Abstract

To produce high quality and low cost carbon fiber-based composites, the optimization of the production process of carbon fiber and its properties is one of the main keys. The stabilization process is the most important step in carbon fiber production that consumes a large amount of energy and its optimization can reduce the cost to a large extent. In this study, two intelligent optimization techniques, namely Support Vector Regression (SVR) and Artificial Neural Network (ANN), were studied and compared, with a limited dataset obtained to predict physical property (density) of oxidative stabilized PAN fiber (OPF) in the second zone of a stabilization oven within a carbon fiber production line. The results were then used to optimize the energy consumption in the process. The case study can be beneficial to chemical industries involving carbon fiber manufacturing, for assessing and optimizing different stabilization process conditions at large.

1. Introduction

Composite materials are becoming increasingly important in a wide range of industries. An advanced composite material is made of a fibrous material system, such as carbon fiber yarns embedded in a resin matrix; therefore, the production process of carbon fiber and its properties are the main keys to high quality and low cost composites. Carbon fiber as a part of advanced composite materials is widely used in industries. Among the precursors used for the production of carbon fibers, polyacrylonitrile (PAN)-based precursors are the most common precursors. Stabilization, carbonization, and graphitization are the three consecutive steps in carbon fiber production. Temperature, Time, and Tension (TTT) are the main controlling parameters in the thermal stabilization process. Stabilization step is the most complex, costly and energy consuming step. Hence, production quality and energy optimization of this step are deemed important to produce high quality and low cost composites. The stabilization oven is normally divided into four zones, each set at different temperature regions, which can be studied as individual systems. This is due to the fact that each zone has its own effect on the properties of resultant carbon fiber. In industrial settings, conducting experiments for all system parameters is often impractical due to the technical and time limitations, and this would make intelligent mathematical models a critical step for reliable process optimization purposes with limited datasets. Intelligent modeling techniques, such as stochastic [1,2] and heuristic [3], are powerful tools to analyze complex nonlinear systems, such as the stabilization process. Stochastic techniques need to have a number of experimental data compare to heuristic techniques. Such heuristic techniques as artificial neural network (ANN), adaptive neuro-fuzzy inference system (ANFIS), fuzzy logic, stochastic models, and support vector regression (SVR) with black box characteristics, have shown great generalization ability through different engineering case studies [4,5,6,7]. One of the frequently used modeling systems in the current literature is the Support Vector Machine (SVM) that is developed by Vapnik [8,9]. Another long-known method is the ANN that provides a viable modeling framework when complex nonlinear relationships exist between the inputs and outputs of a given system [1,2,3,10,11,12,13,14,15,16]; however, they have not been applied methodically to the second zone of thermal oxidative stabilization process. In terms of production quality (chemical, physical, and mechanical properties of oxidized PAN fiber (OPF) and carbon fiber), a few investigations have been reported in the literature. Dynamic models were used to study and analyze the carbon fiber thermal stabilization process [3]. Taylor polynomial method, Gauss-Newton algorithm (GNA), Levenberg-Marquardt algorithm (LMA) neural network, and genetic algorithms were used and compared. Based on the results, a given PAN fiber heat of reaction can be optimized by appropriate values of temperature and heating ramp. Khayyam et al. [2] also developed a stochastic optimization model for energy management in the carbonization process of carbon fiber production line. Their study indicated that it is possible to use stochastic optimization models to predict the production quality and minimize the energy consumption of its industrial process. Badii et al. [13] developed a model to predict density based on PAN precursor and OPF functional groups. Golkarnarenji et al. [17] developed an intelligent predictive model for energy consumption in thermal stabilization process, considering production quality and controlling stochastic defects. That study, however, was carried out for the first zone of stabilization process. Regarding predictive modelling for energy consumption in industrial processes, there are also some studies that are available in literature [18,19,20]. None of the aforementioned studies on energy optimization is based on density in the second zone of stabilization process. Hence, the aim of this article is to test the ANN and SVR techniques against forecasting physical properties of the OPF, with a limited dataset available from the second zone of stabilization oven. The result of this prediction was used for optimization of oxidative stabilization process to reduce the energy consumption and ultimately cost. Different optimization techniques can be used to optimize energy consumption and find the optimal process condition for carbon fiber manufacturing [21,22,23,24,25]. Genetic Algorithm (GA) was selected in this study.

The main objectives and contributions of the present manuscript are:

- Develop a model for physical property of the OPF (here density) in the second zone of stabilization process, which can then be considered in the optimization of energy consumption in the process.

- Develop a surrogate model for energy consumption and management.

- Optimize the energy consumption in the stabilization process, given the range of process constraints, such as fiber density.

The rest of this paper is organized as follows. In Section 2, the experimental procedure is presented. Section 3 discusses the modelling framework for physical property of carbon fiber and energy management in the stabilization process. Section 4 presents the results of predictive models, energy consumption in stabilization process and its optimization. In Section 5, concluding remarks are presented.

2. Materials and Methods

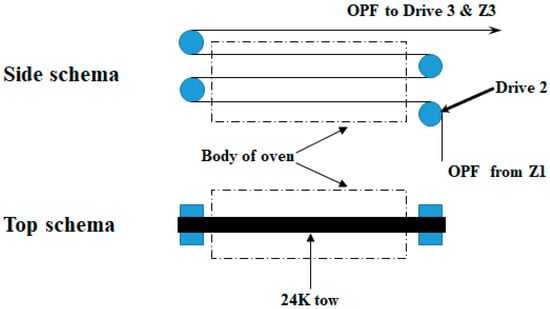

The PAN precursor used in the study was a commercial fiber provided by the Blue Star (China) enterprise with a density of 1.1993 g·cm−3 and linear density of 1.58 dtex. The ANN and SVR modelling were carried out for select combination of the following operational conditions during stabilization of PAN: temperature (five temperatures between 233 and 241 °C, including 233, 235, 238, 239, and 241 °C, based on manufacturing experiences), space velocity (20, 30 and 35 m/h), and stretching-ratio (1.0%, 2.0%, 3.0%, and 4.0%) in the second zone of single tow oxidation pilot oven, designed by Despatch industries. Figure 1 shows the schematic diagram of the second zone of stabilization oven. 13 tests were used for training purpose and three additional tests were performed to validate the developed models. The tests were randomly designed to prevent any prejudgment. The density (g·m−3) of the fiber samples was measured with the density gradient technique [26]. The stretching ratio was controlled by the difference percentage between speed of Drive 1 and Drive 2.

Figure 1.

Schematic diagram of zone 2 of the stabilization oven studied.

3. Modeling Framework

3.1. Support Vector Regression (SVR)

The Support Vector Regression (SVR) is a part of Support Vector Mechine (SVM) that is designed to find unique global solutions to curve fitting problems with highly nonlinear data. The SVM models are commonly used to solve both classification and regression problems. In this method, the data is mapped into a higher dimensional feature space and is fitted to a linear function with minimum complexity using kernel functions [27,28]. Three common kernel functions in SVR are the sigmoid kernel function, the polynomial kernel function, and the Gaussian RBF kernel function. In this article, the Gaussian RBF was selected [29] and the value of C which is the trade-off between error minimization and margin maximization, the value of ε to build the regression function by managing the number of support vectors, and the parameter γ in RBF is to be optimized using GA. Given train dataset {(x1,y1), (x2,y2), ..., (xn,yn)}, SVR defines a function for the relationship between x (input) and y (output) as:

where x is mapped to a new space by φ(x) when the input-output relation is nonlinear. In the new space, the relationship of φ(x) and y is linear. A linear hyperplane is then determined by the variables w and b that can be fit to the training dataset. The goal of SVR solution is to lower the expected risk. This has been presented in Equation (2).

where Lε is ε insensitive loss function per Equation (3).

SVR uses linear regression to minimize the expected risk using ε- insensitive loss function and minimizes to reduce the complexity of the model. This has been shown in Equation (4).

Subject to:

where , (i = 1, …, n) are the non-negative slack variables that show the difference between the f(x) and real value of training data.

This optimization problem can be converted to a dual problem, as in Equation (5).

and are the Lagrange multipliers obtained from the dual problem. is determined by the inner product of φ() and φ(), which is the kernel function. In this study, RBF was selected as the kernel function, which is represented by Equation (6).

3.2. Artificial Neural Network (ANN)

ANN is a highly developed machine learning methodology that has been used in several areas of prediction, control, and process identification [30]. The ANN consists of neurons connected to each other. Neurons are positioned in layers and each layer’s neurons function in parallel. An input layer, hidden layers, and an output layer compose the ANN architecture [31]. Key parameters in ANN are the interconnection of different neuron layers, the updating the weights of the interconnections, training algorithm and activation function. Both the learning error and the prediction error should be minimized by a good artificial network. Some form of gradient descent, using backpropagation is employed by most training algorithms to calculate the function gradients. The common training algorithms for ANN include the Scaled Conjugate Gradient (SCG), Bayesian Regularization (BR), and LM (Levenberg-Marquardt) [32,33]. SCG algorithm needs less memory; however, it has good generalization for noisy datasets. BR typically takes more computational time. LM algorithm [32,34] has good convergence properties. It takes more memory but less computational time; it is the fastest back-propagation algorithm for training and prediction purposes. This algorithm was also used in the current study.

3.3. Performance Validation

The standard error of prediction (SEP) was primarily used to calculate the performance of each predictive model based on the following equation:

where N is total sample size and represent the experimental and predicted dependent variables, respectively.

In addition to SEP, the coefficient of variation (CV) was also used for the performance validation purposes, as follows:

where .

3.4. Energy Sources and Model Structure

Electrical heater for air, recycling fan, exhaust fan, drives (drives 1 and 2 for the second oven), and PAN fiber tow are sources that consume energy (Figure 1). Energy release occurs during the thermal stabilization process. This release is fast and should be taken in to consideration as it increases the possibility of ignition or even combustion. Nonetheless, this release of energy is neutralized and controlled by cold “makeup” air from outside to uniform the temperature inside the oven.

4. Results

Two models were developed for prediction of the OPF density (g·m−3), based on the selected main controlling process parameters: temperature (°C), space velocity (m/h), and stretching ratio (%). In order to predict density based on these parameters, 16 experimental data were randomly distributed into two subsets (70% for training and 30% for testing): 13 for model development and 3 for comparison with experimental data (validation). In terms of data pre-processing, the predictors were normalized to the popular bound between 0 and 1 to improve the model identification performance [35]. To develop a fitting model, the ANN, and SVR, Matlab (Mathworks, Natick, MA, USA) were employed. The leave-one-out cross–validation technique was used to ensure the lack of overfitting. Based on the calculation of CV and SEP, the fitted models were evaluated. For ANN, Fitnet was used as the function fitting feed forward neural network. In order to train the network, different methods were tested and finally the Levenberg–Marquardt function (trainlm) was selected. The configuration of developed ANN model has been shown in Table 1.

Table 1.

Neural network-Levenberg-Marquardt algorithm (LMA) configuration model.

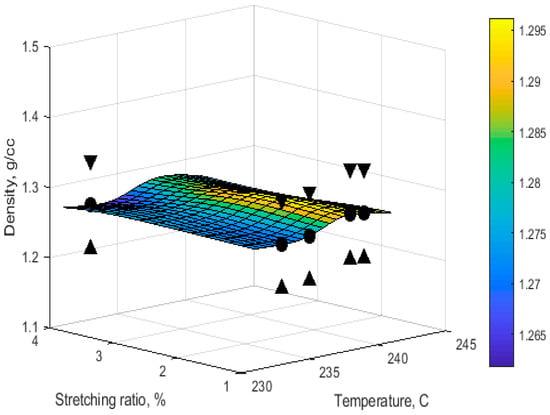

After a number of trials, a neural network with three inputs (temperature, space velocity, and stretching ratio), one intermediate hidden layer with nine neurons and one output (density) was configured. A tangent sigmoid (tansig) transfer function was used within the hidden layer, and a linear (purelin) transfer function was used in the output layer. The CV and SEP obtained were 0.0000149, and 0.0037, respectively. Figure 2 shows the example of the predicted relationship between the density, stretching ratio, and temperature parameters with the space velocity of 20 m/h in the ANN model.

Figure 2.

Temperature-stretching ratio relationship with density at space velocity of 20 m/h using Artificial Neural Network (ANN); the triangle marks show the prediction error.

Next, a SVR model was developed as an alternative to the ANN approach for the prediction of density. Since the general ability of SVR is significantly influenced by the modeling parameters, C, γ, and ε, the GA was used to optimize these values globally. The lowest fitness value was selected based on MSE. Table 2 shows the optimized values for C, γ, and ε. Similar to the ANN case, the dataset was divided into training and testing subsets, 13 samples for training and 3 samples for testing. For training the SVR, the leave-one-out cross–validation technique was used given the limited dataset.

Table 2.

The optimum value of parameters in SVR-GA (support vector regression-genetic algorithm) model.

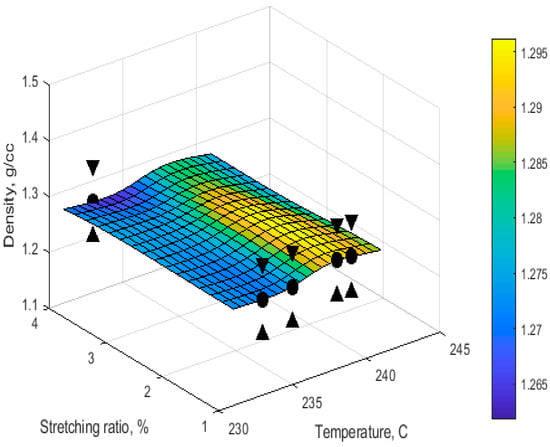

The Gaussian RBF [36] was selected as the kernel function for SVR prediction. In addition, to test the accuracy of the model, CV, SEP was again chosen as performance criteria. The CV and SEP were 0.0000117, 0.0019, respectively. Figure 3 shows the predictability of the SVR model in sample space velocity.

Figure 3.

Temperature-stretching ratio relationship with density at space velocity of 20 m/h using Support Vector Regression (SVR); the triangle marks show the prediction error.

4.1. Predictive Model Validation

Table 3 presents the comparison of the validation results of SVR and ANNs. The results illustrate that the SVR model has had a superior performance over ANN-LMA in the current case study with the limited dataset.

Table 3.

Validation set comparison of the two models.

4.2. Optimization of Energy Consumption

As mentioned in Section 2, electrical heater for air, recycling fan, exhaust fan, and drives (Drives 1 and 2 for the second oven) were the sources that consumed energy. The energy release of the PAN fiber tow was not considered due to higher amount of hot air flow, compared to the size of fiber tow. The amount of released energy from fiber would also have no significant effect on the total energy balances in thermal stabilization system and it was ignored in the calculation procedure of optimization. The temperature of the oven was assumed to be uniform as the system is close to an isothermal state, particularly in the central part of the oven. In the conducted set of experiments, the maximum power of three phased electrical heater was 32,000 W, with a maximum current of 44.5 A, and the voltage of 415 V at 50 Hz. The currents for the exhaust fan, recycling fan, Drive 1, and Drive 2 were 1.5, 5, 0.4, 0.4 A, respectively, based on PLC (programmable logic controller) data logger under steady state condition. The difference of current was negligible between the two drives. The air flow was constant and fully developed turbulent flow.

To estimate the energy consumption of the recycling fan, exhaust fan, drives (Drives 1 and 2) for the second oven, Equation (9) was used [17].

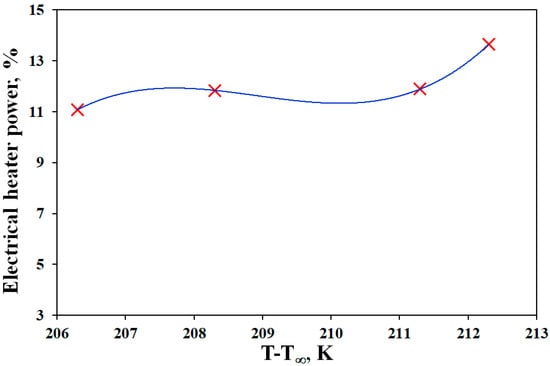

where P, V, I, and φ are power (W), voltage (415 volts), current (A), and phase difference (120°), respectively. In order to estimate the energy consumption of electrical heater for air, Badii et al. [37] explained the structural details of this electrical heater. The power was determined based on the difference between the oven and the ambient temperature. It was assumed that the power of heater was only a function of this difference, as heater and make-up air are the only sources of energy. To predict the power for different levels of temperature, the PLC data was used under steady state conditions. As it has been shown in Figure 4, the data did not follow a linear trend and to find the relationship between the temperature and consumption of energy in the heater, minimum of four data points were used. The PLC data were recorded in steady state condition and the data of power was fitted to a polynomial equation (Equation (10)). The R2 value was 0.9999 for this equation.

where

Figure 4.

Fitted data for the power of electrical heater× as a function of difference between reactor and ambient temperatures; (×) experimental data and (▬▬) fitted curve.

and are the oven and ambient temperatures, respectively. The average temperature of ambient was ~26.7 °C during the test period. The results of Equation (10) were multiplied by 32,000 (total power of heater, W) and divided by 100 (to change percentage to proportion) to predict the power of heater. To change the power to energy, the results were also multiplied by 3600 (to change time from hour to second), length of tow (l), and divided by the space velocity of fiber.

The best model obtained for energy consumption was:

where T is temperature (°C), S is the space velocity (m/h), σ is stretching ratio (%), E is the total energy consumption in joules for 6 m of fibers, L is length of tow (L = 3 × 2 m), is power of electrical heater, and , , , and are the voltage and the current of recycle fan, exhaust fan, and drives, respectively.

The energy consumption (Equation (12)) was then minimized using GA with a population of 20 individuals. In order to optimize the energy of the oven, Equation (12) should be optimized as:

Minimize , subject to:

S is the is the space velocity, is and is 35 m/h. is 233 °C and is 241 °C. σ is stretching ratio. is 1% and is 4%. The desired range of density was considered (1.27 g·cm−3 ≤ ρ ≤ 1.29 g·cm−3) based on the manufacturers demand. Table 4 presents the amount of energy consumption for each experimental condition.

Table 4.

Amount of energy consumption for each of the conducted experiments.

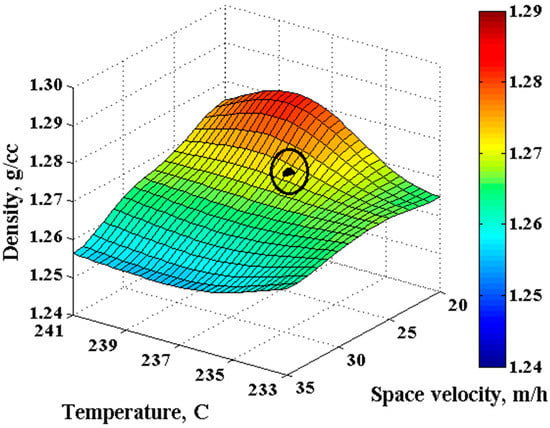

Table 5 presents the results of the optimization process based on the given constraints, using GA method as the optimizer. The obtained optimum operational conditions were tested using additional experiments and the prediction error (Table 5 and Figure 5) was less than 5%, confirming an excellent agreement between the optimization model and experiments. Figure 5 shows the results of energy optimization based on density as a constraint. The results of the model for density of OPF have been presented in this figure as the main parameter for controlling the quality of OPF. The black point is the result of optimization. The energy consumption was 5.513 MJ (seventh column in Table 5) to achieve the density constraint (the first column in Table 5). These results show up to −48.6% energy saving by the developed model (the last column in Table 5). Elapsed time was 61.99 seconds for this system. The error for predicted density (fifth column of Table 5) is ~1.7% (ninth column of Table 5). Actual density (experimental) results are shown in the sixth column of Table 5.

Table 5.

Optimized operational parameters (T, S, and σ) and the corresponding minimum energy consumption based on the given constraints, and using the GA optimizer; the SVR predictive modeling was used for density.

Figure 5.

Position of the optimized energy criteria based on density constraint of 1.27 g/cm3 ≤ ρ ≤ 1.29 g/cm3.

5. Conclusions

The study of stabilization process, as the most energy consuming part of the carbon fiber production line, is the key to optimize the energy and cost during production of carbon fiber-based composites. In order to fulfill this purpose, the SVR and ANN models were tested in a case study to predict the density of OPFs based on the main controlling parameters of thermal stabilization process. In terms of performance criteria, SEP and CV were used, and clearly suggested that SVR has a better accuracy for the given system identification problem with a small/limited dataset. The developed model was further used for optimization of oxidative stabilization process to reduce the energy consumption, and hence, cost, similar to [26]. The best compromise solution was attained, where the energy savings were up to 48.6% while satisfying the design constraints on the fiber physical (density) property. The study is deemed beneficial for chemical industries involving carbon-fiber manufacturing, with the aim of producing high quality and low cost carbon fiber-based composites with limited dataset for optimization purposes.

The study may be extended by running the oxidative stabilisation tests for different zones of thermal stabilisation oven and investigating the interaction between different zones.

Acknowledgments

The authors would like to thank Carbon Nexus carbon fiber and composites research centre at Deakin University, Australia, for making the equipment and staff available to carry out the process tests for this study.

Author Contributions

Gelayol Golkarnarenji and Hamid Khayyam: Conceived and designed the experiments. Gelayol Golkarnarenji and Khashayar Badii: Performed the experiments. Gelayol Golkarnarenji and Hamid Khayyam: Data analysis. Hamid Khayyam and Minoo Naebe: Contributed reagents/materials/ analysis tools. Gelayol Golkarnarenji wrote the first draft of manuscript and Minoo Naebe, Khashayar Badii, Abbas S. Milani, Reza N. Jazar and Hamid Khayyam closely contributed to the group discussions and the technical review of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Khayyam, H. Stochastic models of road geometry and wind condition for vehicle energy management and control. IEEE Trans. Veh. Technol. 2012, 62, 61–68. [Google Scholar] [CrossRef]

- Khayyam, H.; Naebe, M.; Bab-Hadiashar, A.; Jamshidi, F.; Li, Q.; Atkiss, S.; Buckmaster, D.; Fox, B. Stochastic optimization models for energy management in carbonization process of carbon fiber production. Appl. Energy 2015, 158, 643–655. [Google Scholar] [CrossRef]

- Khayyam, H.; Naebe, M.; Zabihi, O.; Zamani, R.; Atkiss, S.; Fox, B. Dynamic Prediction Models and Optimization of Polyacrylonitrile (PAN) Stabilization Processes for Production of Carbon Fiber. IEEE Trans. Ind. Inform. 2015, 11, 887–896. [Google Scholar] [CrossRef]

- Gupta, A.K.; Guntuku, S.C.; Desu, R.K.; Balu, A. Optimisation of turning parameters by integrating genetic algorithm with support vector regression and artificial neural networks. Int. J. Adv. Manuf. Technol. 2014, 77, 331–339. [Google Scholar] [CrossRef]

- Chen, S.-M.; Lee, S.-H.; Lee, C.-H. A new method for generating fuzzy rules from numerical data for handling classification problems. Appl. Artif. Intell. 2001, 15, 645–664. [Google Scholar] [CrossRef]

- Horng, Y.-J.; Chen, S.-M.; Chang, Y.-C.; Lee, C.-H. A new method for fuzzy information retrieval based on fuzzy hierarchical clustering and fuzzy inference techniques. IEEE Trans. Fuzzy Syst. 2005, 13, 216–228. [Google Scholar] [CrossRef]

- Chen, S.-M. A fuzzy reasoning approach for rule-based systems based on fuzzy logics. IEEE Trans. Syst. Man Cybern. Part B (Cybern.) 1996, 26, 769–778. [Google Scholar] [CrossRef] [PubMed]

- Vapnik, V.N.; Vapnik, V. Statistical Learning Theory; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Kulkarni, S.; Harman, G. An Elementary Introduction to Statistical Learning Theory; Wiley Series in Probability and Statistics; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Lu, Z.J.; Xiang, Q.; Wu, Y.M.; Gu, J. Application of support vector machine and genetic algorithm optimization for quality prediction within complex industrial process. In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015; pp. 98–103. [Google Scholar]

- Huang, C.; Moraga, C. A diffusion-neural-network for learning from small samples. Int. J. Approx. Reason. 2004, 35, 137–161. [Google Scholar] [CrossRef]

- Pal, M.; Foody, G.M. Evaluation of SVM, RVM and SMLR for accurate image classification with limited ground data. IEEE J. Sel. Top. Appl. Earth Observ. Remote Sens. 2012, 5, 1344–1355. [Google Scholar] [CrossRef]

- Badii, K.; Church, J.S.; Golkarnarenji, G.; Naebe, M.; Khayyam, H. Chemical structure based prediction of PAN and oxidized PAN fiber density through a non-linear mathematical model. Polym. Degrad. Stab. 2016, 131, 53–61. [Google Scholar] [CrossRef]

- Khayyam, H.; Fakhrhoseini, S.M.; Church, J.S.; Milani, A.S.; Bab-Hadiashar, A.; Jazar, R.N.; Naebe, M. Predictive modelling and optimization of carbon fiber mechanical properties through high temperature furnace. Appl. Therm. Eng. 2017, 125 (Suppl. C), 1539–1554. [Google Scholar] [CrossRef]

- Golkarnarenji, G.; Naebe, M.; Church, J.S.; Badii, K.; Bab-Hadiashar, A.; Atkiss, S.; Khayyam, H. Development of a predictive model for study of skin-core phenomenon in stabilization process of PAN precursor. J. Ind. Eng. Chem. 2017, 49, 46–60. [Google Scholar] [CrossRef]

- Khayyam, H.; Golkarnarenji, G.; Jazar, R.N. Limited Data Modelling Approaches for Engineering Applications. In Nonlinear Approaches in Engineering Applications; Jazar, R.N., Ed.; International Publication Springer: Cham, Switzerland, 2017. [Google Scholar]

- Golkarnarenji, G.; Naebe, M.; Badii, K.; Milani, A.S.; Jazar, R.N.; Khayyam, H. Support vector regression modelling and optimization of energy consumption in carbon fiber production line. Comput. Chem. Eng. 2018, 109, 276–288. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Tang, L. Energy Consumption Prediction in Ironmaking Process Using Hybrid Algorithm of SVM and PSO. In Proceedings of the Advances in Neural Networks—ISNN 2012: 9th International Symposium on Neural Networks, Shenyang, China, 11–14 July 2012; Wang, J., Yen, G.G., Polycarpou, M.M., Eds.; Part II. Springer: Berlin/Heidelberg, Germany, 2012; pp. 594–600. [Google Scholar]

- Curilem, M.; Acuña, G.; Cubillos, F.; Vyhmeister, E. Neural networks and support vector machine models applied to energy consumption optimization in semiautogeneous grinding. Chem. Eng. Trans. 2011, 25, 761–766. [Google Scholar]

- Kant, G.; Sangwan, K.S. Predictive modelling for energy consumption in machining using artificial neural network. Procedia CIRP 2015, 37, 205–210. [Google Scholar] [CrossRef]

- Chen, S.-M.; Chien, C.-Y. Parallelized genetic ant colony systems for solving the traveling salesman problem. Expert Syst. Appl. 2011, 38, 3873–3883. [Google Scholar] [CrossRef]

- Tsai, P.-W.; Pan, J.-S.; Chen, S.-M.; Liao, B.-Y.; Hao, S.-P. Parallel cat swarm optimization. In Proceedings of the 2008 International Conference on Machine Learning and Cybernetics, Kunming, China, 12–15 July 2008; Volume 6, pp. 3328–3333. [Google Scholar]

- Tsai, P.-W.; Pan, J.-S.; Chen, S.-M.; Liao, B.-Y. Enhanced parallel cat swarm optimization based on the Taguchi method. Expert Syst. Appl. 2012, 39, 6309–6319. [Google Scholar] [CrossRef]

- Chen, S.-M.; Kao, P.-Y. TAIEX forecasting based on fuzzy time series, particle swarm optimization techniques and support vector machines. Inf. Sci. 2013, 247, 62–71. [Google Scholar] [CrossRef]

- Chen, S.-M.; Chung, N.-Y. Forecasting enrollments of students by using fuzzy time series and genetic algorithms. Int. J. Inf. Manag. Sci. 2006, 17, 1–17. [Google Scholar]

- Golkarnarenji, G. Predictive Modelling and Multi-Objective Optimisation in Thermal Stabilisation Process of Carbon Fibre. Ph.D. Thesis, IFM, Geelong, Australia, 2017. [Google Scholar]

- Gunn, S.R. Support vector machines for classification and regression. ISIS Tech. Rep. 1998, 14, 5–16. [Google Scholar]

- Vapnik, V.; Golowich, S.E.; Smola, A. Support Vector Method for Function Approximation, Regression Estimation, and Signal Processing. Available online: https://pdfs.semanticscholar.org/43ff/a2c1a06a76e58a333f2e7d0bd498b24365ca.pdf (accessed on 27 February 2018).

- Keerthi, S.S.; Lin, C.-J. Asymptotic behaviors of support vector machines with Gaussian kernel. Neural Comput. 2003, 15, 1667–1689. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; Li, P. The research survey of system identification method. In Proceedings of the 2013 5th International Conference on Intelligent Human-Machine Systems and Cybernetics (IHMSC), Hangzhou, China, 26–27 August 2013; Volume 2, pp. 397–401. [Google Scholar]

- Davim, P. Computational Methods for Optimizing Manufacturing Technology Models and Techniques; IGI Global: Hershey, PA, USA, 2012. [Google Scholar]

- Kermani, B.G.; Schiffman, S.S.; Nagle, H.T. Performance of the Levenberg–Marquardt neural network training method in electronic nose applications. Sens. Actuators B Chem. 2005, 110, 13–22. [Google Scholar] [CrossRef]

- Cherkassky, V.; Mulier, F.M. Learning from Data: Concepts, Theory, and Methods; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Hagan, M.T.; Menhaj, M.B. Training feedforward networks with the Marquardt algorithm. IEEE Trans. Neural Netw. 1994, 5, 989–993. [Google Scholar] [CrossRef] [PubMed]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Hu, W.; Yan, L.; Liu, K.; Wang, H. A short-term traffic flow forecasting method based on the hybrid PSO-SVR. Neural Process. Lett. 2016, 43, 155–172. [Google Scholar] [CrossRef]

- Badii, K.; Naebe, M.; Golkarnarenji, G.; Dhami, N.; Atkiss, S.; Buckmaster, D.; Fox, B.L.; Khayyam, H. Energy Saving in Electric Heater of Carbon Fiber Stabilization Oven. In Proceedings of the 4th International Conference on Artificial Intelligence with Applications in Engineering and Technology (ICAIET), Kota Kinabalu, Malaysia, 3–5 December 2014; pp. 109–114. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).