Effect of Multiwalled Carbon Nanotubes on the Mechanical Properties of Carbon Fiber-Reinforced Polyamide-6/Polypropylene Composites for Lightweight Automotive Parts

Abstract

:1. Introduction

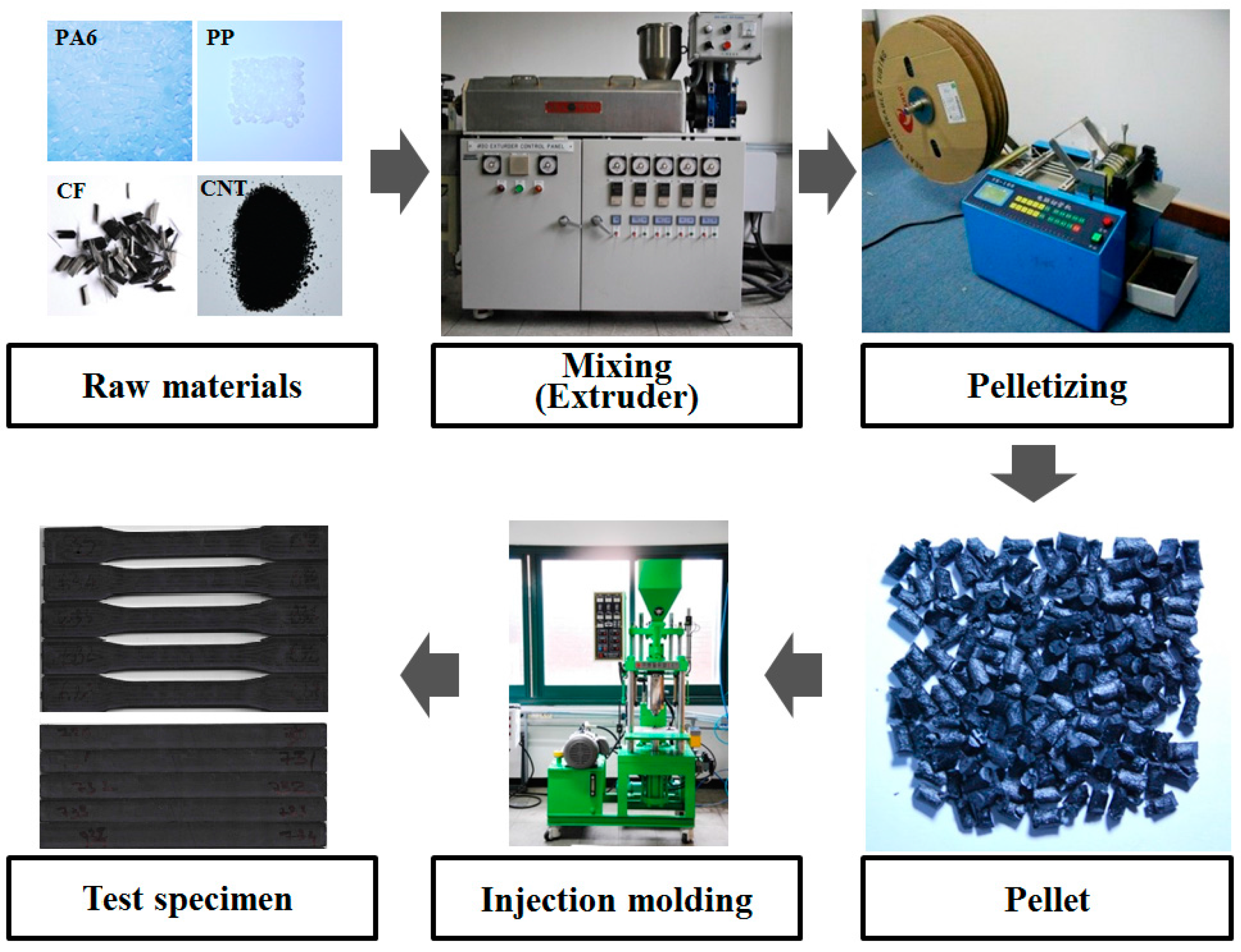

2. Experiment

2.1. Sample Preparation

2.2. Evaluation Methods

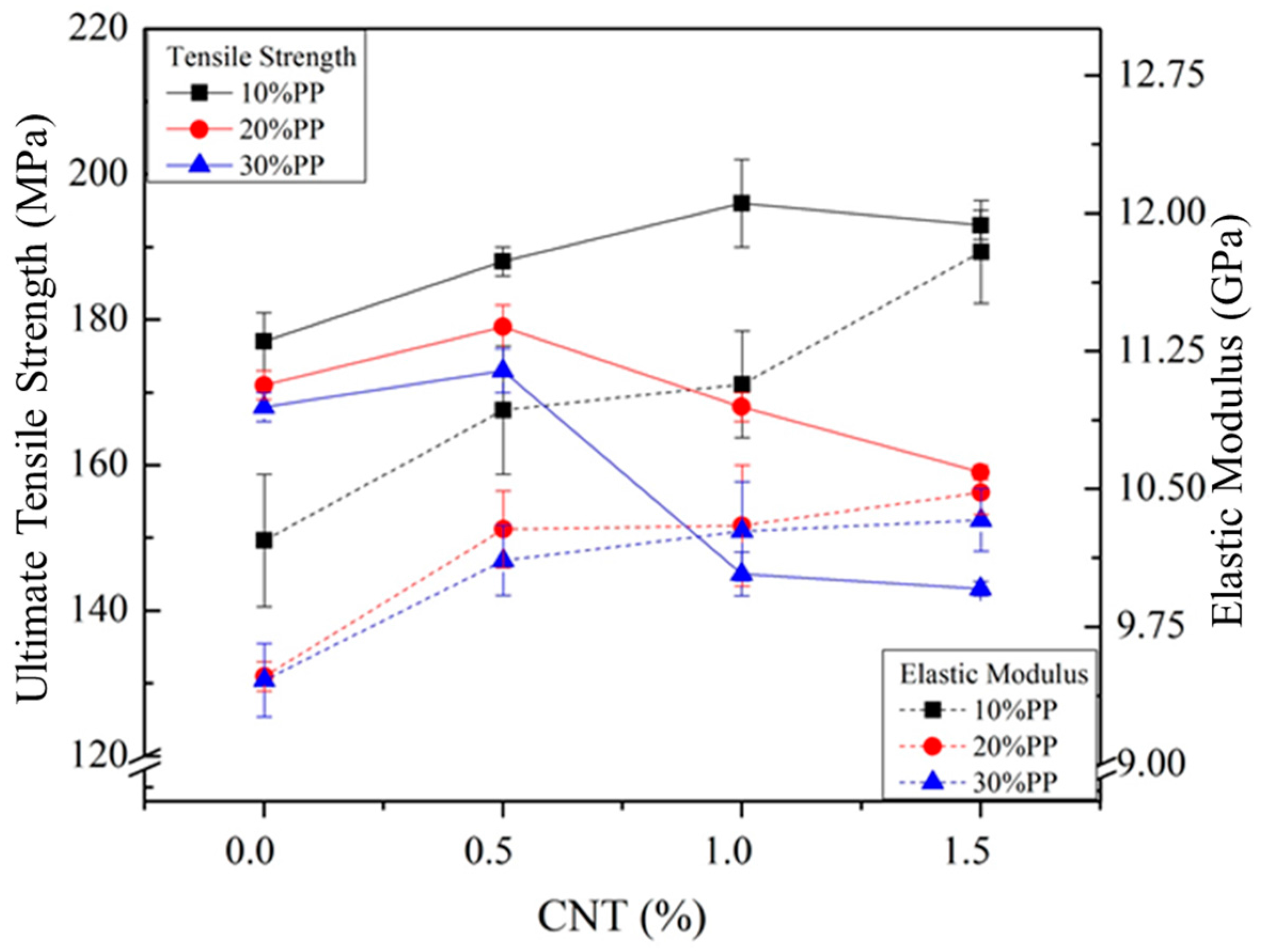

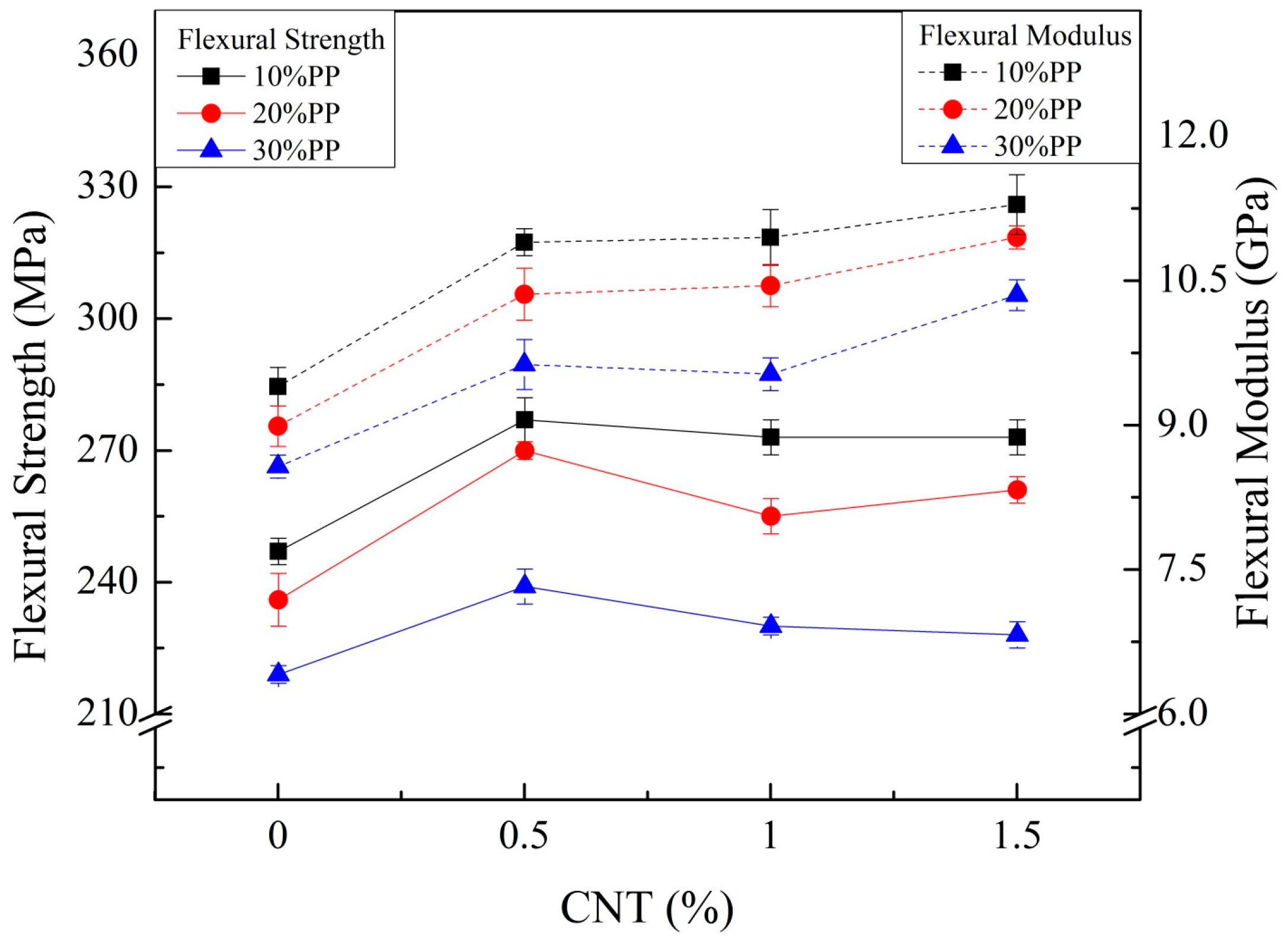

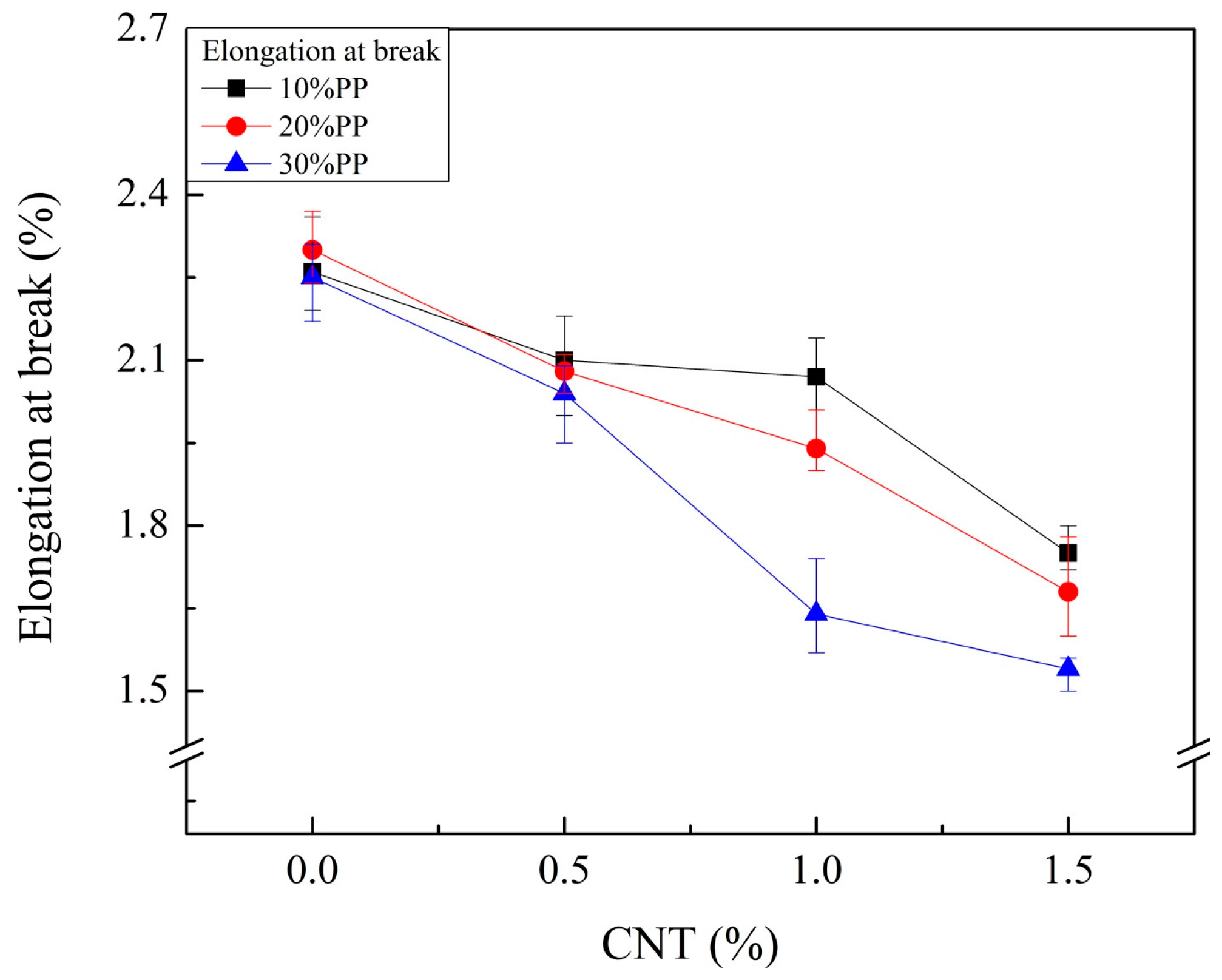

3. Results

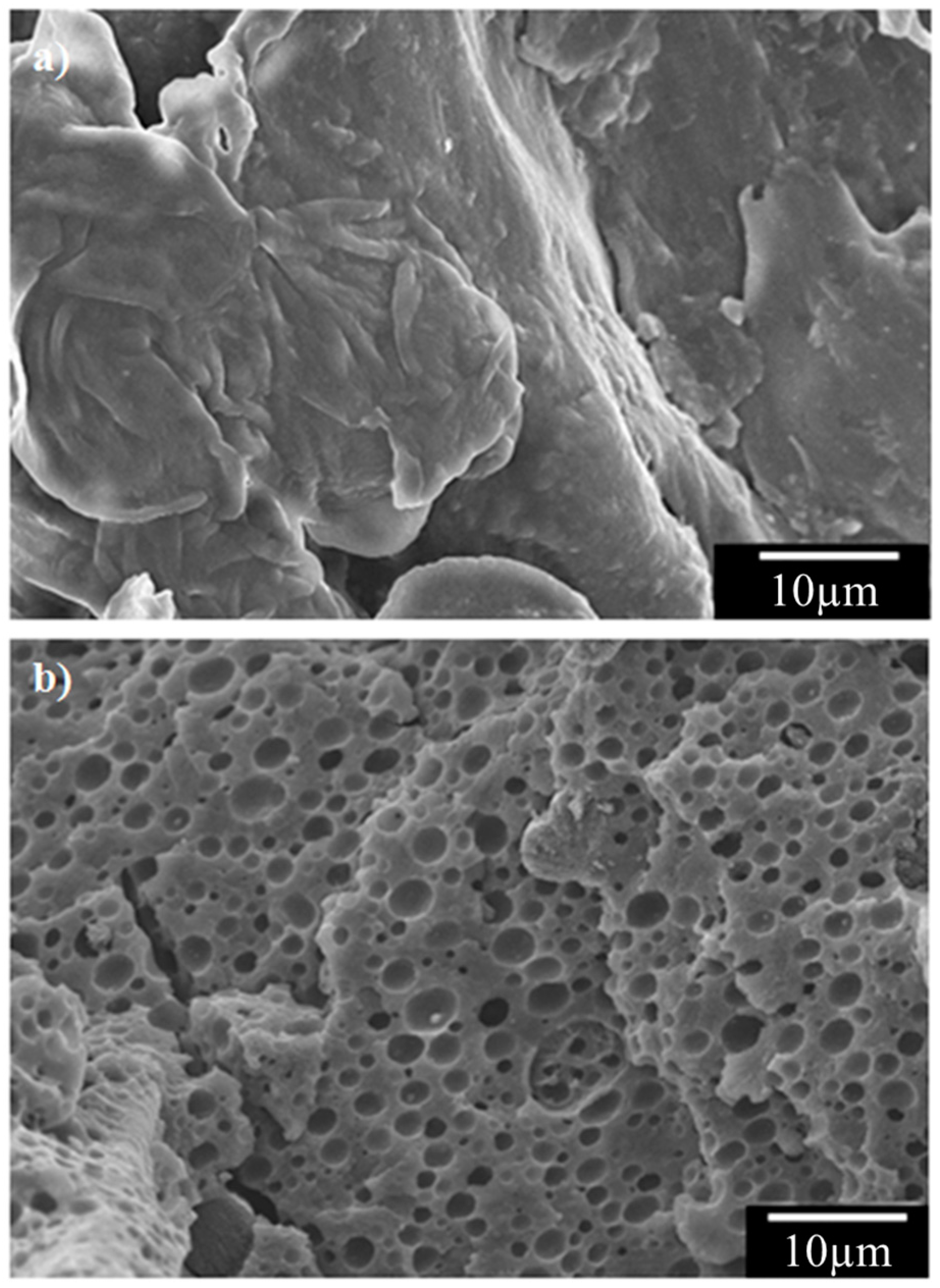

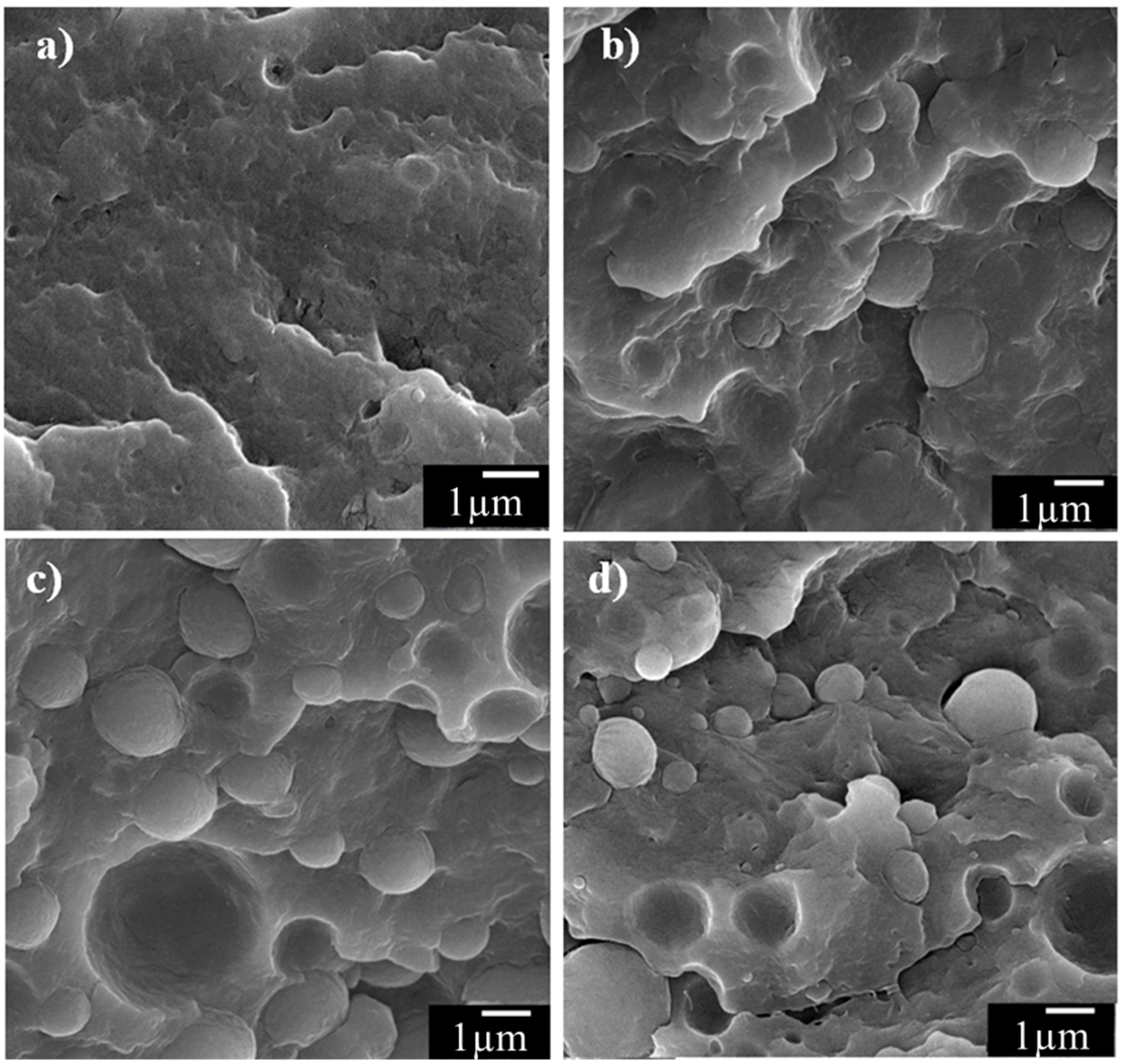

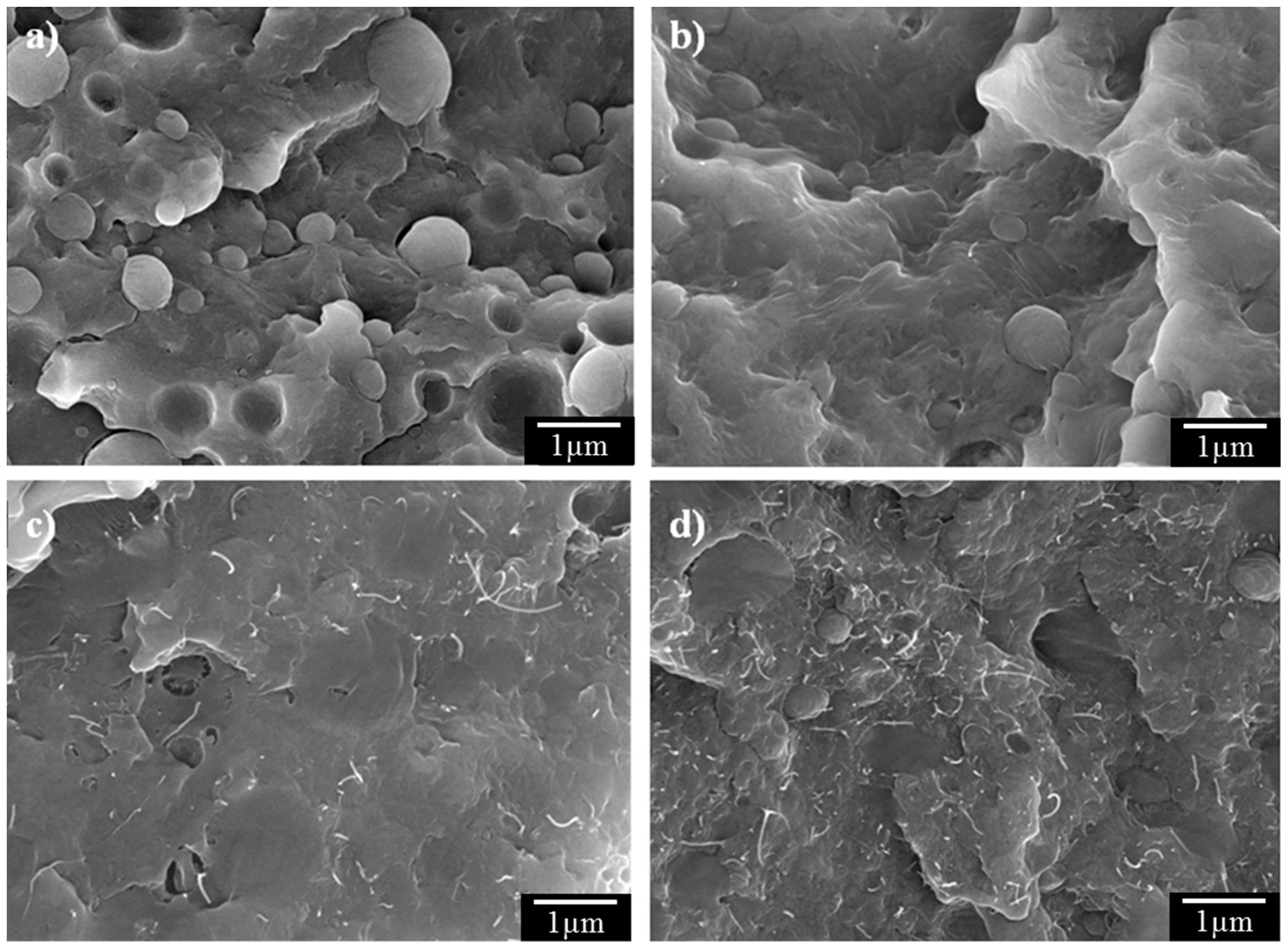

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shan, Z.; Qin, S.; Liu, Q.; Liu, F. Key manufacturing technology & equipment for energy saving and emissions reduction in mechanical equipment industry. Int. J. Precis. Eng. Manuf. 2012, 13, 1095–1100. [Google Scholar]

- Dornfeld, D.A. Moving towards green and sustainable manufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 2014, 1, 63–66. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Park, C.K.; Kan, C.D.S.; Hollowell, W.T.; Hill, S.I. Investigation of Opportunities for Lightweight Vehicles Using Advanced Plastics and Composites; Transportation Research Board: Washington, DC, USA, 2012. [Google Scholar]

- Cheah, L.; Heywood, J. Meeting US passenger vehicle fuel economy standards in 2016 and beyond. Energy Policy 2011, 39, 454–466. [Google Scholar] [CrossRef]

- Park, D.H.; Kwon, H.H. Development of warm forming parts for automotive body dash panel using AZ31B magnesium alloy sheets. Int. J. Precis. Eng. Manuf. 2015, 16, 2159–2165. [Google Scholar] [CrossRef]

- Fu, S.Y.; Lauke, B.; Mäder, E.; Yue, C.Y.; Hu, X. Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Hwang, W.C.; Lee, K.S.; Yang, Y.J.; Yang, I.Y. An experimental study on the optimum collapse characteristics of composite structural member under impact loading. Int. J. Precis. Eng. Manuf. 2011, 12, 521–526. [Google Scholar] [CrossRef]

- Shi, J.W.; Zhu, H.; Wu, G.; Wu, Z.S. Tensile behavior of FRP and hybrid FRP sheets in freeze–thaw cycling environments. Compos. Part B Eng. 2014, 60, 239–247. [Google Scholar] [CrossRef]

- Lyu, M.Y.; Choi, T.G. Research trends in polymer materials for use in lightweight vehicles. International Int. J. Precis. Eng. Manuf. 2015, 16, 213–220. [Google Scholar] [CrossRef]

- Miri, V.; Persyn, O.; Lefebvre, J.M.; Seguela, R. Effect of water absorption on the plastic deformation behavior of nylon 6. Eur. Polym. J. 2009, 45, 757–762. [Google Scholar] [CrossRef]

- Zeng, N.; Bai, S.L.; G’sell, C.; Hiver, J.M.; Mai, Y.W. Study on the microstructures and mechanical behaviour of compatibilized polypropylene/polyamide-6 blends. Polym. Int. 2002, 51, 1439–1447. [Google Scholar] [CrossRef]

- Roeder, J.; Oliveira, R.V.B.; Gonçalves, M.C.; Soldi, V.; Pires, A.T.N. Polypropylene/polyamide-6 blends: Influence of compatibilizing agent on interface domains. Polym. Test. 2002, 21, 815–821. [Google Scholar] [CrossRef]

- Tjong, S.C. The falling weight impact properties of maleic anhydride compatibilized polypropylene–polyamide blends. J. Mater. Sci. 1997, 32, 4613–4617. [Google Scholar] [CrossRef]

- Puch, F.; Hopmann, C. Morphology and tensile properties of unreinforced and short carbon fibre reinforced Nylon 6/multiwalled carbon nanotube-composites. Polymer 2014, 55, 3015–3025. [Google Scholar] [CrossRef]

- Esawi, A.M.; Farag, M.M. Carbon nanotube reinforced composites: Potential and current challenges. Mater. Des. 2007, 28, 2394–2401. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Review of the mechanical properties of carbon nanofiber/polymer composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2126–2142. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Winey, K.I. Polymer nanocomposites containing carbon nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Aldajah, S.; Haik, Y. Transverse strength enhancement of carbon fiber reinforced polymer composites by means of magnetically aligned carbon nanotubes. Mater. Des. 2012, 34, 379–383. [Google Scholar] [CrossRef]

- An, F.; Lu, C.; Li, Y.; Guo, J.; Lu, X.; Lu, H.; He, S.; Yang, Y. Preparation and characterization of carbon nanotube-hybridized carbon fiber to reinforce epoxy composite. Mater. Des. 2012, 33, 197–202. [Google Scholar] [CrossRef]

- Zhang, W.D.; Shen, L.; Phang, I.Y.; Liu, T. Carbon nanotubes reinforced nylon-6 composite prepared by simple melt-compounding. Macromolecules 2004, 37, 256–259. [Google Scholar] [CrossRef]

- Liu, T.; Phang, I.Y.; Shen, L.; Chow, S.Y.; Zhang, W.D. Morphology and mechanical properties of multiwalled carbon nanotubes reinforced nylon-6 composites. Macromolecules 2004, 37, 7214–7222. [Google Scholar] [CrossRef]

- Zhang, L.; Wan, C.; Zhang, Y. Investigation on the multiwalled carbon nanotubes reinforced polyamide 6/polypropylene composites. Polym. Eng. Sci. 2009, 49, 1909–1917. [Google Scholar] [CrossRef]

- Chow, W.; Mohd Ishak, Z.; Karger-Kocsis, J.; Apostolov, A.; Ishiaku, U. Compatibilizing effect of maleated polypropylene on the mechanical properties and morphology of injection molded polyamide 6/polypropylene/organoclay nanocomposites. Polymer 2003, 44, 7427–7440. [Google Scholar] [CrossRef]

- Do, V.T.; Nguyen-Tran, H.D.; Chun, D.M. Effect of polypropylene on the mechanical properties and water absorption of carbon-fiber-reinforced-polyamide-6/polypropylene composite. Compos. Struct. 2016, 150, 240–245. [Google Scholar] [CrossRef]

- Liang, J.; Xu, Y.; Wei, Z.; Song, P.; Chen, G.; Zhang, W. Mechanical properties, crystallization and melting behaviors of carbon fiber-reinforced PA6 composites. J. Therm. Anal. Calorim. 2014, 115, 209–218. [Google Scholar] [CrossRef]

- Chow, W.; Ishak, Z.; Ishiaku, U.; Karger-Kocsis, J.; Apostolov, A. The effect of organoclay on the mechanical properties and morphology of injection-molded polyamide 6/polypropylene nanocomposites. J. Appl. Polym. Sci. 2004, 91, 175–189. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Peng, Q.Y.; Li, Y.B.; He, X.D.; Lv, H.Z.; Hu, P.G.; Shang, Y.Y.; Wang, C.; Wang, R.G.; Sritharan, T.; Du, S.Y. Interfacial enhancement of carbon fiber composites by poly (amido amine) functionalization. Compos. Sci. Technol. 2013, 74, 37–42. [Google Scholar] [CrossRef]

- Gao, S.L.; Mäder, E.; Zhandarov, S.F. Carbon fibers and composites with epoxy resins: Topography, fractography and interphases. Carbon 2004, 42, 515–529. [Google Scholar] [CrossRef]

- Yoo, Y.; Spencer, M.; Paul, D. Morphology and mechanical properties of glass fiber reinforced Nylon 6 nanocomposites. Polymer 2011, 52, 180–190. [Google Scholar] [CrossRef]

- Feng, Q.P.; Deng, Y.H.; Xiao, H.M.; Liu, Y.; Qu, C.B.; Zhao, Y.; Fu, S.Y. Enhanced cryogenic interfacial normal bond property between carbon fibers and epoxy matrix by carbon nanotubes. Compos. Sci. Technol. 2014, 104, 59–65. [Google Scholar] [CrossRef]

| Name of Composite | PA6/PP Blending (wt %) | CNT (wt %) | CF (wt %) |

|---|---|---|---|

| 0% PP + 0.0% CNT | 80.0 (100% PA6:0% PP:0% MaPP) | 0.0 | 20 |

| 0% PP + 0.5% CNT | 79.5 (100% PA6:0% PP:0% MaPP) | 0.5 | |

| 0% PP + 1.0% CNT | 79.0 (100% PA6:0% PP:0% MaPP) | 1.0 | |

| 0% PP + 1.5% CNT | 78.5 (100% PA6:0% PP:0% MaPP) | 1.5 | |

| 10% PP + 0.0% CNT | 80.0 (89.5% PA6:10% PP:0.5% MaPP) | 0.0 | |

| 10% PP + 0.5% CNT | 79.5 (89.5% PA6:10% PP:0.5% MaPP) | 0.5 | |

| 10% PP + 1.0% CNT | 79.0 (89.5% PA6:10% PP:0.5% MaPP) | 1.0 | |

| 10% PP + 1.5% CNT | 78.5 (89.5% PA6:10% PP:0.5% MaPP) | 1.5 | |

| 20% PP + 0.0% CNT | 80.0 (79.0% PA6:20% PP:1.0% MaPP) | 0.0 | |

| 20% PP + 0.5% CNT | 79.5 (79.0% PA6:20% PP:1.0% MaPP) | 0.5 | |

| 20% PP + 1.0% CNT | 79.0 (79.0% PA6:20% PP:1.0% MaPP) | 1.0 | |

| 20% PP + 1.5% CNT | 78.5 (79.0% PA6:20% PP:1.0% MaPP) | 1.5 | |

| 30% PP + 0.0% CNT | 80.0 (68.5% PA6:30% PP:1.5% MaPP) | 0.0 | |

| 30% PP + 0.5% CNT | 79.5 (68.5% PA6:30% PP:1.5% MaPP) | 0.5 | |

| 30% PP + 1.0% CNT | 79.0 (68.5% PA6:30% PP:1.5% MaPP) | 1.0 | |

| 30% PP + 1.5% CNT | 78.5 (68.5% PA6:30% PP:1.5% MaPP) | 1.5 |

| Process | Parameter | Value |

|---|---|---|

| Single screw extruder | Temperature (°C) | 180-250-250-230-230 |

| Rotation speed (RPM) | 300 | |

| Injection molding machine | Temperature (°C) | 260-275-285 |

| Injection pressure (kg/cm2) | 100 | |

| Clamping force (tons) | 15 | |

| Holding time (s) | 20 | |

| Volumetric rate (cm3/s) | 5 |

| Name of Composite | Tensile Strength (MPa) | Elastic Modulus (GPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Density (g/cm3) |

|---|---|---|---|---|---|

| 0% PP + 0.0% CNT | 200 ± 4 | 11.08 ± 0.44 | 275 ± 2 | 10.71 ± 0.33 | 1.214 ± 0.002 |

| 10% PP + 0.0% CNT | 177 ± 4 | 10.22 ± 0.36 | 247 ± 3 | 9.40 ± 0.20 | 1.187 ± 0.003 |

| 20% PP + 0.0% CNT | 171 ± 2 | 9.48 ± 0.08 | 236 ± 6 | 8.99 ± 0.21 | 1.160 ± 0.002 |

| 30% PP + 0.0% CNT | 168 ± 2 | 9.46 ± 0.20 | 219 ± 2 | 8.57 ± 0.12 | 1.131 ± 0.002 |

| Name of Composite | Tensile Strength (MPa) | Elastic Modulus (GPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Density (g/cm3) |

|---|---|---|---|---|---|

| 0% PP + 0% CNT | 200 ± 4 | 11.08 ± 0.44 | 275 ± 2 | 10.71 ± 0.33 | 1.214 ± 0.002 |

| 10% PP + 1% CNT | 196 ± 6 | 11.07 ± 0.29 | 273 ± 4 | 10.95 ± 0.29 | 1.199 ± 0.004 |

| 10% PP + 0% CNT | 177 ± 4 | 10.22 ± 0.36 | 247 ± 3 | 9.40 ± 0.20 | 1.187 ± 0.003 |

| 20% PP + 0.5% CNT | 179 ± 3 | 10.28 ± 0.21 | 270 ± 2 | 10.36 ± 0.27 | 1.163 ± 0.005 |

| 20% PP + 0% CNT | 171 ± 2 | 9.48 ± 0.08 | 236 ± 6 | 8.99 ± 0.21 | 1.160 ± 0.002 |

| 30% PP + 0.5% CNT | 173 ± 3 | 10.11 ± 0.19 | 239 ± 4 | 9.63 ± 0.26 | 1.135 ± 0.003 |

| 30% PP + 0.0% CNT | 168 ± 2 | 9.46 ± 0.20 | 219 ± 2 | 8.57 ± 0.12 | 1.131 ± 0.002 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen-Tran, H.-D.; Hoang, V.-T.; Do, V.-T.; Chun, D.-M.; Yum, Y.-J. Effect of Multiwalled Carbon Nanotubes on the Mechanical Properties of Carbon Fiber-Reinforced Polyamide-6/Polypropylene Composites for Lightweight Automotive Parts. Materials 2018, 11, 429. https://doi.org/10.3390/ma11030429

Nguyen-Tran H-D, Hoang V-T, Do V-T, Chun D-M, Yum Y-J. Effect of Multiwalled Carbon Nanotubes on the Mechanical Properties of Carbon Fiber-Reinforced Polyamide-6/Polypropylene Composites for Lightweight Automotive Parts. Materials. 2018; 11(3):429. https://doi.org/10.3390/ma11030429

Chicago/Turabian StyleNguyen-Tran, Huu-Duc, Van-Tho Hoang, Van-Ta Do, Doo-Man Chun, and Young-Jin Yum. 2018. "Effect of Multiwalled Carbon Nanotubes on the Mechanical Properties of Carbon Fiber-Reinforced Polyamide-6/Polypropylene Composites for Lightweight Automotive Parts" Materials 11, no. 3: 429. https://doi.org/10.3390/ma11030429

APA StyleNguyen-Tran, H.-D., Hoang, V.-T., Do, V.-T., Chun, D.-M., & Yum, Y.-J. (2018). Effect of Multiwalled Carbon Nanotubes on the Mechanical Properties of Carbon Fiber-Reinforced Polyamide-6/Polypropylene Composites for Lightweight Automotive Parts. Materials, 11(3), 429. https://doi.org/10.3390/ma11030429