Wear Behaviours and Oxidation Effects on Different UHMWPE Acetabular Cups Using a Hip Joint Simulator

Abstract

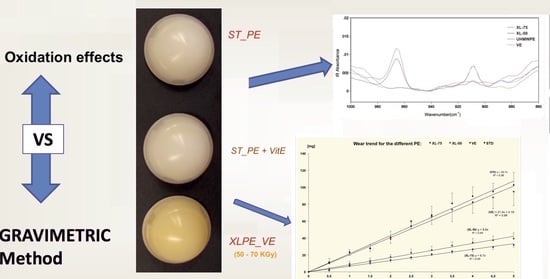

:1. Introduction

2. Materials and Methods

2.1. Specimens Tested

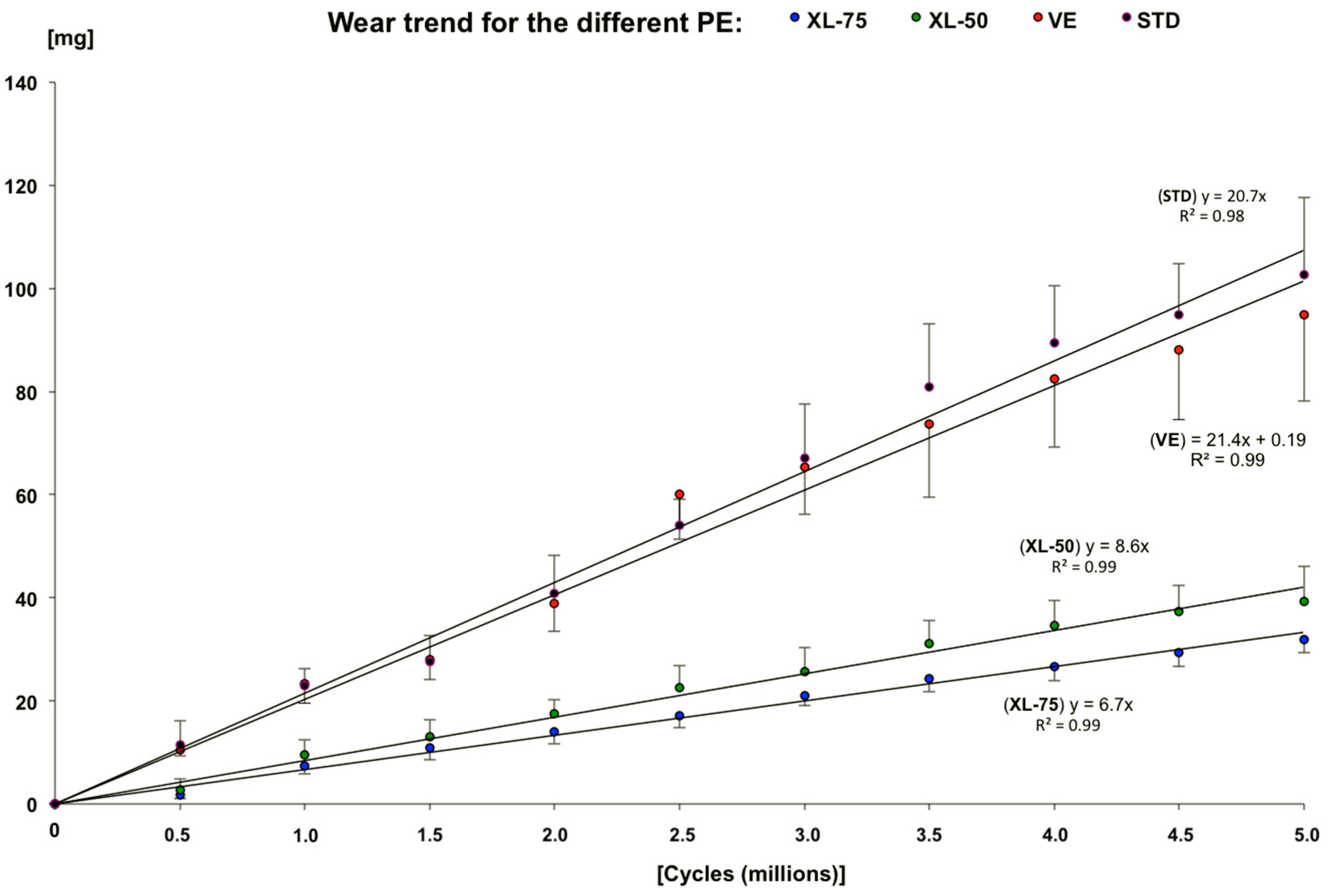

2.2. Experimental Wear Details

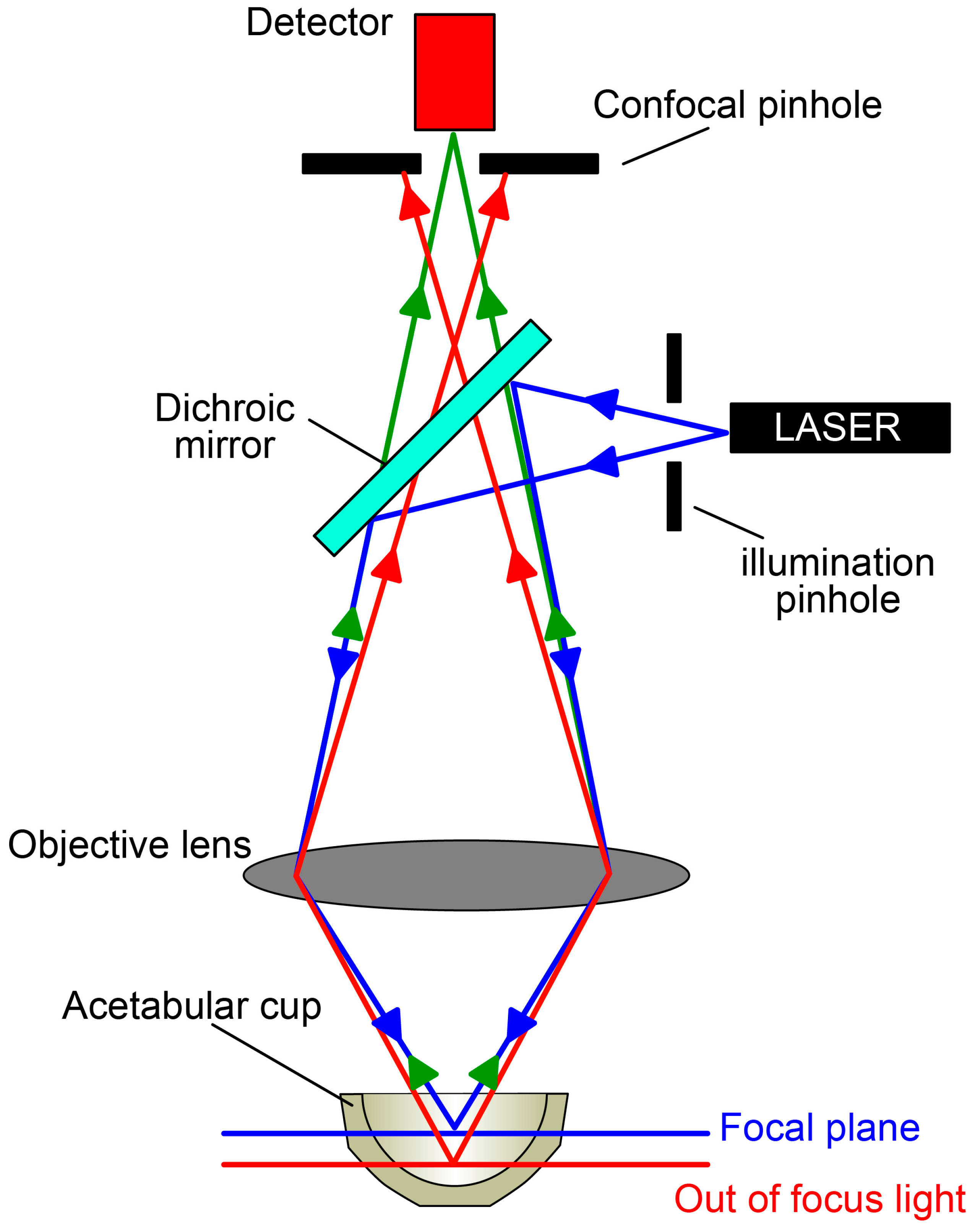

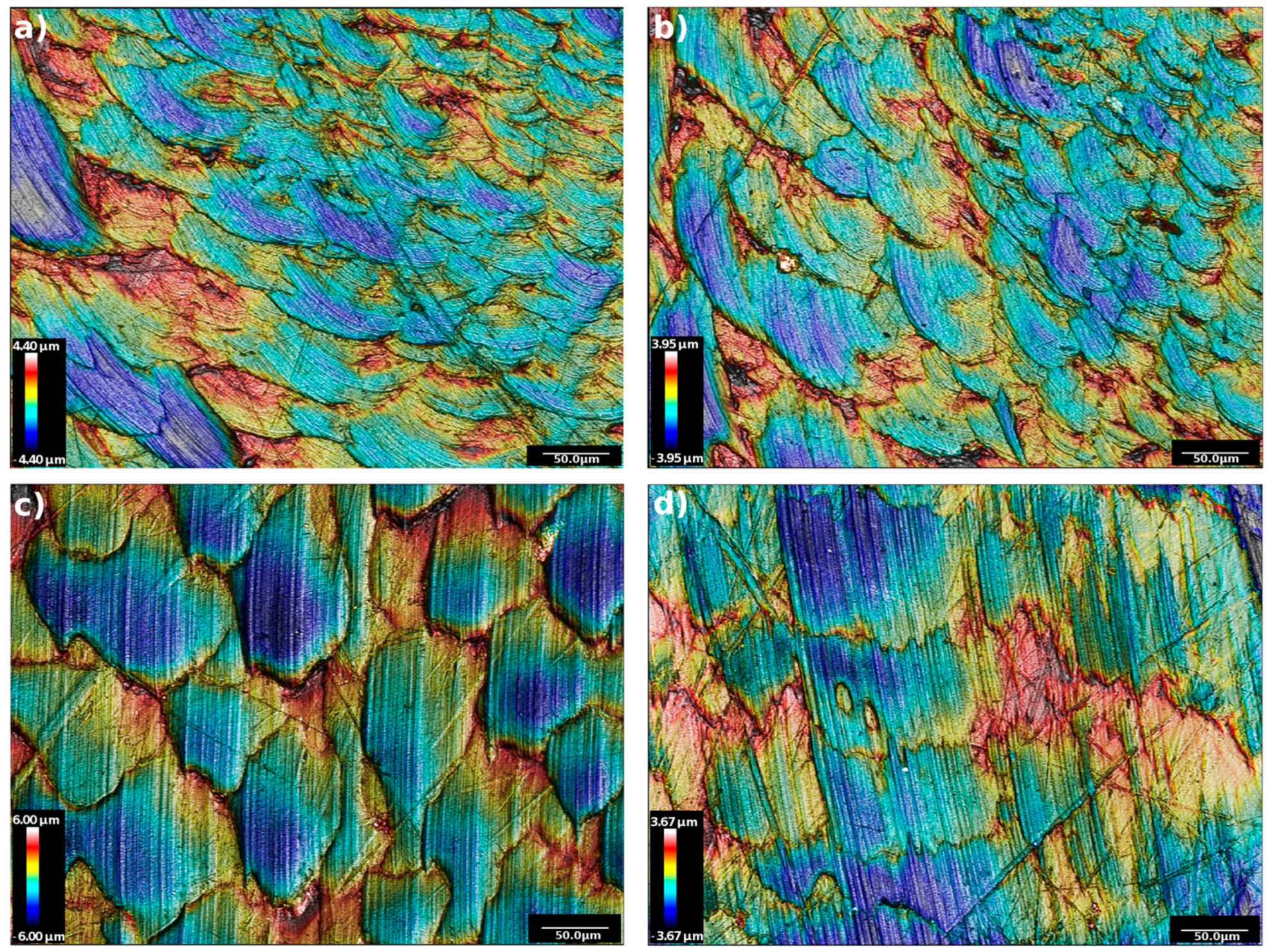

2.3. Surface Topography Characterization

2.4. FTIR Spectroscopy

2.5. Determination of Cross-Link Density and Crystallinity

3. Results

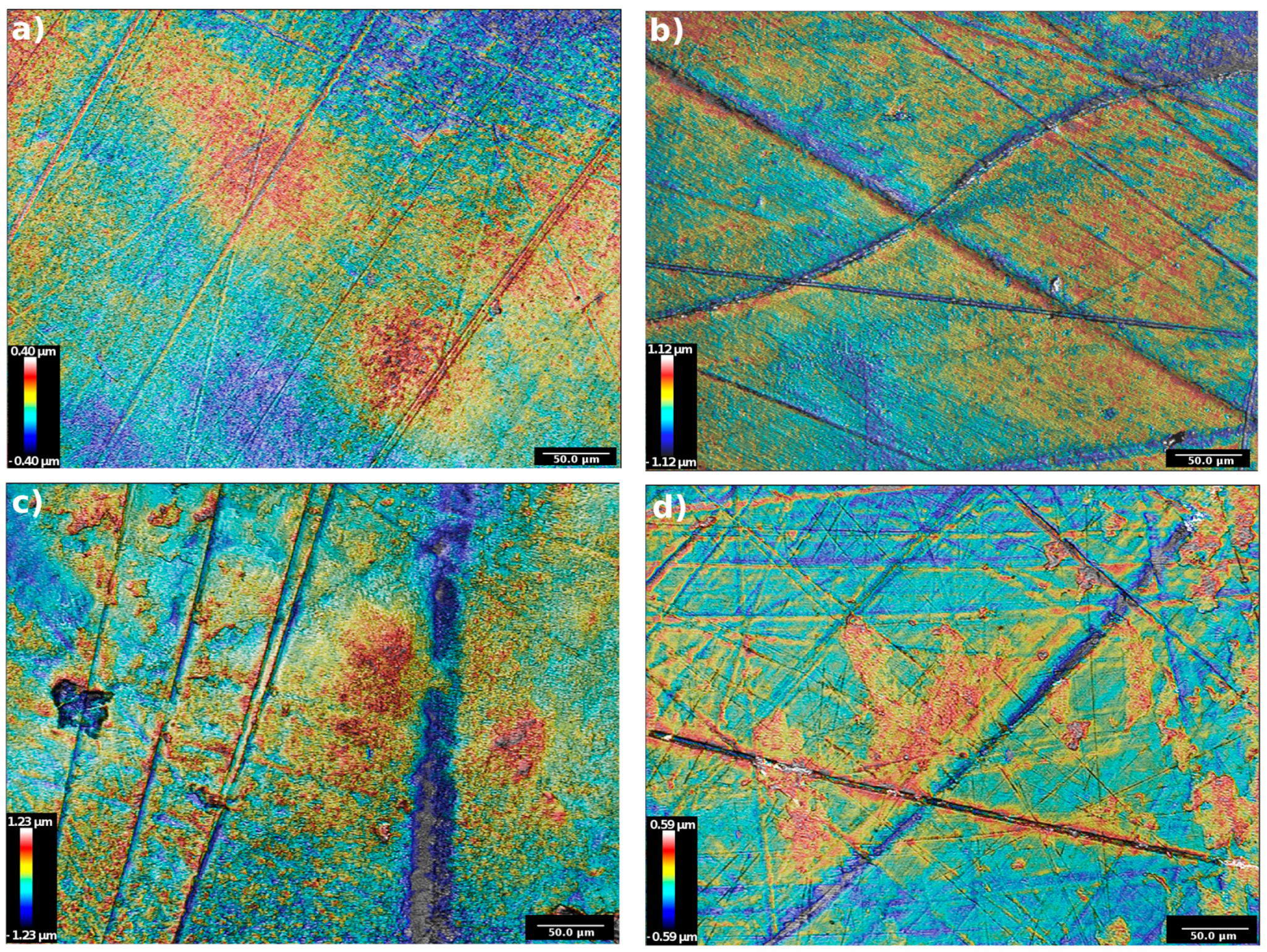

3.1. Surface Topography Analysis

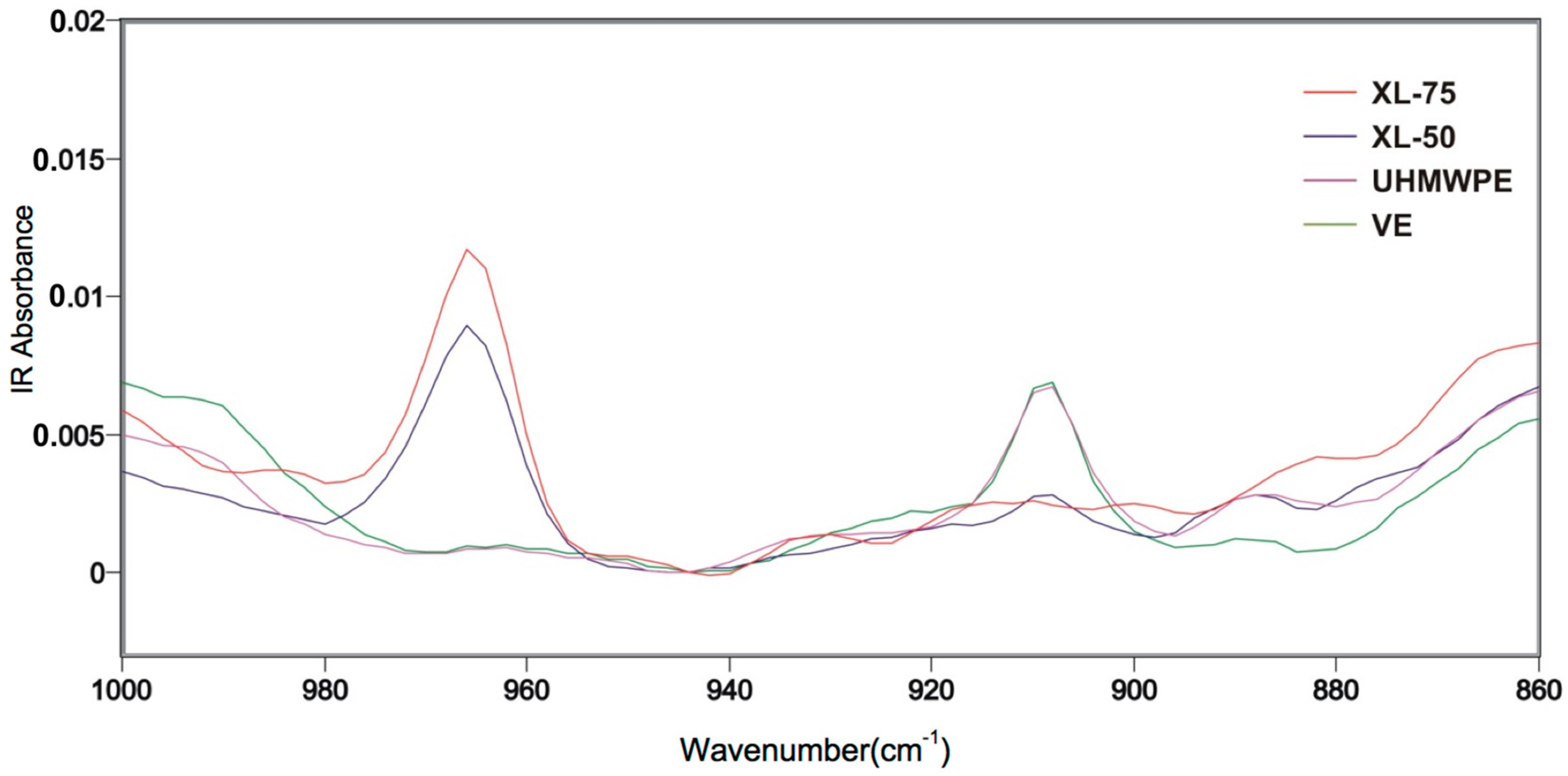

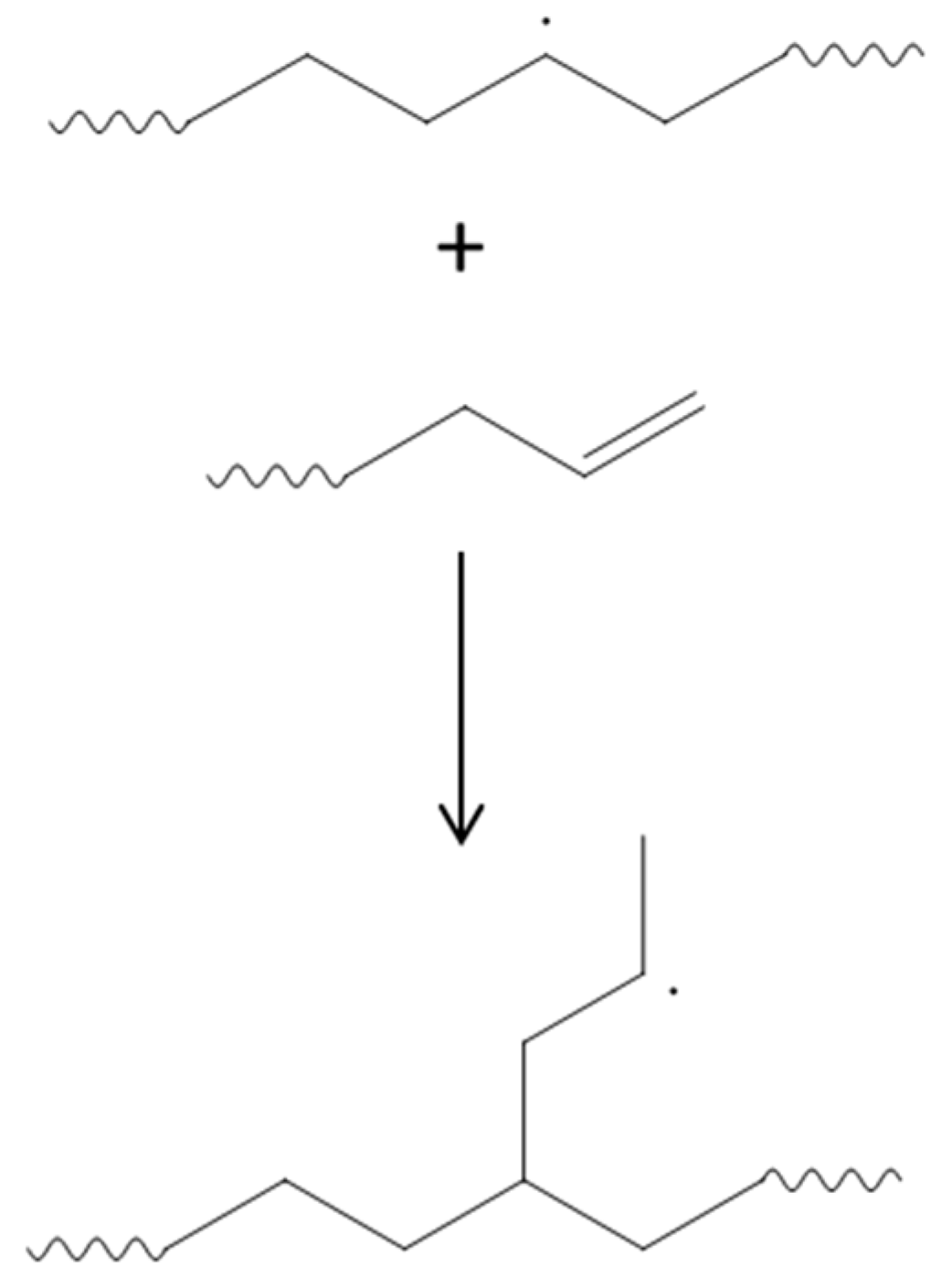

3.2. FTIR Spectroscopy and Cross-Link Density Results

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kurtz, S.M. A Primer on UHMWPE. UHMWPE Biomater. Handb. 2016, 1–6. [Google Scholar] [CrossRef]

- Bracco, P.; Bellare, A.; Bistolfi, A.; Affatato, S. Ultra-High Molecular Weight Polyethylene: Influence of the Chemical, Physical and Mechanical Properties on the Wear Behavior. A Review. Materials 2017, 10, 791. [Google Scholar] [CrossRef] [PubMed]

- Ruggiero, A.; D’Amato, R.; Gómez, E.; Merola, M. Experimental comparison on tribological pairs UHMWPE/TIAL6V4 alloy, UHMWPE/AISI316L austenitic stainless and UHMWPE/AL2O3 ceramic, under dry and lubricated conditions. Tribol. Int. 2016, 96, 349–360. [Google Scholar] [CrossRef]

- Ruggiero, A.; D’Amato, R.; Gómez, E. Experimental analysis of tribological behavior of UHMWPE against AISI420C and against TiAl6V4 alloy under dry and lubricated conditions. Tribol. Int. 2015, 92, 154–161. [Google Scholar] [CrossRef]

- Brach del Prever, E.M.; Bistolfi, A.; Bracco, P.; Costa, L. UHMWPE for arthroplasty: Past or future? J. Orthop. Traumatol. 2009, 10, 1–8. [Google Scholar] [CrossRef] [PubMed]

- McKellop, H.; Shen, F.W.; Lu, B.; Campbell, P.; Salovey, R. Development of an extremely wear-resistant ultra high molecular weight polyethylene for total hip replacements. J. Orthop. Res. 1999, 17, 157–167. [Google Scholar] [CrossRef] [PubMed]

- Harris, W.H.; Muratoglu, O.K. A Review of Current Cross-linked Polyethylenes Used in Total Joint Arthroplasty. Clin. Orthop. Relat. Res. 2005, 46–52. [Google Scholar] [CrossRef]

- Affatato, S.; Freccero, N.; Taddei, P. The biomaterials challenge: A comparison of polyethylene wear using a hip joint simulator. J. Mech. Behav. Biomed. Mater. 2016, 53, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Oral, E.; Malhi, A.S.; Muratoglu, O.K. Mechanisms of decrease in fatigue crack propagation resistance in irradiated and melted UHMWPE. Biomaterials 2006, 27, 917–925. [Google Scholar] [CrossRef] [PubMed]

- Oral, E.; Godleski Beckos, C.; Malhi, A.S.; Muratoglu, O.K. The effects of high dose irradiation on the cross-linking of vitamin E-blended ultrahigh molecular weight polyethylene. Biomaterials 2008, 29, 3557–3560. [Google Scholar] [CrossRef] [PubMed]

- Azzi, A.; Stocker, A. Vitamin E: Non-antioxidant roles. Prog. Lipid Res. 2000, 39, 231–255. [Google Scholar] [CrossRef]

- Oral, E.; Muratoglu, O.K. Vitamin E diffused, highly crosslinked UHMWPE: A review. Int. Orthop. 2011, 35, 215–223. [Google Scholar] [CrossRef] [PubMed]

- Tomita, N.; Kitakura, T.; Onmori, N.; Ikada, Y.; Aoyama, E. Prevention of Fatigue Cracks in Ultrahigh Molecular Weight Polyethylene Joint Components by the Addition of Vitamin E. J. Biomed. Mater. Res. 1999, 48, 474–478. [Google Scholar] [CrossRef]

- Trommer, R.M.; Maru, M.M. Review article Importance of preclinical evaluation of wear in hip implant designs using simulator machines. Rev. Bras. Ortop. 2016, 52, 251–259. [Google Scholar] [CrossRef] [PubMed]

- Viceconti, M.; Affatato, S.; Baleani, M.; Bordini, B.; Cristofolini, L.; Taddei, F. Pre-clinical validation of joint prostheses: A systematic approach. J. Mech. Behav. Biomed. Mater. 2009, 2, 120–127. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Spinelli, M.; Zavalloni, M.; Mazzega-Fabbro, C.; Viceconti, M. Tribology and total hip joint replacement: Current concepts in mechanical simulation. Med. Eng. Phys. 2008, 30, 1305–1317. [Google Scholar] [CrossRef] [PubMed]

- Taddei, P.; Ruggiero, A.; Pavoni, E.; Affatato, S. Transfer of metallic debris after in vitro ceramic-on-metal simulation: Wear and degradation in Biolox® Delta composite femoral heads. Compos. Part B Eng. 2016. [Google Scholar] [CrossRef]

- Oral, E.; Christensen, S.D.; Malhi, A.S.; Wannomae, K.K.; Muratoglu, O.K. Wear resistance and mechanical properties of highly cross-linked, ultrahigh-molecular weight polyethylene doped with vitamin E. J. Arthroplast. 2006, 21, 580–591. [Google Scholar] [CrossRef] [PubMed]

- Wannomae, K.K.; Christensen, S.D.; Micheli, B.R.; Rowell, S.L.; Schroeder, D.W.; Muratoglu, O.K. Delamination and adhesive wear behavior of alpha-tocopherol-stabilized irradiated ultrahigh-molecular-weight polyethylene. J. Arthroplast. 2010, 25, 635–643. [Google Scholar] [CrossRef] [PubMed]

- Micheli, B.R.; Wannomae, K.K.; Lozynsky, A.J.; Christensen, S.D.; Muratoglu, O.K. Knee Simulator Wear of Vitamin E Stabilized Irradiated Ultrahigh Molecular Weight Polyethylene. J. Arthroplast. 2012, 27, 95–104. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Bracco, P.; Costa, L.; Villa, T.; Quaglini, V.; Toni, A. In vitro wear performance of standard, crosslinked, and vitamin-E-blended UHMWPE. J. Biomed. Mater. Res. A 2012, 100, 554–560. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Bersaglia, G.; Rocchi, M.; Taddei, P.; Fagnano, C.; Toni, A. Wear behaviour of cross-linked polyethylene assessed in vitro under severe conditions. Biomaterials 2005, 26, 3259–3267. [Google Scholar] [CrossRef] [PubMed]

- Implants for Surgery—Wear of Total Hip-Joint Prostheses—Part 1: Loading and Displacement Parameters for Wear-Testing Machines and Corresponding Environmental Conditions for Test, 2nd ed.; ISO 14242-1:2012; International Organization for Standardization: Geneva, Switzerland, 2012.

- Ruggiero, A.; Merola, M.; Affatato, S. On the biotribology of total knee replacement: A new roughness measurements protocol on in vivo condyles considering the dynamic loading from musculoskeletal multibody model. Meas. J. Int. Meas. Confed. 2017, 112. [Google Scholar] [CrossRef]

- ISO 4287:1997. In Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; International Organization for Standardization: Geneva, Switzerland, 1997.

- De Kock, R.J.; Hol, P.A.H.M.; Bos, H. Infrared determination of unsaturated bonds in polyethylene. Fresenius’ Zeitschrift Für Analytische Chemie 1964, 205, 371–381. [Google Scholar] [CrossRef]

- Wunderlich, B.; Dole, M. Specific heat of synthetic high polymers. VIII. Low pressure polyethylene. J. Polym. Sci. 1957, 24, 201–213. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Dumbleton, J.H.; Siskey, R.S.; Wang, A.; Manley, M. Trace concentrations of vitamin E protect radiation crosslinked UHMWPE from oxidative degradation. J. Biomed. Mater. Res. A 2009, 90, 549–563. [Google Scholar] [CrossRef] [PubMed]

- Standard Test Method for Evaluating Trans-Vinylene Yield in Irradiated Ultra-High-Molecular-Weight Polyethylene Fabricated Forms Intended for Surgical Implants by Infrared Spectroscopy; ASTM F2381-04; ASTM International: West Conshohocken, PA, USA, 2004.

- Bracco, P.; Brunella, V.; Luda, M.P.P.; Zanetti, M.; Costa, L. Radiation-induced crosslinking of UHMWPE in the presence of co-agents: Chemical and mechanical characterisation. Polymer 2005, 46, 10648–10657. [Google Scholar] [CrossRef]

- Nélias, D.; Dumont, M.L.; Champiot, F.; Vincent, A.; Girodin, D.; Fougéres, R. Role of Inclusions, Surface Roughness and Operating Conditions on Rolling Contact Fatigue. J. Tribol. 1999, 121, 240. [Google Scholar] [CrossRef]

- Baker, D.A.; Hastings, R.S.; Pruitt, L. Study of fatigue resistance of chemical and radiation crosslinked medical grade ultrahigh molecular weight polyethylene. J. Biomed. Mater. Res. 1999, 46, 573–581. [Google Scholar] [CrossRef]

- Cole, J.C.; Lemons, J.E.; Eberhardt, A.W. Gamma irradiation alters fatigue-crack behavior and fracture toughness in 1900H and GUR 1050 UHMWPE. J. Biomed. Mater. Res. 2002, 63, 559–566. [Google Scholar] [CrossRef] [PubMed]

| Cycles (Mc) | Mean ± Standard Deviation (mg) | K–W Test | Post Hoc Test (p-Value) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| STD | VE | XL-50 | XL-75 | (p-Value) | STD vs. VE | STD vs. XL-50 | STD vs. XL-75 | VE vs. XL-50 | VE vs. XL-75 | XL-50 vs. XL-75 | |

| 0.5 | 11.4 ± 4.8 | 10.5 ± 1.2 | 2.7 ± 2.1 | 1.7 ± 0.7 | 0.037 | 0.821 | 0.079 | 0.036 | 0.047 | 0.020 | 0.734 |

| 1.0 | 22.9 ± 3.4 | 23.3 ± 3.8 | 9.6 ± 2.8 | 7.5 ± 1.6 | 0.035 | 0.910 | 0.089 | 0.024 | 0.070 | 0.017 | 0.571 |

| 1.5 | 27.6 ± 5.2 | 28.1 ± 3.9 | 13.0 ± 3.4 | 10.9 ± 2.3 | 0.038 | 0.910 | 0.070 | 0.031 | 0.054 | 0.024 | 0.734 |

| 2.0 | 40.9 ± 7.3 | 39.0 ± 5.5 | 17.4 ± 2.7 | 13.9 ± 2.4 | 0.030 | 0.910 | 0.089 | 0.013 | 0.113 | 0.017 | 0.428 |

| 2.5 | 54.1 ± 5.0 | 60.13 ± 8.8 | 22.5 ± 4.3 | 17.2 ± 2.4 | 0.026 | 0.571 | 0.174 | 0.031 | 0.054 | 0.007 | 0.428 |

| 3.0 | 67.0 ± 10.5 | 65.2 ± 9.1 | 25.7 ± 4.6 | 21.0 ± 1.9 | 0.035 | 0.910 | 0.070 | 0.017 | 0.089 | 0.024 | 0.571 |

| 3.5 | 80.8 ± 12.2 | 73.7 ± 14.2 | 31.2 ± 4.5 | 24.3 ± 2.6 | 0.030 | 0.910 | 0.089 | 0.013 | 0.113 | 0.017 | 0.428 |

| 4.0 | 89.4 ± 11.3 | 82.4 ± 13.3 | 34.6 ± 4.9 | 26.6 ± 2.8 | 0.030 | 0.910 | 0.089 | 0.013 | 0.113 | 0.017 | 0.428 |

| 4.5 | 94.8 ± 10.0 | 88.1 ± 13.6 | 37.3 ± 5.1 | 29.3 ± 2.7 | 0.030 | 0.910 | 0.089 | 0.013 | 0.113 | 0.017 | 0.428 |

| 5.0 | 102.6 ± 15.1 | 94.9 ± 16.7 | 39.3 ± 6.7 | 31.8 ± 2.6 | 0.032 | 0.910 | 0.079 | 0.015 | 0.100 | 0.020 | 0.496 |

| Polyethylene | Crystallinity (%) | Trans-Vinylene (mmol/L) | Cross-Link Density (mol/dm3) |

|---|---|---|---|

| STD | 50.3 ± 0.9 | - | - |

| VE | 51.2 ± 1.2 | - | - |

| XL-50 | 40.8 ± 1.0 | 5.2 | 0.132 ± 0.009 |

| XL-75 | 35.5 ± 0.9 | 5.8 | 0.139 ± 0.010 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Affatato, S.; Ruggiero, A.; Jaber, S.A.; Merola, M.; Bracco, P. Wear Behaviours and Oxidation Effects on Different UHMWPE Acetabular Cups Using a Hip Joint Simulator. Materials 2018, 11, 433. https://doi.org/10.3390/ma11030433

Affatato S, Ruggiero A, Jaber SA, Merola M, Bracco P. Wear Behaviours and Oxidation Effects on Different UHMWPE Acetabular Cups Using a Hip Joint Simulator. Materials. 2018; 11(3):433. https://doi.org/10.3390/ma11030433

Chicago/Turabian StyleAffatato, Saverio, Alessandro Ruggiero, Sami Abdel Jaber, Massimiliano Merola, and Pierangiola Bracco. 2018. "Wear Behaviours and Oxidation Effects on Different UHMWPE Acetabular Cups Using a Hip Joint Simulator" Materials 11, no. 3: 433. https://doi.org/10.3390/ma11030433

APA StyleAffatato, S., Ruggiero, A., Jaber, S. A., Merola, M., & Bracco, P. (2018). Wear Behaviours and Oxidation Effects on Different UHMWPE Acetabular Cups Using a Hip Joint Simulator. Materials, 11(3), 433. https://doi.org/10.3390/ma11030433