Evaluation of Fracture Strength of Ceramics Containing Small Surface Defects Introduced by Focused Ion Beam

Abstract

:1. Introduction

2. Evaluation Equation of Fracture Strength

3. Experimental Procedures

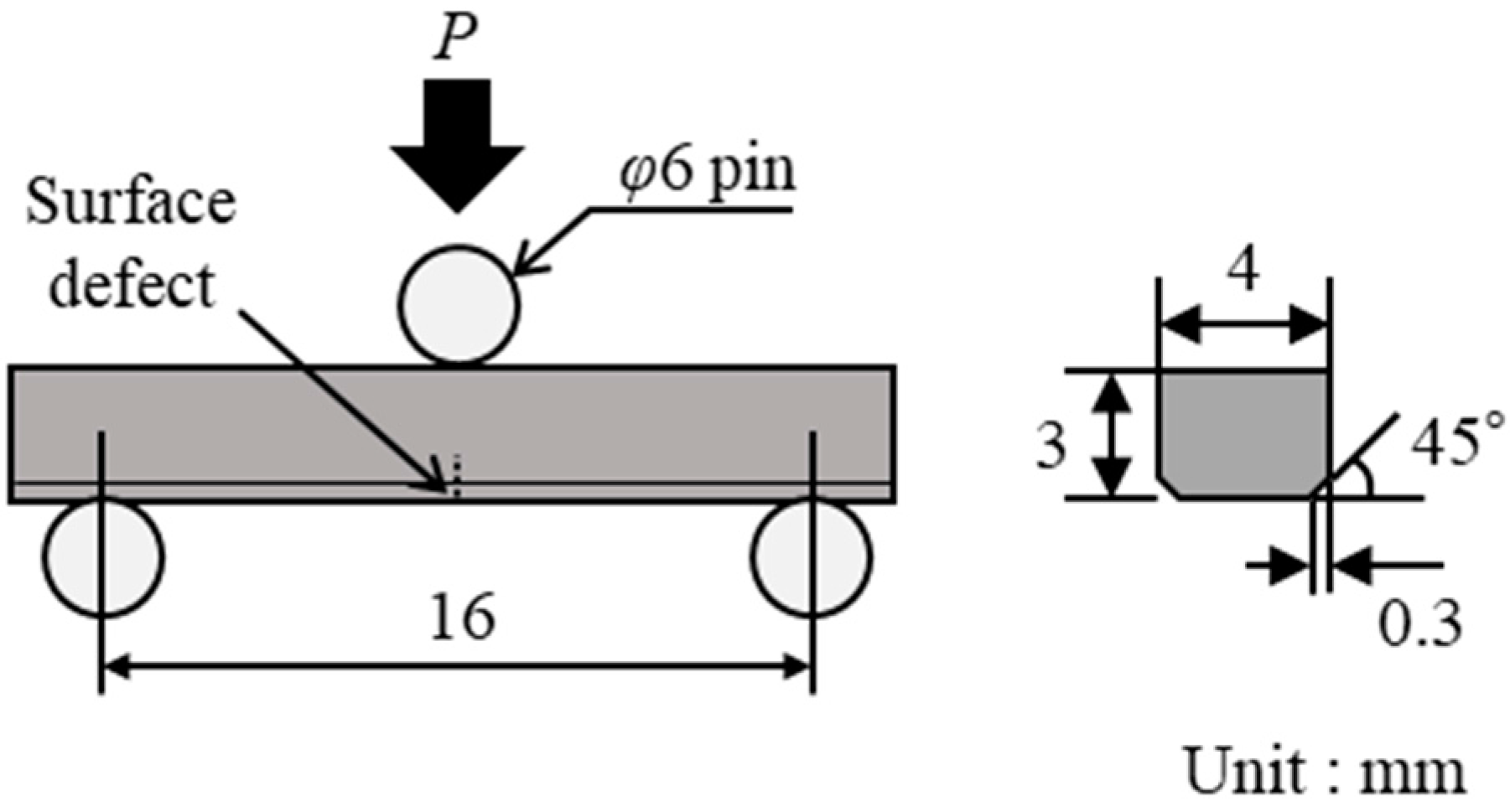

3.1. Test Specimen

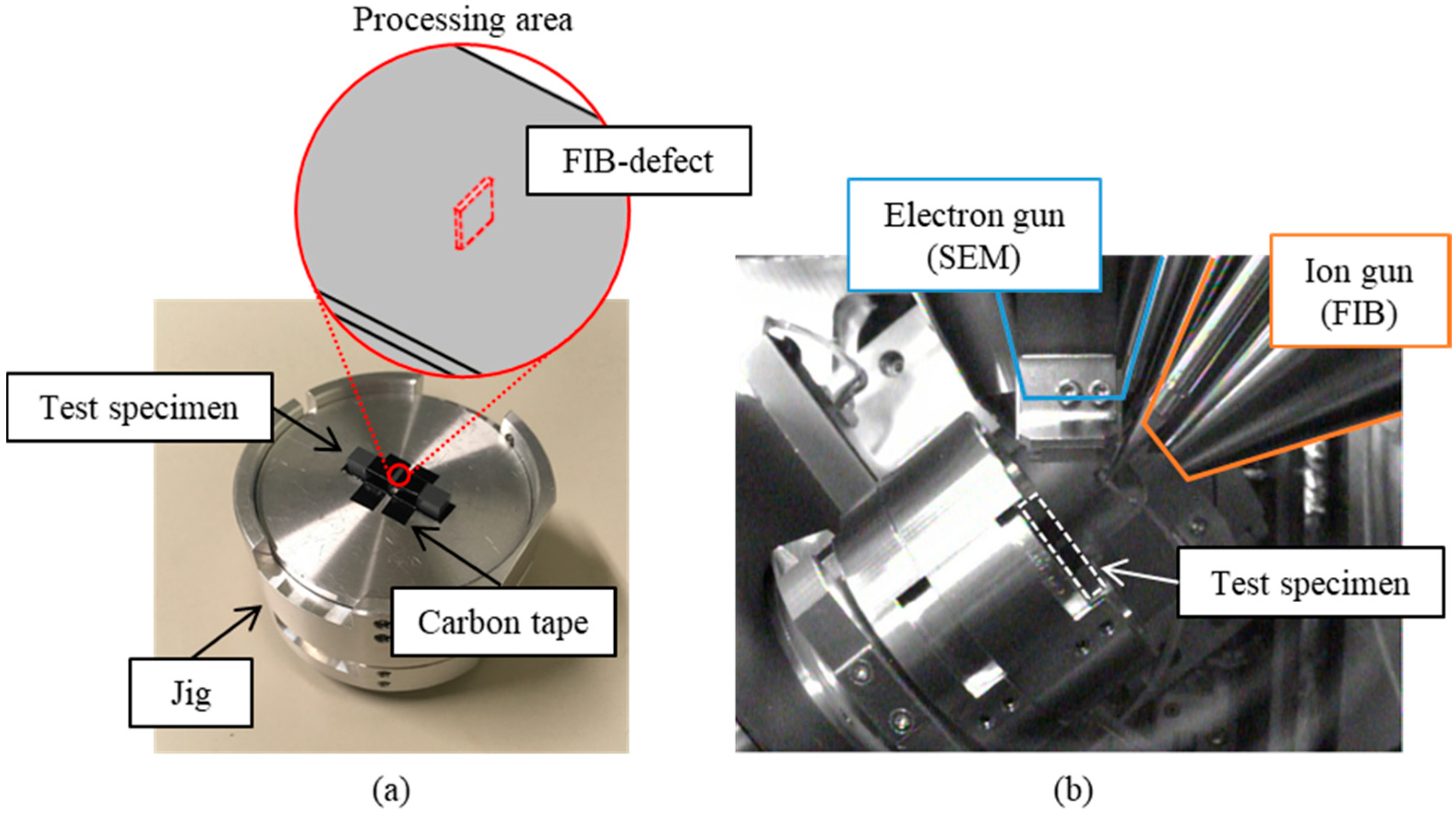

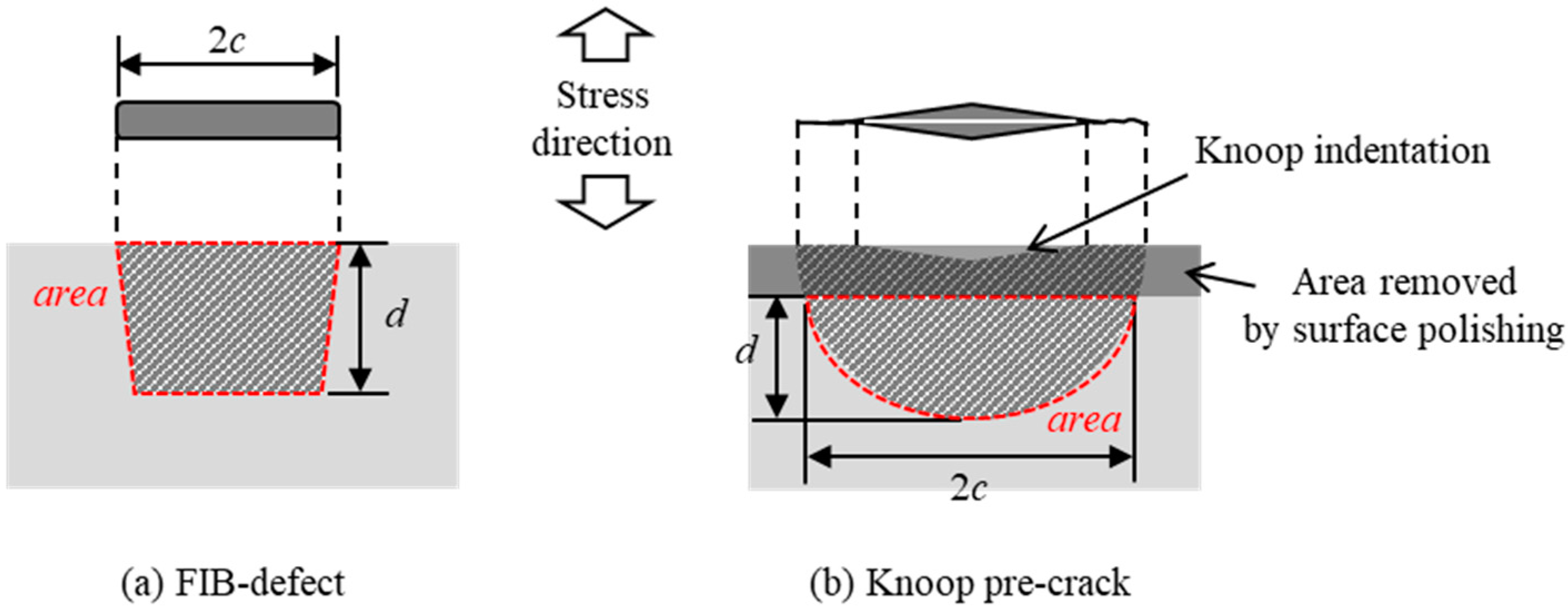

3.2. Specimen Preparations

3.3. Measurement of Fracture Toughness

3.4. Measurement of Fracture Strength

4. Results and Evaluation of Fracture Strength

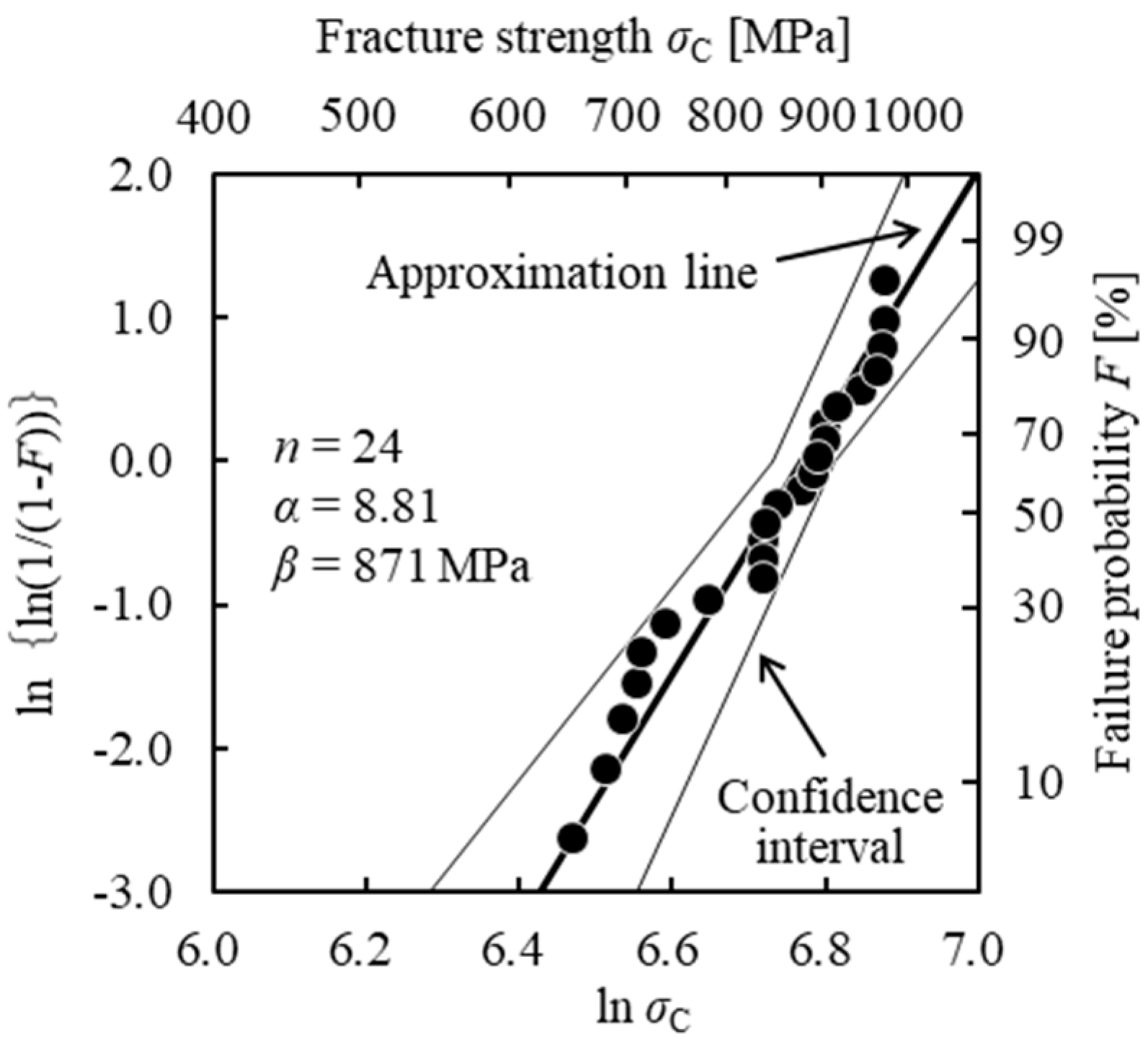

4.1. Mechanical Properties of the Sample Material

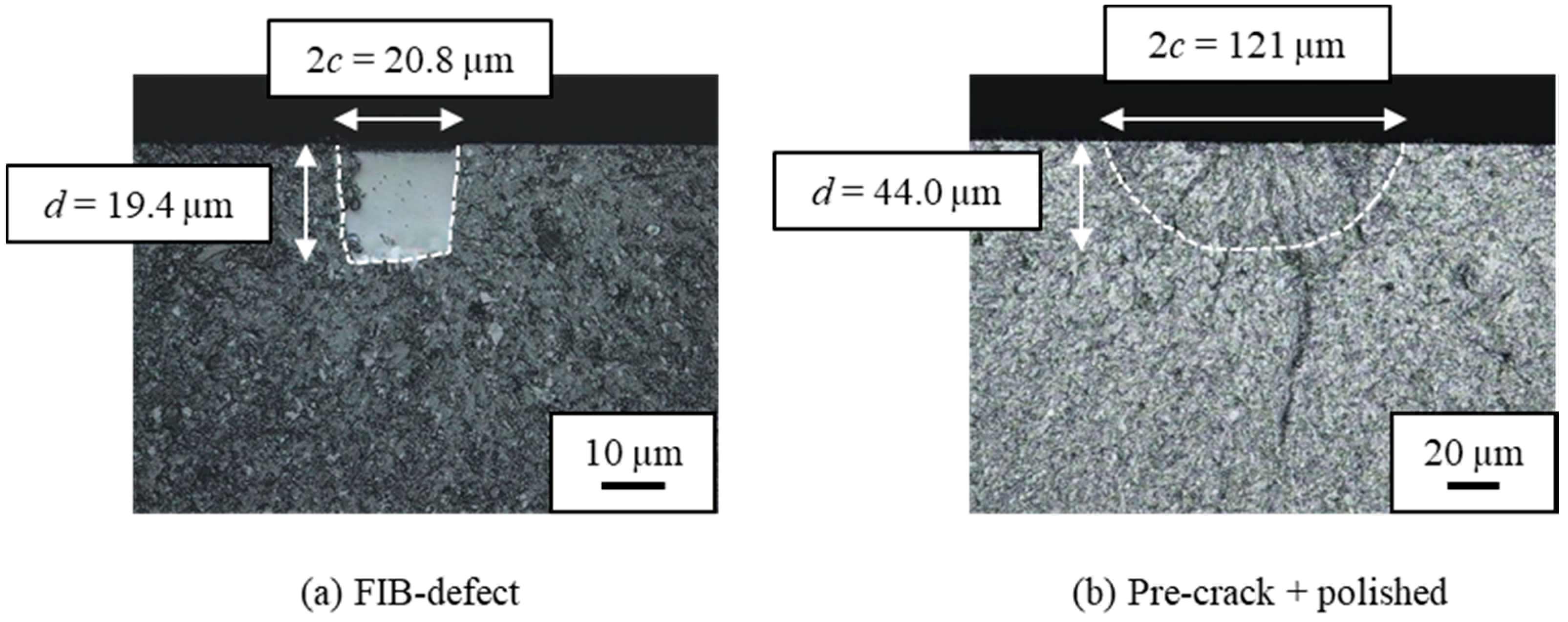

4.2. Fracture Strength of FIB-Defect Specimens

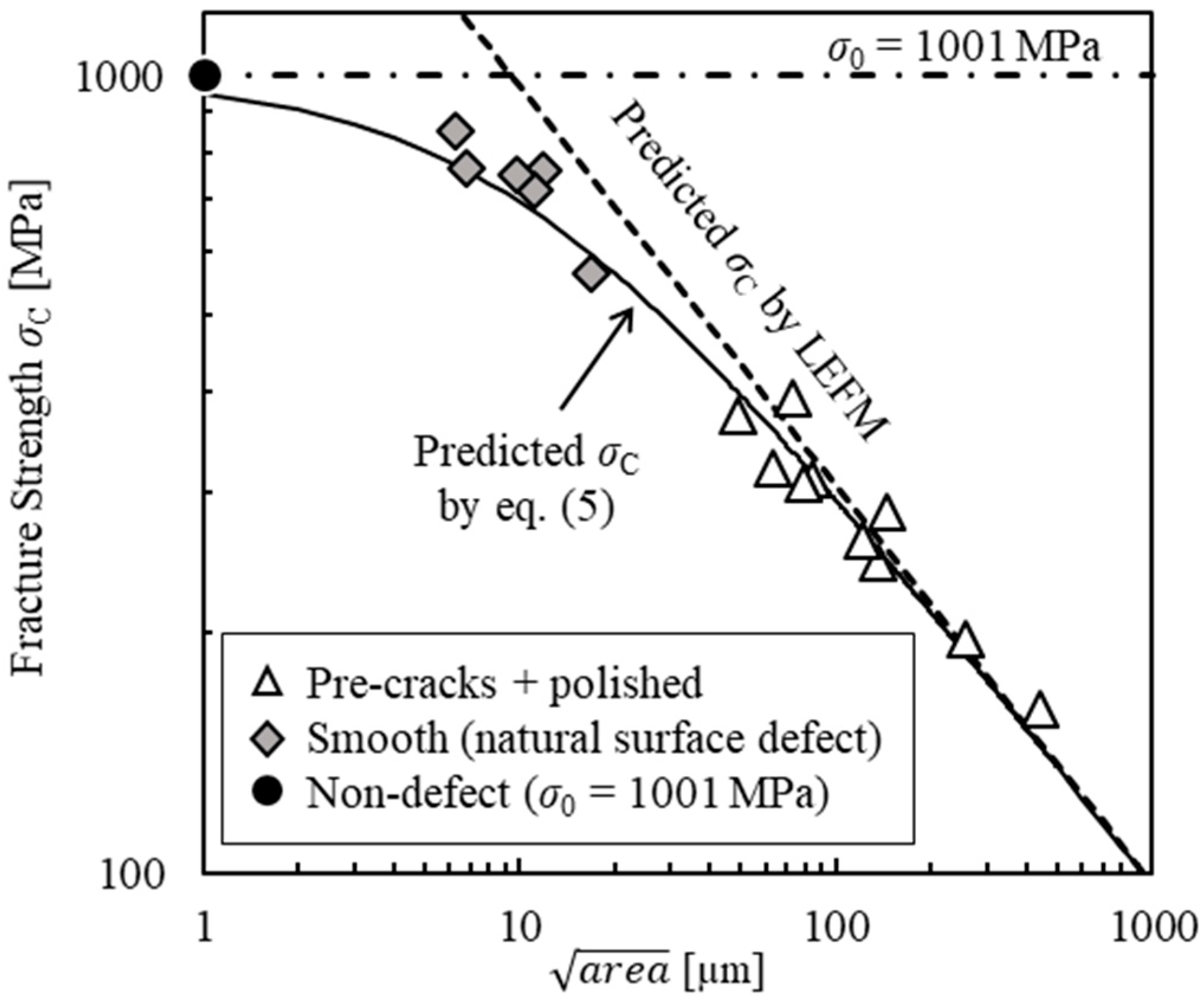

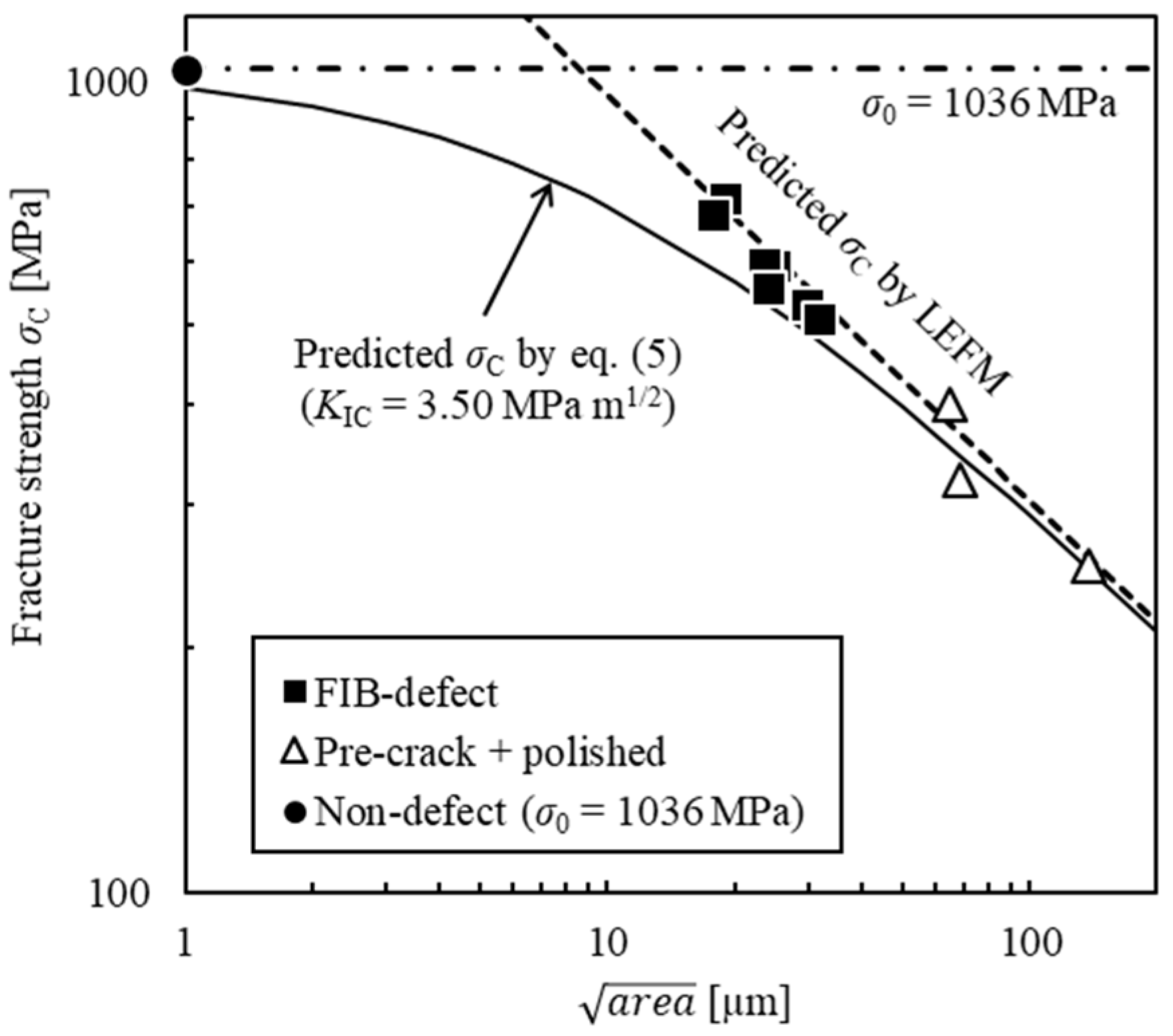

4.3. Comparison Between Predicted Fracture Strength and Test Results

5. Conclusions

- (1)

- The micro surface defects in the size range of = 19–35 µm were introduced on the surface of Al2O3/SiC by the FIB technique.

- (2)

- The fracture strengths of the FIB-defect specimens showed dependency. This result is similar to that obtained for the pre-crack + polished specimens.

- (3)

- FIB-defect can be used as a small initial crack for fracture strength evaluation of ceramics.

- (4)

- The fracture strengths of the FIB-defect specimens predicted by the evaluation equation matched the test results. It was confirmed that the proposed equation for fracture strength evaluation was useful for ceramics containing micro surface defects introduced by FIB.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Usami, S.; Kimoto, H.; Takahashi, I.; Shida, S. Strength of ceramic materials containing small flaws. Eng. Fract. Mech. 1986, 23, 745–761. [Google Scholar] [CrossRef]

- Hoshide, T. Grain fracture model and its application to strength evaluation in engineering ceramics. Eng. Fract. Mech. 1993, 44, 403–408. [Google Scholar]

- Li, C.W.; Lui, S.C.; Goldacker, J. Relation between strength, microstructure, and grain—Bridging characteristics in in situ reinforced silicon nitride. J. Am. Ceram. Soc. 1995, 78, 449–459. [Google Scholar] [CrossRef]

- Taylor, D. Predicting the fracture strength of ceramic materials using the theory of critical distances. Eng. Fract. Mech. 2004, 71, 2407–2416. [Google Scholar] [CrossRef]

- Munz, D. What can we learn from R-curve measurements? J. Am. Ceram. Soc. 2007, 90, 1–15. [Google Scholar] [CrossRef]

- Askes, H.; Susmel, L. Understanding cracked materials: Is linear elastic fracture mechanics obsolete? Fatigue Fract. Eng. Mater. Struct. 2015, 38, 154–160. [Google Scholar] [CrossRef]

- Ando, K.; Kim, B.A.; Iwasa, M.; Ogura, N. Process zone size failure criterion and probabilistic fracture assessment curves for ceramics. Fatigue Fract. Eng. Mater. Struct. 1992, 15, 139–149. [Google Scholar] [CrossRef]

- Murakami, Y.; Endo, M. Quantitative evaluation of fatigue strength of metals containing various small defects or cracks. Eng. Fract. Mech. 1983, 17, 1–15. [Google Scholar]

- Saberifar, S.; Mashreghi, A.R.; Mosalaeepur, M.; Ghasemi, S.S. The interaction between non-metallic inclusions and surface roughness in fatigue failure and their influence on fatigue strength. Mater. Des. 2012, 35, 720–724. [Google Scholar] [CrossRef]

- Beretta, S.; Romano, S. A comparison of fatigue strength sensitivity to defects for materials manufactured by AM or traditional processes. Int. J. Fatigue 2017, 94, 178–191. [Google Scholar] [CrossRef]

- Sato, N.; Takahashi, K. Prediction of fracture strength for ceramics containing a surface defect with arbitrary shape. Trans. Jpn. Soc. Spring Eng. 2018, 63. in press. [Google Scholar]

- Marshall, D.B.; Lawn, B.R. Residual stress effects in sharp contact cracking: Indentation fracture mechanics. J. Mater. Sci. 1979, 14, 2001–2012. [Google Scholar] [CrossRef]

- Chou, I.A.; Chan, H.M.; Harmer, M.P. Effect of Annealing Environment on the Crack Healing and Mechanical Behavior of Silicon Carbide-Reinforced Alumina Nanocomposites. J. Am. Ceram. Soc. 1998, 81, 1203–1208. [Google Scholar] [CrossRef]

- Li, Z.; Ghosh, A.; Kobayashi, A.; Bradt, R.C. Indentation fracture toughness of sintered silicon carbide in the Palmquist crack regime. J. Am. Ceram. Soc. 1989, 72, 904–911. [Google Scholar] [CrossRef]

- Takahashi, K.; Iwanaka, K.; Osada, T.; Koike, H. Increase in strength of partially stabilized zirconia after shot peening. J. Mater. Eng. Perform. 2015, 24, 3573–3578. [Google Scholar] [CrossRef]

- Ćorić, D.; Renjo, M.M.; Ćurković, L. Vickers indentation fracture toughness of Y-TZP dental ceramics. Int. J. Refract. Met. Hard Mater. 2017, 64, 14–19. [Google Scholar] [CrossRef]

- Sakamoto, J.; Takahashi, Y.; Aono, Y.; Noguchi, H. Method for Assessing Applicability of an Artificial Flaw as a Small initial crack for fatigue limit evaluation and its application to a drill Hole and an FIB processed sharp notch in annealed 0.45% carbon steel. J. Test. Eval. 2013, 41, 194–199. [Google Scholar] [CrossRef]

- Roiko, A.; Solin, J. Measurement of small cracks initiating from inclusions, Focused Ion Beam notches and drilled holes. Int. J. Fatigue 2014, 62, 154–158. [Google Scholar] [CrossRef]

- Murakami, Y. Analysis of stress intensity factors of modes I, II and III for inclined surface cracks of arbitrary shape. Eng. Fract. Mech. 1985, 22, 101–114. [Google Scholar] [CrossRef]

- Osada, T.; Nakao, W.; Takahashi, K.; Ando, K.; Saito, S. Kinetics of Self-crack-healing of alumina/Silicon carbide composite including oxygen partial pressure effect. J. Am. Ceram. Soc. 2009, 92, 864–869. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Methods for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature; ASTM C1421-10; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Japanese Standards Association. Testing Methods for Fracture Toughness of Fine Ceramics at Room Temperature; JIS R1607; Japanese Standards Association: Tokyo, Japan, 2015. [Google Scholar]

- Miyazaki, H.; Yoshizawa, Y. Correlation of the indentation fracture resistance measured using high-resolution optics and the fracture toughness obtained by the single edge-notched beam (SEPB) method for typical structural ceramics with various microstructures. Ceram. Int. 2016, 42, 7873–7876. [Google Scholar] [CrossRef]

- Japanese Standards Association. Weibull Statics of Strength Data for Fine Ceramics; JIS R1607; Japanese Standards Association: Tokyo, Japan, 2010. [Google Scholar]

| Ion Source | Ga Liquid Metal Ions |

|---|---|

| Accelerating voltage | 30 kV |

| Prove current | 3000 pA |

| Dose | 190–280 nC/µm2 |

| Type of Defect | Surface Length 2c (µm) | Depth d (µm) | (µm) | Fracture Strength σC (Mpa) |

|---|---|---|---|---|

| FIB-defect test specimen | 20.8 | 19.4 | 19.1 | 687 |

| 20.0 | 23.2 | 20.4 | 715 | |

| 33.4 | 21.1 | 25.3 | 597 | |

| 32.3 | 22.5 | 26.2 | 557 | |

| 32.8 | 23.8 | 27.4 | 592 | |

| 46.2 | 24.1 | 32.6 | 530 | |

| 60.1 | 21.3 | 35.2 | 508 | |

| Pre-crack + polished test specimen | 121 | 44.0 | 64.6 | 400 |

| 124 | 47.5 | 68.0 | 322 | |

| 228 | 106 | 137 | 253 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sato, N.; Takahashi, K. Evaluation of Fracture Strength of Ceramics Containing Small Surface Defects Introduced by Focused Ion Beam. Materials 2018, 11, 457. https://doi.org/10.3390/ma11030457

Sato N, Takahashi K. Evaluation of Fracture Strength of Ceramics Containing Small Surface Defects Introduced by Focused Ion Beam. Materials. 2018; 11(3):457. https://doi.org/10.3390/ma11030457

Chicago/Turabian StyleSato, Nanako, and Koji Takahashi. 2018. "Evaluation of Fracture Strength of Ceramics Containing Small Surface Defects Introduced by Focused Ion Beam" Materials 11, no. 3: 457. https://doi.org/10.3390/ma11030457

APA StyleSato, N., & Takahashi, K. (2018). Evaluation of Fracture Strength of Ceramics Containing Small Surface Defects Introduced by Focused Ion Beam. Materials, 11(3), 457. https://doi.org/10.3390/ma11030457