| Enamel plus Hri | EPH | UD2 | Micerium | UDMA, Bis-GMA, BDDMA | Glass filler, Silicon dioxide (53 vol %) |

| Clearfil Majesty Esthetic | CLM | A2 | Kuraray | Bis-GMA, Hydrophobic aromatic dimethacrylate | Silanated barium glass filler (66 vol %) |

| DEI | DEI | Enamel | DEI Italia | Bis-GMA, UDMA TEGDMA, EBPADMA | Vitreous fillers; pyrogenic silica |

| Smart dentine Replacement | SDR | Flowable Base | Dentsply | Modified UDMA, EBPADMA, TEGDMA | Barium and strontium alumino-fluoro-silicate glasses (45 vol %) |

| Source | Manufacturer | Measured Wavelength (nm) | Optical Power (mW) | Electric Voltage (V) | Electric Current (A) | Electric Power (W) | Optical Energy (J) |

|---|---|---|---|---|---|---|---|

| Blue laser BM-200MW | Sothiclasers | 451 | 185 | 12 | 0.31 | 3.72 | 4.85 (Mode I) |

| 4.93 (Mode II) | |||||||

| Blue LED Dental Starlight | Mectron | 460 | 497 | 19 | 0.42 | 7.98 | 4.89 (Mode I) |

| Blue LED Light engine | 458 | Enfis Uno | 4680 | 12 | 3.57 | 42.84 | 4.86 (Mode II) |

| Light Source | EPH | DEI | CLM | SDR |

|---|---|---|---|---|

| Laser (Mode I) | 19.2 (±1.7) | 15.4 (±1.1) | 14.4 (±1.3) | 18.7 (±1.5) |

| Laser (Mode II) | 14.5 (±0.9) | 10.1 (±0.7) | 9.8 (±0.8) | 14.6 (±1.2) |

| LED Mectron (Mode I) | 16.3 (±1.3) | 12.2 (±1.3) | 12.1 (±1.4) | 15.3 (±1.5) |

| LED Enfis (Mode II) | 15.2 (±1.5) | 9.5 (±0.8) | 10.4 (±1.3) | 16.2 (±1.4) |

| EPH | DEI | CLM | SDR | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LCU | Elastic Modulus (MPa) | Max. Stress (MPa) | Max. Strain (%) | Elastic Modulus (MPa) | Max. Stress (MPa) | Max. Strain (%) | Elastic Modulus (MPa) | Max. Stress (MPa) | Max. Strain (%) | Elastic Modulus (MPa) | Max. Stress (MPa) | Max. Strain (%) |

| Laser (Mode I) | 8.6 (±0.7) | 120.3 (±6.3) | 2.2 (±0.1) | 3.6 (±0.2) | 61.9 (±4.1) | 2.8 (±0.2) | 6.0 (±0.7) | 76.0 (±5.4) | 1.4 (±0.1) | 5.7 (±0.5) | 107.5 (±5.9) | 4.1 (±0.2) |

| Laser (Mode II) | 8.4 (±0.8) | 119.8 (±5.9) | 2.1 (±0.2) | 3.5 (±0.3) | 60.2 (±4.8) | 2.7 (±0.2) | 5.9 (±0.5) | 74.6 (±4.6) | 1.4 (±0.1) | 5.4 (±0.7) | 105.8 (±6.1) | 4.3 (±0.3) |

| LED Mectron (Mode I) | 8.7 (±0.7) | 121.9 (±5.8) | 2.3 (±0.1) | 3.8 (±0.2) | 63.4 (±3.8) | 2.9 (±0.1) | 6.4 (±0.4) | 77.8 (±4.3) | 1.4 (±0.1) | 5.7 (±0.4) | 109.2 (±4.9) | 4.4 (±0.2) |

| LED Enfis (Mode II) | 8.1 (±0.7) | 118.3 (±5.4) | 2.2 (±0.1) | 3.5 (±0.2) | 56.7 (±5.3) | 3.0 (±0.2) | 6.3 (±0.5) | 73.7 (±5.1) | 1.3 (±0.1) | 4.9 (±0.4) | 93.0 (±6.8) | 5.0 (±0.3) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Santis, R.; Gloria, A.; Maietta, S.; Martorelli, M.; De Luca, A.; Spagnuolo, G.; Riccitiello, F.; Rengo, S. Mechanical and Thermal Properties of Dental Composites Cured with CAD/CAM Assisted Solid-State Laser. Materials 2018, 11, 504. https://doi.org/10.3390/ma11040504

De Santis R, Gloria A, Maietta S, Martorelli M, De Luca A, Spagnuolo G, Riccitiello F, Rengo S. Mechanical and Thermal Properties of Dental Composites Cured with CAD/CAM Assisted Solid-State Laser. Materials. 2018; 11(4):504. https://doi.org/10.3390/ma11040504

Chicago/Turabian StyleDe Santis, Roberto, Antonio Gloria, Saverio Maietta, Massimo Martorelli, Alessandro De Luca, Gianrico Spagnuolo, Francesco Riccitiello, and Sandro Rengo. 2018. "Mechanical and Thermal Properties of Dental Composites Cured with CAD/CAM Assisted Solid-State Laser" Materials 11, no. 4: 504. https://doi.org/10.3390/ma11040504

APA StyleDe Santis, R., Gloria, A., Maietta, S., Martorelli, M., De Luca, A., Spagnuolo, G., Riccitiello, F., & Rengo, S. (2018). Mechanical and Thermal Properties of Dental Composites Cured with CAD/CAM Assisted Solid-State Laser. Materials, 11(4), 504. https://doi.org/10.3390/ma11040504